A Flexible Capacitive Pressure Sensor Based on Ionic Liquid

Abstract

:1. Introduction

2. Sensing Principle

3. Experimental Investigation

3.1. Materials and Apparatus

3.2. Sensor Design

4. Results and Discussion

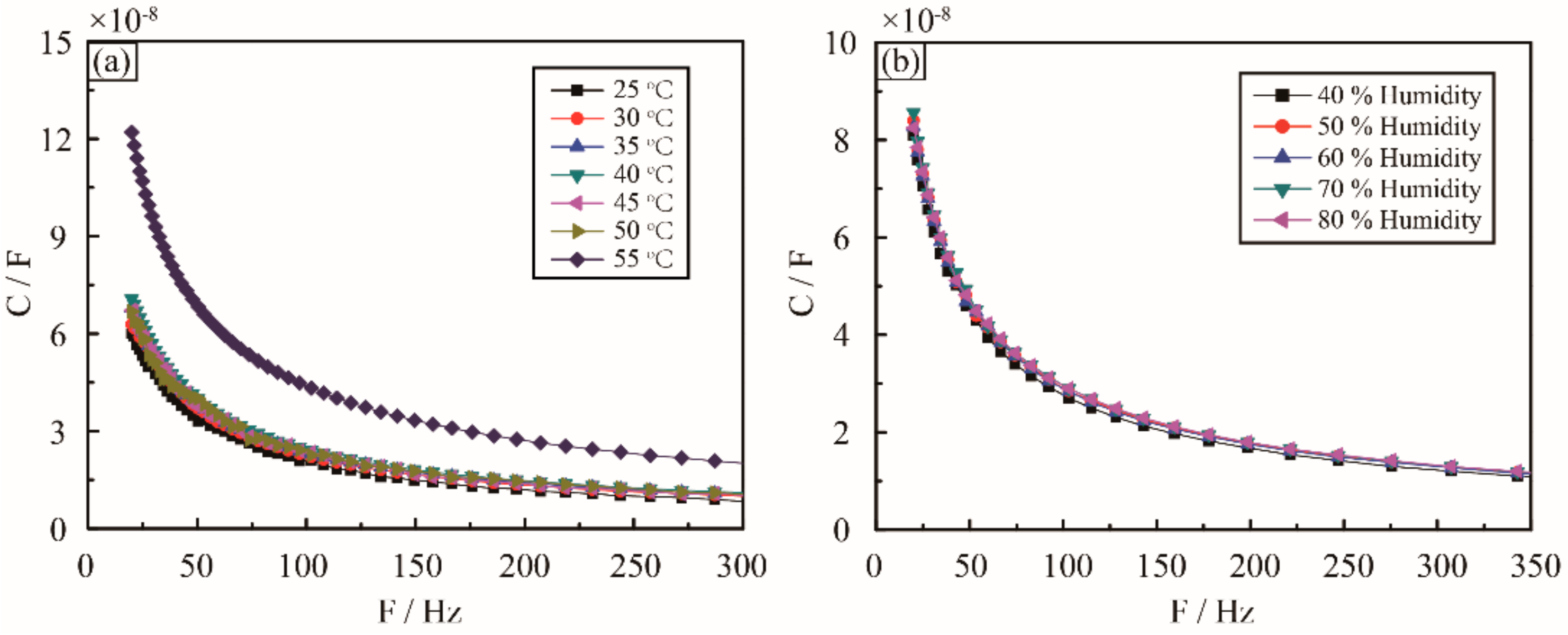

4.1. Response of Capacitance with Driving Frequency

4.2. Relation between Pressure and Change of Capacitance

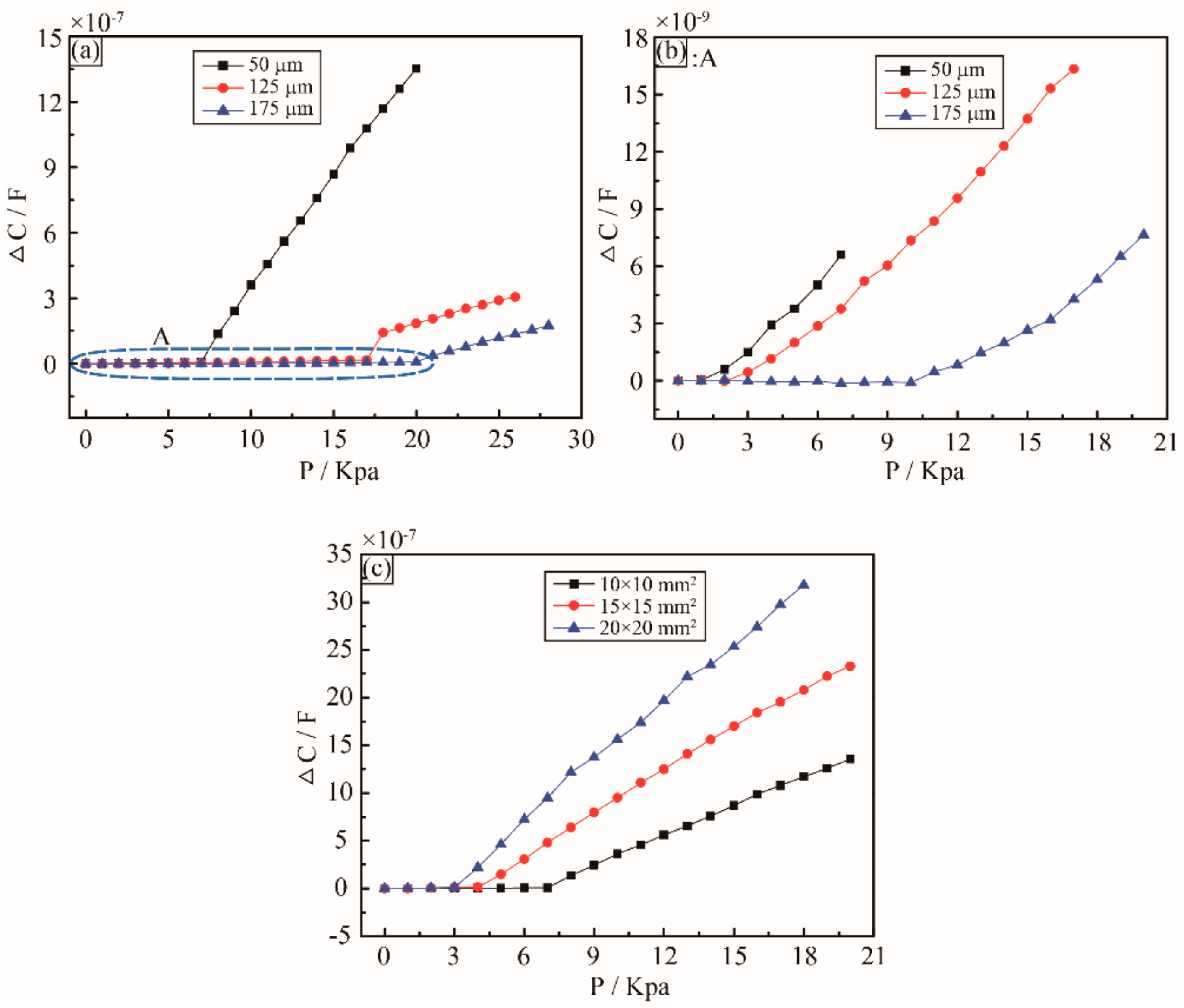

4.3. Effect of the Thickness of the Sensing Membrane

4.4. Effect of Area of the Sensing Chamber

4.5. Effect of Temperature and Humidity

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zhang, T.; Hong, H.; Zhang, X. Aero Optical Effect. In Aero-Optical Effect Correction: Principles, Methods and Applications; University of Science and Technology of China Press: Hefei, China, 2014; pp. 28–30. [Google Scholar]

- Zhang, D.; Bai, L.; Wu, Z.; Gong, Y. Density and temperature characteristics of hypersonic aircraft outflow field near the wall. In Proceedings of the 2016 11th International Symposium on Antennas, Propagation and Em Theory IEEE, Guilin, China, 18–21 October 2016. [Google Scholar]

