1. Introduction

Improved energy efficiency has become a strategic issue and represents a priority for European competitiveness [

1]. Despite the need for increasing industrial energy efficiency, studies indicate that cost-efficient energy conservation measures (a cost-efficient energy efficiency measure is defined as an investment that lowers the use of energy, and that is considered to be cost efficient according to the company’s perspective.) are not always implemented. This finding implies the existence of an “energy efficiency gap” [

2]. The energy efficiency gap is, in turn, explained by the existence of barriers to energy efficiency [

2,

3,

4]. These barriers can differ depending on sector- and region-specific conditions [

3,

5], which imply a need for sector- and region-specific studies in order to identify these barriers and promote the adoption of effective energy policies [

6]. In a recent study, it was found that small- and medium-sized enterprises (SMEs) experienced many different barriers, giving rise to great complexity when trying to implement energy-efficient measures [

7].

Even though studies have found that the size of a business has a significant effect on its adoption of environmental investments, most research has focused on large energy-intensive companies, with less attention being paid to micro- and small-sized enterprises. Large energy-intensive companies have greater incentives to improve energy efficiency since they can usually save more money, but also through their size they often have greater capacity to do so. Therefore, the barriers they face may differ from those faced by small- and medium-sized companies [

8].

SMEs usually experience greater obstacles to improving energy efficiency than larger companies. These difficulties faced by SMEs have a number of reasons. First, they are less likely to have the relevant information about energy efficient measures or the skills to implement those measures through lack of the time, resources, and expertise. Secondly, they also face higher costs per Euro in obtaining data on energy use and costs and have trouble comparing this with relevant benchmark studies. On the motivational side, energy forms a relatively small portion of the total production costs for SMEs and because of that management often pays little attention to energy efficiency. SMEs may also be difficult to target through public policy due to their heterogeneity. SMEs can also be unwilling to take risks regarding investments, especially for large projects, as they cannot afford capital losses in the same way as larger companies [

8].

Industrial SMEs comprise more than 99% of all industrial companies and are an important part of a nation’s GDP. However, in countries, like Sweden, with a high share of energy-intensive industries, the majority of industrial energy end-use does not come from the industrial SMEs. In Sweden only about 30% of the industrial energy end-use comes from industrial SMEs [

9]. Only a few international publications exist that cover improved energy efficiency in SMEs.

Due to this existing energy gap countries on national and local level have begun to look at how they can support industry in their work on increased energy efficiency and, at the same time, fulfill their environmental policy [

10]. One way of providing help has been through different policy programs related to energy efficiency. This paper investigates how municipalities can support local industry with energy efficiency and the existence of different barriers to the implementation of energy efficiency measures in the Swedish micro- and small-sized enterprises that participated in a municipal project called “Energy-Driven Business”.

Energy policies towards industrial SME and non-energy-intensive industry have been few compared with policies and programs targeting large and energy-intensive industries [

6]. Within the EU the European Climate Change Programme (ECCP) concluded that the most effective policy actions essential to fulfill the CO

2-emission reduction potentials in industrial processes are the implementation of comprehensive energy audit -and management schemes with a focus on the non-core processes, in particular in the non-energy intensive sector and SMEs. This programme should also focus on training and education of energy managers and maintenance personnel [

11].

This finding by [

11] is supported by an international study by [

12]. Here, research on industrial SMEs in Belgium, Japan, Spain, and Sweden showed that informative policies formed the main part of the countries’ energy policies towards industrial SMEs. The major informative tools that are used comprise of information campaigns, including seminars, and energy audit programs. Information campaigns have, in previous research, been shown to lead to increased awareness, but are less likely to lead to change in actual behavior, or lead to actual investments.

In the study by [

12] it was found that for medium-sized and energy-intensive industrial SMEs energy policies like long-term agreements (LTA) and voluntary agreements (VA) are effective. These are followed by energy audit programs, preferably located regionally or locally. In a Dutch study of metalworking SMEs the importance of a long-term energy strategy it was agreed upon, but VAs were not considered as a way for improving energy efficiency. For small-sized and non-energy-intensive industrial SMEs, energy audit programs are, instead, found to be the most effective energy policy, again, preferably locally or regionally anchored.

