A Review of Centrifugal Testing of Gasoline Contamination and Remediation

Abstract

:1. Introduction

- Benzene is the most hazardous of these compounds. Its EPA Maximum Contaminant Level (MCL) is 5 parts per billion (ppb). Long-term exposures to benzene in drinking water at levels above the MCL increase the risk of cancer.

- Toluene and ethylbenzene are not considered carcinogenic (cancer-causing). Their MCLs are 1.0 and 0.7 parts per million (ppm). Over the long term, however, toluene and ethylbenzene damage the liver, kidneys, and central nervous system.

- Xylenes are a mixture of compounds (ortho-, meta-, and para-xylene) with two methyl (−CH3) groups attached to a benzene ring. Xylenes also affect the liver, kidneys, and nervous system, but they are not considered nearly as hazardous as the first three—the MCL for total xylenes is 10 ppm.

- Corrosion and leak protection in tanks.

- Provisions for spills during transportation and operation.

- Monitoring and Testing tanks in service.

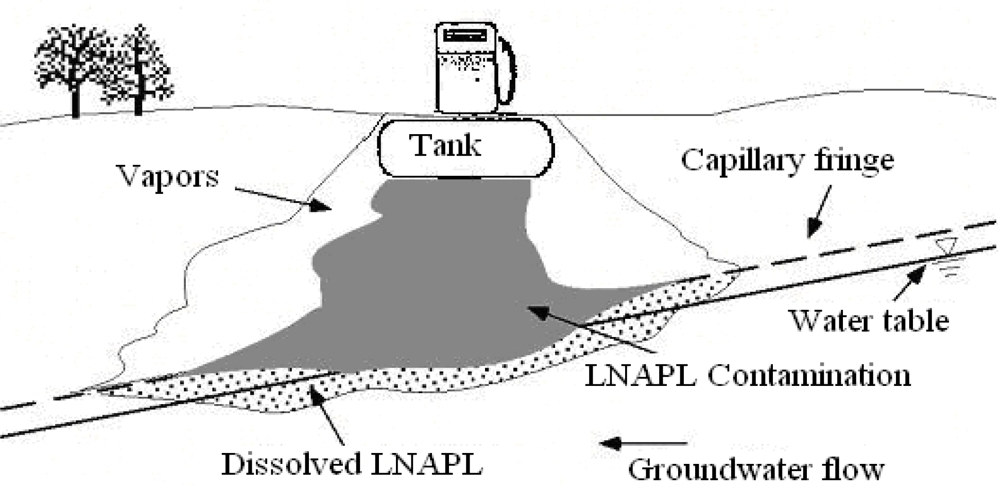

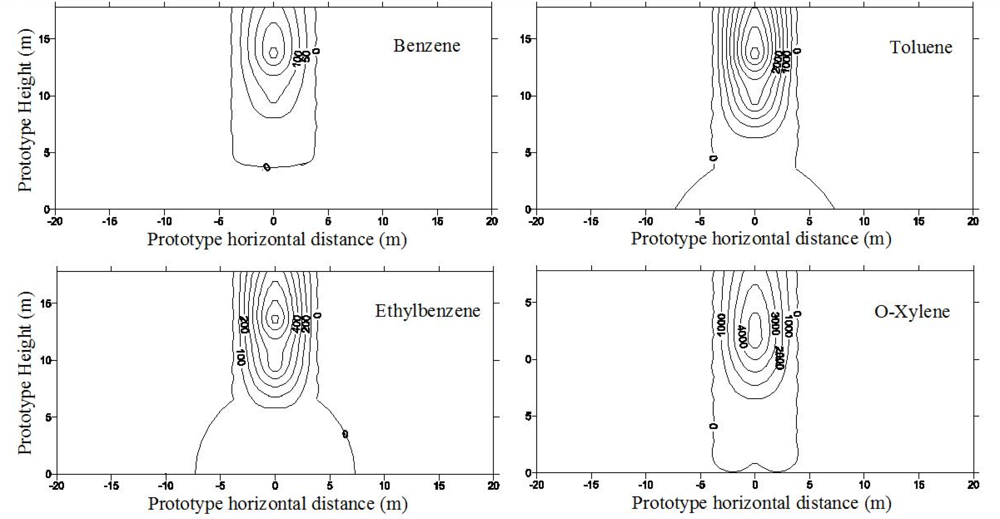

2. Size and Shape of Contamination Plume

2.1. Centrifugal Modeling

2.2. Simulation of LUST under Stationary Groundwater Table

2.3. Simulation of LUST under Flowing Groundwater

3. In-situ Remediation of Gasoline

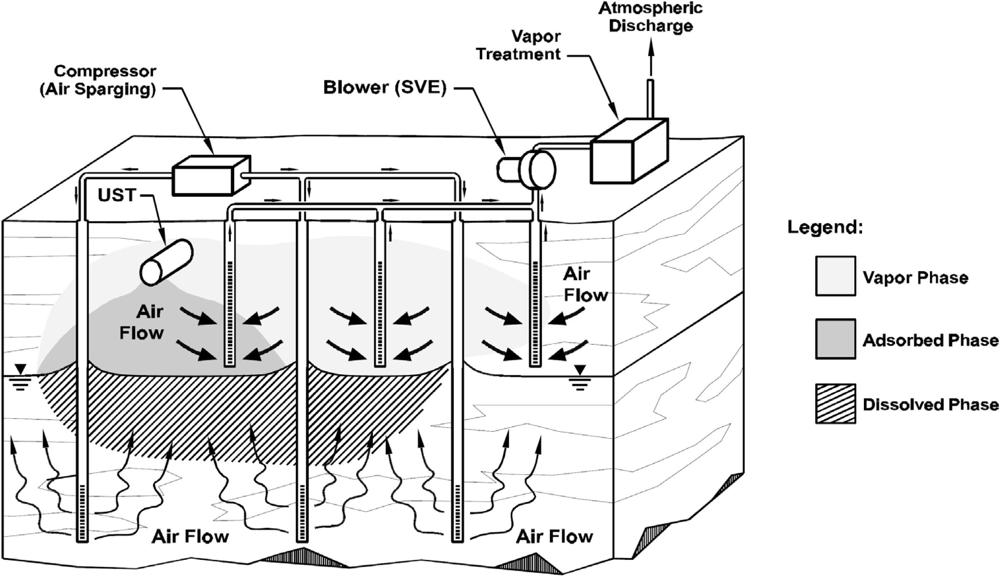

3.1. SVE Remediation

3.2. IAS Remediation

4. Remediation and Reuse of Gasoline Contaminated Soils

| Mica.................................................. | 20.0% Maximum |

| Water Absorption.............................. | 2.0% Maximum |

| Sodium Sulfate Soundness, Loss...... | 5.0% Maximum |

| Plasticity Index.................................. | Non-plastic |

| Clay and clay lumps.......................... | 5.0% Maximum |