- Shyy, W.; Bernal, L.; Yeo, D.; Atkins, E. Aerodynamic Sensing for a Fixed Wing UAS Operating at High Angles of Attack. In Proceedings of the AIAA Atmospheric Flight Mechanics Conference, Minneapolis, MN, USA, 13–16 August 2012. [Google Scholar]

- Bunge, R.A.; Alkurdi, A.E.; Alfaris, E.; Kroo, I. In-Flight Measurement of Wing Surface Pressures on a Small-Scale UAV during Stall/Spin Maneuvers. In Proceedings of the AIAA Flight Testing Conference, Washington, DC, USA, 13–17 June 2016. [Google Scholar]

- Guerreiro, N.; Hubbard, J. Flight Testing of a Model Aircraft with Trailing-Edge Flaps Optimized for Lift Distribution Control. In Proceedings of the AIAA Atmospheric Flight Mechanics Conference and Exhibit, Honolulu, HI, USA, 18–21 August 2008. [Google Scholar]

- Cox, C.; Gopalarathnam, A.; Hall, C.E. Flight Test of Stable Automated Cruise Flap for an Adaptive Wing Aircraft. J. Aircr. 2010, 47, 1178–1188. [Google Scholar] [CrossRef] [Green Version]

- Quindlen, J.; Langelaan, J. Flush Air Data Sensing for Soaring-Capable UAVs. In Proceedings of the 51st AIAA Aerospace Sciences Meeting Including the New Horizons Forum and Aerospace Exposition, Grapevine, TX, USA, 7–10 January 2013. [Google Scholar]

- Xu, W.; Xie, L.; Ying, Y. Mechanisms and applications of terahertz metamaterial sensing: A review. Nanoscale 2017, 9, 13864–13878. [Google Scholar] [CrossRef] [PubMed]

- Dusek, J.E. Development of Bio-Inspired Distributed Pressure Sensor Arrays for Hydrodynamic Sensing Applications. Ph.D. Thesis, Massachusetts Institute of Technology, Boston, MA, USA, 2016. [Google Scholar]

- Gregory, J.W.; Asai, K.; Kameda, M.; Liu, T.; Sullivan, J.P. A review of pressure-sensitive paint for high-speed and unsteady aerodynamics. Proc. Inst. Mech. Eng. Part. G J. Aerosp. Eng. 2008, 222, 249–290. [Google Scholar] [CrossRef] [Green Version]

- Le Sant, Y.; Mérienne, M.C. Surface pressure measurements by using pressure-sensitive paints. Aerosp. Sci. Technol. 2005, 9, 285–299. [Google Scholar] [CrossRef]

- Johnson, F.T.; Tinoco, E.N.; Yu, N.J. Thirty years of development and application of CFD at Boeing Commercial Airplanes, Seattle. Comput. Fluids 2005, 34, 1115. [Google Scholar] [CrossRef]

- Wang, X.; Wan, Z.; Yang, C. A Method of Static Aeroelastic Analysis Based on Three Dimension Aerodynamic Force and Aeroelastic Correction for Hypersonic Vehicles. In Proceedings of the 55th AIAA Aerospace Sciences Meeting, Grapevine, TX, USA, 9–13 January 2017. [Google Scholar]

- Xu, T.-B.; Guerreiro, N.; Hubbard, J.; Kang, J.H.; Park, C.; Harrison, J. One-dimensional contact mode interdigitated center of pressure sensor. Appl. Phys. Lett. 2009, 94, 233503. [Google Scholar] [CrossRef]

- Xu, T.-B.; Kang, J.; Park, C.; Harrison, J.S.; Guerreiro, N.M.; Hubbard, J.E. One-Dimensional Contact Mode Interdigitated Center of Pressure Sensor (CMIPS). Appl. Phys. Lett. 2009, 94, 23353. [Google Scholar] [CrossRef]

