Fast Detection of Copper Content in Rice by Laser-Induced Breakdown Spectroscopy with Uni- and Multivariate Analysis

Abstract

:1. Introduction

2. Materials and Methods

2.1. Rice Material and Sampling

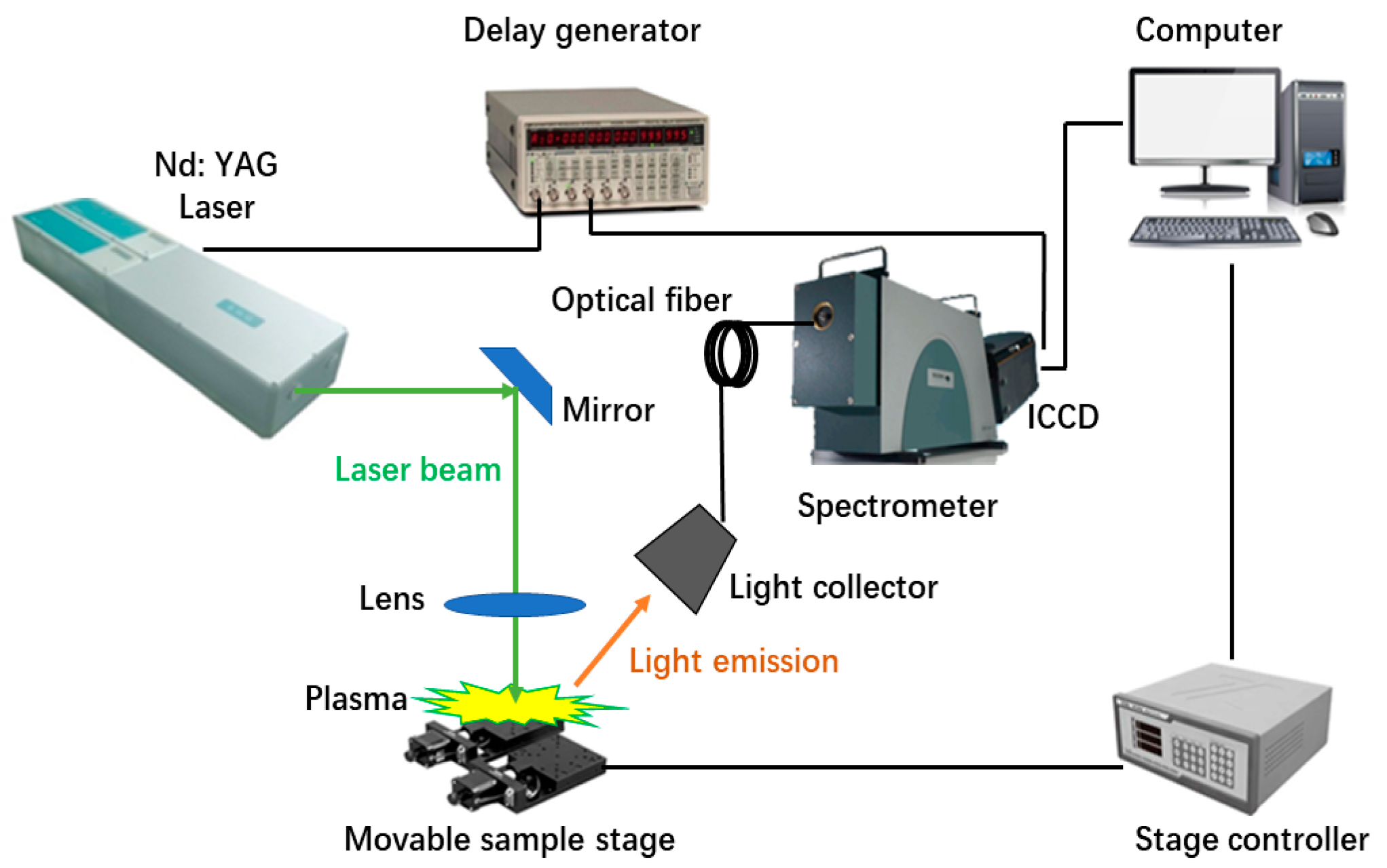

2.2. LIBS Experimental

2.3. Determination of the Reference Value of Copper Content

2.4. Statistical Analysis

3. Results and Discussion

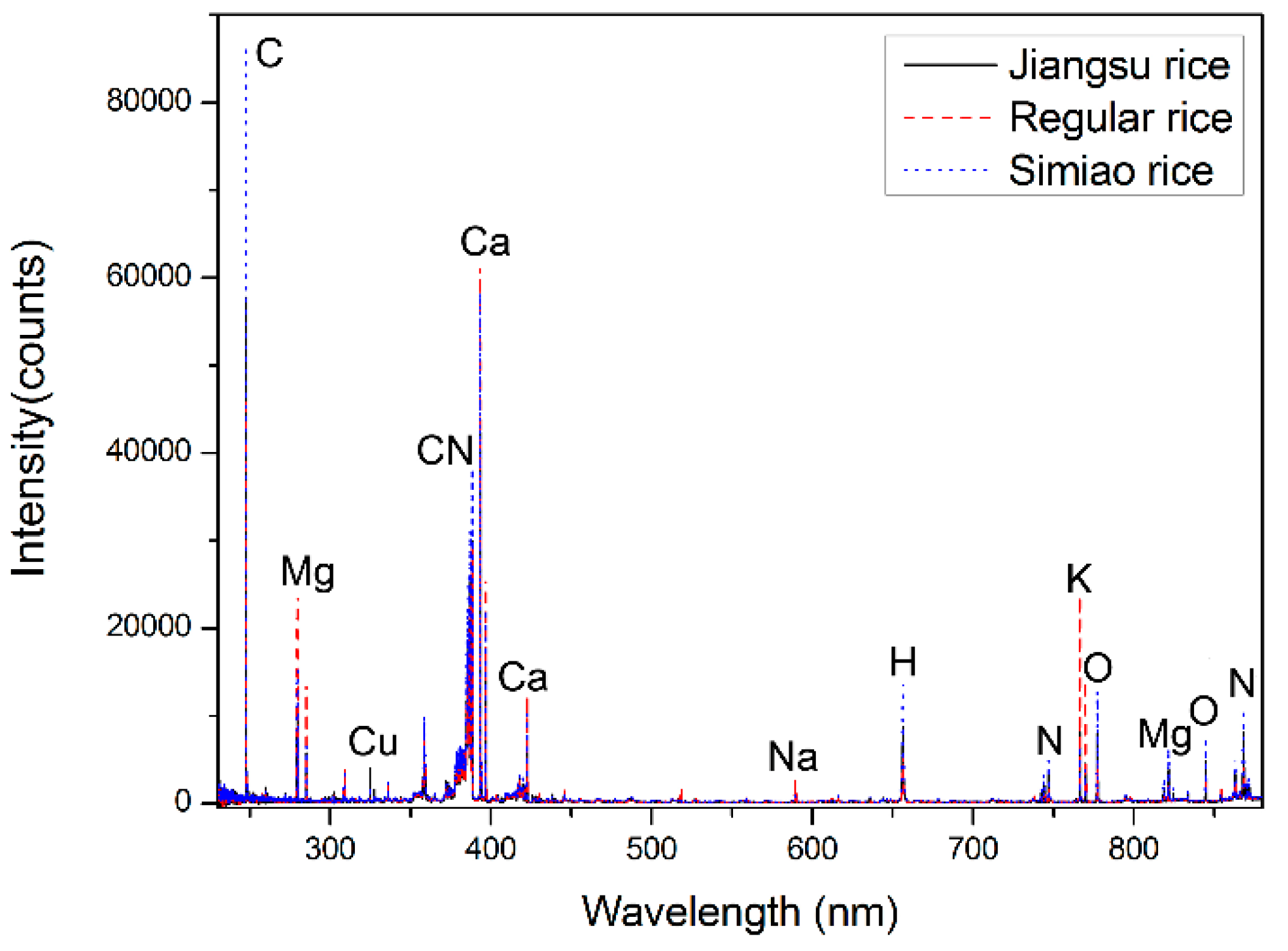

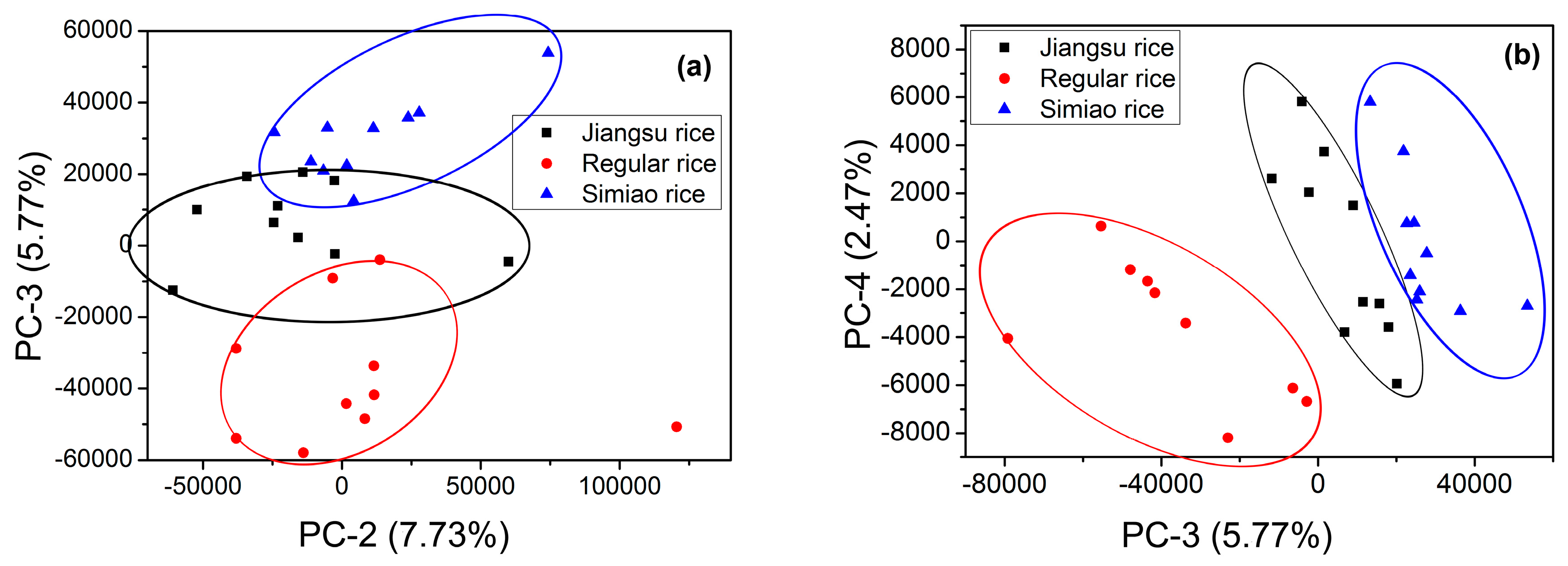

3.1. Spectral Characterization of Rice Samples

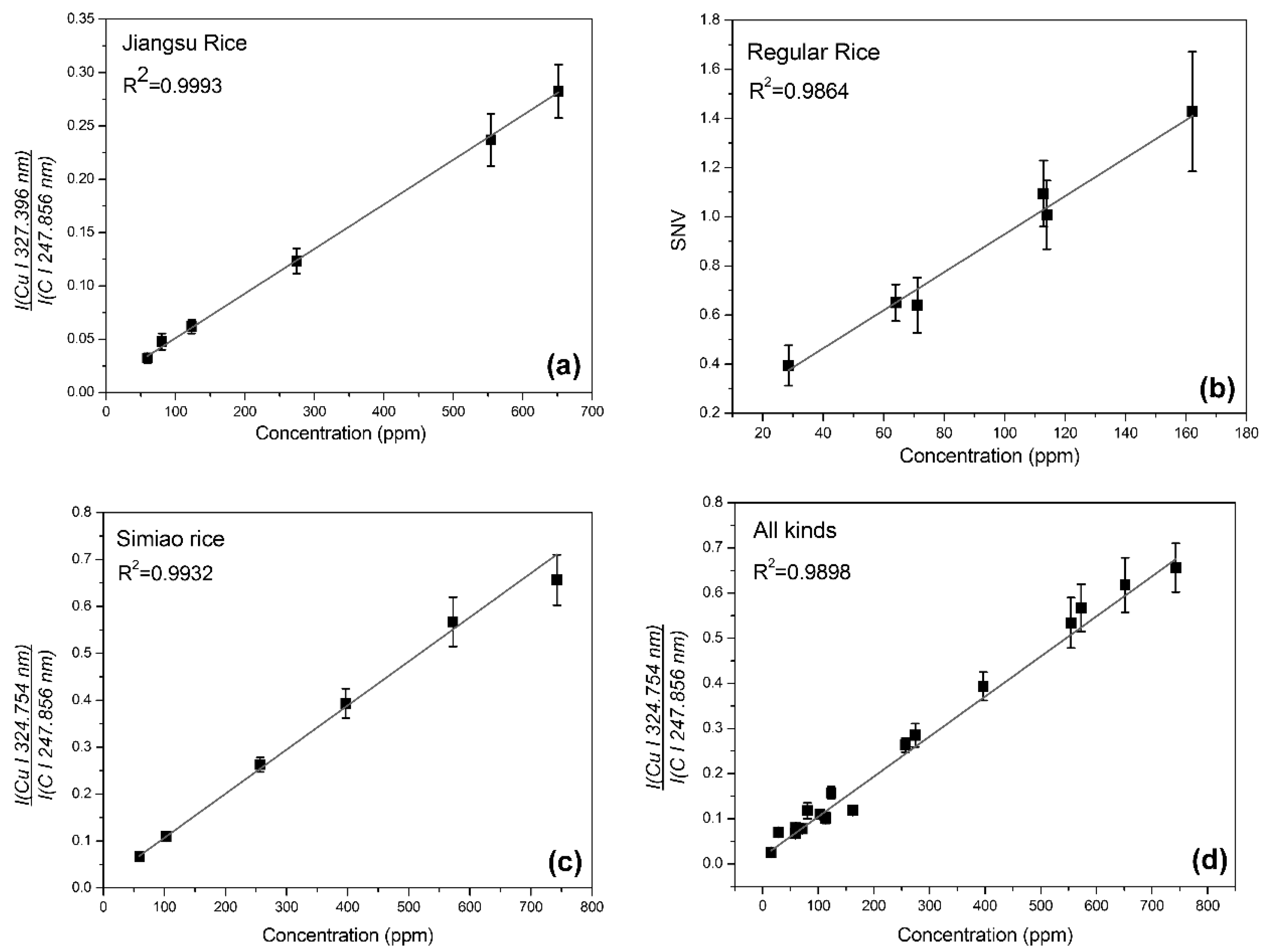

3.2. Comparison the Results of Univariate Analysis with Different Pre-processing Methods—Univariate Calibration

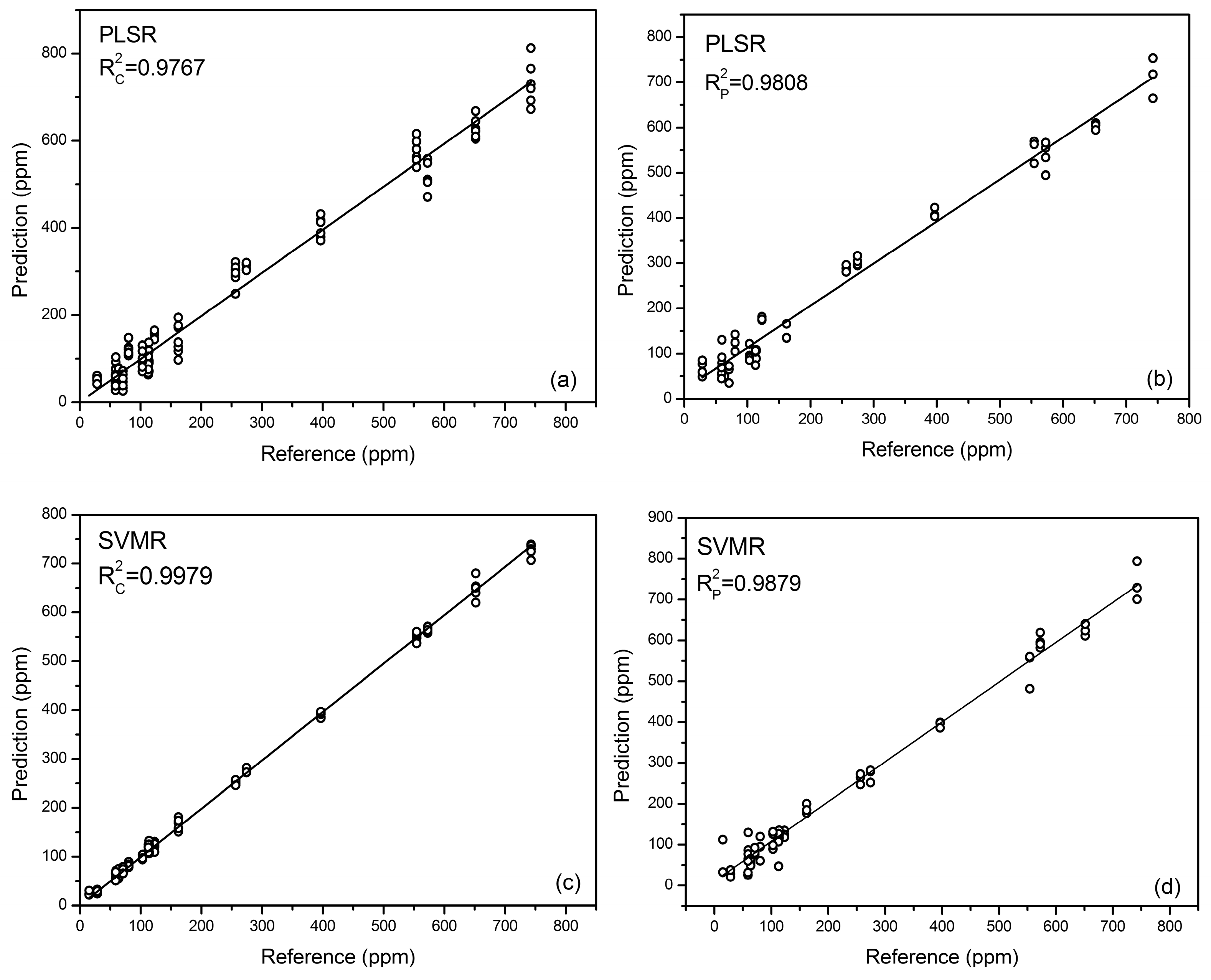

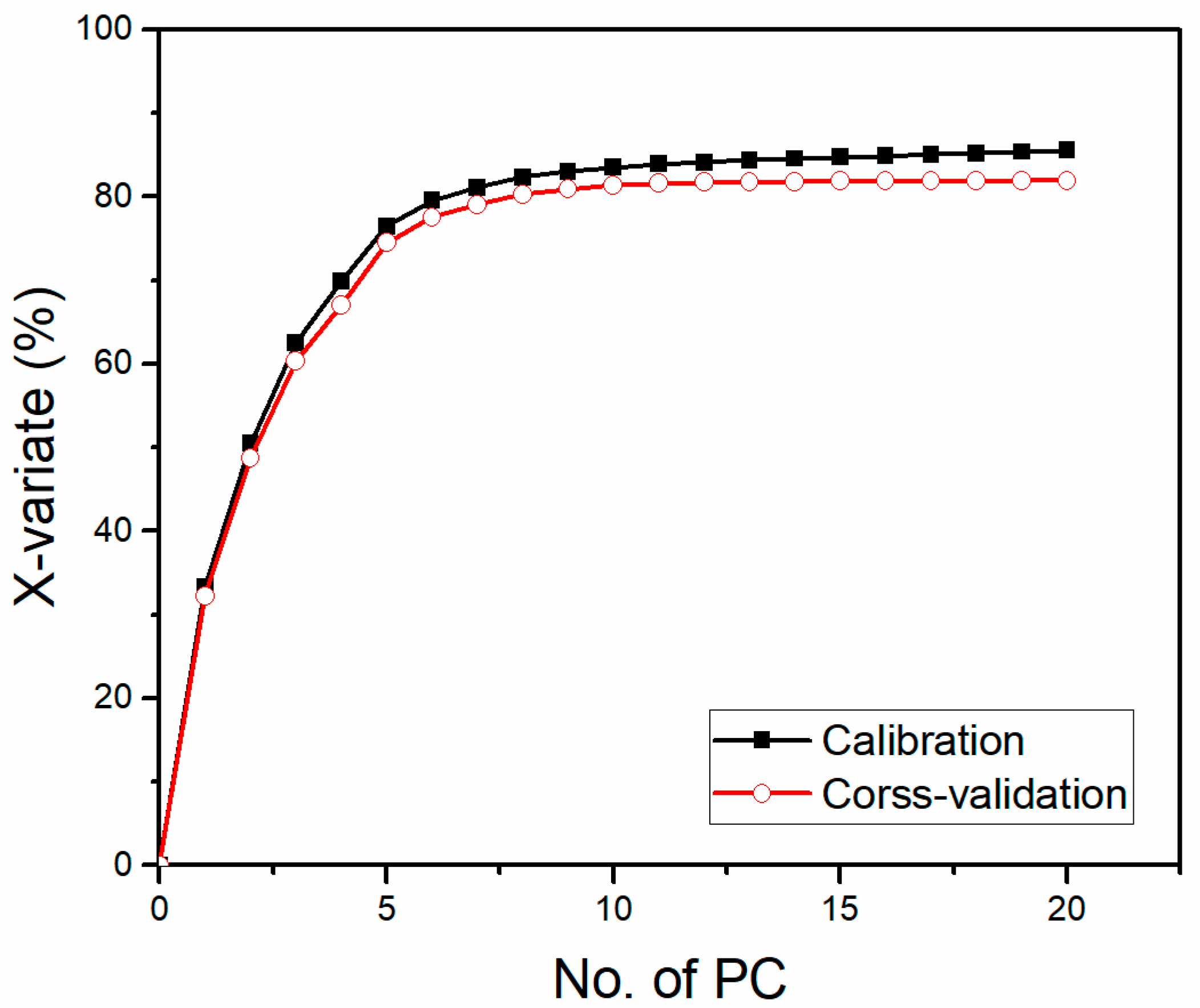

3.3. Comparison the Results of Multivariate Analysis with Different Algorithms (PLS and SVMR)

