Temperature Gradient Effect on Gas Discrimination Power of a Metal-Oxide Thin-Film Sensor Microarray

Abstract

:Introduction

Experimental

The KAMINA gas sensor microarray (GSMA)

Set-up, measuring procedure and data processing

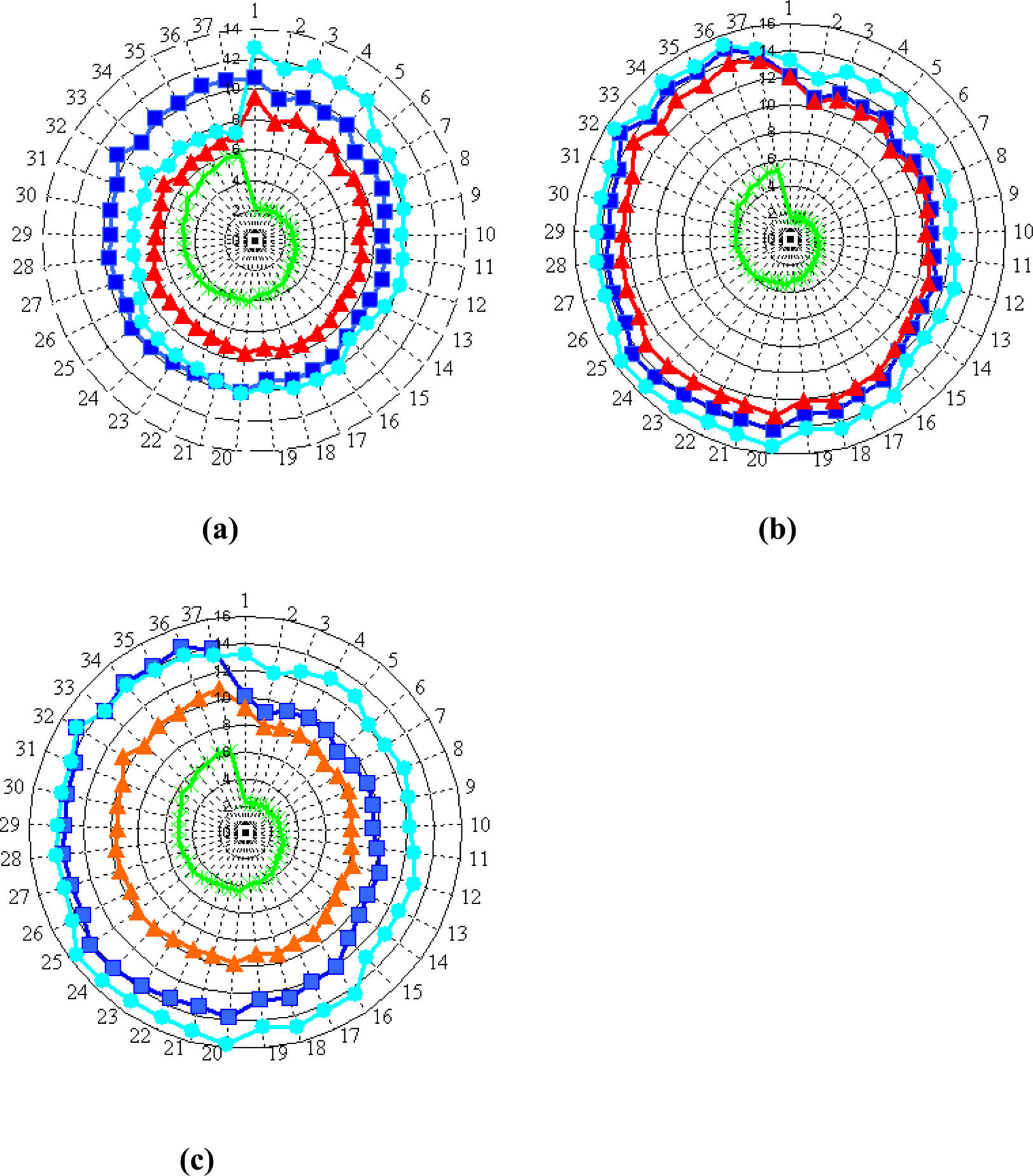

- The heaters' power input was adjusted to homogenize the temperature distribution on the chip measured with the thermoresistors at the chip edges. A temperature of approx. 360 °C was tried to be maintained. Some measurements were performed at other temperatures in the range of 295-400 °C.

