An Improved Flexible Solar Thermal Energy Integration Process for Enhancing the Coal-Based Energy Efficiency and NOx Removal Effectiveness in Coal-Fired Power Plants under Different Load Conditions

Abstract

:1. Introduction

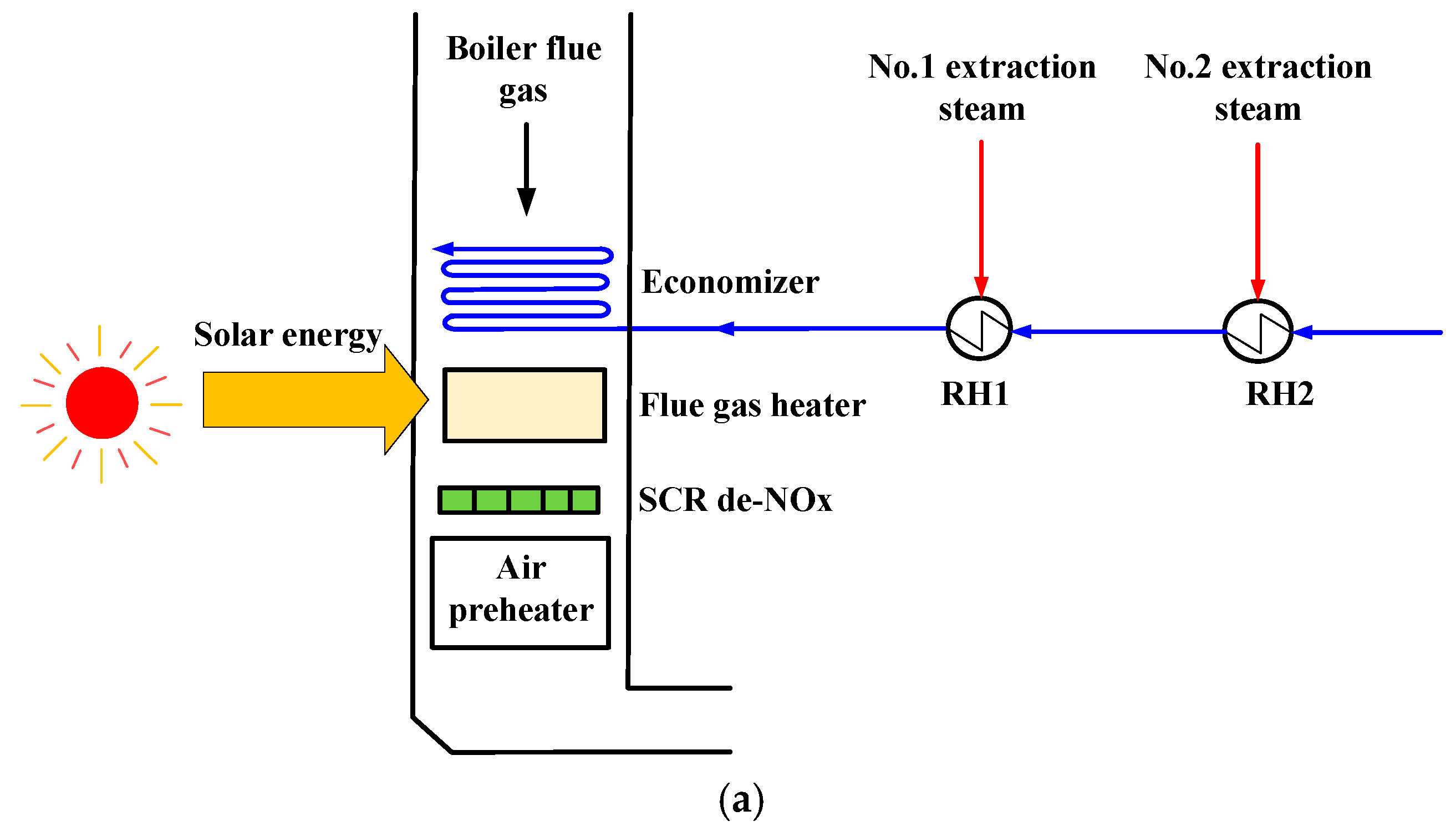

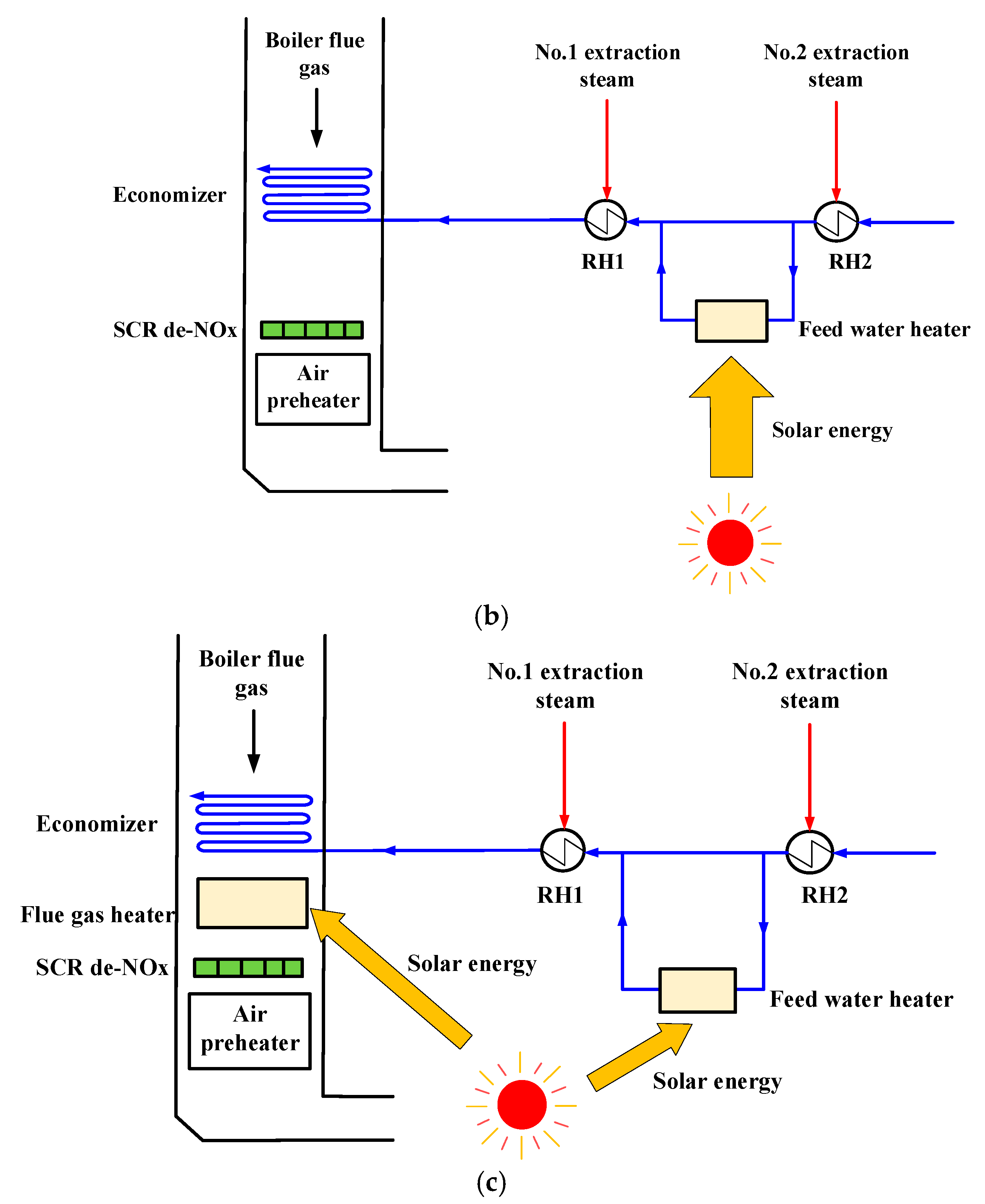

2. System Proposal

3. Application of the Proposed Integrated System in a 1000 MW Coal-Fired Power Plant

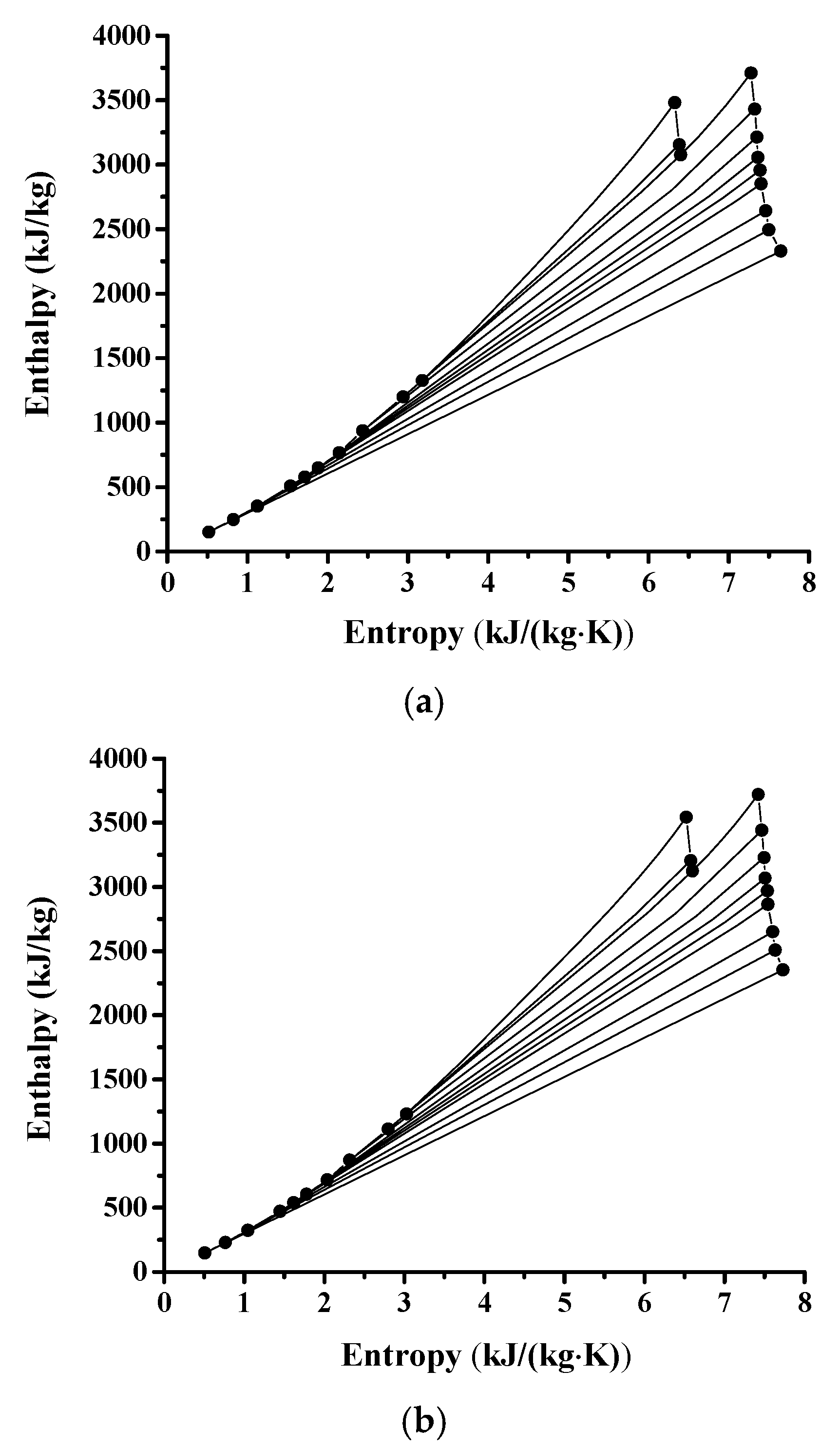

3.1. Description of the Reference Plant

3.2. System Description

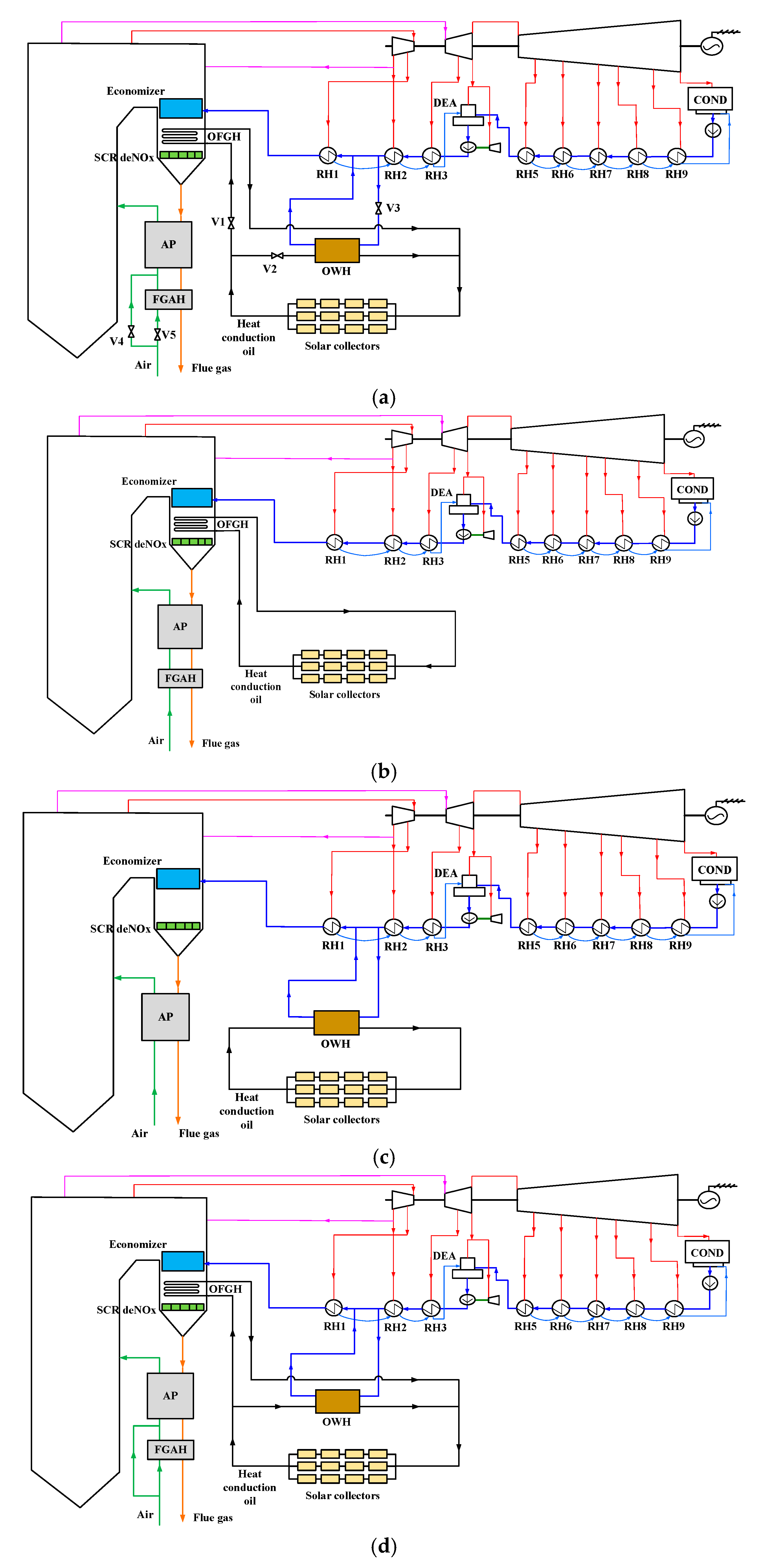

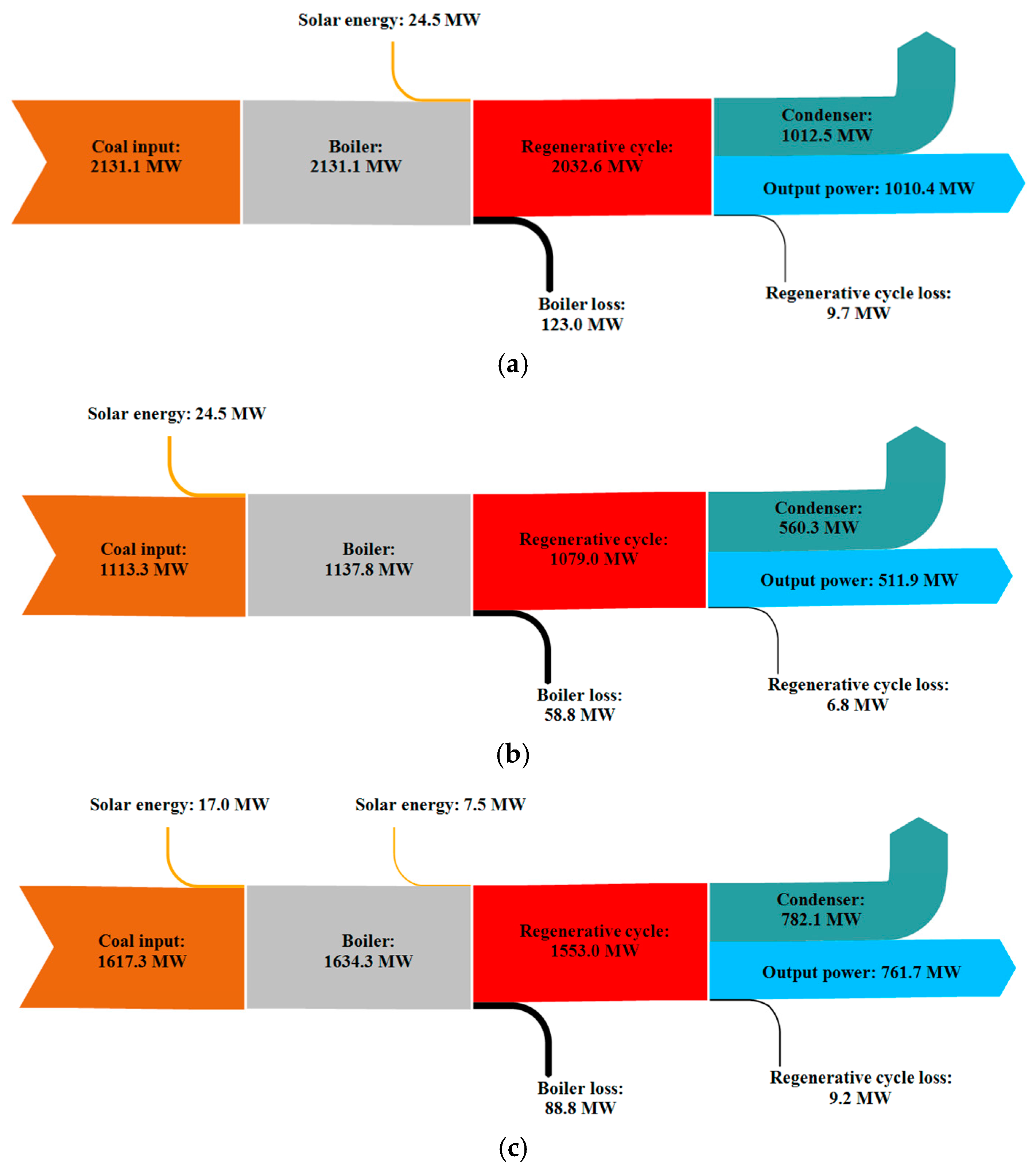

