A Causal and Real-Time Capable Power Management Algorithm for Off-Highway Hybrid Propulsion Systems

Abstract

:1. Introduction

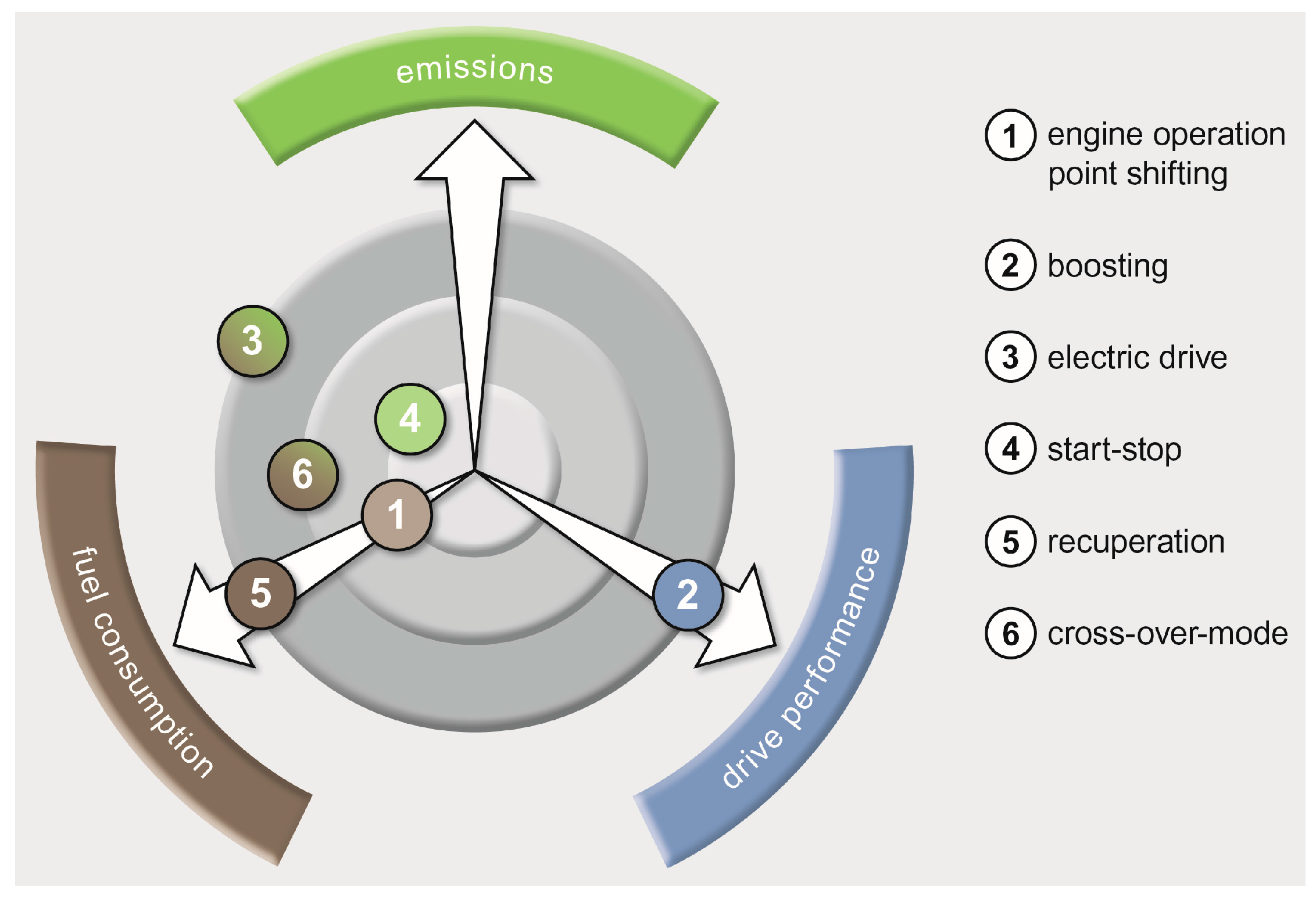

1.1. Motivation

1.2. Classification of Power Management Algorithms

1.3. Requirements for the Off-Highway Application Power Management

- Modular structure

- Real-time capability

- Compatibility to series production propulsion system control units

- Suitability for different mission scenarios and velocity/load control modes (including driver-controlled traction torque demand and automatically controlled drive strategies)

- Consideration of variable auxiliary or external load requests in the PMA.

