Solid Particle Number Emission Factors of Euro VI Heavy-Duty Vehicles on the Road and in the Laboratory

Abstract

:1. Introduction

1.1. PM, Health Effects, and Emission Models

1.2. PN Regulation in EU

1.3. Open Points for SPN Emissions

1.4. Objectives of the Paper

2. Materials and Methods

2.1. Vehicles and Fuels

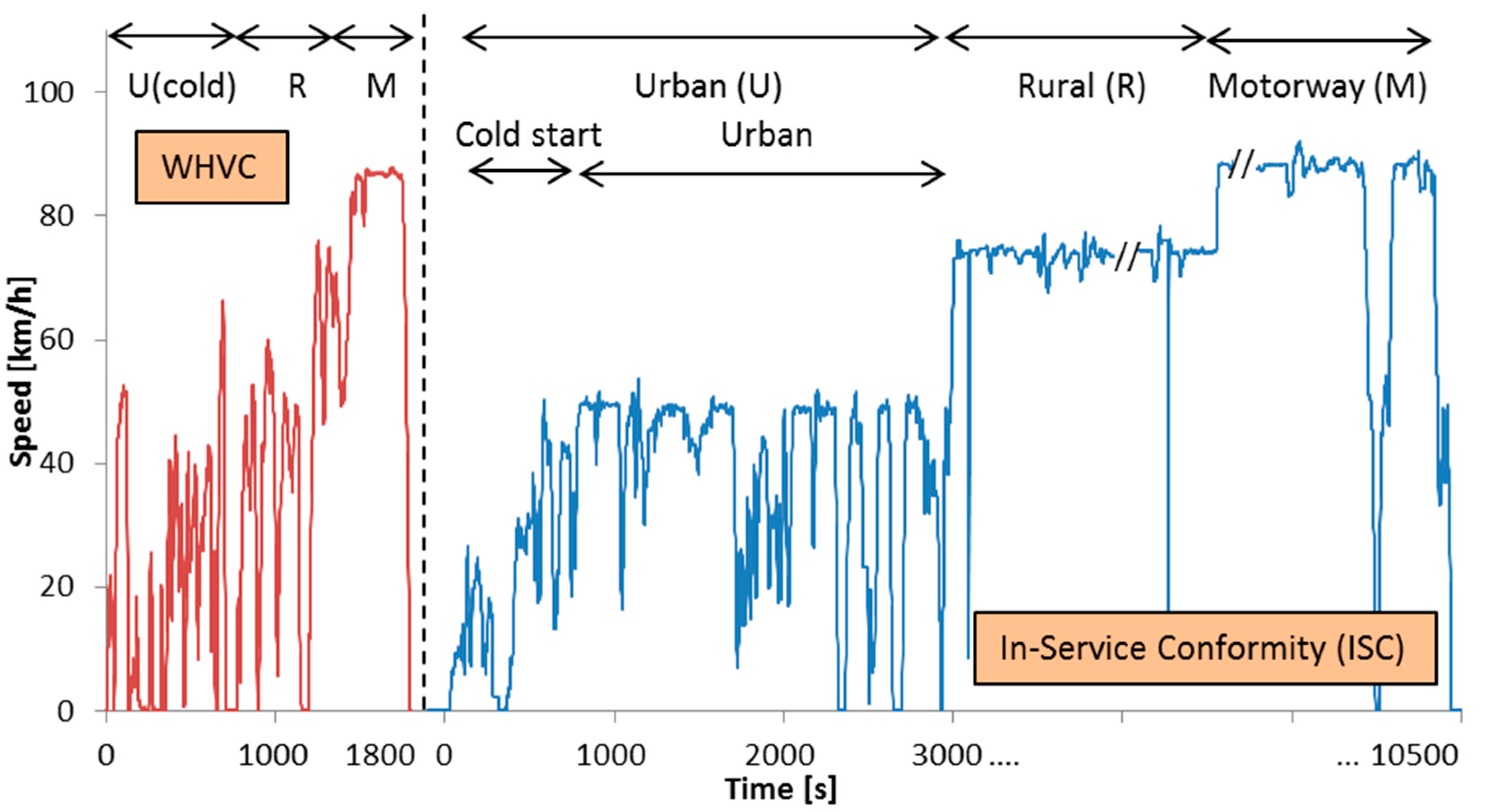

2.2. Laboratory Testing

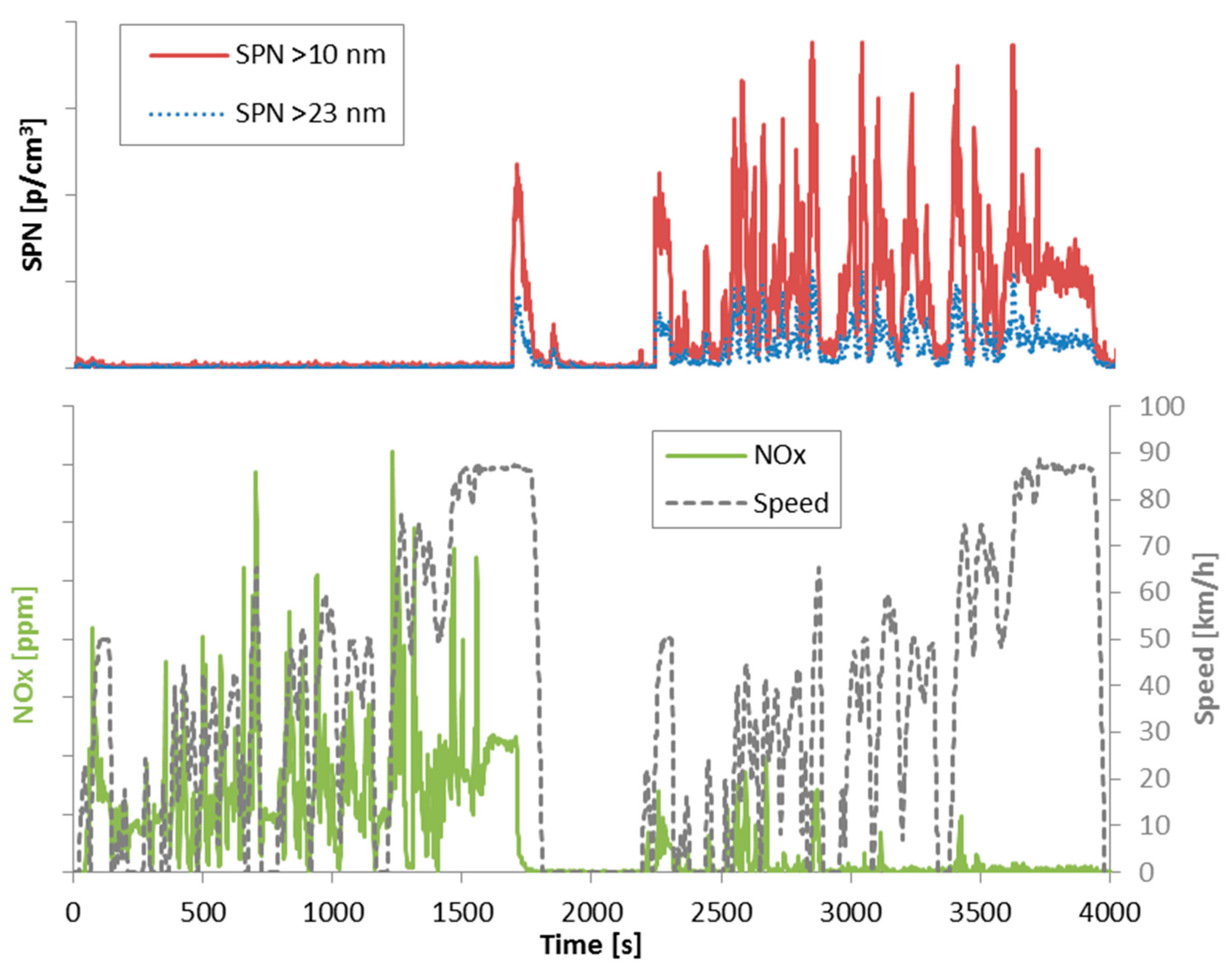

2.3. On-Road Testing

2.4. Literature and Received Data

2.5. Calculations

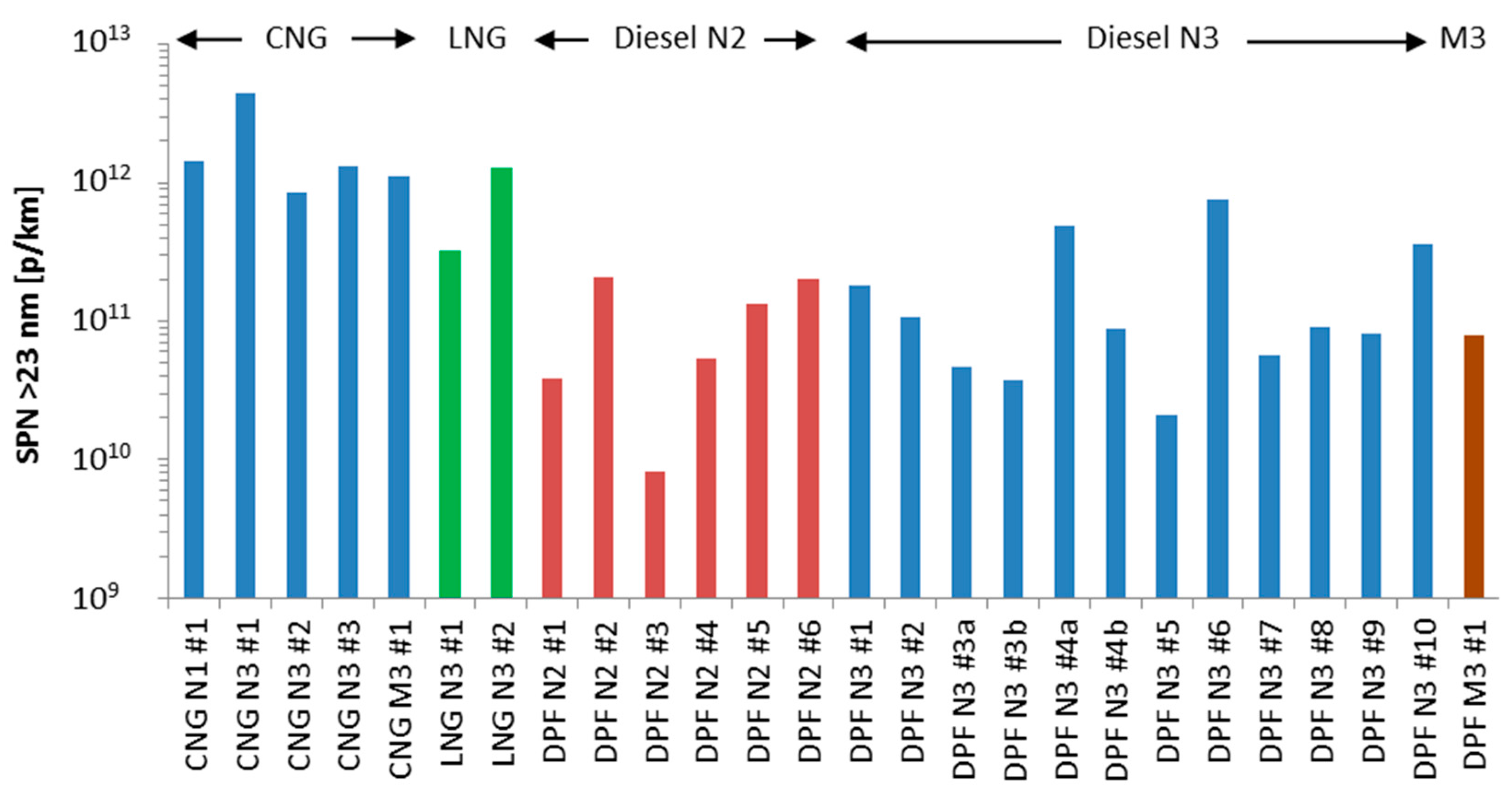

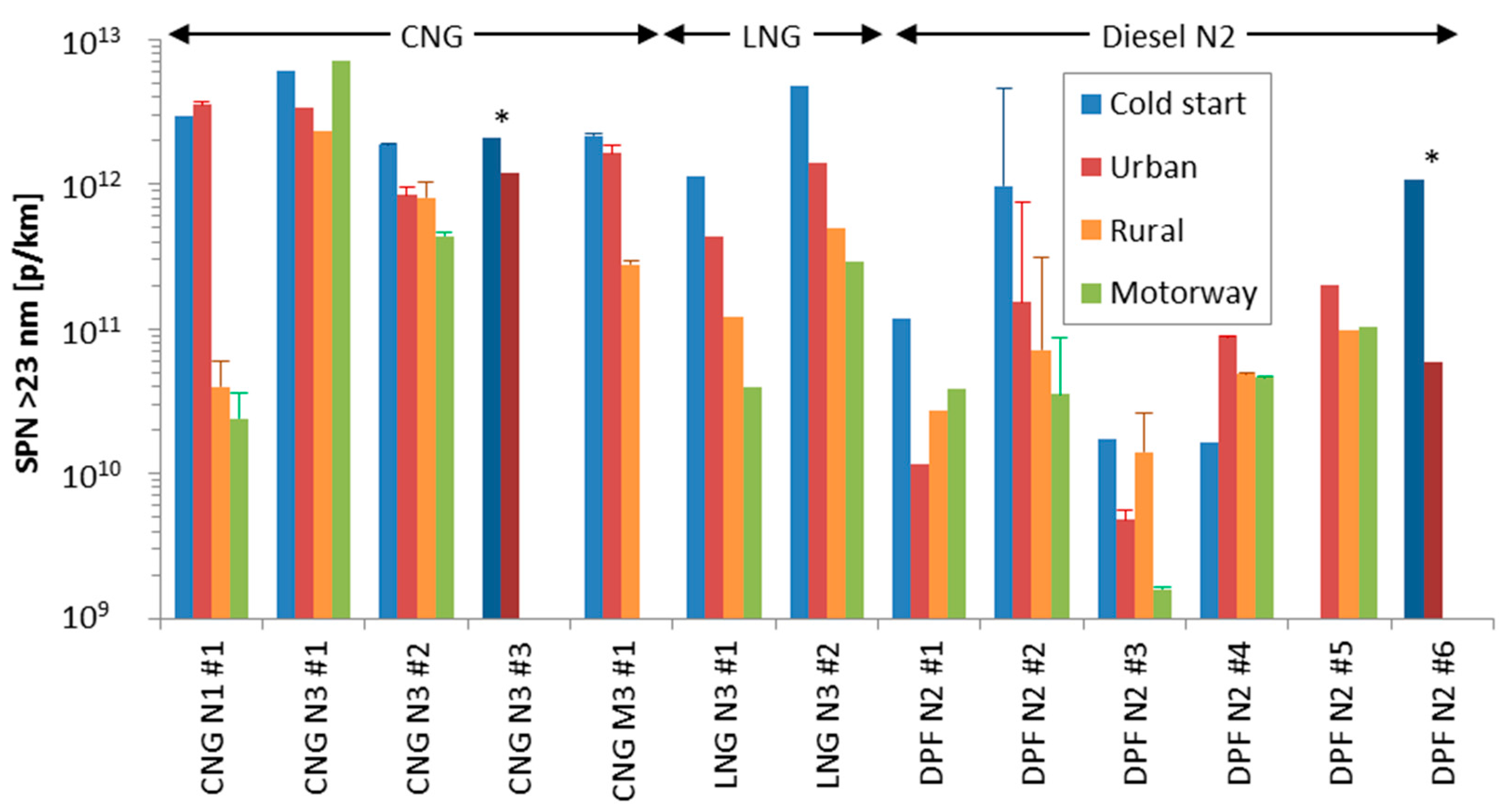

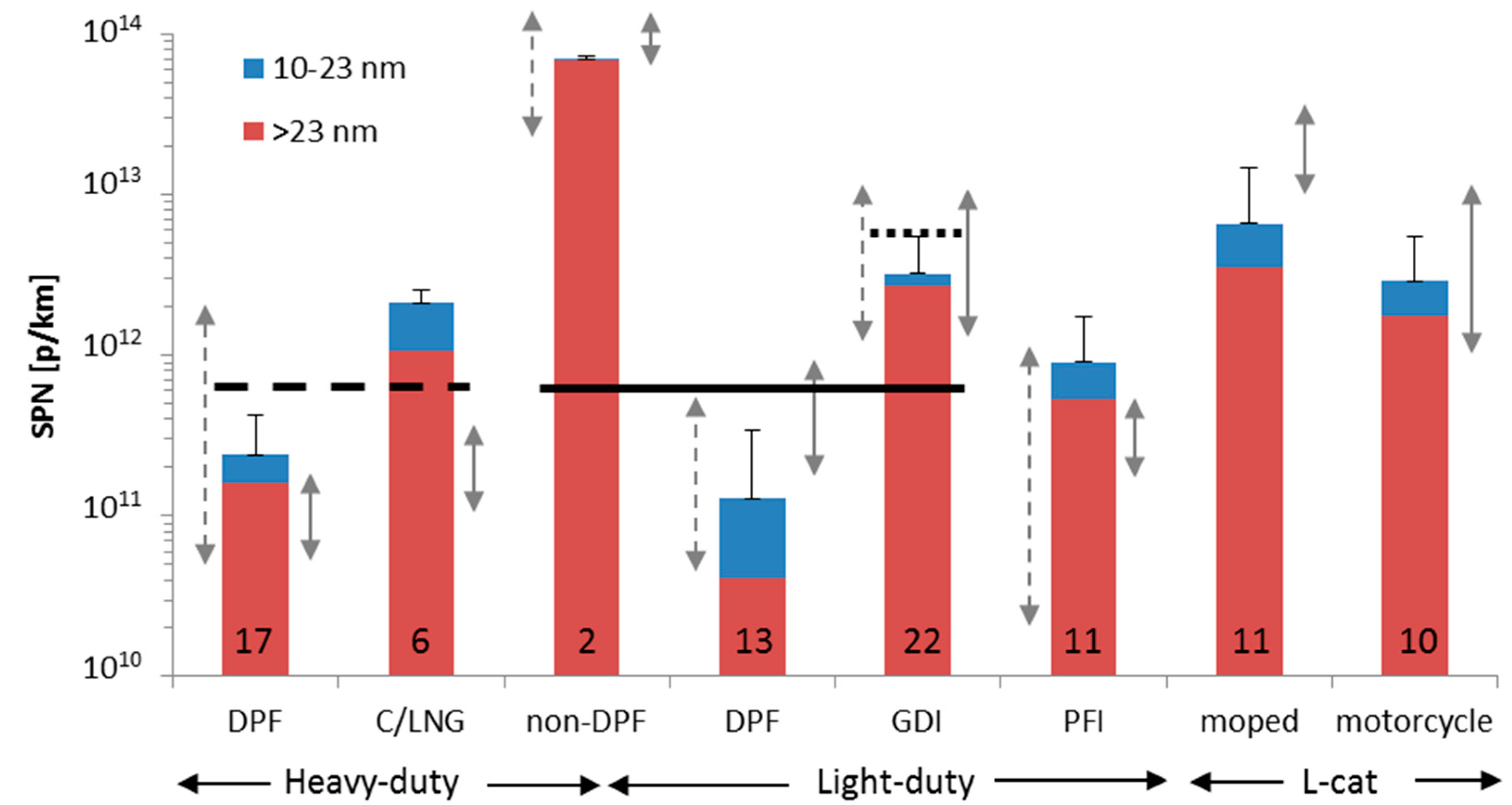

3. Results

4. Discussion

4.1. Emission Levels

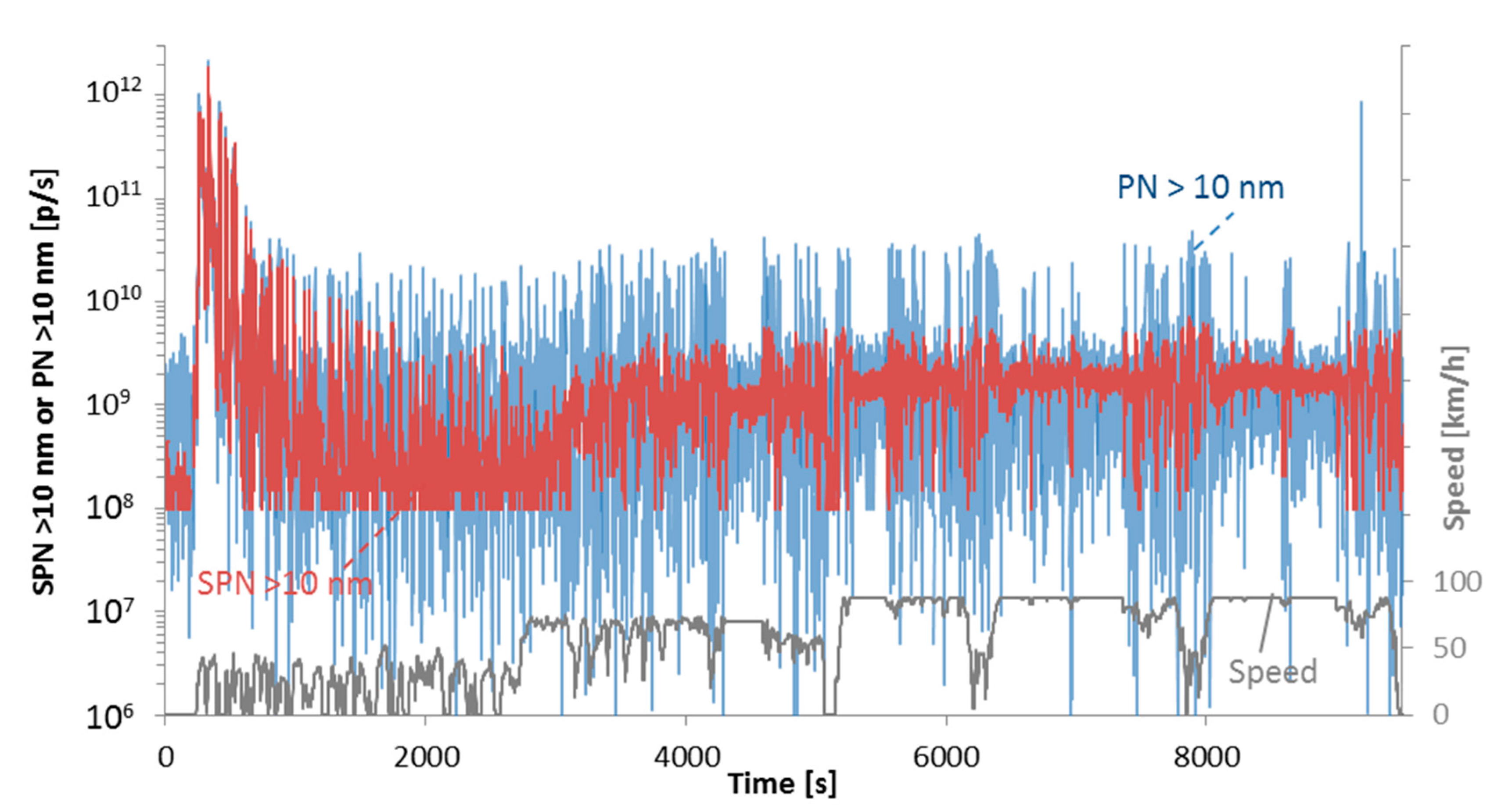

4.2. Engine Cold Start

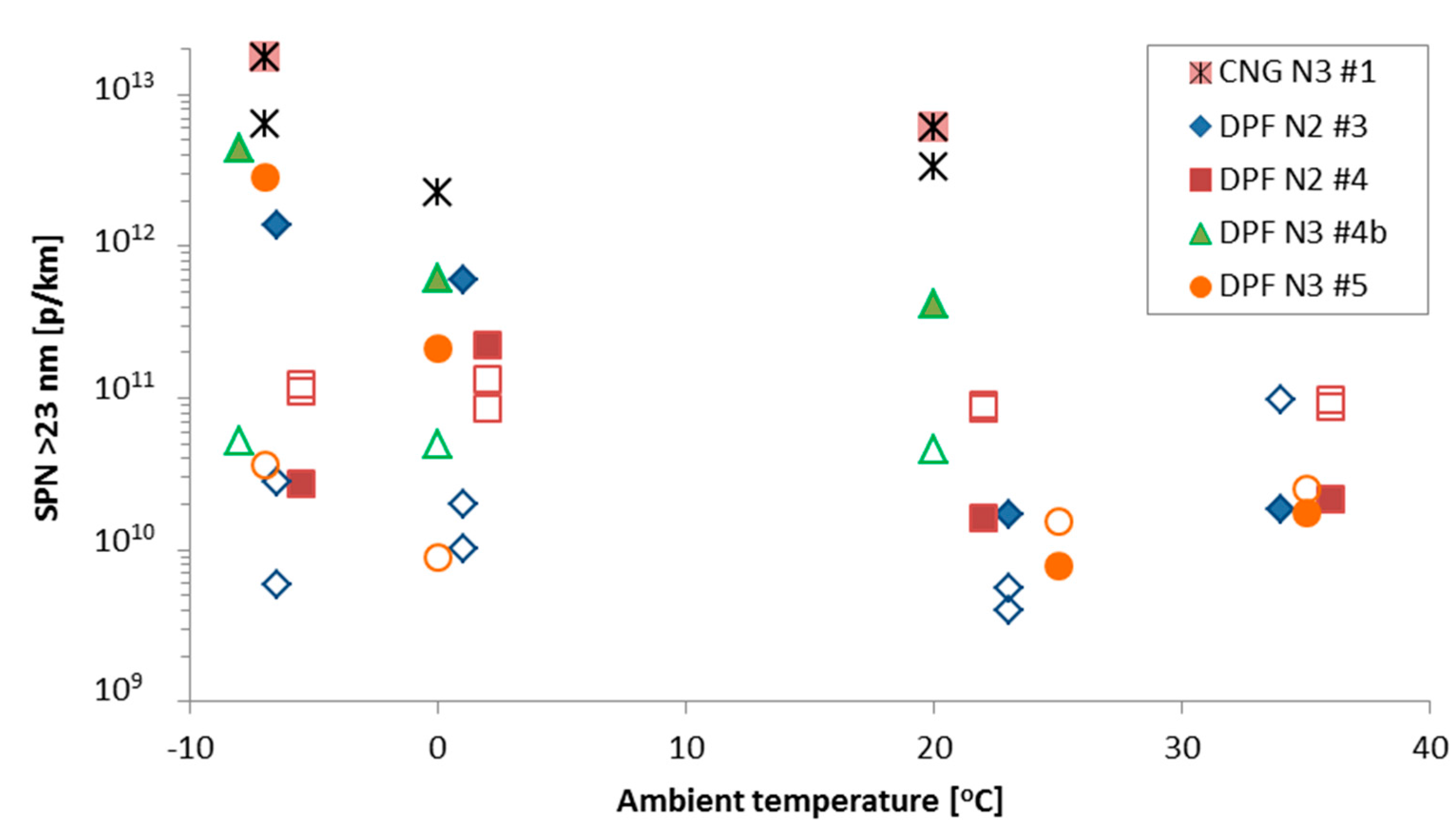

4.3. Ambient Temperature

4.4. Urban, Rural, and Motorway Phases

4.5. Correlation of Cycles

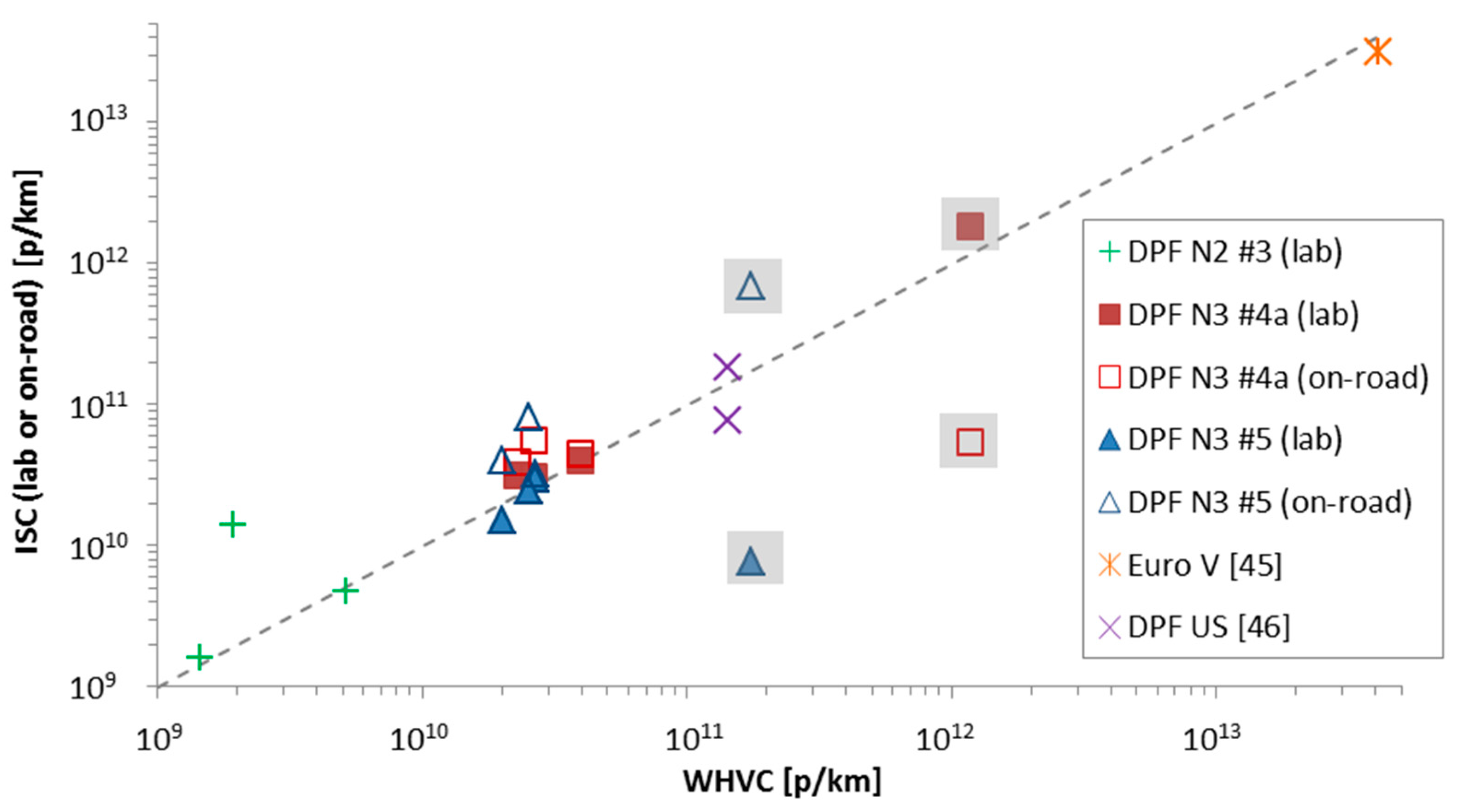

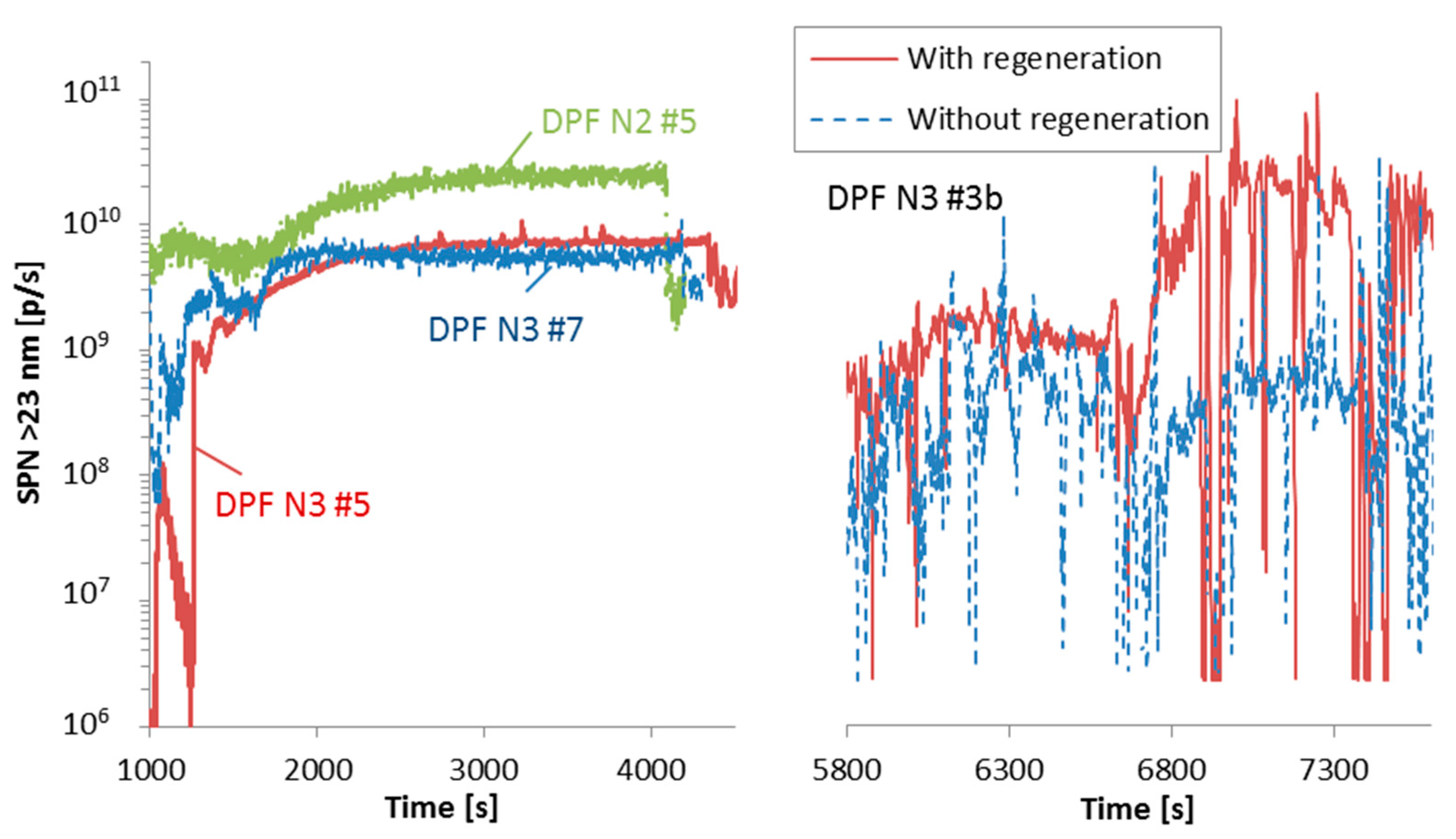

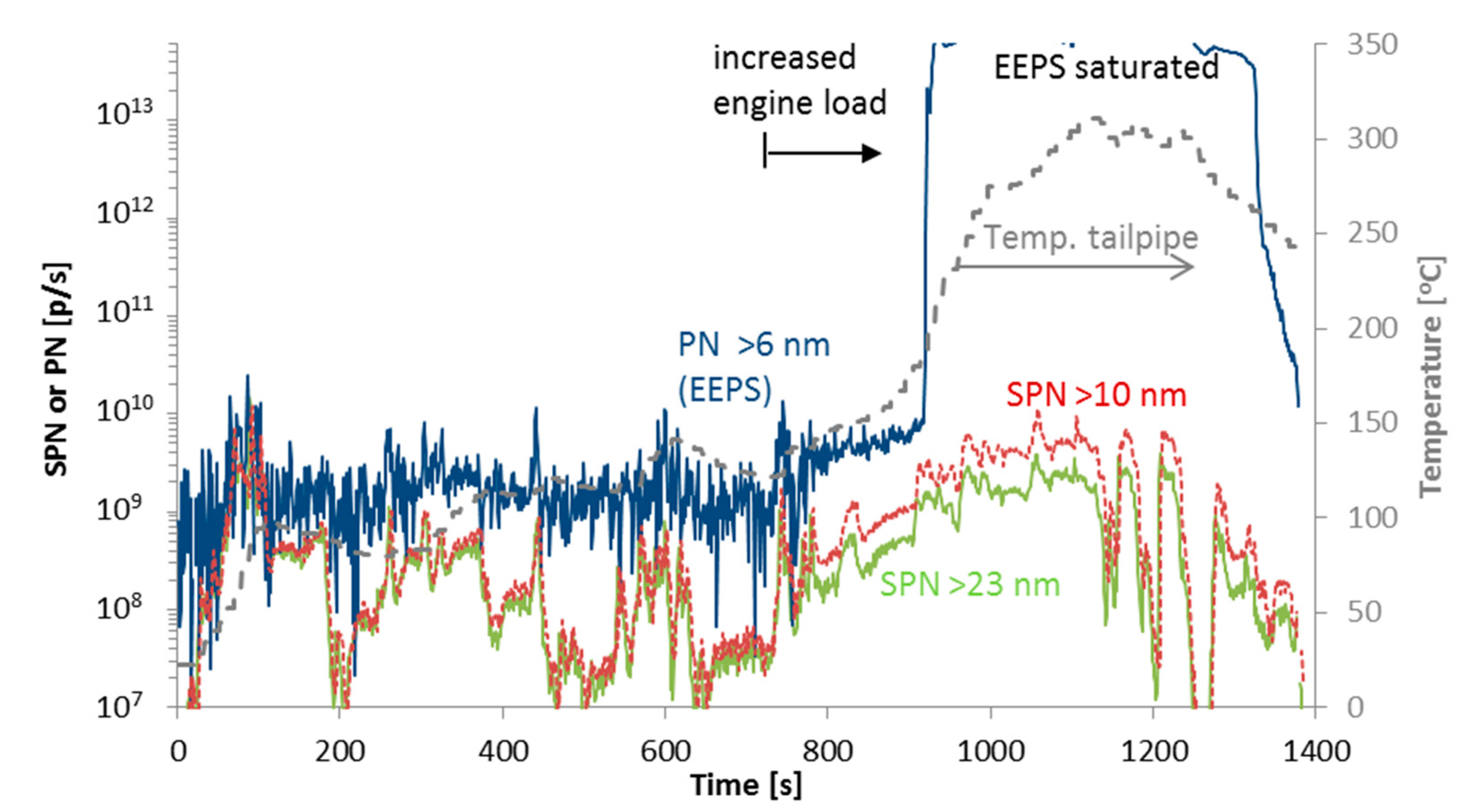

4.6. Regeneration

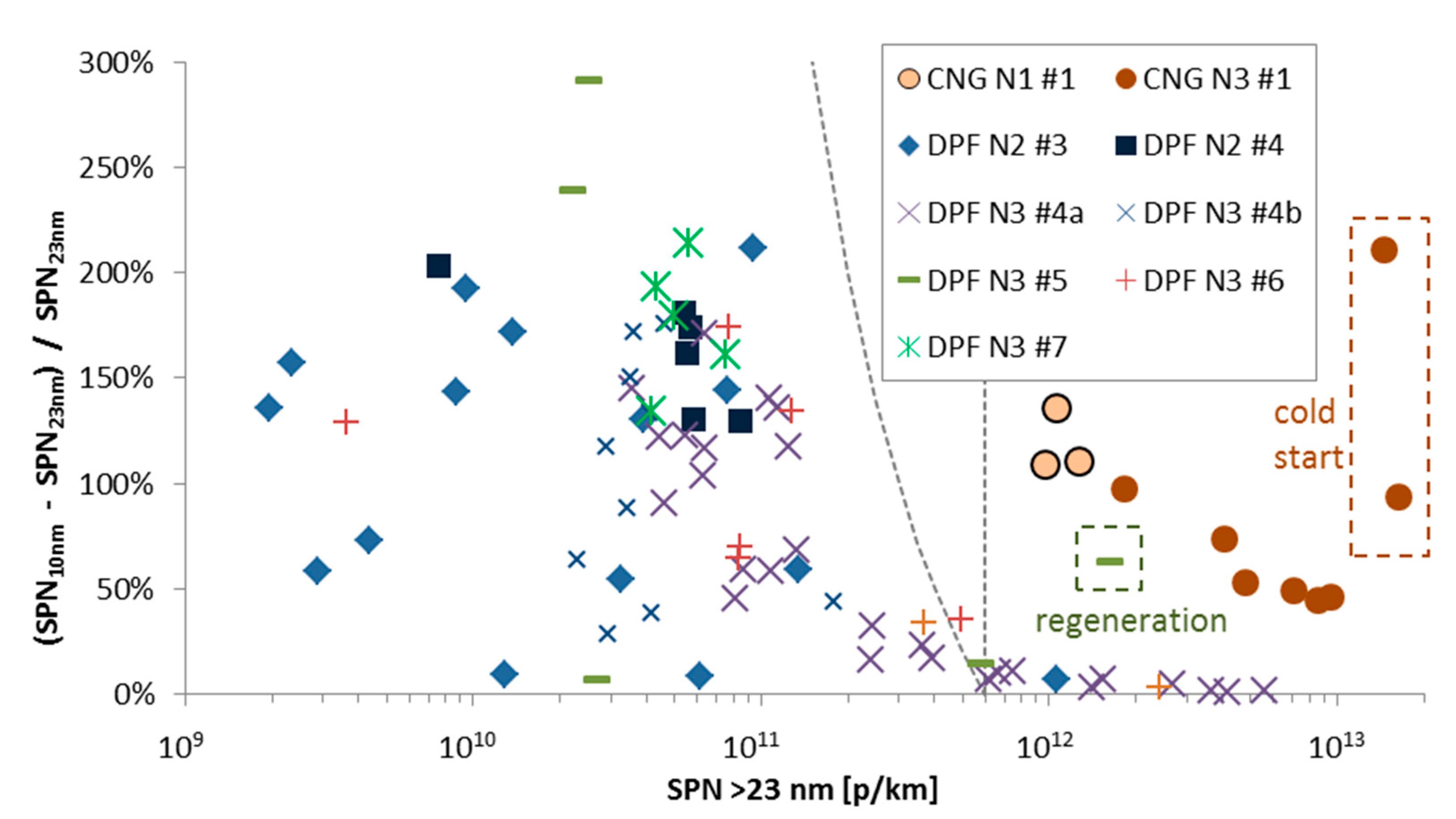

4.7. Sub-23 nm Solid Particles

4.8. Total Particles

4.9. Strengths and Limitations

5. Conclusions

Acknowledgments

Conflicts of Interest

Disclaimer

Abbreviations

| ACEA | European Automobile Manufacturers Association |

| APC | AVL Particle Counter |

| CNG | Compressed Natural Gas |

| COPERT | Computer Programme to calculate emissions from road transport |

| CPC | Condensation Particle Counter |

| CRT | Continuously Regenerating Trap |

