1. Introduction

The trochoidal-gear technology has been growing in groundbreaking areas, such as life science (pharmaceutical and biomedicine) and its presence is becoming more usual in the last years [

1]. Low-pulsation flow ripple, together with simplicity and versatility, are inherent characteristics behind the significant launch of the trochoidal-gear technology towards pumps.

Forthcoming applications, such as the direct dosing in exact quantity, maximum spraying, and precision in their location over the plant in agriculture sector, are demanding trochoidal-gear technology to take a step forward in the conceiving stage of new pumps. Here, the Academia can make contributions with substantial knowledge of the whole process, not only by the numerical approach and performance analysis of existing units, but also in the prototype development and manufacturing of new-born units, which is not minor work, and the expected know-how is of great value.

By reviewing the current state in the research field of hydraulic gear machines, a great amount of works have been published, especially the reference book of Ivantysyn and Ivantysynova [

2]. The consulted literature reveals that trochoidal-gear studies are mainly theoretical methodologies, numerical approaches, and simulations corroborated with experimental validation in existing units, especially projects in collaboration with an industrial partner that is the manufacturer. Nevertheless, a lack of works devoted to the development of a trochoidal-gear (gerotor) pump from scratch is revealed [

3].

The authors, predominantly, would like to focus on the most recent open literature of the last three-year period due to the constant and fast progress of the research area. With regard to hydraulic pumps in this period, the significant publications are mainly devoted to lubricating, deformation, and leakage performance, among others, in an external gear pump [

4], crescent pump [

5], combination of external gear pump, and gerotor pump [

6].

With regard to trochoidal-gear pumps, the novel investigations are primarily related to numerical studies validated with experimental methodology. Altare and Rundo [

7,

8], in their new published works, present an advance in the understanding of gerotor pump technology through the simulation approach, among others, in suction capability, port plate shape, and inlet pipe location. Moreover, the deformation of the cover is studied, revealing two important consequences: the increment of the leakages and the generation of an additional volume variation, which alters the pressure ripple. The work of Pellegri et al. [

9,

10] is devoted to the comparison of two numerical approaches and their agreement with experimental results under proper assumptions. Frosina et al. [

11] focused their work in the analysis of geometrical effects of a lubrication gerotor pump, validated with experimental pressure oscillations. On the other hand, cavitation phenomenon under particular operation conditions of a lubrication gerotor pump of an internal combustion engine is investigated in Buono et al. [

12] by monitoring experimental work.

Undoubtedly, a combination of theoretical and numerical methods to guide the designer in an early stage of the design process is recommendable, even indispensable. Nonetheless, from the initial concept to the first prototype there is an arduous and sinuous journey, where the theoretical approach is not always directly reflected in the prototype performance results. These first results will be taken as a frame of reference of this new-born and proof of concept [

13].

With regard to experimental procedure, non-invasive visualization techniques are being widely used in recent published works such as Stryczek et al. [

6], Garcia-Vilchez et al. [

14], and Raush et al. [

15]. This current experimental research, at different extend and achievement, pursues to be a validation tool of the numerical modeling results.

Other key publications are related to reduce contact stress by new variable clearance strategies that diminish collisions in Hsieh [

16] by changing the geometric parameters of the trochoidal gearing teeth profile in Ivanović et al. [

17,

18] and profile design in hydrostatic units in Nag and Maiti [

19]. As a versatility sign of trochoidal-gear units, the hydraulic flow ripple cancellation by using the primary flow source has been investigated by O’Shea [

20]. The implementation of a feed-forward motor torque control algorithm reduces flow ripple, and therefore pressure ripple, by influencing the speed of a relatively high volumetric displacement low-inertia pump, a gerotor pump, through open loop control of the driving motor torque. The gerotor pumps, as compared to some other displacement units, have been found to have a ripple profile that is dominated by the fundamental pumping harmonic. Another example is the GeroMAG concept, a non shaft-drive gerotor pump with magnetic-driving outer rotor [

13] with the advantages of magnetic power transmission [

21].

The trend of the applications of polymer composite materials instead of metals is being gradually introduced in fluid power elements, as shown in Stryczek et al. [

22]. The work presented by Stryczek et al. [

23] was undoubtedly a step forward in the gerotor pump technology manufacturing a polyoxymethylene (POM) trochoidal-gear set and researching by means of a computational model how the stress and deformations are influenced by the design factors. Another remarkable work has been carried out by Mancini et al. [

24] with their study of polyphthalamide/glass-fiber and polyphthalamide/glass-fiber/polytetrafluoroethylene-based composites as substitutes for aluminum and steel, respectively, in the production of motorcycle oil gerotor pump parts (housing, shaft/inner, and outer gear). Experimental curves were obtained by monitoring gerotor pump pressure, speed, flow rate and temperature in a 150 cc motorcycle, with the engine rotation increasing from zero to its maximum of about 11,200 rpm. Numerical mechanical analyses are performed and results suggest that mechanical properties and stresses generated can withstand with pressure up to 1.8 bar. Unfortunately, volumetric efficiency indexes are not reported. Rodinov and Rekadze [

25] performed an experimental vibroacustic study in spur gear pumps with different materials concerning the noise. The driven and driver/shaft gear were made of different composite materials and the case with stainless steel. As a result, it can be stated that materials with lower strength characteristics radiate less noise and vibration. Regrettably, durability and volumetric efficiency indexes are not reported.

The next topic to be covered is the scale, the miniature size although not being micro size, where few studies are available in the open literature regarding trochoidal-gear pumps with the exception of Mancò et al. [

26]. In small scales, the current knowledge, design criteria, and know-how used in conventional sizes become questionable, as it is conditioned by the demanding axial and radial clearances, as it has also recently been evidenced by Gamez-Montero et al. [

27], Castilla et al. [

28], and this present work.

The compendium of the qualities of trochoidal-gear technology, gerotor pump versatility, polymer composite materials, and the scale/size factor, together with magnetic-driven transmission has led to the idea of a magnet-sleeve-sealed mini trochoidal-gear pump (mTGp). From its original concept to the last phase of the design development, the prototype, this new product mTGp intends to overcome problems such as noise, vibration, maintenance, materials, and dimensions. The paper aims to show the technological path followed from the concept, design, and model to the manufacture of the first prototype, where the analytical and simulation studies are not always directly mirrored in the prototype performance indexes.

Thus, the aim of the mini trochoidal-gear pump is to achieve an average volumetric flow rate at a low rotational speed with satisfactory volumetric efficiency together with being leakage-free (sleeve sealed) and reducing air-borne noise (compact and polymer material). The configuration of the mini trochoidal-gear pump, as a variable flow pump operating powered by a magnet-sleeve brushless motor profiting the configuration, will be able to influence future applications, among others, domestic and mobile hydraulic packs.

As far as authors’ knowledge, such technological proposals have not been shown, not yet proving viability. Subsequently, the prototype of the mini trochoidal-gear pump is a feasible proof of concept supported by functional indexes and experimental results.

2. The Mini Trochoidal-Gear Pump Prototype

Basically, a trochoidal-gear pump is an internal gear pump, also known as gerotor pump, with a couple of mated trochoidal-gears so that each tooth is always in sliding contact. The process of pumping is carried out when the rotational movement of the gear set creates circulation of increasing volumes from the inlet to the outlet port of the pump.