2. Boundaries of the Simulation Case Study

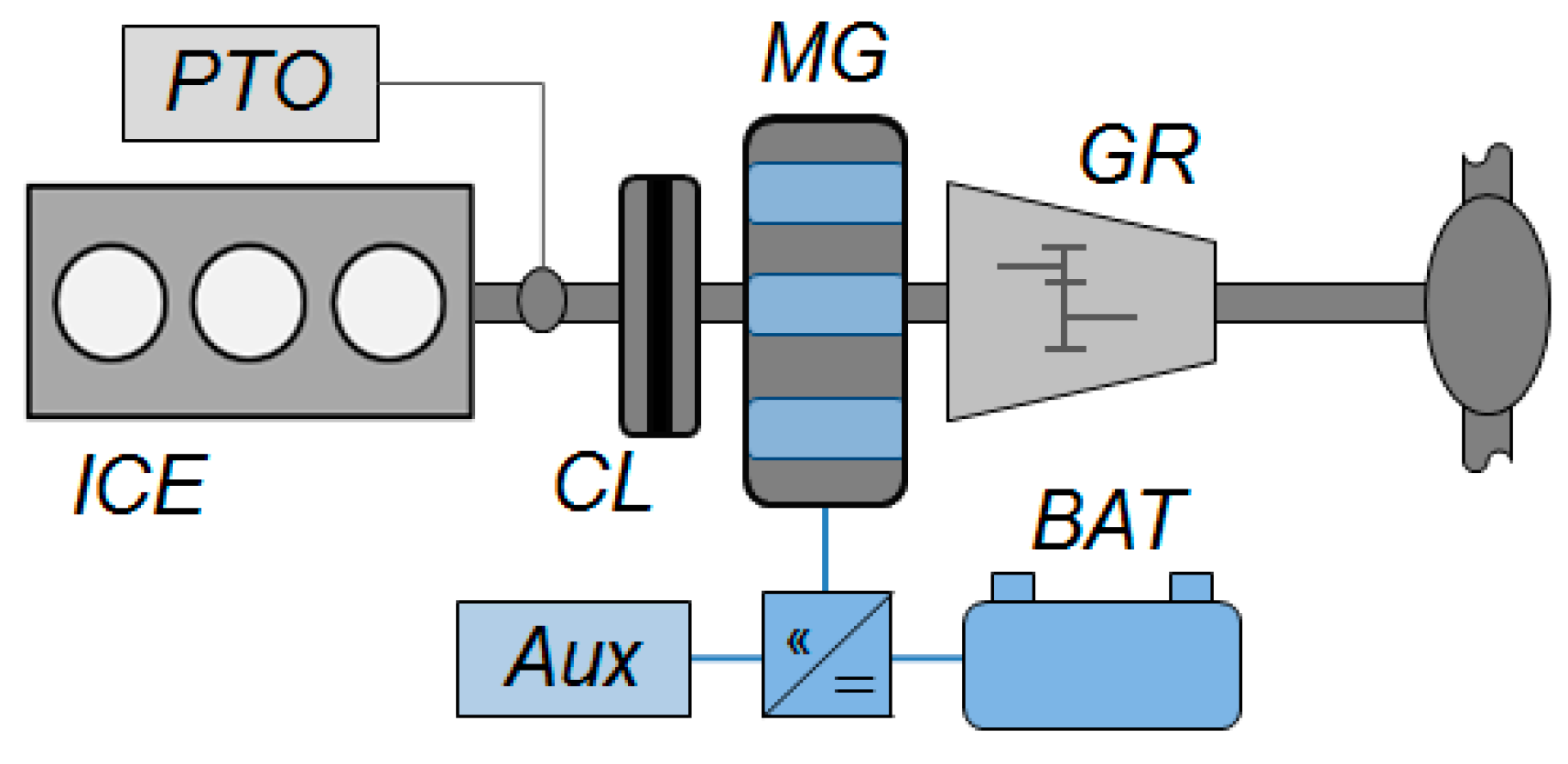

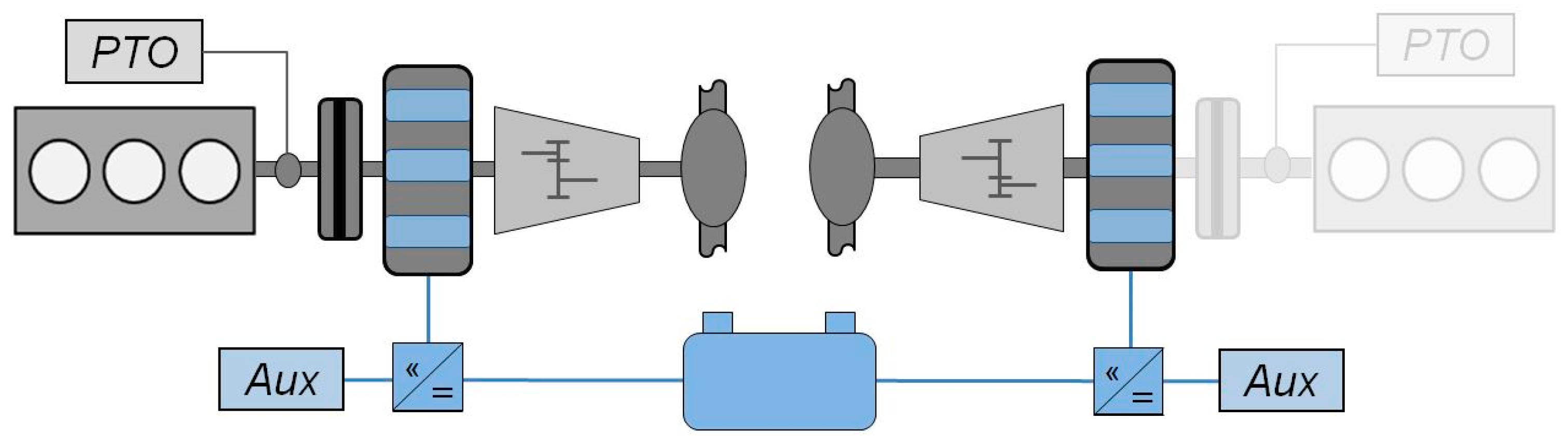

2.1. Hybrid Diesel Multiple Unit Train (DMU) System Specification

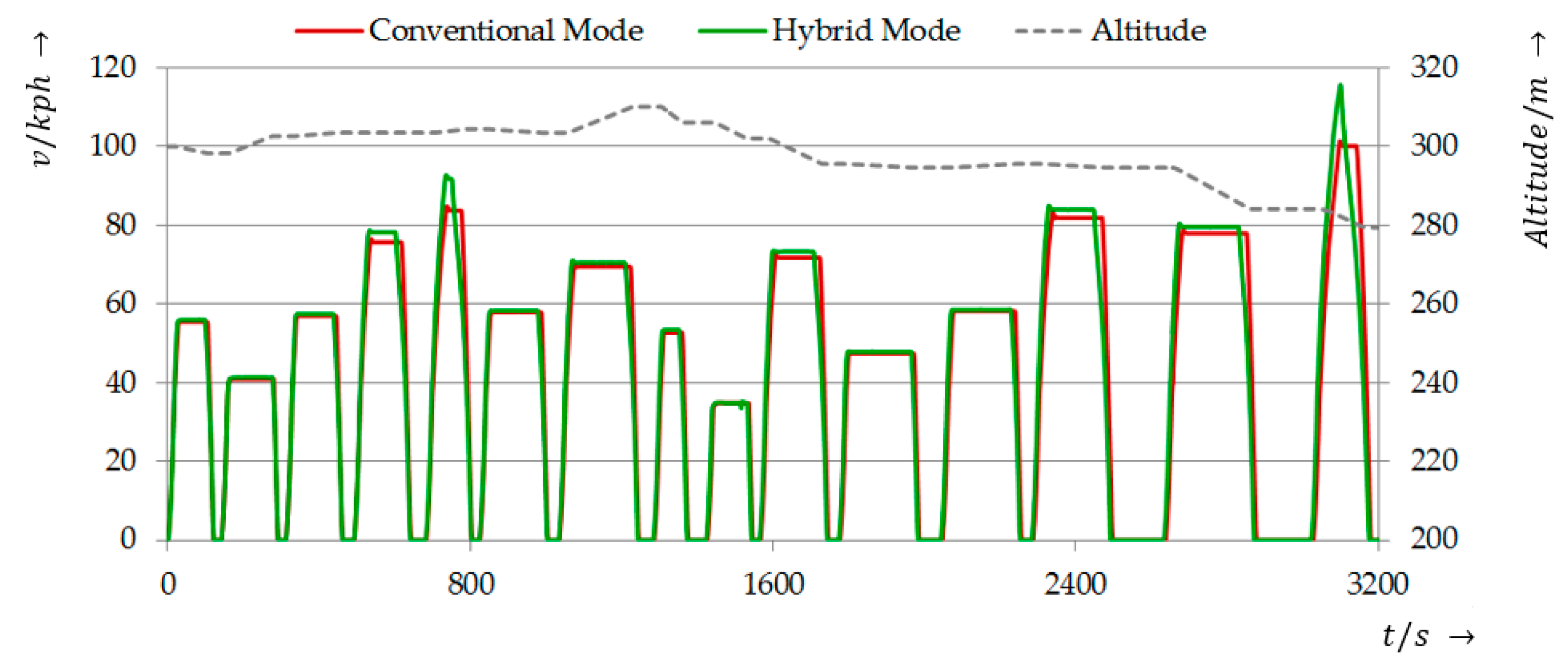

2.2. Drive Strategy

3. System Simulation Model and Validation

3.1. Modelling System Components

3.1.1. Vehicle Model

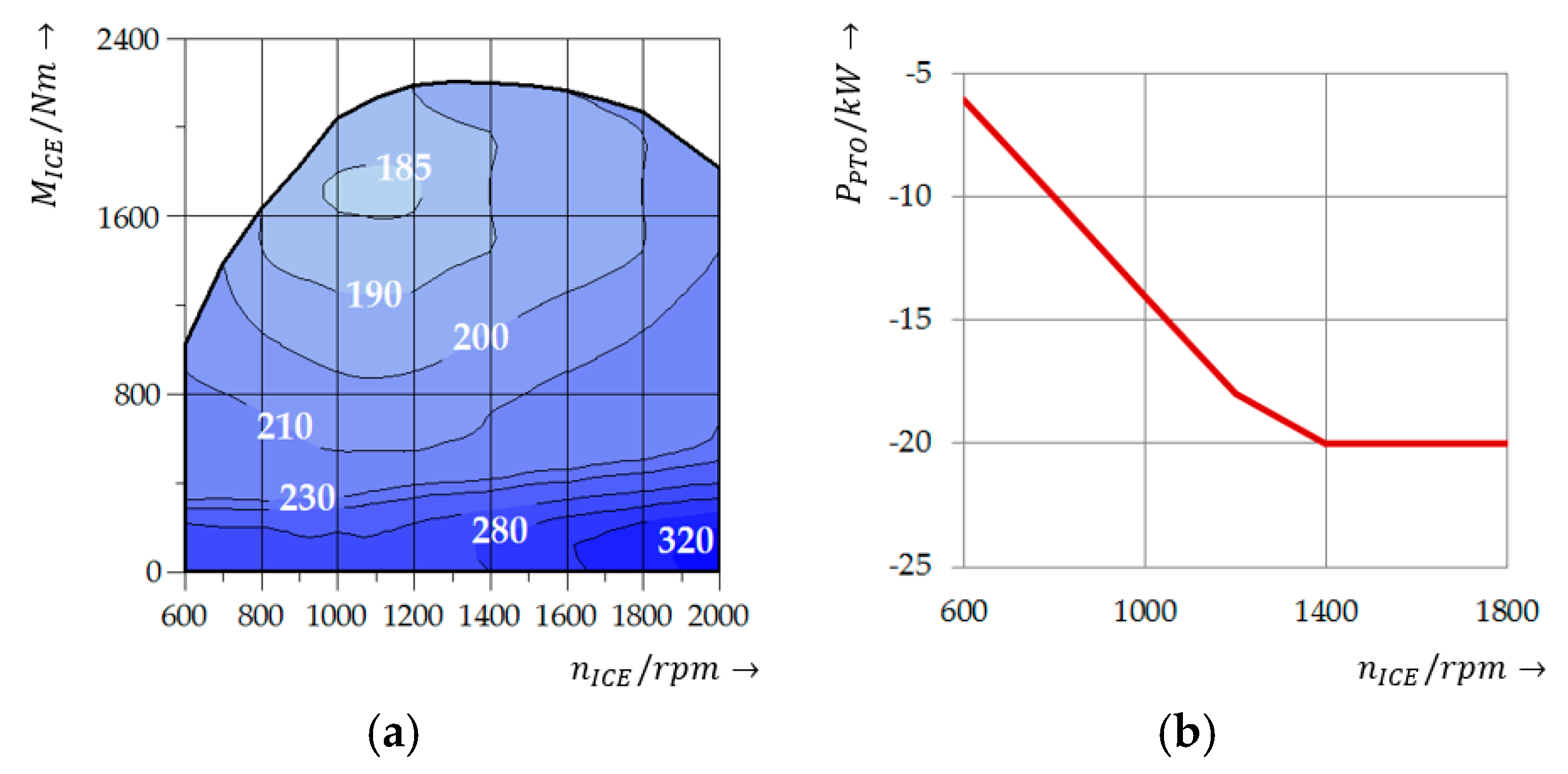

3.1.2. Engine Model

3.1.3. Gearbox Model

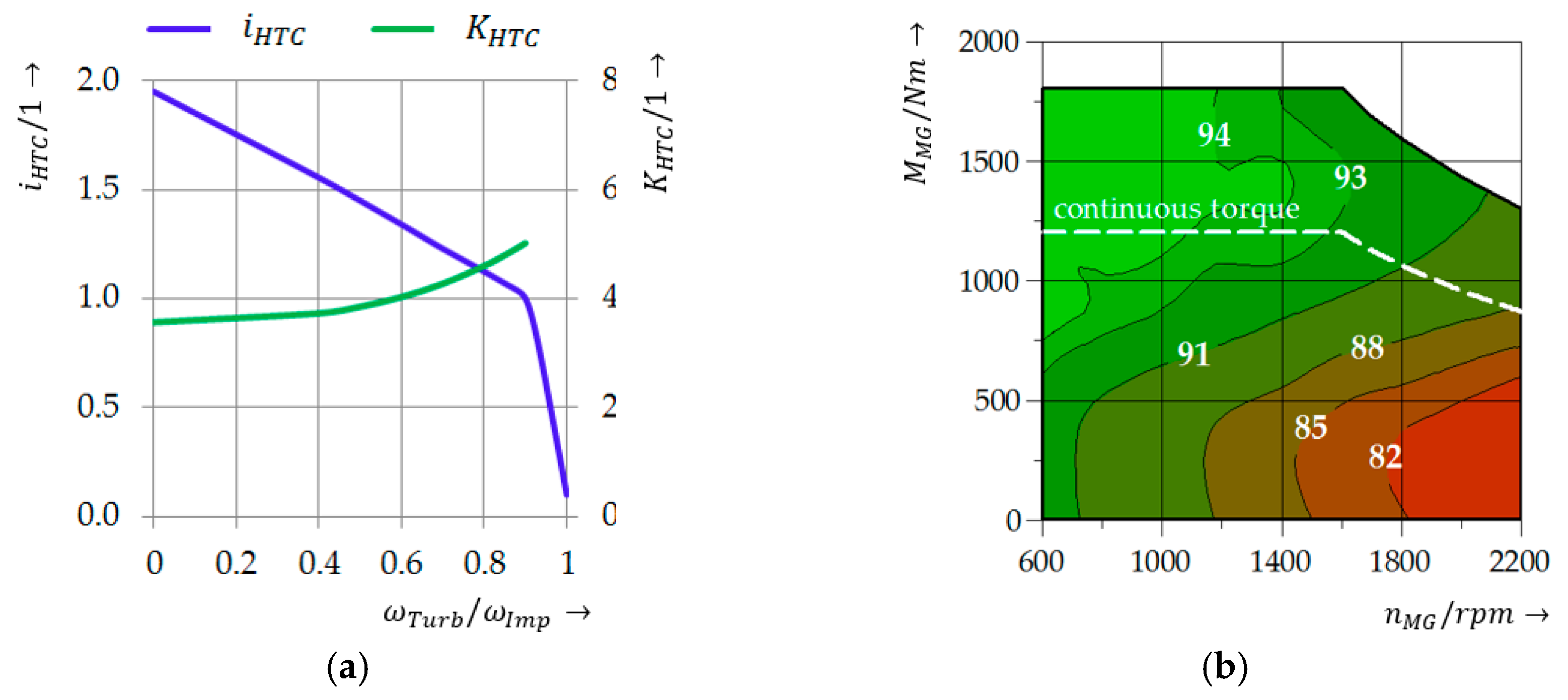

3.1.4. Motor/Generator Model

3.1.5. Battery Model

3.2. Model Validation

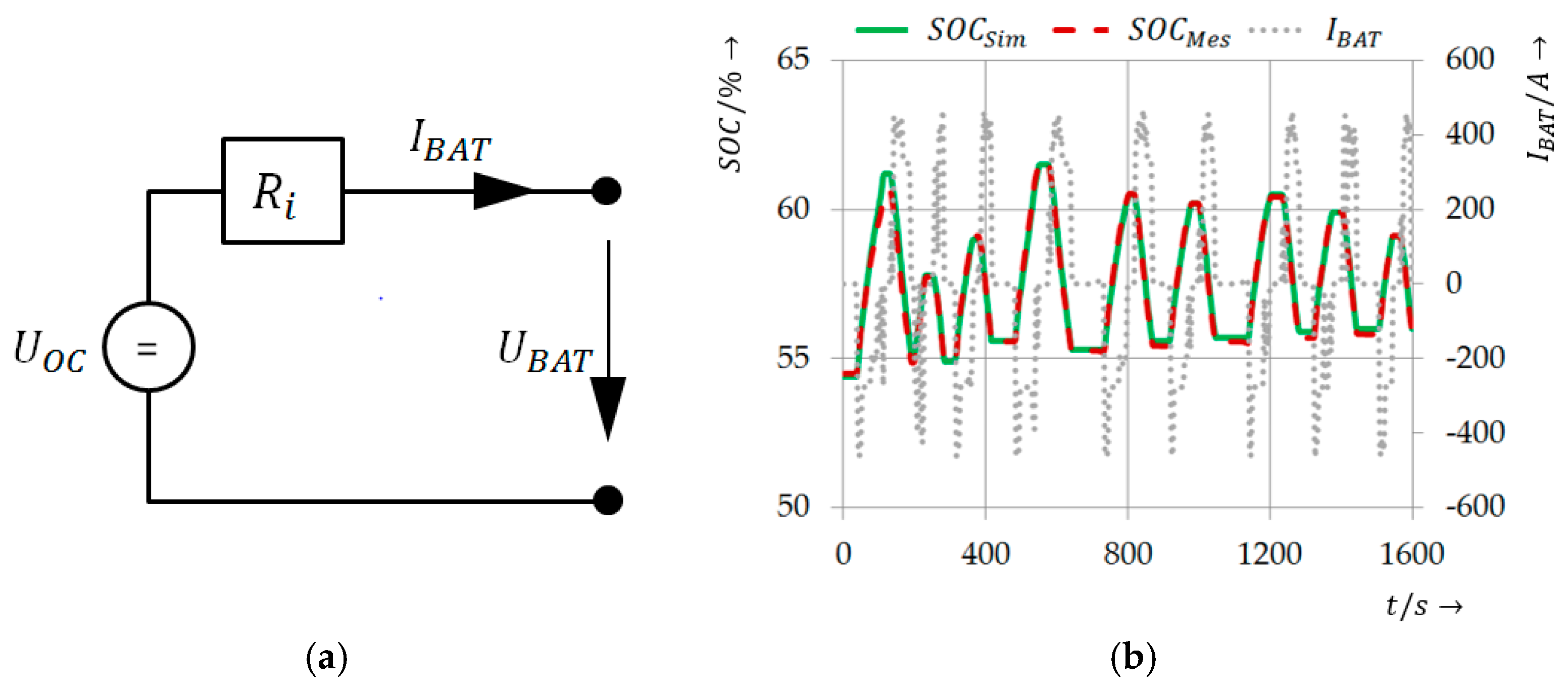

3.2.1. Battery Model Validation

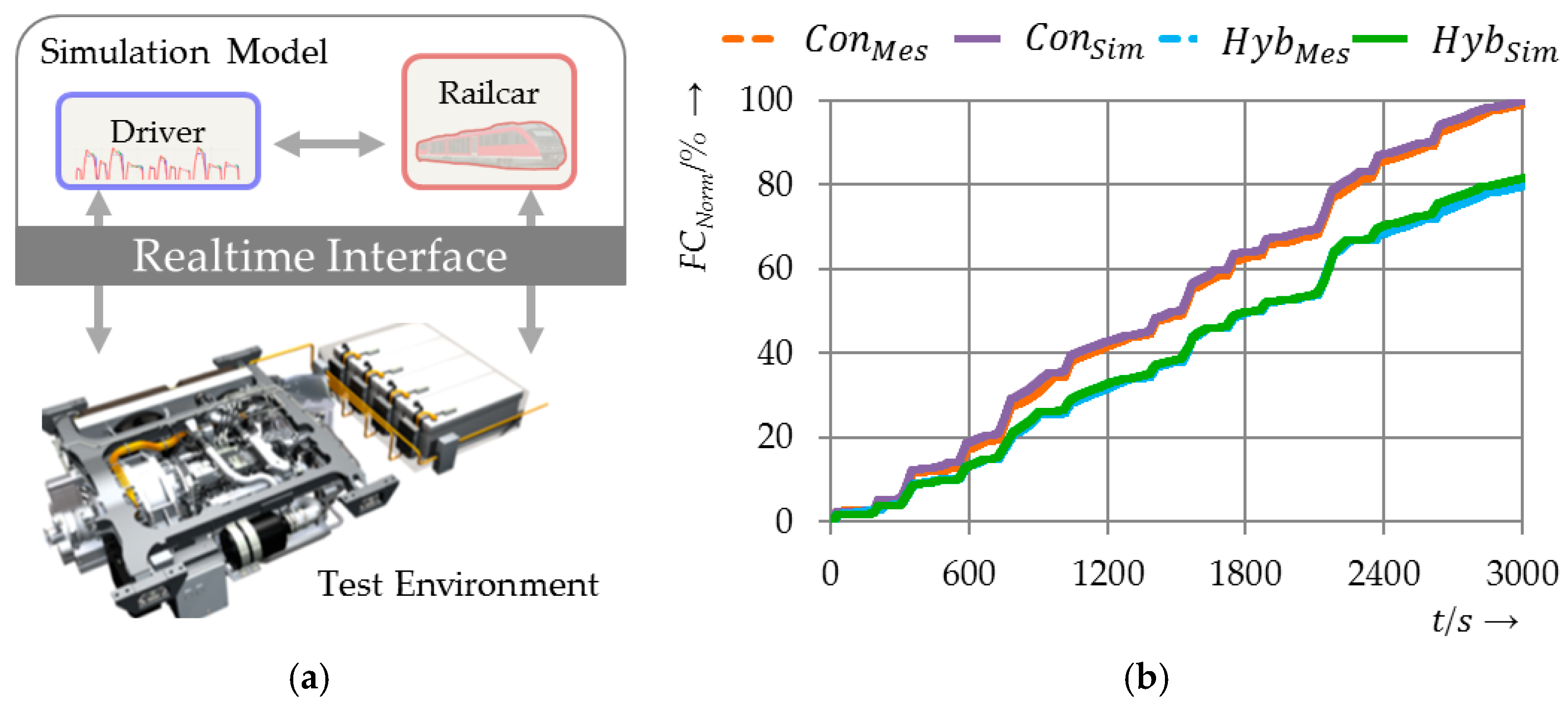