| CVS | Constant Volume Sampling |

| DOC | Diesel Oxidation Catalyst |

| DPF | Diesel Particulate Filter |

| EEPS | Engine Exhaust Particle Sizer |

| EGR | Exhaust Gas Recirculation |

| EU | European Union |

| GDI | Gasoline Direct Injection |

| ISC | In-Service Conformity |

| HBEFA | Handbook Emission Factors for Road Transport |

| JRC | Joint Research Centre |

| LNG | Liquefied Natural Gas |

| MOVES | Motor Vehicle Emission Simulator |

| NPET | Nanoparticle Emission Tester |

| NTE | Not-To-Exceed |

| PCRF | Particle Concentration Reduction Factor |

| PEMS | Portable Emissions Measurement System |

| PFI | Port Fuel Injection |

| PM | Particulate Matter |

| PMP | Particle Measurement Programme |

| PN | Particle Number |

| RDE | Real Driving Emissions |

| SCR | Selective Catalytic Reduction |

| SPN | Solid Particle Number |

| STA | Swedish Transport Agency |

| TNO | Netherlands Organization for Applied Scientific Research |

| TWC | Three-Way Catalyst |

| USA | United States of America |

| USSD | Urban Dynamometer Driving Schedule |

| VELA | Vehicle Emissions Laboratory |

| VPR | Volatile Particle Remover |

| WHTC | Worldwide Harmonized Transient Cycle |

| WHVC | Worldwide Harmonized Test Cycle |

References

- Health Effects Institute. State of global air. In Special Report; HEI: Boston, MA, USA, 2017. [Google Scholar]

- World Health Organization. Review of Evidence on Health Aspects of Air Pollution—REVIHAAP Project; WHO Regional Office for Europe: Copenhagen, Denmark, 2013. [Google Scholar]

