1. Introduction

Synthetic diamond has unique physical and chemical characteristics, such as hardness, semi-conductivity and high thermal conductivity [

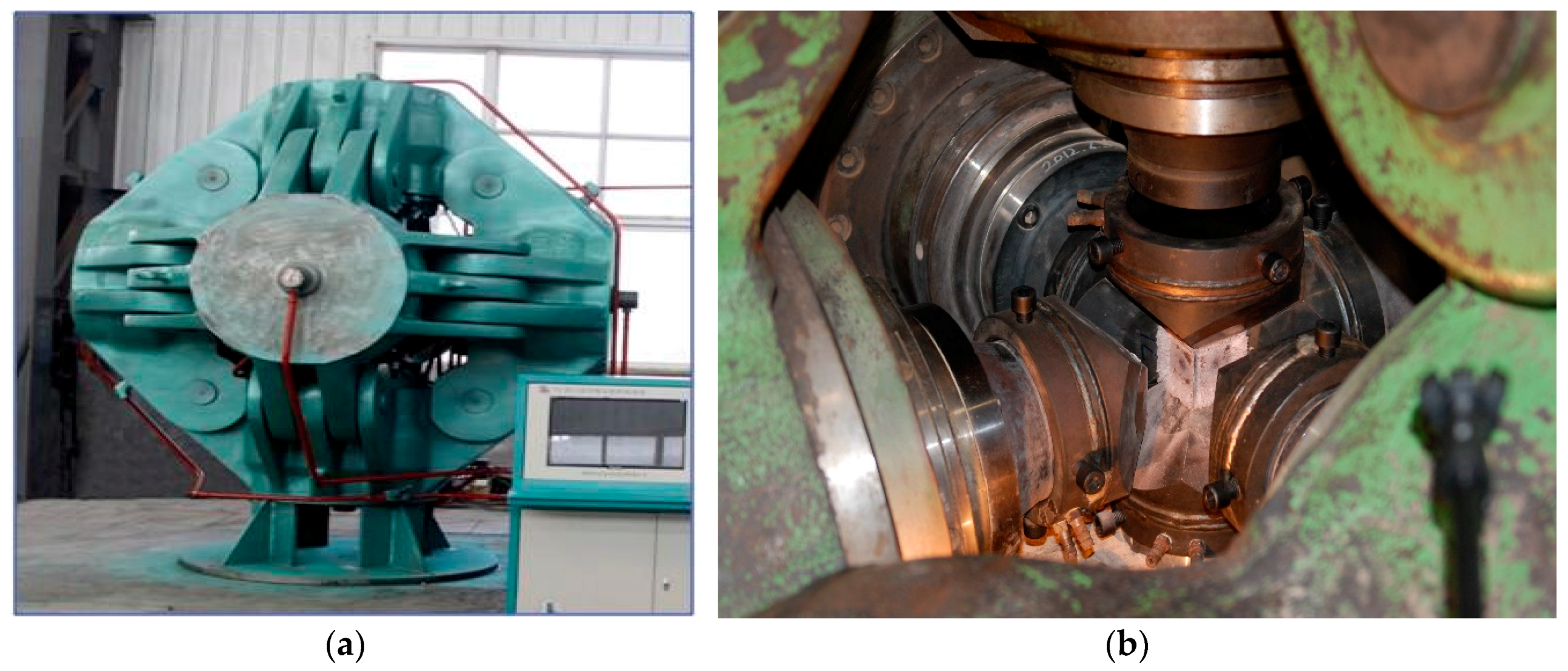

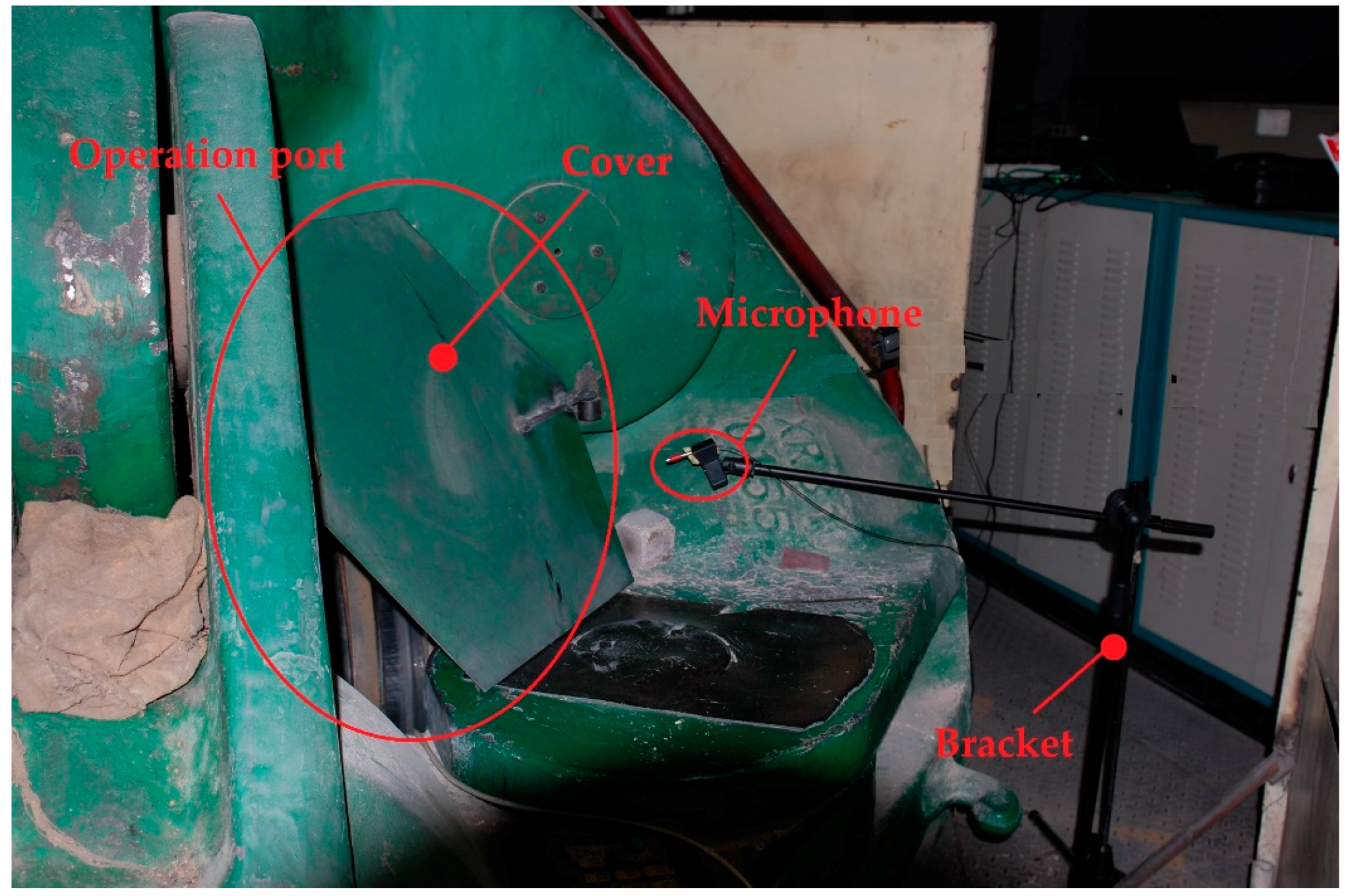

1]. In China, synthetic diamond is commonly produced by large-volume cubic high-pressure apparatus, which has three pairs of tungsten carbide anvils, as shown in

Figure 1. When the apparatus is in operation, it provides 5 GPa pressure and 1500 °C temperature, which is required for the growth of diamond through six hydraulic rams and electric heating mode [

2].

Nowadays, the total amount of cubic apparatuses has reached about 6000 in China. Due to the high pressure, high temperature and alternative stresses, the carbide anvil is highly prone to material fatigue. A common form of the failure is cracking, including nucleation, propagation and fragmentation. If the released energy is less than a critical value, the crack does not grow; otherwise, it grows spontaneously. When a cracked anvil is still operating, an unbalance force is exerted on the other five anvils. If not found early enough, it is extremely easy for a cracked carbide anvil to have a serious blowout or even cause casualties. The destruction of tungsten carbide anvils due to blowouts has become one of the most significant economic losses for the manufactures since the apparatuses have a value of 0.05 g/carat.

Traditionally, regular maintenance and subsequent maintenance methods have been applied in synthetic diamond production. During downtime, the anvil is overhauled by observing or sweeping the surface with a saw blade. While in the production process, the currently available detection method is manual monitoring by experienced workers, seriously influenced by strong background noise. In conclusion, these methods lack the ability to accurately judge the state or analyze the health of the carbide anvil, thereby causing poor reliability and inaccuracy. To adequately protect the rest of the anvils prior to a blowout and improve the market competitiveness and production safety, conducting on-line crack detection of the tungsten carbide anvils is necessary.

When a crack occurs in the material, it results in a rapid release of energy, transmitting in the form of an elastic wave, namely acoustic emission (AE). The AE-based detection method has been intensively used in nondestructive assessments of cracks [

