Fabrication of Biochips with Micro Fluidic Channels by Micro End-milling and Powder Blasting

Abstract

:1. Introduction

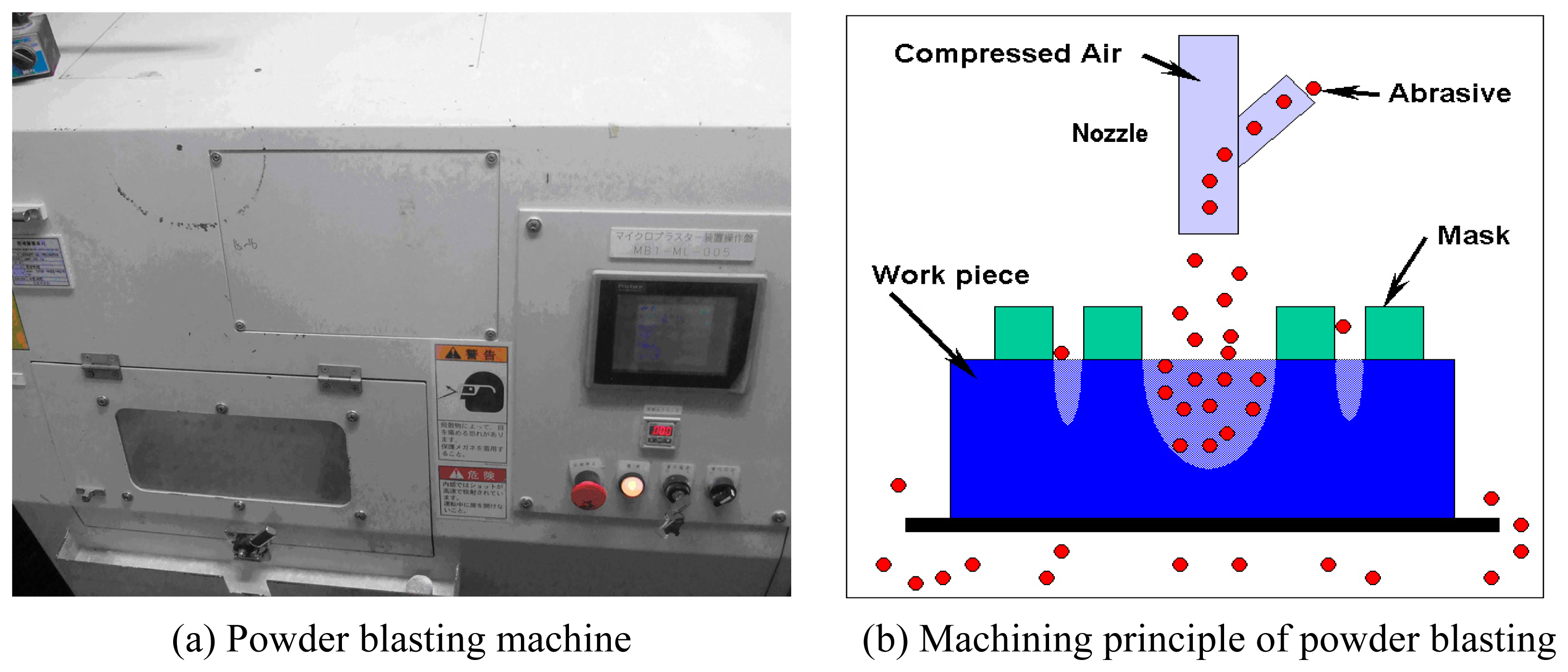

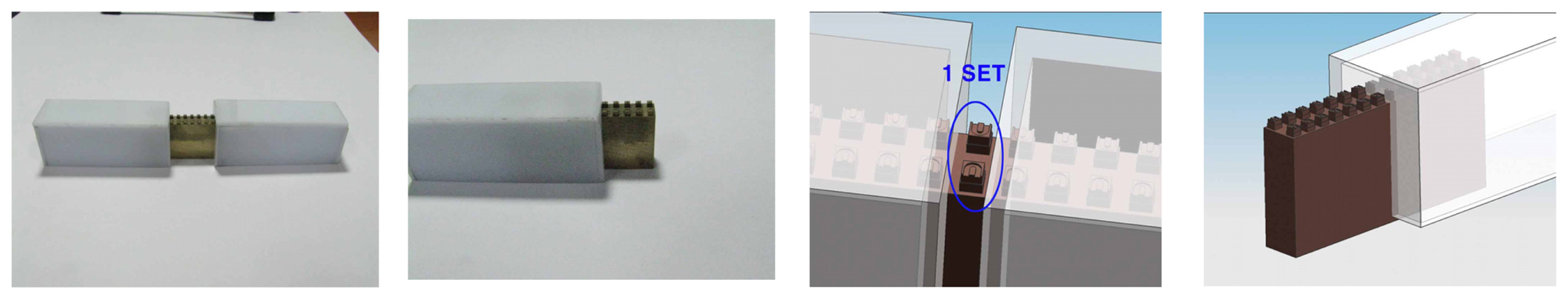