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Balabin, R.M.; Lomakina, E.I. Support vector machine regression (SVR/LS-SVM)—An alternative to neural networks (ANN) for analytical chemistry? Comparison of nonlinear methods on near infrared (NIR) spectroscopy data. Analyst 2011, 136, 1703–1712. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.Y.; Deng, F.; Yamaji, N.; Pinson, S.R.; Fujii-Kashino, M.; Danku, J.; Douglas, A.; Guerinot, M.L.; Salt, D.E.; Ma, J.F. A heavy metal P-type ATPase OsHMA4 prevents copper accumulation in rice grain. Nature Commun. 2016, 7, 12138. [Google Scholar] [CrossRef] [PubMed]

- Feng, J.F.; Wang, Y.X.; Zhao, J.; Zhu, L.Q.; Bian, X.M.; Zhang, W.J. Source attributions of heavy metals in rice plant along highway in Eastern China. J. Environ. Sci.-China 2011, 23, 1158–1164. [Google Scholar] [CrossRef]

- Li, Z.Y.; Ma, Z.W.; van der Kuijp, T.J.; Yuan, Z.W.; Huang, L. A review of soil heavy metal pollution from mines in China: Pollution and health risk assessment. Sci. Total Environ. 2014, 468, 843–853. [Google Scholar] [CrossRef] [PubMed]