2.1. The Mini Trochoidal-Gear Unit

2.1.1. A Trochoidal-Gear Set

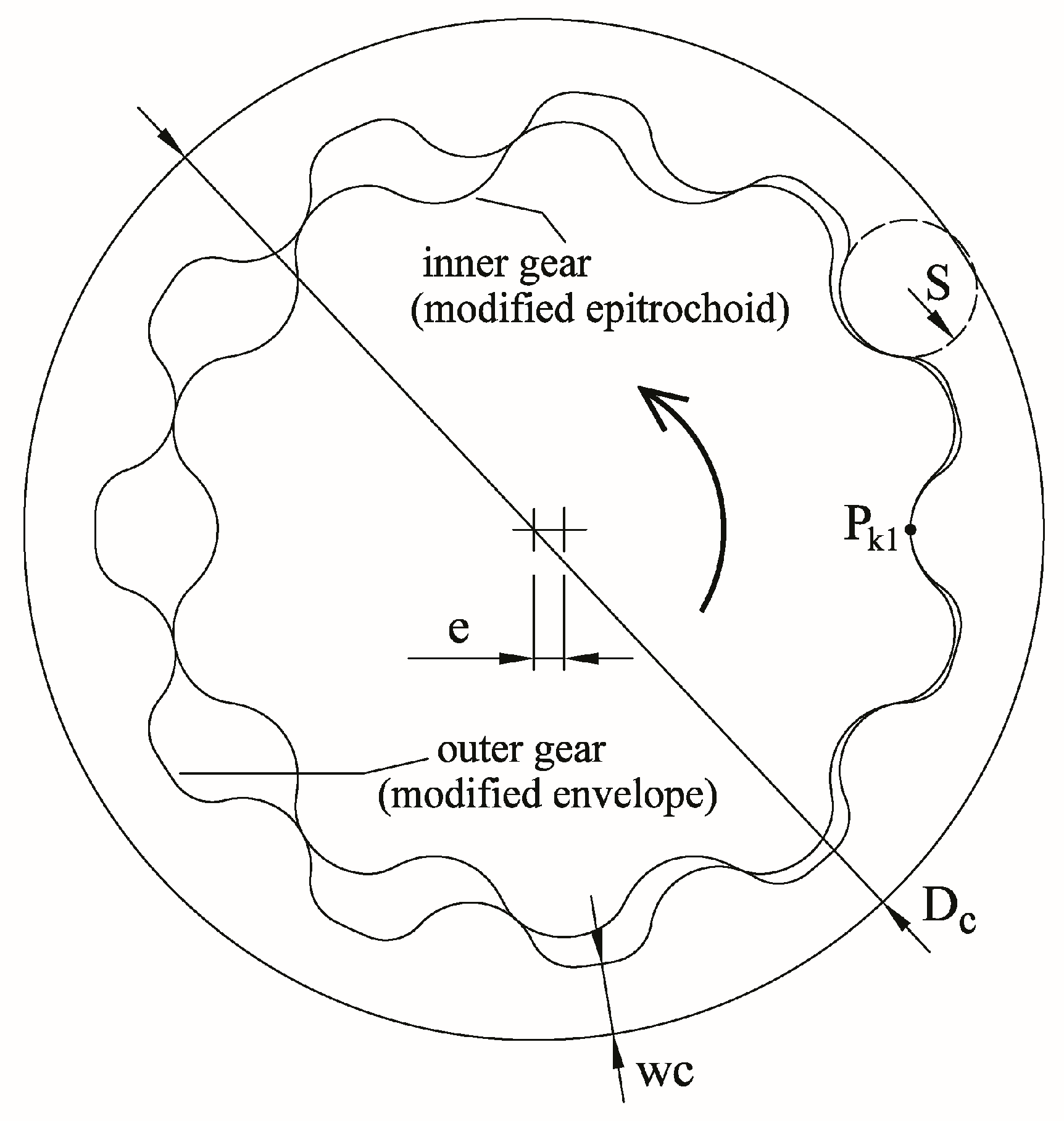

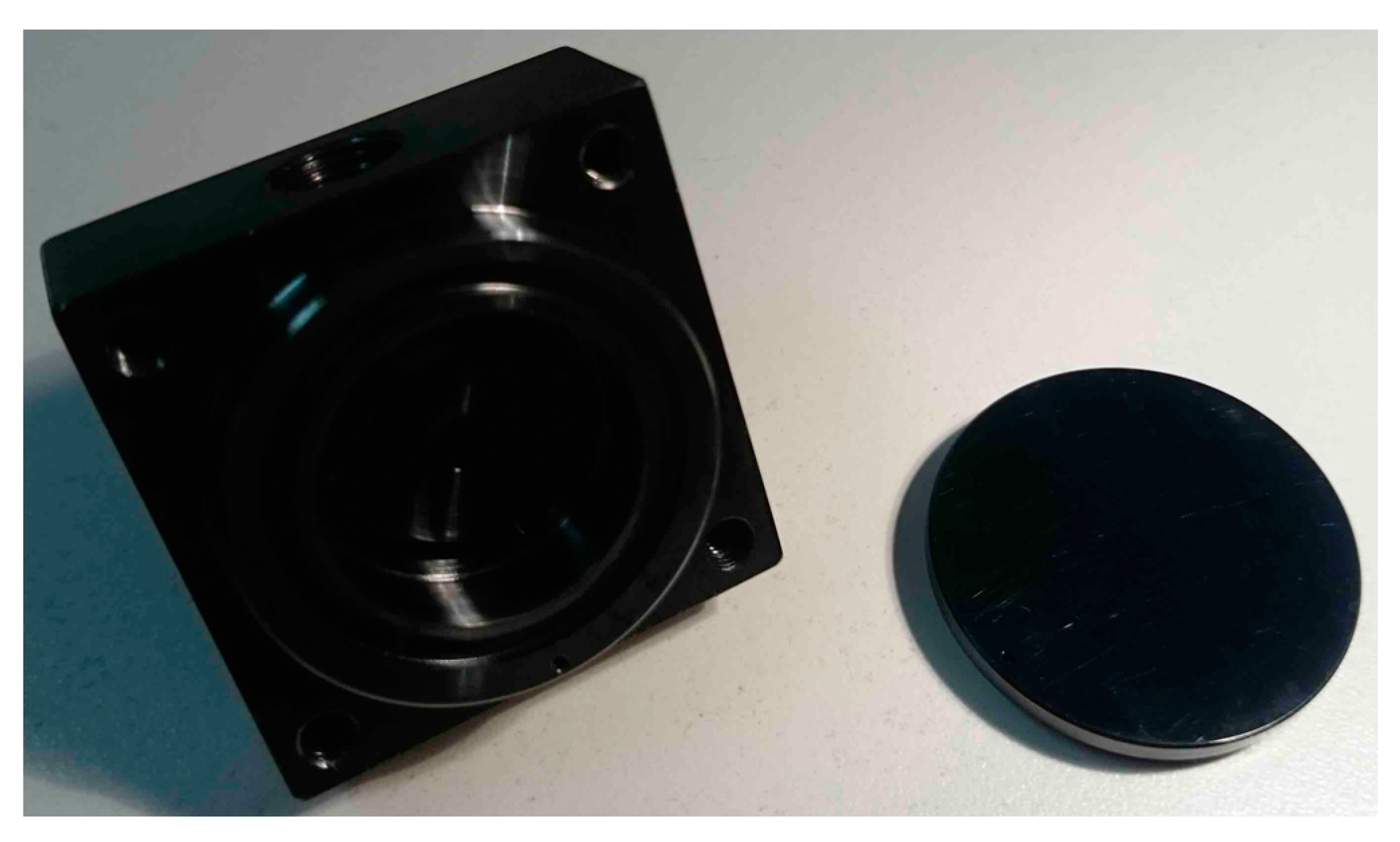

A trochoidal-gear set of a gerotor pump is a pair of gears with a trochoidal-teeth profile: inner/internal and outer/external gears (see

Figure 1). The two gears are mated so that each tooth of the inner gear is always in sliding contact with a tooth of the outer gear, and interteeth contact occurs. Both gears rotate in the same direction but at different speeds because of the external gear has one tooth more than the inner gear, and consequently, the inner gear is slightly faster than the outer gear.