- Kim, D.-H.; Ghaffari, R.; Lu, N.; Rogers, J.A. Flexible and stretchable electronics for biointegrated devices. Annu. Rev. Biomed. Eng. 2012, 14, 113–128. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Xu, J.; Chen, D.; Shen, G. Flexible electronics based on inorganic nanowires. Chem. Soc. Rev. 2015, 44, 161–192. [Google Scholar] [CrossRef] [PubMed]

- Lipomi, D.J.; Vosgueritchian, M.; Tee, B.C.; Hellstrom, S.L.; Lee, J.A.; Fox, C.H.; Bao, Z. Skin-like pressure and strain sensors based on transparent elastic films of carbon nanotubes. Nat. Nanotechnol. 2011, 6, 788. [Google Scholar] [CrossRef] [PubMed]

- Mannsfeld, S.C.B.; Tee, B.C.K.; Stoltenberg, R.M.; Chen, C.V.H.; Barman, S.; Muir, B.V.; Bao, Z. Highly sensitive flexible pressure sensors with microstructured rubber dielectric layers. Nat. Mater. 2010, 9, 859. [Google Scholar] [CrossRef] [PubMed]

- Tiwana, M.I.; Redmond, S.J.; Lovell, N.H. A review of tactile sensing technologies with applications in biomedical engineering. Sens. Actuators A 2012, 179, 17–31. [Google Scholar] [CrossRef]

- Pang, C.; Lee, G.-Y.; Kim, T.-I.; Kim, S.M.; Kim, H.N.; Ahn, S.-H.; Suh, K.-Y. A flexible and highly sensitive strain-gauge sensor using reversible interlocking of nanofibres. Nat. Mater. 2012, 11, 795. [Google Scholar] [CrossRef] [PubMed]

- Tee, B.C.; Wang, C.; Allen, R.; Bao, Z. An electrically and mechanically self-healing composite with pressure-and flexion-sensitive properties for electronic skin applications. Nat. Nanotechnol. 2012, 7, 825. [Google Scholar] [CrossRef] [PubMed]

- Ali, M.A.; Jiang, H.; Mahal, N.K.; Weber, R.J.; Kumar, R.; Castellano, M.J.; Dong, L. Microfluidic impedimetric sensor for soil nitrate detection using graphene oxide and conductive nanofibers enabled sensing interface. Sens. Actuators B 2017, 239, 1289–1299. [Google Scholar] [CrossRef]

- Gaal, G.; Mendes, M.; de Almeida, T.P.; Piazzetta, M.H.O.; Gobbi, Â.L.; Riul, A.; Rodrigues, V. Simplified fabrication of integrated microfluidic devices using fused deposition modeling 3D printing. Sens. Actuators B 2017, 242, 35–40. [Google Scholar] [CrossRef]

- Armand, M.; Endres, F.; MacFarlane, D.R.; Ohno, H.; Scrosati, B. Ionic-liquid materials for the electrochemical challenges of the future. Nat. Mater. 2009, 8, 621. [Google Scholar] [CrossRef] [PubMed]

- Yuan, H.; Shimotani, H.; Tsukazaki, A.; Ohtomo, A.; Kawasaki, M.; Iwasa, Y. High-density carrier accumulation in ZnO field-effect transistors gated by electric double layers of ionic liquids. Adv. Funct. Mater. 2009, 19, 1046–1053. [Google Scholar] [CrossRef]

- Nie, B.; Li, R.; Cao, J.; Brandt, J.D.; Pan, T. Flexible transparent iontronic film for interfacial capacitive pressure sensing. Adv. Mater. 2015, 27, 6055–6062. [Google Scholar] [CrossRef] [PubMed]

- Sun, J.-Y.; Zhao, X.; Illeperuma, W.R.; Chaudhuri, O.; Oh, K.H.; Mooney, D.J.; Vlassak, J.J.; Suo, Z. Highly stretchable and tough hydrogels. Nature 2012, 489, 133. [Google Scholar] [CrossRef] [PubMed]

- Sun, J.Y.; Keplinger, C.; Whitesides, G.M.; Suo, Z. Ionic skin. Adv. Mater. 2014, 26, 7608–7614. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, R.; Si, Y.; Zhu, Z.; Guo, Y.; Zhang, Y.; Pan, N.; Sun, G.; Pan, T. Supercapacitive Iontronic Nanofabric Sensing. Adv. Mater. 2017, 29, 1700253. [Google Scholar] [CrossRef] [PubMed]