3,

4,

5,

6,

7,

8]. Caesarendra et al. proposed an AE-based method for low speed reversible slew bearings, including AE signal processing, feature extraction and pattern classification [

3]. Rabiei and Modarres revealed a log-linear relationship between the AE features and crack growth rate, and presented an end-to-end approach for structural health management [

4]. Qu et al. presented a comparative study of the damage level diagnostics of gearbox tooth using AE and vibration measurements; the results indicated that vibration signals were easily affected by mechanical resonance, while the AE signals showed a more stable performance [

5]. Zhang et al. studied defect detection of rails using AE and wavelet transform at a high speed [

7]. In the above methods, the AE sensors are usually attached to the surface of the monitoring object. This is not suitable for crack detection of the carbide anvil because of the high temperature and limited inner space in the apparatus.

More recently, some scholars introduced an AE technique for crack detection of carbide anvils using microphones and have produced in-depth studies on the criterion mechanism of the crack [

9,

10,

11,

12]. Han et al. successfully established a tungsten carbide anvil model based on the finite element method (FEM) and indicated that the cracks usually arise around the bevel edge [

9]. Li and Wang created a template library of cracking sounds and designed a detection device using voiceprint recognition with an accuracy of 77% [

10]. Han et al. combined the Hurst exponent and the neural network to develop a crack detection algorithm of carbide anvils [

11]. Subsequently, Yan et al. designed a signal sampling and processing platform based on the digital signal processor and the field-programmable gate array, with a low false-alarm rate of

using the sliding time window (STW) technique [

12]. This method suffers from the trade-off between the missing-alarm rate and false-alarm rate, with 24 cracked samples misclassified as normal ones among 63 testing samples. The recognition rate is 95% when combined with the STW technique, which takes cost of the real-time performance into account. A more practical crack detection method is still lacking.

