Sensor Fault Diagnosis for Aero Engine Based on Online Sequential Extreme Learning Machine with Memory Principle

Abstract

:1. Introduction

2. Review of Online Sequential Extreme Learning Machine (OS-ELM)

- (1)

- Assign learning parameters randomly, and set ;

- (2)

- Compute and ;

- (3)

- Compute corresponding to (k + 1)-th data chunk as Equation (13);

- (4)

- Calculate iteratively as Equations (15) and (16);

- (5)

- If the new data chunk comes, then let and skip to the third step. Otherwise, let to be the last iteration value ;

- (6)

- Compute .

3. Proposed Online Sequential Extreme Learning Machine with Memory Principle (MOS-ELM)

3.1. Formula Derivation

- (1)

- Assign learning parameters randomly, and set ;

- (2)

- Compute and as Equations (9) and (10);

- (3)

- Compute corresponding to (k + 1)-th chunk as Equation (13);

- (4)

- Calculate iteratively as Equations (19)–(21);

- (5)

- If the new data chunk comes, then let and skip to the third step. Otherwise, let be the last iteration value ;

- (6)

- Compute .

3.2. Evaluation Test

4. Sensor Fault Diagnosis for Aero Engines

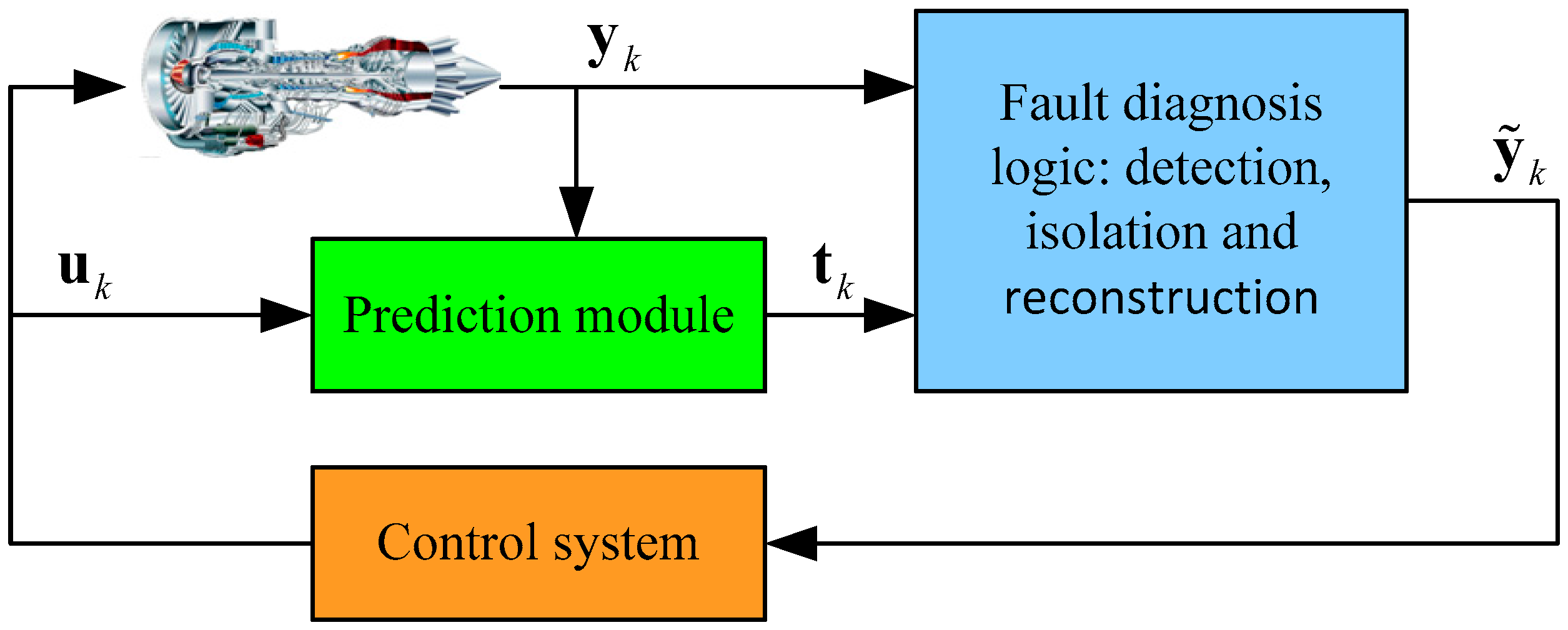

4.1. Diagnosis Method

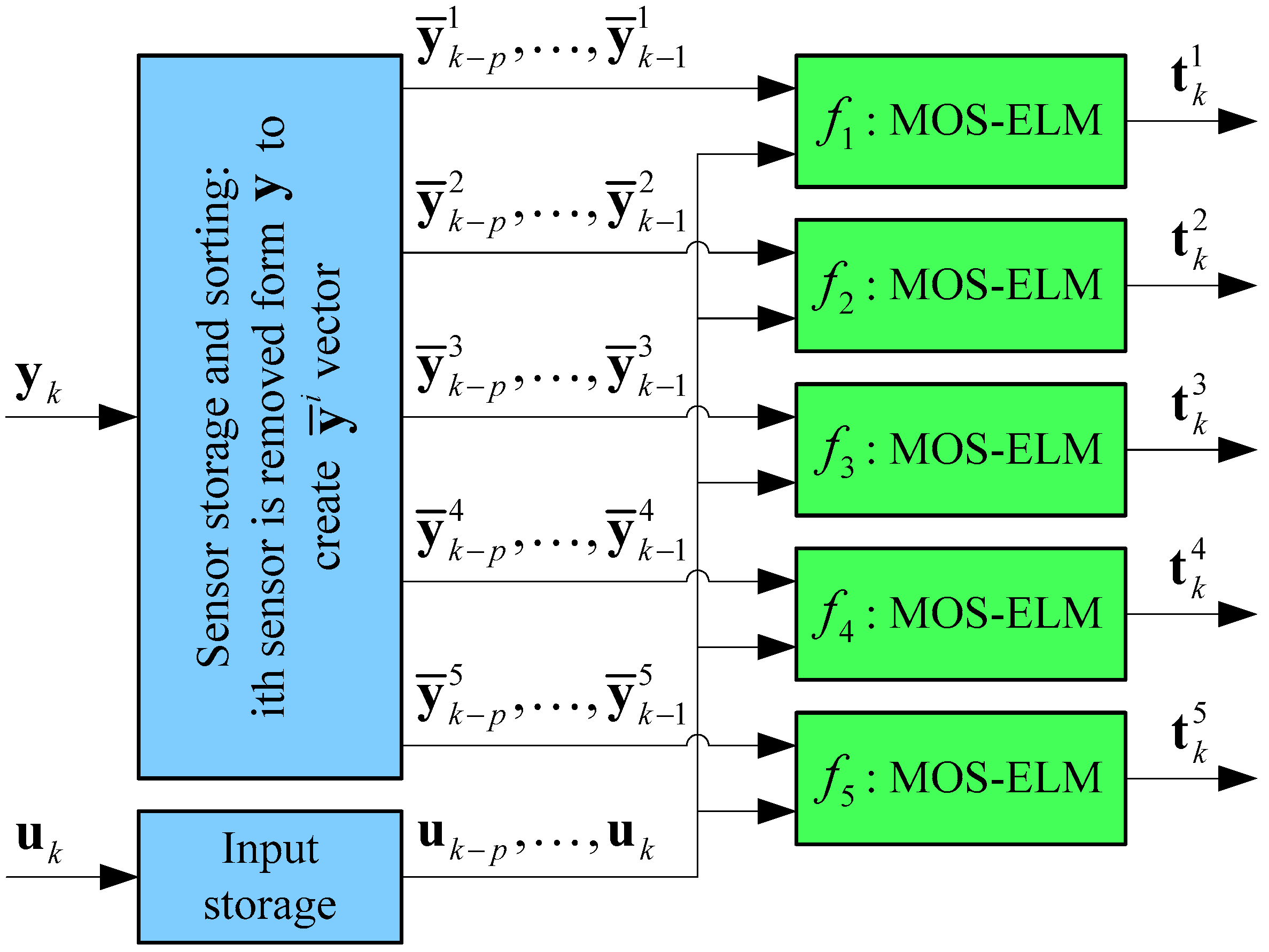

4.2. Diagnosis System for Sensor

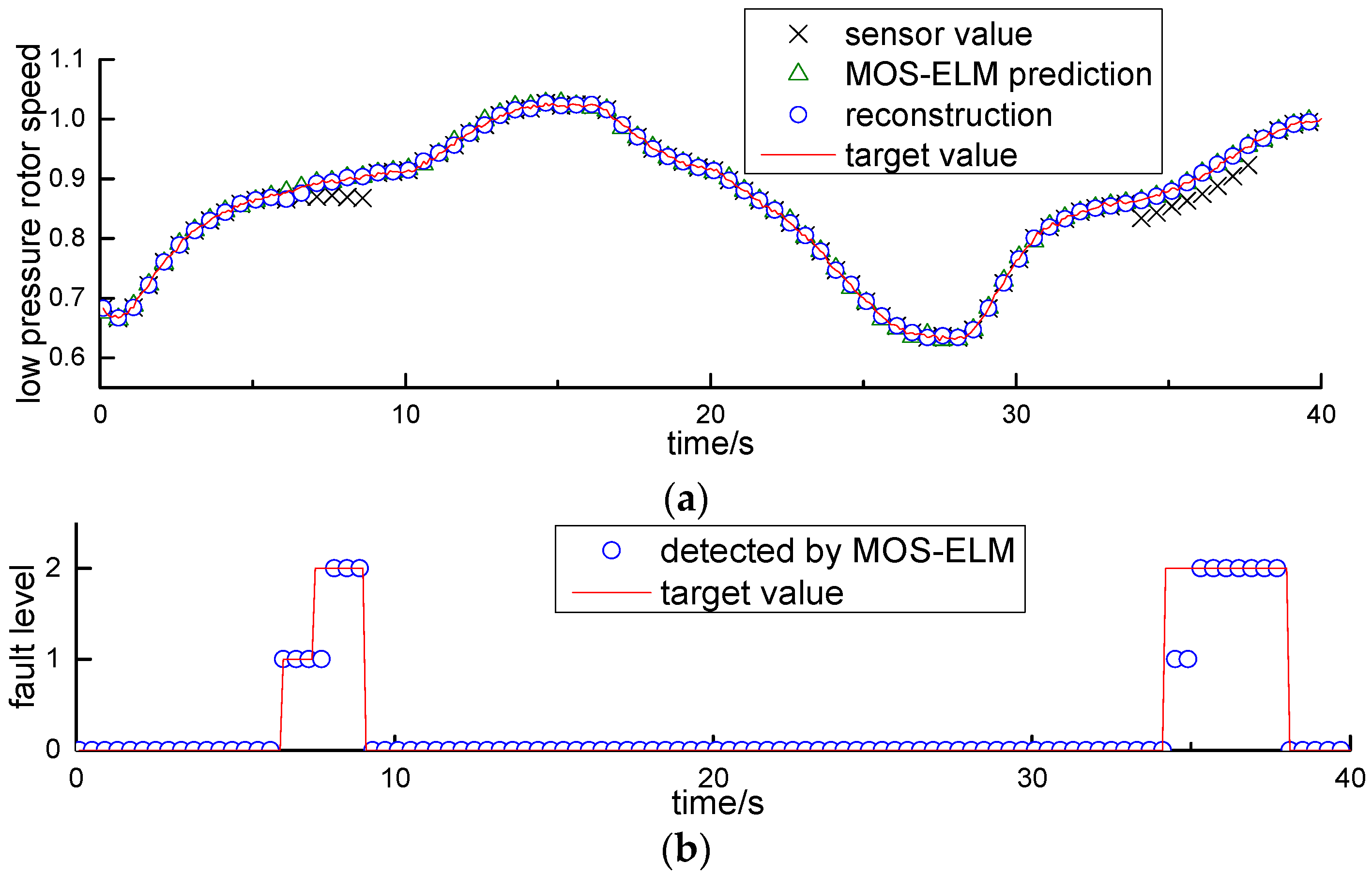

4.3. Statistical Performance for Different Fault Mode

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Litt, J.S.; Simon, D.L.; Garg, S.; Guo, T.H.; Mercer, C.; Millar, R.; Behbahani, A.; Bajwa, A.; Jensen, D.T. A survey of intelligent control and health management technologies for aircraft propulsion systems. J. Aerosp. Comput. Inf. Commun. 2005, 1, 543–563. [Google Scholar] [CrossRef]

- Jaw, L. Recent advancements in aircraft engine health management (EHM) technologies and recommendations for the next step. In Proceedings of the ASME Turbo Expo 2005: Power for Land, Sea and Air, Reno, NV, USA, 6–9 June 2005.

- Patton, R.J.; Chen, J. Robust fault detection of jet engine sensor systems using eigenstructure assignment. J. Guid. Control Dyn. 1992, 15, 1491–1497. [Google Scholar] [CrossRef]