- Arunakumara, K.K.I.U.; Walpola, B.C.; Yoon, M.H. Current status of heavy metal contamination in Asia's rice lands. Rev. Environ. Sci. Biol. 2013, 12, 355–377. [Google Scholar] [CrossRef]

- Hang, X.S.; Wang, H.Y.; Zhou, J.M.; Ma, C.L.; Du, C.W.; Chen, X.Q. Risk assessment of potentially toxic element pollution in soils and rice (Oryza sativa) in a typical area of the Yangtze river delta. Environ. Pollut. 2009, 157, 2542–2549. [Google Scholar] [CrossRef] [PubMed]

- ALOthman, Z.A.; Habila, M.; Yilmaz, E.; Soylak, M. Solid phase extraction of Cd(Ⅱ), Pb(Ⅱ), Zn(Ⅱ) and Ni(Ⅱ) from food samples using multiwalled carbon nanotubes impregnated with 4-(2-thiazolylazo) resorcinol. Microchim. Acta 2012, 177, 397–403. [Google Scholar] [CrossRef]

- Mao, X.L.; Ciocan, A.C.; Borisov, O.V.; Russo, R.E. Laser ablation processes investigated using inductively coupled plasma atomic emission spectroscopy (ICP-AES). Appl. Surf. Sci. 1998, 127, 262–268. [Google Scholar] [CrossRef]

- Fortes, F.J.; Moros, J.; Lucena, P.; Cabalin, L.M.; Laserna, J.J. Laser-induced breakdown spectroscopy. Anal. Chem. 2013, 85, 640–669. [Google Scholar] [CrossRef] [PubMed]

- Shao, Y.; Zhang, Y.B.; Gao, X.; Du, C.; Lin, J.Q. Latest research on and applications progress in laser-induced breakdown spectroscopy. Spectrosc. Spect. Anal. 2013, 33, 2593–2598. [Google Scholar]

- Peng, J.Y.; Liu, F.; Zhou, F.; Song, K.L.; Zhang, C.; Ye, L.H.; He, Y. Challenging applications for multi-element analysis by laser-induced breakdown spectroscopy in agriculture: A review. Trac.-Trend. Anal. Chem. 2016, 85, 260–272. [Google Scholar] [CrossRef]

- Agrawal, R.; Kumar, R.; Rai, S.; Pathak, A.K.; Rai, A.K.; Rai, G.K. LIBS: A quality control tool for food supplements. Food Biophys. 2011, 6, 527–533. [Google Scholar] [CrossRef]

- Peruchi, L.C.; Nunes, L.C.; de Carvalho, G.G.A.; Guerra, M.B.B.; de Almeida, E.; Rufini, I.A.; Santos, D.; Krug, F.J. Determination of inorganic nutrients in wheat flour by laser-induced breakdown spectroscopy and energy dispersive X-ray fluorescence spectrometry. Spectrochim. Acta B 2014, 100, 129–136. [Google Scholar] [CrossRef]

- Alvira, F.C.; Reyes, T.F.; Cabrera, L.P.; Osorio, L.M.; Baez, Z.P.; Bautista, G.V. Qualitative evaluation of Pb and Cu in fish using laser-induced breakdown spectroscopy with multipulse excitation by ultracompact laser source. Appl. Optics 2015, 54, 4453–4457. [Google Scholar] [CrossRef] [PubMed]

- Ferreira, E.C.; Milori, D.M.B.P.; Ferreira, E.J.; Da Silva, R.M.; Martin-Neto, L. Artificial neural network for Cu quantitative determination in soil using a portable laser induced breakdown spectroscopy system. Spectrochim. Acta B 2008, 63, 1216–1220. [Google Scholar] [CrossRef]