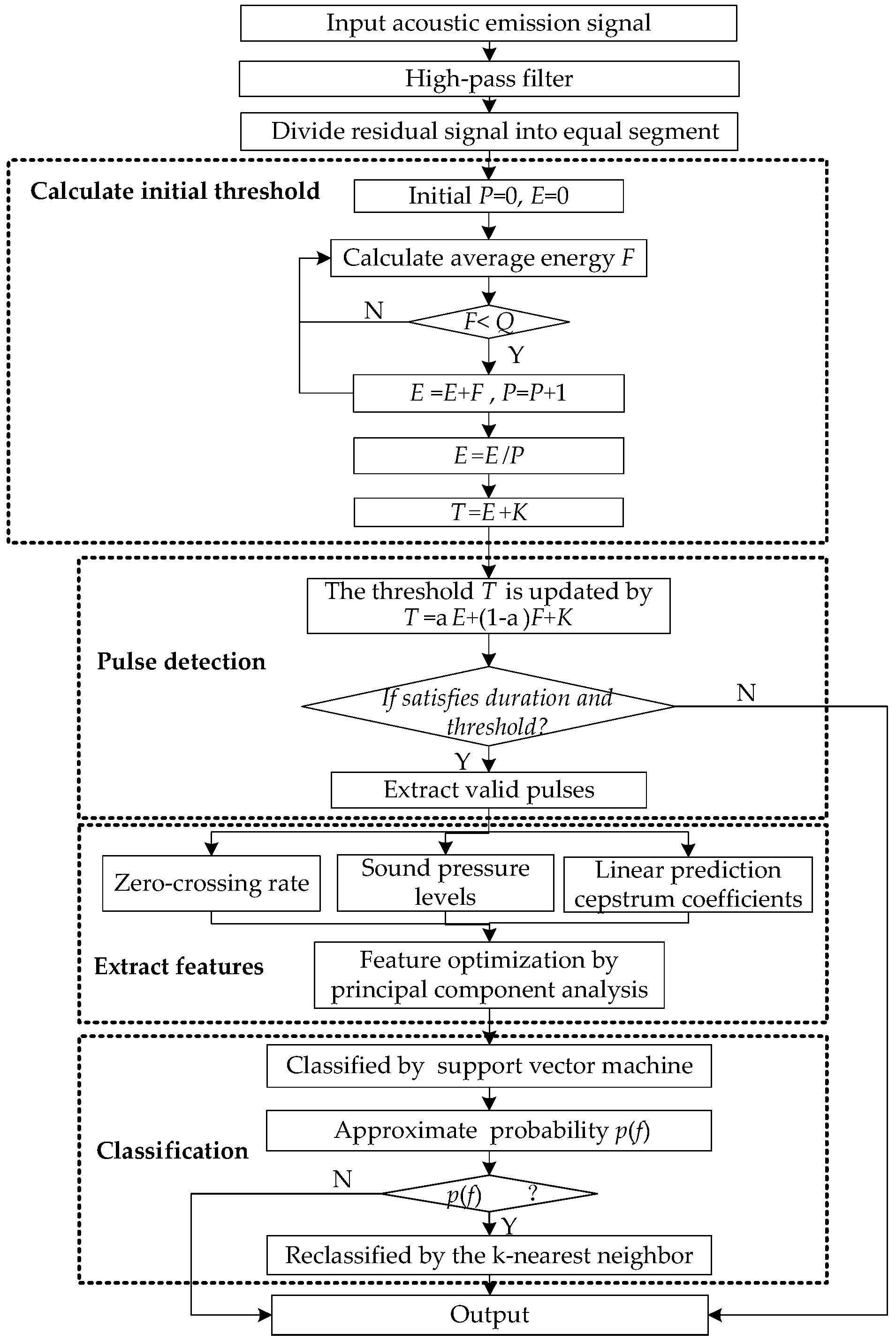

Aiming to improve recognition accuracy and generalization, a novel crack detection method based on acoustic emission and pattern recognition is proposed. In this method, the cracked sound pulses are firstly separated from the original signal by preprocessing. According to the mechanism of the crack, three different kinds of features are presented. The high-dimensional features are reduced adaptively by using principal component analysis (PCA). The algorithm combines a k-nearest neighbor (kNN) classifier with a support vector machine (SVM) to refine the classification outcome. Finally, experiments are carried out in a practical synthetic diamond workshop to validate the feasibility and efficiency of the proposed method.

The remainder of the paper is organized as follows.

Section 2 presents the principle of the acoustical crack detection method of the carbide anvil based on acoustic emission and pattern recognition. The effectiveness of the proposed method is supported by the experimental work described in

Section 3. Finally, conclusions are drawn in

Section 4.

3. Experiment and Discussions

To validate the effectiveness of the proposed method, experiments are conducted in the practical synthetic diamond workshop in Henan Golden Canal Group Co., Ltd. in China. The measuring microphone, B&K 4189, is mounted at one operation port of the apparatus by a bracket, as shown in

Figure 5. The acoustic signal is recorded by the B&K Pulse. The normal sound pulses are directly collected from the apparatuses in regular operation, consisting of pressurization, maintaining pressure and decompression pressurization; moreover, these apparatuses continuously work well after a long time. The cracked sound pulses are recorded from experimental apparatus preinstalled on six cracked anvils.

Figure 6 shows a cracked anvil with serious surface damage caused by the crack, the location of which is marked by a circular red line. It is noted that the cracked sound pulses are confirmed and labeled by playbacks and discussions with experienced workers.

The choice of sampling frequency is based on the following considerations. In practice, the cracked sound pulses can be distinguished from the normal ones through artificial hearing (20 Hz–20,000 Hz). This means the upper sampling frequency of the measuring signal only needs to be 40,000 Hz. However, the applied B&K Pulse can only adjust the sampling frequency to 8192 Hz, 16,384 Hz, 32,768 Hz, 65,536 Hz or 131,072 Hz. Thus, the 65,536 is finally chosen. The parameters in the sound pulse detection algorithm are listed in

Table 1.

