Sensitivity Improvement of a Humidity Sensor Based on Silica Nanospheres on a Long-Period Fiber Grating

Abstract

:1. Introduction

2. Theoretical Considerations

3. Experimental

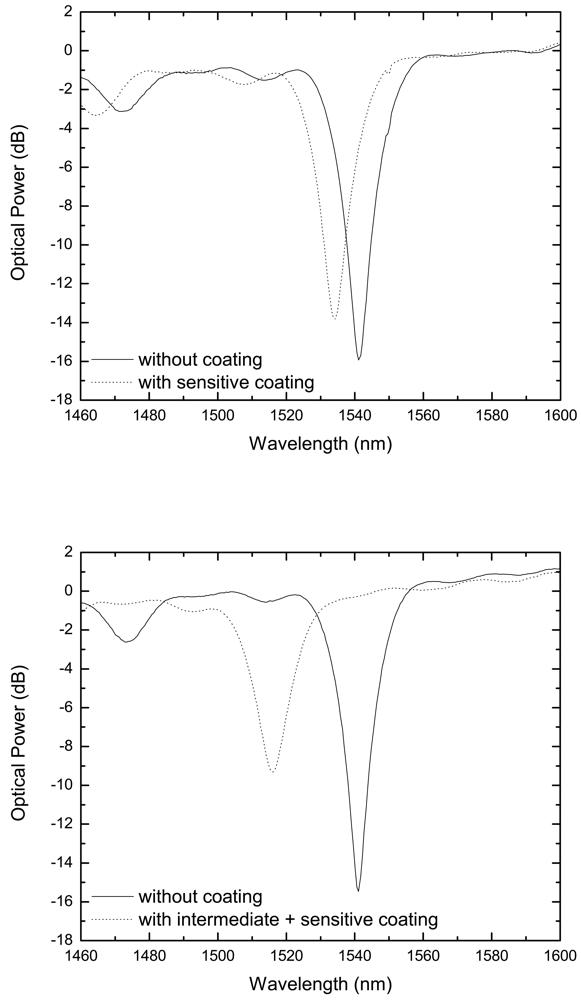

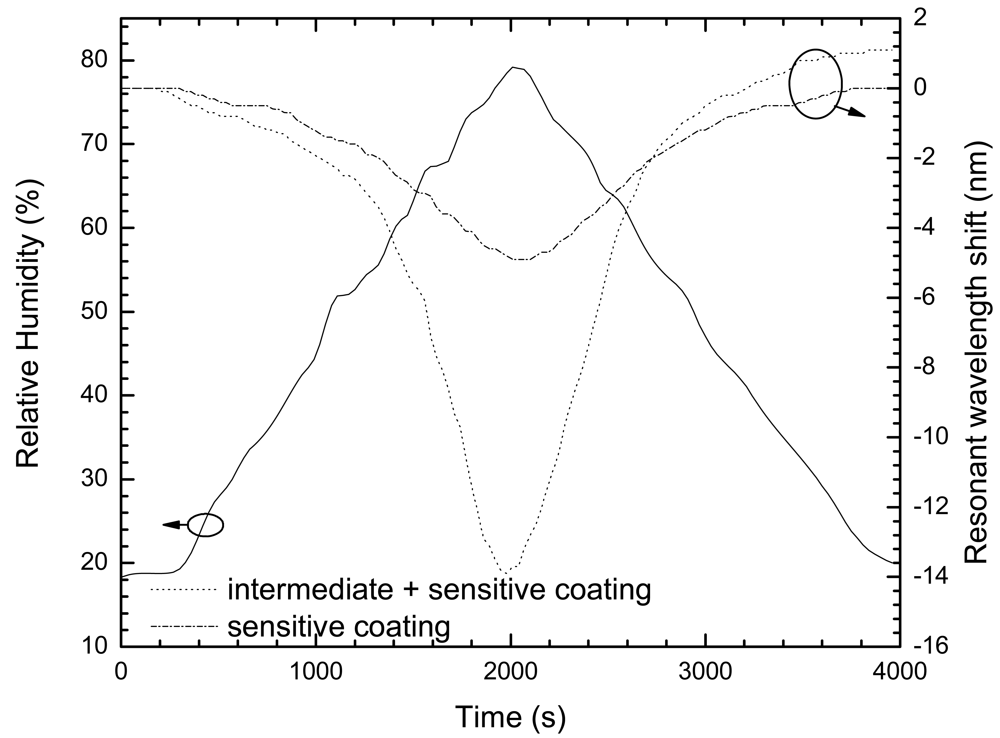

4. Results and Discussion

| Sensitive coating (PAH/SM30) | |

| Intermediate + sensitive coating (PDDA/PolyR + PAH/SM30) |

5. Conclusions

Acknowledgments

References and Notes

- Corres, J.M.; Matias, I.R.; Hernaez, J.M.; Bravo, J.; Arregui, F.J. Optical fiber humidity sensors using nanostructured coatings of SiO2 nanoparticles. IEEE Sensors J. 2008, 8, 281–285. [Google Scholar]