2. Policy Programmes and Their Impact on SMEs Barriers to Energy Efficiency

In Germany a project was started 2008 for SMEs with the aim of overcoming know-how deficits and other obstacles to implementing energy efficient measures. In general, the companies had between 11 and 50 employees. They were given both an initial energy audit lasting 1–2 days, and then a more detailed audit that could last up to 10 days at reduced costs. This reduced cost was seen in the project as vital in lowering the threshold for going through with energy audits. The companies had access to consultants with expert knowledge and technologies and equipment relevant to specific sectors were covered in the audits. The profitability of the recommended measure was mentioned and the consultants personally presented the audit results to the company manager. This was seen as a good way to get the companies involved and push the energy efficiency work further. On average, each company implemented around half of the recommended measures found in the audits [

13].

On a more local level Project Highland, which, in terms of participating companies, is the largest Swedish energy program since 1990, has been implemented. The focus in this project was on giving the local industry free energy audits in order to lower barriers and increase energy efficient measures. This project aimed at small and medium-sized industries with an average energy use of about 4000 MWh/year. Here the companies received a one day energy audit but no investment assessments. At the end of the project, 20% of the measures had been implemented, 40% if which include planned measures [

14].

Although not much research exists on the adoption of energy technologies and management practices in non-energy-intensive sectors, the results indicate that cost-saving energy conservation proposals are perceived as risky and capital intensive and may, therefore, be uninteresting to managers [

6]. Some studies on SME involvement in energy efficiency programs argue that lack of capital and insufficient information are two of the main barriers to adopting energy efficiency measures [

15,

16]. Shipley and Elliott [

17] studied barriers in the form of how industrial managers in SMEs made energy-related decisions. They found that energy is just one of many concerns for an industrial manager. From this finding, they concluded that SMEs require much more help to implement cost-efficient energy efficiency measures. This help would optimally involve a combination of education, prescriptive recommendations, and implementation assistance. In another study of German SMEs, reference [

15] concluded that a lack of capital was the only statistically significant barrier. In an Australian survey of micro to small SMEs [

18], it was found that these enterprises were reluctant to make high-cost technology changes, as cost remained a major barrier—supporting the research described above—and/or that renting premises might hinder energy-efficient measures, a finding that is related to split incentives, according to [

3].

Barriers to Energy Efficiency in Swedish SMEs at the Regional and Local Level

Research on improved energy efficiency in SMEs at the regional and local level has also been done in Sweden, but this research is not extensive, and studies involving micro-enterprises are even fewer in number. On examination of these existing studies, the major barriers to energy efficiency were found to be: a lack of time or having other priorities for capital investments; a lack of access to capital or lack of budget funding; cost of production disruption; technical risks, such as the risk of production disruptions; and the difficulty/cost of obtaining information on the energy use of purchased equipment [

9,

14,

19]. Apart from barriers concerning costs and technical risks in the form of production disruptions, other barriers that were found indicated a need for external support (lack of time and other priorities), a need for this support to be of low cost (lack of access to capital), and a need for it to involve the provision of information to the companies (difficulty/cost of obtaining information) [

9,

14,

19]. These studies also found a possible need for other types of external support, such as support from energy service companies (ESCOs) complementing the provision of energy audits in an industrial energy program.

3. The Case and Methodology

This study involves SMEs that have been part of a project in which a relatively small Swedish municipality addressed energy efficiency in 60 local businesses in order to fulfill a local political vision. The municipality has ambitious environmental goals, and gave the environmental office in 2011 the mandate to proceed with a project named “Energy-Driven Business Concern” for the environment and the opportunity to increase the competitiveness of local business were both important reasons in the initiation of this project. The project focused on improving energy efficiency in micro- and small-sized enterprises that used 500 MWh of total energy end-use per year or less. In this municipality, local business is dominated by industrial manufacturing, although trade is also important. The municipality had earlier experienced the problem described above, of companies not investing in energy efficiency even though there was money to be made from such measures [

20].

“We see that there is a gap between energy audits and actual investment. We want to lower barriers that hinder actual investment.”

—Municipal Environmental Strategist

One starting point for the municipal project was that the companies seemed to be more concerned with other capital investments over energy efficiency measures. At the start of the project, it was calculated that several of the companies could save up to 20% in energy costs with the use of simple and cheap measures. To overcome this apparent paradox, the municipality worked to motivate the enterprises by lowering thresholds for them, such as the lack of time and knowledge. This was done by providing a person hired by the municipality, who devoted his time to analyzing possible energy-efficient measures in the companies, providing free energy audits, and helping the companies develop investment plans. The municipality also provided an engaged project leader who was passionate about energy efficiency and who, by his enthusiasm, tried to help the companies to move forward.