- For a partial load (below 50% of the base load) scenario, valves 1 and 5 open while valves 2–4 close. The schematic of the proposed SAPG is shown in Figure 4b. All the collected solar energy is used to heat the flue gas in the OFGH and the SCR de-NOx operation temperature increases correspondingly. The additional flue gas heat is recovered in the FGAH and the combustion air temperature is increased.

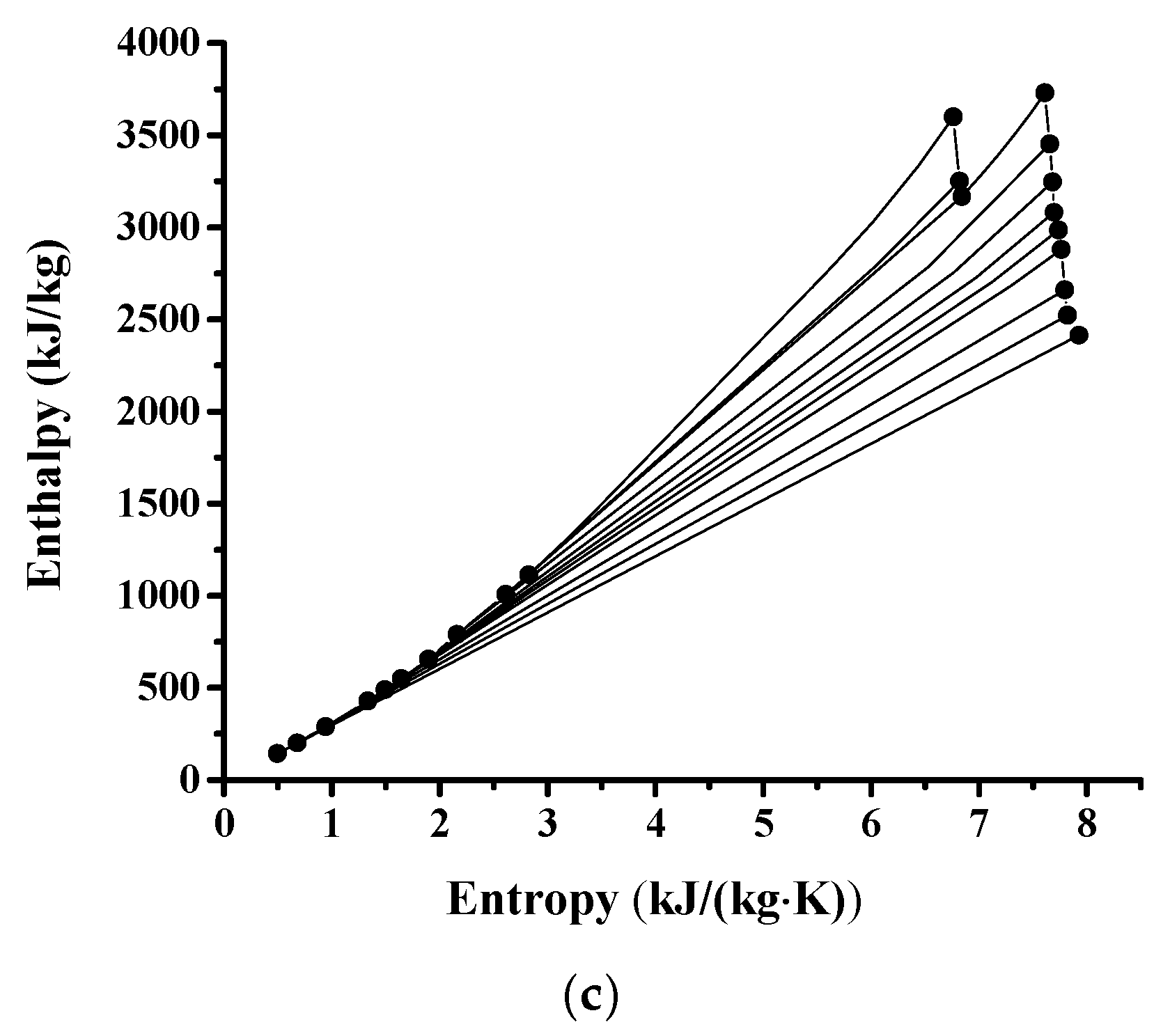

- For the baseload, valves 2–4 open while valves 1 and 5 are closed. The schematic of the proposed SAPG is shown in Figure 4c. All the collected solar energy is used to heat the feed water in OWH and save high-grade extraction steam. The SCR de-NOx temperature is in the optimal operation range and there is no need to increase it, so the OFGH does not work (valve 1 in Figure 4a closes). The FGAH in high load is bypassed and not in operation because there is no additional flue gas heat (valve 5 in Figure 4a closes).

- For the medium power load, all the valves open and the schematic of the proposed SAPG is shown in Figure 4d. The solar energy is used to heat both the flue gas in OFGH and the feed water in OWH, increasing SCR de-NOx temperature and saving high-grade extraction steam. Besides, the FGAH is employed to recover the additional flue gas heat, while part of the air is bypassed to keep the exhaust flue gas temperature in a reasonable range.

