4.1. Modeling of Mixed Logic Dynamical Predictive Control Strategy

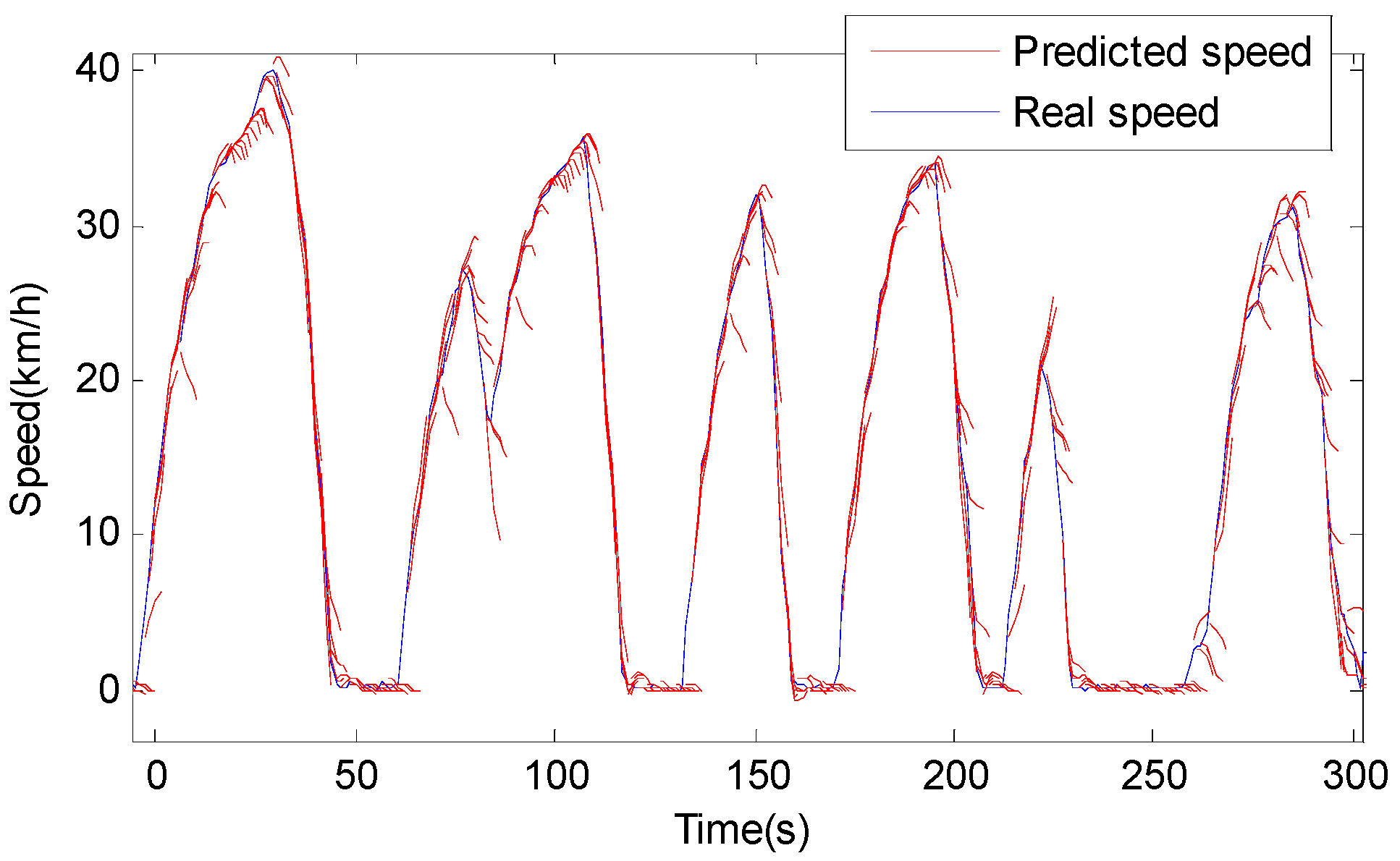

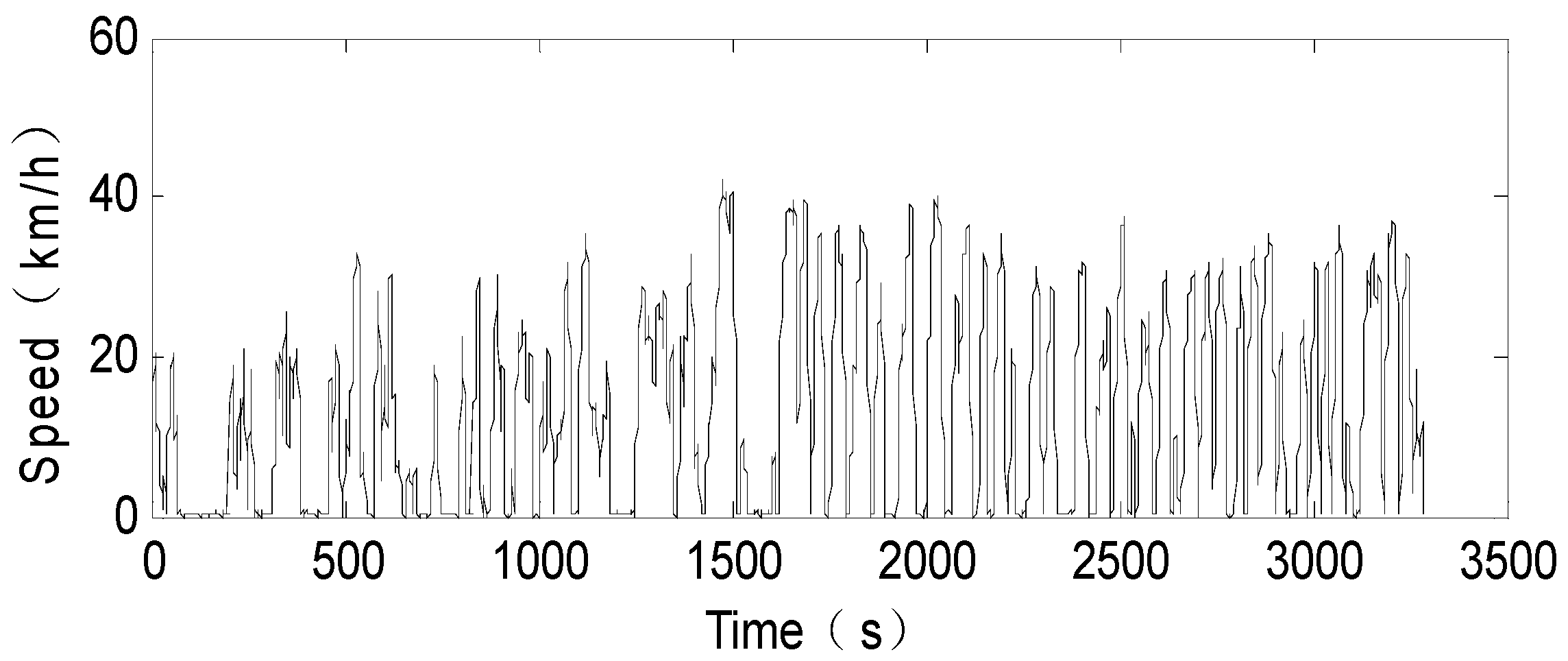

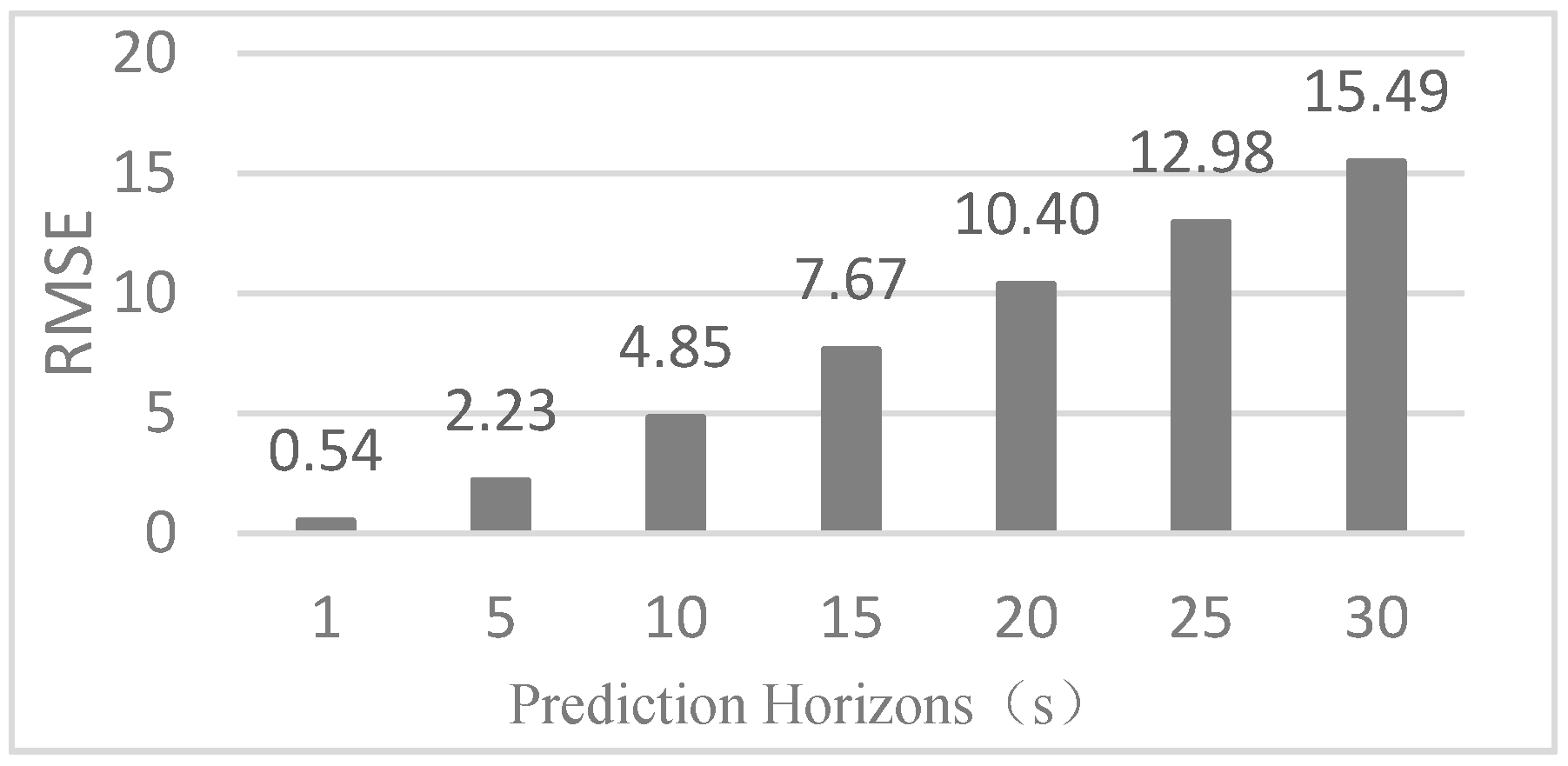

The short-term future vehicle speed in each receding horizon can be obtained through the proposed speed prediction method in

Section 3. Then the predicted vehicle speed is used to calculate the vehicle required torque at each moment within the receding horizon. The proposed MLD-MPC control strategy aims to distribute the vehicle required torque between motor and engine reasonably at each moment within the prediction horizon to achieve optimal fuel economic. Thus MLD model is established to tackle this optimization problem with the objective function of equivalent fuel consumption, the control variable of motor torque

u(

k) and the state variable of

SOC x(

k). The optimal control variable sequence are obtained by minimizing the total equivalent fuel consumption in the receding horizon through MLD model and only the first control variable need to be applied in the controlled PHEV model at the present moment. The MLD-MPC receding horizon control procedure is described as follows:

- (1)

at time k, predict the short-term future speed profile for the current control horizon (k–k + N, where N is the receding horizon) and calculate the corresponding required torque through Equations (1) and (2);

- (2)

the MLD model calculates the optimal control policy (u(k)–u(k + N)) for the current prediction horizon (k–k + N);

- (3)

apply the first time-step of the optimal control policy u(k) in the controlled PHEV model;

- (4)

update the state variable and system constraints, repeat the computation procedure 1–3 at the next time instant (time k + 1).