The municipal project lasted from 2012 to 2015. The data was collected in 2016, about 1.5–2 years after the companies had participated in this project.

Most of the companies involved in the municipal project were micro- and small-sized enterprises. The focus of micro-companies makes this paper one of very few studies that explore barriers to energy efficiency for Swedish micro- and small-sized enterprises that uses 500 MWh of electrical energy per year or less.

3.1. Data Collection

This exploratory study was carried out as a case study [

21] using semi-structured interviews [

22] during spring–summer 2016. A questionnaire was used to enable an understanding of what factors where perceived as barriers to energy efficiency by local industry in a Swedish municipality.

The questionnaire was used in order to be able to compare the results with earlier research that had used the same form regarding barriers to energy efficient measures [

9,

19,

23]. For a more thorough presentation of the questionnaire, see

Appendix A.

The chosen target group for the questionnaire was already decided within the boundaries of my research project. The group consisted of 60 local companies who had been active in a project called “Energy-Driven Business” run by a municipality regarding energy efficient measures funded by the Swedish Energy Agency (SEA). The companies in the study were micro- and small-sized enterprises working in different sectors and using 500 MWh/year of energy or less. The companies, employing between 1 and 60 people, were of a wide variety including, among others, farmers, garden centers, grocery stores, and smaller industrial manufacturing companies. The list containing contact information of those 60 companies that were involved in the project, was provided to me by the municipal representative who was also the project leader.

My sample was, therefore, selected in line with a theoretical sampling process commonly used in qualitative research [

24,

25]. This type of sampling is a form of analytical sampling and the results can therefore not be used for statistical generalization. This means that the selection of companies are not statistically representative of the total population of Swedish micro- and small-sized enterprises. However, as the purpose of this study is to extend our understanding of the barriers that local companies in a municipality experience when attempting to increase their energy efficiency, the aim is theoretical and analytical generalization instead of statistical. Theoretical sampling is appropriate to select companies that are suitable to contribute to “discover categories, properties, and interrelationships that will extend the theory” [

26].

I first contacted the companies by email, with a short introduction regarding my research, and then followed up by phone. In the end 27 companies responded to my emails and phone calls and were subsequently interviewed by phone. Interviews were chosen because they give the opportunity to explain questions, and because both the interviewer and the respondents can ask for clarifications. The informants can also elaborate more freely on their answers and can give unpredictable comments that go beyond the assumptions in the questionnaire [

27].

The people I interviewed where either a managing director, owner, or the person responsible for their energy work. Twenty-two of the respondents answered all of my questions, including the questionnaire. The other five did not want to answer the questionnaire and only gave short answers to my more general background questions (see

Appendix A). In order to evaluate the answers from all the questionnaires, a Likert scale was used, ranging from 1 to 5: (1) disagree; (2) partly disagree; (3) neutral; (4) partly agree; and (5) agree. For a more thorough list of how the companies perceived barriers, see

Table B1 in

Appendix B.

Throughout all of the interviews, a structured and fixed set of questions was used. The questions were always presented to the respondent in a fixed order, making it possible to both replicate the interview and later compare the information from all the interviews. Using a fixed set of questions is important if the researcher is unable to interview the informant more than once and, therefore, is not likely to be repeat the interview. Presenting the questions in a fixed order also helps to limit so-called context effects since preceding questions can influence the interpretation of subsequent questions. This, in turn, can influence which information respondents divulge during the interview [

28,

29].

The interviews were divided into two parts. First, each respondent was asked open questions regarding economic information, what they had done after the audit, and what drives their energy efficiency work. Next, a session took place in which the respondents were asked to answer a questionnaire covering various aspects of barriers to energy efficiency. Each interview lasted, in general, between 15 and 20 min, depending on how much each company had done after the energy audit.

3.2. The Use of Barriers as an Analytical Tool

According to [

3], “a barrier is a mechanism that inhibits a decision or behavior that appears to be both energy-efficient and economically efficient”. Such barriers are claimed to prevent companies from investing in energy-efficient technologies.

