Characterization of Long-period Grating Refractive Index Sensors and Their Applications

Abstract

:1. Introduction

2. Experimental Procedure

3. Results and Discussion

3.1. Influence of grating length on RI sensitivity

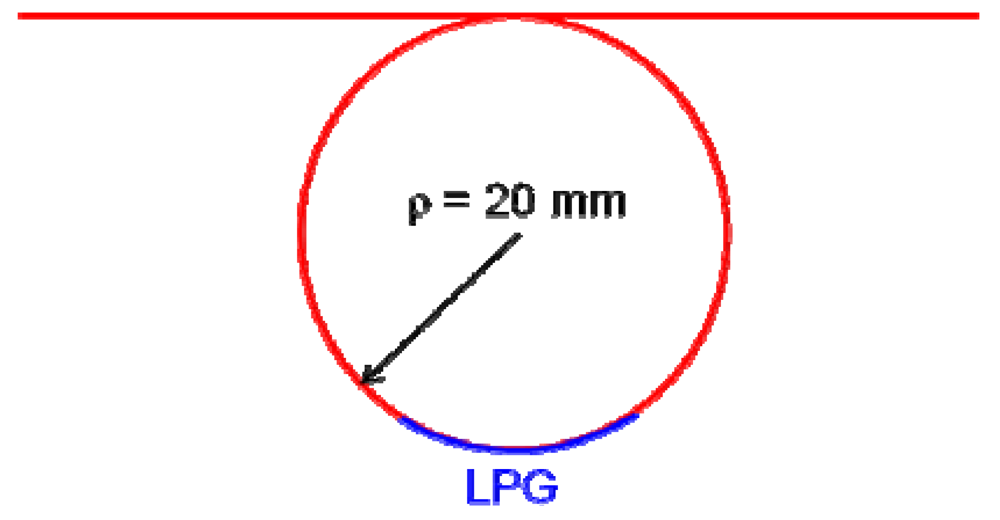

3.2. Effect of bending on RI sensitivity

3.3. Discrimination between water and saline water using a bent LPG

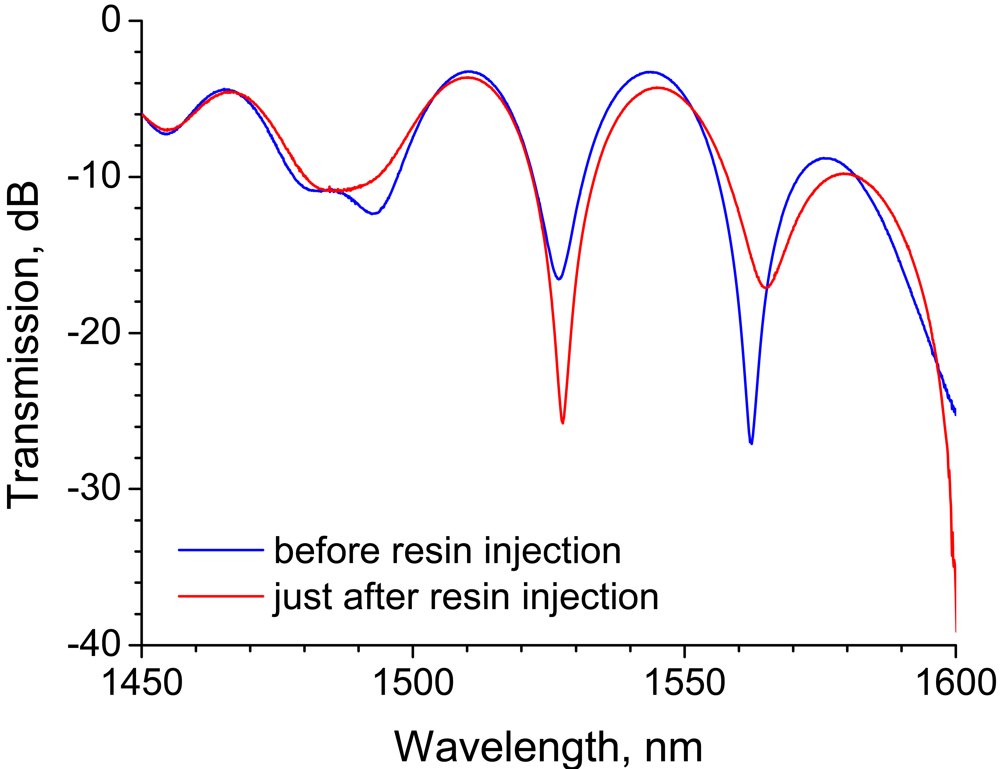

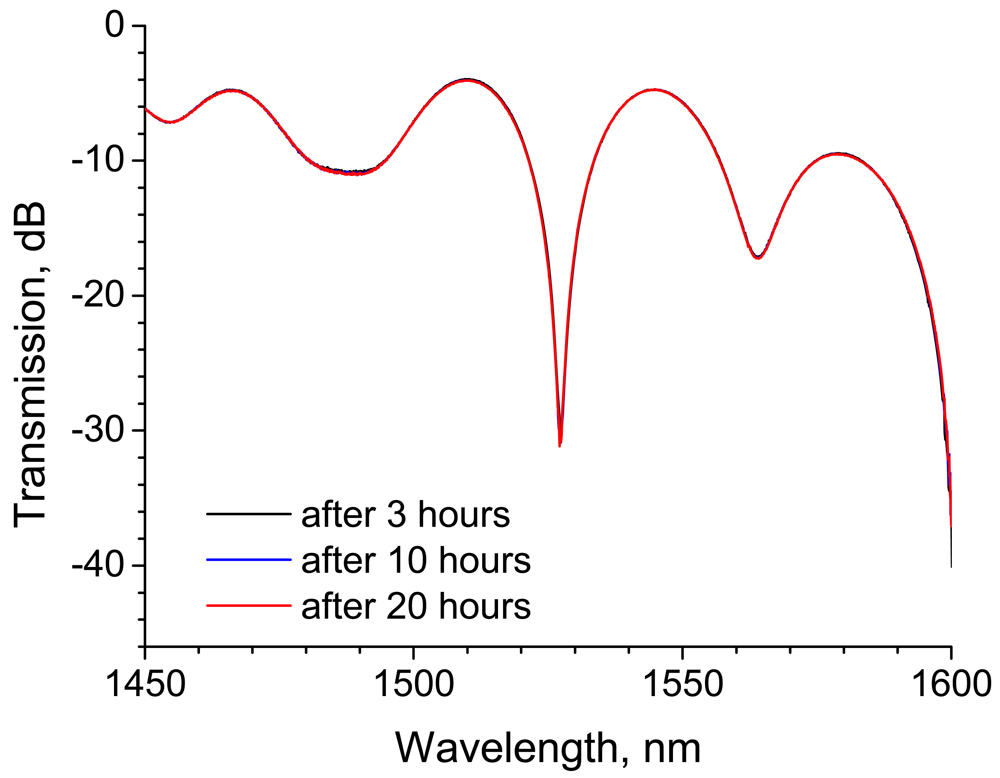

3.4. Epoxy resin cure monitoring using an LPG

4. Conclusions

References and Notes

- Chong, J.H.; Shum, P.; Haryono, H.; Yohana, A.; Rao, M.K.; Lu, C.; Zhu, Y.N. Measurements of refractive index sensitivity using long-period grating refractometer. Opt. Commun. 2004, 229, 65–69. [Google Scholar]

- Rindorf, L.; Bang, O. Highly sensitive refractometer with a photonic-crystal-fiber long-period grating. Optics Letters 2008, 33, 563–565. [Google Scholar]

- Wu, D.K.C.; Kuhlmey, B.T.; Eggleton, B.J. Ultrasensitive photonic crystal fiber refractive index sensor. Optics Letters 2009, 34, 322–324. [Google Scholar]

- James, S.W.; Tatam, R.P. Optical fibre long-period grating sensors: Characteristics and application. Meas. Sci. Technol. 2003, 14, R49–R61. [Google Scholar]

- Melle, S.M.; Liu, K.X.; Measures, R.M. Practical fiberoptic Bragg grating strain-gauge system. Appl. Opt. 1993, 32, 3601–3609. [Google Scholar]

- Othonos, A. Fiber Bragg gratings. Rev. Sci. Instrum. 1997, 68, 4309–4341. [Google Scholar]