- Li, N.; Georas, S.; Alexis, N.; Fritz, P.; Xia, T.; Williams, M.; Horner, E.; Nel, A. A work group report on ultrafine particles (American Academy of Allergy, Asthma & Immunology): Why ambient ultrafine and engineered nanoparticles should receive special attention for possible adverse health outcomes in human subjects. J. Allergy Clin. Immunol. 2016, 138, 386–396. [Google Scholar] [PubMed]

- Limbach, L.; Wick, P.; Manser, P.; Grass, R.; Bruinink, A.; Stark, W. Exposure of engineered nanoparticles to human lung epithelial cells: Influence of chemical composition and catalytic activity on oxidative stress. Environ. Sci. Technol. 2007, 41, 4158–4163. [Google Scholar] [CrossRef] [PubMed]

- Kreyling, W.; Semmler-Behnke, M.; Moller, W. Ultrafine particle lung interactions: does size matter? J. Aerosol. Med. 2006, 19, 74–83. [Google Scholar] [CrossRef] [PubMed]

- Peters, A.; Veronesi, B.; Calderón-Garcidueñas, L.; Gehr, P.; Chen, L.; Geiser, M.; Reed, W.; Rothen-Rutishauser, B.; Schürch, S.; Schulz, H. Translocation and potential neurological effects of fine and ultrafine particles a critical update. Part Fibre Toxicol. 2006, 3, 13. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bakand, S.; Hayes, A.; Dechsakulthorn, F. Nanoparticles: A review of particle toxicology following inhalation exposure. Inhal. Toxicol. 2012, 24, 125–135. [Google Scholar] [CrossRef] [PubMed]