2. Micromachining System

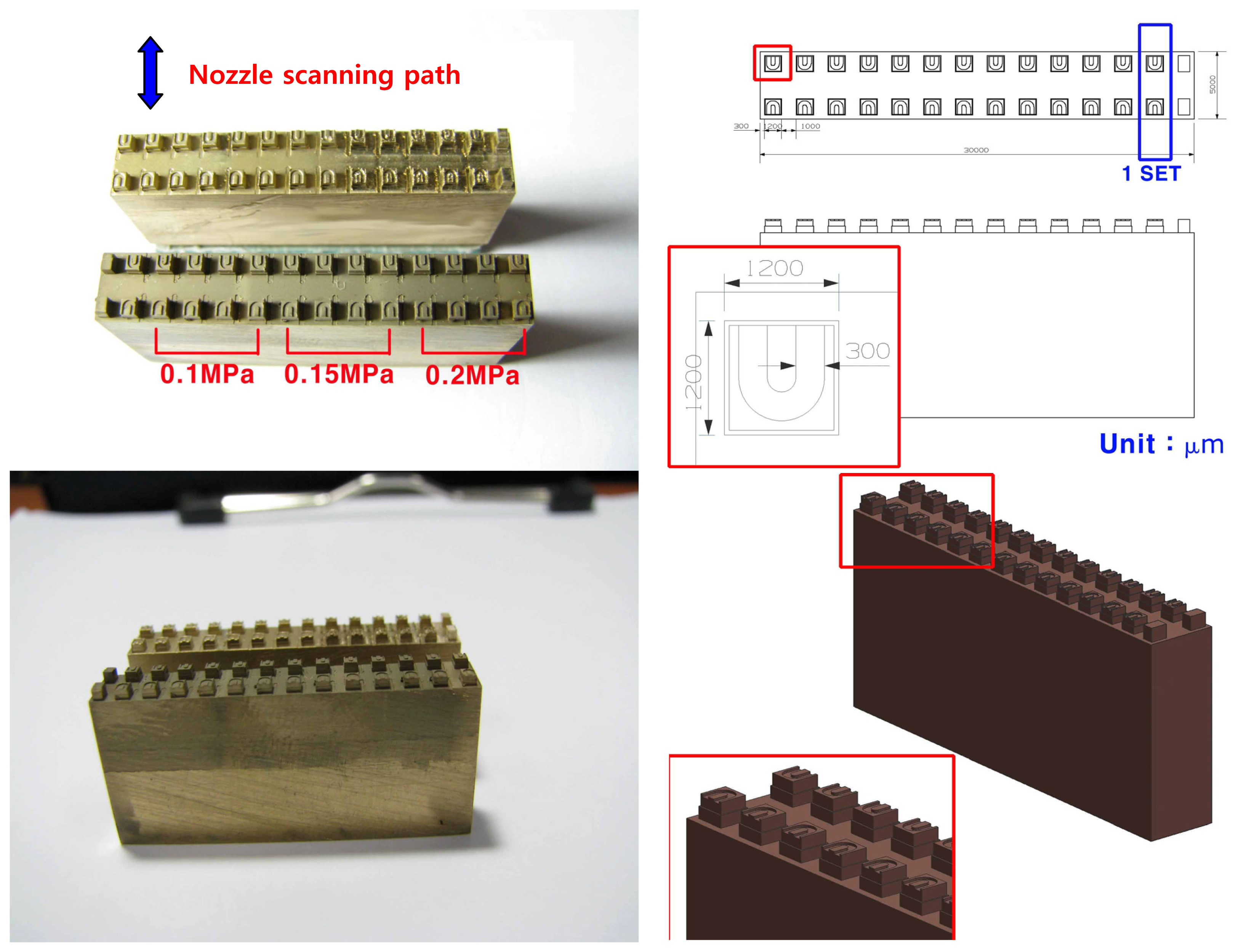

3. Powder Blasting

4. Experimental Method

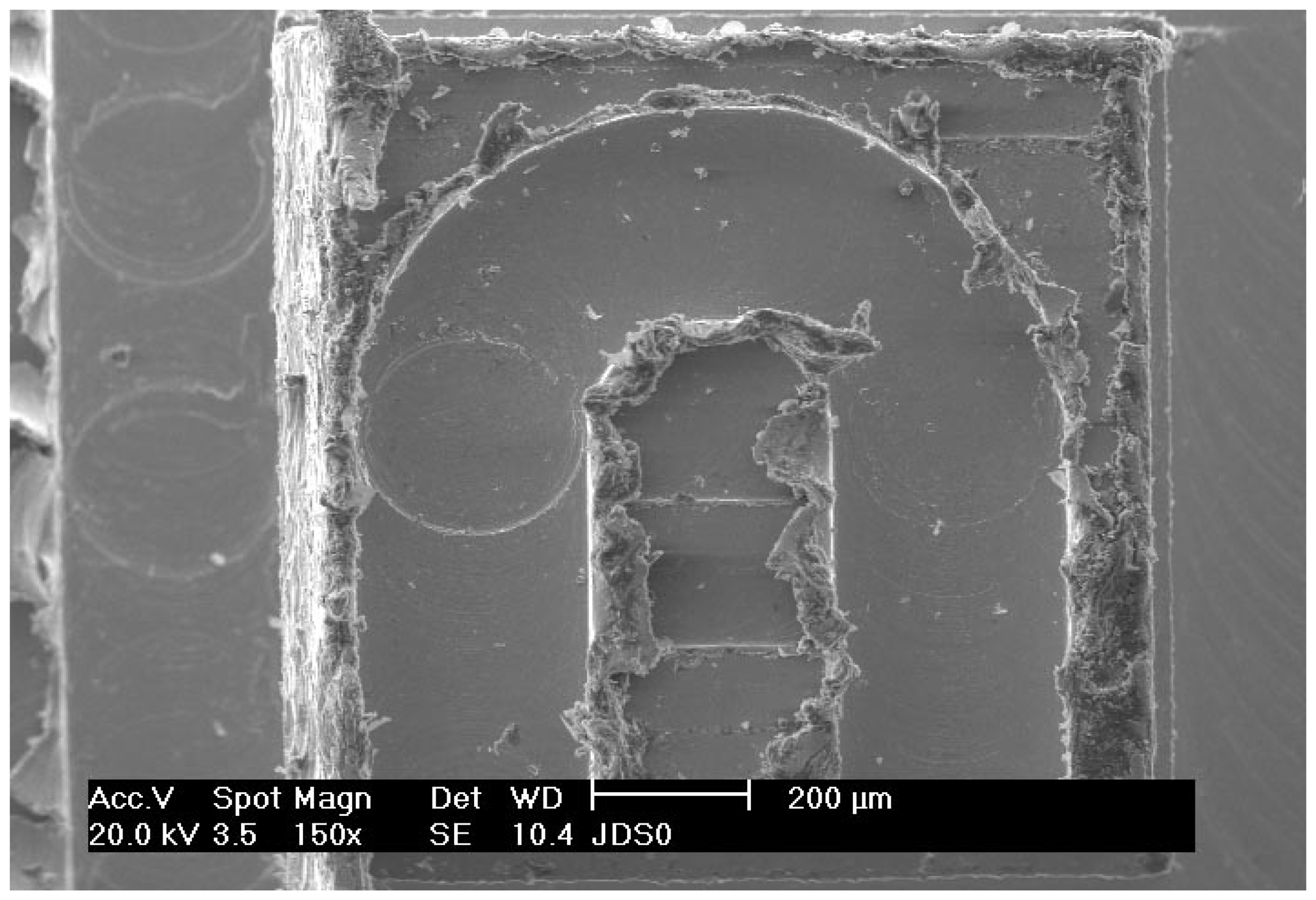

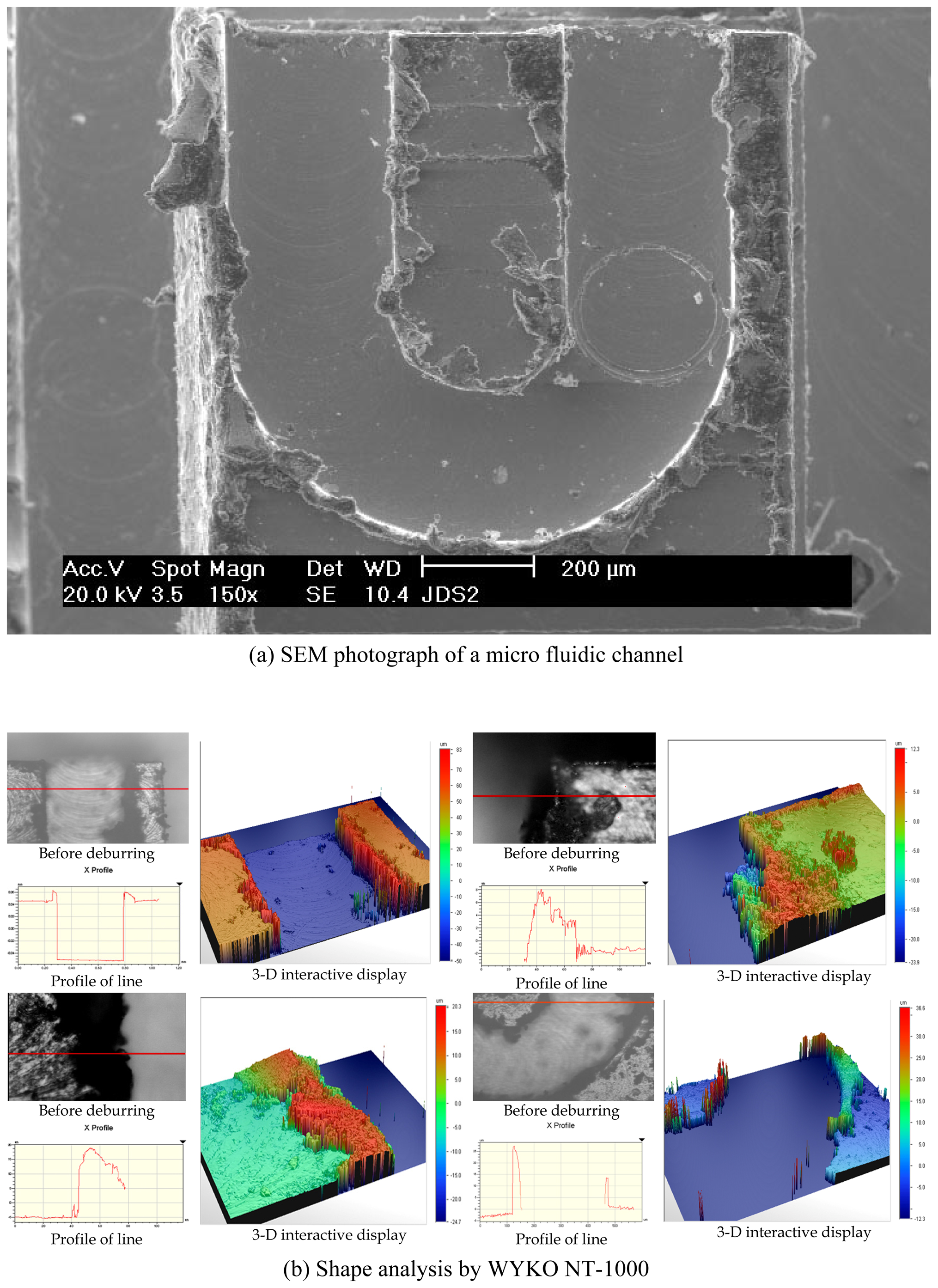

5. Result and Discussion