- Lee, B.H.; Nishii, J.J. Bending sensitivity of in-series long-period fiber gratings. Optics Letters 1998, 23, 1624–1626. [Google Scholar]

- Jung, J.; Nam, H.; Lee, B.; Byun, J.O.; Kim, N.S. Fiber Bragg grating temperature sensor with controllable sensitivity. Appl. Opt. 1999, 38, 2752–2754. [Google Scholar]

- Han, Y.G.; Lee, B.H.; Han, W.T.; Paek, U.C.; Chung, Y. Fibre-optic sensing applications of a pair of long-period fibre gratings. Proceedings of 14th International Conference on Optical Fiber Sensors, Venice, Italy; 2000. [Google Scholar]

- Iadicicco, A.; Cusano, A.; Cutolo, A.; Bernini, R.; Giordano, M. Thinned fiber Bragg gratings as high sensitivity refractive index sensor. IEEE Photonic Technol. Lett. 2004, 16, 1149–1151. [Google Scholar]

- Bhatia, V.; Vengsarkar, A.M. Optical fiber long-period grating sensors. Optics Letters 1996, 21, 692–694. [Google Scholar]

- Lee, B.H.; Liu, Y.; Lee, S.B.; Choi, S.S.; Jang, J.N. Displacements of the resonant peaks of a long-period fiber grating induced by a change of ambient refractive index. Optics Letters 1997, 22, 1769–1771. [Google Scholar]

- Duhem, O.; Henninot, J.F.; Warenghem, M.; Douay, M. Demonstration of long-period-grating efficient couplings with an external medium of a refractive index higher than that of silica. Appl. Opt. 1998, 37, 7223–7228. [Google Scholar]

- Duhem, O.; Henninot, J.F.; Douay, M. Study of in fiber Mach-Zehnder interferometer based on two spaced 3-dB long period gratings surrounded by a refractive index higher than that of silica. Opt. Commun. 2000, 180, 255–262. [Google Scholar]

- Ng, M.N.; Chen, Z.H.; Chiang, K.S. Temperature compensation of long-period fiber grating for refractive-index sensing with bending effect. IEEE Photonic Technol. Lett. 2002, 14, 361–362. [Google Scholar]

- Shu, X.W.; Zhang, L.; Bennion, I. Sensitivity characteristics of long-period fiber gratings. J. Lightwave Technol. 2002, 20, 255–266. [Google Scholar]

- Tang, J.L.; Wang, J.N. Chemical sensing sensitivity of long-period grating sensor enhanced by colloidal gold nanoparticles. Sensors 2008, 8, 171–184. [Google Scholar]

- Khaliq, S.; James, S.W.; Tatam, R.P. Enhanced sensitivity fibre optic long period grating temperature sensor. Meas. Sci. Technol. 2002, 13, 792–795. [Google Scholar]

- Levita, G.; Livi, A.; Rolla, P.A.; Culicchi, C. Dielectric monitoring of epoxy cure. J. Polym. Sci., Part B: Polym. Phys. 1996, 34, 2731–2737. [Google Scholar]

- Available online: http://www.rontec.co.jp/basic/plastic/charaep.htm.

- Urabe, K.; Takahashi, J.; Tsuda, H.; Kemmochi, K. Cure monitoring of matrix resin with high-frequency electromagnetic wave transmission line. J. Reinf. Plast. Compos. 2000, 19, 1235–1250. [Google Scholar]

© 2009 by the authors; licensee Molecular Diversity Preservation International, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Tsuda, H.; Urabe, K. Characterization of Long-period Grating Refractive Index Sensors and Their Applications. Sensors 2009, 9, 4559-4571. https://doi.org/10.3390/s90604559

Tsuda H, Urabe K. Characterization of Long-period Grating Refractive Index Sensors and Their Applications. Sensors. 2009; 9(6):4559-4571. https://doi.org/10.3390/s90604559

Chicago/Turabian StyleTsuda, Hiroshi, and Kei Urabe. 2009. "Characterization of Long-period Grating Refractive Index Sensors and Their Applications" Sensors 9, no. 6: 4559-4571. https://doi.org/10.3390/s90604559