- Body, D.; Chadwick, B.L. Optimization of the spectral data processing in a LIBS simultaneous elemental analysis system. Spectrochim. Acta B 2001, 56, 725–736. [Google Scholar] [CrossRef]

- Li, X.W.; Wang, Z.; Fu, Y.T.; Li, Z.; Liu, J.M.; Ni, W.D. Application of a spectrum standardization method for carbon analysis in coal using laser-induced breakdown spectroscopy (LIBS). Appl. Spectrosc. 2014, 68, 955–962. [Google Scholar] [CrossRef] [PubMed]

- Ismail, M.A.; Imam, H.; Elhassan, A.; Youniss, W.T.; Harith, M.A. LIBS limit of detection and plasma parameters of some elements in two different metallic matrices. J. Anal. Atom. Spectrom. 2004, 19, 489–494. [Google Scholar] [CrossRef]

- Tawfik, W. Study of the matrix effect on the plasma characterization of six elements in aluminum alloys using LIBS with a portable echelle spectrometer. Prog. Phys. 2007, 2, 46–52. [Google Scholar]

- Jantzi, S.C.; Motto-Ros, V.; Trichard, F.; Markushin, Y.; Melikechi, N.; De Giacomo, A. Sample treatment and preparation for laser-induced breakdown spectroscopy. Spectrochim. Acta B 2016, 115, 52–63. [Google Scholar] [CrossRef]

- Garcimuno, M.; Pace, D.M.D.; Bertuccelli, G. Laser-induced breakdown spectroscopy for quantitative analysis of copper in algae. Opt. Laser Technol. 2013, 47, 26–30. [Google Scholar] [CrossRef]

- Zorov, N.B.; Gorbatenko, A.A.; Labutin, T.A.; Popov, A.M. A review of normalization techniques in analytical atomic spectrometry with laser sampling: From single to multivariate correction. Spectrochim. Acta B 2010, 65, 642–657. [Google Scholar] [CrossRef]

- Porizka, P.; Klus, J.; Hrdlicka, A.; Vrabel, J.; Skarkova, P.; Prochazka, D.; Novotny, J.; Novotny, K.; Kaiser, J. Impact of laser-induced breakdown spectroscopy data normalization on multivariate classification accuracy. J. Anal. Atom. Spectrom. 2017, 32, 277–288. [Google Scholar] [CrossRef]

- Lasheras, R.J.; Bello-Galvez, C.; Anzano, J.M. Quantitative analysis of oxide materials by laser-induced breakdown spectroscopy with argon as an internal standard. Spectrochim. Acta B 2013, 82, 65–70. [Google Scholar] [CrossRef]

- Muller, K.; Stege, H. Evaluation of the analytical potential of laser-induced breakdown spectrometry (LIBS) for the analysis of historical glasses. Archaeometry 2003, 45, 421–433. [Google Scholar] [CrossRef]

- Huang, J.S.; Lin, K.C. Laser-induced breakdown spectroscopy of liquid droplets: Correlation analysis with plasma-induced current versus continuum background. J. Anal. Atom. Spectrom. 2005, 20, 53–59. [Google Scholar] [CrossRef]

- Liu, F.; Nie, P.C.; Huang, M.; Kong, W.W.; He, Y. Nondestructive determination of nutritional information in oilseed rape leaves using visible/near infrared spectroscopy and multivariate calibrations. Sci. China-Inform. Sci. 2011, 54, 598–608. [Google Scholar] [CrossRef]

- Syvilay, D.; Wilkie-Chancellier, N.; Trichereau, B.; Texier, A.; Martinez, L.; Serfaty, S.; Detalle, V. Evaluation of the standard normal variate method for laser-induced breakdown spectroscopy data treatment applied to the discrimination of painting layers. Spectrochim. Acta B 2015, 114, 38–45. [Google Scholar] [CrossRef]

- Garcia-Ayuso, L.E.; Amador-Hernandez, J.; Fernandez-Romero, J.M.; de Castro, M.D.L. Characterization of jewellery products by laser-induced breakdown spectroscopy. Anal. Chim. Acta 2002, 457, 247–256. [Google Scholar] [CrossRef]

- Ortiz, M.C.; Sarabia, L.; Jurado-Lopez, A.; de Castro, M.D.L. Minimum value assured by a method to determine gold in alloys by using laser-induced breakdown spectroscopy and partial least-squares calibration model. Anal. Chim. Acta 2004, 515, 151–157. [Google Scholar] [CrossRef]

- Braga, J.W.B.; Trevizan, L.C.; Nunes, L.C.; Rufini, I.A.; Santos, D.; Krug, F.J. Comparison of univariate and multivariate calibration for the determination of micronutrients in pellets of plant materials by laser induced breakdown spectrometry. Spectrochim. Acta B 2010, 65, 66–74. [Google Scholar] [CrossRef]

- Feundale, R.N.; Woody, N.A.; Tan, H.W.; Myles, A.J.; Brown, S.D.; Ferre, J. Transfer of multivariate calibration models: A review. Chemometr. Intell. Lab. 2002, 64, 181–192. [Google Scholar] [CrossRef]

- Nunes, L.C.; Braga, J.W.B.; Trevizan, L.C.; de Souza, P.F.; de Carvalho, G.G.A.; Santos, D.; Poppi, R.J.; Krug, F.J. Optimization and validation of a LIBS method for the determination of macro and micronutrients in sugar cane leaves. J. Anal. Atom. Spectrom. 2010, 25, 1453–1460. [Google Scholar] [CrossRef]

- Liu, F.; He, Y. Use of visible and near infrared spectroscopy and least squares-support vector machine to determine soluble solids content and pH of cola beverage. J. Agric. Food Chem. 2007, 55, 8883–8888. [Google Scholar] [CrossRef] [PubMed]