5. Summary and Conclusions

Acknowledgments

References and Notes

- Chang, KG; Meegoda, JN; Khera, RP. Centrifugal modeling of leaking underground storage tanks. In Transportation Research Record No. 1504, Modeling and Model Verification; Testing Pavement Layers and Materials; and Low-Cost Drainage Structure; Transportation Research Board: Washington, DC, USA, 1995; pp. 47–56. [Google Scholar]

- Bedient, PB; Rifai, HS; Newell, CJ. Ground Water Contamination: Transport and Remediation; Prentice Hall: Upper Saddle River, NJ, USA, 1994; pp. 349–389. [Google Scholar]

- Reddi, LN; Inyang, HI. Geo-environmental Engineering: Principles and Applications; Marcel Dekker, Inc: New York, NY, USA, 2000. [Google Scholar]

- U.S. Environmental Protection Agency (USEPA). How to Evaluate Alternative Cleanup Technologies for Underground Storage Tank Sites; EPA 510-95-007; USEPA: Research Triangle Park, NC, USA, 1995. [Google Scholar]

- Arulanandan, K; Thompson, PY; Kutter, BL; Meegoda, NJ; Muraleetharan, KK; Yogachandran, C. Centrifuge modeling of transport processes for pollutants in soils. J. Geotech. Eng. 1988, 114, 185–205. [Google Scholar]

- Cooke, B; Mithchell, RJ. Physical modeling of a dissolved contaminant in an unsaturated sand. Can. Geotech. J. 1991, 28, 829–833. [Google Scholar]

- Knight, MA; Mitchell, RJ. Modeling of Light non-aqueous phase liquid (LNAPL) releases into unsaturated sand. Can. Geotech. J. 1996, 33, 913–925. [Google Scholar]

- Meegoda, NJ; Chang, KG. Discussion on Modeling Solute Transport by Centrifuge by J.A. Celori, T.S. Vinson, S.L. Woods and J.D. Istok, June 1989, Vol. 115 #3, in ASCE Environmental Engineering Journal. J. Environ. Eng. 1991, 116, 388–389. [Google Scholar]