- Morakinyo, O.; Mokgobu, M.; Mukhola, M.; Hunter, R. Health outcomes of exposure to biological and chemical components of inhalable and respirable particulate matter. Int. J. Environ. Res. Public Health 2016, 13, 592. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Lane, K.; Corlin, L.; Patton, A.; Durant, J.; Thanikachalam, M.; Woodin, M.; Wang, M.; Brugge, D. Association of long-term near-highway exposure to ultrafine particles with cardiovascular diseases, diabetes and hypertension. Int. J. Environ. Res. Public Health 2017, 14, 461. [Google Scholar] [CrossRef] [PubMed]

- Ntziachristos, L.; Polidori, A.; Phuleria, H.; Geller, M.; Sioutas, K. Application of a diffusion charger for the measurement of particle surface concentration in different environments. Aerosol Sci. Technol. 2007, 41, 571–580. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Alföldy, B.; Drossinos, Y. A metric for health effect studies of diesel aerosol particles. J. Aerosol Sci. 2009, 40, 639–651. [Google Scholar] [CrossRef]

- European Environmental Agency. Air Quality in Europe 2017; EEA: Copenhagen, Denmark, 2017. [Google Scholar]

- Karagulian, F.; Belis, C.; Dora, C.; Pruss-Ustun, A.; Bonjour, S.; Adair-Rohani, H.; Adair-Rohani, H.; Amann, M. Contributions to cities’ ambient particulate matter (PM): A systematic review of local source contributions at global level. Atmos. Environ. 2015, 120, 475–483. [Google Scholar] [CrossRef]

- Fang, X.; Li, R.; Xu, Q.; Bottai, M.; Fang, F.; Cao, Y. A two-stage method to estimate the contribution of road traffic to PM2.5 concentrations in Beijing, China. Int. J. Environ. Res. Public Health 2016, 13, 124. [Google Scholar] [CrossRef] [PubMed]

