1. Introduction

The use of biomass for the production of low carbon energy is recognized as an important goal of sustainable development [

1]. Among the various ways to use biomass for energy production, one of the most widely used and commonly available in the market is BSDF [

2,

3]. BSDF refers to fuel of a certain shape that is of high density and is obtained from loose biomass pressed at a certain temperature and under a certain pressure. The general shape of BSDF can be a pellet, briquette or rod. Its volume is 1/8–1/6 of the biomass raw materials, and the density is 1.0–1.4 t/m

3. With an energy density equal to that of intermediate soft coal, BSDF has attracted widespread attention in recent years [

4], including in China. In China, the raw materials of BSDF are mainly forestry and agricultural residues and BSDF is utilized mainly as a clean fuel for heating boilers in communities, industrial parks and other public or industrial facilities. China’s total production of BSDF in 2015 was 8 million tonnes [

5], which was less than the planned 2015 target of 10 million tonnes [

6]. For the year 2020, China’s planned target of BSDF production is 30 million tonnes [

5], which requires an annual 30% increase of BSDF production, so it is necessary to take measures to promote the healthy and rapid development of China’s BSDF industry [

3]. Moreover, being a large corn producer with abundant crop straw resources, especially in Liaoning Province, Jilin Province and Heilongjiang Province in northeastern China, China has seen serious air pollution problems arise due to the large scale field incineration of crop straw waste [

6,

7,

8,

9]. As estimated, China’s agricultural residues available for energy use are about 0.2 billion tce [

6], which accounts for 4.7% of China’s total energy consumption of 4.3 billion tce [

10] in 2015. Therefore, to promote the energy use of biomass and also reduce the field incineration of corn straw, the development of corn straw solid densified fuel (CSDF) for heating should be prioritized in the development of China’s BSDF industry.

Referring to a literature review, economic analysis is a popular area of international research on the development of BSDF [

11], and many studies have applied economic analyses of BSDF heating systems on the district level or building level. For example, Thomson [

12] reviewed the suitability of wood pellet heating for domestic households and discussed the advantages, issues, and barriers. Vallios [

13] designed biomass district heating systems considering the optimum design of building structures and urban settlements around the plant and carried out an environmental and economic evaluation. Chau [

14,

15], Michopoulos [

16], and Stolarski [

17] analyzed the economic performance and other performance of BSDF utilization in buildings heating systems. Hendricks [

18] evaluated the cost-effectiveness of biomass district heating in rural communities. Stephen [

19] analyzed the economics and influence factors of biomass use for residential and commercial heating in a remote Canadian aboriginal community. Tabata [

20] discussed the effectiveness of a woody biomass utilization system with wood pellet production and energy recovery processes for household energy demand, taking the case of Gifu Japan as an example. Ren et al. [

21] analyzed and compared the logistics cost of corn stover feedstock supply systems based on China’s case. Zhao et al. [

22] researched the techno-economic performance of bioethanol production from corn straw in China.

In addition, it is also well recognized that BSDF development policies have a major impact on its economic performance. For example, Toka [

23] researched how to manage the diffusion of biomass in the residential energy sector and discussed an illustrative real-world case study. Moiseyev et al. [

24] indicated that subsidies were likely to be the major driving force to increase the energy use of woody biomass and found that subsidies and carbon prices can effectively promote the energy use of woody biomass in the E.U. and reduce carbon dioxide emissions. Madlener [

25] investigated the innovation diffusion, public policy, and local initiative of using biomass for energy production, taking the case of wood-fueled district heating systems in Austria as an example. Gan [

26] researched policy options and co-benefits of bioenergy transition in rural China, pointing out that there is great potential for developing and disseminating household-based biomass technologies in rural areas, especially with energy-efficient modern biomass stoves, which can produce far more economic, social and environmental benefits. Shan [

27] proposed a novel and viable village-level BSDF utilization mode based on the field survey of China’s BSDF industry and the results from demonstration projects, which is helpful to boost the utilization of BSDF mainly in rural China. Wang et al. [

28] assessed densified biomass solid fuel utilization policies and strategies in China based on the supply chain framework. Therefore, it is concluded that economic and policy analysis for district heating system is a key area of international research on BSDF development. Scientific economic analysis system need to be established with field survey and literature review results to analyze the influence of relevant support policies. However, currently, few studies have been published on the economic and policy analysis methods and case studies of CSDF for district heating systems, especially in China.