- The temperature gradient (hereafter, gradT) of 6.7 °C/mm was applied across the SSs, resulting in a temperature difference of approx. 50 °C across the array. The minimum temperature was about 310 °C.

- An intermediate gradT of 3.3 °C/mm was applied across the SSs. This regime corresponded to a temperature variation of approx. 25 °C. The minimum temperature was about 330 °C.

Results and Discussion

Conclusions

Acknowledgments

References

- Persaud, K.; Dodd, G. Analysis of discrimination mechanisms in the mammalian olfactory system using a model nose. Nature 1982, 299, 352. [Google Scholar]

- Stetter, J.R.; Penrose, W.R. Sensors Update; Baltes, H., Fedder, G.K., Korvink, J.G., Eds.; Wiley-VCH: Weinheim, 2002; Volume 10, p. 189. [Google Scholar]

- Gardner, J.; Persaud, K.C. Electronic noses and olfaction 2000. Proceedings of the 7thInternational Symposium on Olfaction and Electronic Noses; IOP Publ.: Bristol & Philadelphia, 2000. [Google Scholar]

- Albert, K.J.; Lewis, N.S.; Schauer, C.L.; Sotzing, G.A.; Stitzel, S.E.; Vaid, T.P.; Walt, D.R. Cross-reactive chemical sensor arrays. Chemical Reviews 2000, 100, 2595. [Google Scholar]

- Hagleitner, C.; Hierlemann, A.; Lauge, D.; Kimmer, A.; Kerness, N.; Brand, O.; Baltes, H. Smart single-chip gas sensor microsystem. Nature 2001, 414, 293. [Google Scholar]

- Fukuda, T.; Menz, W. (Eds.) Micromechanical systems: principles and technology. Handbook of Sensors & Actuators; vol. 6, Elsevier: Amsterdam, 1998.

- Althainz, P.; Dahkle, A.; Frietsch-Klarhof, M.; Goschnick, J.; Ache, H.J. Reception tuning of gas-sensor microsystems by selective coatings. Sensors and Actuators B 1995, 24-25, 366. [Google Scholar]

- Goschnick, J. An electronic nose for intelligent consumer products based on a gas analytical gradient microarray. Microelectronic Engineering 2001, 57-58, 693. [Google Scholar]

- Jurs, P.C.; Bakken, G.A.; McClelland, H.E. Computational methods for the analysis of chemical sensor array data from volatile analytes. Chemical Reviews 2000, 100, 2649. [Google Scholar]

- Henrion, R.; Henrion, G. Multivariate Datenanalyse.; Springer-Verlag: Berlin, 1995. [Google Scholar]

- Kisin, V.V.; Sysoev, V.V.; Voroshilov, S.A. Discrimination of acetone and ammonia vapour using an array of thin-film sensors of the same type. Technical Physics Letters 1999, 25, 657. [Google Scholar]

© 2004 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Sysoev, V.V.; Kiselev, I.; Frietsch, M.; Goschnick, J. Temperature Gradient Effect on Gas Discrimination Power of a Metal-Oxide Thin-Film Sensor Microarray. Sensors 2004, 4, 37-46. https://doi.org/10.3390/s40400037

Sysoev VV, Kiselev I, Frietsch M, Goschnick J. Temperature Gradient Effect on Gas Discrimination Power of a Metal-Oxide Thin-Film Sensor Microarray. Sensors. 2004; 4(4):37-46. https://doi.org/10.3390/s40400037

Chicago/Turabian StyleSysoev, Victor V., Ilya Kiselev, Markus Frietsch, and Joachim Goschnick. 2004. "Temperature Gradient Effect on Gas Discrimination Power of a Metal-Oxide Thin-Film Sensor Microarray" Sensors 4, no. 4: 37-46. https://doi.org/10.3390/s40400037