Planar Amperometric Glucose Sensor Based on Glucose Oxidase Immobilized by Chitosan Film on Prussian Blue Layer

Abstract

:Introduction

Experimental

Chemicals

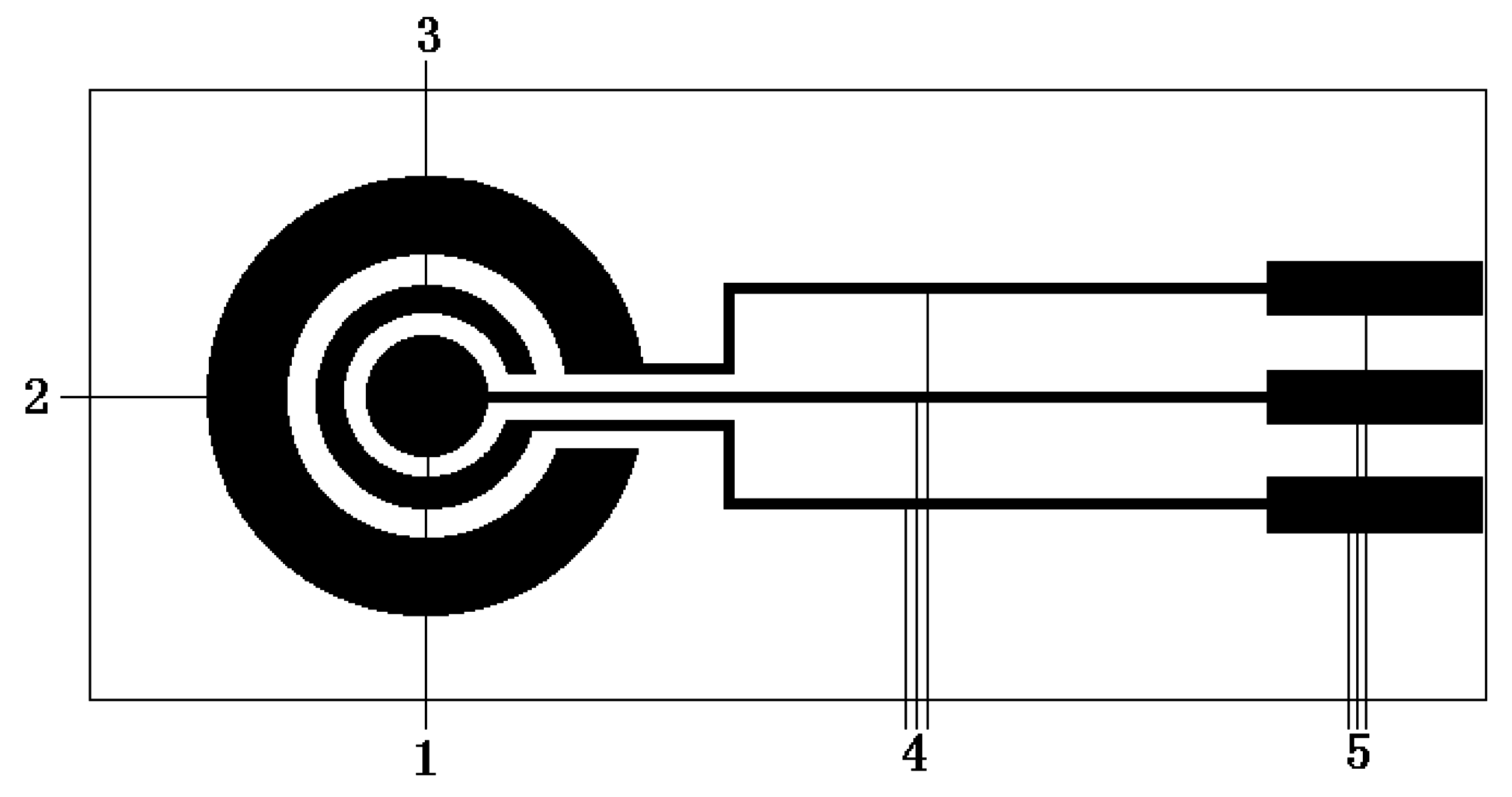

Microelectrode preparation