- Gu, Y.H.; Zhao, N.J.; Ma, M.J.; Meng, D.S.; Yu, Y.; Jia, Y.; Fang, L.; Liu, J.G.; Liu, W.Q. Monitoring the heavy element of Cr in agricultural soils using a mobile laser-induced breakdown spectroscopy system with support vector machine. Chin. Phys. Lett. 2016, 33, 8. [Google Scholar] [CrossRef]

- Hu, H.Q.; Huang, L.; Liu, M.H.; Chen, T.B.; Yang, P.; Yao, M.Y. Nondestructive determination of Cu residue in orange peel by laser induced breakdown spectroscopy. Plasma Sci. Technol. 2015, 17, 711–715. [Google Scholar] [CrossRef]

- Aman, T.; Kazi, A.A.; Sabri, M.U.; Bano, Q. Potato peels as solid waste for the removal of heavy metal copper(Ⅱ) from waste water/industrial effluent. Colloid Surf. B 2008, 63, 116–121. [Google Scholar] [CrossRef] [PubMed]

- Popov, A.M.; Colao, F.; Fantoni, R. Spatial confinement of laser-induced plasma to enhance LIBS sensitivity for trace elements determination in soils. J. Anal. Atom. Spectrom. 2010, 25, 837–848. [Google Scholar] [CrossRef]

- Yang, J.; Zhang, D.; Frangi, A.F.; Yang, J.Y. Two-dimensional PCA: A new approach to appearance-based face representation and recognition. IEEE T Pattern Anal. 2004, 26, 131–137. [Google Scholar] [CrossRef]

- Hoehse, M.; Paul, A.; Gornushkin, I.; Panne, U. Multivariate classification of pigments and inks using combined Raman spectroscopy and LIBS. Anal. Bioanal. Chem. 2012, 402, 1443–1450. [Google Scholar] [CrossRef] [PubMed]

- Pathak, A.K.; Kumar, R.; Singh, V.K.; Agrawal, R.; Rai, S.; Rai, A.K. Assessment of LIBS for spectrochemical analysis: A review. Appl. Spectrosc. Rev. 2012, 47, 14–40. [Google Scholar] [CrossRef]

- Unnikrishnan, V.K.; Choudhari, K.S.; Kulkarni, S.D.; Nayak, R.; Kartha, V.B.; Santhosh, C. Analytical predictive capabilities of laser induced breakdown spectroscopy (LIBS) with principal component analysis (PCA) for plastic classification. Rsc. Adv. 2013, 3, 25872–25880. [Google Scholar] [CrossRef]

- Haaland, D.M.; Thomas, E.V. Partial least-squares methods for spectral analyses. 1. Relation to other quantitative calibration methods and the extraction of qualitative information. Anal. Chem. 1988, 60, 1193–1202. [Google Scholar] [CrossRef]

- Zhang, T.; Liang, L.; Wang, K.; Tang, H.; Yang, X.; Duan, Y.; Li, H. A novel approach for the quantitative analysis of multiple elements in steel based on laser-induced breakdown spectroscopy (LIBS) and random forest regression (RFR). J. Anal. Atom. Spectrom. 2014, 29, 2323–2329. [Google Scholar] [CrossRef]

- Thissen, U.; Pepers, M.; Ustun, B.; Melssen, W.J.; Buydens, L.M.C. Comparing support vector machines to PLS for spectral regression applications. Chemometr. Intell. Lab. 2004, 73, 169–179. [Google Scholar] [CrossRef]

- Huang, C.L.; Dun, J.F. A distributed PSO-SVM hybrid system with feature selection and parameter optimization. Appl. Soft Comput. 2008, 8, 1381–1391. [Google Scholar] [CrossRef]

- Hawkins, D.M. The problem of overfitting. J. Chem. Inf. Comp. Sci. 2004, 44, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Pontes, M.J.; Cortez, J.; Galvao, R.K.; Pasquini, C.; Araujo, M.C.; Coelho, R.M.; Chiba, M.K.; de Abreu, M.F.; Madari, B.E. Classification of brazilian soils by using LIBS and variable selection in the wavelet domain. Anal. Chim. Acta 2009, 642, 12–18. [Google Scholar] [CrossRef] [PubMed]

- Bulajic, D.; Corsi, M.; Cristoforetti, G.; Legnaioli, S.; Palleschi, V.; Salvetti, A.; Tognoni, E. A procedure for correcting self-absorption in calibration free-laser induced breakdown spectroscopy. Spectrochim. Acta B 2002, 57, 339–353. [Google Scholar] [CrossRef]

- Xie, C.L.; Lu, J.D.; Li, P.Y.; Li, J.; Lin, Z.X. Correction and analysis of lead content in soil by laser-induced breakdown spectroscopy. Chin. Opt. Lett. 2009, 7, 545–548. [Google Scholar]

- Colao, F.; Fantoni, R.; Lazic, V.; Paolini, A.; Fabbri, F.; Ori, G.G.; Marinangeli, L.; Baliva, A. Investigation of LIBS feasibility for in situ planetary exploration: An analysis on martian rock analogues. Planet. Space Sci. 2004, 52, 117–123. [Google Scholar] [CrossRef]

- Trevizan, L.C.; Santos, D.; Samad, R.E.; Vieira, N.D.; Nunes, L.C.; Rufini, I.A.; Krug, F.J. Evaluation of laser induced breakdown spectroscopy for the determination of micronutrients in plant materials. Spectrochim. Acta B 2009, 64, 369–377. [Google Scholar] [CrossRef]

