Monitoring System for Farming Operations with Wearable Devices Utilized Sensor Networks

Abstract

:1. Introduction

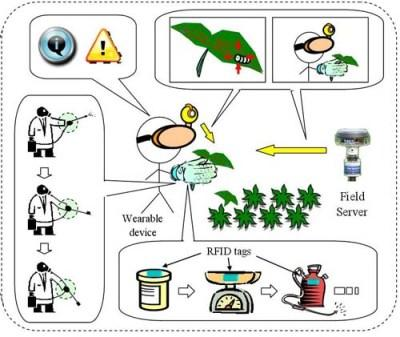

2. Farm Operation Monitoring System

2.1. Field Server System

2.2. Concept

- The system should not encumber the farmer’s activities during farming operations.

- It should be easy to use for non-experts and should not involve complicated processes.

- It should be available under many conditions without changing the facilities and equipment.

- It should monitor detailed farming operation and various conditions such as plant growth.

- It should make effective use of monitoring information in real-time.

2.3. System Design

3. Experiments

3.1. Performance of RFID Reader

3.2. Recognition of Farming Operation

3.3. Support Application According to Farming Operation

4. Discussion and Conclusions

References and Notes

- Kahn, J.M.; Katz, R.H.; Pister, K.S.J. Next Century Challenges: Mobile Networking for “Smart Dust”. Proceedings of the 5th Annual ACM/IEEE International Conference on Mobile Computing and Networking, Seattle, WA, USA, August 1999; pp. 271–278.

- Akyildiz, I.F.; Su, W.; Sankarasubramaniam, Y.; Cayirci, E. Wireless sensor networks: a survey. Comput. Netw 2002, 38, 393–422. [Google Scholar]

- Fukatsu, T.; Hirafuji, M. Field monitoring using sensor-nodes with a Web server. J. Rob. Mechatron 2005, 17, 164–172. [Google Scholar]

- Otuka, A.; Sugawara, K. A labor management application using handheld computers. Agric. Inf. Res 2003, 12, 95–104. [Google Scholar]

- Bange, M.P.; Deutscher, S.A.; Larsen, D.; Linsley, D.; Whiteside, S. A handheld decision support system to facilitate improved insect pest management in Australian cotton systems. Comput. Electron. Agric 2004, 43, 131–147. [Google Scholar]

- Yokoyama, K. Promoting the Good Agricultural Practice Movement through Interactive and Seamless Communication based on User-friendly Mobile Information Technology. Proceedings of the International Seminar on Technology Development for Good Agricultural Practice in Asia and Oceania, Tsukuba, Japan, October 2005; pp. 213–219.

- Zazueta, F.S; Vergot, P., III. Use of Handheld Computers in Agricultural Extension Programs. Proceedings of the 4th International Conference of European Federation for Information Technology in Agriculture, Debrecen, Hungary, July 2003; pp. 12–16.

- Szilagyi, R.; Herdon, M.; Lengyel, P. Agricultural Application Development for Mobile Devices. Proceedings of the International Conference on Agricultural Economics, Rural Development and Informatics, Debrecen, Hungary, April 2005.

- Guan, S.; Shikanai, T.; Minami, T.; Nakamura, M.; Ueno, M.; Setouchi, H. Development of a system for recording farming data by using a cellular phone equipped with GPS. Agric. Inf. Res 2006, 15, 241–254. [Google Scholar]

- Matsumoto, K.; Machida, T. Studies on Development of Work Journal Supporting Systems with Speech Recognition. Proceedings of the 3rd Asian Conference for Information Technology in Agriculture, Beijing, China, October 2002; pp. 434–438.

- Stafford, J.V.; Le Bars, J.M.; Ambler, B. A hand-held data logger with integral GPS for producing weed maps by field walking. Comput. Electron. Agric 1996, 14, 235–247. [Google Scholar]

- Fukatsu, T.; Hirafuji, M.; Saito, Y.; Suzuki, T.; Kobayashi, K. A Long-term Field Monitoring System with Field Servers at A Grape Farm. Proceedings of the International Symposium on Application of Precision Agriculture for Fruits and Vegetables, Orlando, FL, USA, January 2008; pp. 183–190.

- Fukatsu, T.; Hirafuji, M.; Kiura, T. An agent system for operating Web-based sensor nodes via the Internet. J. Rob. Mechatron 2006, 18, 186–194. [Google Scholar]

- Fukatsu, T.; Hirafuji, M.; Kiura, T. A Distributed Agent System for Managing A Web-based Sensor Network with Field Servers. Proceedings of the 4th World Congress on Computers in Agriculture, Orland, FL, USA, July 2006; pp. 223–228.