PB layer electropolymerization

GOD immobilization

Measurements

Results and Discussion

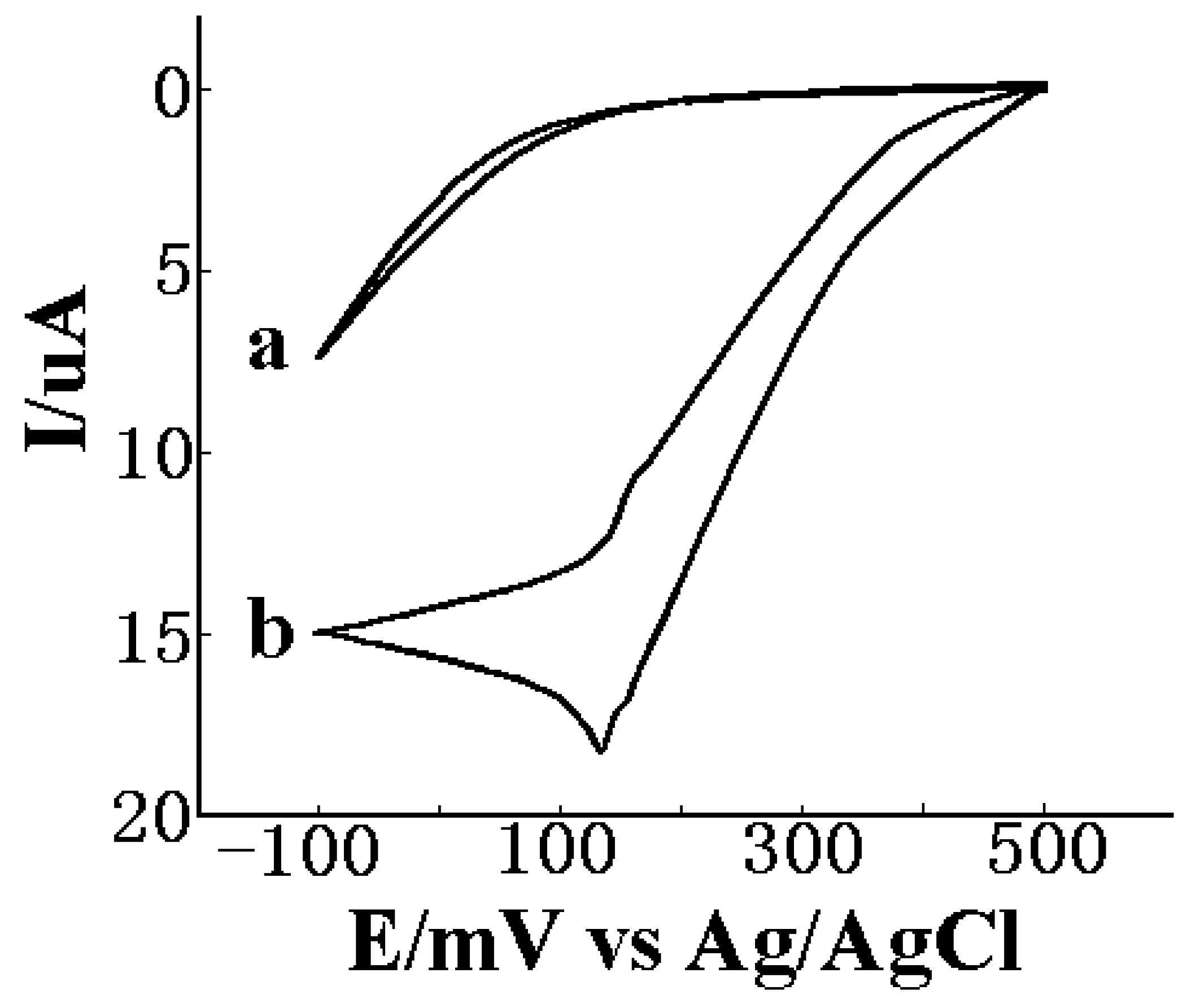

Electrocatalytic properties to H2O2 for PB/Pt electrode

Effects of experimental parameter on performances of the sensor