- Mitchell, RJ. Centrifugation in geoenvironmental practice and education. Can. Geotech. J. 1998, 35, 630–640. [Google Scholar]

- Culligan-Hensley, PJ; Savvidou, C. Environmental geotechnics and transport processes. In Geotechnical Centrifuge Technology; Taylor, RN, Ed.; Blackie Academic & Professional: Glasgow, UK, 1995; pp. 196–263. [Google Scholar]

- Nimmo, JR. Experimental testing of transient unsaturated flow theory at low water content in a centrifugal field. Water Resour. Res. 1990, 26, 1951–1960. [Google Scholar]

- Nakajima, H; Hirooka, A; Takemura, J; Marino, MA. Centrifuge modeling of one dimensional subsurface contamination. J. Am. Water Resour. Assoc. 1998, 34, 1415–1425. [Google Scholar]

- Illangasekare, TH; Znidarcic, D; Al-Sheridda, M; Reible, DD. Multiphase flow in porous media, Centrifuge 91. Proceedings of the International Conference Centrifuge 1991, Boulder, CO, USA, 13–14 June 1991; A.A. Balkema: Rotterdam, Netherland, 1991; pp. 517–523. [Google Scholar]

- Mitchell, RJ; Stratton, BC. LNAPL penetration into porous media, Centrifuge 94. Proceedings of the International Conference Centrifuge 1994, Singapore, Singapore, 31 August–2 September 1994; A.A. Balkema: Rotterdam, Netherland, 1994; pp. 345–349. [Google Scholar]

- Hu, L; Lo, MC; Meegoda, JN. Centrifuge testing of LNAPL migration and soil vapor extraction for soil remediation. Prac. Period. Haz. Toxic Radio. Waste Manag. 2006, 10, 33–40. [Google Scholar]

- Schofield, AN. Cambridge geotechnical centrifuge operations. Geotechnique 1980, 20, 227–268. [Google Scholar]

- Gravelle, CF; Knight, MA; Mitchell, RJ. Measurement of two-fluid saturations in a fine to medium sand. Can. Geotech. J. 1996, 33, 1014–1017. [Google Scholar]

- Esposito, G; Allersma, HGB; Selvadurai, APS. Centrifuge modeling of LNAPL transport in partially saturated sand. J. Geotech. Geoenviron. Eng. 1999, 125, 1066–1071. [Google Scholar]

- Culligan, PJ; Banno, K; Barry, DA; Steenhuis, TS; Parlange, JY. Preferential flow of a nonaqueous phase liquid in dry sand. J. Geotech. Geoenviron. Eng. 2002, 128, 327–337. [Google Scholar]

- Kechavarzi, C; Soga, K; Wiart, P. Multi-spectral image analysis method to determine dynamic fluid saturation distribution in to dimensional three-fluid phase flow laboratory experiments. J. Contam. Hydrol. 2000, 46, 265–293. [Google Scholar]

- Kechavarzi, C; Soga, K. Determination of water saturation using miniature resistivity probes during intermediate scale and centrifuge multiphase flow laboratory experiments. Geotech. Test. J. 2002, 25, 95–103. [Google Scholar]

- Hu, LM; Shu, SZ; Lo, MC; Zhang, JH; Meegoda, JN; Pu, JL. Centrifuge modeling of LNAPLs in porous media. Proceedings of the International Conference on Physical Modeling in Geotechnics—ICPMG’02, St. John’s, Newfoundland, Canada, 10–12 July 2002; Phillips, R, Guo, P, Popescu, R, Eds.; A.A. Balkema: Rotterdam, Netherland, 2002; pp. 367–372. [Google Scholar]

- Soga, K; Kawabata, J; Kechavarzi, C; Coumoulos, H; Waduge, AP. Centrifuge modeling of non-aqueous phase liquid movement and entrapment in unsaturated layered soils. J. Geotech. Geoenviron. Eng. 2003, 129, 173–182. [Google Scholar]

- Lo, IMC; Hu, LM. Long-term migration of LNAPL in unsaturated soils: Clayey silt and fine sand. Prac. Period. Haz. Toxic Radio. Manag. 2004, 8, 228–237. [Google Scholar]

- Lo, IMC; Hu, LM; Meegoda, JN. Centrifuge modeling of LNAPL transport in unsaturated soils. J. Geotech. Geoenviron. Eng. 2004, 130, 535–539. [Google Scholar]

- Lo, IMC; Hu, LM; Meegoda, JN. Feasibility study of using centrifuge for investigating LNAPL migration in unsaturated soils. Soil Sed. Contam. 2005, 14, 85–103. [Google Scholar]