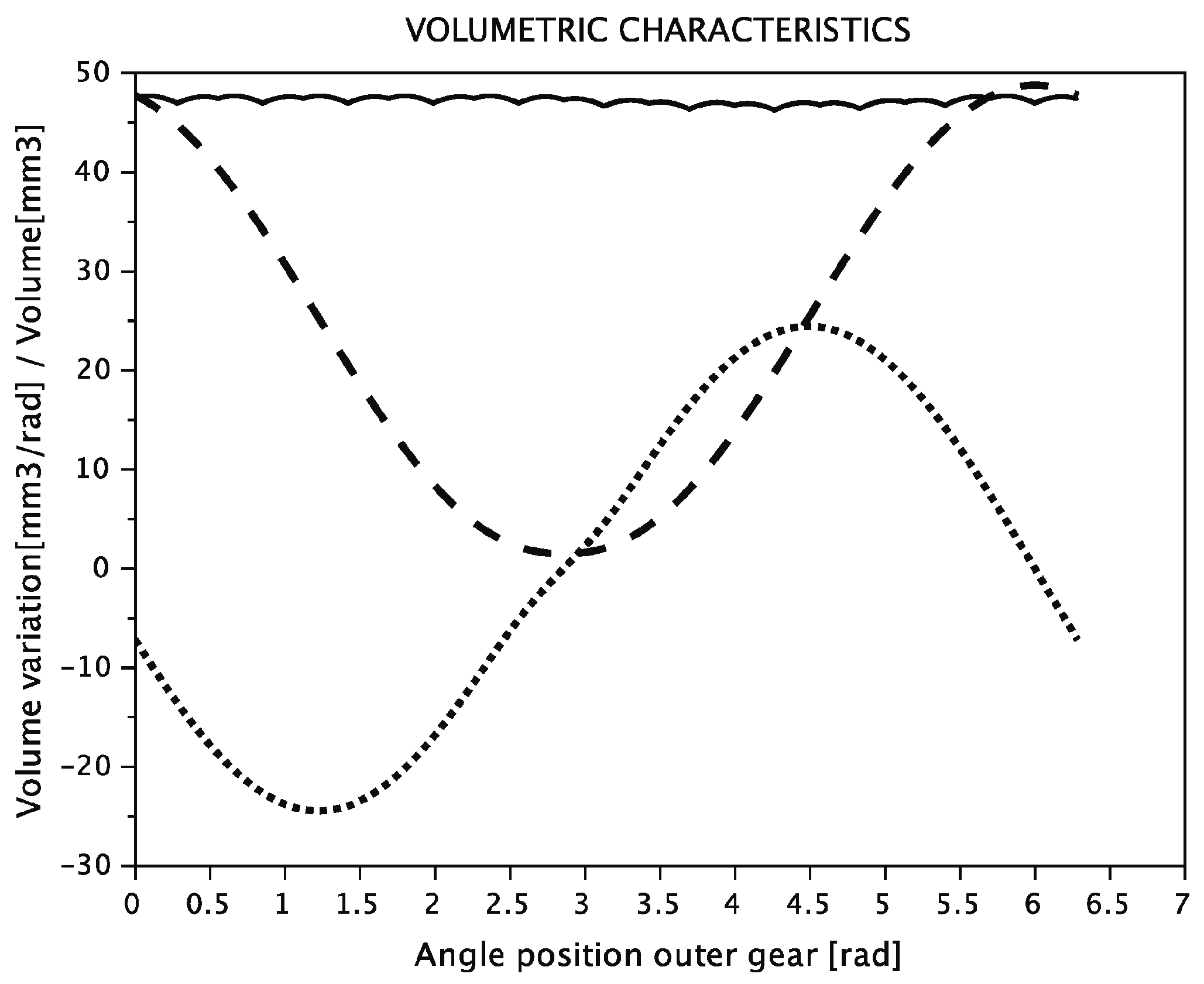

2.1.2. Model of the Mini Trochoidal-Gear Unit

In a different approach from previous authors’ works [

13], the authors required in this work to conceive the mini trochoidal-gear unit by using a standard-commercial trochoidal-gear set widely use, among others, in in-line and in-tank fuel pumps. Although very basic information can be obtained from the specification data sheet of such pumps, it could be taken as a frame of reference in the proposed concept of a mini trochoidal-gear pump.

An extensive study of available sheet commercial literature shows a great number of standard trochoidal-gear sets, and each application has to be adapted to fit one of them. However, the selection of the design parameters that has led to the geometry of these standard sets is not clear, at least in the available information sheets. In this work, the design parameters of the selected standard trochoidal-gear set that characterizes the performance of contact stress, volumetric characteristics, and flow irregularity are investigated by means of GeroLAB Package System [

29], along with the authors’ methodology based on best practice rules [

3].

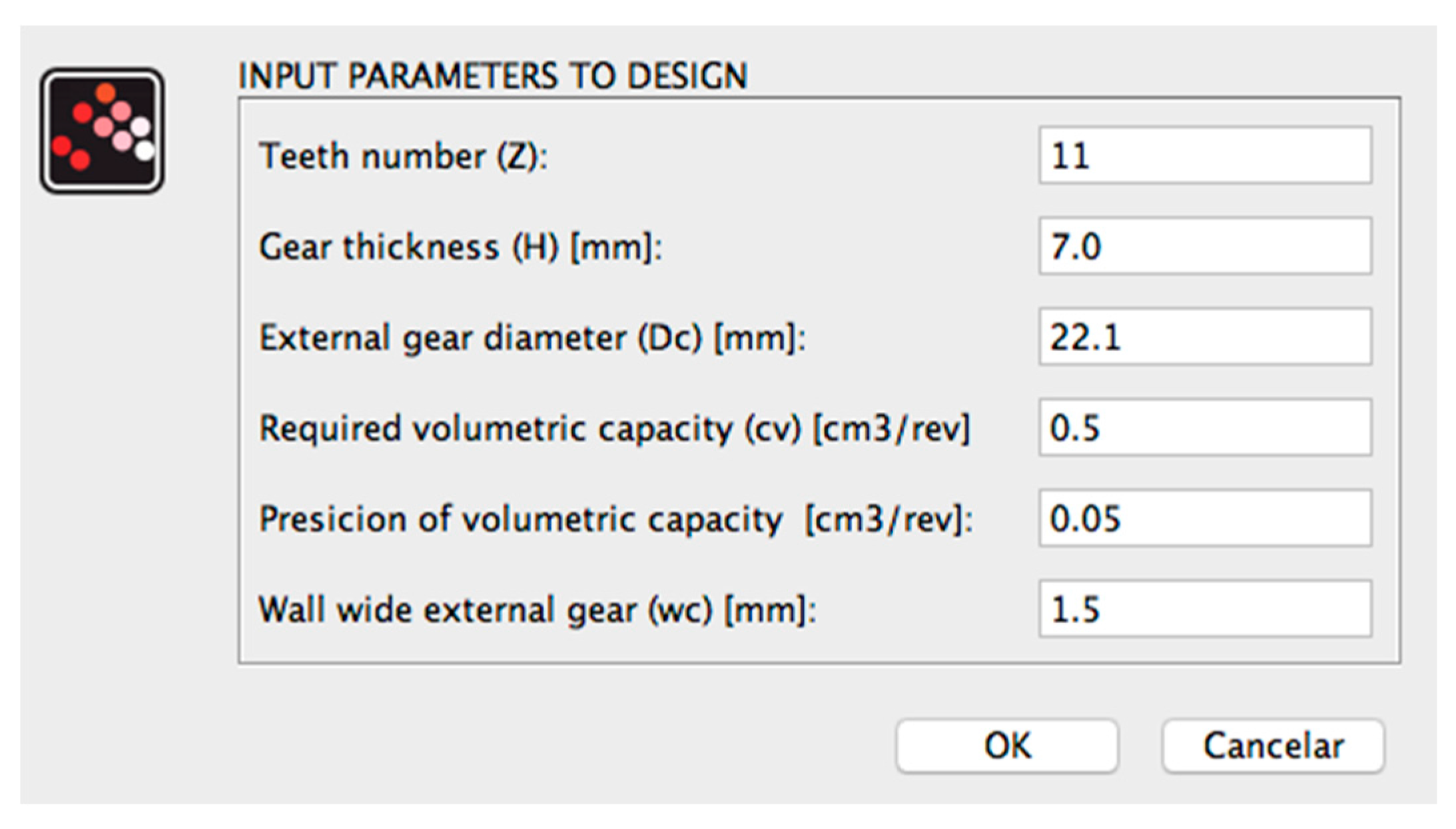

By accurately measuring the selected standard trochoidal-gear set of

Z = 11 outer gear teeth, the dimensional constraints, see

Figure 1, of thickness

H in [mm], the external diameter of outer gear

Dc in [mm], and the wall wide of the outer gear

wc in [mm] are introduced in the Design module of the GeroLAB 2.0 software, as shown in

Figure 2. The characterization of the system implies a standard volumetric flow rate that can be calculated by the volumetric capacity

cv in [cm

3/rev].

