EEMD-Based Steady-State Indexes and Their Applications to Condition Monitoring and Fault Diagnosis of Railway Axle Bearings

Abstract

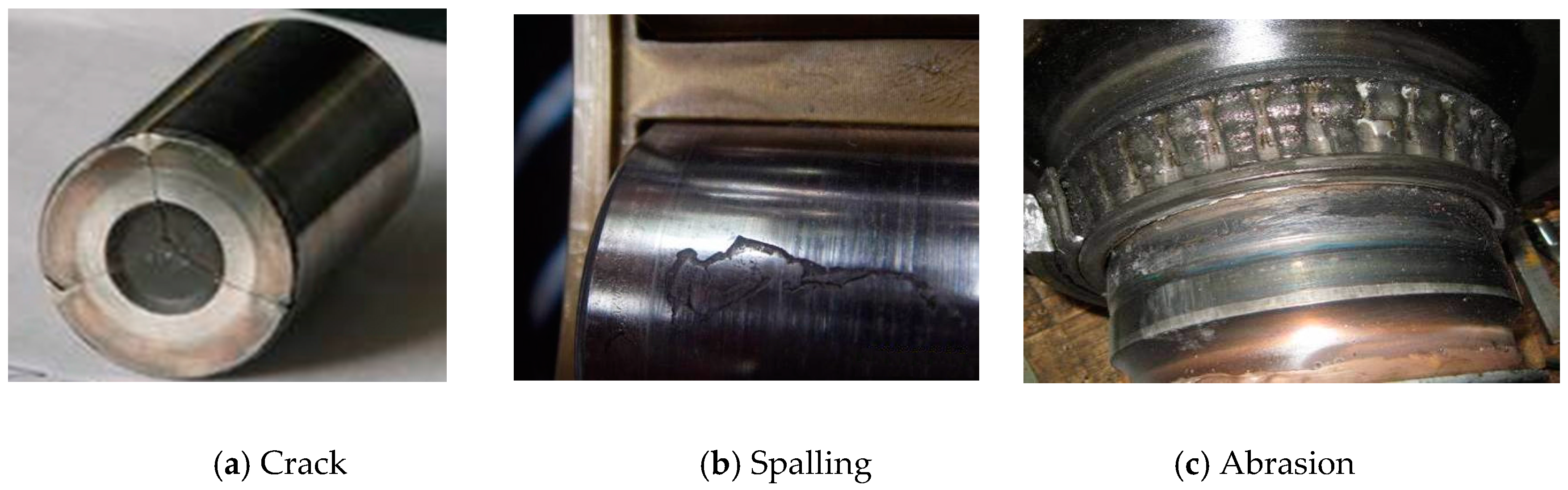

:1. Introduction

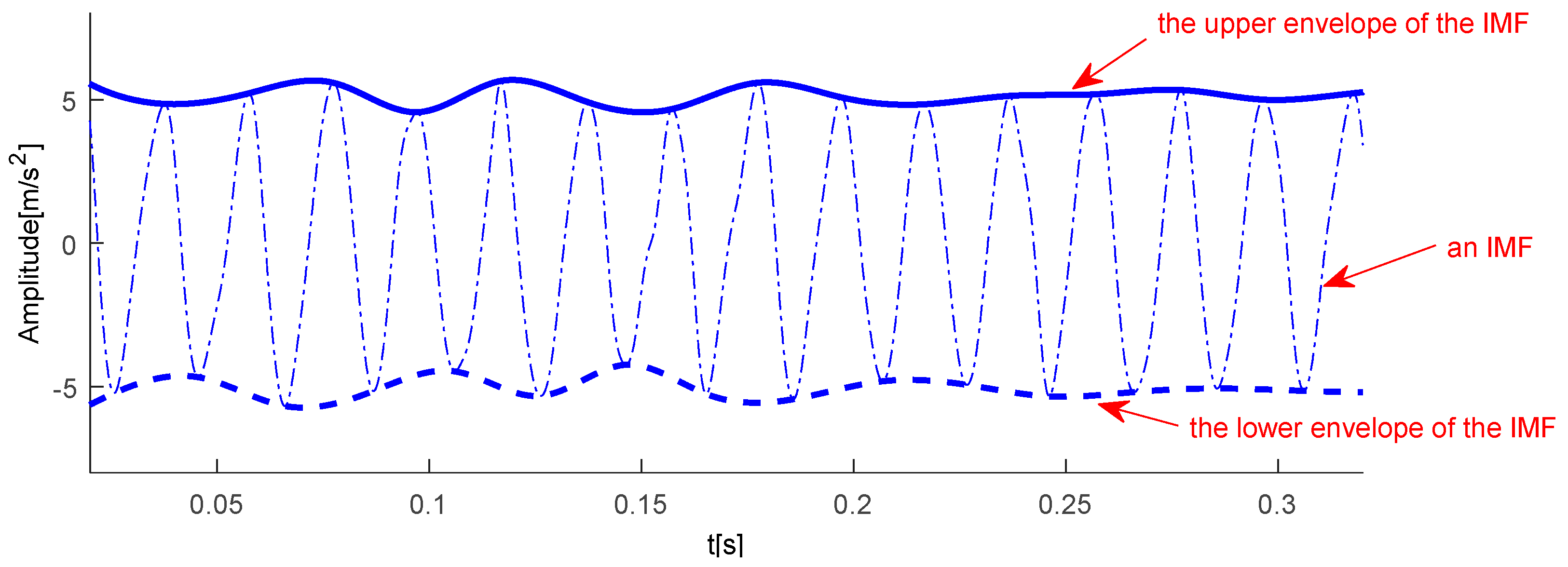

2. Adaptive Signal Decomposition

2.1. Ensemble Empirical Mode Decomposition

- Step 1:

- Generate a new series by adding white noises into an original series . When the white noises, which consist of components of different frequency scales and are uniformly distributed with a constant standard deviation, are added to the original signal of concern to form a series corrupted by the white noises. Here, the white noises will make different scale signals reside in their corresponding IMFs.

- Step 2:

- Identify all local maximum and minimum of the time series .

- Step 3:

- Generate an upper envelope and a lower envelope of .

- Step 4:

- Calculate the mean from the upper and lower envelopes.

- Step 5:

- Calculate the difference between and as the first component .

- Step 6:

- The sifting process has to be iterated several times until satisfies the definition of an IMF, and then the first IMF is generated.