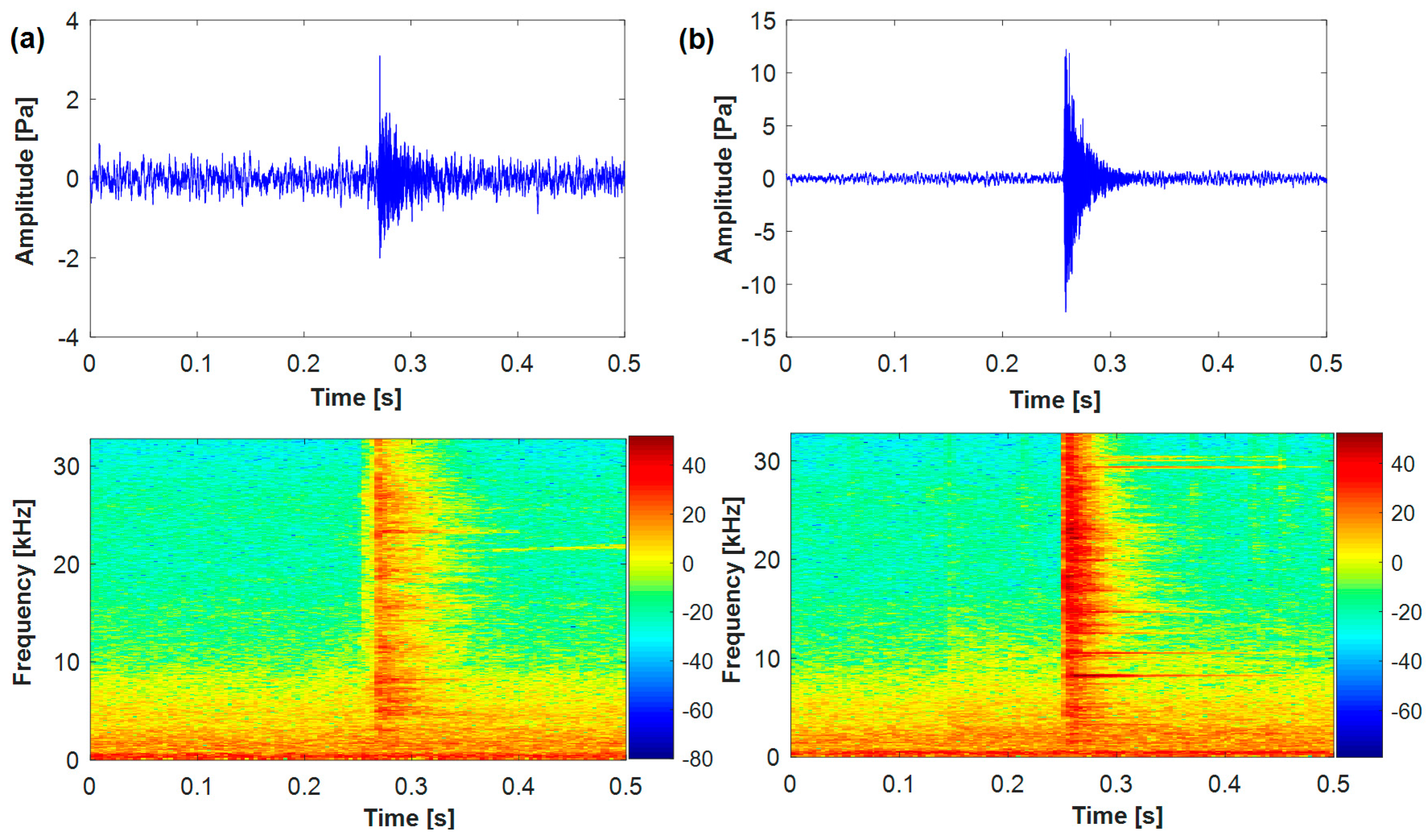

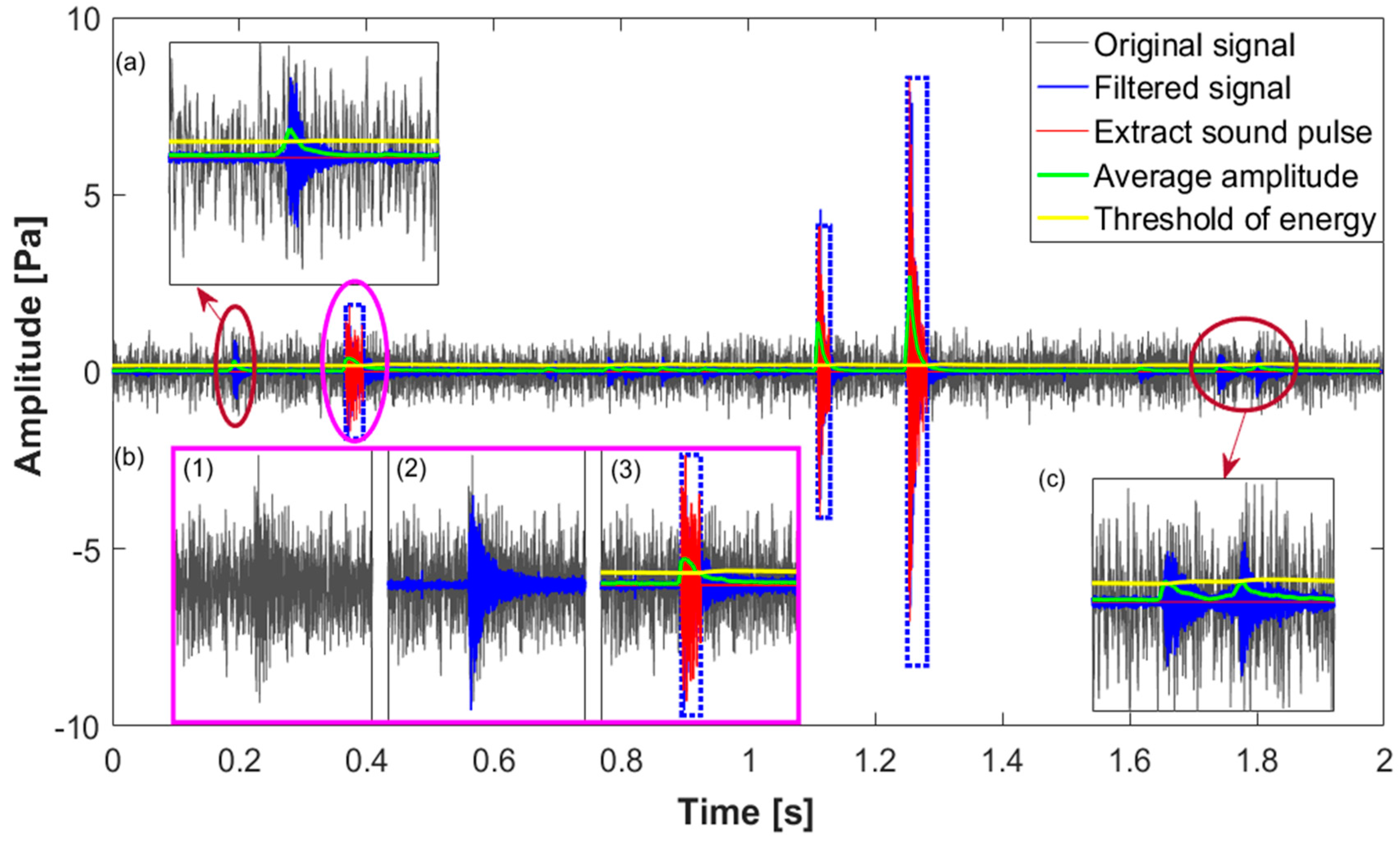

Figure 7 shows an example of the cracked sound pulse extraction from a continuous signal recording from the apparatus preinstalled on six cracked anvils. Clearly, three cracked sound pulses are located at about 0.35 s, 1.1 s and 1.25 s and are indicated in the blue dashed frame. Compared to the last two pulses, the first one is covered up by significant background noise as shown in subgraph (b); however, it becomes more obvious by using a 5000 Hz high-pass filter. The start and end coordinates are located by comparing the average amplitude and threshold of energy. Besides, some sound pulses are still observed from the filtered signal, as shown in subgraphs (a) and (c). These sound pulses do not match the criteria of duration and average energy as illustrated in

Section 2.1, thus they are discarded. This confirms that the proposed method extracts the cracked sound pulses effectively.