- Hwang, I.; Kim, S.; Kim, Y.; Seah, C.E. A survey of fault detection, isolation, and reconfiguration methods. IEEE Trans. Control Syst. Technol. 2010, 18, 636–653. [Google Scholar] [CrossRef]

- Chow, E.Y.; Willsky, A.S. Analytical redundancy and the design of robust failure detection systems. IEEE Trans. Autom. Control 1984, 29, 603–614. [Google Scholar] [CrossRef]

- Willsky, A.S. A survey of design methods for failure detection in dynamic systems. Automatica 1976, 12, 601–611. [Google Scholar] [CrossRef]

- Wallhagen, R.E.; Arpasi, D.J. Self-Teaching Digital-Computer Program for Fail-Operational Control of a Turbojet Engine in a Sea-Level Test Stand; Report No. NASA/TM-X-3043; National Aeronautics and Space Administration, Glenn Research Center: Washington, DC, USA, 1974.

- Bras, S.; Rosa, P.; Silvestre, C.; Oliveira, P. Fault detection and isolation in inertial measurement units based on bounding sets. IEEE Trans. Autom. Control 2015, 60, 1933–1938. [Google Scholar] [CrossRef]

- Lu, F.; Chen, Y.; Huang, J.Q.; Zhang, D.; Liu, N. An integrated nonlinear model-based approach to gas turbine engine sensor fault diagnostics. Proc. Inst. Mech. Eng. G J. Aerosp. 2014, 228, 2007–2021. [Google Scholar] [CrossRef]

- Bahareh, P.; Meskin, N.; Khorasani, K. Sensor fault detection, isolation, and identification using multiple-model-based hybrid Kalman filter for gas turbine engines. IEEE Trans. Control Syst. Technol. 2016, 24, 1184–1190. [Google Scholar]

- Escobar, R.F.; Astorga-Zaragoza, C.M.; Hernandez, J.A.; Juarez-Romero, D.; Garcia-Beltran, C.D. Sensor fault compensation via software sensors: Application in a heat pump’s helical evaporator. Chem. Eng. Res. Des. 2015, 93, 473–482. [Google Scholar] [CrossRef]

- Mattern, D.L.; Jaw, L.C.; Guo, T.H.; Graham, R.; McCoy, W. Using neural networks for sensor validation. In Proceedings of the 35th AIAA/ASME/SAE/ASEE Joint Propulsion Conference, Cleveland, OH, USA, 12–15 July 1998.