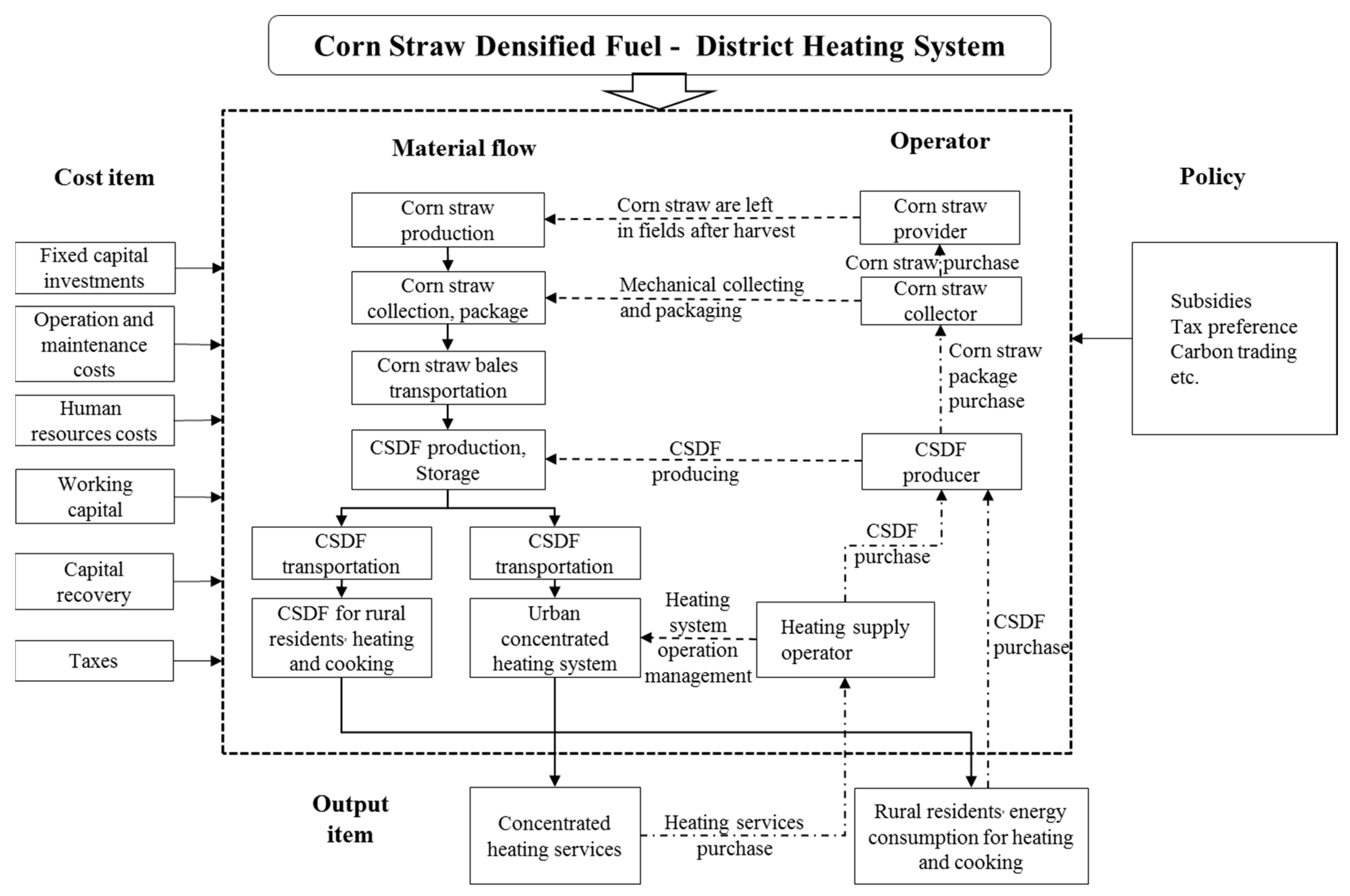

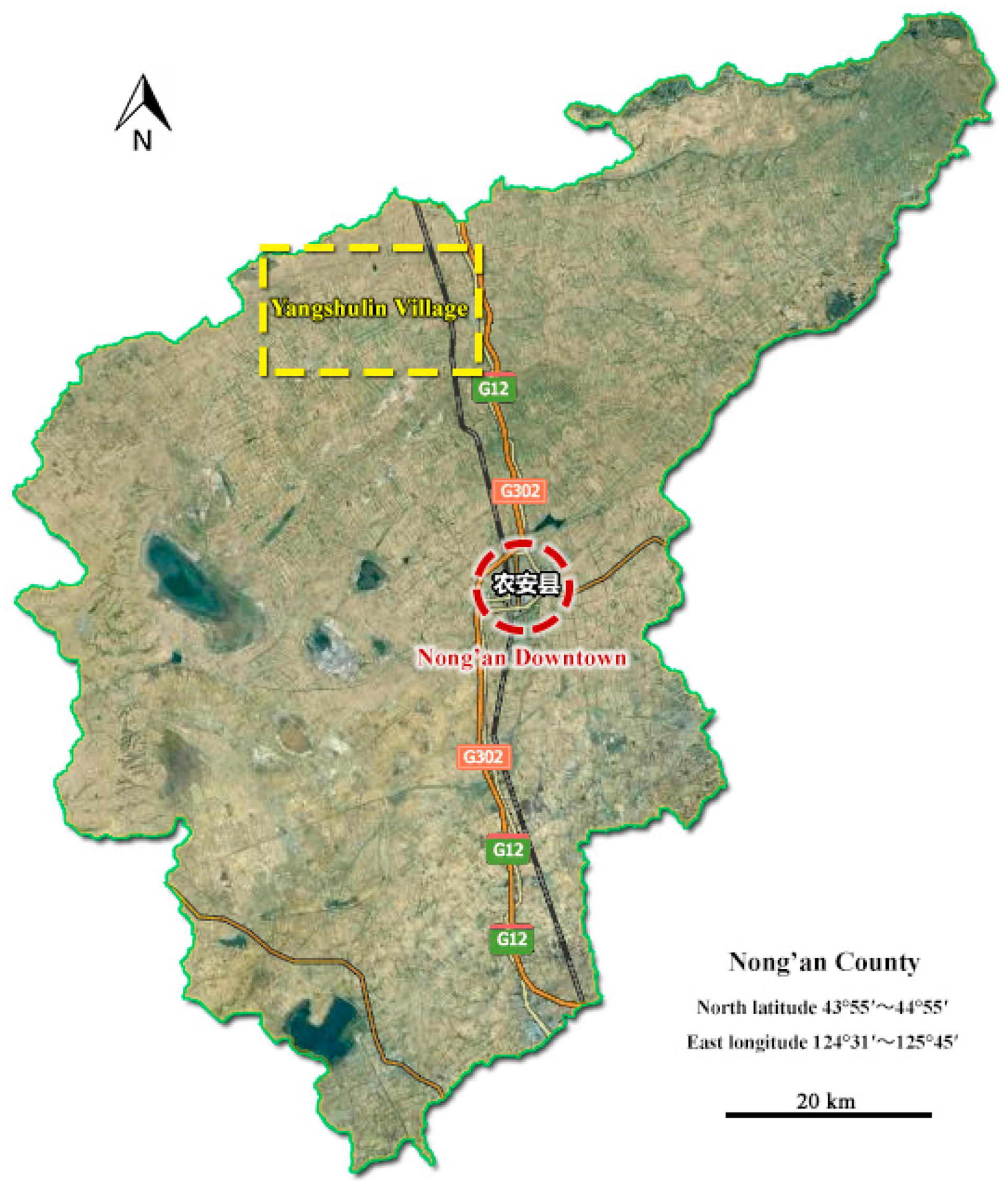

The aim of this manuscript is to develop a techno-economic model to evaluate the economic performance of a corn straw densified fuel-district heating system (CSDF-DHS) and analyze the influence of polices using a case study of Nong’an County in Jilin Province, China. First, we investigate the system description of a CSDF-DHS and basic information about the case, which are introduced in

Section 2. Then, we develop a technical model of a CSDF-DHS, construct a two-stage economic model to evaluate its economic performance, and set two scenarios to analyze the influence of policies. Those methods and data are introduced in

Section 3. Finally, we provide the results and discussion in

Section 4 and main conclusions and policy implications in

Section 5.

4. Results and Discussion

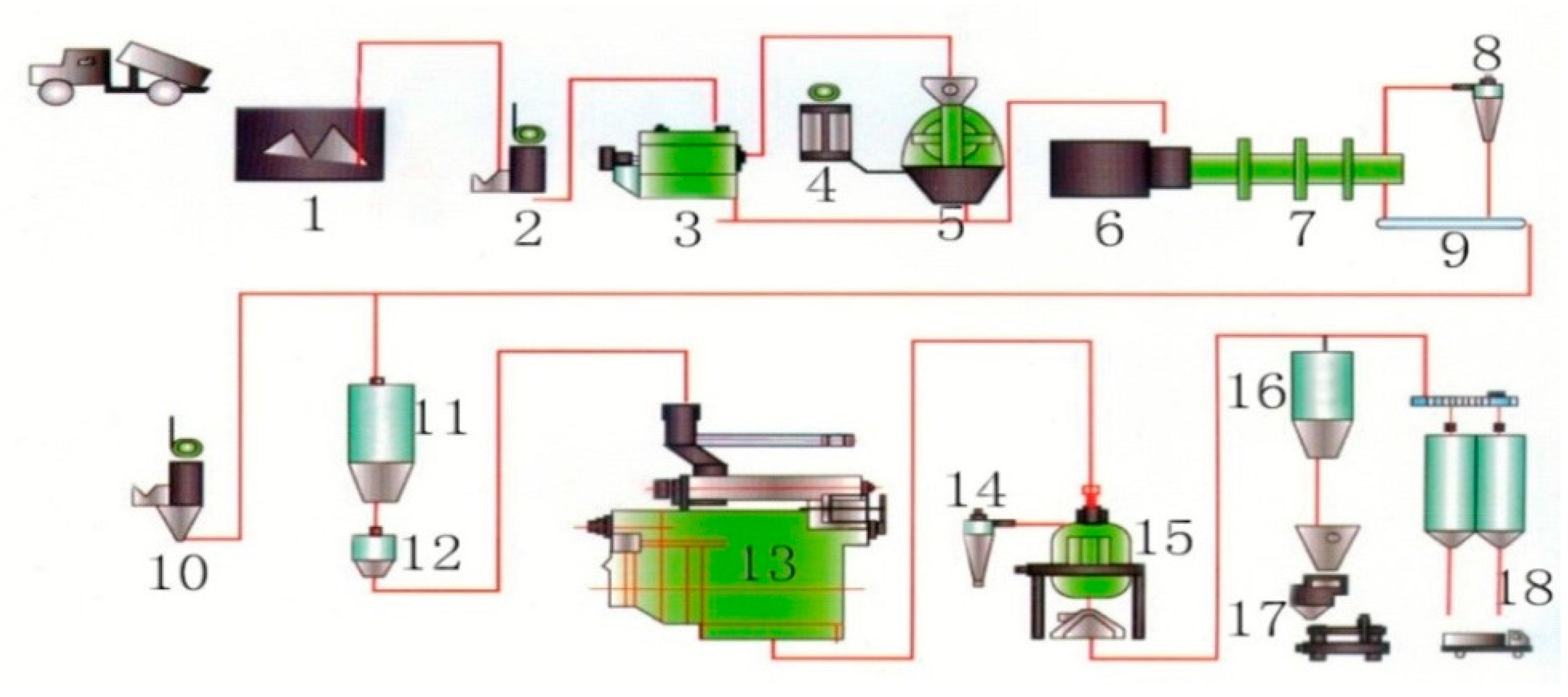

4.1. The Technical Process of a CSDF-DHS

The technical process of a CSDF-DHS decided by the technical model is illustrated by

Table 6 (from corn straw resources to CSDF production) and

Table 7 (CSDF utilization in rural and urban areas). The total utilization scale is 58,000 t/a corn straw, and the CSDF produced can serve for 4714 households in rural areas and 1.08 million m

2 of concentrated heating service in urban areas. The CSDF production is either CSPF or CSBF in

Table 6.