3.2.2. Powertrain Model Validation

4. Hybrid Power Management Algorithm (PMA)

4.1. Problem Definition

4.2. Hybrid Operation Modes

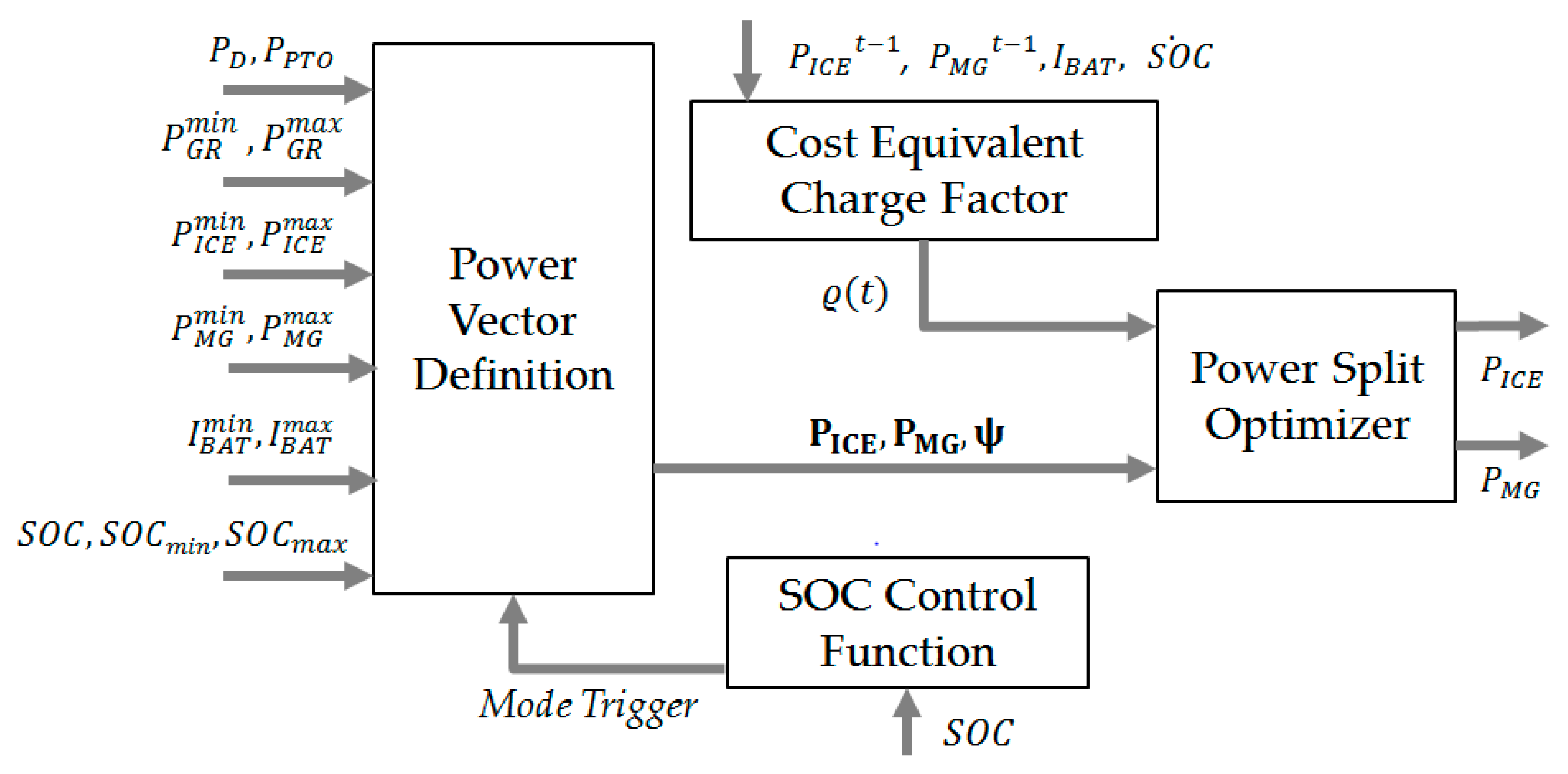

4.3. PMA Optimization Routine

4.3.1. Power Vector Definition

4.3.2. Power Split Optimization

4.3.3. Energy Cost Equivalent Charge Factor

4.3.4. SOC Control Function

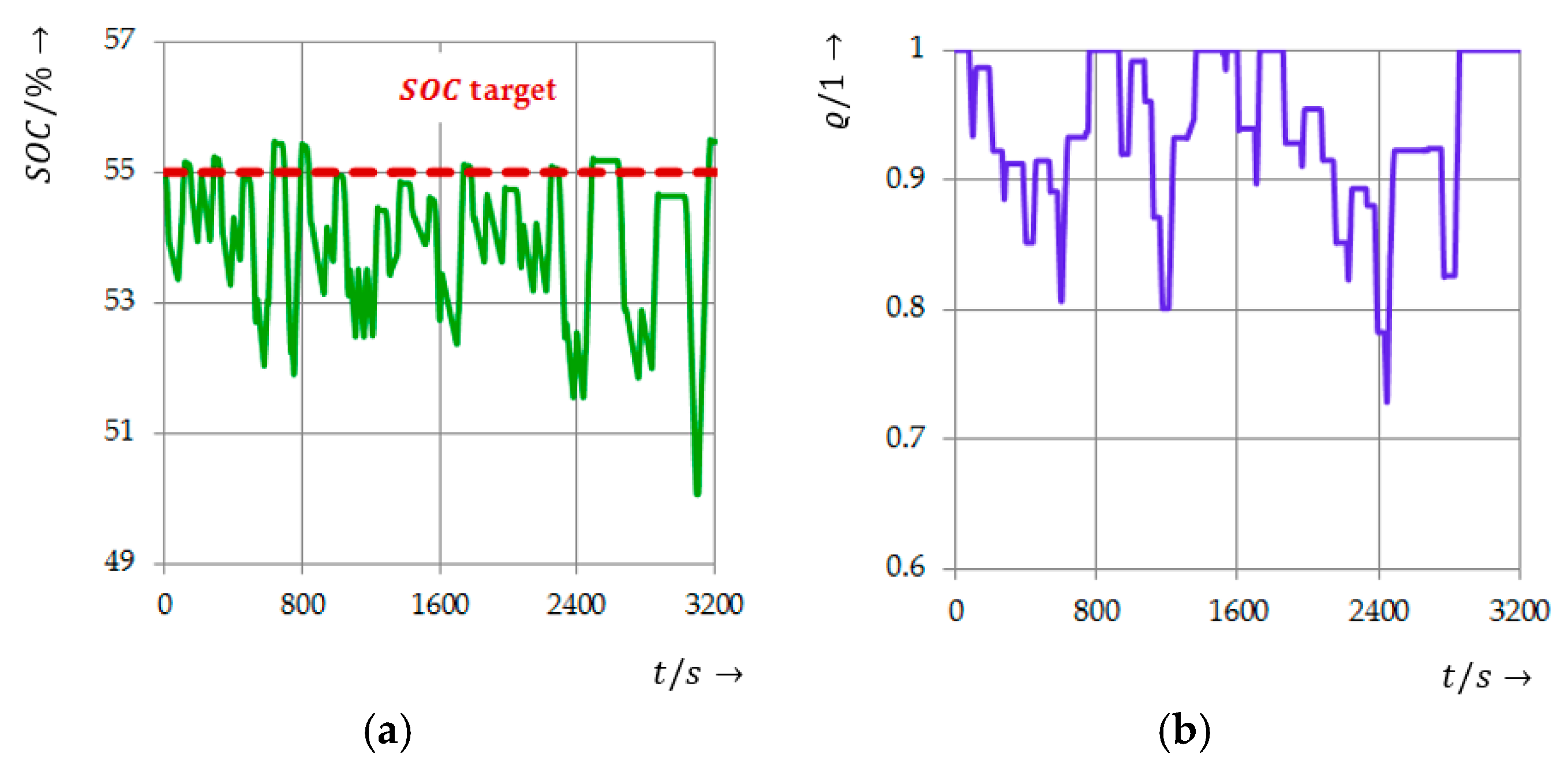

5. Case Study Results

6. Conclusions and Outlook

Author Contributions

Conflicts of Interest

References

- European Parliament and Council of the European Union. REGULATION (EG) No 443/2009 Setting Emission Performance Standards for New Passenger Cars as Part of the Community’s Integrated Approach