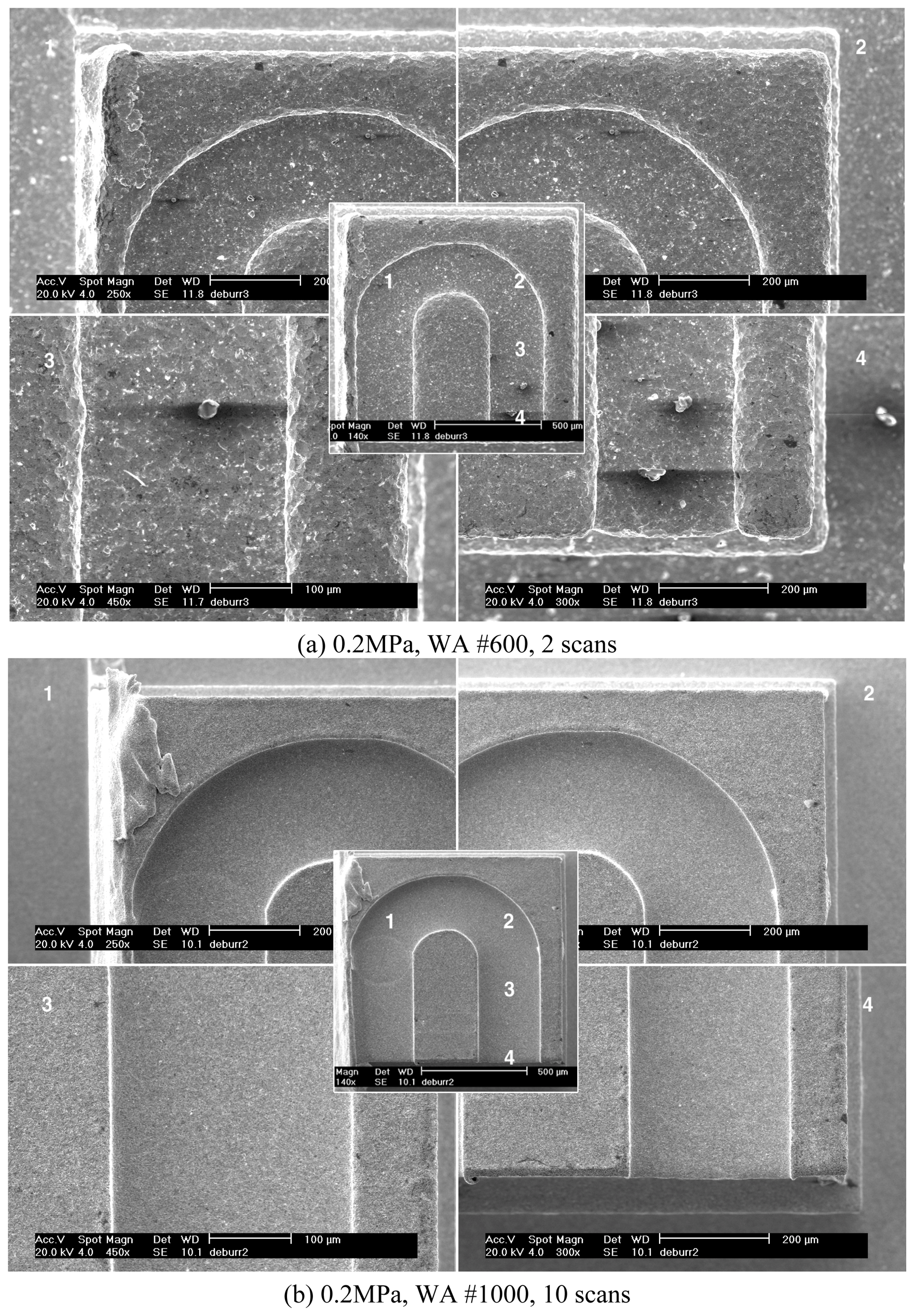

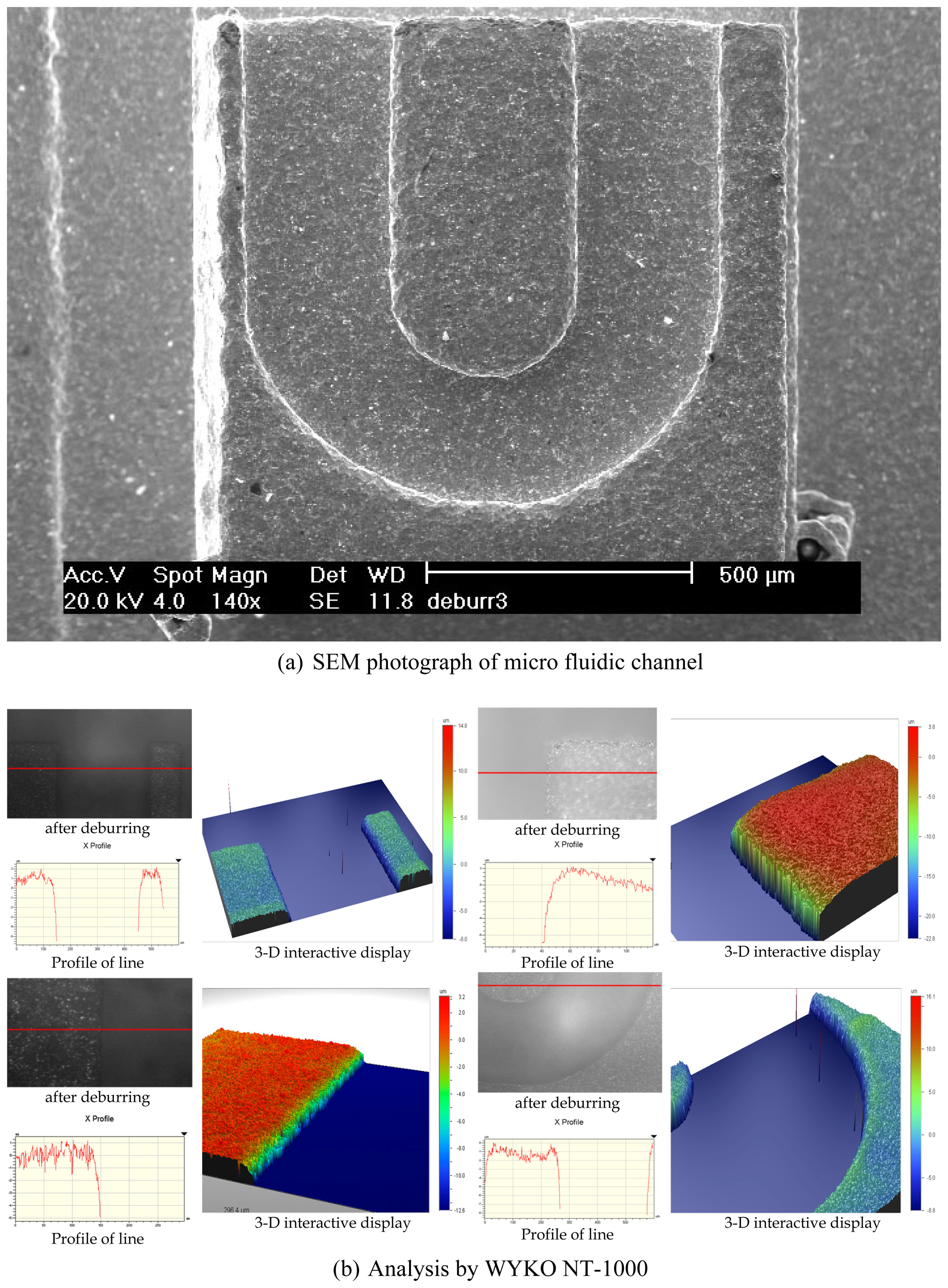

5.1 In case of blasting pressure 0.2MPa

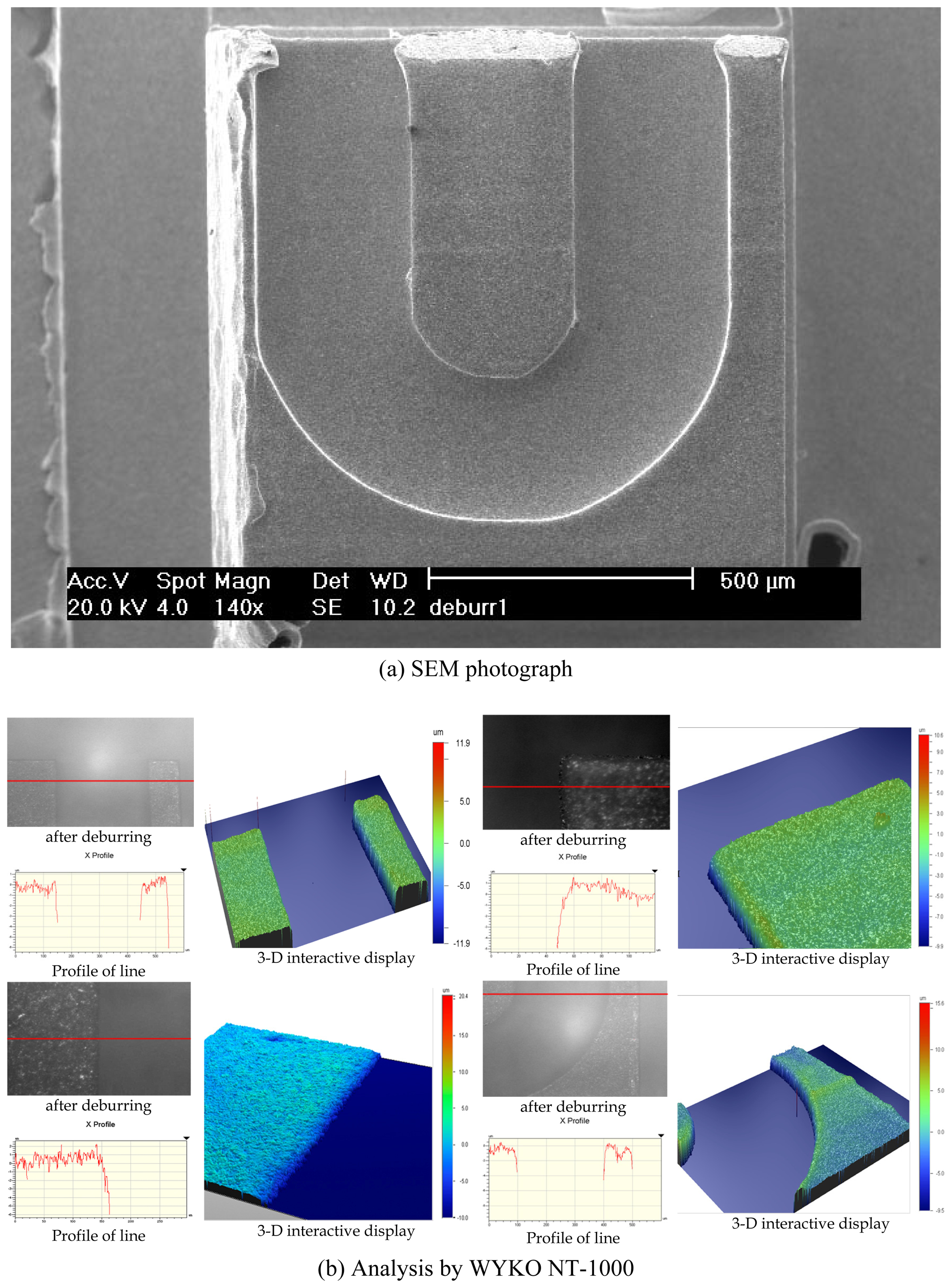

5.2 In case of blasting pressure 0.15MPa

6. Conclusion

Acknowledgments

References

- Mouradian, S. Lab-on-a-chip: Applications in proteomics. Current opinion in chemical biology 2002, 6, 51–56. [Google Scholar]

- Tseng, F.G.; Chuang, Y.J.; Lin, W.K. A novel fabrication method of embedded micro channels employing simple UV dosage control and antireflection coating. IEEE 15th International Conference on Micro Electro Mechanical Systems 2002, 69–72. [Google Scholar]

- Belloy, E.; Thurre, S.; Walckiers, E.; Sayah, A.; Gijs, M.A.M. The introduction of powder blasting for sensor and microsystem applications. Sensors and Actuators A: Physical 2000, 84, 330–337. [Google Scholar]

- Solignac, D.; Sayah, A.; Constantin, S.; Freitag, R.; Gijs, M.A.M. Powder blasting for the realisation of microchips for bio-analytic applications. Sensors and Actuators A: Physical 2001, 92, 388–393. [Google Scholar]