In the experiment, 144 cracked sound pulses and 738 normal ones are extracted and used as a data set.

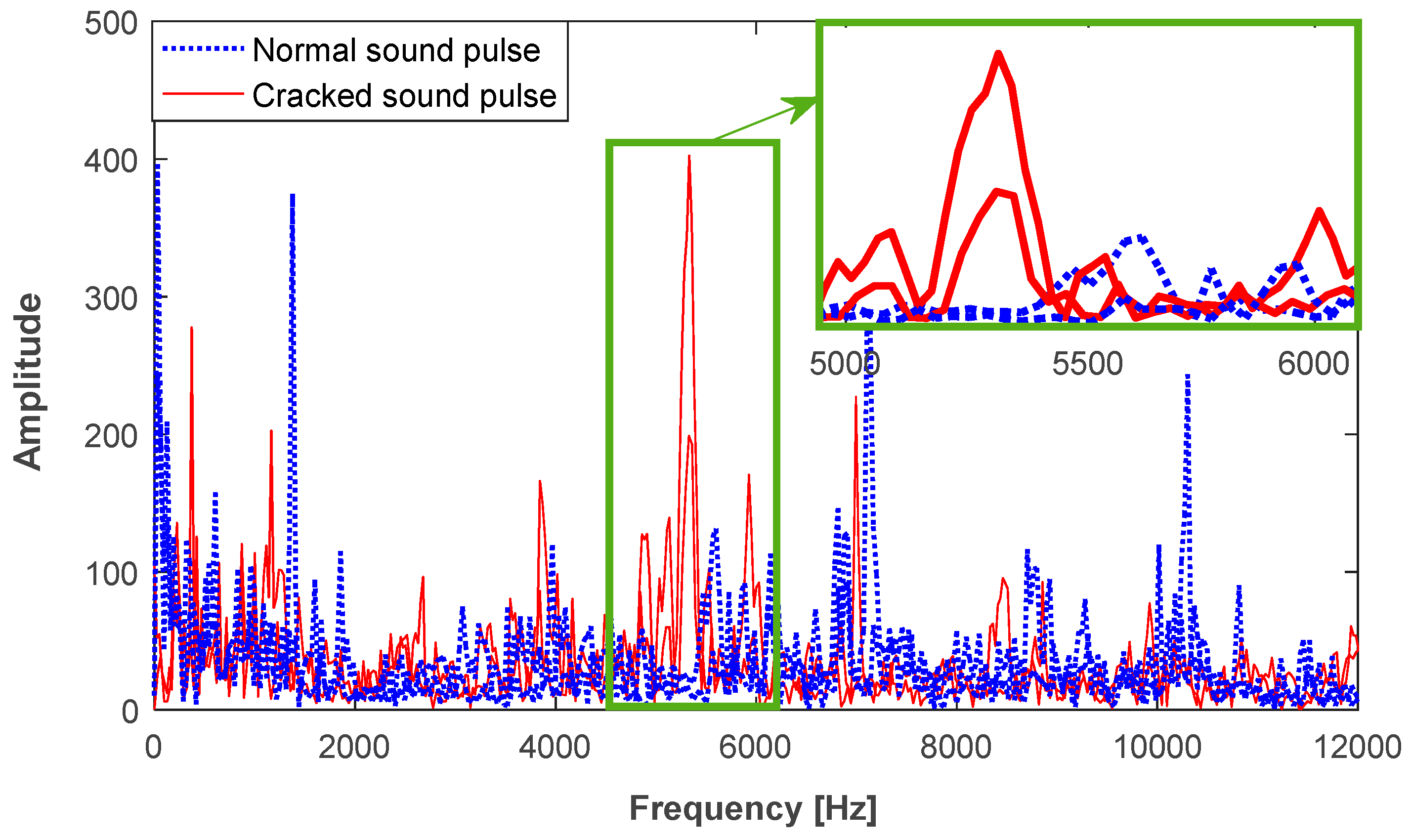

Figure 8 shows results of the ZCR, SPLs and LPCCs for some of the cracked sound pulses in combination with the normal ones.

As shown in

Figure 8a, the ZCR of normal sound pulses is stable with the predominant value at about 0.38, while the cracked ones have a greater value, distributed over a larger interval [0.3, 0.55]. This indicates that the cracked sound pulse has more energy in a high frequency band, and the ZCR has an ability to distinguish cracked sound pulses from normal ones. Besides, there is a slight overlap between the normal and cracked sound pulses. With an increase in the number of samples, the overlaps become more serious due to the dispersion and randomness.

Figure 8b shows the SPLs in the 1/6 octave frequency band [500 Hz, 32,768 Hz]. Since the cracked sound pulses may have a short duration of 16 ms, the SPLs below 500 Hz do not exist. Compared to the normal sound pulses, distinct peaks exist in cracked ones, e.g., the 1/6 octave frequency bands [5339 Hz, 5993 Hz], marked by a dashed rectangle. Besides, the SPLs for a majority of the cracked sound pulses have a greater value in the frequency band above 10 kHz. It should be pointed out that this phenomenon does not always exist. In terms of the 1/6 octave frequency band, 35 SPL features are extracted from a sound pulse.

Figure 8c depicts the results of the thirteenth-order LPCCs, the average value of which is described by marked lines. Obviously, the second-order coefficient for the cracked sound pulses ranges from −0.2 to 0.4, which is different from the normal ones. There are randomly some slight differences at other orders. Since the first-order LPCC has no practical relevance, with a value of one, the other 12 LPCC features are extracted to characterize the sound pulses.