- Chaloulakou, A.; Kassomenos, P.; Spyrellis, N.; Demokritou, P.; Koutrakis, P. Measurements of PM10 and PM2.5 particle concentrations in Athens, Greece. Atmos. Environ. 2005, 37, 649–660. [Google Scholar] [CrossRef]

- Wagner, W.; Rutherford, D. Survey of best practices in emission control of in-use heavy-duty diesel vehicles. In International Council Clean Transportation (ICCT) Report; ICCT: Washington, DC, USA, 2013. [Google Scholar]

- Kheirbek, I.; Haney, J.; Douglas, S.; Ito, K.; Matte, T. The contribution of motor vehicle emissions to ambient fine particulate matter public health impacts in New York City: A health burden assessment. Environ. Health 2016, 15. [Google Scholar] [CrossRef] [PubMed]

- Segersson, D.; Eneroth, K.; Gidhagen, L.; Johansson, C.; Omstedt, G.; Nylén, A.; Forsberg, B. Health impact of PM10, PM2.5 and black carbon exposure due to different source sectors in Stockholm, Gothenburg and Umea, Sweden. Int. J. Environ. Res. Public Health 2017, 14, 742. [Google Scholar] [CrossRef]

- Kumar, P.; Morawska, L.; Birmili, W.; Paasonen, P.; Hu, M.; Kulmala, M.; Harrison, R.; Norford, L.; Britter, R. Ultrafine particles in cities. Environ. Int. 2014, 66, 1–10. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Morawska, L.; Ristovski, Z.; Jayaratne, R.; Keogh, D.; Ling, X. Ambient nano and ultrafine particles from motor vehicle emissions: Characteristics, ambient processing and implications on human exposure. Atmos. Environ. 2008, 42, 8113–8138. [Google Scholar] [CrossRef] [Green Version]