to Reduce CO2 Emissions from Light-Duty Vehicles, April 2009. Available online: http://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32009R0443&from=EN (accessed on 20 August 2016).

- Baffes, J.; Kose, M.A.; Ohnsorge, F.; Stocker, M. The Great Plunge in Oil Prices: Causes, Consequences and Policy Responses; Policy Research Note; World Bank Group: Washington, DC, USA, 2015. [Google Scholar]

- Dittus, H.; Hülsebusch, D.; Ungethüm, J. Reducing DMU fuel consumption by means of hybrid energy storage. Eur. Transp. Res. Rev. 2011, 3, 149–159. [Google Scholar] [CrossRef] [Green Version]

- Oszfolk, B.; Radke, M.; Ibele, Y. Hybridantrieb stellt Marktreife unter Beweis. ETR Eisenbahntechnische Rundsch. 2015, 9, 44–49. [Google Scholar]

- Yuan, L.C.W.; Tjahjowidodo, T.; Lee, G.S.G.; Chan, R. Equivalant consumption minimization strategy for hybrid all-electric tugboats to optimize fuel savings. In Proceedings of the American Control Conference (ACC), Boston, MA, USA, 6–8 July 2016.

- Jayaram, V.; Khan, M.Y.; Welch, W.A.; Johnson, K.; Miller, J.W.; Cocker, D.R. A generalized approach for varifying the emission benefits of off-road hybrid mobile sources. Emiss. Control Sci. Technol. 2016, 2, 89–98. [Google Scholar] [CrossRef]

- Hass, C.; Oszfolk, B.; Schalk, J. Emissions of a hybrid propulsion system for regional trains as an example for innovative