The characteristics of the mini-trochoidal gear be additionally evaluated by taking the formerly published author’s own procedure. The eccentricity

e in [mm] of the trochoidal-gear set can be first evaluated by using a heuristic approach to the equation,

where

wc is calculated as follows,

being just an estimation because it is not taking into account the number of teeth of the outer gear, working pressure, contact stress, and gear material. Now, the arc radius of the outer gear tooth

S in [mm] can be calculated as (see

Figure 1):

where

λ is the tooth profile height correction coefficient—function of the eccentricity, the number of teeth, the arc radius of the outer gear tooth, and the tip diameter of the inner gear—with recommended values going from 0.6 (larger

S) to 0.8 (shorter

S) [

23].

The theoretical torque

T in [N·m/bar], theoretical power

N in [W/bar·rpm], the tip velocity of the internal gear

Vt in [m/s·rpm], and the theoretical radial load

RL in [N/bar] can be estimated by using the following expressions:

Finally, the mini trochoidal-gear figures are abridged in

Table 1.

2.1.3. Profiles of the Mini Trochoidal-Gear Unit

Previously, geometric and characteristics of the trochoidal-gear unit were set, and now the well-stablished expressions to draw the trochoidal profiles (see

Figure 3) are used by means of the free software GeroLAB [

30].

2.1.4. Materials and Manufacture of the Mini Trochoidal-Gear Unit

A first unit of the mini trochoidal-gear set has been manufactured by Aleaciones de Metales Sinterizados (AMES) of sintered metal material. The powder metallurgical material follows the requirements and specifications of the standard ISO 5755:2012 owing to its combination of hardness and mechanical strength.

The gear set has a tolerance grade of trochoidal tip-clearance from 10 to 64 μm to achieve precise rotation, together with a precision thickness of 40 μm and a surface roughness of 0.4 Ra.

The trend of applications of polymer composite materials and their benefits wanted to be examined with the mTGp. Based on the analysis of the mini trochoidal-gear unit, working operation, and expertise of Stryczek et al. [

31], the decision of choosing as polymer composite material the pure polyoxymethylene (POM) is grounded on the following characteristics: high strength and rigidity, its accessibility on the market, low price, and among other things, its handling by means of the injection molding; summarizing, its average characteristics and qualities are presented in

Table 2. The mini trochoidal-gear POM set has been manufactured by the Fluid Power Research Group at Wrocław University of Technology, and it is shown in

Figure 4.