4.2. Economic Performance in the Benchmark Market Scenario

The results of the economic model in the BMS are listed in

Table 8 and

Table 9. The costs of CSPF and heating services provided by CSPF are both higher than those of CSBF because CSPF has higher investment and operation and maintenance costs than CSPF. However, CSPF is more beneficial for the local economy, with higher taxes, profits, and labor income created.

In this case, CSDF is used to replace traditional energy, mainly coal, LPG, and directly burned firewood and corn straw. According to data collected in Nong’an County, the local price of coal is approximately $101/t and that of LPG is approximately $1.3/kg. Firewood and corn straw have no economic expenses. Therefore, it is estimated that the annual expense of heating and cooking per household is $181/a, which is lower than the expense using CSDF. However, using CSDF can benefit the local economy because it can avoid the payment flowing to other regions to buy coal and LPG. The total payment of 684 households on coal and LPG is 0.85 million USD.

In urban concentrated heating, CSDF mainly replaces coal. The current government-guided price for concentrated heating services mainly by coal is $3.8/m2, which is lower than that of CSDF and means poor economic performance by a CSDF-DHS in the BMS. However, using CSDF for urban heating can also avoid the payment of coal flowing to other regions. According to the field survey, the concentrated heating coal consumption in Nong’an County is approximately 20 kgce/m2, the price of purchased coal is approximately $109/tce, and the total expense of coal is approximately 2.35 million USD with a heating area of 1.08 million m2.

In potential, the total expense of traditional energy flowing out of Nong’an is approximately 3.21 million USD. Using CSDF can avoid this outflow of payments and create taxes, profits, and labor income to help local economic growth, though CSDF has poor economic performance compared to traditional energy in the BMS.

4.3. Economic Performance in the Current Policy Scenario

The results of the economic model in the CPS are listed in

Table 10 and

Table 11. Compared to the BMS, the cost of corn straw and CSPF/CSBF are cut by 5.6% and 8.2%–8.7%/8.7%–9.2%, respectively, because of tax-free policies and subsidies for fixed capital investment. The cost of heating services by CSPF/CSBF for rural residents and urban concentrated heating is reduced by 14.3%/16.1% and 8.8%/9.1%, respectively because of the policies, whereas the taxes and profits created by the CSDF-DHS are also reduced to a certain extent. However, the costs of heating services for rural and urban areas are still higher than those of the traditional energy benchmark ($181/household·a and $3.8/m

2), though the economic performance has been improved by policy support totaling 2.0 million USD subsidies and tax-free for corn straw collection and CSPF production.

4.4. Influencing Factors of Economic Performance under the CPS

The economic performance of this CSDF-DHS case is poor even with the current policy support. Therefore, we discuss the influence factors of economic performance under the Current Policy Scenario (CPS). These factors includes the subsidy for fixed capital investment, the corn straw price, the CSDF price, the concentrated heating price, carbon trading, and the preferential electricity price, which can be further intervened by government policy in the future.