The barriers referred to in the questionnaire (see

Appendix B,

Table B1) are based on scientific literature [

2,

3,

4,

6,

30,

31,

32,

33,

34,

35,

36,

37,

38,

39]. Even though several classifications of barriers exist, the use of models can provide insight into technical and social aspects of energy consumption and how they are linked to each other [

39].

Thollander et al. [

40] discuss how barriers are a dominating analytical framework in understanding the energy efficiency gap, and state that this framework has many merits. At the same time, it is important to take a critical view of the barrier theory and to discuss its delimitations and possible development paths. Therefore, identified barriers must be used in different ways in order to challenge existing definitions and develop new, creative ways of approaching companies and other actors [

41]. It is also essential to put greater focus on company culture; how companies relate to, for example, suggested energy-efficient measures in energy audits; and how they perceive and understand the existence of barriers to these measures [

13]. To obtain such insights, interviews should be conducted in such a way that the informants are free to express themselves and share their reflections on, and interpretations of, barriers; therefore, this style of interview was chosen for this study.

As mentioned above, the classification of barriers may be somewhat ambiguous. One type of real-world phenomena may be explained by several of the barriers presented. Many of the barriers expressed by respondents also fit into more than one of the theoretical categories of barriers. I categorized the respondents’ answers in relation to how the informants were motivated by, and discussed, a barrier; this categorization usually made a phenomenon fit better in relation to the description of a certain barrier.

It should also be noted that simplifications are made when quantifying barriers. The quantified results contain several perspectives on the issue other than receiving a single score on a ranking, and the objectivity of a single score on a ranking can be questioned. However, this ranking has worked well as a way to assess whether a barrier is regarded as more or less important in relation to another barrier. Nevertheless, this uncertainty must be kept in mind when drawing conclusions from these types of studies [

19]. The barriers in this study include behavioral, organizational, and economic barriers [

39].