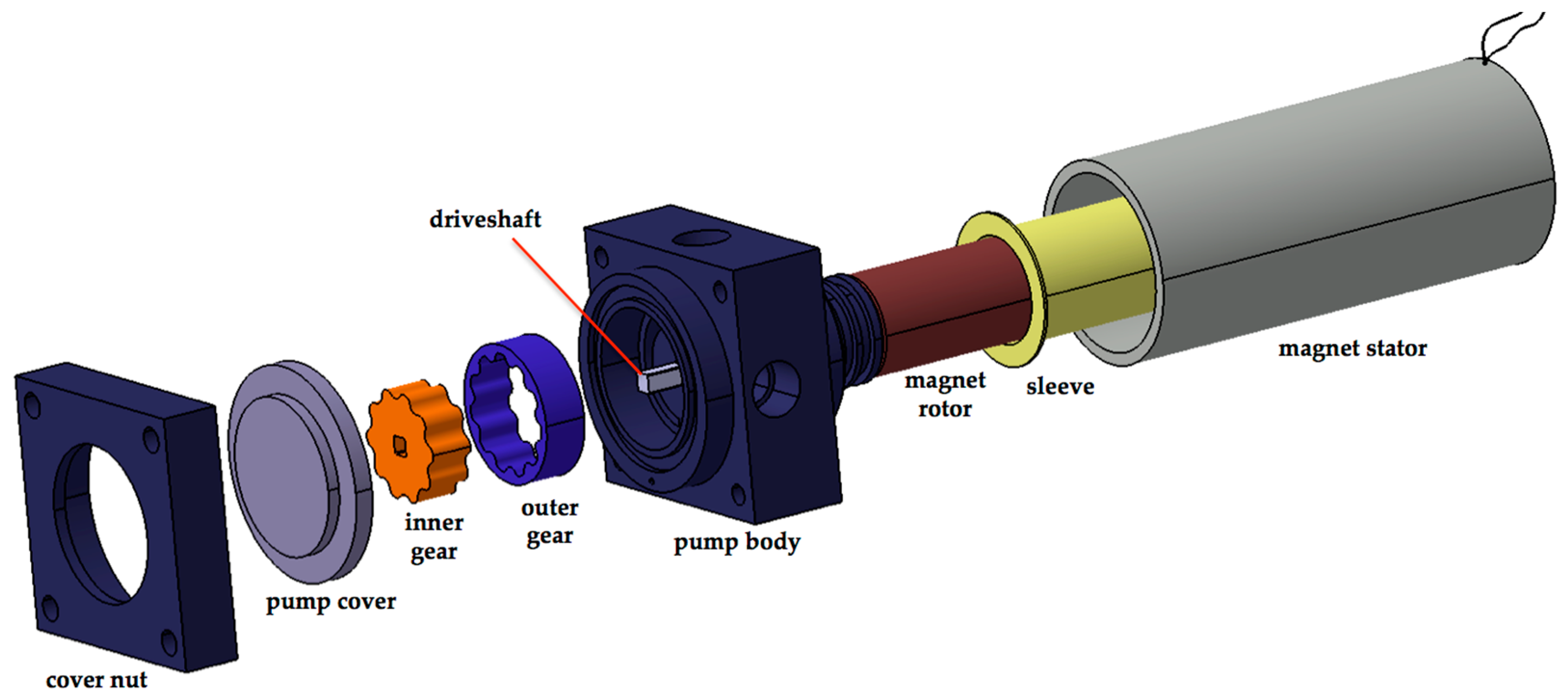

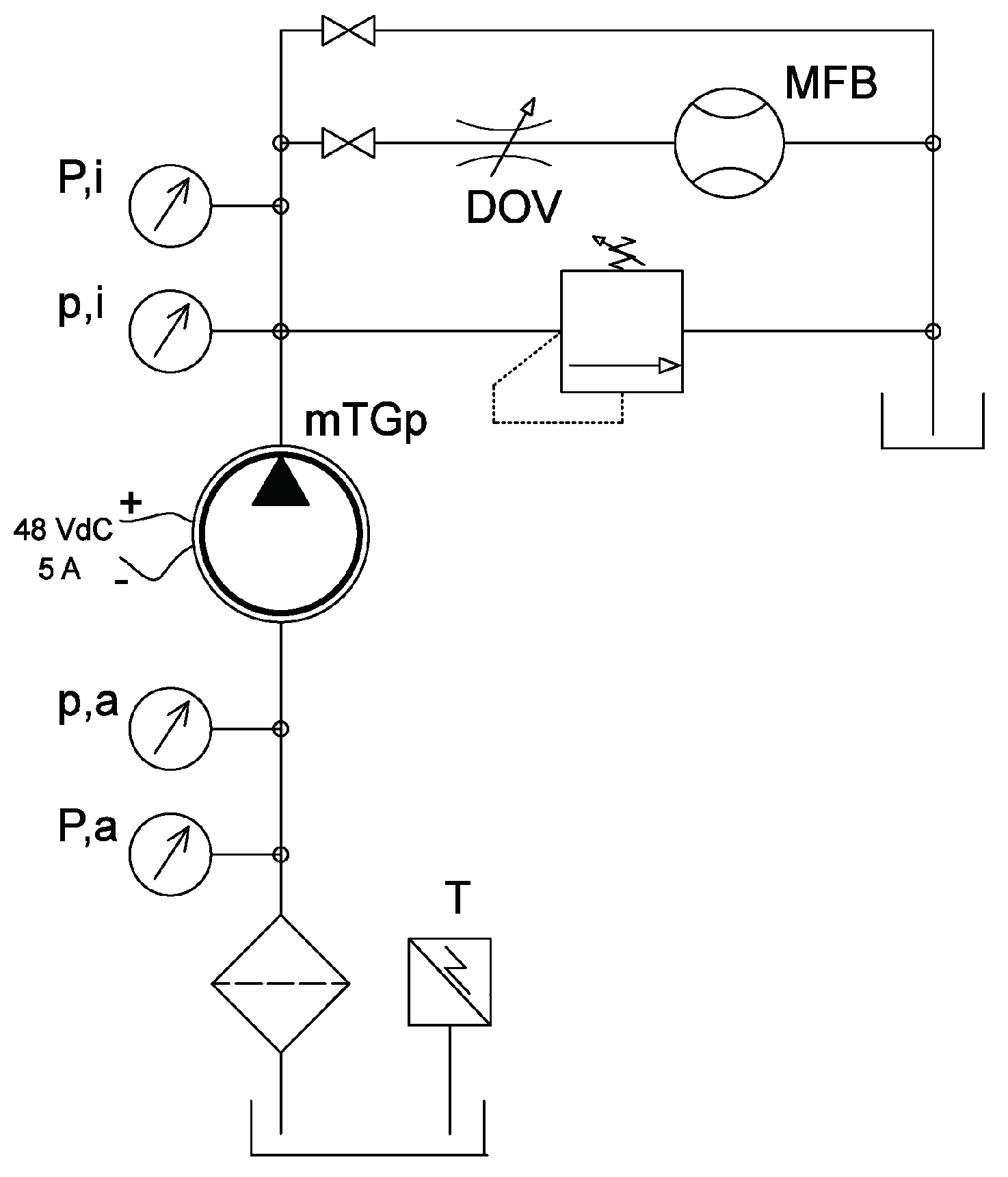

2.2. The Mini Trochoidal-Gear Pump Architecture

The mini trochoidal-gear pump architecture embodies the mini trochoidal-gear set, the magnetic-driving motor, and the pump body and covers. This configuration of the pump is compact and sealed without the exterior driveshaft.

Figure 5 depicts the preliminary pump design as a technology demonstration by means of the construction of a prototype with three main elements: the magnet stator, the pump body, and the pump cover. The pump body includes the inlet and outlet ports without the metering porting with grooves owing to the special design of the damping outlet port and the possibility of bi-directional work. The depth of the porting is such that it does not restrict the pump flow.

Special attention is taken to enclose the ensemble. On one hand, the magnet stator is screwed in the pump body with two main functions: to tighten the sleeve against the pump body to guarantee the sealing and to ensure concentricity and minimum magnetic-gap between pole pieces, and to stator through the thin wall of the sleeve. On the other hand, the division into two covers, the pump cover and the cover nut, allows for a perfect flat fitting of the pump cover over both inlet and outlet gears, while a margin of axial clearance can be adjusted by means of the tight level of the cover nut. In this first prototype, there is no shadow porting carved on the pump cover.

The magnet rotor is coupled directly by a driveshaft to the inner gear. This is a decisive advantage of using an internal direct drive is the prevention of sealing the driveshaft.

The material of the pump body, pump cover, cover nut and driveshaft is the same, that is, steel of high quality. In this first prototype, steel was thought to be under control in the manufacturing process, surface roughness, and tolerance accuracy, as well as the temperature effects. The superficial roughness is 0.05 Ra where the trochoidal-gear is allocated, the housing of the pump body, with a maximum tolerance in the external diameter of external gear of 20 μm. In the next step, the material of a second prototype will be aluminum, or similar alloy to be studied, thus reducing weight.