4. Methodology

4.1. Thermodynamic Evaluation

4.1.1. System Simulation

4.1.2. Heat Transfer Area Calculation

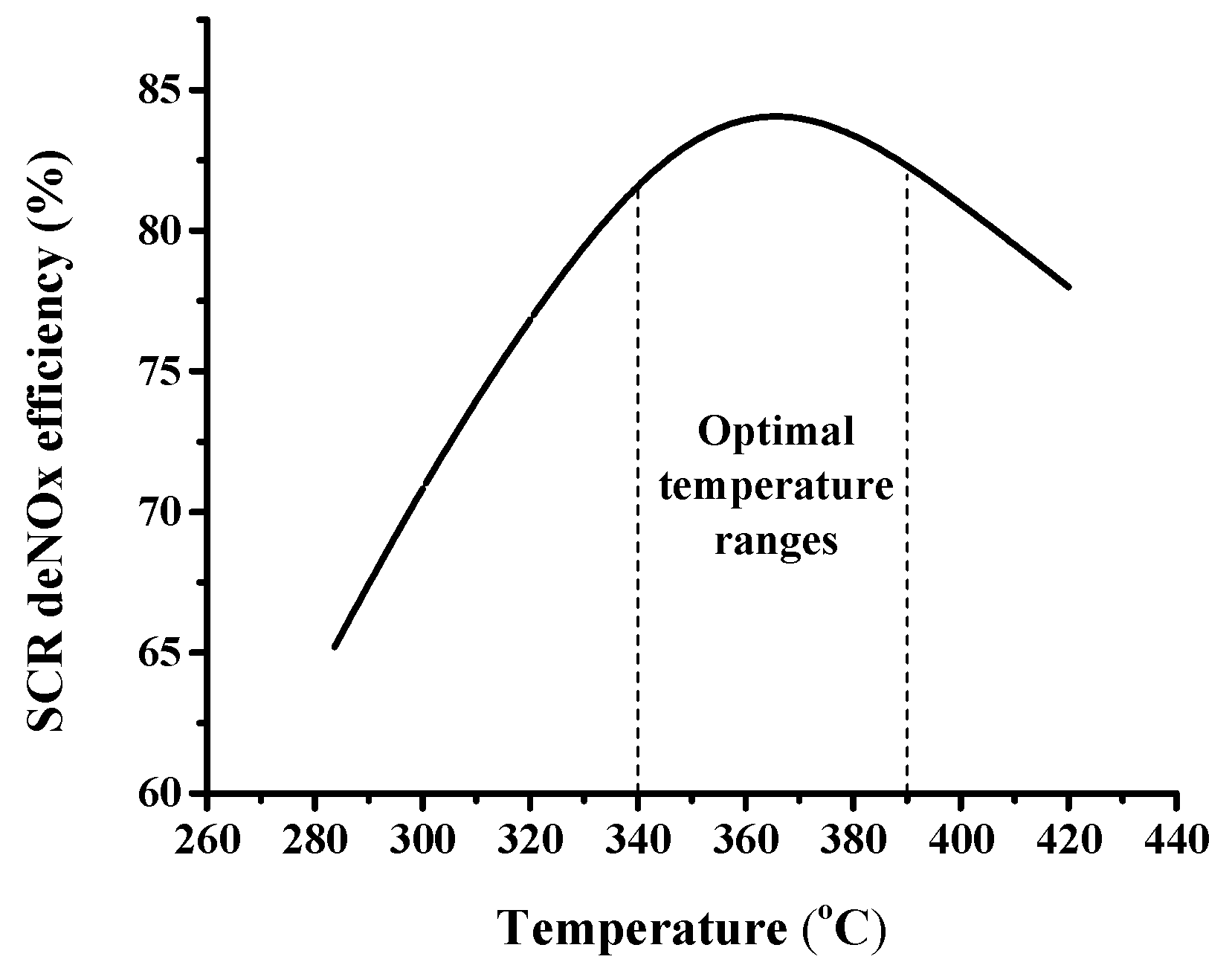

4.2. SCR de-NOx Performance Evaluation

4.3. Briefly Economic Evaluation

5. Results and Discussion

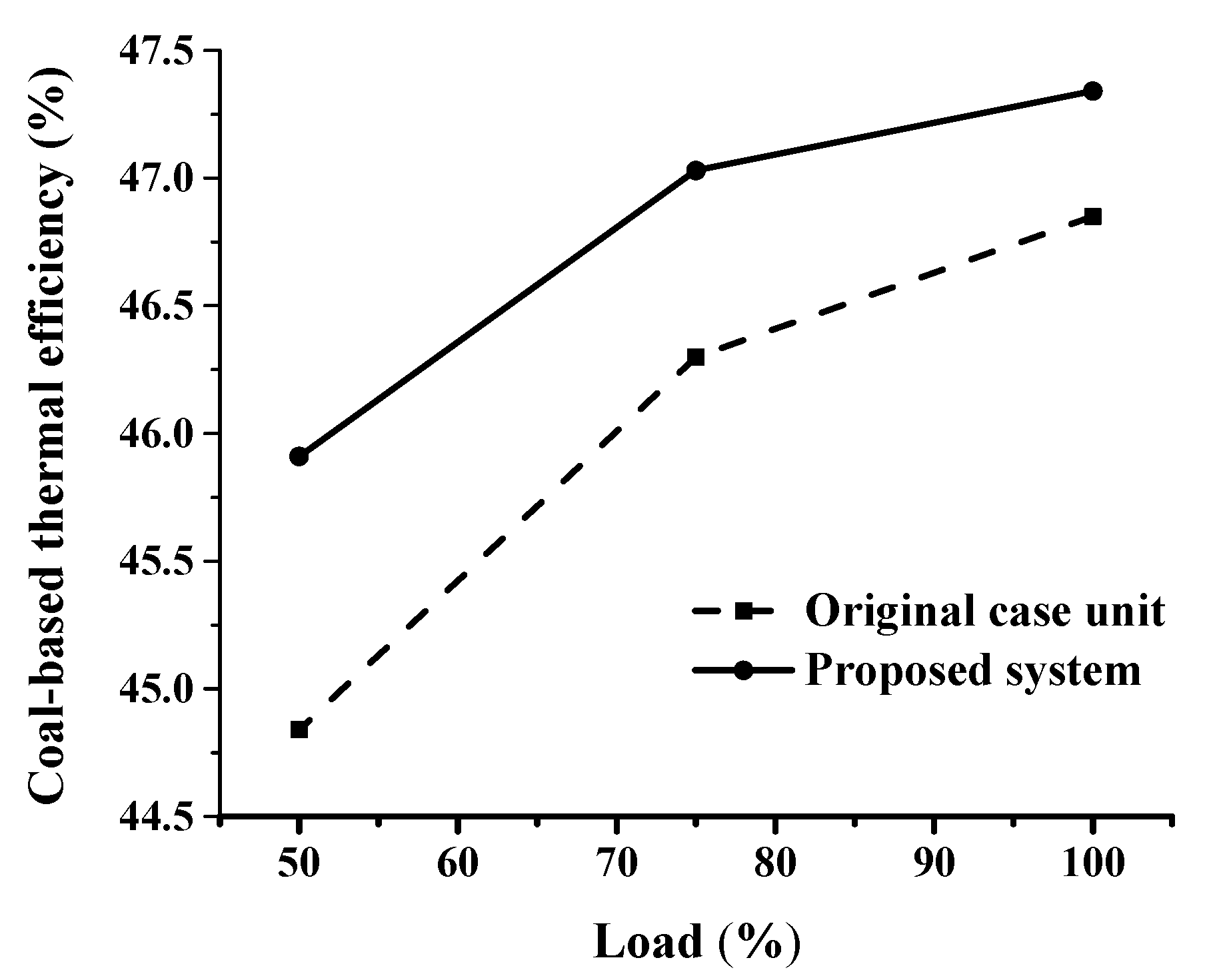

5.1. Thermal Performance