- Khidwania, S.K.; Shrinivasan, K.L.; Singh, J.P. An evanescent-wave optical fiber relative humidity sensor with enhanced sensitivity. Sens. Actuat. B 2005, 104, 217–222. [Google Scholar]

- Arregui, F.J.; Liu, Y.; Matias, I.R.; Claus, R.O. Optical fiber humidity sensor using a nano-fabry-perot cavity formed by the ionic self-assembly method. Sens. Actuat. B 1999, 8, 100–105. [Google Scholar]

- Corres, J.M.; Bravo, J.; Matias, I.R.; Arregui, F.J. Nonadiabatic Tapered Single-Mode Fiber Coated with Humidity Sensitive Nanofilms. IEEE Photon. Technol. Lett. 2006, 18, 935–937. [Google Scholar]

- James, S.; Tatam, R. Fiber optic sensors with nano-structured coatings. J. Opt. A: Pure Appl. Opt. 2006, 8, S430–S444. [Google Scholar]

- Corres, J.M.; Arregui, F.J.; Matias, I.R. Sensitivity optimization of tapered optical fiber humidity sensors by means of tuning the thickness of nanostructured sensitive coatings. Sens. Actuat. B-Chem. 2007, 122, 442–449. [Google Scholar]

- Bravo, J.; Matias, I.R.; del Villar, I.; Corres, J.M.; Arregui, F.J. Nanofilms on hollow core fiber-based structures: An optical study. IEEE/OSA J. Lightw. Technol. 2006, 24, 2100–2107. [Google Scholar]

- Viegas, D.; Goicoechea, J.; Santos, J.L.; Ferreira, L.A.; Araújo, F.M.; Matias, I.R. Humidity sensor based on a long-period fiber grating coated with a SiO2-nanospheres film. 19-OFS (19th International Conference on Optical Fibre Sensors), Perth, Western Australia, April 14-18, 2008.

- Cusano, A.; Iadicicco, A.; Pilla, P.; Contessa, L.; Campopiano, S.; Cutolo, A.; Giordano, M.; Guerra, G. Coated Long-Period Fiber Gratings as High-Sensitivity Optochemical Sensors. J. Lightwave Technol. 2003, 21, 218–227. [Google Scholar]

- Rego, G.; Marques, P.V.S.; Santos, J.L.; Salgado, H.M. Arc-induced long-period gratings. Fiber Integrated Opt. 2005, 24, 245–259. [Google Scholar]

- Decher, G. Fuzzy nanoassemblies: Toward layered polymeric multicomposites. Science 1997, 277, 1232–1237. [Google Scholar]

- Villar, I.; Matias, I.R.; Arregui, F. Enhancement of sensitivity in long-period fiber gratings with deposition of low-refractive-index materials. Opt. Lett. 2005, 30, 2363–2365. [Google Scholar]

- Villar, I.; Matias, I.R.; Arregui, F. Influence on cladding mode distribution of overlay deposition on long-period fiber gratings. J. Opt. Soc. America A. 2006, 23, 651–658. [Google Scholar]

- Villar, I.; Matias, I.R.; Arregui, F.; Lalanne, P. Optimization of sensitivity in Long Period Fiber Gratings with overlay deposition. Opt. Express. 2005, 13, 56–69. [Google Scholar]

- Corres, J.M.; Matias, I.R.; Villar, I.; Arregui, F. Design of pH Sensors in Long-Period Fiber Gratings Using Polymeric Nanocoatings. IEEE Sensors J. 2007, 7, 455–463. [Google Scholar]

© 2009 by the authors; licensee Molecular Diversity Preservation International, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Viegas, D.; Goicoechea, J.; Santos, J.L.; Araújo, F.M.; Ferreira, L.A.; Arregui, F.J.; Matias, I.R. Sensitivity Improvement of a Humidity Sensor Based on Silica Nanospheres on a Long-Period Fiber Grating. Sensors 2009, 9, 519-527. https://doi.org/10.3390/s90100519

Viegas D, Goicoechea J, Santos JL, Araújo FM, Ferreira LA, Arregui FJ, Matias IR. Sensitivity Improvement of a Humidity Sensor Based on Silica Nanospheres on a Long-Period Fiber Grating. Sensors. 2009; 9(1):519-527. https://doi.org/10.3390/s90100519

Chicago/Turabian StyleViegas, Diana, Javier Goicoechea, José Luís Santos, Francisco Moita Araújo, Luís Alberto Ferreira, Francisco J. Arregui, and Ignacio R. Matias. 2009. "Sensitivity Improvement of a Humidity Sensor Based on Silica Nanospheres on a Long-Period Fiber Grating" Sensors 9, no. 1: 519-527. https://doi.org/10.3390/s90100519