non-road propulsion systems. In Proceedings of the 8th Emission Control, Dresden, Germany, 2–3 June 2016.

- Hofman, T.; Steinbuch, M.; Van Druten, R.; Serrarens, A. Rule-based energy management strategies for hybrid vehicles. Int. J. Electr. Hybrid Veh. 2007, 1, 71–94. [Google Scholar] [CrossRef]

- Guzella, L.; Sciarretta, A. Vehicle Propulsion Systems: Introduction to Modeling and Optimization; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Goerke, D. Untersuchungen zur Kraftstoffoptimalen Betriebsweise von Parallelhybridfahrzeugen und Darauf Basierende Auslegung Regelbasierter Betriebsstrategien; Springer: Wiesbaden, Germany, 2016. [Google Scholar]

- Guzella, L.; Sciarretta, A. Control of hybrid electric vehicles. IEEE Control Syst. 2007, 27, 60–70. [Google Scholar]

- Helbing, D.I.M.; Uebel, D.I.S.; Tempelhahn, D.I.C.; Bäker, I.B. Bewertender Überblick von Methoden zur Antriebsstrangsteuerung in Hybrid- und Elektrofahrzeugen. ATZelektronik 2015, 10, 66–71. [Google Scholar] [CrossRef]

- Karbaschian, M.A.; Söffker, D. Review and comparison of power management approaches for hybrid vehicles with focus on hydraulic drives. Energies 2014, 7, 3512–3536. [Google Scholar] [CrossRef]

- Lampe, A. Regelbasierte Betriebsstrategien zur Vorauslegung von Hybridantriebssträngen. ATZ Automobiltech. Z. 2016, 116, 76–82. [Google Scholar] [CrossRef]