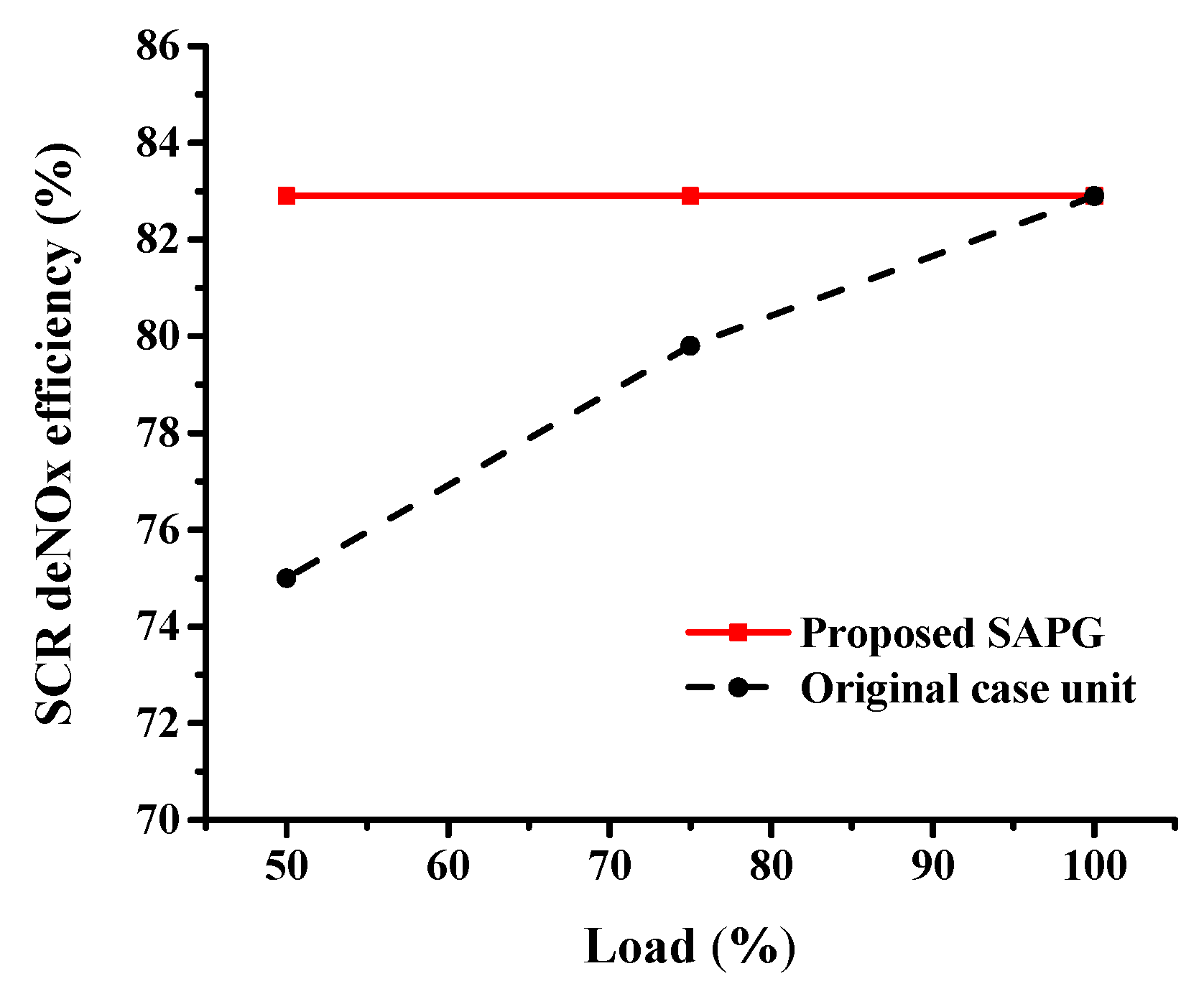

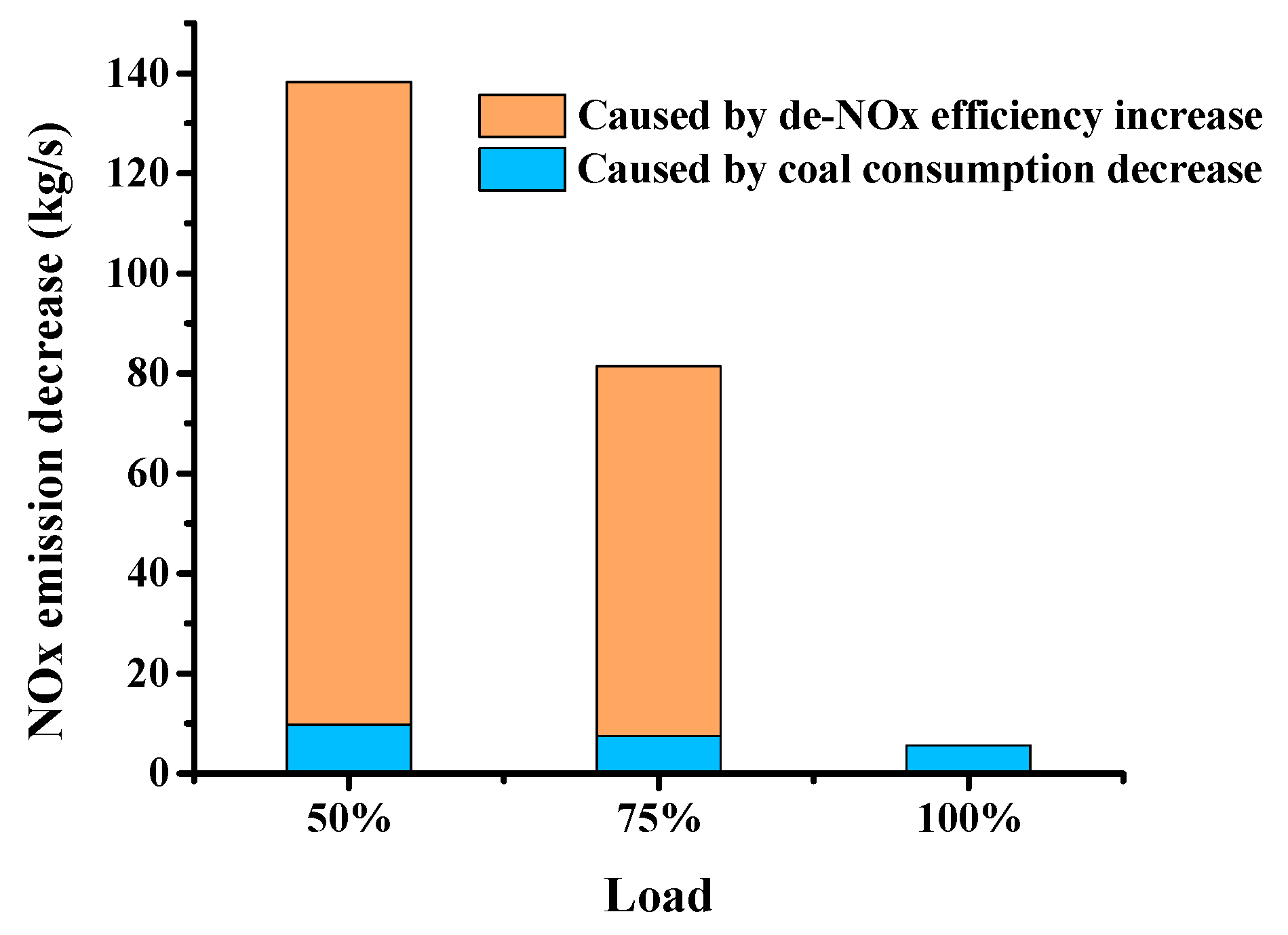

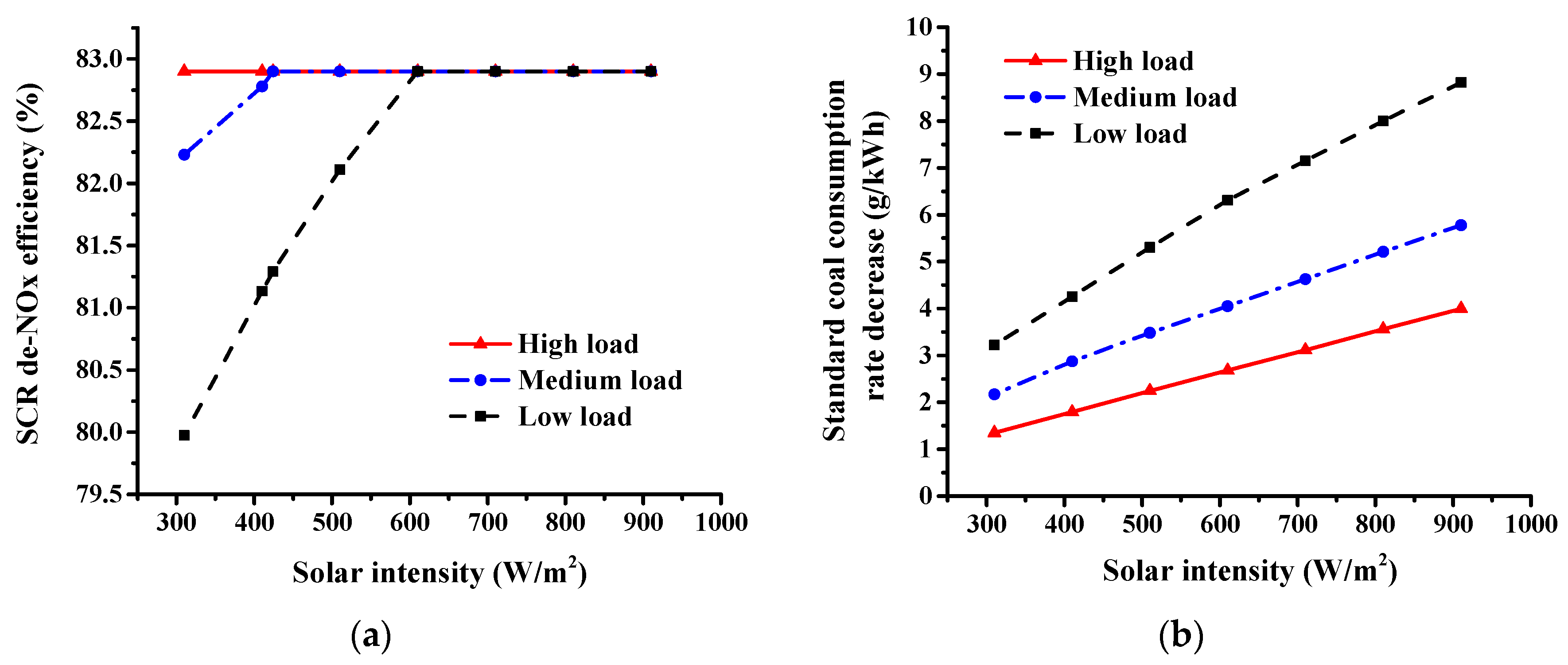

5.2. SCR de-NOx Efficiency Increase

5.3. Sensitivity Analysis

5.4. Economic Performance

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| Abbreviations: | Full name |