MLD model is suitable for solving problems combining binary variables and continuous variables. In [

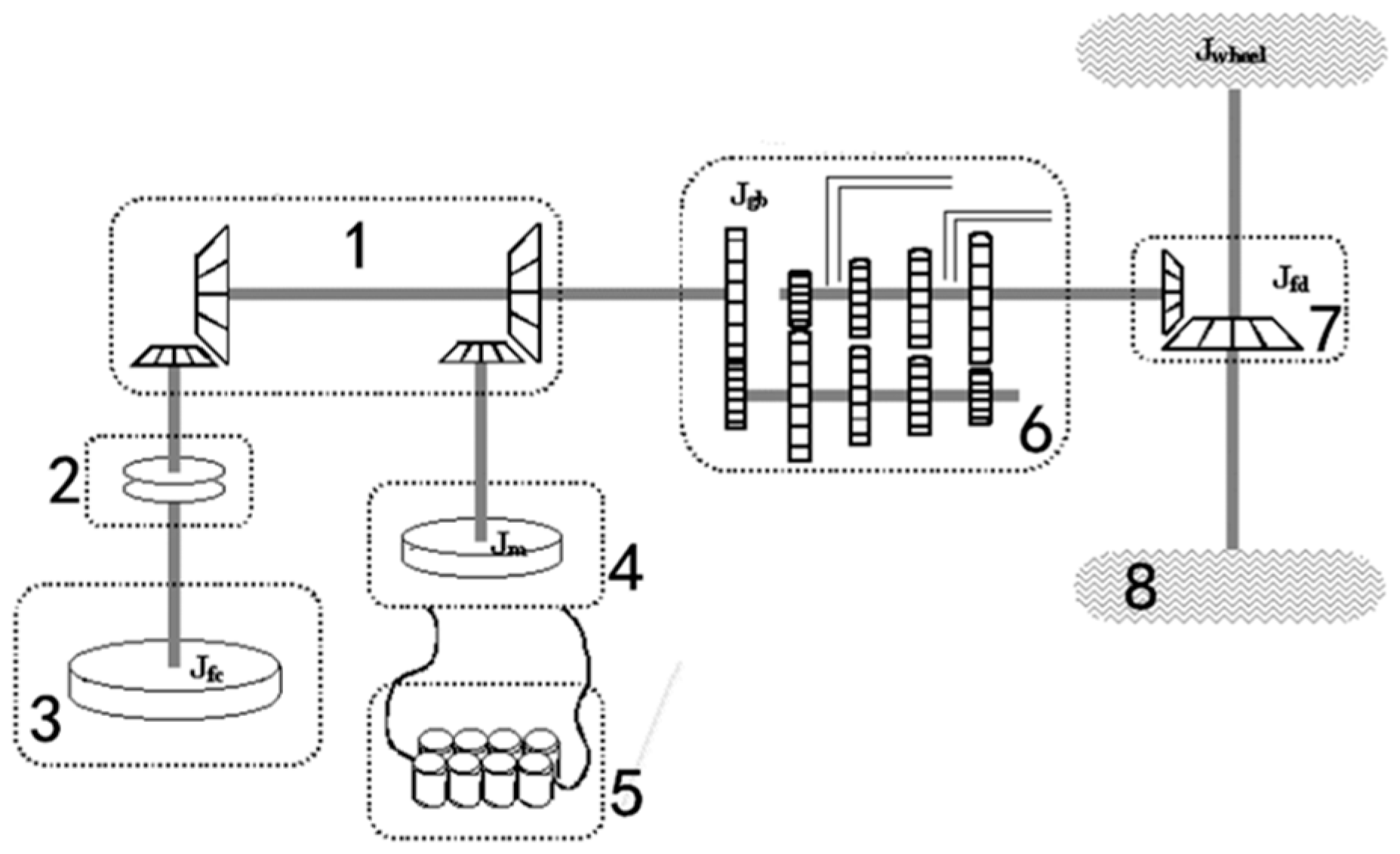

28], a constrained optimal problem is formulated and solved based on MPC using the simplified MLD model for DC-DC boost converter. Similarly, in our PHEV energy management control strategy, based on the simplified powertrain model in