- European Commission. A Roadmap for Moving to a Competitive Low Carbon Economy in 2050; European Commission: Brussels, Belgium, 2011. [Google Scholar]

- European Commission. Roadmap to a Single European Transport Area—Towards a Competitive and Resource Efficient Transport System. Transport White Paper; European Commission: Brussels, Belgium, 2011. [Google Scholar]

- Facanha, C.; Blumberg, K.; Miller, J. Global Transportation Energy and Climate Roadmap; ICCT: Washington, DC, USA, 2012. [Google Scholar]

- Javid, R.; Nejat, A.; Hayhoe, K. Selection of CO2 mitigation strategies for road transportation in the United States using a multi-criteria approach. Renew. Sustain. Energy Rev. 2014, 38, 960–972. [Google Scholar] [CrossRef]

- Gambhir, A.; Tse, L.; Tong, D.; Martinez-Botas, R. Reducing China’s road transport sector CO2 emissions to 2050: Technologies, costs and decomposition analysis. Appl. Energy 2015, 157, 905–917. [Google Scholar] [CrossRef]

- EMEP/EEA. Air Pollutant Emission Inventory Guidebook 2016; EEA Report No. 21/2016; EEA: Copenhagen, Denmark, 2016. [Google Scholar]

- Gkatzoflias, D.; Kouridis, C.; Ntziachristos, L.; Samaras, Z. COPERT4: Computer Programme to Calculate Emissions from Road Transport, User Manual; European Environment Agency: Maastricht, The Netherlands, 2012. [Google Scholar]

- Hausberger, S.; Rexeis, M.; Zallinger, M.; Luz, R. Emission Factors from the Model PHEM for the HBEFA Version 3; Report Nr. I-20/2009 Haus-Em 33/08/679 from 07.12.2009; Graz University of Technology: Graz, Austria, 2009. [Google Scholar]

- U.S. Environmental Protection Agency. Motor Vehicle Emission Simulator (MOVES): User Guide Version; EPA-420-B-15-05; EPA: Washington, DC, USA, 2015.

- Takeshita, T. Global scenarios of air pollutant emissions from road transport through to 2050. Int. J. Environ. Res. Public Health 2011, 8, 3032–3062. [Google Scholar] [CrossRef] [PubMed]

- Smit, R.; Ntziachristos, L.; Boulter, P. Validation of road vehicle and traffic emission models—A review and meta-analysis. Atmos. Environ. 2010, 44, 2943–2953. [Google Scholar] [CrossRef]

- Franco, V.; Kousoulidou, M.; Muntean, M.; Ntziachristos, L.; Hausberger, S.; Dilara, P. Road vehicle emission factors development: A review. Atmos. Environ. 2013, 70, 84–97. [Google Scholar] [CrossRef]

- Rexeis, M.; Hausberger, S.; Kühlwein, J.; Luz, R.; Ligterink, N. Update of Emission Factors for EURO 5 and EURO 6 Vehicles for the HBEFA Version 3.2; Report No. I-31/2013/Rex EM-I 2011/20/679 from 06.12.2013; Graz University of Technology: Graz, Austria, 2013. [Google Scholar]

- Vouitsis, I.; Ntziachristos, L.; Samaras, C.; Samaras, Z. Particulate mass and number emission factors for road vehicles based on literature data and relevant gap filling methods. Atmos. Environ. 2017, 168, 75–89. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Mamakos, A.; Andersson, J.; Dilara, P.; Martini, G.; Schindler, W.; Bergmann, A. Measurement of automotive non-volatile particle number emissions within the European legislative framework: A review. Aerosol. Sci. Technol. 2012, 46, 719–749. [Google Scholar] [CrossRef]

- European Commission. Commission Regulation (EC) No 692/2008 of 18 July 2008 “implementing and amending Regulation (EC) No. 715/2007 of the European Parliament and of the Council on type approval of motor vehicles with respect to emissions from light passenger and commercial vehicles (Euro 5 and Euro 6) and on access to vehicle repair and maintenance information”. Off. J. Eur. Union 2008, L199, 1–136. [Google Scholar]

- European Commission. Commission Regulation (EU) No 459/2012 of 29 May 2012 “amending Regulation (EC) No 715/2007 of the European Parliament and of the Council and Commission Regulation (EC) No 692/2008 as regards emissions from light passenger and commercial vehicles (Euro 6)”. Off. J. Eur. Union 2012, L142, 16–24. [Google Scholar]

- European Commission. Commission Regulation (EU) 2017/1151 of 1 June 2017 supplementing Regulation (EC) No 715/2007 of the European Parliament and of the Council on type-approval of motor vehicles with respect to emissions from light passenger and commercial vehicles (Euro 5 and Euro 6) and on access to vehicle repair and maintenance information, amending Directive 2007/46/EC of the European Parliament and of the Council, Commission Regulation (EC) No 692/2008 and Commission Regulation (EU) No 1230/2012 and repealing Commission Regulation (EC) No 692/2008. Off. J. Eur. Union 2017, L175, 1–732. [Google Scholar]

- European Commission. Commission Regulation (EU) No 582/2011 of 25 May 2011 “implementing and amending Regulation (EC) No 595/2009 of the European Parliament and of the Council with respect to emissions from heavy-duty vehicles (Euro VI) and amending Annexes I and III to Directive 2007/46/EC of the European Parliament and of the Council”. Off. J. Eur. Union 2011, L167, 1–168. [Google Scholar]

- European Commission. Commission Regulation (EU) No 133/2014 of 31 January 2014 amending, for the purposes of adapting to technical progress as regards emission limits, Directive 2007/46/EC of the European Parliament and of the Council, Regulation (EC) No 595/2009 of the European Parliament and of the Council and Commission Regulation (EU) No 582/2011. Off. J. Eur. Union 2014, L47, 1–57. [Google Scholar]

- European Commission. Regulation (EU) 64/2012 of 23 January 2012 amending Regulation (EU) No 582/2011 implementing and amending Regulation (EC) No 595/2009 of the European Parliament and of the Council with respect to emissions from heavy duty vehicles (Euro VI). Off. J. Eur. Union 2012, L28, 1–23. [Google Scholar]

- United Nations. Economic Commissions for Europe, Regulation No. 49, Revision 6, 4 March 2013, Uniform Provisions Concerning the Measures to Be Taken against the Emission of Gaseous and Particulate Pollutants from Compression-Ignition Engines for Use in Vehicles, and the Emission of Gaseous Pollutants from Positive-Ignition Engines Fueled with Natural Gas or Liquefied Gas for Use in Vehicles; United Nations: Geneva, Switzerland, 2013. [Google Scholar]

- European Commission. Commission Regulation. (EU) 2016/1718 of 20 September 2016 amending Regulation (EU) No 582/2011 with respect to emissions from heavy-duty vehicles as regards the provisions on testing by means of portable emission measurement systems (PEMS) and the procedure for the testing of the durability of replacement pollution control devices. Off. J. Eur. Union 2016, L259, 1–41. [Google Scholar]

- Mamakos, A.; Bonnel, P.; Perujo, A.; Carriero, M. Assessment of portable emission measurement systems (PEMS) for heavy-duty diesel engines with respect to particulate matter. J. Aerosol Sci. 2013, 57, 54–70. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Riccobono, F.; Vlachos, T.; Mendoza-Villafuerte, P.; Suarez-Bertoa, R.; Fontaras, G.; Bonnel, P.; Weiss, M. Vehicle emission factors of solid nanoparticles in the laboratory and on the road using portable emission measurement systems (PEMS). Front. Environ. Sci. 2015, 3. [Google Scholar] [CrossRef]

- Zheng, Z.; Durbin, T.; Xue, J.; Johnson, K.; Li, Y.; Hu, S.; Huai, T.; Ayala, A.; Kittelson, D.; Jung, H. Comparison of particle mass and solid particle number (SPN) emissions from a heavy-duty diesel vehicle under on-road driving conditions and a standard testing cycle. Environ. Sci. Technol. 2014, 48, 1779–1786. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.; Quiros, D.; Thiruvengadam, A.; Pradhan, S.; Hu, S.; Huai, T.; Lee, E.; Zhu, Y. Total particle number emissions from modern diesel, natural gas, and hybrid heavy-duty vehicles during on-road operation. Environ. Sci. Technol. 2017, 51, 6990–6998. [Google Scholar] [CrossRef] [PubMed]

- Mathis, U.; Mohr, M.; Forss, A. Comprehensive particle characterization of modern gasoline and diesel passenger cars at low ambient temperatures. Atmos. Environ. 2005, 39, 107–117. [Google Scholar] [CrossRef]

- Ristimäki, J.; Keskinen, J.; Virtanen, A.; Maricq, M.; Aakko, P. Cold temperature PM emissions measurement: Method evaluation and application to light duty vehicles. Environ. Sci. Technol. 2005, 39, 9424–9430. [Google Scholar] [CrossRef] [PubMed]

- Book, E.; Snow, R.; Long, T.; Fang, T.; Baldauf, R. Temperature effects on particulate emissions from DPF-equipped diesel trucks operating on conventional and biodiesel fuels. J. Air Waste Manag. Assoc. 2015, 65, 751–758. [Google Scholar] [CrossRef] [PubMed]

- Dardiotis, C.; Martini, G.; Marotta, A.; Manfredi, U. Low-temperature cold-start gaseous emissions of late technology passenger cars. Appl. Energy 2013, 111, 468–478. [Google Scholar] [CrossRef]

- Mendoza-Villafuerte, P.; Suarez-Bertoa, R.; Giechaskiel, B.; Riccobono, F.; Bulgheroni, C.; Astorga, C.; Perujo, A. NOx, NH3, N2O and PN real driving emissions from a Euro VI heavy-duty vehicle. Impact of regulatory on-road test conditions on emissions. Sci. Total Environ. 2017, 609, 546–555. [Google Scholar] [CrossRef] [PubMed]

- Giechaskiel, B.; Vanhanen, J.; Väkevä, M.; Martini, G. Investigation of vehicle exhaust sub-23 nm particle emissions. Aerosol. Sci. Technol. 2017, 51, 626–641. [Google Scholar] [CrossRef]