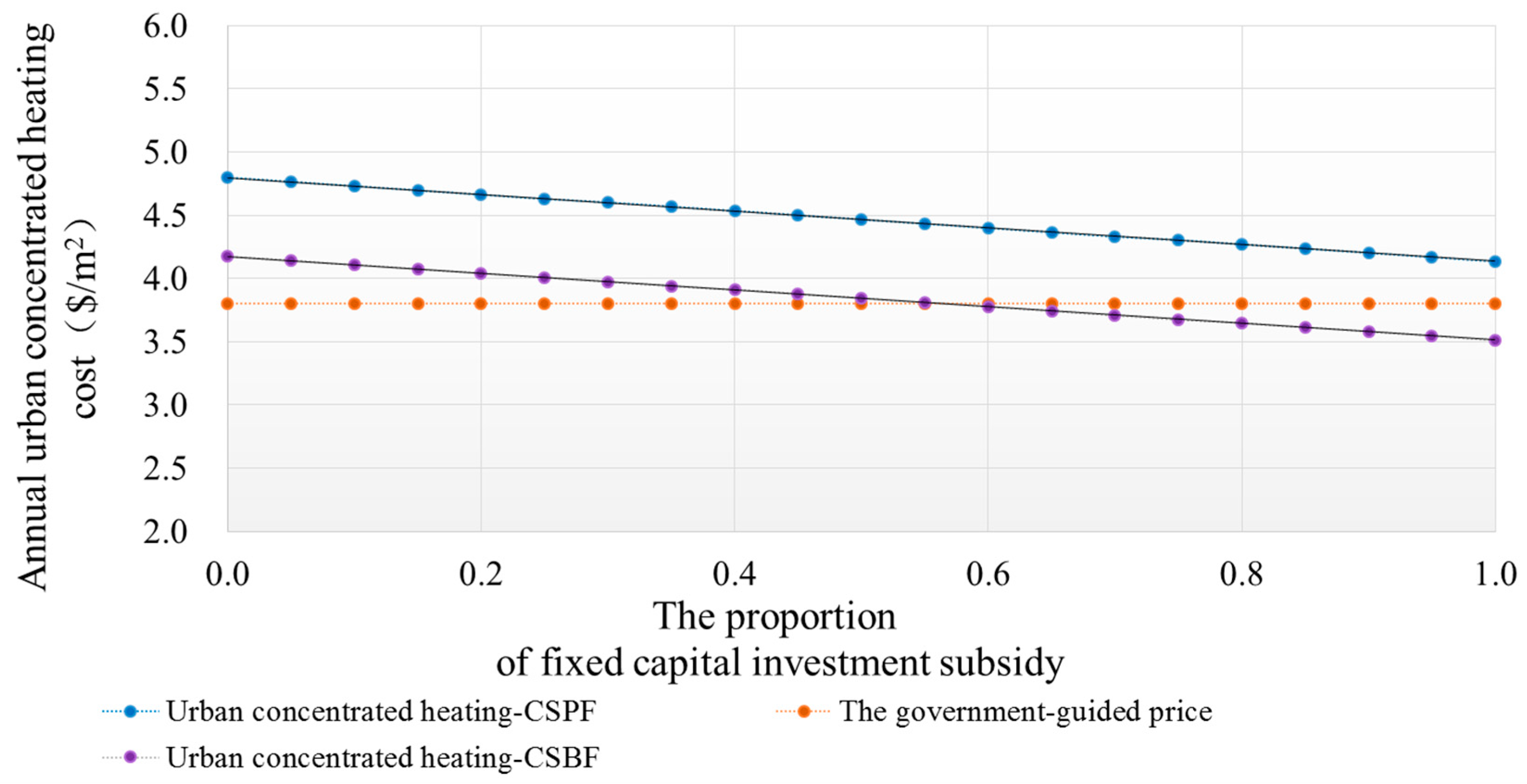

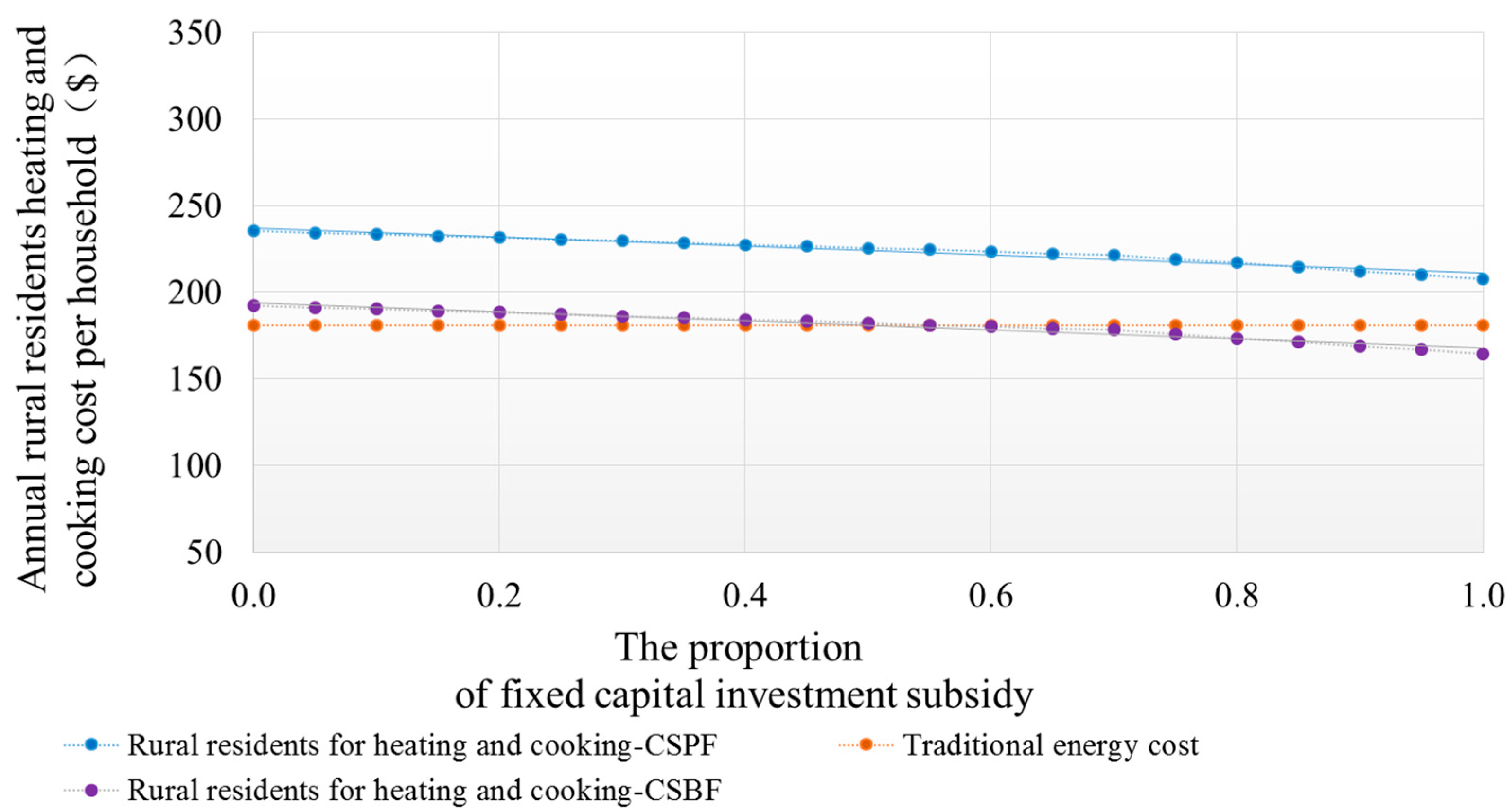

4.4.1. Influence of Fixed Capital Investment Subsidy

The influence of economic performance on CSDF-DHS heating service costs for a fixed capital investment subsidy is shown in

Figure 4 and

Figure 5. To discuss the influence of the subsidy proportion changes on heating service cost under the CPS, we set the proportion of fixed capital investment subsidies from 0% to 100%. First, we analyze the urban concentrated heating cost. The results indicate that if the subsidy proportion increased by 10%, the urban concentrated heating cost would decrease by $0.07/m

2.

For CSPF, the urban concentrated heating cost is always higher than the government-guided price. For CSBF, if the subsidy proportion reached 49.0% or higher, the urban concentrated heating cost would be lower than the government-guided price, being competitive in the market. Second, we analyze rural residents’ heating and cooking costs. The results show that if the subsidy proportion increased by 10%, the rural residents heating and cooking cost would decrease by $2.6 per household. For CSPF, rural residents’ heating and cooking costs are always higher than the cost of traditional energy. For CSBF, if the subsidy proportion reached 62.0% or higher, rural residents’ heating and cooking cost would be lower than the cost of traditional energy, being competitive in the market.