- Sadough-Vanini, Z.N.; Meskin, N.; Khorasani, K. Multiple-model sensor and components fault diagnosis in gas turbine engines using autoassociative neural networks. J. Eng. Gas Turbines Power 2014, 136, 76–82. [Google Scholar] [CrossRef]

- Torella, G.; Torella, R. Probabilistic expert systems for the diagnostics and trouble-shooting of gas turbine apparatuses. In Proceedings of the 35th AIAA/ASME/SAE/ASEE Joint Propulsion Conference, Los Angeles, CA, USA, 20–24 June 1999.

- Garg, S.; Schadow, K.; Horn, W.; Pfoertner, H.; Stiharu, I. Sensor and actuator needs for more intelligent gas turbine engines. In Proceedings of the GT2005 ASME Turbo Expo 2010: Power for Land, Sea and Air, Glasgow, UK, 14–18 June 2010.

- Bahareh, P.; Meskin, N.; Khorasani, K. Sensor fault detection and isolation using multiple robust filters for linear systems with time-varying parameter uncertainty and error variance constraints. In Proceedings of the 2014 IEEE Multi-Conference on Systems and Control, Antibes, France, 8–10 October 2014.

- Kobayashi, T.; Simon, D.L. Evaluation of an enhanced bank of Kalman filters for in-flight aircraft engine sensor fault diagnostics. J. Eng. Gas Turbines Power 2014, 127, 635–645. [Google Scholar]

- Saravanakumar, R.; Manimozhi, M.; Kothari, D.P.; Tejenosh, M. Simulation of sensor fault diagnosis for wind turbine generators DFIG and PMSM using Kalman filter. Energy Procedia 2014, 54, 494–505. [Google Scholar] [CrossRef]

- Sadough-Vanini, Z.N.; Khorasani, K.; Meskin, N. Fault detection and isolation of a dual spool gas turbine engine using dynamic neural networks and multiple model approach. Inf. Sci. 2014, 259, 234–251. [Google Scholar] [CrossRef]

- Tayarani-Bathaie, S.S.; Khorasani, K. Fault detection and isolation of gas turbine engines using a bank of neural networks. J. Process Control 2015, 36, 22–41. [Google Scholar] [CrossRef]

- Shah, B.; Sarvajith, M.; Sankar, B.; Vijayendranath, V. Fault identification, isolation, estimation of sensor measurement using auto associative neural network for aero-engine. In Proceedings of the National Conference on Condition Monitoring, Chennai, India, 12–13 December 2014.

- Ogaji, S.O.T.; Singh, R.; Probert, S.D. Multiple-sensor fault-diagnoses for a 2-shaft stationary gas-turbine. Appl. Energy 2002, 71, 321–339. [Google Scholar] [CrossRef]

- Xu, L.; Cai, T.; Deng, F. Sensor fault diagnosis based on least squares support vector machine online prediction. In Proceedings of the 2011 IEEE 5th International Conference on Robotics, Automation and Mechatronics (RAM), Qingdao, China, 17–19 September 2011.

- Zhang, S.; Li, Y. Simulation research on FLS_SVM in sensor fault diagnosis. In Proceedings of the 2011 International Conference on Electronic & Mechanical Engineering and Information Technology, Harbin, China, 12–14 August 2011.

- Huang, G.B.; Zhu, Q.Y.; Siew, C.K. Extreme learning machine: A new learning scheme of feedforward neural networks. In Proceedings of the International Joint Conference on Neural Networks (IJCNN), Budapest, Hungary, 25–29 July 2004.