- Nie, B.; Li, R.; Brandt, J.D.; Pan, T. Microfluidic tactile sensors for three-dimensional contact force measurements. Lab Chip 2014, 14, 4344–4353. [Google Scholar] [CrossRef] [PubMed]

- Nie, B.; Xing, S.; Brandt, J.D.; Pan, T. Droplet-based interfacial capacitive sensing. Lab Chip 2012, 12, 1110–1118. [Google Scholar] [CrossRef] [PubMed]

- Meng, G.; Ko, W.H. Modeling of circular diaphragm and spreadsheet solution programming for touch mode capacitive sensors. Sens. Actuators A 1999, 75, 45–52. [Google Scholar] [CrossRef]

- Kohli, S.; Saini, A.; Pillai, A.J. MEMs based capacitive pressure sensor simulation for healthcare and biomedical applications. Int. J. Sci. Eng. Res. 2013, 4, 1855–1862. [Google Scholar]

- Oldham, K.B. A Gouy–Chapman–Stern model of the double layer at a (metal)/(ionic liquid) interface. J. Electroanal. Chem. 2008, 613, 131–138. [Google Scholar] [CrossRef]

- Kornyshev, A.A. Double-layer in ionic liquids: Paradigm change? J. Phys. Chem. B 2007, 111, 5545–5557. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.K.; Lee, S.; Yun, K.S. Capacitive tactile sensor array for touch screen application. Sens. Actuators A 2011, 165, 2–7. [Google Scholar] [CrossRef]

- Joo, Y.; Byun, J.; Seong, N.; Ha, J.; Kim, H.; Kim, S.; Hong, Y. Silver nanowire-embedded PDMS with a multiscale structure for a highly sensitive and robust flexible pressure sensor. Nanoscale 2015, 7, 6208–6215. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Jiu, J.; Nogi, M.; Sugahara, T.; Nagao, S.; Koga, H.; Suganuma, K. A highly sensitive and flexible pressure sensor with electrodes and elastomeric interlayer containing silver nanowires. Nanoscale 2015, 7, 2926–2932. [Google Scholar] [CrossRef] [PubMed]

- Lee, B.Y.; Kim, J.; Kim, H.; Kim, C.; Lee, S.D. Low-cost flexible pressure sensor based on dielectric elastomer film with micro-pores. Sens. Actuators A 2016, 240, 103–109. [Google Scholar] [CrossRef]

| Types | Dielectric Layer | Sensitivity | Sensing Range |

|---|---|---|---|

| Silicon-based | Air [37] | 3.47 fF/KPa | 0–30 Kpa |

| Elastic material-based | PDMS [38] | 7.2 pF/KPa | 0.5–2.5 KPa |

| CNT/PDMS [39] | 0.55 nF/KPa | 0–0.03 KPa | |

| Pyramid PDMS [19] | 18.6 fF/KPa | 0–2 KPa | |

| Porous PDMS [40] | 0.1 pF/KPa | 0–0.02 KPa | |

| Microfluidic-based | Hydrogel [29] | 0.1 pF/kPa | 0–40 KPa |

| Nanofiber [30] | 114 nF/Kpa | 0–1 KPa | |

| Air/ionic liquid filter paper [this work] | 178.5 nF/kPa | 7–18 KPa |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, X.; Wang, Y.; Qing, X. A Flexible Capacitive Pressure Sensor Based on Ionic Liquid. Sensors 2018, 18, 2395. https://doi.org/10.3390/s18072395

Yang X, Wang Y, Qing X. A Flexible Capacitive Pressure Sensor Based on Ionic Liquid. Sensors. 2018; 18(7):2395. https://doi.org/10.3390/s18072395

Chicago/Turabian StyleYang, Xiaofeng, Yishou Wang, and Xinlin Qing. 2018. "A Flexible Capacitive Pressure Sensor Based on Ionic Liquid" Sensors 18, no. 7: 2395. https://doi.org/10.3390/s18072395