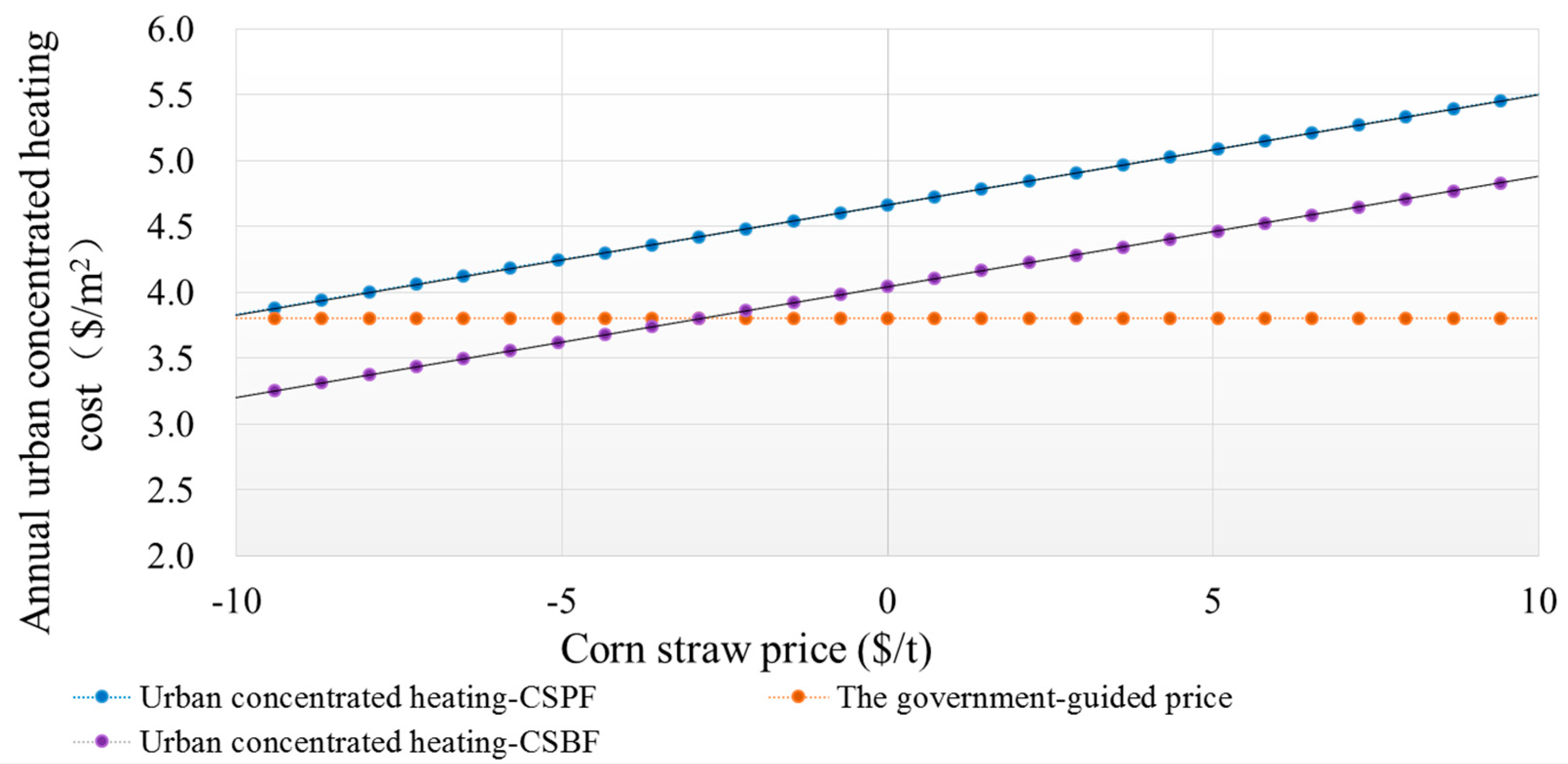

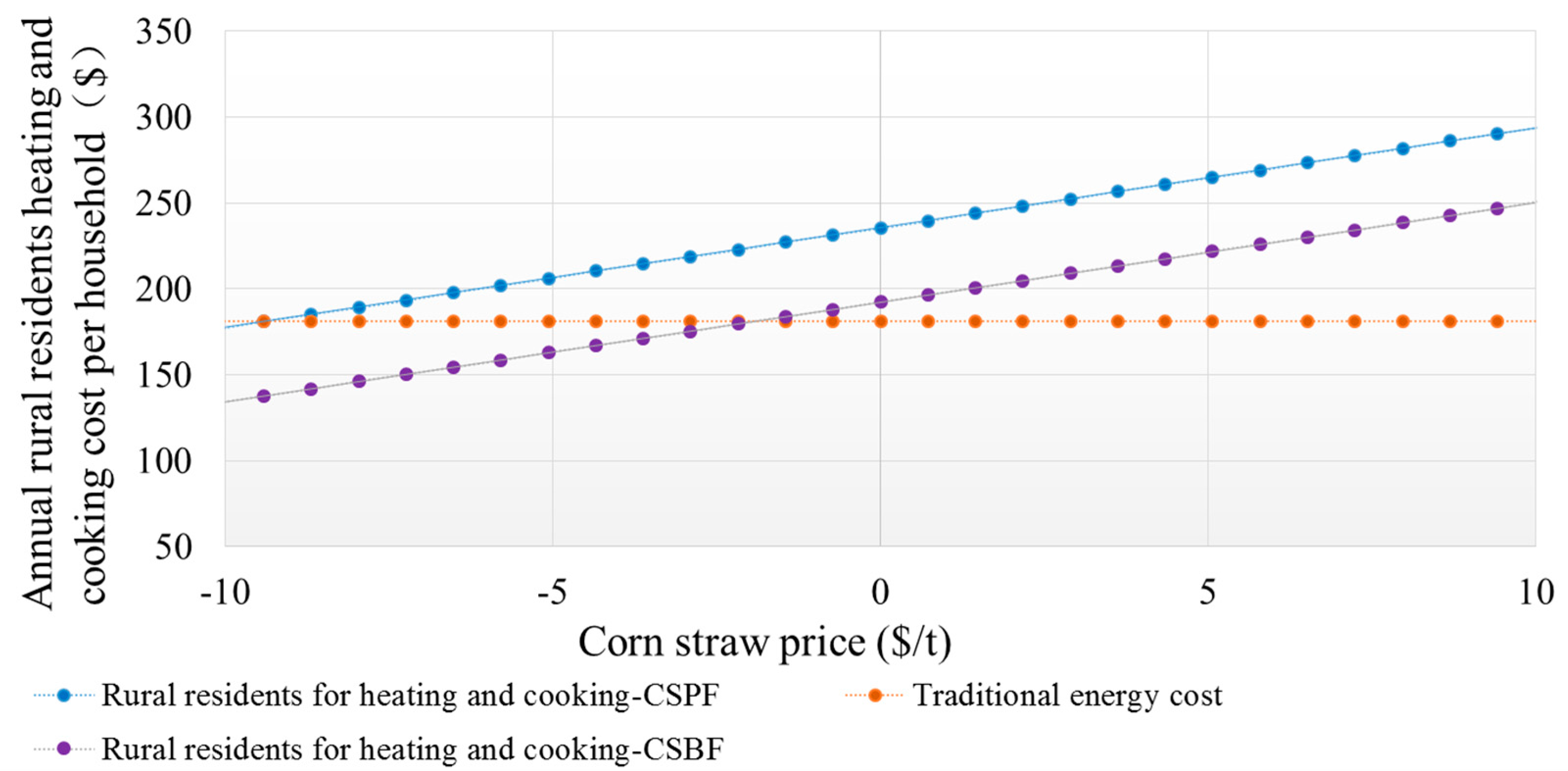

4.4.2. Influence of Corn Straw Price

The purchase price of corn straw is set to be zero in both two scenarios. However, when the corn straws are utilized in a large scale as an energy source, the purchase price of corn straw may increase. In addition, to support CSDF-DHS development, the government can also consider corn straw price subsidy to achieve a negative corn straw purchase price, meaning that the collection enterprises can even be paid to obtain corn straw for free, which actually happens in some regions of China because local government tends to reduce field incineration of corn straw to alleviate air pollution by CSDF-DHS.

Under the CPS, we set the purchase price of corn straw to change from −$11.6/t to $11.6/t. The influence of corn straw price on the economic performance of a CSDF-DHS heating service is shown in

Figure 6 and

Figure 7. The results indicate that if the corn straw price increased by $1.4, the urban concentrated heating cost will rise by $0.12/m

2. The urban concentrated heating cost for CSPF and CSBF can reach government-guided price when the corn straw price subsidies are at least $10.7/t and $3.3/t, respectively, indicating corn straw prices of −$10.7/t and −$3.3/t, respectively. In terms of rural residents’ heating and cooking costs, if the corn straw price increased by $1.4, the rural residents heating and cooking cost will rise by $8.4 per household. The rural residents’ heating and cooking costs for CSPF and CSBF can be equal to the average cost of traditional energy per household when the corn straw price subsidies are $9.4/t and $1.9/t, respectively, which indicates that the corn straw price are −$9.4/t and −$1.9/t, respectively.

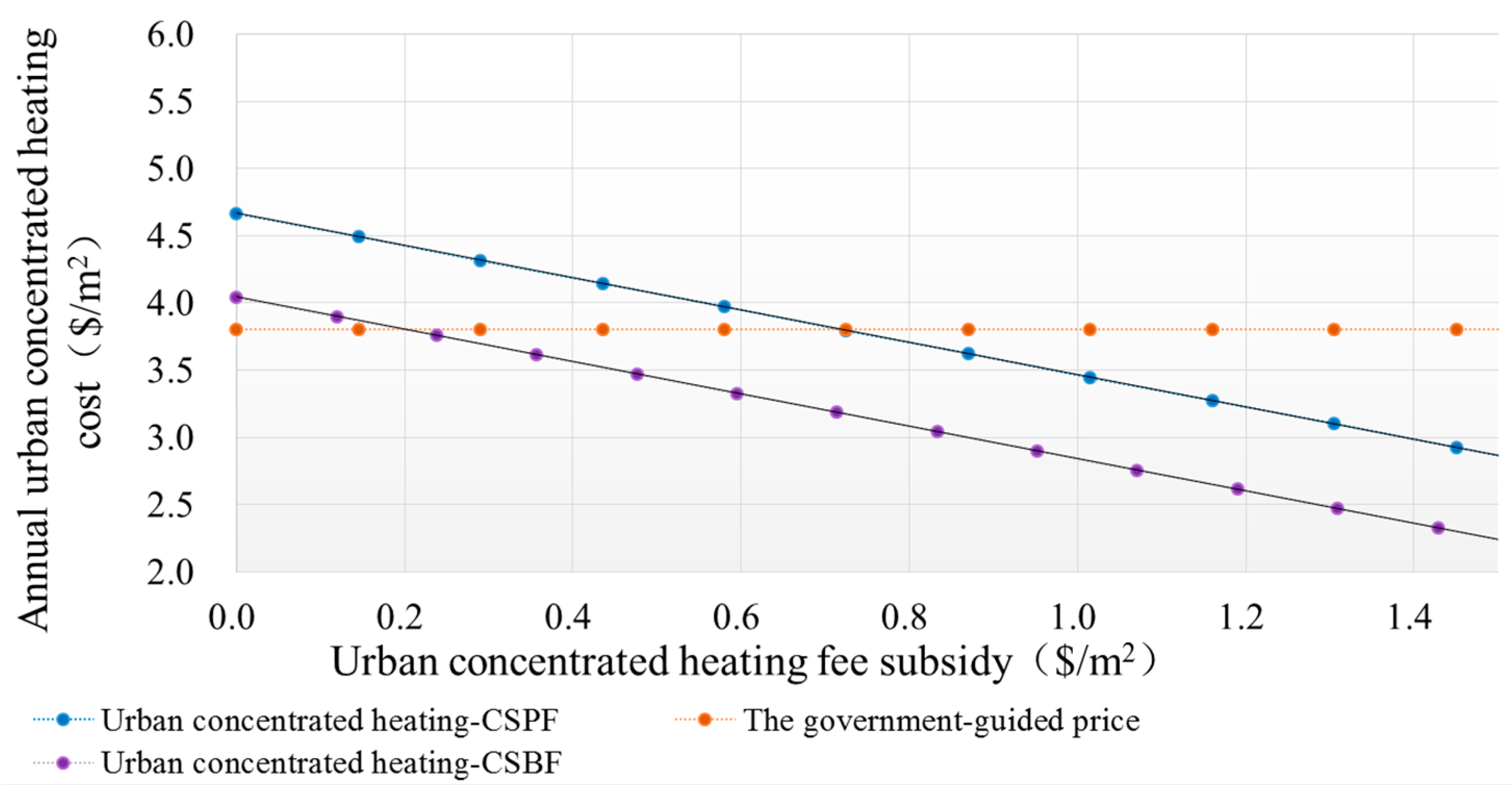

4.4.3. Influence of Concentrated Heating Fee Subsidy and CSDF Subsidy

Subsidies for urban concentrated heating fees and CSDF subsidies for rural residents can directly reduce final service costs. According to the first law of thermodynamics, an urban concentrated heating fee subsidy can be calculated by the following expression:

, where

is the CSDF subsidy ($/t),

is the heating fee subsidy ($/m

2),

is the boiler efficiency,

is the low heating value of CSDF (GJ/t) and

is the annual heating consumption on space-heating (GJ/m

2·a). The influence of subsidies for urban concentrated heating fees and CSDF subsidies for rural residents on the economic performance of a CSDF-DHS heating service is shown in

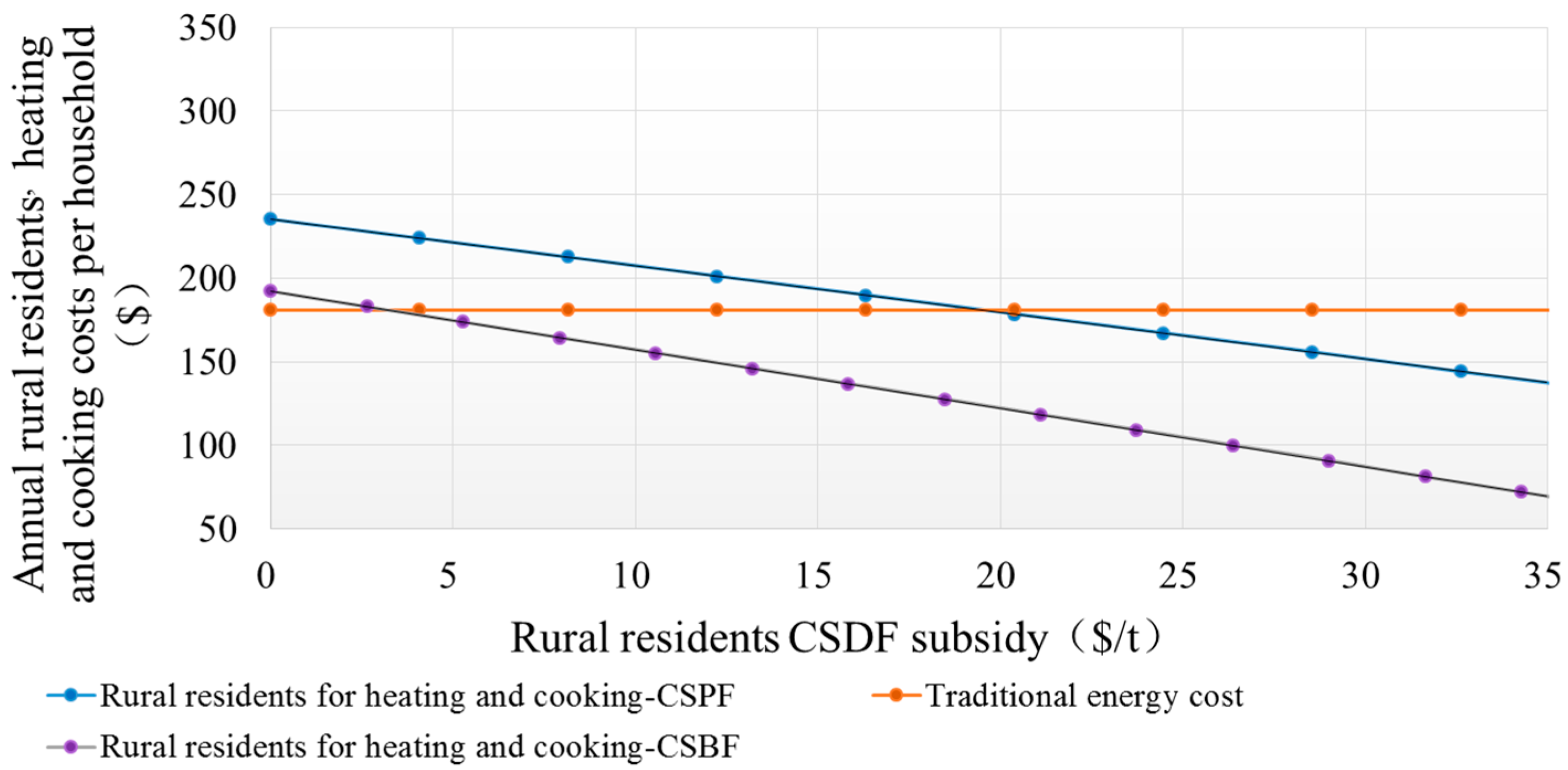

Figure 8 and

Figure 9. The results indicate that for urban concentrated heating cost, when the urban concentrated heating fee subsidy increases by $0.14/m

2, the urban concentrated heating cost decreases by $0.2/m

2 for both CSPF and CSBF. The urban concentrated heating cost reaches the government-guided price when the heating fee subsidies are $0.75/m

2 and $0.23/m

2, respectively. In terms of rural residents’ heating and cooking cost, when the rural CSDF subsidy increases by $1.4, the rural residents heating and cooking cost decreases by $5.1 and $4.1 per household for CSPF and CSBF, respectively. Rural residents’ heating and cooking costs for CSPF and CSBF can meet average traditional energy costs per household when their subsidy prices are $18.4/t and $3.2/t, respectively.