| AP | Air preheater |

| COE | Cost of electricity |

| COND | Condenser |

| CRF | Capital recovery factor |

| DEA | Deaerator |

| DNI | Direct normal irradiation |

| FCI | Fixed capital investment |

| FGAH | Flue gas-air heater |

| OFGH | Oil-flue gas heater |

| OWH | Oil-water heater |

| RH | Regenerative heater |

| SAPG | Solar aided power generation |

| SCR | Selective catalytic reduction |

| Symbols: | Content |

| Coal combustion rate | |

| Thermal NOx produced by coal | |

| Cn | Rotational speed factor |

| Additional solar electricity output | |

| f | Scale factor |

| Total produced NOx | |

| I | Enthalpy of flue gas |

| Enthalpy of air | |

| K | Heat transfer coefficient |

| n | Number of years |

| O&M | Ratio of annual operating and management |

| Q | Heat transfer capacity |

| Rth | Thermal resistance |

| r | Fraction interest rate per year |

| S | Scale parameter |

| Flue gas flow rate | |

| x | Proportion |

| Convective heat transfer coefficients | |

| Excess air ratio | |

| Transform ratio of fuel-nitrogen to NOx | |

| Utilization factor | |

| Receiver fluid temperature above ambient air temperature | |

| Logarithmic mean temperature difference | |

| Solar collector efficiency | |

| Subscripts: | Content |

| a | Air |

| a1 | Primary air |

| a2 | Secondary air |

| c | Case unit |

| fg | Flue gas |

| p | Proposed system |

| r | Reference device |

| s | Solar energy |

References

- Xu, C.; Xu, G.; Zhao, S.; Zhou, L.; Yang, Y.; Zhang, D. An improved configuration of lignite pre-drying using a supplementary steam cycle in a lignite fired supercritical power plant. Appl. Energy 2015, 160, 882–891. [Google Scholar] [CrossRef]

- Hong, H.; Zhao, Y.; Jin, H. Proposed partial repowering of a coal-fired power plant using low-grade solar thermal energy. Int. J. Thermodyn. 2011, 14, 21–28. [Google Scholar]

- Zoschak, R.J.; Wu, S.F. Studies of the direct input of solar energy to a fossil-fueled central station steam power plant. Sol. Energy 1975, 17, 297–305. [Google Scholar] [CrossRef]

- Yang, Y.P.; Cui, Y.H.; Hou, H.J.; Guo, X.Y.; Yang, Z.P.; Wang, N.L. Research on solar aided coal-fired power generation system and performance analysis. Sci. China Ser. E Technol. Sci. 2008, 51, 1211–1221. [Google Scholar] [CrossRef]

- Yang, Y.; Yan, Q.; Zhai, R.; Kouzani, A.; Hu, E. An efficient way to use medium-or-low temperature solar heat for power generation—Integration into conventional power plant. Appl. Therm. Eng. 2011, 31, 157–162. [Google Scholar] [CrossRef]

- Yan, Q.; Hu, E.; Yang, Y.; Zhai, R. Evaluation of solar aided thermal power generation with various power plants. Int. J. Energy Res. 2011, 35, 909–922. [Google Scholar] [CrossRef]

- Yan, Q.; Yang, Y.; Nishimura, A.; Kouzani, A.; Hu, E. Multi-point and multi-level solar integration into a conventional coal-fired power plant. Energy Fuels 2010, 24, 3733–3738. [Google Scholar] [CrossRef]

- Popov, D. An option for solar thermal repowering of fossil fuel fired power plants. Sol. Energy 2011, 85, 344–349. [Google Scholar] [CrossRef]

- Suresh, M.V.J.J.; Reddy, K.S.; Kolar, A.K. 4-E (Energy, exergy, environment, and economic) analysis of solar thermal aided coal-fired power plants. Energy Sustain. Dev. 2010, 14, 267–279. [Google Scholar] [CrossRef]

- Zhong, W.; Chen, X.; Zhou, Y.; Wu, Y.; López, C. Optimization of a solar aided coal-fired combined heat and power plant based on changeable integrate mode under different solar irradiance. Sol. Energy 2017, 150, 437–446. [Google Scholar] [CrossRef]

- Zhai, R.; Liu, H.; Li, C.; Zhao, M.; Yang, Y. Analysis of a solar-aided coal-fired power generation system based on thermo-economic structural theory. Energy 2016, 102, 375–387. [Google Scholar] [CrossRef]

- Zhai, R.; Li, C.; Chen, Y.; Yang, Y.; Patchigolla, K.; Oakey, J.E. Life cycle assessment of solar aided coal-fired power system with and without heat storage. Energy Convers. Manag. 2016, 111, 453–465. [Google Scholar] [CrossRef]

- Peng, S.; Hong, H.; Wang, Y.; Wang, Z.; Jin, H. Off-design thermodynamic performances on typical days of a 330 MW solar aided coal-fired power plant in China. Appl. Energy 2014, 130, 500–509. [Google Scholar] [CrossRef]

- Bakos, G.C.; Tsechelidou, C. Solar aided power generation of a 300 MW lignite fired power plant combined with line-focus parabolic trough collectors field. Renew. Energy 2013, 60, 540–547. [Google Scholar] [CrossRef]

- Hou, H.; Xu, Z.; Yang, Y. An evaluation method of solar contribution in a solar aided power generation (SAPG) system based on exergy analysis. Appl. Energy 2016, 182, 1–8. [Google Scholar] [CrossRef]

- Pierce, W.; Gauché, P.; Backström, T.V.; Brent, A.C.; Tadros, A. A comparison of solar aided power generation (SAPG) and stand-alone concentrating solar power (CSP): A South African case study. Appl. Therm. Eng. 2013, 61, 657–662. [Google Scholar] [CrossRef]

- Xu, C.; Bai, P.; Xin, T.; Hu, Y.; Xu, G.; Yang, Y. A novel solar energy integrated low-rank coal fired power generation using coal pre-drying and an absorption heat pump. Appl. Energy 2017, 20, 170–179. [Google Scholar] [CrossRef]

- Yang, J.; Fan, L.; Zhao, H. Coordinated optimization control of flue gas temperature for improving reaction efficiency of catalyst. Proc. CSEE 2014, 34, 2244–2250. (In Chinese) [Google Scholar]

- Xu, Y.; Zhang, Y.; Wang, J.; Yuan, Y. Application of CFD in the optimal design of a SCR–DeNOx, system for a 300 MW coal-fired power plant. Comput. Chem. Eng. 2013, 49, 50–60. [Google Scholar] [CrossRef]

- Gao, Y. Experimental and Mechanism Analysis on Selective Catalytic Reduction DeNOx Catalyst; Shandong University: Shandong, China, 2013. (In Chinese) [Google Scholar]

- Wang, L.; Yang, Y.; Dong, C.; Morosuk, T.; Tsatsaronis, G. Multi-objective optimization of coal-fired power plants using differential evolution. Appl. Energy 2014, 115, 254–264. [Google Scholar] [CrossRef]

- Gewald, D.; Karellas, S.; Schuster, A.; Spliethoff, H. Integrated system approach for increase of engine combined cycle efficiency. Energy Convers. Manag. 2012, 60, 36–44. [Google Scholar] [CrossRef]

- Dudley, V.E.; Kolb, G.J.; Mahoney, A.R.; Mancini, T.R.; Matthews, C.W. Test Results: SEGS LS-2 Solar Collector; Sandia National Laboratories: Albuquerque, NM, USA, 1994.