4. Results: Experienced Barriers in Micro- and Small-Sized Enterprises

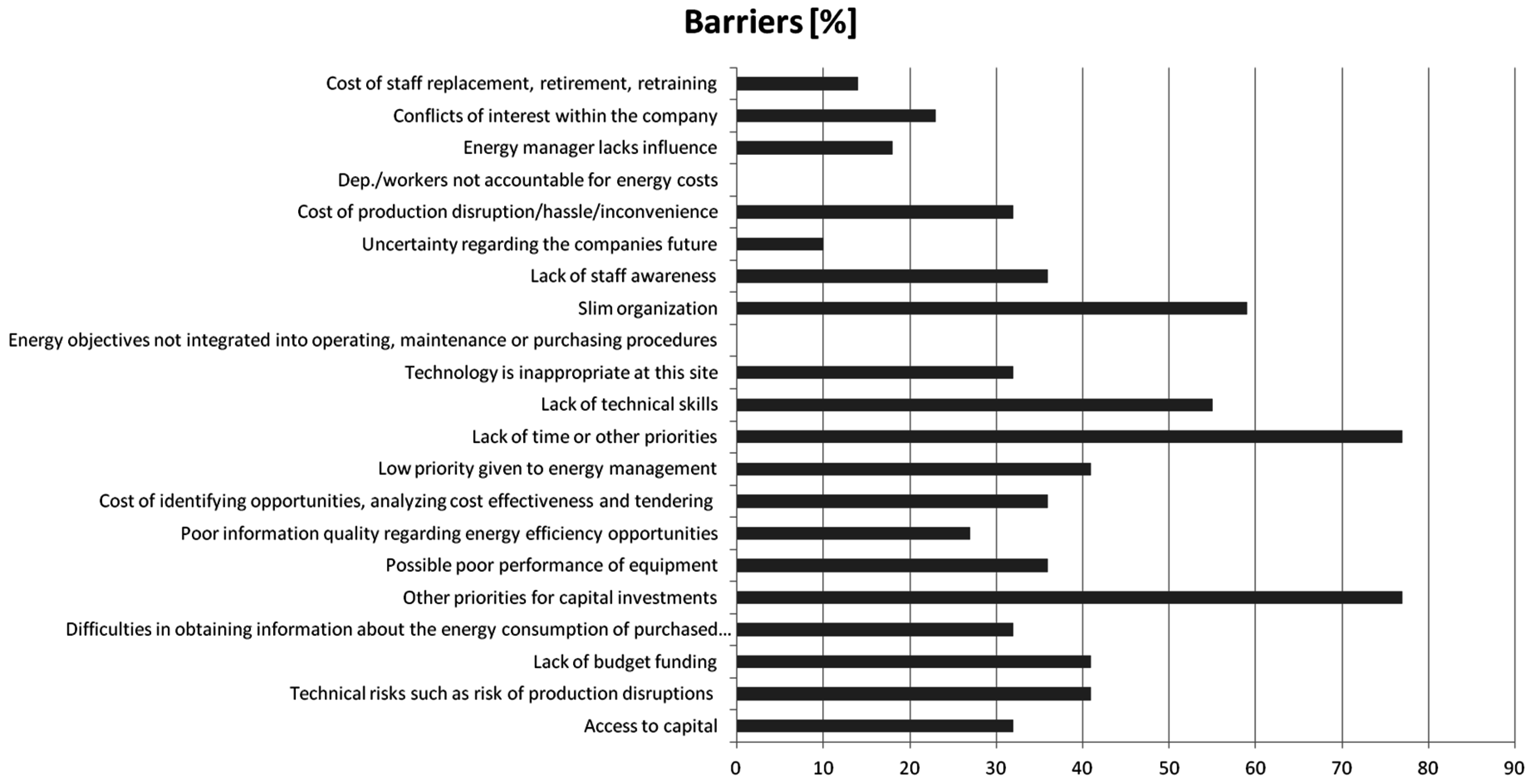

The respondents verified the existence of barriers to energy efficiency (

Figure 1). In response to four of the 21 graded questions, more than 50% of the respondents claimed that the stated barrier was important in explaining the existence of an energy efficiency gap at their company. Answers to the other questions showed a more complex picture of barriers, and several of the respondents felt that many barriers were dependent on each other and therefore difficult to rank individually (compare with [

42]). Respondents from all companies claimed that cost-efficient energy efficiency measures were available for their company, verifying the existence of an energy efficiency gap. When asked why they worked with energy efficiency, all but three companies said that increased profit in the form of lowered energy costs was their major driving force.

4.1. Risk

The results from this study show that, among the studied companies, all but one showed net profits and several of the companies had their order books filled. Uncertainty regarding the company’s future was, therefore, not considered a major issue among the studied companies at present, although some of the companies would consider it a barrier to energy efficiency if they do run into financial difficulties or have an uncertain future.

Technical risks, such as the risk of production disruptions and possible poor performance of equipment, were seen as possible technological barriers, especially for those companies that had filled their order books and were working overtime to fulfill customer requests. Under more normal circumstances, companies did not consider these to be major barriers and thought that, with some planning, these types of disruption could be avoided. Another barrier associated with those described above was inappropriate technology for the company. A technology or measure can be cost-efficient in general, but may not be so in all cases. This issue was raised in connection with the municipal project when all 60 energy audits were studied in an attempt to find common energy-efficient measures for all the companies involved in order to obtain economy of scope in a future purchase. One such common measure was the purchase of light-emitting diode lighting (LED), which would enable almost all companies to save energy, and which was considered cost efficient according to the company’s investment criteria. This solution could have been much cheaper if all the companies had bought the product. However, after testing on site, it was found that LED lighting was not suitable for many companies, due to bad lighting as compared with older lighting or because other costs made it more expensive. Although this example may be used as an explanation for the avoidance of some energy-efficient technologies in special cases, it does not explain the low adoption of energy efficiency technologies at the studied companies.

4.2. Imperfect Information

Barriers that were related to imperfect information, such as the cost of obtaining information regarding opportunities or analyzing cost effectiveness, is of interest because, according to economic theory, this kind of barrier may constitute a market/organizational failure. This may be interpreted as a justification for the municipality’s information activities concerning free energy audits and investment plans. Of the companies, 59% lacked a long-term strategy for energy use. Instead, they carried out investments in a less formalized fashion. Several of the companies said that they make a decision when the issue is raised by someone in the organization, such as the energy manager. Here, a connection to another barrier can be seen: low priority given to energy management.