Section 2, the state transition equation and evaluation equation of MLD model can be described in Equation (10):

where,

where

is the

SOC of battery at time

k,

is the equivalent rate of fuel consumption at time

k,

is the operation mode matrix at time

k, which is a

matrix whose entries are either 0 or 1 (logic variables), and only one of the six elements of the matrix is 1 and others are all 0.

is the auxiliary variable,

, in which

u(

k) is the control variable which represents the torque of electric motor, and its inequality constraints are described in Equation (11).

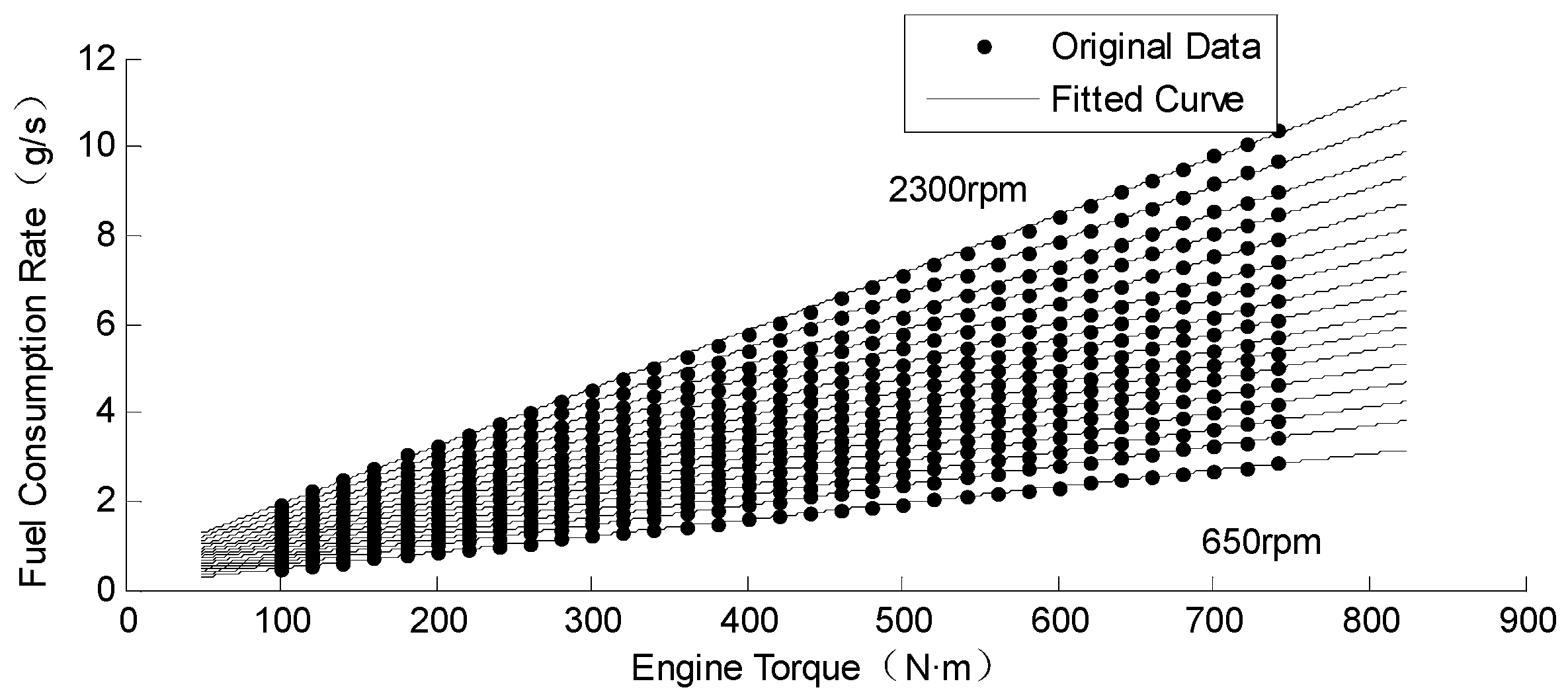

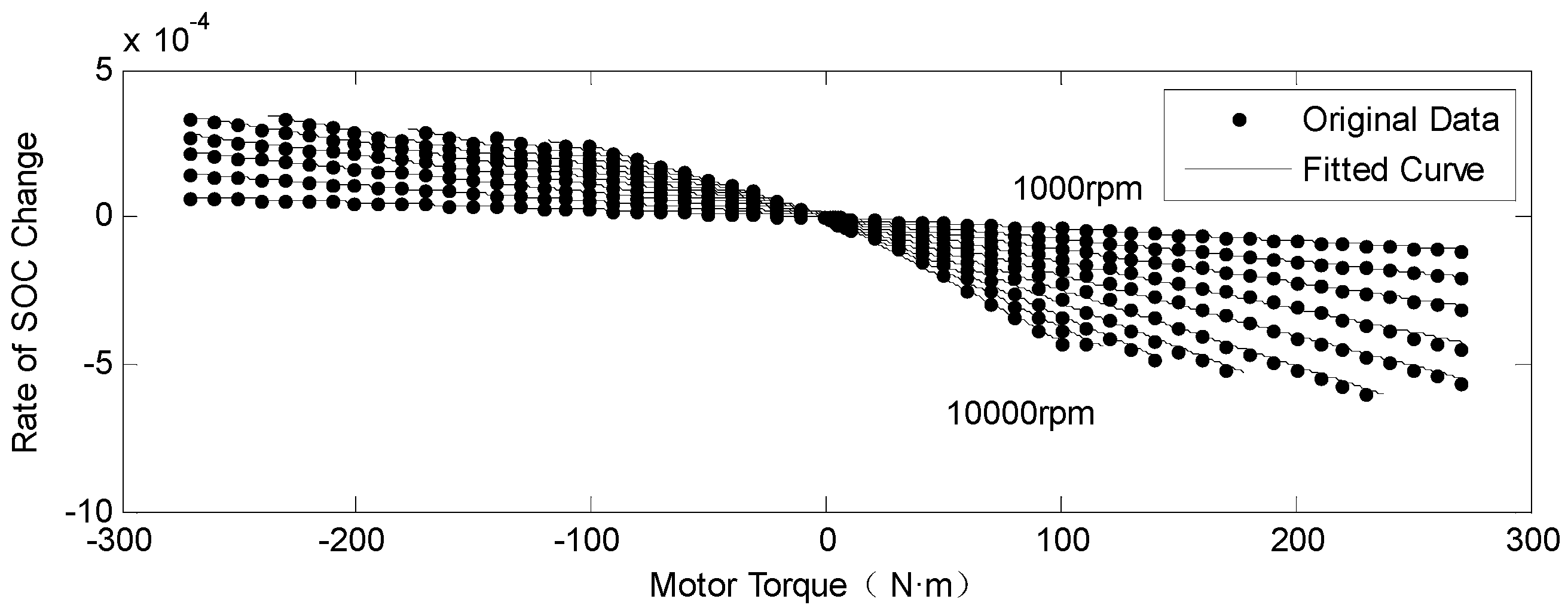

is the transmission ratio of the torque coupler which connects the engine to the motor. In the equation, the variables are obtained based on the linearized engine and battery model in

Section 2.