- Wu, X. General Methods of Calculation and Design for Industrial Boiler; Standards Press of China: Beijing, China, 2003. (In Chinese) [Google Scholar]

- Liu, J. Theory and Design for Fin-Tube Heat Exchangers; Harbin Institute of Technology Press: Harbin, China, 2013. (In Chinese) [Google Scholar]

- Wang, M.; Liao, C. Evaluation of nitrogen oxides emission from fossil fuel burning. Contemp. Chem. Ind. 2011, 40, 304–306. (In Chinese) [Google Scholar]

- Xu, G.; Xu, C.; Yang, Y.; Fang, Y.; Li, Y.; Song, X. A novel flue gas waste heat recovery system for coal-fired ultra-supercritical power plants. Appl. Therm. Eng. 2014, 67, 240–249. [Google Scholar] [CrossRef]

- Lin, H.; Jin, H.; Gao, L.; Wei, H. Techno-economic evaluation of coal-based polygeneration systems of synthetic fuel and power with CO2 recovery. Energy Convers. Manag. 2011, 52, 274–283. [Google Scholar] [CrossRef]

- China Power Engineering Consulting Group Corporation. Reference Price Index of Thermal Power Engineering Design; China Electric Power Press: Beijing, China, 2011. (In Chinese) [Google Scholar]

- Xu, G.; Yuan, X.; Yang, Y.; Lu, S.; Huang, S.; Zhang, K. Optimization of flue gas desulfurization systems in power plants for energy conservation. Proc. CSEE 2012, 32, 22–29. [Google Scholar]

- Michael, J.M.; Howard, N.S. Fundamentals of Engineering Thermodynamics; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2006. [Google Scholar]

| Items | Mar (%) | Aar (%) | Car (%) | Har (%) | Oar (%) | Nar (%) | Sar (%) | Qnet,ar (MJ·kg−1) |

|---|---|---|---|---|---|---|---|---|

| Parameters | 18.50 | 10.24 | 57.33 | 3.26 | 9.43 | 0.61 | 0.63 | 21.23 |

| Items | 100% (High Load) | 75% (Medium Load) | 50% (Low Load) |

|---|---|---|---|

| Coal input rate (kg/s) | 100.4 | 76.2 | 52.4 |

| Total energy of coal input (MWth) | 2134.3 | 1619.7 | 1115.0 |

| Live steam/reheat steam mass flow rate (kg/s) | 748.2/620.4 | 541.8/460.8 | 354.1/309.2 |

| SCR de-NOx temperature (°C) | 350.0 | 330.0 | 311.0 |

| Exhaust flue gas temperature (°C) | 121.0 | 115.0 | 109.0 |

| Combustion air temperature (°C) | 320.0 | 304.0 | 290.0 |

| Excess air coefficient | 1.15 | 1.24 | 1.35 |

| Gross power output (MW) | 1000.0 | 750.0 | 500.0 |

| Standard coal consumption rate (g/kWh) | 262.06 | 265.17 | 273.80 |

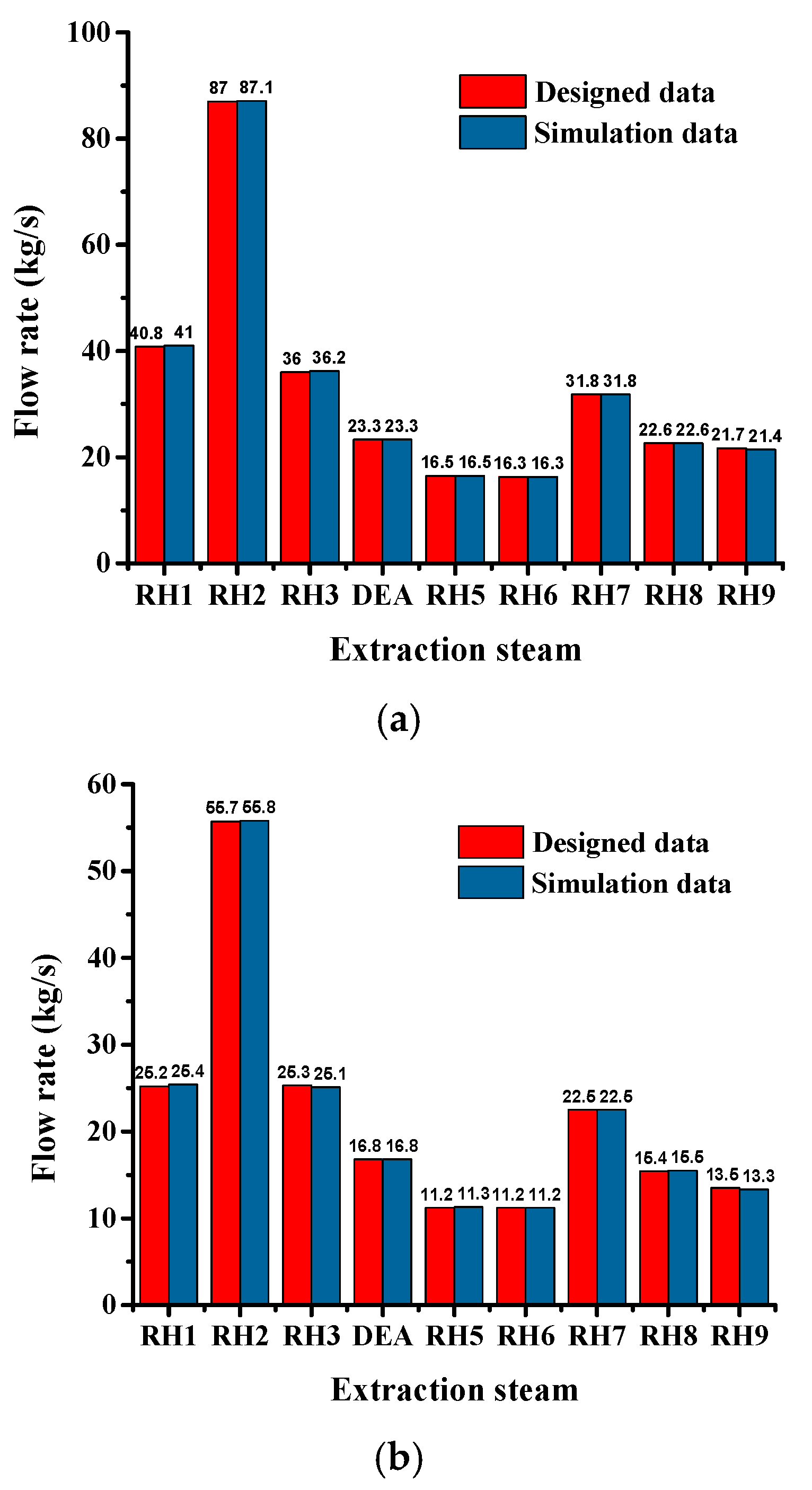

| Load | Items | 1# | 2# | 3# | DEA | 5# | 6# | 7# | 8# | 9# |

|---|---|---|---|---|---|---|---|---|---|---|

| 100% (design load) | Extraction steam temperature (°C) | 406.0 | 359.3 | 302.5 | 376.6 | 297.1 | 246.4 | 191.2 | 88.1 | 63.2 |

| Extraction steam pressure (MPa) | 8.09 | 5.78 | 2.29 | 1.09 | 0.60 | 0.38 | 0.23 | 0.07 | 0.02 | |

| Extraction steam flow rate (kg/s) | 40.8 | 87.0 | 36.0 | 23.3 | 16.5 | 16.3 | 31.8 | 22.6 | 21.7 | |

| Outlet feed water temperature (°C) | 299.2 | 273.7 | 216.3 | 180.6 | 153.8 | 137.5 | 120.8 | 84.0 | 59.3 | |

| Outlet feed water pressure (MPa) | 32.20 | 32.21 | 32.22 | 1.02 | 1.02 | 1.03 | 1.04 | 1.05 | 1.06 | |

| Water flow rate (kg/s) | 748.2 | 748.2 | 748.2 | 748.2 | 561.1 | 561.1 | 561.1 | 496.6 | 496.6 | |

| 75% (medium load) | Extraction steam temperature (°C) | 411.0 | 365.0 | 283.0 | 382.4 | 301.5 | 250.7 | 196.4 | 83.2 | 58.6 |

| Extraction steam pressure (MPa) | 6.05 | 4.32 | 1.73 | 0.84 | 0.46 | 0.29 | 0.18 | 0.05 | 0.02 | |

| Extraction steam flow rate (kg/s) | 25.2 | 55.7 | 25.3 | 16.81 | 11.2 | 11.2 | 22.5 | 15.4 | 13.5 | |

| Outlet feed water temperature (°C) | 280.0 | 255.6 | 202.2 | 169.6 | 143.8 | 128.5 | 112.8 | 77.5 | 54.7 | |

| Outlet feed water pressure (MPa) | 23.81 | 23.82 | 23.83 | 0.78 | 0.78 | 0.79 | 0.80 | 0.81 | 0.82 | |

| Water flow rate (kg/s) | 541.8 | 541.8 | 541.8 | 541.8 | 418.7 | 418.7 | 418.7 | 373.9 | 373.9 | |