- Step 7:

- A residue generated by subtracting the first IMF from the time series is treated as a new series, and then repeat Steps 2 to 6 to gain all IMFs and an ultimate residue.

2.2. Selection of IMFs

- (1)

- Choose a fixed IMF to derive the unsteadiness of a vibration signal of axle bearings, such as the third IMF or the fourth IMF. The basic property variation of a specific IMF, such as amplitude and energy change and so on, may measure the dynamic instability of axle bearings.

- (2)

- Choose an IMF due to a specific frequency component, such as an IMF with a location of a rotating frequency of axle bearings; in this way, a particular frequency cluster does not always exist in a fixed IMF.

- (3)

- Choose an IMF thanks to a specific characteristic, such as an IMF with the largest energy.

3. The Definition of EEMD Based Steady-State Indexes

3.1. A Steady-State Index in Time Domain

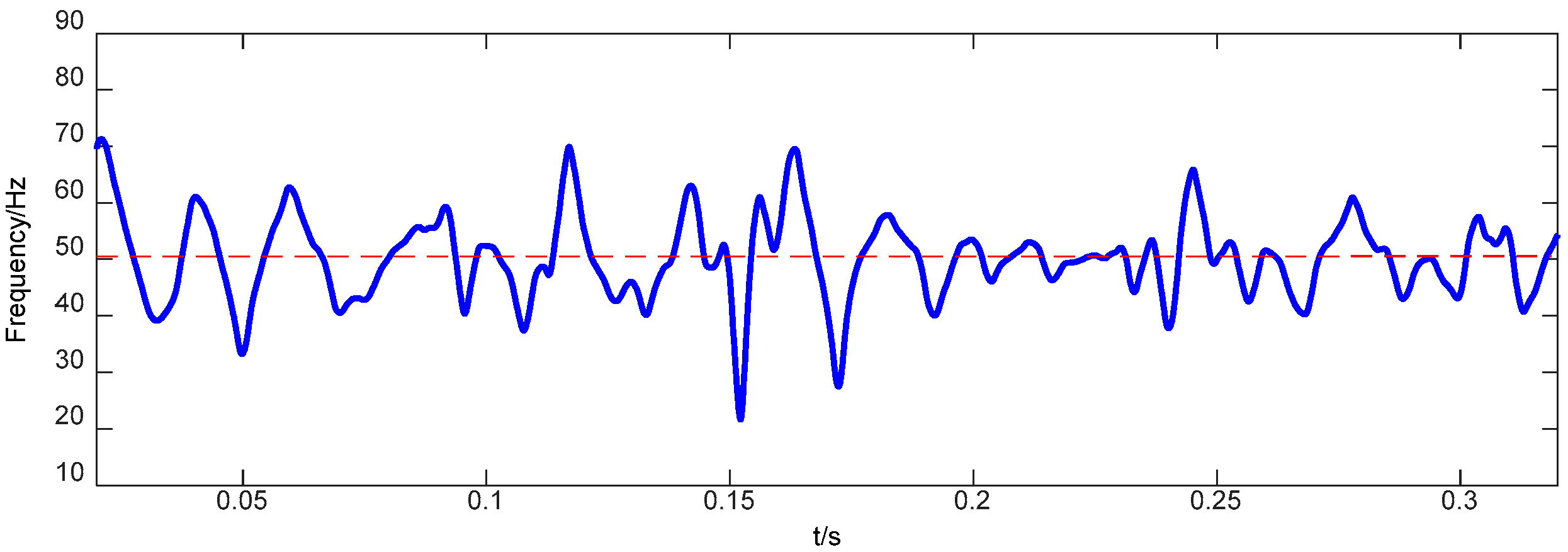

3.2. A Steady-State Index in an Instantaneous Frequency Domain

- Step 1:

- Decompose an original signal into IMFs using EEMD.

- Step 2:

- Identify all local maxima of the absolute value for the th IMF . Here that the normalized data that are symmetric with respect to a zero axis would be guaranteed by using the absolute value fitting.

- Step 3:

- Constructing a cubic spline curve by connecting all these maxima points. The spline curve is designated as an empirical envelope of the IMF.

- Step 4:

- Normalization of the envelope curve by with as normalized data.

- Step 5:

- Ideally, should have all the extrema with unity value. At the locations of fast changing amplitudes, the envelope spline line passing through the maxima can go below some data points. If the normalized data still have amplitudes higher than unity occasionally, unfortunately, the normalization procedure can be implemented repeatedly with defined as the empiric envelope for , and so on. So if , the calculation process will black out; if not, Steps 2 to 4 will be repeated until satisfies that , where is the number of repeats.