Finally, 48 high-dimensional raw features, consisting of ZCR, 35 SPLs and 12 LPCCs, are extracted.

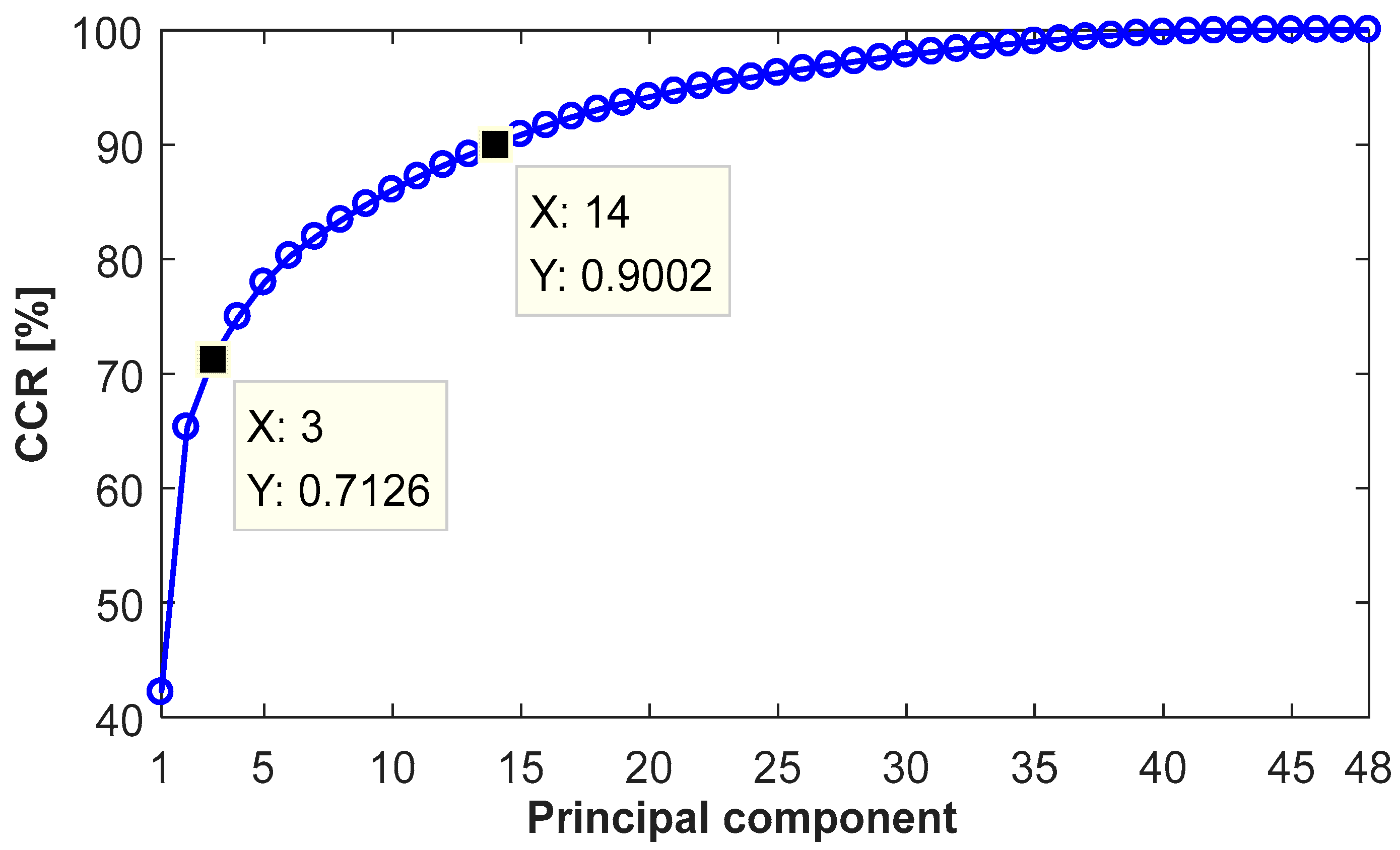

Figure 9 plots the results of the feature reduction by the PCA. It can be seen that the CCR significantly increases when the number of principal components rises from one to three, reaching 71.26%. It indicates that three low-dimension principal components contain the most information in sound pulses. Then, the increasing trend gradually flattens due to a reduced amount of information contained in the principal components. When the number increases to 14, the CCR reaches 90.02%. Subsequently, the CCR improves by only 10%, with the number of principal components rising from 14 to 48. A proper number of the principal component is determined by the trade-off between CCR and data simplification. In this way, the feature dimension is reduced significantly.

The selected principal components are used as an input feature vector of the SVM-kNN classifier. In the algorithm, to decrease the false alarm rate, is set greater than as ; is set to one-third of the total support vectors; is set as 0.5.

The kernel parameter

of the radial basis function and penalty factor

are optimized by a grid search with a 3-fold cross validation. For example, 70% of the normal and cracked samples is randomly selected as a training set, and the others are selected for testing.