Another barrier that may be termed organizational failure is slim organization. Slim organization is a term which, implicitly, is often a result of a company’s focus on core business. This means that non-core areas, such as improved energy efficiency, are often organizationally structured with a minimum of staff and are therefore perceived as “slim”. In this study, 59% of the companies saw it as a major barrier that hindered their work with energy efficiency. Slim organization may be another barrier that is dependent on something else, such as lack of technical skill regarding energy-efficient technology, which 55% of the companies regarded as a major barrier. For example, one respondent in the food retail business, who is both the owner and energy manager and can be considered to have a very slim organization, took the energy audit to heart. He saw the cost-saving potential and invested around 8000 EUR in an extra and more thorough energy audit. He was so successful with his cost reductions that it won him an energy efficiency award from the municipal energy company. This example is indicative of a behavioral part coming from bounded rationality, meaning that it can fit into more than one theoretical barrier. Many of the companies expressed a notion that they did not look at energy differently from any other budget line.

Minor barriers included in imperfect information were difficulties in obtaining information about the energy consumption of purchased equipment, poor information quality regarding energy efficiency opportunities, and lack of staff awareness regarding energy efficiency.

4.3. Hidden Costs

Barriers in the form of hidden costs (i.e., cost of production disruption/hassle/inconvenience; cost of identifying opportunities, analyzing cost effectiveness, and tendering; and cost of staff replacement, retirement, and retraining) were found to be only minor barriers to energy efficiency.

4.4. Access to Capital

It should be noted that, with regard to formal investment criteria, 55% of the companies did not have a special pay-off criteria for energy-efficient investments, and only 19% had a pay-off of less than two years for energy-efficient investments.

Other studies have found that limited access to capital may constitute a substantial barrier to energy efficiency [

3]. In this study, however, limited access to capital was not considered a major barrier. This finding may partly be explained by the fact that several of the companies in the study are successful businesses. Although limited access to capital was not considered a significant barrier in this study, capital is a prerequisite for carrying out investments. Companies also considered that even though energy efficiency was usually not specifically in the budget, they did not have any problems getting funding for energy-efficient measures from the owners if there was a need for them.

4.5. Split Incentives

Regarding split incentives, all of the respondents claimed that production-related issues have higher priority than energy-related issues, meaning that other priorities for capital investments were definitely seen as a major barrier. Many respondents said that this barrier could, together with a lack of time and slim organization, be dependent on each other and were, therefore, difficult to rank individually.

Other barriers, such as the energy manager lacking influence and conflicts of interest within the company, were seen as only minor barriers. Conflict of interest can also exist with external actors, affecting the company. For example, some of the companies did not own their facilities; therefore, renting premises might hinder energy-efficient measures. One company said that this conflict made them change facilities in order to lower their costs, since the owner was not interested in upgrading for energy efficiency. The theoretical barrier of departments and/or workers not being accountable for energy costs was not regarded by any of the interviewees to be a barrier, which is in line with earlier research on barriers [

23].

After the project was done, 67% of the companies implemented some type of measure. In general, these measures were relatively minor, such as changes in lighting, installing light sensors, or adjusting compressors or pumps. These are standard solutions and must be considered common knowledge nowadays. Very few of the companies undertook measures that required specialist knowledge or skills. From this perspective, it can be concluded that the supply of energy efficiency services in this form does not result in more significant energy efficiency improvements, as was hoped for from the start of the project. There is, however, one positive aspect: the micro- and small-sized enterprises in the study gained help in obtaining information regarding energy efficiency measures for their support installations (consisting of lighting, ventilation, and compressed air), possibly making it easier for them to make the actual investments. Studies have shown that information should be specific, personal, vivid, and simple in order to increase its chances of being accepted [

3]. All of the respondents claimed that the information provided by the energy audit reports was satisfactory, and that less information would have been gained about possible efficiency measures for these installations without the free energy audit. Even so, some felt that the energy audits and investment plans lacked insight into what micro- and small-sized enterprises can actually do. One respondent was very annoyed with both the energy audit, which he did not understand, and the investment plan, which he thought was impossible for a micro-sized enterprise to actually implement.

4.6. Bounded Rationality

The overall results from the questionnaire show that lack of time and/or having other priorities for capital investments constitute by far the largest barriers to energy efficiency. Of the interviewees, 77% said that lack of time concerning energy efficiency or other priorities was seen as a barrier. Other studies have identified the low status of energy management as a barrier to energy efficiency [

3]. This study, however, found no evidence that this was a major barrier. In many cases, the findings in this study indicated the opposite, since the companies were micro- or small-sized, so that the energy manager worked in a very close relationship with the executive manager, or held both roles.