3.3. A Steady-State Index in a Shape Domain

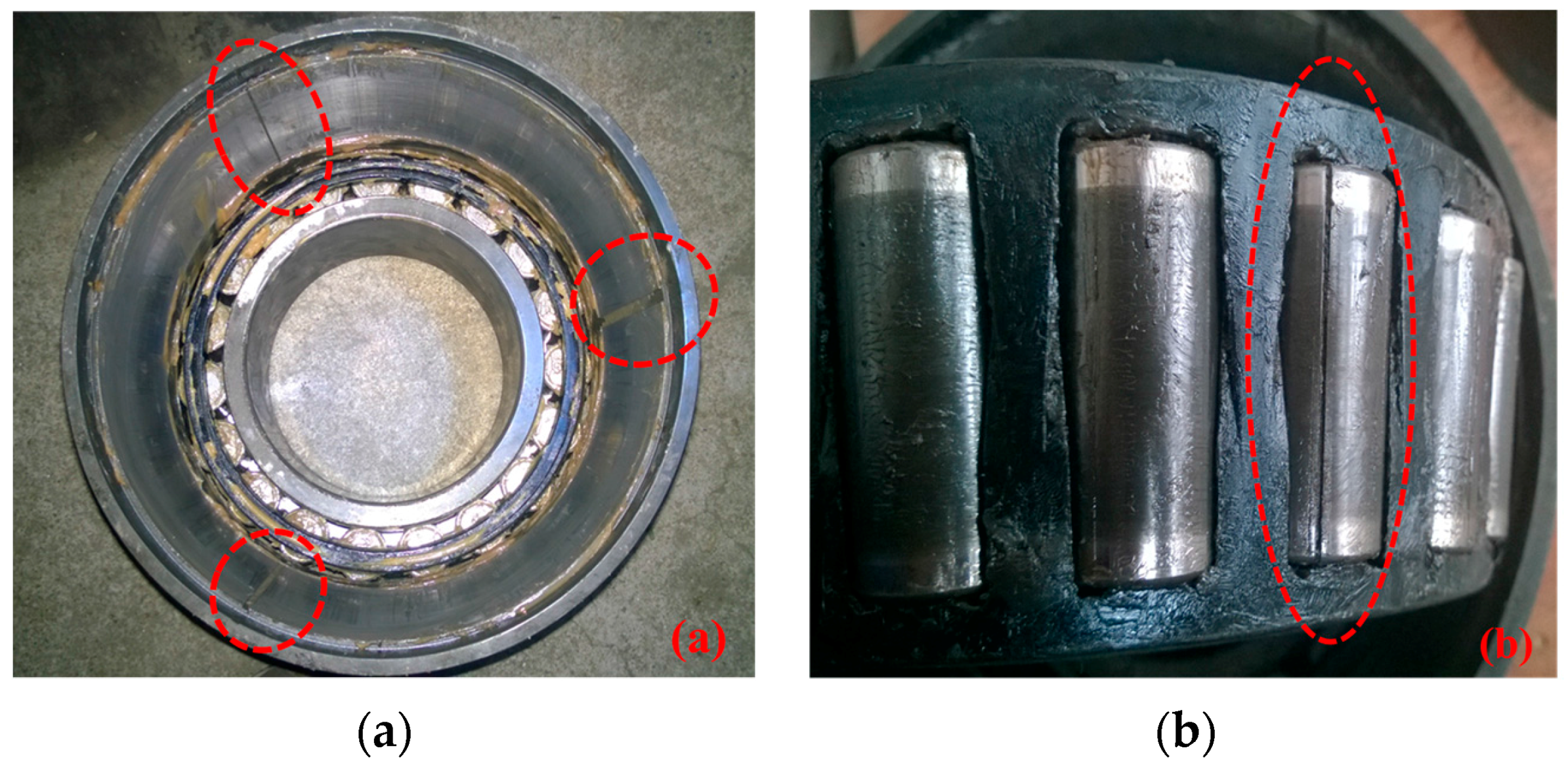

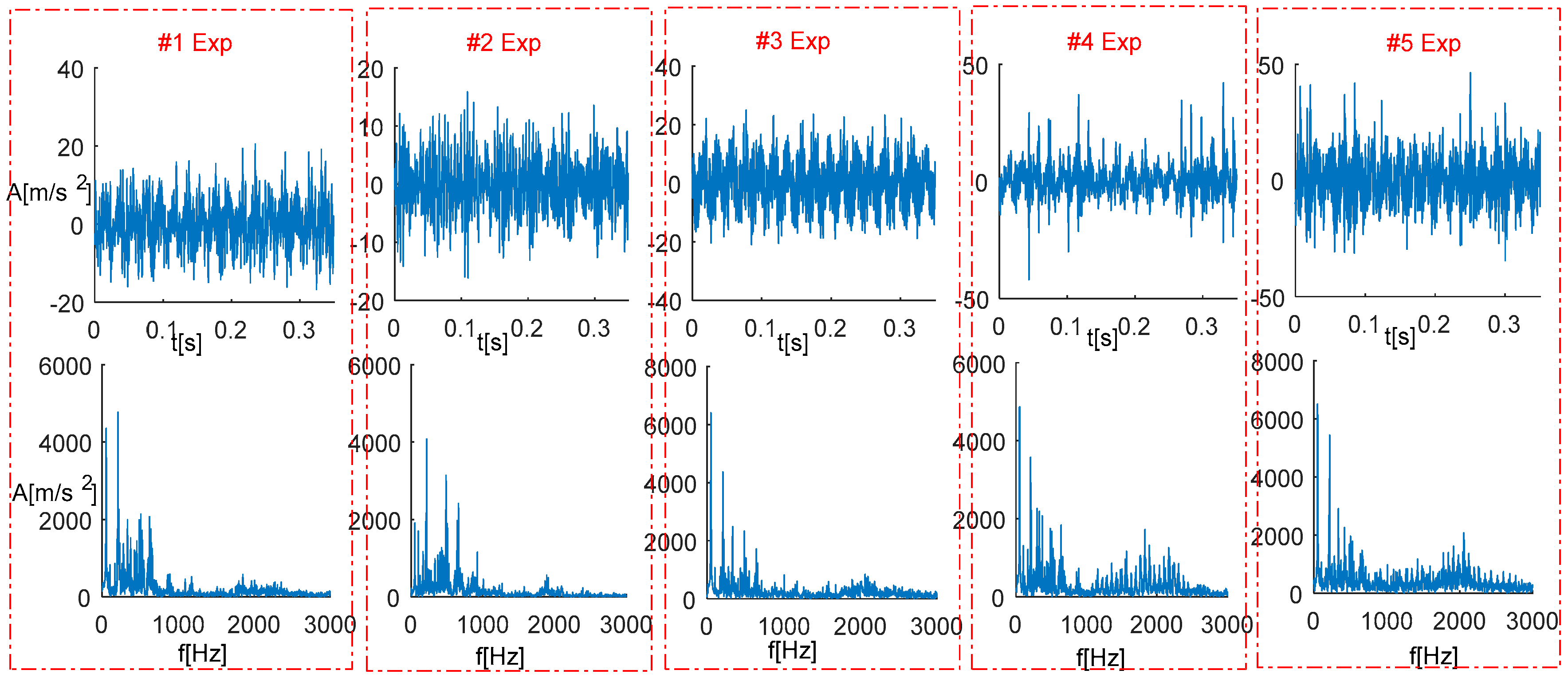

4. Descriptions of Experiments and Railway Axle Bearing Data

5. Application of Steady-State Indexes to Characterizing Railway Axle Bearing States

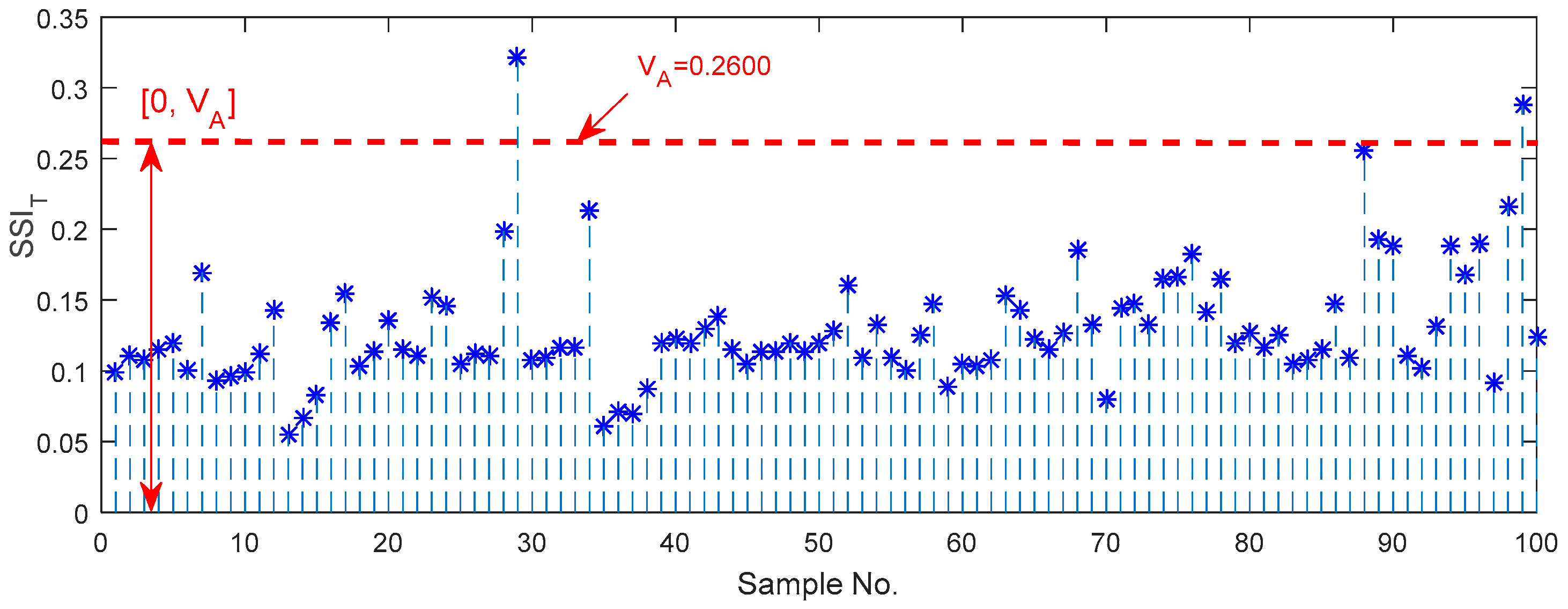

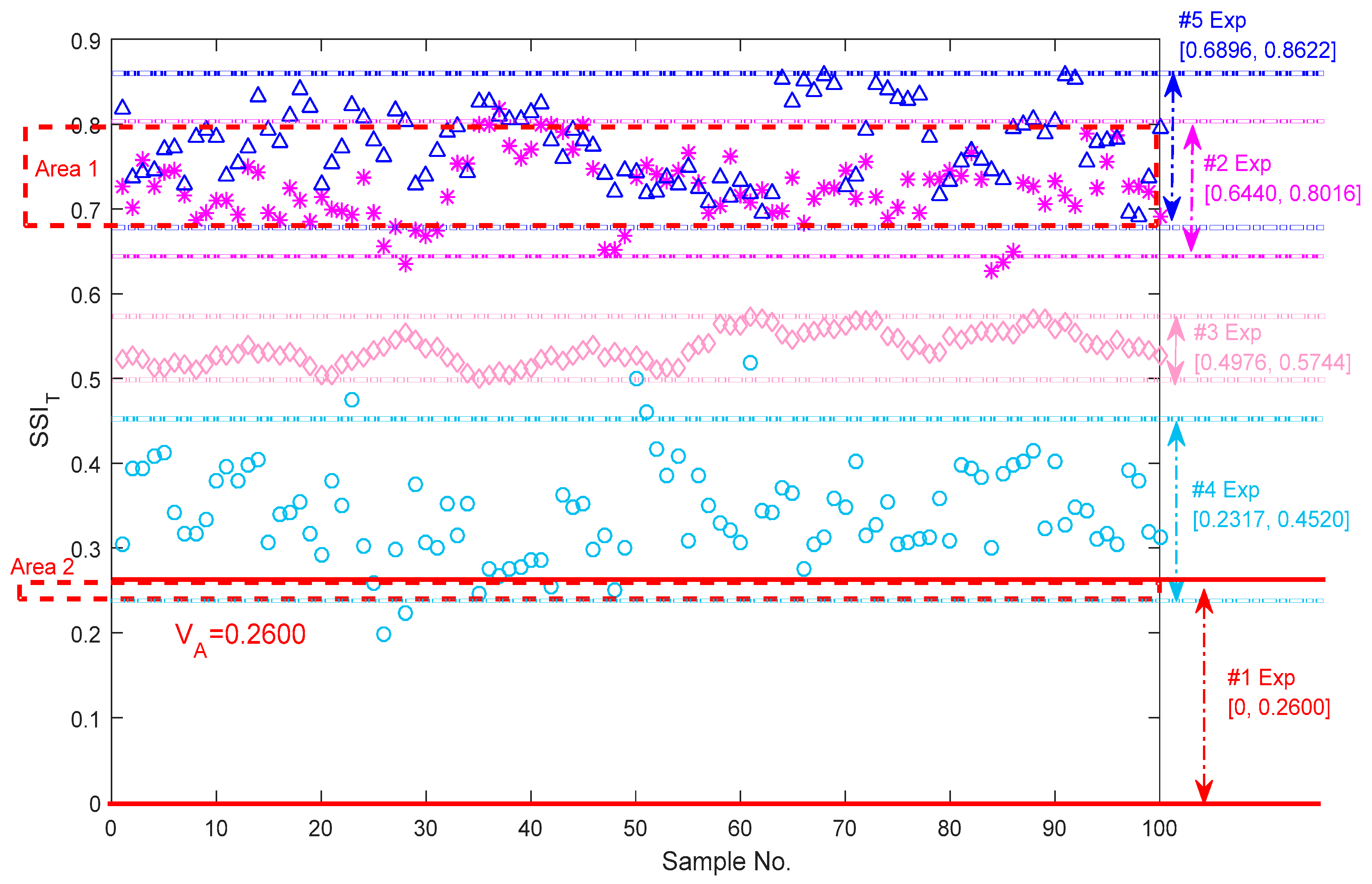

5.1. Characterization of Bearing Vibration Signals Using the SSI in a Time Domain

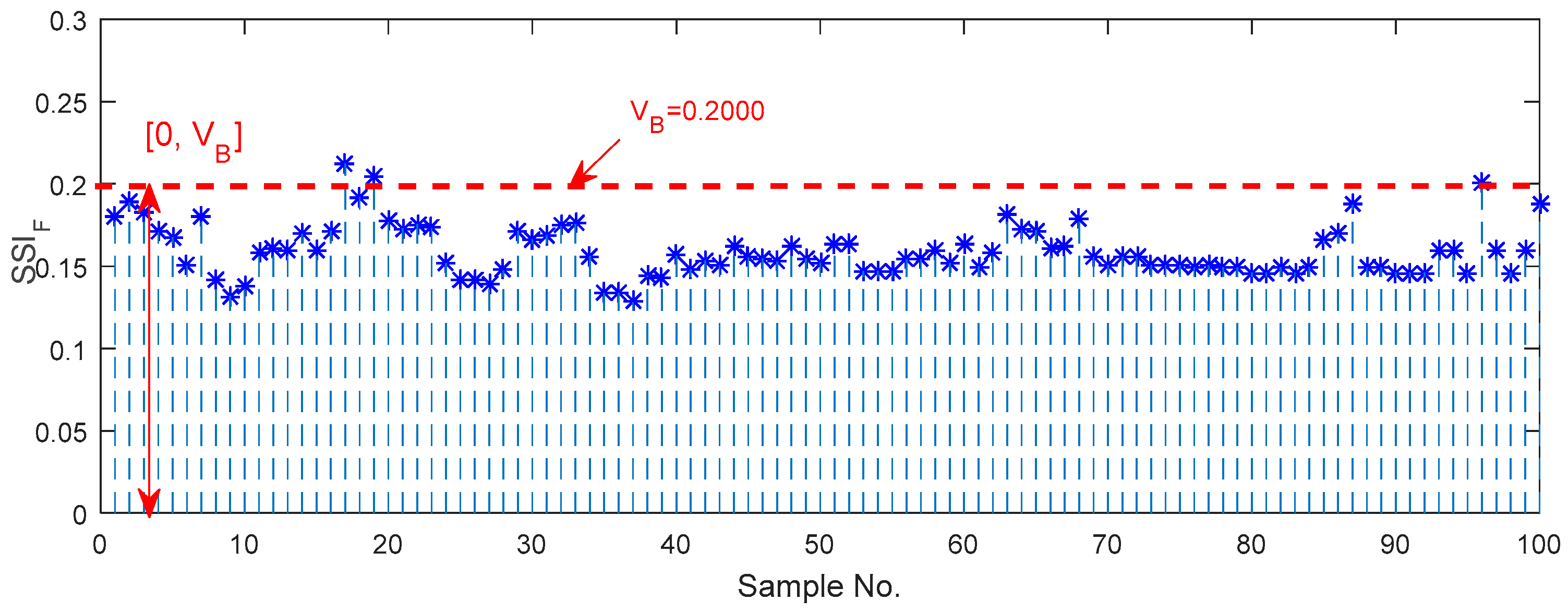

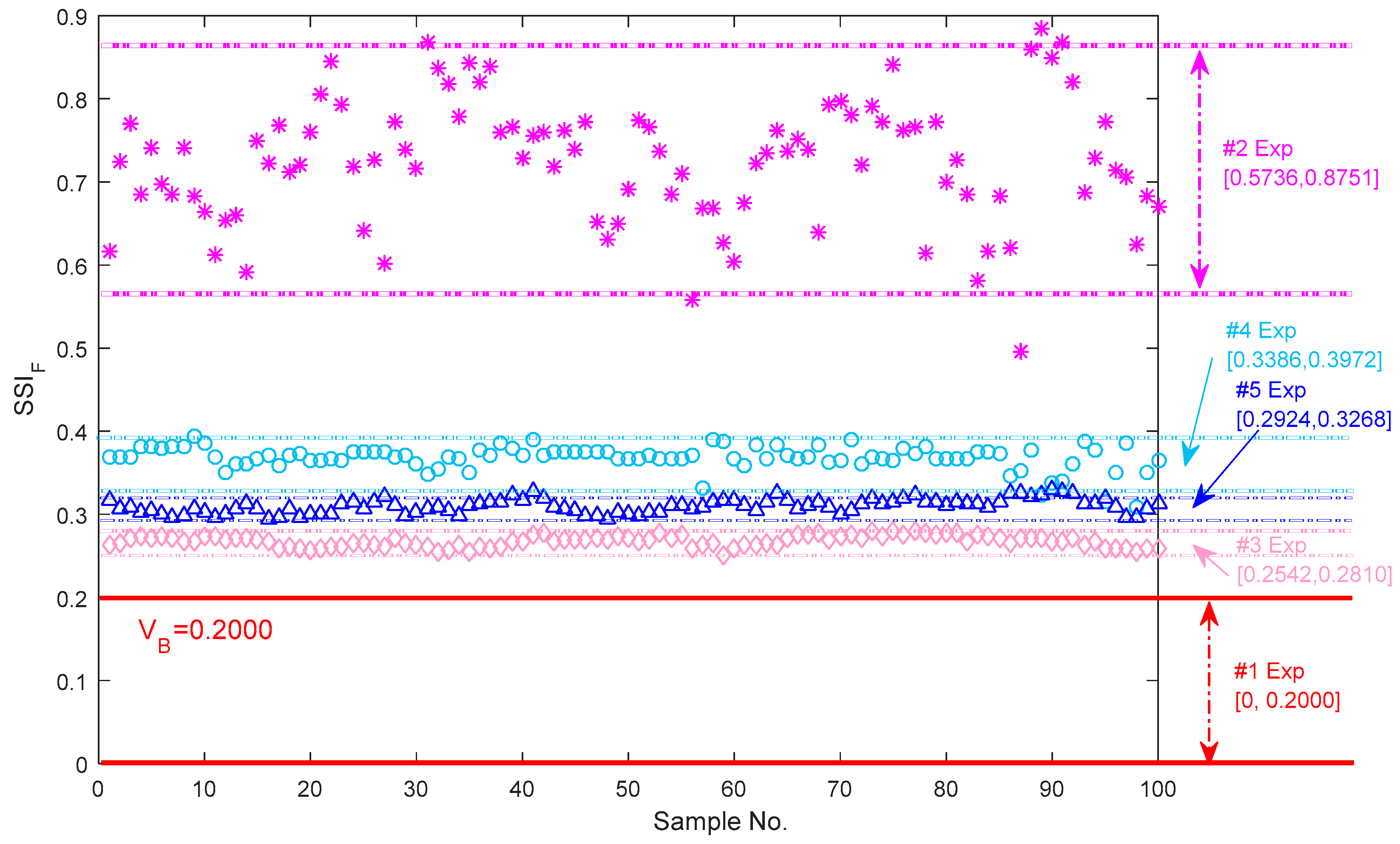

5.2. Characterization of Bearing Vibration Signals Using SSI in Frequency Domain

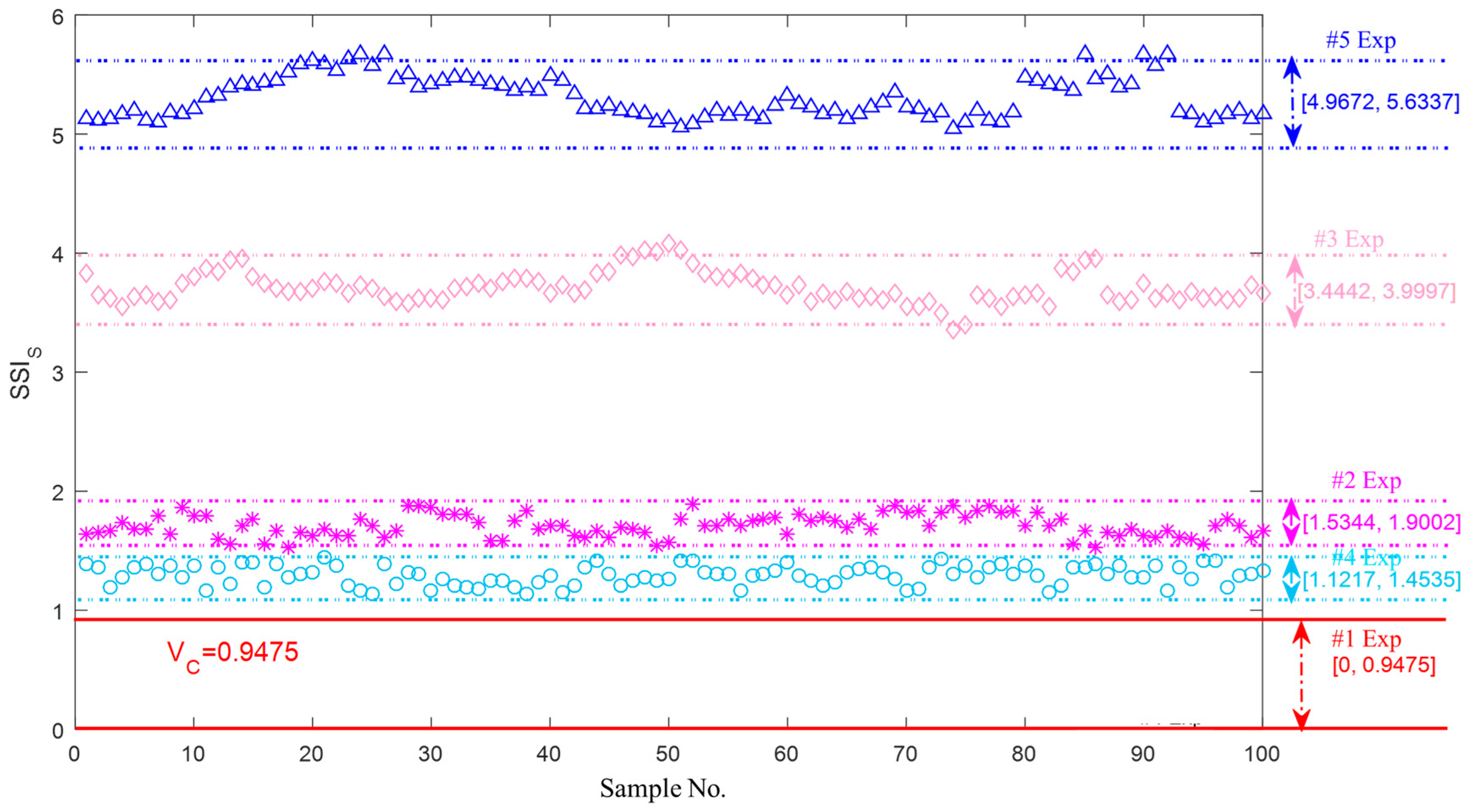

5.3. Characterization of Bearing Vibration Signals Using the SSI in a Shape Domain

5.4. Summary

- (1)