B1,

B2 is used to calculate the

SOC change corresponding to the specific motor torque,

b0(

k) and

b1(

k) are the fitting coefficients for the specific motor speed at time

k, and they are obtained from Equation (8). Similarly,

D1 and

D2 is used to calculate the sum of engine fuel consumption and motor equivalent fuel consumption,

a0(

k) and

a1(

k) are from Equation (4):

The inequality constraint of the six operation modes for PHEV presented in

Table 4 includes electric power mode, fuel consumption mode, mixed driven mode, drive charging mode, regenerate braking mode and stopping mode. The constraint describes the relationship of motor torque

u and the vehicle required torque

in each operation mode. In

Table 4,

and

are the maximum motor torque and vehicle required torque respectively;

and

are the maximum engine torque and motor torque respectively;

is the maximum regenerative braking torque;

;

is the machine accuracy,

= 0.0001;

is the required torque, which can be can be calculated from Equations (1) and (2);

is the logic variable representing the operation mode of the vehicle (if

, it means that the vehicle is running under the operation mode

i); Consider the inequality constraints above into time sequence

k and transfer them into the unified matrix inequality as follows, where

E1,

E2,

E3 and

E4 are all the coefficients in the form of Matrix converted from

Table 4.

Applying receding horizon optimization based predictive control theory to the MLD model, and the optimal model is set-up as given in Equations (13) and (14), where the optimization metric is the sum of equivalent fuel consumption in the receding horizon at time

k, the state transition and evaluation equality constraint are from Equation (10), the inequality constraints are taken from Equation (12):

s.t.

within it,

B1,

B2,

D1,

D2 is the same as Equation (10), and

E1,

E2,

E3,

E4, is defined as follows:

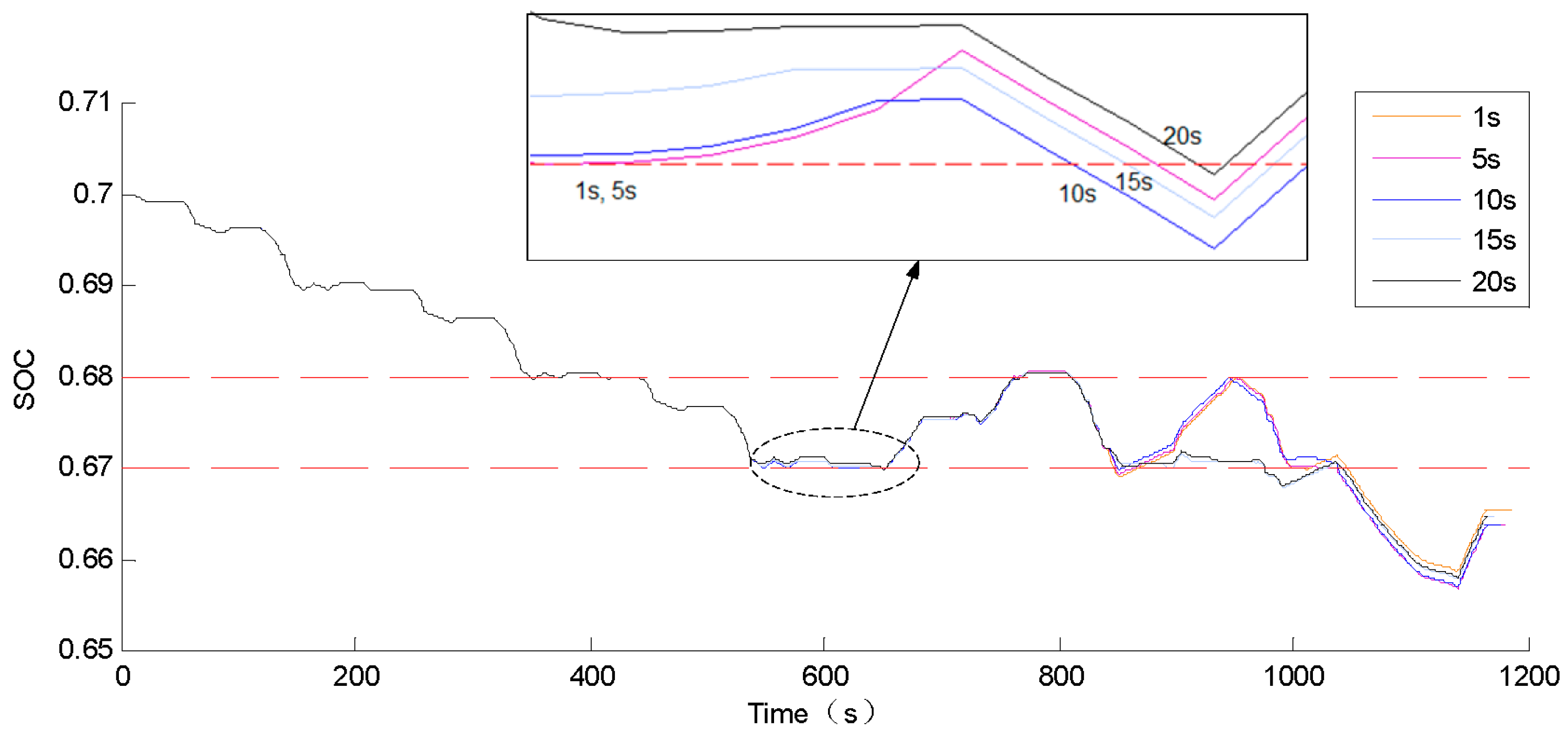

In the equation, N is the prediction horizon, k is the specific second in the prediction horizon, and are the upper and lower limit of SOC accessible domains respectively at time k. Considering the values of matrices B1, B2, D1, D2, E1, E2, E3 and E4 at every sampling time k and according to the objective function of minimal equivalent fuel consumption, Equations (13) and (14) can be converted into a MILP problem.

4.2. Solution of Mixed Integer Linear Programming

The MILP problem can be modeled using YALMIP toolbox in the Matlab platform and solved using the Gurobi optimizer. The optimal control variable sequence (u(k)–u(k + N)) in the prediction horizon (k–k + N) can be calculated at time k, and the first value of the optimal control variable sequence u(k) is applied to the controlled object. Then utilizing the receding horizon optimization method, the former solving steps are repeated to get a new control value at time k + 1 to realize the PHEV MPC. In the process of updating the model state variable, SOC, the original nonlinear model as shown in Equation (6) is used instead of the simplified linear equality constraint model in MILP to obtain a better estimate of the true SOC value at the end of the control time domain. The obtained value is considered as the initial state value to the next receding horizon optimization, so as to realize the feedback correction in predictive control.

Heuristic rules for some special driving conditions are set to reduce the range of feasible solution of MILP and improve the real-time performance of the control strategy. The introduced heuristic rules are presented in

Table 5. While the condition in the first column is satisfied, the corresponding operation mode

and motor torque can be decided respectively. Total required torque

can be used as a measure to judge whether the car is braking or stopping. Based on the value of total required torque, whether it is less than or equal to zero, the vehicle can choose regenerate braking mode or stop mode directly, and the corresponding control variable value can be determined directly. When the vehicle is in urgent acceleration or at high speed, and the total inquired torque is larger than the maximum engine torque at that speed, the vehicle can choose mixed driven mode directly. Otherwise, the control strategy can switch among four modes, i.e., electric power mode, fuel consumption mode, mixed driven mode, drive charging mode. The control variable value in electric power mode and fuel consumption mode can be directly obtained. The control variable in the mixed driven mode and drive charging mode can be selected through the optimization of the objective function. These heuristic rules can significantly reduce the search space of MILP and thus improve the efficiency of the algorithm.

When SOC approaches to the lower limit, once the required torque is larger than the maximum torque of the engine and the objective function in MLD-MPC is not modified, the motor needs to output the power which would make the SOC of the battery to exceed the lower limit. This violates the constraints defined in MILP problem and cannot find a feasible solution. Thus, when SOC is around the lower limit, the heuristic rule is applied to solve the control problem. First, estimate the highest SOC at each step in the prediction horizon under the assumption that the engine outputs its maximum torque. If the estimated highest SOC is higher than the lower limit of SOC, the current SOC constraints are imposed in MILP, otherwise the corresponding SOC constraints will be removed. When the current SOC is lower than the lower limit of SOC, the algorithm will stop solving the MILP problem and change to the heuristic solver mode. In this mode, the maximum charging torque (or the minimum discharging torque) of the motor is calculated directly while the engine is set to output its maximum torque. After the SOC rises to a certain value higher than the lower limit of SOC, the MILP solver will be restarted.