- Culligan, P; Soga, K. Non-aqueous phase liquid behavior in the subsurface: Transportation, source zone characterization and remediation. Proceedings of the International Conference on Physical Modeling in Geotechnics—ICPMG’06, Hong Kong, China, 4–6 August 2006; Ng, CWW, Wang, YH, Zhang, LM, Eds.; Taylor & Francis: London, UK, 2006. [Google Scholar]

- Hu, L; Lo, MC; Meegoda, JN. Numerical analysis and centrifuge modeling on LNAPLs transport in subsurface system. Progr. Nat. Sci. 2006, 16, 416–424. [Google Scholar]

- Hu, L; Xing, W; Wu, Z. Numerical modeling of NAPL migration in porous media. Rock Soil Mech. 2007, 28, 951–955. [Google Scholar]

- Adams, JA; Reddy, KR. Extent of benzene biodegradation in saturated soil columns during air sparging. Ground Water Monit. Remed 2003, 23, 85–94. [Google Scholar]

- Fischer, U; Schulin, R; Keller, M. Experimental and numerical investigation of soil vapor extraction. Water Resour. Res. 1996, 32, 3413–3427. [Google Scholar]

- Harper, BM; Stiver, WH; Zytner, RG. Influence of water content on SVE in a silt loam soil. J. Environ. Eng. 1998, 124, 1047–1053. [Google Scholar]

- Kirtland, BC; Aelion, CM; Widdowson, MA. Long-term AS/SVE for petroleum removal in low-permeability Piedmont saprolite. J. Environ Eng 2001, 127, 134–144. [Google Scholar]

- Reddy, KR; Chinthamreddy, S. Comparison of different extractants for removing heavy metals from contaminated clayey soils. J. Soil Sed. Contam. 2000, 9, 449–462. [Google Scholar]

- Reddy, KR; Adams, JA. Effect of groundwater flow on remediation of dissolved-phase VOC contamination using air sparging. J. Haz. Mater. 2000, 72, 147–165. [Google Scholar]

- Waduge, WAP; Soga, K; Kawabata, J. Laboratory testing of air sparging/SVE system for remediation of NAPLs entrapped in heterogeneous soil. Proceedings of the International Conference on Physical Modeling in Geotechnics—ICPMG’02, St. John’s, NL, Canada, 10–12 July 2002; Phillips, R, Guo, P, Popescu, R, Eds.; A.A. Balkema: Rotterdam, The Netherlands, 2002; pp. 367–372. [Google Scholar]

- Widdowson, MA; Haney, OR; Reeves, HW; Aelion, CM; Ray, RP. Multilevel soil-vapor extraction test for heterogeneous soil. J. Environ. Eng. 1997, 123, 160–168. [Google Scholar]

- Yoon, H; Kim, JH; Liljestrand, HM; Khim, J. Effect of water content on transient nonequilibrium NAPL-gas mass transfer during soil vapor extraction. J. Contam. Hydrol. 2002, 54, 1–18. [Google Scholar]

- Hu, L; Liu, Y. Physical modeling of air-sparging technique for groundwater remediation. Chin. J. Geotech. Eng. 2008, 30, 835–839. [Google Scholar]

- Hu, L; Wu, X; Liu, Y; Meegoda, JN; Gao, S. Physical modeling of air flow during air sparging remediation. Environ. Sci. Technol. 2010, 44, 3883–3888. [Google Scholar]

- Hu, L; Meegoda, JN; Du, J; Wu, X; Gao, S. Centrifugal study of zone of influence during air-sparging. J. Environ. Monit. 2011. [Google Scholar] [CrossRef]

- Du, JT. Physical Modeling on Air Sparging Technique. M.S. Thesis, Tsinghua University: Beijing, China,. 2011. [Google Scholar]

- Wang, J. Numerical Modeling of Groundwater Remediation by Air Sparging. M.S. Thesis, Tsinghua University: Beijing, China,. 2011. [Google Scholar]

- Ratnaweera, P; Meegoda, JN. Treatment of oil contaminated soils for identification and classification. ASTM Geotech. Test. J. 1995, 18, 41–49. [Google Scholar]

- Meegoda, JN; Chen, B; Gunasekera, SD; Pederson, P. Compaction characteristics of contaminated soils-reuse as a road base material. In Recycled Materials in Geotechnical Applications; Geotechnical Special Publication No. 79; Geo-Institute of ASCE: Reston, VA, USA, 1998; pp. 195–209. [Google Scholar]