- All three types of steady-state indexes based on EEMD can distinguish the normal and abnormal axle bearings, and their upper and lower boundaries can be considered as some monitoring guideline thresholds.

- (2)

- All three types of steady-state indexes can be used to classify and characterize the single defects well, and the metrological boundaries for the three types of the single faults are established.

- (3)

- The steady-state indexes in the frequency domain and the shape domain outperform that defined in the time domain for characterizing the multiple coupling defects because the has some overlapped regions when it is used to distinguish the coupling defects with the outer race defect.

- (4)

- The steady-state index in the time domain has fastest computational efficiency than those defined in the frequency domain and the shape domain. The needs the extensive time because of the Hilbert transform process. For the steady-state index in the shape domain, the shape function is computed firstly and then the can be obtained based on two sets of shape functions. But the computational efficiency of the whole computing program is slightly higher than that required in the frequency domain.

- (5)

- The steady-state index in the shape domain is derived from the basic shape function in the normal condition and the shape function related to the detected signal, and a fixed period facilitates the calculation process, but the prior data mode and the fixed period make this method difficult to be implemented. The steady-state index in the time domain has a simplest calculation process, and the method is in a medium level of difficulty in implementing.

- (6)

- All of the three types of steadiness indexes are non-dimensional so that the different bearing conditions can be characterized by the numerical values in the same domain. However, the threshold values and metrological boundaries between the three index definitions are different from each other. This is because these steady-state indexes do not have a direct mapping with mechanical physical stability. Moreover, these non-steadiness indices are based on different computing principles so that the resulting values are far apart among the three characterization methods.