- Robinson, M.; Backhaus, J.; Foley, R.; Liu, G. The effect of diesel exhaust fluid dosing on tailpipe particle number emissions. SAE Tech. Pap. 2016. [Google Scholar] [CrossRef]

- Amanatidis, S.; Ntziachristos, L.; Giechaskiel, B.; Bergmann, A.; Samaras, Z. Impact of selective catalytic reduction on exhaust particle formation over excess ammonia events. Environ. Sci. Technol. 2014, 48, 11527–11534. [Google Scholar] [CrossRef] [PubMed]

- Lehtoranta, K.; Murtonen, T.; Vesala, H.; Alanen, J.; Simonen, P.; Rönkkö, T.; Timonen, H.; Saarikoski, S.; Maunula, T.; Kallinen, K.; et al. Natural gas engine emission reduction by catalysts. Emiss. Control Sci. Technol. 2017, 3, 142–152. [Google Scholar] [CrossRef]

- Yoon, S.; Quiros, D.; Dwyer, H.; Collins, J.; Burnitzki, M.; Chernich, D.; Herner, J. Characteristics of particle number and mass emissions during heavy-duty diesel truck parked active DPF regeneration in an ambient air dilution tunnel. Atmos. Environ. 2015, 122, 58–64. [Google Scholar] [CrossRef]

- Vermeulen, R.; Verbeek, R.; van Goethem, S.; Smokers, R. Emissions Testing of Two Euro VI LNG Heavy-Duty Vehicles in The Netherlands: Tank-to-Wheel Emissions; TNO Report 2017 R11336; TNO: The Hague, The Netherlands, 2017. [Google Scholar]

- AVL. Swedish in-Service Testing Programme on Emissions from Heavy-Duty Vehicles 2014; AVL Report #OMT2006; AVL: Graz, Austria, 2014. [Google Scholar]

- Giechaskiel, B.; Riccobono, F.; Mendoza-Villafuerte, P.; Grigoratos, T. Particle Number (PN) Portable Emissions Measurement Systems (PEMS): Heavy Duty Vehicles Evaluation Phase at the Joint Research Centre (JRC); JRC Report 2016, EUR 28256 EN; Publication Office for the European Union: Luxembourg, 2016. [Google Scholar]

- Zacharof, N.; Fontaras, G.; Grigoratos, T.; Ciuffo, B.; Savvidis, D.; Delgado, O.; Rodriguez, F. Estimating the CO2 emissions reduction potential of various technologies in European trucks using VECTO simulator. SAE Tech. Pap. 2017. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Cresnoverh, M.; Jörgl, H.; Bergmann, A. Calibration and accuracy of a particle number measurement system. Meas. Sci. Technol. 2010, 21. [Google Scholar] [CrossRef]

- Khan, Y.; Shimpi, S.; Martin, W. The repeatability and reproducibility of particle number measurements from a heavy duty diesel engine. Emiss. Control Sci. Technol. 2015, 1, 298–307. [Google Scholar] [CrossRef]

- Steven, H. Development of a Worldwide Harmonised Heavy-Duty Engine Emissions Test Cycle; Final Report. TRANS/WP29/GRPE/2001/2; United Nations: Geneva, Switzerland, 2001. [Google Scholar]

- Otsuki, Y.; Tochino, S.; Kondo, K.; Haruta, K. Portable emissions measurement system for solid particle number including nanoparticles smaller than 23 nm. SAE Tech. Pap. 2017. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Manfredi, U.; Martini, G. Engine exhaust solid sub-23 nm particles: I. literature survey. SAE Int. J. Fuels Lubr. 2014, 7, 950–964. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Zardini, A.; Martini, G. Particle emission measurements from L-category vehicles. SAE Int. J. Eng. 2015, 8, 2322–2337. [Google Scholar] [CrossRef]

- Ntziachristos, L.; Galassi, C. Emission Factors for New and Upcoming Technologies in Road Transport; EU Report EUR 26952 EN; EUR: Ispra, Italy, 2014. [Google Scholar]

- Liu, Z.; Ge, Y.; Johnson, K.; Shah, A.; Tan, J.; Wang, C.; Yu, L. Real-world operation conditions and on-road emissions of Beijing diesel buses measured by using portable emission measurement system and electric low-pressure impactor. Sci. Total Environ. 2011, 409, 1476–1480. [Google Scholar] [CrossRef] [PubMed]

- Herner, J.; Hu, S.; Robertson, W.; Huai, T.; Collins, J.; Dwyer, H.; Ayala, A. Effect of advanced aftertreatment for PM and NOx control on heavy-duty diesel truck emissions. Environ. Sci. Technol. 2009, 43, 5928–5933. [Google Scholar] [CrossRef] [PubMed]

- Czerwinski, J.; Zimmerli, Y.; Mayer, A.; Heeb, N.; Lemaire, J.; D’Urbano, G.; Bunge, R. Testing of Combined DPF-SCR systems for HD-retrofitting-VERTdePN. SAE Tech. Pap. 2009. [Google Scholar] [CrossRef]

- Guo, J.; Ge, Y.; Hao, L.; Tan, J.; Li, J.; Feng, X. On-road measurement of regulated pollutants from diesel and CNG buses with urea selective catalytic reduction systems. Atmos. Environ. 2014, 99, 1–9. [Google Scholar] [CrossRef]

- Thiruvengadam, A.; Besch, M.; Thiruvengadam, P.; Pradhan, S.; Carder, D.; Kappanna, H.; Gautam, M. Emission rates of regulated pollutants from current technology heavy-duty diesel and natural gas goods, movement vehicles. Environ. Sci. Technol. 2015, 49, 5236–5244. [Google Scholar] [CrossRef] [PubMed]

- Bielaczyc, P.; Szczotka, A.; Woodburn, J. An overview of cold start emissions from direct injection spark-ignition and compression ignition engines of light duty vehicles at low ambient temperatures. Combust. Eng. 2013, 154, 96–103. [Google Scholar]

- Mamakos, A.; Martini, G.; Manfredi, U. Assessment of the legislated particle number measurement procedure for a Euro 5 and a Euro 6 compliant diesel passenger cars under regulated and unregulated conditions. J. Aerosol Sci. 2013, 55, 31–47. [Google Scholar] [CrossRef]

- Yamada, H. PN emissions from heavy-duty diesel engine with periodic regenerating DPF. SAE Int. J. Eng. 2013, 6, 1178–1189. [Google Scholar] [CrossRef]

- Jayaratne, E.; Meyer, N.; Ristovski, Z.; Morawska, L. Volatile properties of particles emitted by compressed natural gas and diesel buses during steady-state and transient driving modes. Environ. Sci. Technol. 2012, 46, 196–203. [Google Scholar] [CrossRef] [PubMed]

- Thiruvengadam, A.; Besch, M.; Yoon, S.; Collins, J.; Kappanna, H.; Carder, D.; Ayala, A.; Herner, J.; Gautam, M. Characterization of particulate matter emissions from a current technology natural gas engine. Environ. Sci. Technol. 2014, 48, 8235–8242. [Google Scholar] [CrossRef] [PubMed]

- Shrivastava, M.; Nguyen, A.; Zheng, Z.; Wu, H.; Jung, H. Kinetics of soot oxidation by NO2. Environ. Sci. Technol. 2010, 44, 4796–4801. [Google Scholar] [CrossRef] [PubMed]

- Andersson, J.; Mamakos, T.; Giechaskiel, B.; Carriero, M.; Martini, G. Particle Measurement Programme (PMP) Heavy-Duty Inter-Laboratory Correlation Exercise (ILCE HD) Final Report; JRC Report 2010, EUR 24561 EN; Publication office for the European Union: Luxembourg, 2010. [Google Scholar]

- Johnson, K.; Durbin, T.; Jung, H.; Chaudhary, A.; Cocker, D.; Herner, J.; Robertson, W.; Huai, T.; Ayala, A.; Kittelson, D. Evaluation of the European PMP methodologies during on-road and chassis dynamometer testing for DPF equipped heavy-duty diesel vehicles. Aerosol Sci. Technol. 2009, 43, 962–969. [Google Scholar] [CrossRef]

- Zheng, Z.; Johnson, K.; Liu, Z.; Durbin, T.; Hu, S.; Huai, T.; Kittelson, D.; Jung, H. Investigation of solid particle number measurement: Existence and nature of sub-23 nm particles under PMP methodology. J. Aerosol Sci. 2011, 42, 883–897. [Google Scholar] [CrossRef]

- Rönkkö, T.; Virtanen, A.; Kannosto, J.; Keskinen, J.; Lappi, M.; Pirjola, L. Nucleation mode particles with a non-volatile core in the exhaust of a heavy-duty diesel vehicle. Environ. Sci. Technol. 2007, 41, 6384–6389. [Google Scholar] [CrossRef] [PubMed]

- Swanson, J.; Watts, W.; Kittelson, D.; Newman, R.; Ziebarth, R. Filtration efficiency and pressure drop of miniature diesel particulate filters. Aerosol. Sci. Technol. 2013, 47, 452–461. [Google Scholar] [CrossRef]

- Pant, P.; Harrison, R. Estimation of the contribution of road traffic emissions to particulate matter concentrations from field measurements: A review. Atmos. Environ. 2013, 77, 78–97. [Google Scholar] [CrossRef]

- Hallquist, Å.; Jerksjö, M.; Fallgren, H.; Westerlund, J.; Sjödin, Å. Particle and gaseous emissions from individual diesel and CNG buses. Atmos. Chem. Phys. 2013, 13, 5337–5350. [Google Scholar] [CrossRef]

- Hajbabaei, M.; Karavalakis, G.; Johnson, K.; Lee, L.; Durbin, T. Impact of natural gas fuel composition on criteria, toxic, and particle emissions from transit buses equipped with lean burn and stoichiometric engines. Energy 2013, 62, 425–434. [Google Scholar] [CrossRef]

- Biswas, S.; Hu, S.; Verma, V.; Herner, J.; Robertson, W.; Ayala, A.; Sioutas, C. Physical properties of particulate matter (PM) from late model heavy duty diesel vehicles operating with advanced emission control technologies. Atmos. Environ. 2008, 42, 5622–5634. [Google Scholar] [CrossRef]