- Meegoda, NJ; Mueller, RT; Huang, DR; DuBose, BH; Chen, YQ; Chuang, KY. Petroleum contaminated soils in hot mix asphalt concrete—An overview. Proceedings of the Symposium on a Critical Look at the Use of Waste Materials in Hot-Mix Asphalt, Miami, FL, USA, 8 December 1992; ASTM: West Conshohocken, PA, USA, 1992. [Google Scholar]

- Meegoda, NJ; Mueller, RT; Huang, DR; DuBose, BH; Chen, YQ; Chuang, KY. Petroleum contaminated soils in hot mix asphalt concrete—An overview. In Use of Waste Materials in Hot-Mix Asphalt; ASTM Special Technical Publication No. 1193; Waller, HF, Ed.; ASTM: Philadelphia, PA, USA, 1993; pp. 183–194. [Google Scholar]

- Meegoda, JN; Ezeldin, AS; Vaccari, DA; Mueller, RT. Petroleum contaminated soils in highway construction. Proceedings of the 3rd Materials Engineering Conference, San Diego, CA, USA, 13–16 November 1994; ASCE: New York, NY, USA, 1994; pp. 904–911. [Google Scholar]

- Meegoda, JN; Mueller, RT; Palise, F. Use of remediated petroleum contaminated soils in highway construction. In Engineered Contaminated Soils and Interaction of Soil Geomembranes; Geotechnical Special Publication, No. 59; ASCE: New York, NY, USA, 1996; pp. 1–16. [Google Scholar]

- Meegoda, JN. Stabilization/solidification of petroleum-contaminated soils with asphalt emulsions. Prac. Period. Haz. Toxic Radio. Waste Manag. 1999, 3, 46–55. [Google Scholar]

- Meegoda, JN; Ezeldin, AS; Fang, HY; Inyang, HI. Immobilization technologies. Prac. Period. Haz. Toxic Radio. Waste Manag. 2003, 7, 46–58. [Google Scholar]

| Contaminants | Migration for 1 year | SVE for 2 months | SVE for 4 months |

|---|---|---|---|

| Benzene | 46% | 13% | 9% |

| Toluene | 88% | 53% | 32% |

| Ethylbenzene | 90% | 64% | 41% |

| o-Xylene | 100% | 58% | 36% |

| Total BTEX | 88% | 53% | 32% |

| Sample No. | Particle size (mm) | Dry density (g/cm3) | Porosity (%) |

|---|---|---|---|

| 1 | 0.8–1.0 | 1.617 | 35 |

| 2 | 1.5–2.0 | 1.684 | 33 |

| 3 | 4.0–5.0 | 1.676 | 33 |

| 4 | 0.8–5.0 | 1.953 | 22 |

| Sample No. | g level | Static water pressure (kPa) (1) | Critical AS pressure (kPa) (2) | (2)-(1) (kPa) (3) |

|---|---|---|---|---|

| 1 | 15 | 64.8 | 100 | 35.2 |

| 30 | 112.4 | 170 | 57.6 | |

| 2 | 15 | 68.1 | 105.0 | 36.9 |

| 30 | 134.2 | 180.0 | 45.8 | |

| 40 | 170.7 | 240.0 | 69.3 | |

| 50 | 204.5 | 300.0 | 95.5 | |

| 3 | 15 | 72 | 110.0 | 38.0 |

| 30 | 137.5 | 180.0 | 42.5 | |

| 40 | 178.3 | 230.0 | 51.7 | |

| 50 | 211.6 | 290.0 | 78.4 | |

| 4 | 15 | 66.9 | 100.0 | 33.1 |

| 30 | 129.8 | 180.0 | 50.2 | |

| 40 | 168.3 | 240.0 | 71.7 | |

| 50 | 203.3 | 300.0 | 96.7 | |

© 2011 by the authors; licensee MDPI, Basel, Switzerland. This article is an open-access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Meegoda, J.N.; Hu, L. A Review of Centrifugal Testing of Gasoline Contamination and Remediation. Int. J. Environ. Res. Public Health 2011, 8, 3496-3513. https://doi.org/10.3390/ijerph8083496

Meegoda JN, Hu L. A Review of Centrifugal Testing of Gasoline Contamination and Remediation. International Journal of Environmental Research and Public Health. 2011; 8(8):3496-3513. https://doi.org/10.3390/ijerph8083496

Chicago/Turabian StyleMeegoda, Jay N., and Liming Hu. 2011. "A Review of Centrifugal Testing of Gasoline Contamination and Remediation" International Journal of Environmental Research and Public Health 8, no. 8: 3496-3513. https://doi.org/10.3390/ijerph8083496