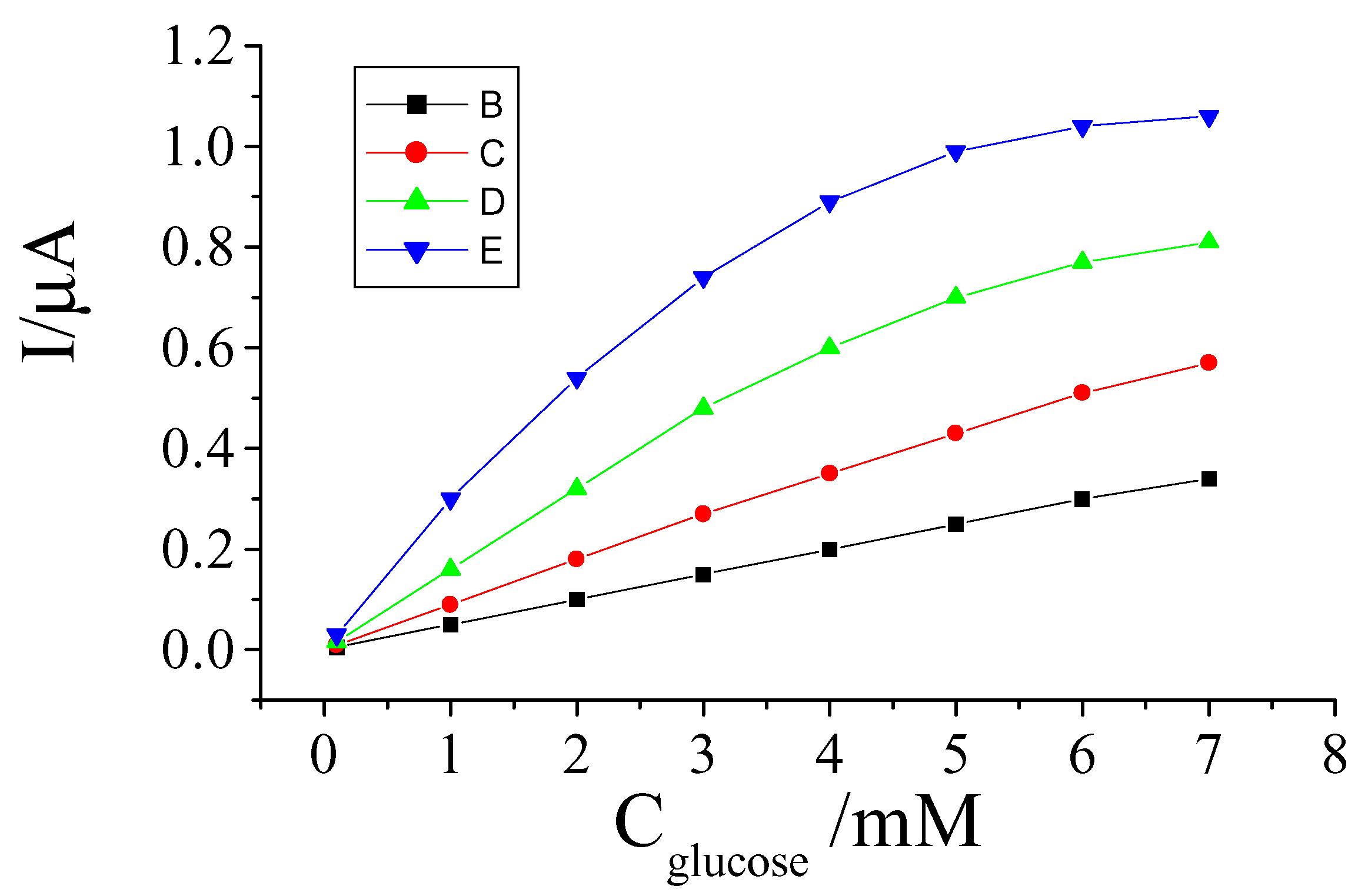

Effect of PB film thickness

Effect of enzyme quantity

Selection of WE potential

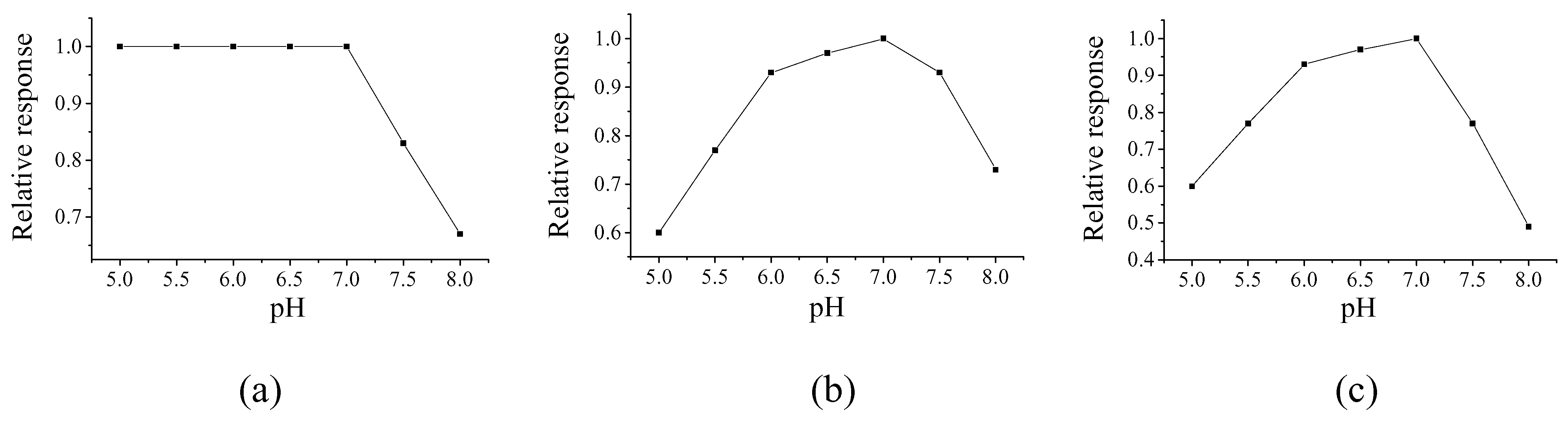

Selection of pH value

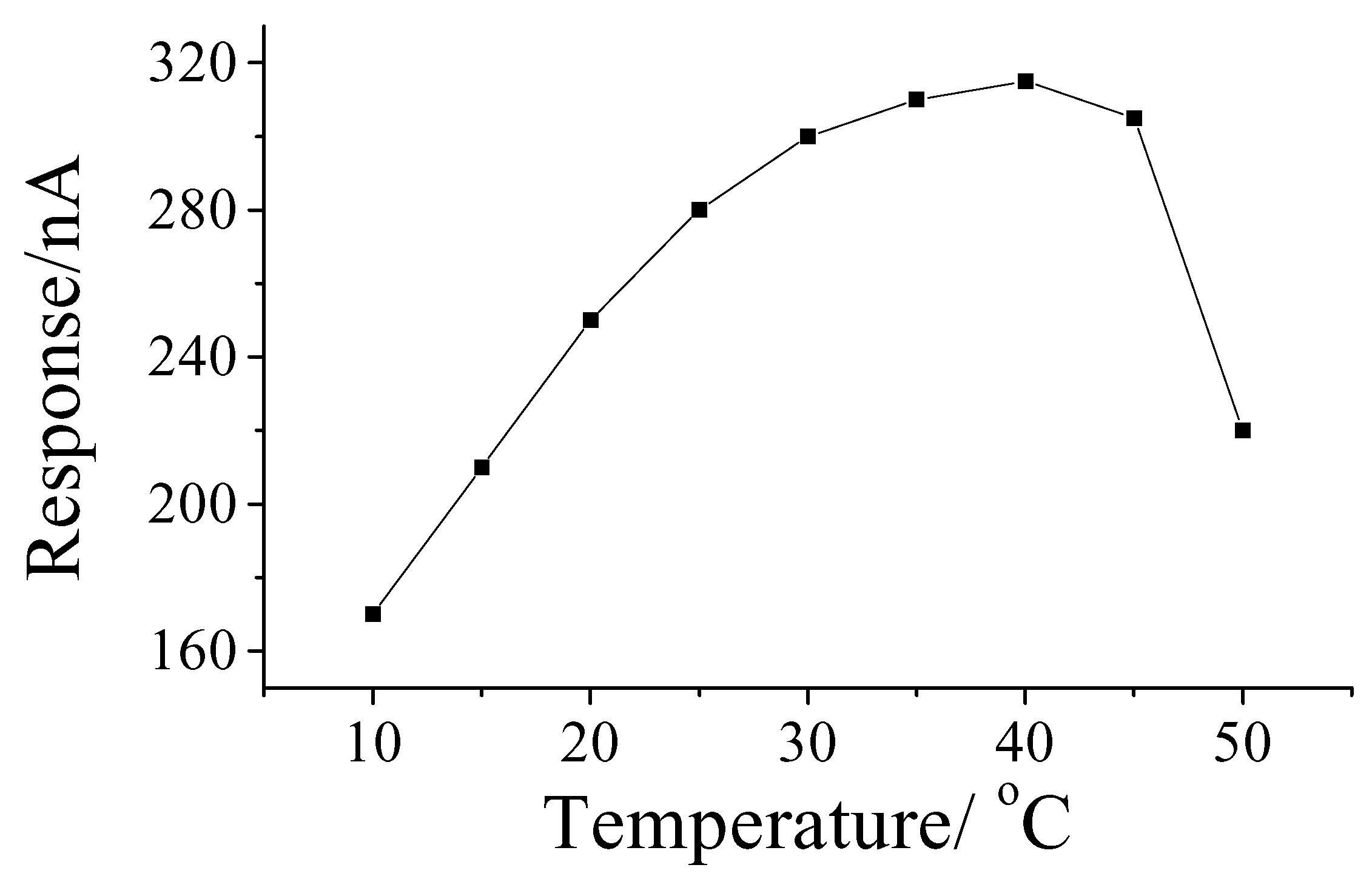

Effect of temperature on response

Performances of the sensor

Response time

Precision

| No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| I/nA | 291 | 294 | 298 | 292 | 297 | 295 | 290 | 289 | 299 | 295 | 294 |