- Jo, B.H.; Van Lerberghe, L.M.; Motsegood, K. M.; Beebe, D. J. Three-dimensional microchannel fabrication in polydimethylsiloxane(PDMS) elastomer. Journal of Microelectromechanical Systems 2000, 9, 76–81. [Google Scholar]

- Chung, G.S.; Woo, H. S. Fabrication of SiCN microstructures for super-high temperature MEMS using PDMS mold and its characteristics. Journal of the Korean Sensors Society 2006, 15, 53–57. [Google Scholar]

- Chien, R.D. Micromolding of biochip devices designed with microchannels. Sensors and Actuators A: Physical 2006, 128, 238–247. [Google Scholar]

- Lee, K.; Dornfeld, D.A. Micro-burr formation and minimization through process control. Precision Engineering 2005, 29, 246–252. [Google Scholar]

- Lee, K.; Dornfeld, D. A. An experimental study on burr formation in micro milling aluminum and copper. Technical paper - Society of Manufacturing Engineers. AD. 2002, 202. ALL-. [Google Scholar]

- Ko, S.L.; Baron, Y. M.; Park, J. I. Micro deburring for precision parts using magnetic abrasive finishing method. Journal of Materials Processing Technology 2007, 187, 19–25. [Google Scholar]

- Yeo, S.H.; Ngoi, B. K. A.; Chua, L. Y. Ultrasonic Deburring. International Journal of Advanced Manufacturing Technology 1997, 13, 333–341. [Google Scholar]

- Slikkerveer, P.J.; Bouten, P. C. P.; de Haas, F. C. M. High quality mechanical etching of brittle materials by powder blasting. Sensors and Actuators A: Physical 2000, 85, 296–303. [Google Scholar]

- Park, D.S.; Yun, D. J.; Cho, M. W.; Shin, B. C. An Experimental Study on the Fabrication of Glass-based Acceleration Sensor Body Using Micro Powder Blasting Method. Sensors 2007, 7, 697–707. [Google Scholar]

- Park, D.S.; Seo, T. I.; Cho, M. W. Mechanical etching of micro pockets by powder blasting. International Journal of Advanced Manufacturing Technology 2005, 25, 1098–1104. [Google Scholar]

| Traveling range | 600×600×200 mm | Rotational speed | Max. 100,000 rpm |

| Resolution | 0.1 μm | Spindle run-out | Max. 0.7 μm |

| Accuracy | X, Y: 6 μm, Z: 2 μm | Static radial load | Min. 58.8 N |

| Repeatability | 0.2 μm | Lubrication | Dry cutting |

| Max. velocity | X, Y: 200 mm/s, Z: 100 mm/s | Workpiece weight | Max. 440 N |

| Feedrate of table | 300 mm/min |

| Spindle rpm | 40,000 rpm |

| Axial depth of cutting | 100 μm |

| Tool | φ300 μm, 2-flute flat end-mill |

| Specimen material | 6:4 Brass |

| Powder | WA #600, WA #1000 |

| Blasting pressure | 0.1, 0.15, 0.2 MPa |

| Stand-off distance | 100 mm |

| Impact angle | 90° |

| Mass flow rate | 100 g/min |

| Feed of table | X, Y: 100 mm/sec |

| Scanning times | 2 ∼ 30 times |

© 2008 by MDPI Reproduction is permitted for noncommercial purposes.

Share and Cite

Yun, D.J.; Seo, T.I.; Park, D.S. Fabrication of Biochips with Micro Fluidic Channels by Micro End-milling and Powder Blasting. Sensors 2008, 8, 1308-1320. https://doi.org/10.3390/s8021308

Yun DJ, Seo TI, Park DS. Fabrication of Biochips with Micro Fluidic Channels by Micro End-milling and Powder Blasting. Sensors. 2008; 8(2):1308-1320. https://doi.org/10.3390/s8021308

Chicago/Turabian StyleYun, Dae Jin, Tae Il Seo, and Dong Sam Park. 2008. "Fabrication of Biochips with Micro Fluidic Channels by Micro End-milling and Powder Blasting" Sensors 8, no. 2: 1308-1320. https://doi.org/10.3390/s8021308