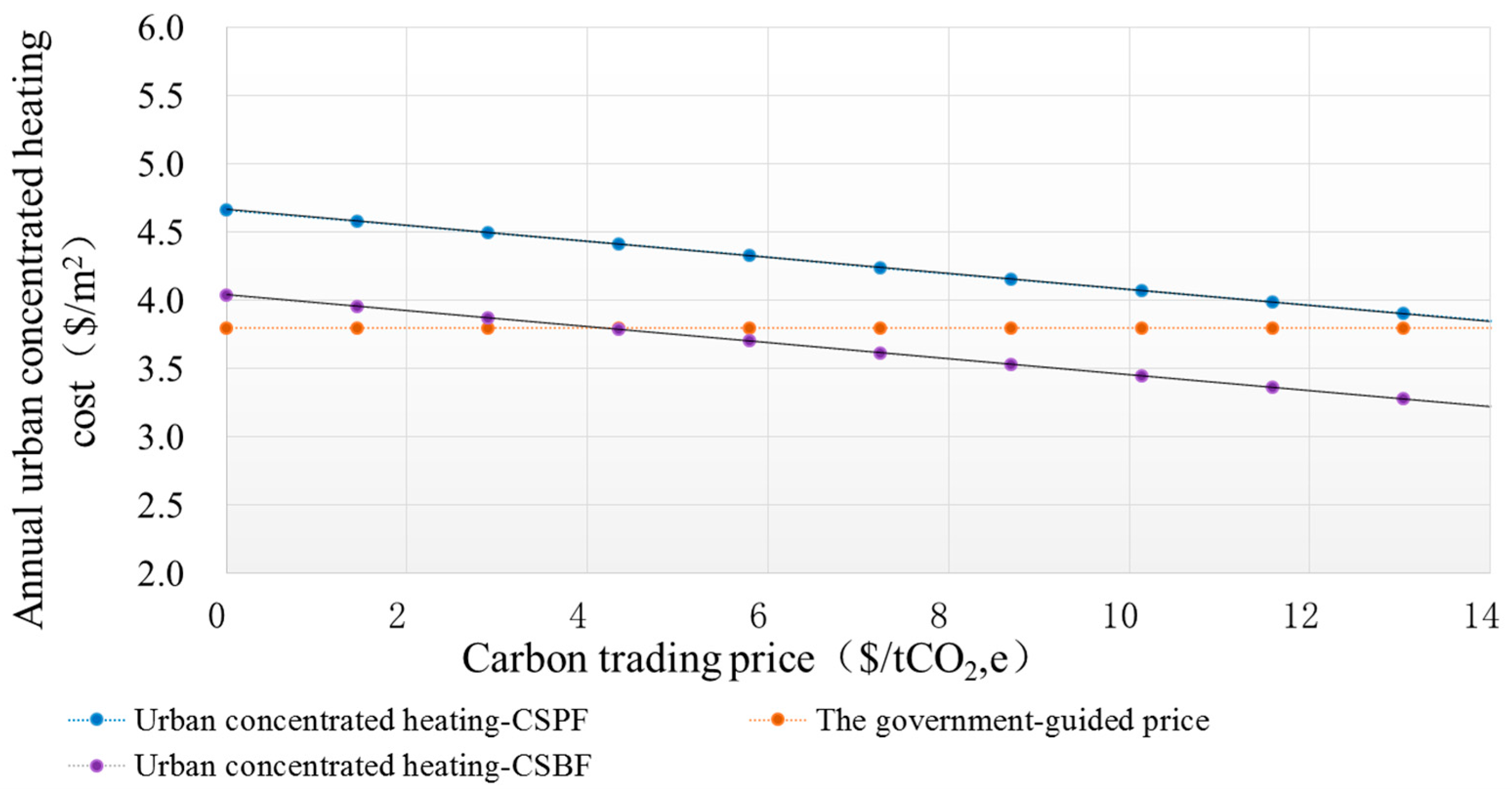

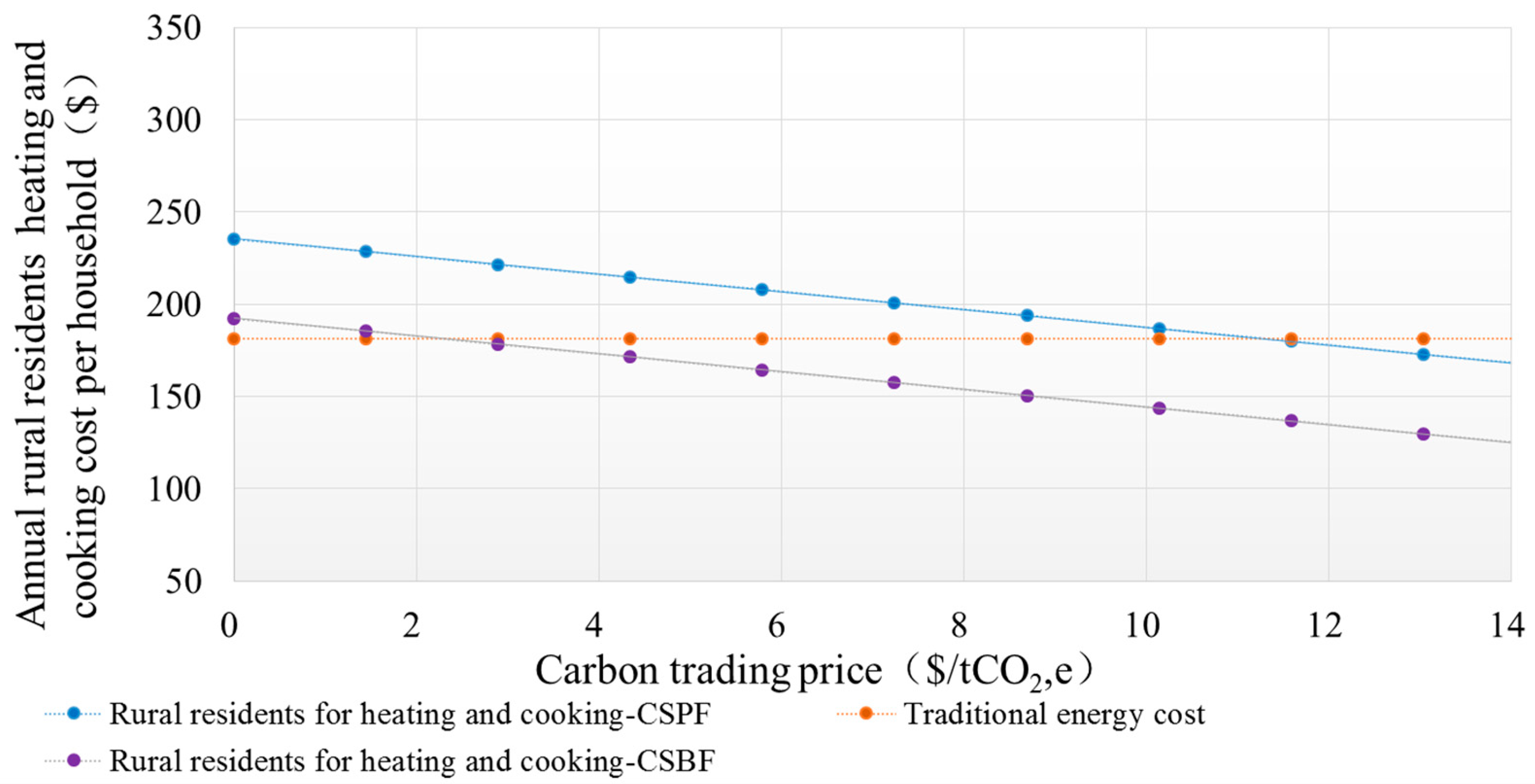

4.4.4. Influence of Carbon Trading

Recognized as a renewable energy project, the economic performance of a CSDF-DHS can be improved through carbon trading. Sun [

47] studied CDM project development and found that one tonne CSDF can create 1.37 t CO

2,e reduction. Accordingly, we set the carbon trading price from 0 to $14.5/t CO

2,e. The influence of carbon trading on the economic performance of a CSDF-DHS is illustrated in

Figure 10 and

Figure 11. The results indicate that, the urban concentrated heating costs of taking CSPF and CSBF reach government-guided prices when carbon trading prices are $15.3/tCO

2,e and $4.8/tCO

2,e respectively, and rural residents’ heating and cooking costs of taking CSPF and CSBF can meet average traditional energy cost per household when carbon trading prices are $11.3/tCO

2,e and $2.3/tCO

2,e respectively.

4.4.5. Influence of Preferential Electricity Price of CSDF Production

China has launched a preferential electricity price policy for the pretreating industry of agricultural products [

48]. Some experts argue that CSDF production should be listed in the catalog of the pretreating industry of agricultural products to decrease costs of CSDF production. According to the field survey, the electricity price for agricultural production is 27% lower than that of commerce and industry. The influence of this preferential electricity price for agriculture production on the economic performance of a CSDF-DHS heating service is shown in

Table 12.

The heating service cost of a CSDF-DHS under this policy is reduced compared to that under the CPS, but is still higher than that of traditional energy.