- Huang, G.B.; Chen, L.; Siew, C.K. Universal approximation using incremental constructive feedforward networks with random hidden nodes. IEEE Trans. Neural Netw. 2006, 17, 879–892. [Google Scholar] [CrossRef] [PubMed]

- Huang, G.B.; Zhou, H.M.; Ding, X.J.; Zhang, R. Extreme learning machine for regression and multiclass classification. IEEE Trans. Syst. Man Cybern. B 2012, 42, 513–529. [Google Scholar] [CrossRef] [PubMed]

- Liang, N.Y.; Huang, G.B.; Saratchandran, P.; Sundararajan, N. A fast and accurate online sequential learning algorithm for feedforward networks. IEEE Trans. Neural Netw. 2006, 17, 1411–1423. [Google Scholar] [CrossRef] [PubMed]

- Wang, N.; Er, M.J.; Han, M. Parsimonious extreme learning machine using recursive orthogonal least squares. IEEE Trans. Neural Netw. Learn. 2014, 25, 1828–1841. [Google Scholar] [CrossRef] [PubMed]

- Deng, C.Y. A generalization of the Sherman-Morrison-Woodbury formula. Appl. Math. Lett. 2011, 24, 1561–1564. [Google Scholar] [CrossRef]

- EI-Sayed, A.M.; Salman, S.M.; Elabd, N.A. On a fractional-order delay Mackey-Glass equation. Adv. Differ. Equ. 2016, 2016, 1–11. [Google Scholar]

- Berezowski, M.; Grabski, A. Chaotic and non-chaotic mixed oscillations in a logistic systems with delay. Chaos Solitons Fractals 2002, 14, 97–103. [Google Scholar] [CrossRef]

- Sunspot Index and Long-Term Solar Observations. Available online: http://www.sidc.be/silso/DATA/SN_m_tot_V2.0.txt (accessed on 10 June 2016).

- Lu, F.; Huang, J.Q.; Xing, Y.D. Fault Diagnostics for Turbo-Shaft Engine Sensors Based on a Simplified On-Board Model. Sensors 2012, 12, 11061–11076. [Google Scholar] [CrossRef] [PubMed]

- Kobayashi, T.; Simon, D.; Litt, J.S. Application of a constant gain extended Kalman filter for in-flight estimation of aircraft engine performance parameters. In Proceedings of the GT2005 ASME Turbo Expo 2005: Power for Land, Sea and Air, Reno, NV, USA, 6–9 June 2005.

- Zhou, J.; Liu, Y.; Zhang, T.H. Analytical redundancy design for aeroengine sensor fault diagnostics based on SROS-ELM. Math. Probl. Eng. 2016, 2016, 8153282. [Google Scholar] [CrossRef]

- Azad, A.K.; Rasul, M.G.; Yusaf, T. Statistical diagnosis of the best weibull methods for wind power assessment for agricultural applications. Energies 2014, 7, 3056–3085. [Google Scholar] [CrossRef]