- Hanho, S.; Hyunsoo, K. Development of near optimal rule-based control for plug-in hybrid electric vehicles taking into account drivetrain component losses. Energies 2016, 9, 420. [Google Scholar] [CrossRef]

- Paschero, M.; Storti, G.L.; Rizzi, A.; Mascioli, F.M.F. Implementation of a fuzzy control system for a parallel hybrid vehicle powertrain on compactrio. Int. J. Comput. Theory Eng. 2013, 5, 273. [Google Scholar] [CrossRef]

- Khoucha, F.; Benbouzid, M.; Kheloui, A. An optimal fuzzy logic power shift strategy for parallel hybrid electric vehicles. In Proceedings of the IEEE Vehicle Power and Propulsion Conference, Lille, France, 1–3 September 2010.

- Yuan, Z.; Teng, L.; Fengchun, S.; Peng, H. Comparative study of dynamic programming and pontryagin’s minimum principle on energy management of a parallel hybrid electric vehicle. Energies 2013, 6, 2305–2318. [Google Scholar] [CrossRef]

- Leska, M.; Aschemann, H. Fuel-optimal combined driving strategy and energy management for a parallel hybrid electric railway vehicle. In Proceedings of the 20th International Conference on Methods and Models in Automation and Robotics, Miedzyzdroje, Poland, 24–27 August 2015.

- Sivertsson, M.; Sundström, C.; Eriksson, L. Adaptive Control of a Hybrid Powertrain with Map-Based ECMS; IFAC World Congress: Prague, Czech Republic, 2011. [Google Scholar]

- Mustardo, C.; Rizzoni, G.; Guezennec, Y.; Staccia, B. A-ECMS: An adaptive algorithm for hybrid electric vehicle energy management. Eur. J. Control 2005, 11, 509–524. [Google Scholar] [CrossRef]

- Nüesch, T.; Cerofolini, A.; Mancini, G.; Cavina, N.; Onder, C.; Guzzella, L. Equivalent consumption minimization strategy for control of real driving NOx emissions of a diesel hybrid electric vehicle. Energies 2014, 7, 3148–3178. [Google Scholar] [CrossRef]

- Onori, S.; Serrao, L. On adaptive-ECMS strategies for hybrid electric vehicles. In Proceedings of the International Scientific Conference on Hybrid and Electric Vehicles, Rueil-Malmaison, France, 6–7 December 2011.

- Winkler, M.; Geulen, S.; Josevski, M.; Tegethoff, M.; Abel, D.; Vöcking, B. Online parameter tuning methods for adaptive ECMS control strategies in hybrid electric vehicles. In Proceedings of the FISTA World Automotive Congress, Maastricht, The Netherlands, 2–6 June 2014.

- Katsargyri, G.-E.; Kolmanovsky, I.V.; Michelini, J.; Kuang, M.L.; Phillips, A.M.; Rinehart, M.; Dahleh, M.A. Optimally controlling electric hybrid vehicles using path forecasting. In Proceedings of the 2009 American Control Conference, St. Louis, MO, USA, 10–12 June 2009.

- Geering, H.P. Optimal Control with Engineering Applications; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Gamma Technologies. GT-SUITE User Manual. GT-SUITE Optimisation Manual, version 2016; Gamma Technologies: Westmont, IL, USA, 2015. [Google Scholar]

| Vehicle | type | Siemens Desiro VT642 |

| number PUs | 2 | |

| operating weight | 83,000 kg | |

| Engine | type | MTU 6H1800R85LP |

| number cylinders | 6 | |

| rated power | 390 kW | |

| rated speed | 1800 rpm | |

| Motor/Generator | type | p. magnet synchron. motor |

| rated power | 200 kW (continuous) | |

| rated speed | 1600 rpm | |

| Gearbox | type | ZF EcoLife |

| number gears | 6 | |

| Battery | type | Lithium-ion battery |

| nom. voltage | 670 V | |

| nom. capacity | 90 Ah | |

| max./min. current | +/-300 A |

| Parameter | Symbol | Unit | Value |

|---|---|---|---|

| Vehicle mass | kg | 83,000 | |

| Track coefficient | - | 0.001 | |

| Drag coefficient | - | 0.8 | |

| Frontal area | m2 | 10.8 | |

| Dynamic roll radius | m | 0.38 | |

| Differential ratio | - | 2.59 | |

| Differential efficiency | - | 0.95 |

| Drive Event | Operation Mode | ||||

|---|---|---|---|---|---|

| Acceleration | Pure ICE | ++ | ++ | - | 0 |

| Combined Mode | ++ | + | + | - | |

| Cruising | Pure ICE | + | + | - | 0 |

| Pure Electric | + | 0 | + | - | |

| Combined Mode | + | + | + | - | |

| Charge Mode | + | ++ | - | + | |

| Deceleration | Recuperation | -- | + | -- | + |

| Halt | Normal Halt | 0 | + | - | 0 |

| Start/Stop | 0 | 0 | 0 | - | |

| Charge Mode | 0 | + | - | + |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schalk, J.; Aschemann, H. A Causal and Real-Time Capable Power Management Algorithm for Off-Highway Hybrid Propulsion Systems. Energies 2017, 10, 10. https://doi.org/10.3390/en10010010

Schalk J, Aschemann H. A Causal and Real-Time Capable Power Management Algorithm for Off-Highway Hybrid Propulsion Systems. Energies. 2017; 10(1):10. https://doi.org/10.3390/en10010010

Chicago/Turabian StyleSchalk, Johannes, and Harald Aschemann. 2017. "A Causal and Real-Time Capable Power Management Algorithm for Off-Highway Hybrid Propulsion Systems" Energies 10, no. 1: 10. https://doi.org/10.3390/en10010010