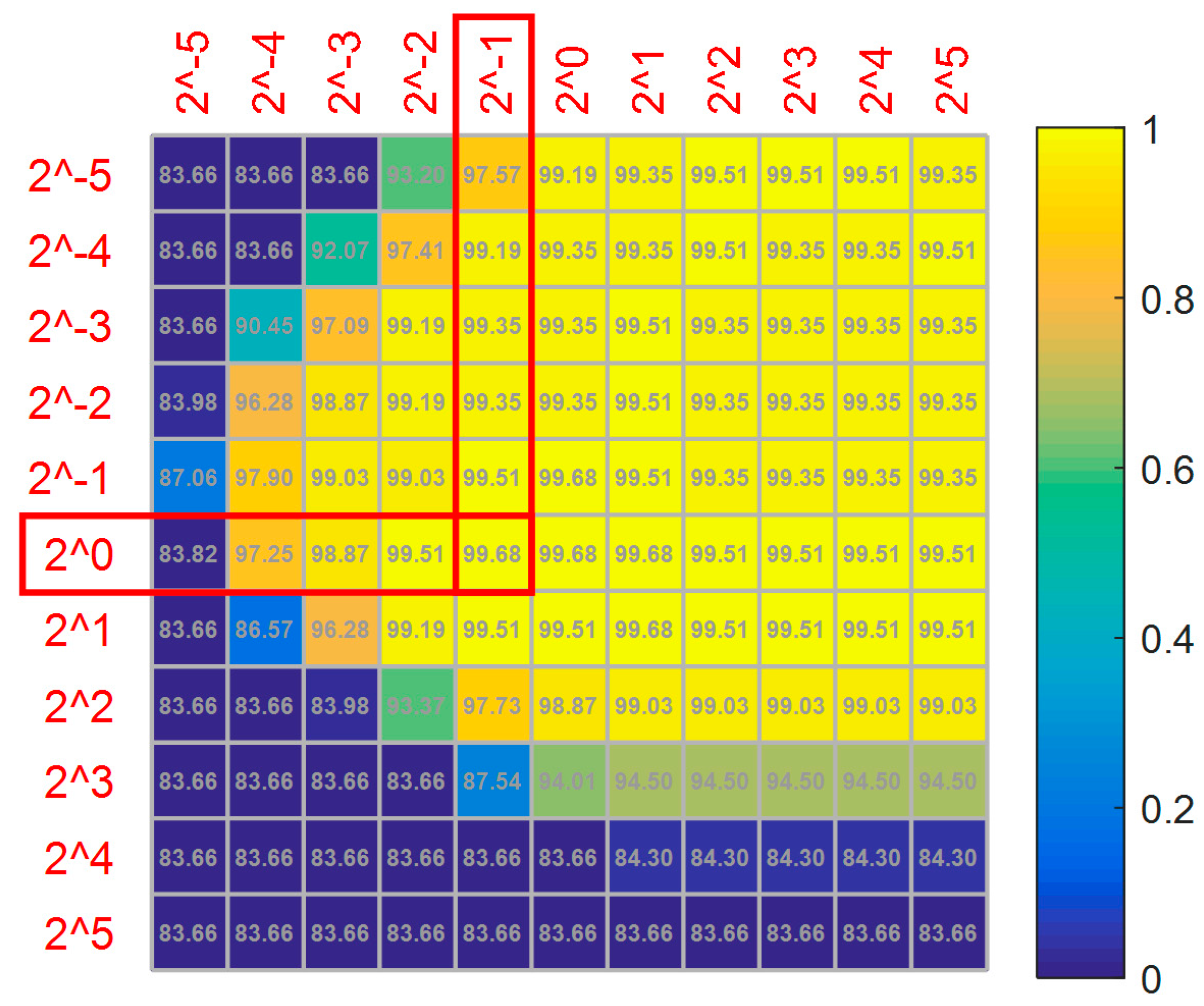

Figure 10 gives the optimization results with

as abscissa and

as ordinate, with the values ranging from

to

. The numbers in squares represent the classification accuracy.

It can be seen from

Figure 10 that the accuracy reaches a maximum and then decreases with the increase of the penalty factor when the kernel parameter is fixed. It is clear that the best accuracy is 99.68% among 121 (

,

) pairs. To avoid over-fitting and improve recognition accuracy on the testing set, the minimum pair (0.5, 1) is chosen among five candidate pairs with the same value of 99.68%.