| AV | 294 | ||||||||||

| RSD | 3.0% | ||||||||||

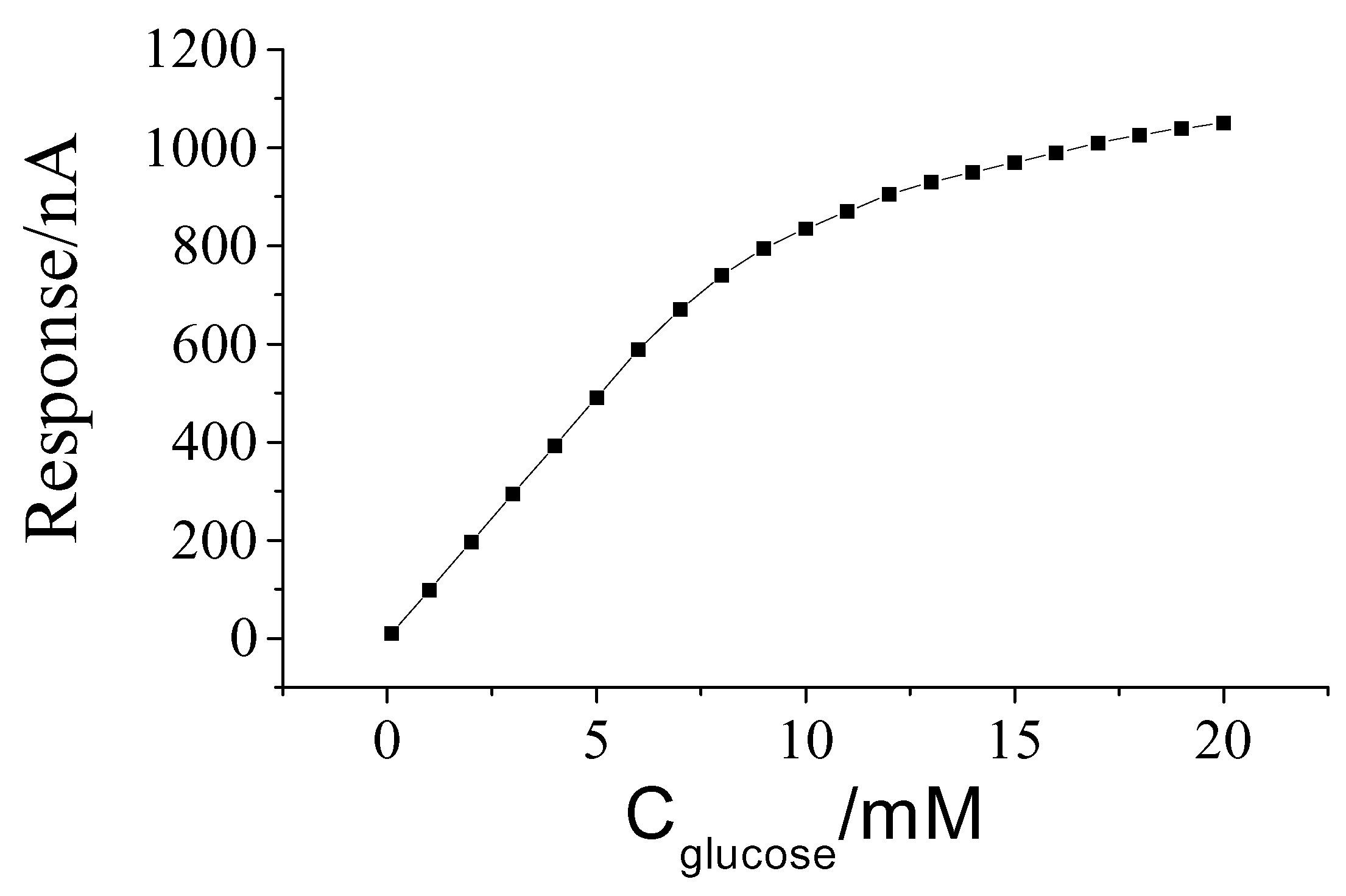

Calibration curve

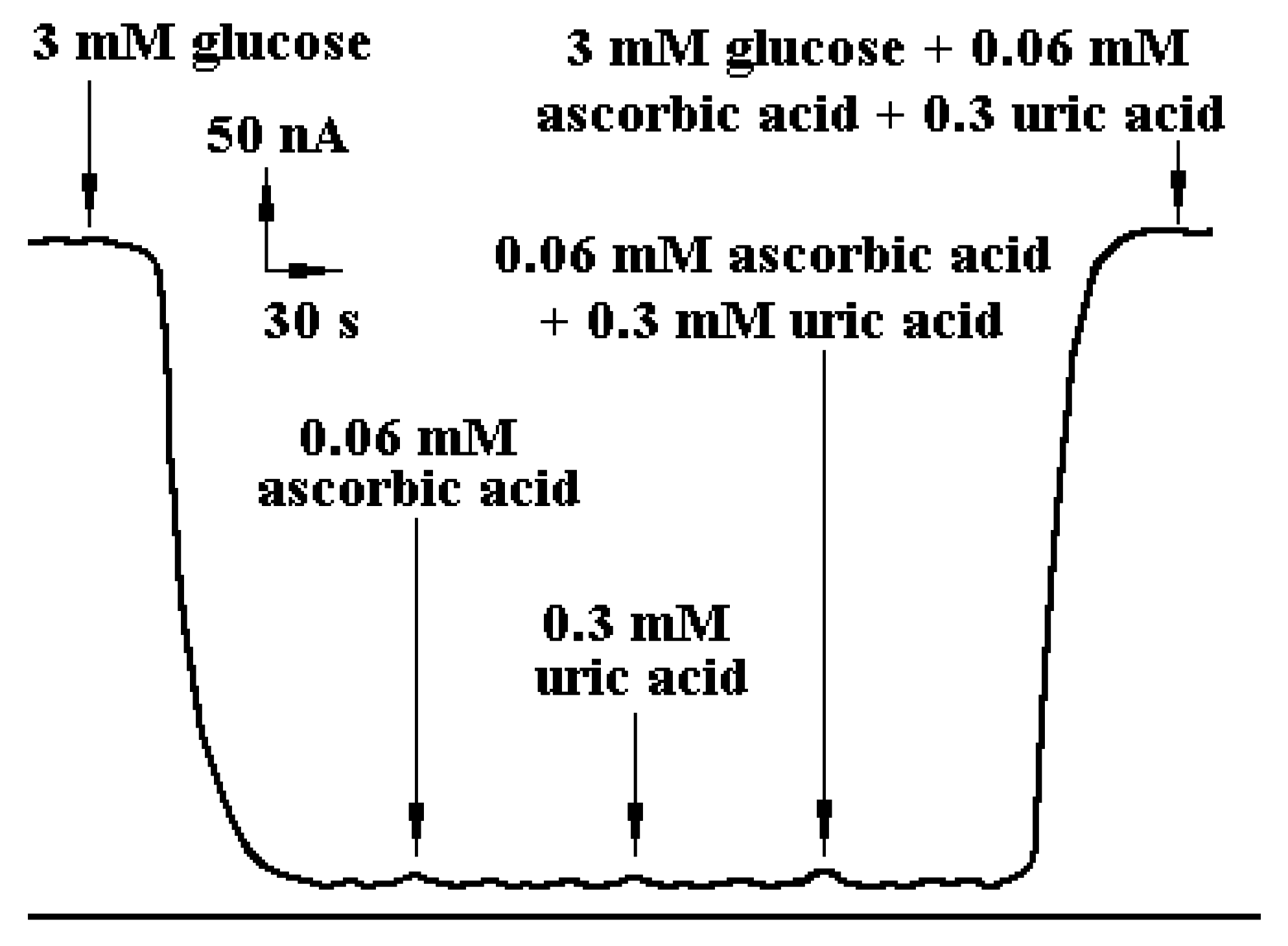

Testing of anti-interference

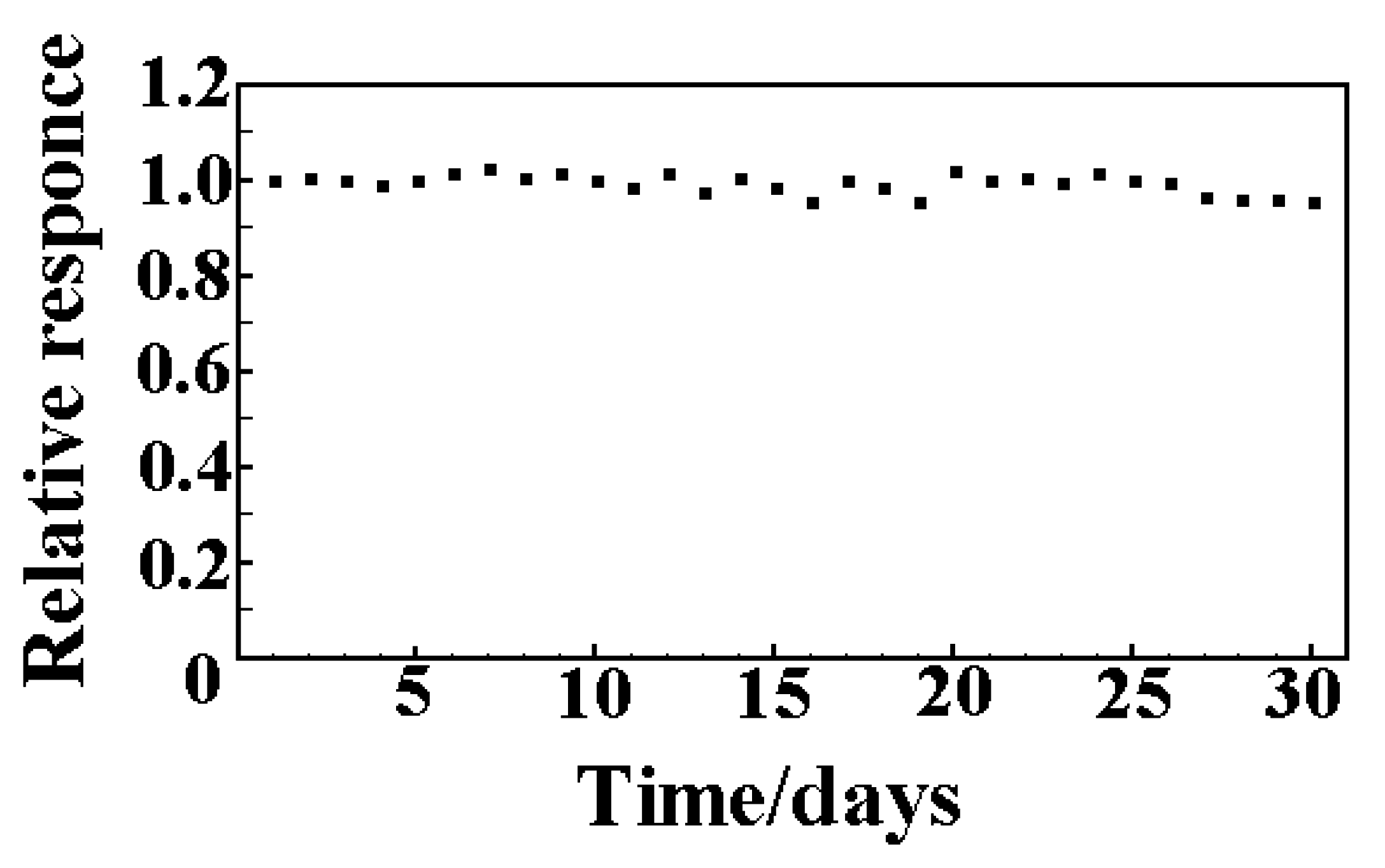

Long-term stability

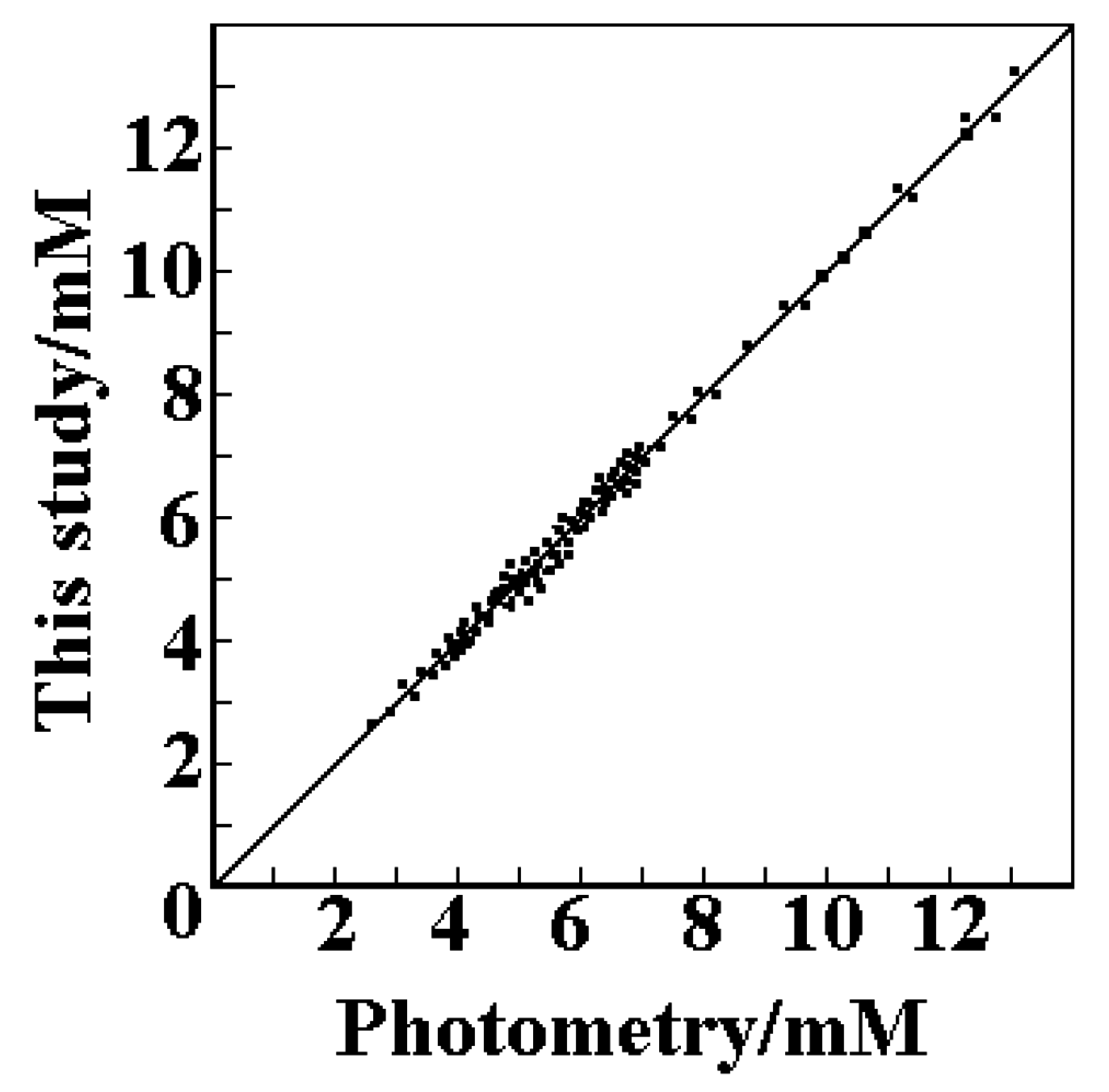

Accuracy

Acknowledgements

References

- Bacon, N. C.; Hall, E. A. H. Electroanalysis 1999, 11, 749.

- Li, Q. S. Anal. Lett. 1998, 31, 937.

- Mizutani, F.; Sato, Y.; Hirata, Y.; Sawaguchi, T.; Yabuki, S. Anal. Chim. Acta 1998, 364, 173. [CrossRef]

- Sasso, S. V.; Pierce, R. J.; Walla, R.; Yacynych, A. M. Anal Chem. 1990, 62, 1111. [CrossRef]

- Vaidya, R.; Wilkins, E. Electroanalysis 1994, 6, 677. [CrossRef]