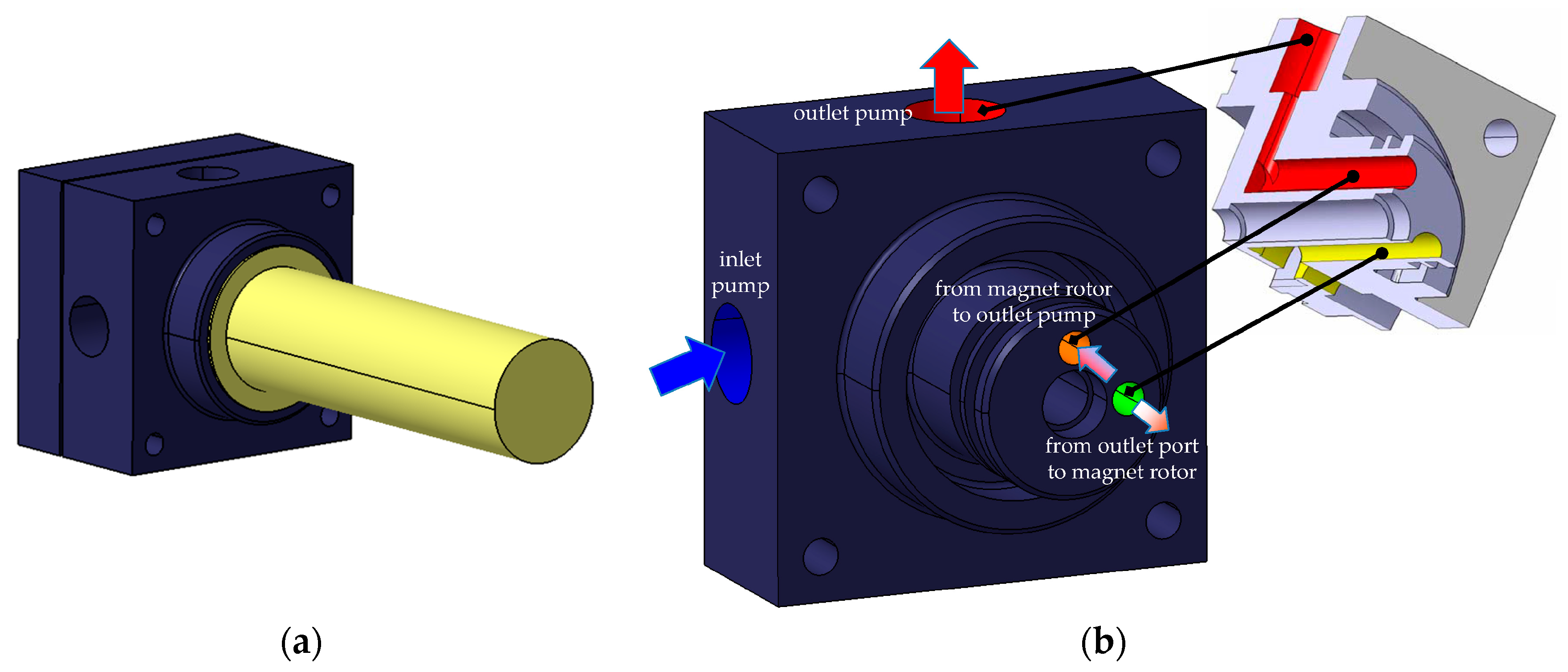

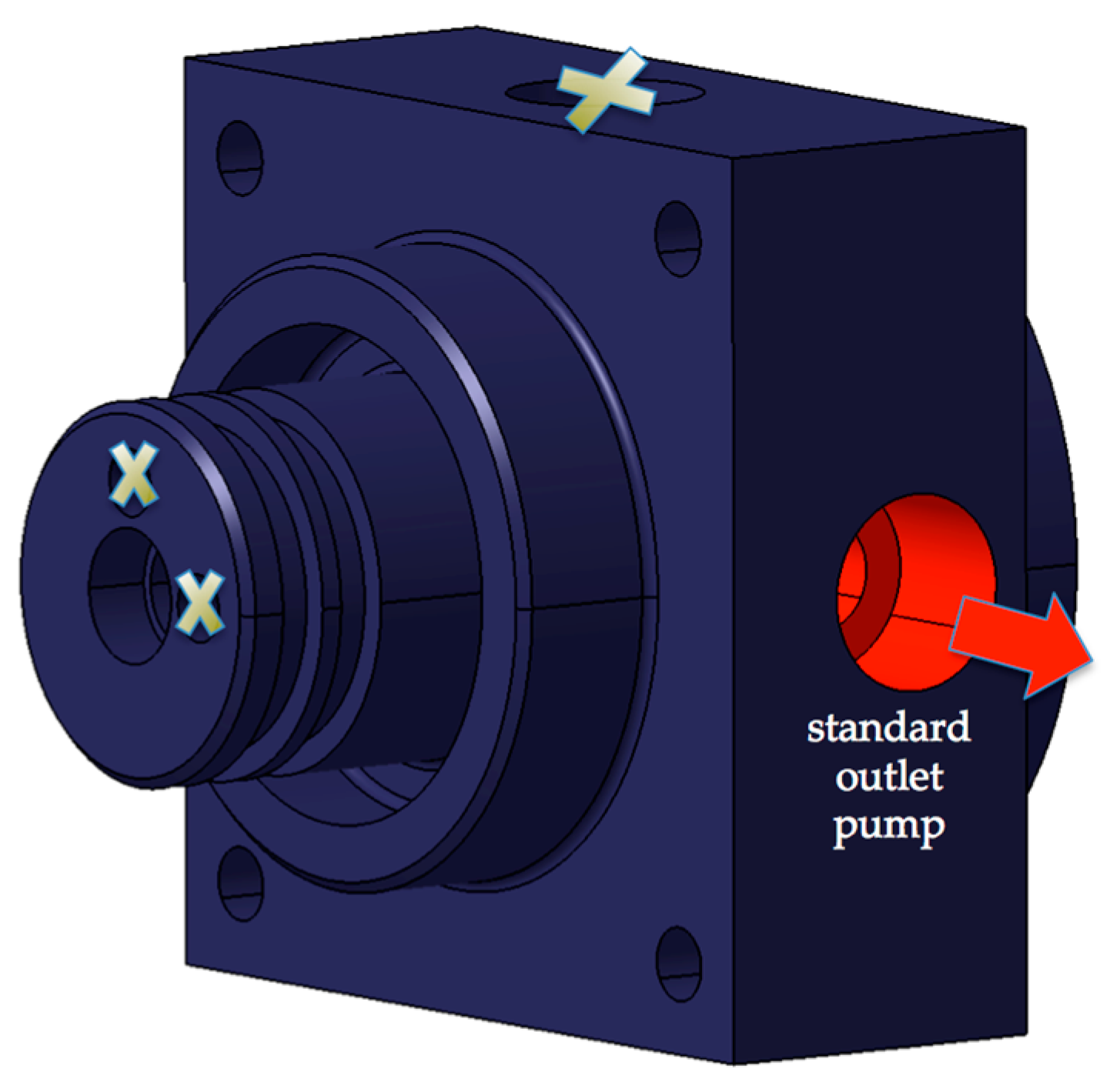

2.2.1. Conception of the ‘In-Out Sleeve Passageway’ Configuration

The sleeve embodies the magnet rotor becoming a hermetic set together with the pump body and pump cover filled with liquid (see

Figure 6a). A tight magnet-gap is formed and intended for avoiding sliding contact between the sleeve and the magnet rotor, creating hydrodynamic lubrication helping to support it. The coaxially of each gear in its own rotation axis and its eccentricity is guaranteed by the guide provided by the pump body to the mechanical driveshaft connected to the inner gear. Then, the electro-magnetic driving on the magnet stator performs the necessary torque to the rotation.

The mTGp confronts then the main technological challenge of ensuring whole interior of the pump is filled and wetted with working fluid and the formation of the hydrodynamic film. The conception of this challenge is named ‘in-out sleeve passageway’ and it is schemed in

Figure 6b. From the outlet port, the working fluid is not directly guided to the outlet of the pump, but it is redirected to the interior of the sleeve, from the outlet port to the magnet rotor through a smart conduction drilled in the pump body. Then, from the magnet rotor to the outlet of the pump, the working fluid is guided outside of the sleeve through another conduction drilled in the pump body.

Since the brushless motor is a part of the mini pump, the ‘in-out sleeve passageway’ additionally has the function of heat dissipation to ensure its operation within the defined temperature limits. Besides, the rotational movement of the magnet rotor is also helping the film formation and the pumping effect.

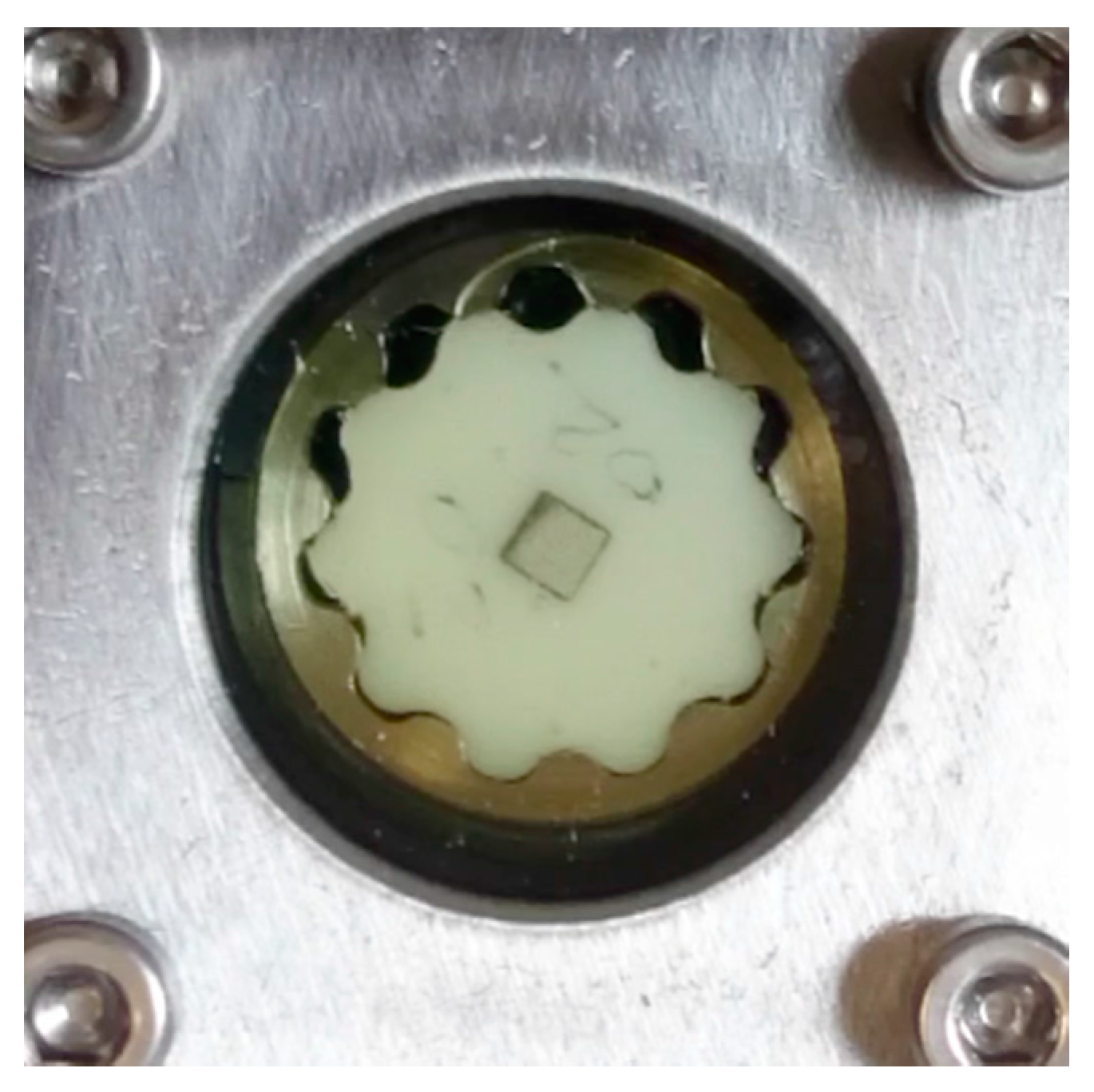

2.2.2. The Surface and Coating Preparation

A special treatment with the surface characteristics, the coating ‘diamond-like-carbon’ (DLC), has been performed on the pump body and pump cover in contact with the trochoidal-gear unit by FLUBETECH. DLC Molt is a ‘physical vapor deposition’ (PVD) coating based on multilayers of carbon compounds. The obtaining features and the multilayers sequence that DLC Molt coating presents, allows for achieving excellent benefits such as resistance towards adhesive and abrasive wear, less friction due to the tribology properties of carbon, absence of the dimensional distortions during the coating process, an increase of the lifetime while maintaining the original polish, and protection against scratches. Its technical characteristics are summarized in

Table 3, and

Figure 7 shows the result.