- Finkenzeller, K. RFID Handbook: Fundamentals and Applications in Contactless Smart Cards and Identification, 2nd ed; Wiley and Sons: New York, NY, USA, 2003. [Google Scholar]

- Whitaker, J.; Mithas, S.; Krishnan, M.S. A field study of RFID deployment and return expectations. Prod. Oper. Manage 2007, 16, 599–612. [Google Scholar]

- Rizzotto, P.; Wolfram, G. Intelligent Tagging—Getting Supply Chain Smart! Proceedings of the Official ECR Europe Conference, Barcelona, Spain, April 2002.

- Wang, N.; Zhang, N.; Wang, M. Wireless sensors in agriculture and food industry—recent development and future perspective. Comput. Electron. Agric 2006, 50, 1–14. [Google Scholar]

- Trevarthen, A.; Michael, K. The RFID-enabled Dairy Farm: Towards Total Farm Management. Proceedings of the 7th International Conference on Mobile Business, Barcelona, Spain, July 2008; pp. 241–250.

- Gebhardt-Henrich, S.G.; Buchwalder, T.; Froehich, E.; Gantner, M. RFID Identification System to Monitor Individual Outdoor use by Laying Hens. Proceedings of 42nd Congress of the International Society for Applied Ethology, Dublin, Ireland, August 2008; p. 113.

- Murray, B.B.; Rumbles, I.; Rodenburg, J. Application of RFID Technology in Herd Management on Dairy Herds in Canada. Proceedings of the Joint International Agricultural Conference, Wageningen, Netherlands, July 2009; pp. 259–265.

- Nanseki, T.; Sugahara, K.; Fukatsu, T. Farming Operation Automatic Recognition System with RFID. Agric. Inf. Res 2007, 16, 132–140. [Google Scholar]

- Itoh, T.; Ishii, H.; Nanseki, T. A model of crop planning under uncertainty in agricultural management. J. Prod. Econ 2003, 81–82, 555–558. [Google Scholar]

- Cox, P.G. Some issues in the design of agricultural decision support systems. Agric. Syst 1996, 52, 355–381. [Google Scholar]

- Pierce, F.J.; Cavalieri, R.P. Globalization and Traceability of Agricultural Production: The Role of Mechanization. Proceedings of Club of Bologna meeting, Chicago, IL, USA, July 27, 2002; International Commission of Agricultural Engineering: Liège, Belgium, September 2002; IV. [Google Scholar]

- Khaw, M.K.; Mohd-Yasin, F.; Reaz, M.L. Recent Advances in the Integrated Circuit Design of RFID Transponder. Proceedings of the IEEE International Conference Semiconductor Electronics, Kuala Lumpur, Malaysia, December 2004.

- Nanseki, T.; Sugahara, K. A Navigation System for Appropriate Pesticide Use: System Development and Application in Japan. Proceedings of the 5th Conference of the Asian Federation for Information Technology in Agriculture, Bangalore, India, November 2006; pp. 293–300.

- Fukatsu, T.; Kiura, T.; Tanaka, K.; Hirafuji, M. Hierachical Agent System for Web-based Sensor Network. Proceedings of the International Symposium on Applications and the Internet Workshops, Hiroshima, Japan, January 2007.

- Wang, H.; Wang, G.; Shu, Y. Design of RFID Reader Using Multi-Antenna with Difference Spatial Location. Proceedings of the 3rd International Conference on Wireless Communications, Networking and Mobile Computing, Shanghai, China, September 2007; pp. 2070–2073.

- Bohn, J.; Mattern, F. Super-distributed RFID Tag Infrastructures. Proceedings of the 2nd European Symposium on Ambient Intelligence, Eindhoven, The Netherlands, November 2004; pp. 1–12.

- Smith, I.G.; Furness, A. Food Traceability around the World, 1st ed; Vicarage Publications Ltd: York, UK, 2008. [Google Scholar]

© 2009 by the authors; licensee MDPI, Basel, Switzerland This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Fukatsu, T.; Nanseki, T. Monitoring System for Farming Operations with Wearable Devices Utilized Sensor Networks. Sensors 2009, 9, 6171-6184. https://doi.org/10.3390/s90806171

Fukatsu T, Nanseki T. Monitoring System for Farming Operations with Wearable Devices Utilized Sensor Networks. Sensors. 2009; 9(8):6171-6184. https://doi.org/10.3390/s90806171

Chicago/Turabian StyleFukatsu, Tokihiro, and Teruaki Nanseki. 2009. "Monitoring System for Farming Operations with Wearable Devices Utilized Sensor Networks" Sensors 9, no. 8: 6171-6184. https://doi.org/10.3390/s90806171