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Yi, C.; Lin, J.; Zhang, W.; Ding, J. Faults Diagnostics of Railway Axle Bearings Based on IMF’s Confidence Index Algorithm for Ensemble EMD. Sensors 2015, 15, 10991–11011. [Google Scholar] [CrossRef] [PubMed]

- Symonds, N.; Corni, I.; Wood, R.J.K.; Wasenczuk, A.; Vincent, D. Observing early stage rail bearing damage. Eng. Fail. Anal. 2015, 56, 216–232. [Google Scholar] [CrossRef]

- Vale, C.; Bonifacio, C.; Seabra, J.; Calcada, R.; Mazzino, N.; Elisa, M.; Terribile, S.; Anguitac, D.; Fumeo, E.; Saborido, C.; et al. Novel efficient technologies in Europe for axle bearing condition monitoring—The MAXBE project. Transp. Res. Procedia 2016, 14, 635–644. [Google Scholar] [CrossRef]

- Papaelias, M.; Amini, A.; Huang, Z.; Vallely, P.; Dias, D.C.; Keykyras, S. Online condition monitoring of rolling stock wheels and axle bearing. J. Rail. Rapid Transit 2016, 230, 709–723. [Google Scholar] [CrossRef]

- Wang, C.; Shen, C.; He, Q.; Zhang, A.; Liu, F.; Kong, F. Wayside acoustic defective bearing detection based on improved Dopplerlet transform and Doppler transient matching. Appl. Acoust. 2016, 101, 141–155. [Google Scholar] [CrossRef]

- Zhao, M.; Lin, J.; Miao, Y.; Xu, X.Q. Detection and recovery of fault impulses via improved harmonic product spectrum and its application in defect size estimation of train bearings. Measurement 2016, 91, 421–439. [Google Scholar] [CrossRef]

- Cao, H.; Fan, F.; Zhou, K.; He, Z. Wheel-bearing fault diagnosis of trains using empirical wavelet transform. Measurement 2016, 82, 439–449. [Google Scholar] [CrossRef]

- Li, Y.; Liang, X.; Lin, J.; Chen, Y.J. Train axle bearing fault detection using a feature selection scheme based multi-scale morphological filter. Mech. Syst. Signal Process. 2018, 101, 435–448. [Google Scholar] [CrossRef]

- Li, X.; Jia, L.; Yang, X. Fault diagnosis of train axle bearing based on multifeature parameters. Discret. Dyn. Nat. Soc. 2015, 2015. [Google Scholar] [CrossRef]

- Henao, H.; Capolino, G.A.; Fernandez-Cabanas, M.; Filippetti, F.; Bruzzese, C.; Strangas, E.; Pusca, R.; Estima, J.; Riera-Guasp, M.; Hedayati-Kia, S. Trends in Fault Diagnosis for Electrical Machines: A Review of Diagnostic Techniques. IEEE Ind. Electron. Mag. 2014, 8, 31–42. [Google Scholar] [CrossRef]

- Frosini, L.; Harlişca, C.; Szabó, L. Induction Machine Bearing Fault Detection by Means of Statistical Processing of the Stray Flux Measurement. IEEE Trans. Ind. Electron. 2015, 62, 1846–1854. [Google Scholar] [CrossRef]

- Wang, J. Research on Fault Vibration Characteristics and Key Diagnosis Technology of Train Wheelset. Ph.D. Thesis, Central South Universtiy, Changsha, China, 2012. [Google Scholar]

- Bolotin, V.V.; Shipkov, A.A. A model of the environmentally affected growth of fatigue cracks. J. Appl. Math. Mech. 1998, 62, 289–296. [Google Scholar] [CrossRef]

- Li, F.; Shi, P.; Lim, C.C.; Wu, L. Fault Detection Filtering for Nonhomogeneous Markovian Jump Systems via Fuzzy Approach. IEEE Trans. Fuzzy Syst. 2018, 26, 131–141. [Google Scholar] [CrossRef]

- Chibani, A.; Chadli, M.; Shi, P.; Braiek, N.B. Fuzzy Fault Detection Filter Design for T-S Fuzzy Systems in Finite Frequency Domain. IEEE Trans. Fuzzy Syst. 2017, 25, 1051–1061. [Google Scholar] [CrossRef]

- Dahmani, H.; Chadli, M.; Rabhi, A.; El Hajjaji, A. Road curvature estimation for vehicle lane departure detection using a robust Takagi–Sugeno fuzzy observer. Veh. Syst. Dyn. 2013, 51, 581–599. [Google Scholar] [CrossRef]

- Chadli, M.; Abdo, A.; Ding, S.X. H−/H∞ fault detection filter design for Discrete-time Takagi–Sugeno fuzzy system. Automatica 2013, 49, 1996–2005. [Google Scholar] [CrossRef]

- Baraldi, P.; Cannarile, F.; Di Maio, F.; Zio, E. ZioHierarchical k-nearest neighbours classification and binary differential evolution for fault diagnostics of automotive bearings operating under variable conditions. Eng. Appl. Artif. Intell. 2016, 56, 1–13. [Google Scholar] [CrossRef]

- Kumar, S.; Pecht, M. Modeling approaches for prognostics and health management of electronics. Int. J. Perform. Eng. 2010, 6, 467–476. [Google Scholar]

- Hu, C.; Jing, H.; Wang, R.; Yan, F.; Chadli, M. Robust H∞ output-feedback control for path following of autonomous ground vehicles. Mech. Syst. Signal Process. 2016, 70, 414–427. [Google Scholar] [CrossRef]

- Youssef, T.; Chadli, M.; Karimi, H.R.; Wang, R. Actuator and sensor faults estimation based on proportional integral observer for TS fuzzy model. J. Frankl. Inst. 2017, 354, 2524–2542. [Google Scholar] [CrossRef]

- Zhang, X.; Xu, R.; Kwan, C.; Liang, S.Y.; Xie, Q.; Haynes, L. An integrated approach to bearing fault diagnostics and prognostics. In Proceedings of the American Control Conference, Portland, OR, USA, 8–10 June 2005. [Google Scholar]

- Coble, J.; Hines, J.W. Identifying optimal prognostic parameters from data: A genetic algorithm approach. In Proceedings of the Annual Conference of the Prognostics and Health Management Society, San Diego, CA, USA, 27 September 2009. [Google Scholar]

- Baraldi, P.; Bonfanti, G.; Zio, E. Differential evolution-based multi-objective optimization for the definition of a health indicator for fault diagnostics and prognostics. Mech. Syst. Signal Process. 2018, 101, 382–400. [Google Scholar] [CrossRef]

- Singh, J.; Darpe, A.K.; Singh, S.P. Bearing damage assessmet using Jensen-Rényi Divergence based on EEMD. Mech. Syst. Signal Process. 2017, 87, 307–339. [Google Scholar] [CrossRef]