2.2.3. PJG-23v2 Magnet-Sleeve Brushless Motor

The electrical motor is an ad hoc multipolar surface mounted permanent magnet-sleeve brushless motor model PJG-23v2 designed and manufactured by Mavilor Motors for the mini trochoidal-gear pump, as shown in

Figure 8. The PJG-23v2 has deeply considered two imperative conceptions in its design. Firstly, the torque to rotate the gear set is not intended for working as a gearbox, but working as a part of a hydraulic pump. Secondly, the contact area arises between rotor-stator-fluid.

The PJG-23v2 is controlled by the sensorless drive Infranor EASY AK 230/17 + FCL EASY 230. The system is supplied for the tests with 48 Vdc and a limit current of 5 A in a continuous mode. The power is analyzed by means of a Circuitor CVM-C10-ITF-485-ict2.

Table 4 arranges the main motor data.

2.2.4. mTGp Prototype

The ensemble of the mTGp prototype is shown in

Figure 9. The prototype is intended to be the proof of concept and the technology demonstration with lab testing in an experimental test bench. Using an in-house pump cover manufactured with a transparent polymer, as shown in

Figure 10, the first performance tests were carried out. The transparent pump cover allowed for directly seeing the operation of the prototype and also recording it with a high-speed video camera for slow motion analysis.

5. Conclusions

The investigation conducted in this paper is the technology development of a progressive concept of trochoidal-gear technology: a sealed non-exterior driveshaft mini gerotor pump with a magnet-sleeve driving rotor. This research intends to show the laborious and challenging journey from the original concept to the first prototype, where the theoretical approach is not always directly reflected in the prototype performance results.

Formerly, early in the design process from a standard-commercial mini trochoidal-gear set, basic performance and dimensional requirements have been evaluated, becoming the key parameters that led to the configuration of the mini trochoidal-gear pump architecture: mTGp.

The mTGp confronts the main technological challenge of being sealed with a non-exterior driveshaft, ensuring the whole interior of the pump was filled and wetted with working fluid. The conception of this challenge is named ‘in-out sleeve passageway’ and helps the hydrodynamic film formation, the pumping effect, and the heat dissipation. The ultimate stage of this design process has been the manufacture of the hydraulic parts of the mini pump together with the ad hoc multipolar surface mounted permanent magnet-sleeve brushless motor. The final ensemble is the technology demonstration validated with experimental work in a well-instrumented mini test bench.

The trend of applications of polymer composite materials and their benefits are assessed in this trochoidal-gear technology application. From the analysis of previous works, the decision of choosing as polymer the pure polyoxymethylene (POM) is based on, among others, its high strength and stiffness, accessibility on the market, and its low price. Then, a POM mini trochoidal-gear unit was manufactured and the inner gear was tested.