- Saari, S.; Karjalainen, P.; Ntziachristos, L.; Pirjola, L.; Matilainen, P.; Keskinen, J.; Rönkkö, T. Exhaust particle and NOx emission performance of an SCR heavy duty truck operating in real-world conditions. Atmos. Environ. 2016, 126, 136–144. [Google Scholar] [CrossRef]

- Karavalakis, G.; Hajbabaei, M.; Durbin, T.; Johnson, K.; Zheng, Z.; Miller, W. The effect of natural gas composition on the regulated emissions, gaseous toxic pollutants, and ultrafine particle number emissions from a refuse hauler vehicle. Energy 2013, 50, 280–291. [Google Scholar] [CrossRef]

- Karavalakis, G.; Hajbabaei, M.; Jiang, Y.; Yang, J.; Johnson, K.; Cocker, D.; Durbin, T. Regulated, greenhouse gas, and particulate emissions from lean-burn and stoichiometric natural gas heavy-duty vehicles on different fuel compositions. Fuel 2016, 175, 146–156. [Google Scholar] [CrossRef]

- Herner, J.; Hu, S.; Robertson, W.; Huai, T.; Chang, M.; Rieger, P.; Ayala, A. Effect of advanced aftertreatment for PM and NOx reduction on heavy-duty diesel engine ultrafine particle emissions. Environ. Sci. Technol. 2011, 45, 2413–2419. [Google Scholar] [CrossRef] [PubMed]

- Giechaskiel, B.; Ntziachristos, L.; Samaras, Z.; Casati, R.; Volker, S.; Rainer, V. Effect of speed and speed transition on the formation of nucleation mode particles from a light-duty diesel vehicle. SAE Tech. Pap. 2007. [Google Scholar] [CrossRef]

- Kittelson, D.; Watts, W.; Johnson, J.; Thorne, C.; Higham, C.; Payne, M.; Goodier, S.; Warrens, C.; Preston, H.; Zink, U.; et al. Effect of fuel and lube oil sulfur on the performance of a diesel exhaust gas continuously regenerating trap. Environ. Sci. Technol. 2008, 42, 9276–9282. [Google Scholar] [CrossRef] [PubMed]

- Rönkkö, T.; Virtanen, A.; Vaaraslahti, K.; Keskinen, J.; Pirjola, L.; Lappi, M. Effect of dilution conditions and driving parameters on nucleation mode particles in diesel exhaust: Laboratory and on-road study. Atmos. Environ. 2006, 40, 2893–2901. [Google Scholar] [CrossRef]

- Kim, D.; Gautam, M.; Gera, D. Parametric studies on the formation of diesel particulate matter via nucleation and coagulation modes. J. Aerosol Sci. 2002, 33, 1609–1621. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Ntziachristos, L.; Samaras, Z.; Scheer, V.; Casati, R.; Vogt, R. Formation potential of vehicle exhaust nucleation mode particles on-road and in the laboratory. Atmos. Environ. 2005, 39, 3191–3198. [Google Scholar] [CrossRef]

- Khalek, I.; Kittelson, D.; Brear, F. The influence of dilution conditions on diesel exhaust particle size distribution measurements. SAE Tech. Pap. 1999. [Google Scholar] [CrossRef]

- Maricq, M.; Podsiadlik, D.; Chase, R. Examination of the size-resolved and transient nature of motor vehicle particle emissions. Environ. Sci. Technol. 1999, 33, 1618–1626. [Google Scholar] [CrossRef]

- Ntziachristos, L.; Samaras, Z. The potential of a partial-flow constant dilution ratio sampling system as a candidate for vehicle exhaust aerosol measurements. J. Air Waste Manag. Assoc. 2010, 60, 1223–1236. [Google Scholar] [CrossRef] [PubMed]

- Keskinen, J.; Rönkkö, T. Can real-world diesel exhaust particle size distribution be reproduced in the laboratory? A critical review. J. Air Waste Manag. Assoc. 2010, 60, 1245–1255. [Google Scholar] [CrossRef] [PubMed]

- Vogt, R.; Scheer, V.; Casati, R.; Bender, T. On-road measurement of particle emission in the exhaust plume of a diesel passenger car. Environ. Sci. Technol. 2003, 37, 4070–4076. [Google Scholar] [CrossRef] [PubMed]

- Swanson, J.; Kittelson, D.; Watts, W.; Gladis, D.; Twigg, M. Influence of storage and release on particle emissions from new and used CRTs. Atmos. Environ. 2009, 43, 3998–4004. [Google Scholar] [CrossRef]

| Nomenclature | Fuel | Category | Description | Engine Size 1 (L) | Power 1 (kW) |

|---|---|---|---|---|---|

| CNG N1 #1 | CNG | N1 | Rigid truck | 3 | 100 |

| CNG N3 #1 | CNG | N3 | Refuse collection | 9 | 185 |

| CNG N3 #2 | CNG | N3 | Rigid truck | 8 | 220 |

| CNG N3 #3 | CNG | N3 | Refuse collection | 9 | 250 |

| CNG M3 #1 | CNG | M3 | City bus | 13 | 230 |

| LNG N3 #1 | LNG | N3 | Tractor semi trailer | 9 | 300 |

| LNG N3 #2 | LNG | N3 | Tractor semi trailer | 9 | 250 |

| DPF N2 #1 | Diesel | N2 | Rigid truck | 8 | 200 |

| DPF N2 #2 | Diesel | N2 | Rigid truck | 5 | 180 |

| DPF N2 #3 | Diesel | N2 | Rigid truck | 5 | 180 |

| DPF N2 #4 | Diesel | N2 | Rigid truck | 5 | 155 |

| DPF N2 #5 | Diesel | N2 | Rigid truck | 5 | 180 |

| DPF N2 #6 | Diesel | N2 | Rigid truck | 8 | 180 |

| DPF N3 #1 | Diesel | N3 | Tractor semi trailer | 13 | 340 |

| DPF N3 #2 | Diesel | N3 | Tractor semi trailer | 13 | 340 |

| DPF N3 #3 | Diesel | N3 | Tractor semi trailer | 13 | 320 |

| DPF N3 #4 | Diesel | N3 | Tractor semi trailer | 13 | 340 |

| DPF N3 #5 | Diesel | N3 | Tractor semi trailer | 13 | 340 |

| DPF N3 #6 | Diesel | N3 | Tractor semi trailer | 13 | 340 |

| DPF N3 #7 | Diesel | N3 | Rigid truck | 8 | 240 |

| DPF N3 #8 | Diesel | N3 | Rigid truck | 11 | 270 |

| DPF N3 #9 | Diesel | N3 | Rigid truck | 8 | 180 |

| DPF N3 #10 | Diesel | N3 | Crane | 11 | 240 |

| DPF M3 #1 | Diesel | M3 | Bus | 11 | 330 |

| Nomenclature | Tested by | Cycle | Place | Tamb (°C) | Test Weight 1 (t) | Add. Testing |

|---|---|---|---|---|---|---|

| CNG N1 #1 | ACEA | ISC | On-road | 24 | 2.5 | <23 nm |

| CNG N3 #1 | JRC | ISC | Lab | 22 | 20 | <23 nm, T |

| CNG N3 #2 | ACEA | ISC | On-road | 29 | 27 | |

| CNG N3 #3 | STA [59] | WHVC | Lab | 23 | 20 | |

| CNG M3 #1 | ACEA | ISC | On-road | 21 | 20 | |

| LNG N3 #1 | TNO [58] | ISC | On-road | 0 | 31 | |

| LNG N3 #2 | TNO [58] | ISC | On-road | 3 | 31 | |

| DPF N2 #1 | ACEA | ISC | On-road | 25 | 12 | |

| DPF N2 #2 | ACEA | ISC | On-road | 24 | 9 | |

| DPF N2 #3 | JRC | ISC | Lab | 23 | 9 | <23 nm, T, C |

| DPF N2 #4 | JRC | ISC | Lab | 22 | 9 | <23 nm, T |

| DPF N2 #5 | JRC | ISC | Lab | 20 | 12 | Reg. |

| DPF N2 #6 | STA [59] | WHVC | Lab | 23 | 10 | |

| DPF N3 #1 | ACEA | ISC | On-road | 20 | 26 | |

| DPF N3 #2 | ACEA | ISC | On-road | 28 | 22 | |

| DPF N3 #3a,b | JRC [45,52] | ISC | On-road | 15 | 27 | Reg. |

| DPF N3 #4a,b | JRC | ISC | Lab | 20 | 27 | <23 nm, T, C |

| DPF N3 #5 | JRC | ISC | Lab | 20 | 27 | <23 nm, T, C, Reg. |

| DPF N3 #6 | JRC | WHVC | Lab | 21 | 27 | <23 nm |

| DPF N3 #7 | JRC | WHVC | Lab | 23 | 16 | <23 nm |

| DPF N3 #8 | STA [59] | WHVC | Lab | 23 | 18 | |

| DPF N3 #9 | STA [59] | WHVC | Lab | 23 | 15 | |

| DPF N3 #10 | STA [59] | WHVC | Lab | 23 | 21 | |

| DPF M3 #1 | ACEA | ISC | Lab | 24 | 18 |

© 2018 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Giechaskiel, B. Solid Particle Number Emission Factors of Euro VI Heavy-Duty Vehicles on the Road and in the Laboratory. Int. J. Environ. Res. Public Health 2018, 15, 304. https://doi.org/10.3390/ijerph15020304

Giechaskiel B. Solid Particle Number Emission Factors of Euro VI Heavy-Duty Vehicles on the Road and in the Laboratory. International Journal of Environmental Research and Public Health. 2018; 15(2):304. https://doi.org/10.3390/ijerph15020304

Chicago/Turabian StyleGiechaskiel, Barouch. 2018. "Solid Particle Number Emission Factors of Euro VI Heavy-Duty Vehicles on the Road and in the Laboratory" International Journal of Environmental Research and Public Health 15, no. 2: 304. https://doi.org/10.3390/ijerph15020304