| Databases | Algorithm | RMSE | SD | #Hidden Nodes | Training Time (s) |

|---|---|---|---|---|---|

| Sunspot | MOS-ELM () | 0.0839 | 0.0005 | 20 | 0.0409 |

| OS-ELM | 0.0863 | 0.0005 | 20 | 0.0399 | |

| Mackey-Glass | MOS-ELM () | 0.0120 | 0.0014 | 20 | 0.1298 |

| OS-ELM | 0.0172 | 0.0024 | 20 | 0.1363 | |

| Logistic | MOS-ELM () | 0.0595 | 0.0303 | 40 | 0.0839 |

| OS-ELM | 0.0767 | 0.0351 | 40 | 0.0883 | |

| Auto-MPG | MOS-ELM () | 0.0649 | 0.0013 | 25 | 0.0087 |

| OS-ELM | 0.0651 | 0.0013 | 25 | 0.0094 | |

| Housing | MOS-ELM () | 0.0992 | 0.0044 | 30 | 0.0081 |

| OS-ELM | 0.0998 | 0.0056 | 30 | 00075 |

| Fault Mode | Algorithms | Drift Fault | Bias Fault | ||||

|---|---|---|---|---|---|---|---|

| RMSE | SD | Training Time (s) | RMSE | SD | Training Time (s) | ||

| OS-ELM | 0.0293 | 0.0001 | 3.35 | 0.0284 | 0.0007 | 3.33 | |

| MOS-ELM | 0.0183 | 0.0008 | 3.32 | 0.0177 | 0.0010 | 3.27 | |

| OS-ELM | 0.0508 | 0.0067 | 3.34 | 0.0558 | 0.0078 | 3.28 | |

| MOS-ELM | 0.0221 | 0.0032 | 3.31 | 0.0261 | 0.0056 | 3.27 | |

| OS-ELM | 0.0432 | 0.0029 | 3.35 | 0.0456 | 0.0042 | 3.27 | |

| MOS-ELM | 0.0267 | 0.0033 | 3.32 | 0.0259 | 0.0027 | 3.32 | |

| OS-ELM | 0.0405 | 0.0041 | 3.35 | 0.0315 | 0.0016 | 3.30 | |

| MOS-ELM | 0.0347 | 0.0070 | 3.34 | 0.0217 | 0.0019 | 3.27 | |

| OS-ELM | 0.0471 | 0.0072 | 3.29 | 0.0464 | 0.0049 | 3.27 | |

| MOS-ELM | 0.0293 | 0.0042 | 3.36 | 0.0271 | 0.0045 | 3.31 | |

| OS-ELM | 0.0384 | 0.0029 | 3.33 | 0.0319 | 0.0014 | 3.31 | |

| MOS-ELM | 0.0367 | 0.0046 | 3.32 | 0.0239 | 0.0020 | 3.32 | |

| OS-ELM | 0.0696 | 0.0114 | 3.33 | 0.0800 | 0.0126 | 3.38 | |

| MOS-ELM | 0.0335 | 0.0063 | 3.36 | 0.0347 | 0.0050 | 3.30 | |

| Fault Mode | Algorithms | Drift Fault | Bias Fault | ||

|---|---|---|---|---|---|

| CDR (%) | SD (%) | CDR (%) | SD (%) | ||

| OS-ELM | 78.64 | 8.31 | 77.15 | 9.48 | |

| MOS-ELM | 90.31 | 5.04 | 96.13 | 2.42 | |

| OS-ELM | 97.80 | 0.89 | 98.35 | 0.99 | |

| MOS-ELM | 97.23 | 0.95 | 99.48 | 0.47 | |

| OS-ELM | 96.12 | 1.77 | 97.35 | 1.3 | |

| MOS-ELM | 99 | 0.83 | 99.48 | 0.41 | |

| OS-ELM | 92.24 | 2.81 | 79.78 | 7.74 | |

| MOS-ELM | 93.5 | 1.65 | 95.55 | 2 | |

| OS-ELM | 96.96 | 1.75 | 98.13 | 0.99 | |

| MOS-ELM | 96.92 | 1.3 | 99.45 | 0.46 | |

| OS-ELM | - | - | - | - | |

| MOS-ELM | 98.94 | 3.68 | 99.63 | 1.3 | |

| OS-ELM | 100 | 0 | 100 | 0 | |

| MOS-ELM | 99.94 | 0.14 | 99.84 | 0.73 | |

© 2017 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, J.; Huang, J.; Lu, F. Sensor Fault Diagnosis for Aero Engine Based on Online Sequential Extreme Learning Machine with Memory Principle. Energies 2017, 10, 39. https://doi.org/10.3390/en10010039

Lu J, Huang J, Lu F. Sensor Fault Diagnosis for Aero Engine Based on Online Sequential Extreme Learning Machine with Memory Principle. Energies. 2017; 10(1):39. https://doi.org/10.3390/en10010039

Chicago/Turabian StyleLu, Junjie, Jinquan Huang, and Feng Lu. 2017. "Sensor Fault Diagnosis for Aero Engine Based on Online Sequential Extreme Learning Machine with Memory Principle" Energies 10, no. 1: 39. https://doi.org/10.3390/en10010039