The issue of energy objectives not being integrated into operating, maintenance, or purchasing procedures was not seen by any company to be a barrier.

5. Concluding Discussion

This paper has added new insights to the subject of understanding barriers to energy efficiency in the non-energy-intensive sector. The major barriers to energy efficiency found in this study were: lack of time and/or other priorities and having other priorities for capital investments, followed by slim organization and lack of technical skills. According to [

3], constraints on time, attention, and the ability to process information will hinder companies from making economically optimal decisions; this can explain why many of the companies in this study did not do anything after the energy audit and investment plans.

Except for lack of technical skill, these major barriers may be difficult to overcome by means of municipal energy policies or by information campaigns, such as free energy audits, investment plans, or collective buying of energy-efficient technologies, since these barriers are related to difficulties within the organizations. Instead, company-oriented policy instruments, such as striving for long-term energy strategies and energy and environmental management systems, are more likely to encourage energy efficiency investments [

19]. The most important driver for energy-efficient measures was found to be cost reduction, something to keep in mind for energy policies in the future.

These findings are important for future work with energy efficiency because most of the major barriers may be classified as behavioral/organizational failures; therefore, they justify policy interventions within organizations. This also confirms [

11] findings that most of the focus should be put on non-core processes. However, this also indicates that the barriers found in these local companies cannot be easily solved through governmental or municipal energy policy activities, at least not such policies designed in traditional ways. This also suggests that there is a role to play for local efforts experimenting with different ways to approach local industries. Even if the municipal energy efficient project studied here was not overwhelmingly successful lessons can be drawn for future local initiatives.

The involved companies said that information related to what could be done to increase energy efficiency in the organization was the main thing that they obtained from participating in the project initiated by the municipality. Information coming from the government-sponsored energy audits was generally seen as something positive that gave companies relevant information for future energy efficiency work, and that acted as an “eye-opener” for the company. At the same time, the results confirm findings in earlier research that information from the audits are necessary, but more is needed when it comes to actual implementation [

14]. Most of the implemented energy-efficient measures were not related to the energy audit and were done regardless of the audit.

Relating the results of this study to previous research, it is clear that the lack of access to capital/lack of budget funding, technical risks, such as risk of production disruptions, lack of time and other priorities (indicating a need for external support), and other priorities for capital investments, are also considered barriers in this study. A more telling result of this study is, perhaps, the indication that slim organization and lack of technical skills are considered major barriers that hinder energy-efficient investments, relating to research about how the size of a company affects its work with energy efficiency [

8]. To develop decision-tools and management processes that can easily travel between organizations, which support micro- and small-sized enterprises in decision-making in relation to investment in energy efficient investments are a challenge for the future. In this development local authorities together with the micro- and small-sized enterprises can play important roles to try out and experiment with different tools. Then there is also a need for national meeting arenas where the experiences of local authorities and companies can be shared and discussed to strengthen learning processes that develop from these local projects.

6. Conclusions

In relation to the barrier-model outlined by [

3] and used here, the results show that major explanatory factors relating to the non-implementation of cost-effective energy efficiency measures among micro- and small-sized industrial enterprises were imperfect information (slim organization and lack of technical skill) and split incentives (lack of time and/or other priorities and other priorities for capital investments). Barriers to energy efficiency that were considered minor included access to capital, hidden costs, and bounded rationality.

In line with the findings of [

7], this paper also found support for the idea that voluntary municipal energy efficiency programs should be flexibly designed and implemented in order to accommodate the many and various barriers. Factors driving companies’ work should be emphasized and barriers should be identified upfront so that policy programs can be tailored to the often varied needs of SMEs. For example, a segmentation of companies according to size could be one such measure.

When comparing the Energy-Driven Business-Project with Project Highland [

14] and the German version [

13] important lessons can be learned. First of all, an audit needs to be done in a context with detail and, for the specific company, with relevant measures that are in line with their economic means. Secondly, the only output cannot be only a report handed over with no explanation. Instead a forum for discussion and questions must be created so that the companies are actively involved in the process and not just silent bystanders.