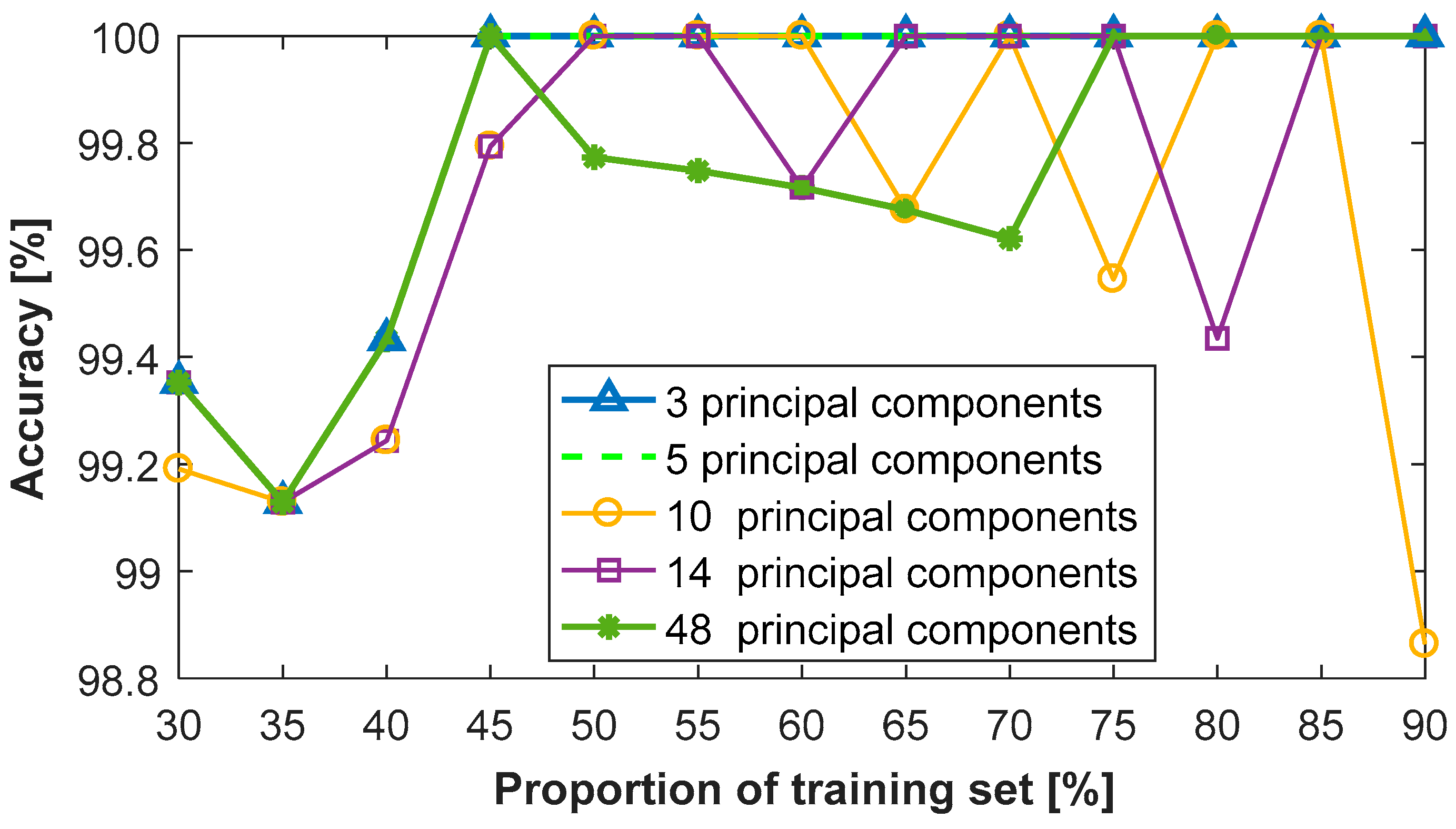

Figure 11 shows the classification results using the SVM-kNN classifier with different proportions of the training set and five representative numbers of the principal components, being values of the 3, 5, 10, 14 and 48. Clearly, there is a high accuracy of more than 98.8% for all conditions. The curve of the three principle components overlaps with the one of five principal components. Their accuracies increase rapidly and then remain constant, with an accuracy of 100% with the proportion rising from 45% to 90%. When the number of principal components is 10, 14 or 48, their accuracies slightly decrease randomly after reaching the highest value of 100%.

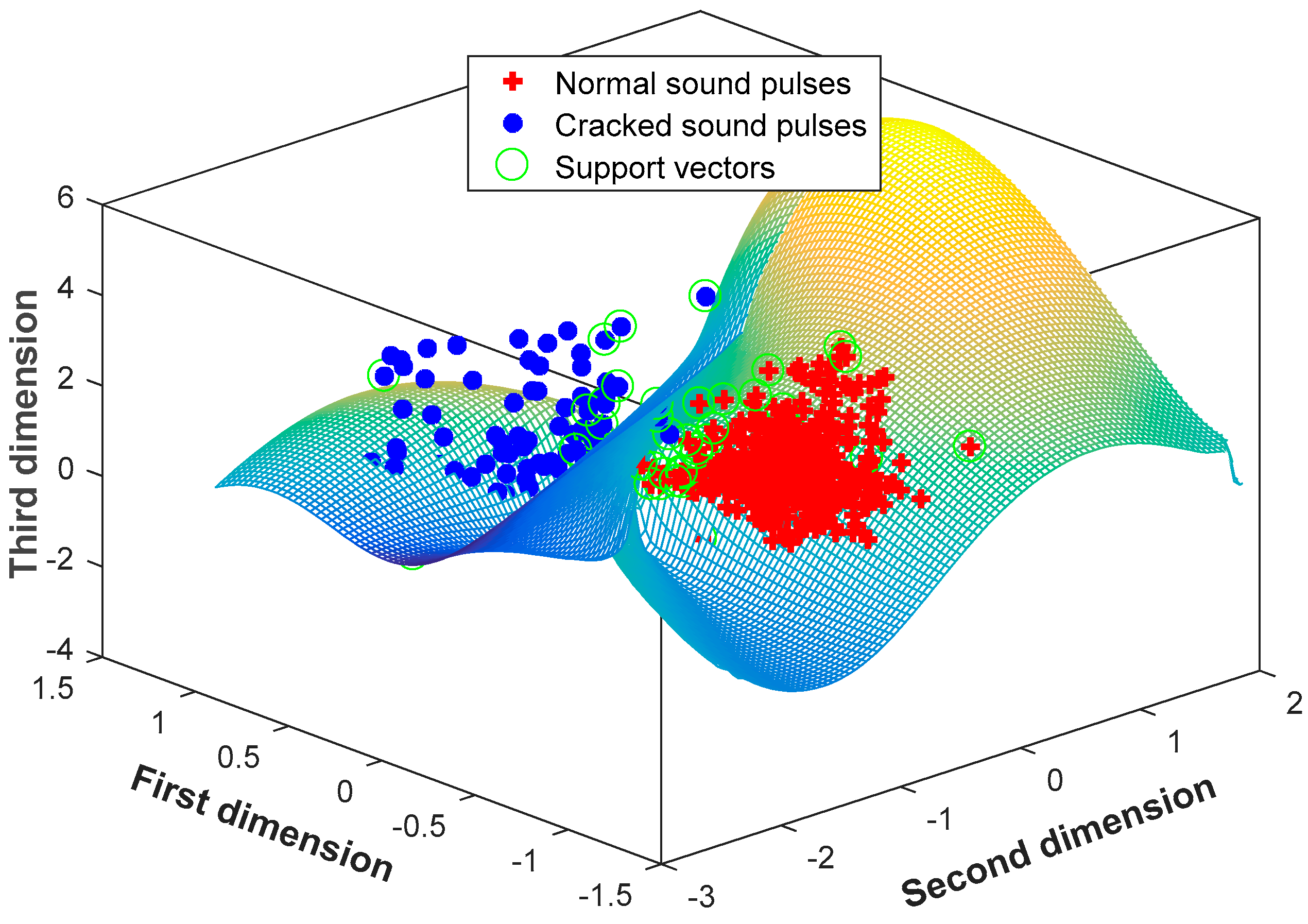

Obviously, the performance of the SVM-kNN classifier does not improve with an increase of principal components. Taking three principal components as an input feature vector,

Figure 12 plots the distribution of training samples, with a proportion of 70%, and the trained classification surface in the three-dimensional coordinate. The number of normal support vectors is 25; the number of cracked support vectors is 26. The normal sound pulses well aggregate, while the cracked ones scatter. They are classified by the hyperplane, with an accuracy of 100%.

Figure 13 compares the classification results of the proposed SVM-kNN model in combination with stand-alone SVM using three principal components. Clearly, the designed SVM-kNN classifier performs better than the stand-alone SVM; notably, the proportion ranges from 40% to 80%.