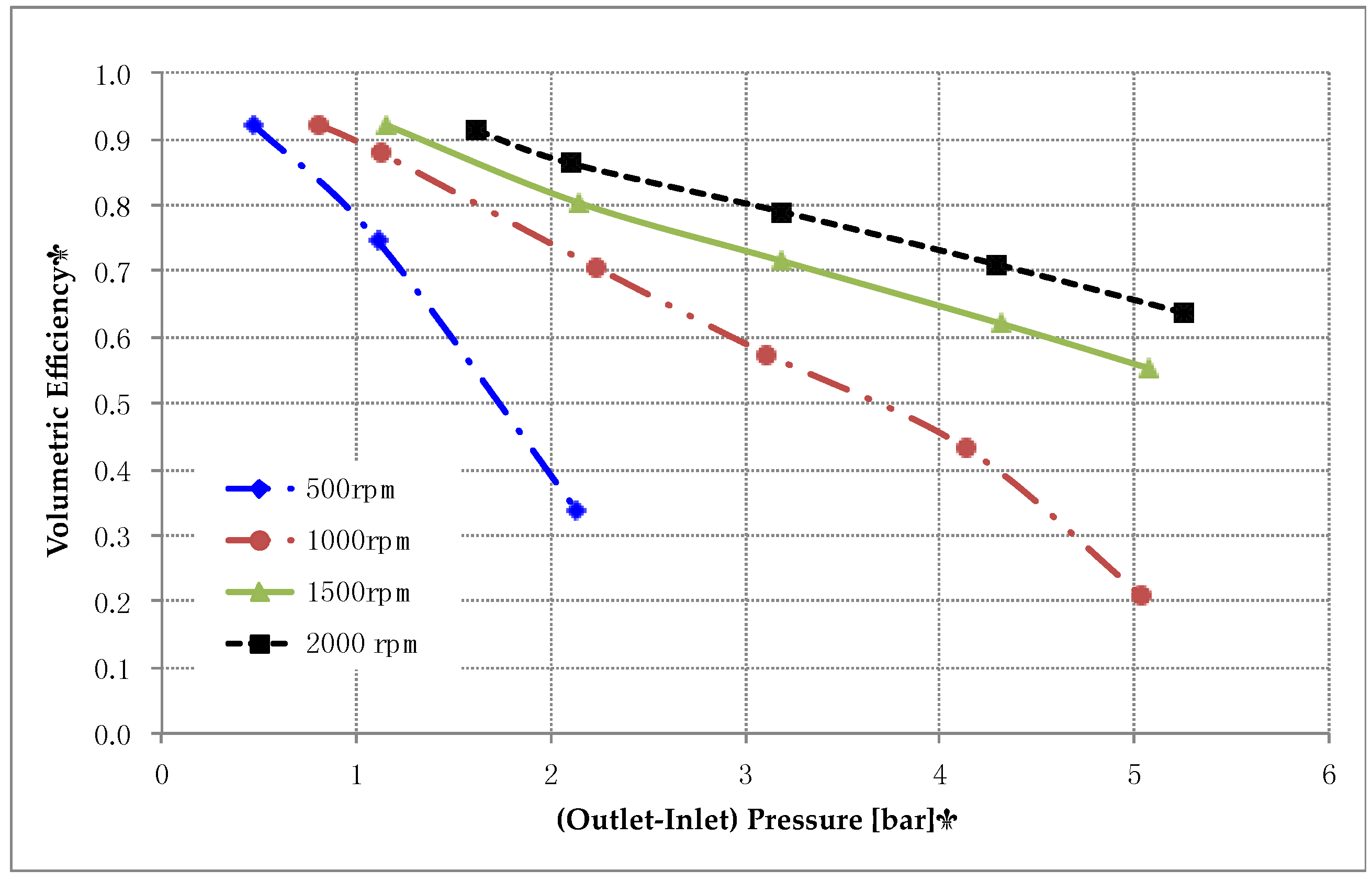

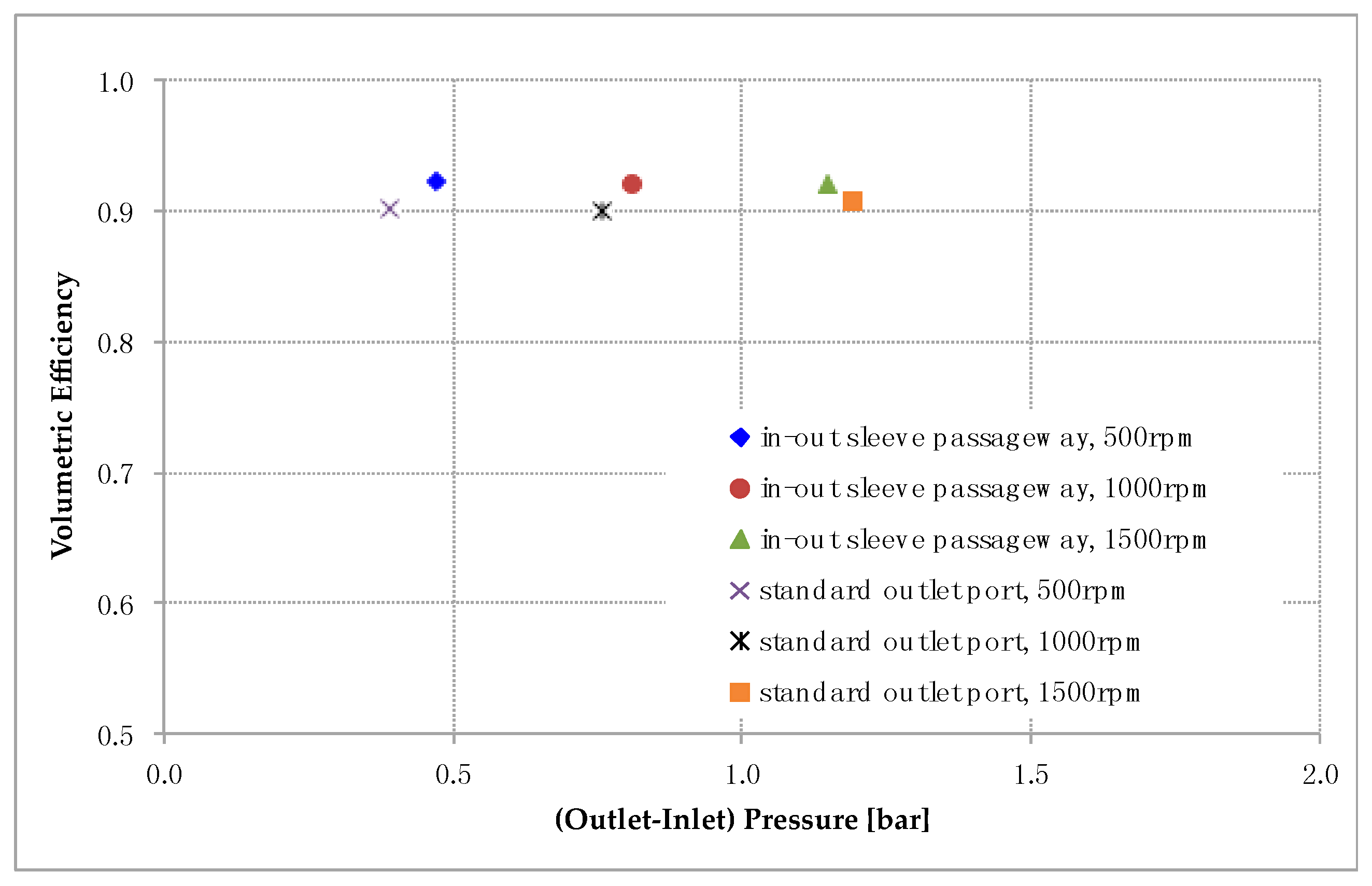

This novel variable flow pump configuration, despite the difficulties that occurred and several disappointed fallouts obtained, such as frictional performance of the trochoidal-gear units, accomplishes a standard volumetric flow rate at a low rotational speed with satisfactory volumetric efficiency. Experimental results prove feasibility as well as proof of concept.

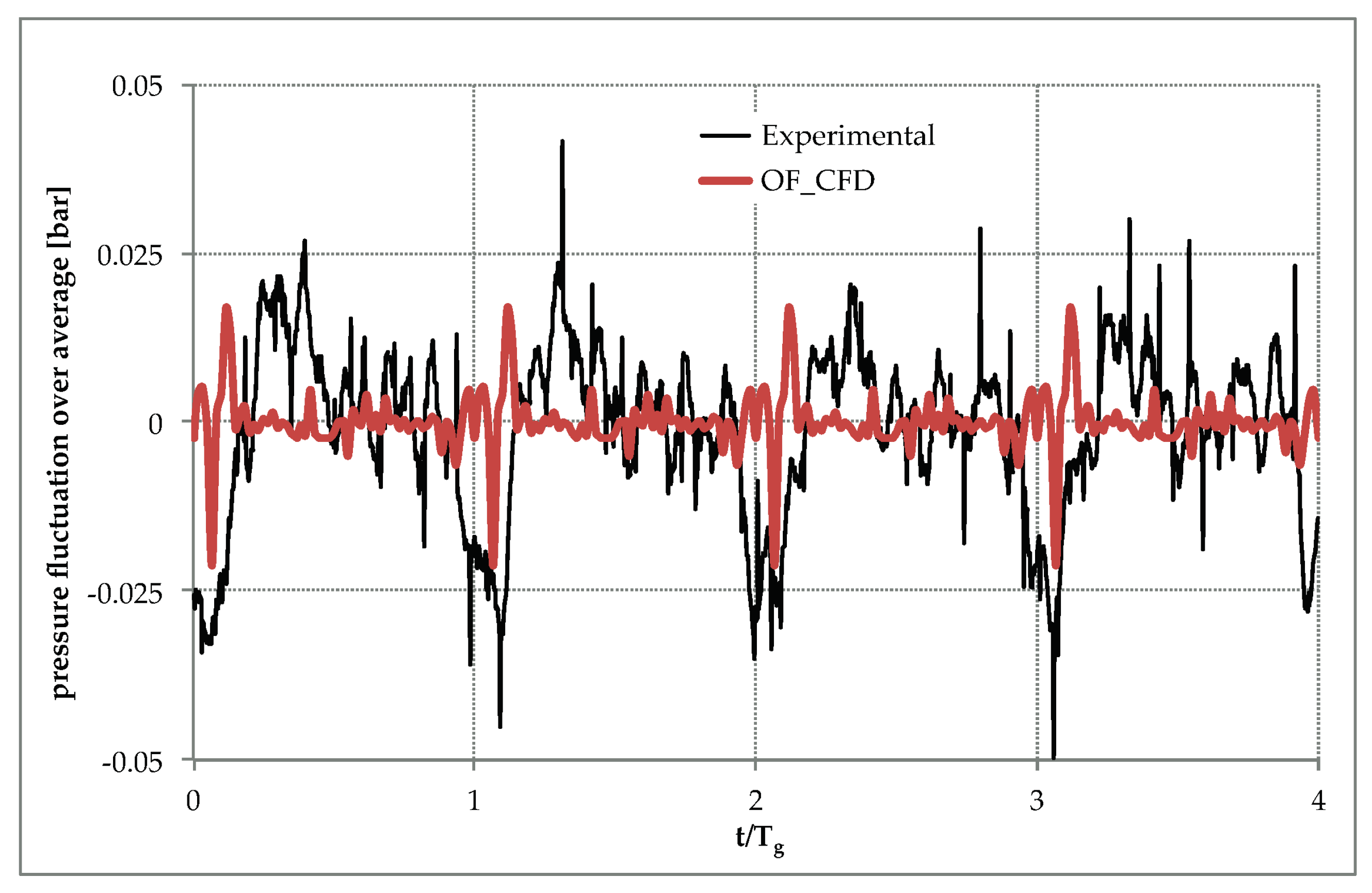

Finally, previous numerical simulation results and experimental work have been compared. A good agreement has been found in volumetric efficiency estimation and with regard to the pressure ripple, band extension agrees very well, although it seems that the numerical calculation is not able to correctly capture the overpressure at the beginning of the gearing cycle.

As a next step, the technology readiness has still to evolve to system development and field test with other operating conditions, where a most powerful electrical motor unit is desirable. Moreover, a step forward in the polymer composite in the trochoidal-gear technology has started in the mini size, though surface finishing, roughness and tolerances have to be improved. This mini pump prototype is believed to lead to a cleaner and noiseless hydraulic technology to be part of a wider part of sectors. Hence, important advantages can be foreseen.

The most forthcoming future work is to overcome the high mechanical friction and perform new experimental tests with a complete POM gear set. Besides, another POM gear set with new geometrical parameters is being designed and manufactured to be working in a new body pump. As well, using the pure POM and adding other ingredients such as glass or carbon fiber, it is possible at the next stage of work to obtain new materials of different qualities.