- Vaidya, R.; Atanasov, P.; Wilkins, E. Med Eng Phys 1995, 17, 416. [CrossRef]

- McAteer, K.; O’Neill, R. D. Analyst 1996, 121, 773. [CrossRef]

- Zhu, J. Z.; Zhu, Z. Q.; Lai, Z. S. Sensors and Materials. in press.

- Garjonyte, R.; Malinauskas, A. Sensors and Actuators B 1999, 56, 85-92. 1-6.

- Karyakin, A.; Gitelmacher, O. V.; Karyakina, E. E. Anal. Chem. 1995, 67, 2419.

- Itaya, K.; Shoji, N.; Uchida, I. J. Am. Chem. Soc. 1984, 106, 3423. [CrossRef]

- Karyakin, A.; Karyakina, E. E.; Gorton, L. Electrochem. Commun. 1999, 1, 78.

- Malev, V. V.; Tikhomirova, A. V.; Kondratiev, V. V.; Rubashkin, A. A. Russ. J. Electrochem. 1999, 35, 1038.

- Kondratiev, V. V.; Tikhomirova, A. V.; Malev, V. V. Electrochim Acta 1999, 45, 751.

- Karyakin, A.; Karyakina, E. E.; Gorton, L. J. Electroanal. Chem. 1998, 456, 97. [CrossRef]

- De Mattos, L.; Gorton, L.; Laurell, T.; Malinauskas, A.; Karyakin, A. A. Talanta 2000, 52, 791–799. [PubMed]

- De Mattos, L.; Lukachova, L. V.; Gorton, L.; Laurell, T.; Karyakin, A. A. Talanta 2001, 54, 963–974.

- O’Halloran, M. P.; Pravda, M.; Guilbault, G. G. Talanta 2001, 55, 605–611.

- Sample Availability: Available from the authors.

© 2002 by MDPI (http://www.mdpi.net). Reproduction is permitted for noncommercial purposes.

Share and Cite

Zhu, J.; Zhu, Z.; Lai, Z.; Wang, R.; Guo, X.; Wu, X.; Zhang, G.; Zhang, Z.; Wang, Y.; Chen, Z. Planar Amperometric Glucose Sensor Based on Glucose Oxidase Immobilized by Chitosan Film on Prussian Blue Layer. Sensors 2002, 2, 127-136. https://doi.org/10.3390/s20400127

Zhu J, Zhu Z, Lai Z, Wang R, Guo X, Wu X, Zhang G, Zhang Z, Wang Y, Chen Z. Planar Amperometric Glucose Sensor Based on Glucose Oxidase Immobilized by Chitosan Film on Prussian Blue Layer. Sensors. 2002; 2(4):127-136. https://doi.org/10.3390/s20400127

Chicago/Turabian StyleZhu, Jianzhong, Ziqiang Zhu, Zongsheng Lai, Rong Wang, Xiaoming Guo, Xiaqin Wu, Guoxiong Zhang, Zongrang Zhang, Yiting Wang, and Zongyou Chen. 2002. "Planar Amperometric Glucose Sensor Based on Glucose Oxidase Immobilized by Chitosan Film on Prussian Blue Layer" Sensors 2, no. 4: 127-136. https://doi.org/10.3390/s20400127