- Senesi, G.S.; Dell’Aglio, M.; Gaudiuso, R.; De Giacomo, A.; Zaccone, C.; De Pascale, O.; Miano, T.M.; Capitelli, M. Heavy metal concentrations in soils as determined by laser-induced breakdown spectroscopy (LIBS), with special emphasis on chromium. Environ. Res. 2009, 109, 413–420. [Google Scholar] [CrossRef] [PubMed]

- Colao, F.; Fantoni, R.; Ortiz, P.; Vazquez, M.A.; Martin, J.M.; Ortiz, R.; Idris, N. Quarry identification of historical building materials by means of laser induced breakdown spectroscopy, X-ray fluorescence and chemometric analysis. Spectrochim. Acta B 2010, 65, 688–694. [Google Scholar] [CrossRef]

- Braga, J.W.B.; Poppi, R.J. Figures of merit for the determination of the polymorphic purity of carbamazepine by infrared spectroscopy and multivariate calibration. J. Pharm. Sci. 2004, 93, 2124–2134. [Google Scholar] [CrossRef] [PubMed]

- Ponce, L.V.; Flores, T.; Sosa-Saldana, M.; Alvira, F.C.; Bilmes, G.M. Laser-induced breakdown spectroscopy determination of toxic metals in fresh fish. Appl. Optics 2016, 55, 254–258. [Google Scholar] [CrossRef] [PubMed]

| Regular Rice | Content (ppm) | Jiangsu Rice | Content (ppm) | Simiao Rice | Content (ppm) |

|---|---|---|---|---|---|

| 1 | 5.68 ± 0.06 | 1 | 7.60 ± 0.11 | 1 | 5.10 ± 0.06 |

| 2 | 28.54 ± 0.78 | 2 | 59.48 ± 0.58 | 2 | 59.07 ± 1.18 |

| 3 | 46.35 ± 0.57 | 3 | 80.45 ± 1.53 | 3 | 103.18 ± 1.07 |

| 4 | 63.99 ± 1.17 | 4 | 123.09 ± 1.56 | 4 | 256.52 ± 4.43 |

| 5 | 71.09 ± 1.02 | 5 | 274.34 ± 4.22 | 5 | 396.65 ± 4.91 |

| 6 | 113.94 ± 2.26 | 6 | 554.35 ± 7.78 | 6 | 572.53 ± 9.72 |

| 7 | 116.84 ± 4.94 | 7 | 651.68 ± 8.07 | 7 | 742.62 ± 11.13 |

| 8 | 1162.10 ± 34.86 | 8 | 1104.76 ± 19.10 | 8 | 1074.92 ± 11.06 |

| 9 | 1668.75 ± 33.36 | 9 | 1115.28 ± 13.49 | 9 | 1213.76 ± 15.41 |

| Analytical Signal | ||||

|---|---|---|---|---|

| Regular Rice | Simiao Rice | All Kinds | ||

| 324.754 nm | ||||

| Peak intensity | 0.9962 | 0.9051 | 0.9880 | 0.9875 |

| Peak intensity/Background | 0.9971 | 0.9601 | 0.9884 | 0.9845 |

| Voigt profile (peak height) | 0.9958 | 0.8985 | 0.9863 | 0.9853 |

| Voigt profile (area) | 0.9941 | 0.9033 | 0.9822 | 0.9807 |

| Peak intensity/C I 247.856 nm | 0.9989 | 0.9717 | 0.9932 | 0.9898 |

| SNV | 0.9984 | 0.9719 | 0.9895 | 0.9873 |

| 327.396 nm | ||||

| Peak intensity | 0.9985 | 0.9303 | 0.9918 | 0.9884 |

| Peak intensity/Background | 0.9964 | 0.9769 | 0.9893 | 0.9829 |

| Voigt profile (peak height) | 0.9984 | 0.9227 | 0.9920 | 0.9886 |

| Voigt profile (area) | 0.9985 | 0.9183 | 0.9912 | 0.9830 |

| Peak intensity/C I 247.856 nm | 0.9993 | 0.9125 | 0.9880 | 0.9863 |

| SNV | 0.9986 | 0.9864 | 0.9889 | 0.9872 |

| Algorithm | Calibration | Validation | ||||

|---|---|---|---|---|---|---|

| RMSEC | RMSCV | RMSEP | ||||

| PLSR | 0.9767 | 34.8186 | 38.1774 | 0.9727 | 0.9808 | 33.2252 |

| SVMR | 0.9929 | 33.5980 | 121.6671 | 0.8816 | 0.8858 | 84.0770 |

| SVMR (data reduction) | 0.9979 | 11.1120 | 26.6166 | 0.9866 | 0.9879 | 24.7755 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, F.; Ye, L.; Peng, J.; Song, K.; Shen, T.; Zhang, C.; He, Y. Fast Detection of Copper Content in Rice by Laser-Induced Breakdown Spectroscopy with Uni- and Multivariate Analysis. Sensors 2018, 18, 705. https://doi.org/10.3390/s18030705

Liu F, Ye L, Peng J, Song K, Shen T, Zhang C, He Y. Fast Detection of Copper Content in Rice by Laser-Induced Breakdown Spectroscopy with Uni- and Multivariate Analysis. Sensors. 2018; 18(3):705. https://doi.org/10.3390/s18030705

Chicago/Turabian StyleLiu, Fei, Lanhan Ye, Jiyu Peng, Kunlin Song, Tingting Shen, Chu Zhang, and Yong He. 2018. "Fast Detection of Copper Content in Rice by Laser-Induced Breakdown Spectroscopy with Uni- and Multivariate Analysis" Sensors 18, no. 3: 705. https://doi.org/10.3390/s18030705