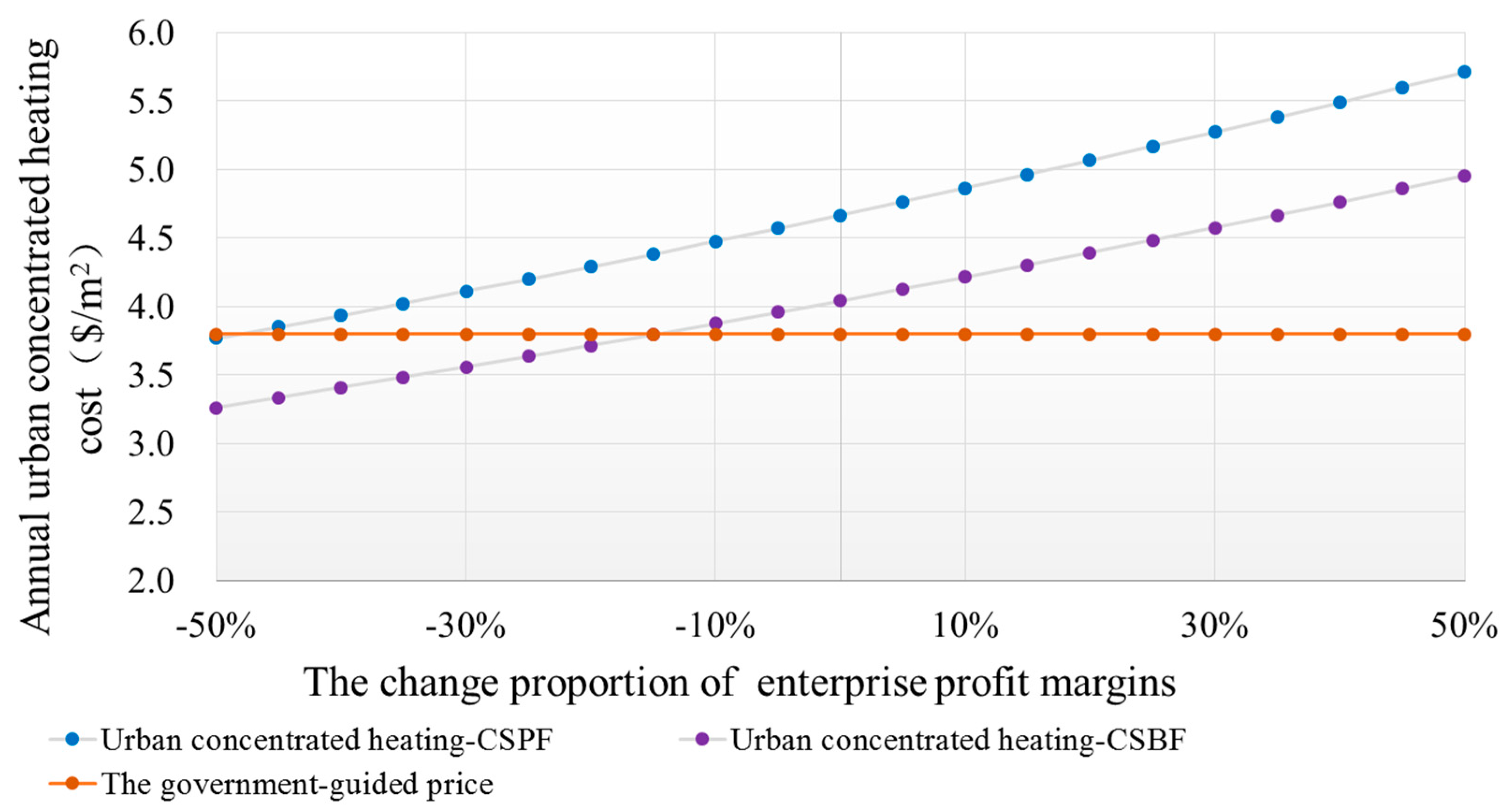

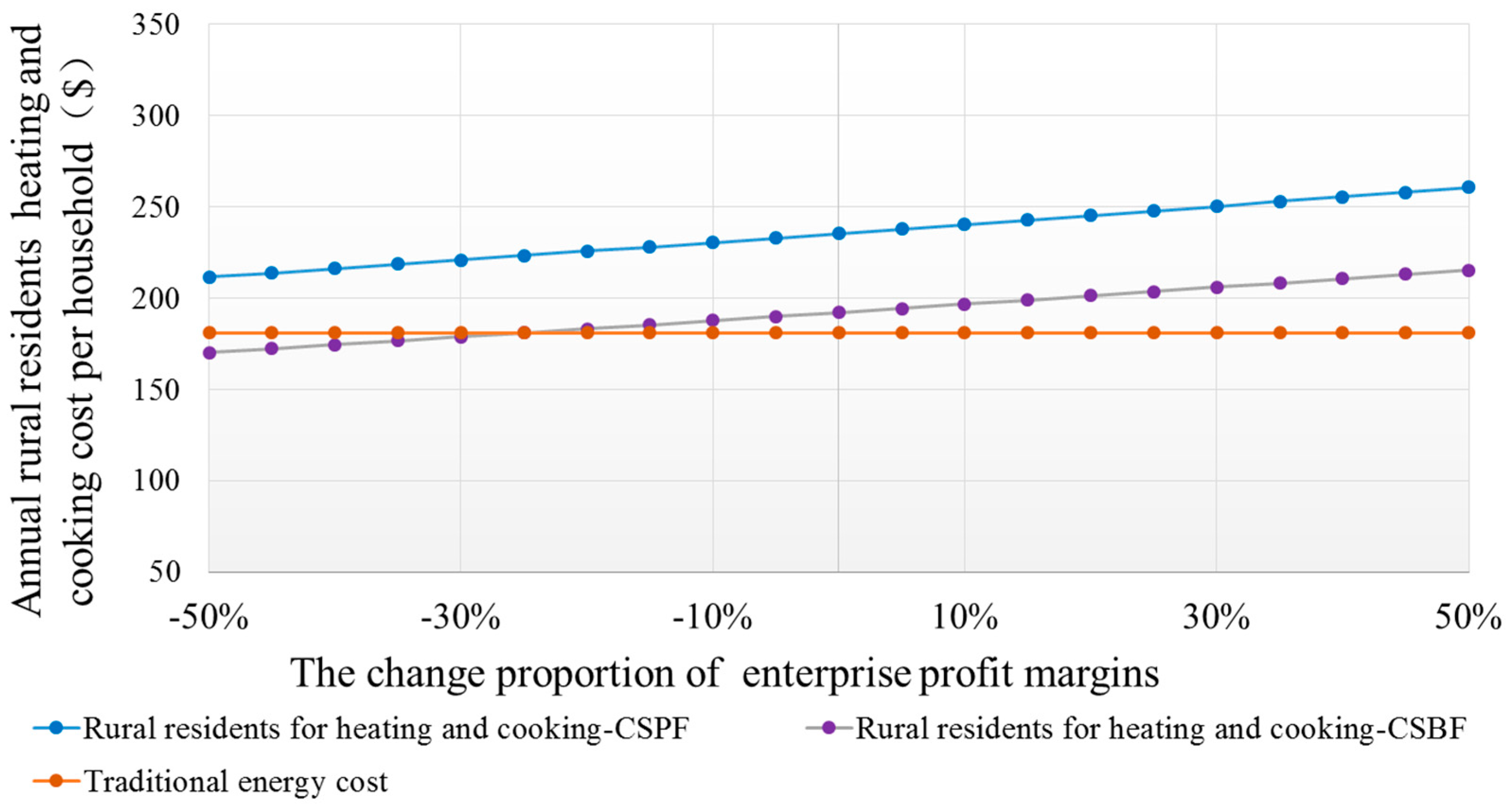

4.4.6. Influence of Enterprise Profit Margins

Under the CPS, enterprise profit margins in the three stages of a CSDF-DHS, which are: (1) corn straw collection and bale transportation; (2) CSDF production; and (3) CSDF utilization, are set to be (1) 30%; (2) 30% for urban heating and 10% for rural residents; and (3) 20%, respectively. Based on current enterprise profit margins, enterprises will adjust the profit margins according to the change of market price in CSDF. We set the enterprise profit margins to be increased by 50% or to be reduced by 50% for sensitivity analysis. In the case of increased margins, the profit increase is: (1) 45%; (2) 45% for urban heating and 15% for rural residents; and (3) 30%. In the case of decreased margins, the profit decrease is: (1) 15%; (2) 15% for urban heating and 5% for rural residents; and (3) 10%. The influence of enterprise profit margins in the supply chain on the economic performance of a CSDF-DHS is shown in

Figure 12 and

Figure 13.

The results indicate that, in terms of CSPF and CSBF, urban concentrated heating costs reach a government-guided price when enterprise profit margins in the supply chain reduce by 47.8% and 17.8%, respectively. In terms of CSPF and CSBF, rural residents’ heating and cooking costs can meet average traditional energy costs when enterprise profit margins in the supply chain reduce by 111.2% and 25.0%, respectively.

4.4.7. Influence of the Boiler Efficiency of Urban Concentrated Heating Station

Improving energy efficiency of CSDF boilers can also reduce heating service cost. How heating station boiler efficiency influences the economic performance of a CSDF-DHS is shown in

Figure 14. The results indicate that when CSDF quantity is constant, the urban concentrated heating service area increases with improvement in the energy efficiency of CSDF boilers and the urban concentrated heating cost declines. When the energy efficiency of CSBF boilers is 87.7%, the urban concentrated heating cost can reach the government-guided price. Also, the urban concentrated heating cost for CSPF is always higher than the government-guided price.

4.5. Data Uncertainty

Many data used referring to the above in this case study are obtained by a field survey and expert interviews, which are basically constant with the average and rough level of the selected samples but may be different to a certain extent with actual data or statistics accounted by other methods.