- Ali, J.B.; Fnaiech, N.; Saidi, L.; Chebel-Morello, B.; Fnaiech, F. FnaiechApplication of empirical mode decomposition and artificial neural network for automatic bearing fault diagnosis based on vibration signals. Appl. Acoust. 2015, 89, 16–27. [Google Scholar]

- Antoni, J. The spectral kurtosis: A useful tool for characterising non-stationary signals. Mech. Syst. Signal Process. 2006, 20, 282–307. [Google Scholar] [CrossRef]

- Wang, D.; Tsui, K.L.; Miao, Q. Prognostics and Health Management: A Review of Vibration based Bearing and Gear Health Indicators. IEEE Access 2017, 6, 665–676. [Google Scholar] [CrossRef]

- Miao, Y.; Zhao, M.; Lin, J.; Lei, Y. Application of an improved maximum correlated kurtosis deconvolution method for fault diagnosis of rolling element bearings. Mech. Syst. Signal Process. 2017, 92, 173–195. [Google Scholar] [CrossRef]

- Zhang, N.; Lin, A.; Shang, P. Multidimensional k-nearest neighbor model based on EEMD for financial time series forecasting. Phys. A Stat. Mech. Appl. 2017, 477, 161–173. [Google Scholar] [CrossRef]

- Lei, Y.; Lin, J.; He, Z.; Zuo, M.J. A review on empirical mode decomposition in fault diagnosis of rotating machinery. Mech. Syst. Signal Process. 2013, 35, 108–126. [Google Scholar] [CrossRef]

- Wu, Z.; Huang, N.E. Ensemble empirical mode decomposition: A noise-assisted data analysis method. Adv. Adapt. Data Anal. 2009, 1, 1–41. [Google Scholar] [CrossRef]

- Wu, Z.; Huang, N.E. A study of the characteristics of white noise using the empirical mode decomposition method. Proc. R. Soc. Lond. A Math. Phys. Eng. Sci. 2004, 460, 1597–1611. [Google Scholar] [CrossRef]

- Lei, Y.; Zuo, M.J. Fault diagnosis of rotating machinery using an improved HHT based on EEMD and sensitive IMFs. Meas. Sci. Technol. 2009, 20, 2280–2294. [Google Scholar] [CrossRef]

- Rai, V.K.; Mohanty, A.R. Bearing fault diagnosis using FFT of intrinsic mode functions in Hilbert–Huang transform. Mechan. Syst. Signal Process 2007, 21, 2607–2615. [Google Scholar] [CrossRef]

- Abraham, M.H.; Acree, W.E., Jr. The correlation and prediction of the temperature variation of infinite dilution activity coefficients of compounds in water. Fluid Phase Equilibria 2018, 455, 1–5. [Google Scholar] [CrossRef]

- Charier, D.J.; Zantour, D.; Pichot, V.; Chouchou, F.; Barthelemy, J.C.M.; Roche, F.; Molliex, S.B. Assessing Pain Using the Variation Coefficient of Pupillary Diameter. J. Pain 2017, 18, 1346–1353. [Google Scholar] [CrossRef] [PubMed]

- Curto, J.D.; Pinto, J.C. The coefficient of variation asymptotic distribution in the case of non-iid random variables. J. Appl. Stat. 2009, 36, 21–32. [Google Scholar] [CrossRef]

- Shekel, J. Instantaneous frequency. Proc. Inst. Radio Eng. 1953, 41, 548. [Google Scholar]

- Huang, N.E.; Shen, Z.; Long, S.R.; Wu, M.C.; Shih, H.H.; Zheng, Q.; Liu, H.H. The empirical mode decomposition and the Hilbert spectrum for nonlinear and non-stationary time series analysis. Proc. R. Soc. Lond. A Math. Phys. Eng. Sci. 1998, 454, 903–995. [Google Scholar] [CrossRef]

- Huang, N.E.; Wu, Z.; Long, S.R.; Arnold, K.C.; Chen, X.; Blank, K. On Instantaneous Frequency. Adv. Adapt. Data Anal. 2009, 1, 177–229. [Google Scholar] [CrossRef]

- Zhou, Y.; Chen, W.; Gao, J.; He, Y. Application of Hilbert–Huang transform based instantaneous frequency to seismic reflection data. J. Appl. Geophys. 2012, 82, 68–74. [Google Scholar] [CrossRef]

- Hou, T.Y.; Shi, Z. Data-driven time-frequency analysis. Appl. Comput. Harmon. Anal. 2013, 35, 284–308. [Google Scholar] [CrossRef]

- Stankovičová, Z.; Dekýš, V.; Novák, P. Time average synchronization in thermoelastic stress analysis. Procedia Eng. 2016, 136, 204–210. [Google Scholar] [CrossRef]

- Wang, D.; Zhao, Y.; Yi, C.; Tsui, K.L.; Lin, J. Sparsity guided empirical wavelet transform for fault diagnosis of rolling element bearings. Mech. Syst. Signal Process. 2018, 101, 292–308. [Google Scholar] [CrossRef]

| Experiment No. | #1 | #2 | #3 | #4 | #5 |

|---|---|---|---|---|---|

| Values | 0.0992 | 0.7271 | 0.5228 | 0.3038 | 0.8176 |

| Steady-State Indexes | |||

|---|---|---|---|

| Abnormal diagnosis accuracy | High | High | High |

| Single defect characterization performance | High | High | High |

| Coupling defects characterization performance | Low | High | High |

| Computational efficiency | High | Low | Medium |

| Difficulty in implementing | Low | Medium | High |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yi, C.; Wang, D.; Fan, W.; Tsui, K.-L.; Lin, J. EEMD-Based Steady-State Indexes and Their Applications to Condition Monitoring and Fault Diagnosis of Railway Axle Bearings. Sensors 2018, 18, 704. https://doi.org/10.3390/s18030704

Yi C, Wang D, Fan W, Tsui K-L, Lin J. EEMD-Based Steady-State Indexes and Their Applications to Condition Monitoring and Fault Diagnosis of Railway Axle Bearings. Sensors. 2018; 18(3):704. https://doi.org/10.3390/s18030704

Chicago/Turabian StyleYi, Cai, Dong Wang, Wei Fan, Kwok-Leung Tsui, and Jianhui Lin. 2018. "EEMD-Based Steady-State Indexes and Their Applications to Condition Monitoring and Fault Diagnosis of Railway Axle Bearings" Sensors 18, no. 3: 704. https://doi.org/10.3390/s18030704