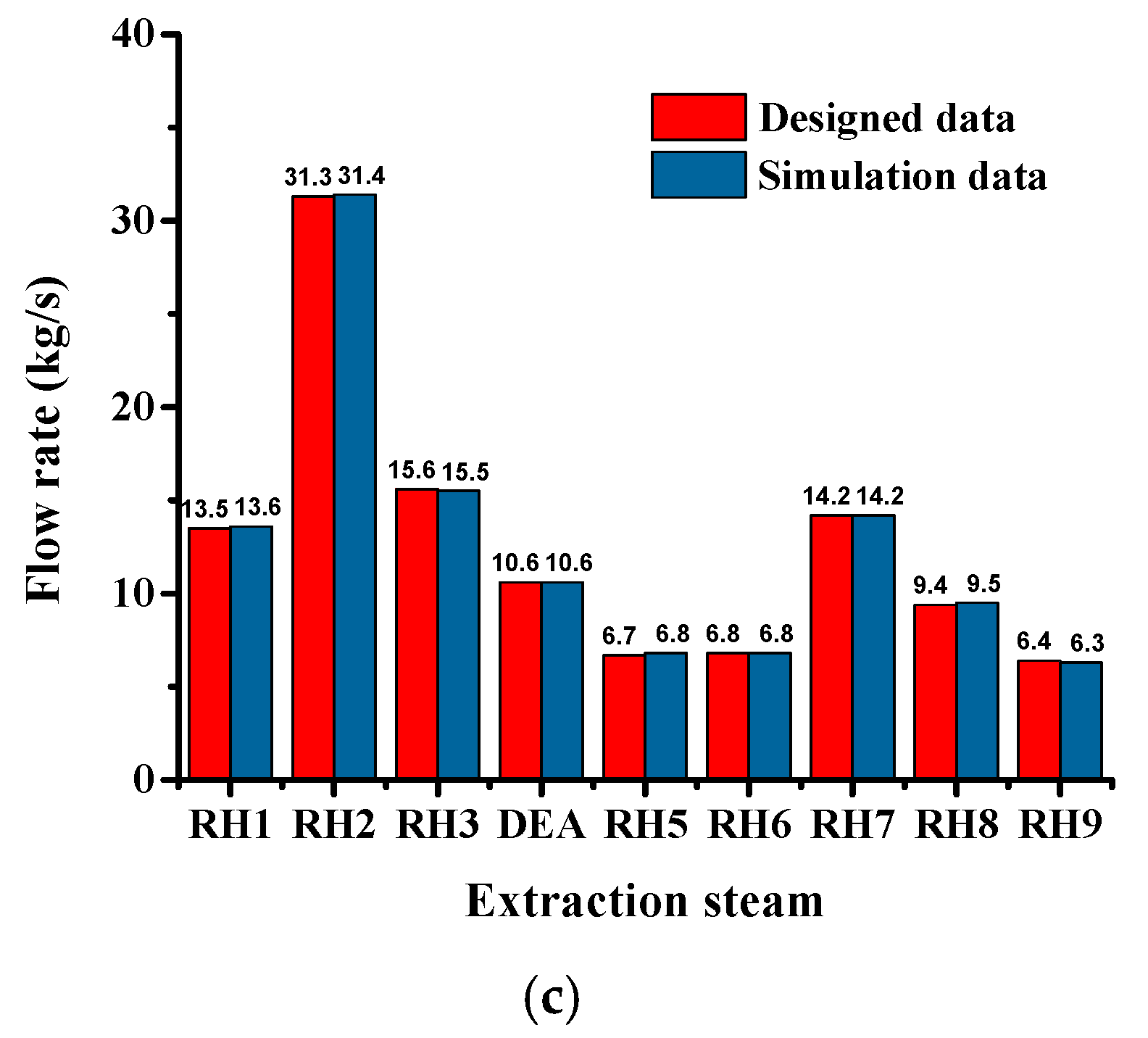

| 50% (low load) | Extraction steam temperature (°C) | 416.6 | 371.5 | 258.7 | 388.6 | 306.3 | 257.1 | 202.9 | 88.1 | 52.0 |

| Extraction steam pressure (MPa) | 4.07 | 2.91 | 1.18 | 0.59 | 0.32 | 0.20 | 0.12 | 0.04 | 0.01 | |

| Extraction steam flow rate (kg/s) | 13.5 | 31.3 | 15.6 | 10.6 | 6.7 | 6.8 | 14.2 | 9.4 | 6.4 | |

| Outlet feed water temperature (°C) | 255.9 | 233.1 | 184.4 | 155.3 | 130.9 | 116.7 | 102.3 | 68.9 | 48.1 | |

| Outlet feed water pressure (MPa) | 15.97 | 15.98 | 15.99 | 0.55 | 0.55 | 0.56 | 0.57 | 0.58 | 0.59 | |

| Water flow rate (kg/s) | 354.1 | 354.1 | 354.1 | 354.1 | 283.0 | 283.0 | 283.0 | 255.3 | 255.3 |

| Components | Models |

|---|---|

| Steam generator | Dry ash extraction and single reheat is modeled as a black box |

| Steam turbines | Inlet pressure is defined for the steam turbine. In most cases, the outlet pressure is defined by the inlet pressure of the following turbine stage. For the last turbine stage, the outlet pressure is defined by the inlet pressure of the condenser (0.00575 MPa). Mechanical Efficiency = 0.998 |

| RHs | Upper terminal temperature difference and the lower terminal temperature difference of the after-cooler are to be specified. Pressure loss = 3.3–5% in the steam extraction of different RHs, Heat loss = 0% |

| Condenser | Inlet temperature (20 °C) and pressure (0.1 MPa) of the cooling medium is specified, upper temperature difference = 5 °C, pressure loss = 0.005 Mpa |

| Pumps | Isentropic efficiencies = 0.8, mechanical efficiency = 0.998 |

| Electric generator | Generator efficiency = 0.99 |

| Solar collector, OFGH, OWH and FGAH | The heat transfer capacity is calculated using the heat balance equation in Section 4.1.1 |

| Items | Values |

|---|---|

| Annual effective interest rate (r) | 8% |

| Plant economic life (n) | 25 years |

| O&M | 4% of FCI |

| Annual operating hours | 3037 h/year |

| Annual high load (100%) operating hours | 1263 h/year |

| Annual medium load (75%) operating hours | 1120 h/year |

| Annual low load (50%) operating hours | 1867 h/year |

| Component | Reference FCI (Million USD) | Reference Scale | Scale Unit | Scaling Factor |

|---|---|---|---|---|

| Solar collector | 34.78 | 186,000 | Area (m2) | 0.90 |

| OFGH | 0.69 | 13,149 | Heat transfer area (m2) | 0.68 |

| OWH | 0.80 | 8372 | Heat transfer area (m2) | 0.68 |

| FGAH | 6.24 | 353,949 | Heat transfer area (m2) | 0.68 |

| Heat Exchangers | Items | 100% (High Load) | 75% (Medium Load) | 50% (Low Load) |

|---|---|---|---|---|

| Solar collector | Inlet/outlet oil temperature (°C) | 380.0/338.0 | 380.0/338.0 | 380.0/338.0 |

| Oil flow rate (kg/s) | 244.0 | 244.0 | 244.0 | |

| Efficiency | 70.8 | 70.8 | 70.8 | |

| Heat transfer capacity (MWth) | 24.5 | 24.5 | 24.5 | |

| Heat transfer area (m2) | 56,729 | 56,729 | 56,729 | |

| OFGH | Inlet/outlet oil temperature (°C) | -/- | 380.0/338.0 | 380.0/338.0 |

| Inlet/outlet flue gas temperature (°C) | -/- | 330.0/350.0 | 311.0/350.0 | |

| Oil/flue gas flow rate (kg/s) | -/- | 169.3/761.6 | 244.0/566.6 | |

| Overall heat transfer coefficient (W/m2 K) | - | 40.0 | 33.7 | |

| Heat transfer capacity (MWth) | - | 17.0 | 24.5 | |

| Heat transfer area (m2) | - | 25,545 | 25,545 | |

| OWH | Inlet/outlet oil temperature (°C) | 380.0/338.0 | 380.0/338.0 | -/- |

| Inlet/outlet feed water temperature (°C) | 273.7/280.6 | 255.6/349.9 | -/- | |

| Oil/water flow rate (kg/s) | 244.0/745.7 | 74.7/15.4 | -/- | |

| Overall heat transfer coefficient (W/m2 K) | 279.6 | 132.8 | - | |

| Heat transfer capacity (MWth) | 24.5 | 7.5 | - | |

| Heat transfer area (m2) | 1087 | 1087 | - | |

| FGAH | Inlet/outlet flue gas temperature (°C) | -/- | 135.1/115.0 | 147.5/109.0 |

| Inlet/outlet air temperature (°C) | -/- | 28.8/90.5 | 34.6/83.1 | |

| Flue gas/air flow rate (kg/s) | -/- | 804.5/257.4 | 607.4/501.5 | |

| Overall heat transfer coefficient (W/m2 K) | - | 10.3 | 13.5 | |

| Heat transfer capacity (MWth) | - | 17.0 | 24.5 | |

| Heat transfer area (m2) | - | 26,172 | 26,172 |

| Items | 100% (High Load) | 75% (Medium Load) | 50% (Low Load) |

|---|---|---|---|

| Combustion air temperature increase (°C) | - | 28.3 | 50.6 |

| Saved high-grade extraction steam (kg/s) | 12.3 | 3.2 | - |

| Gross power generated (MWe) | 1010.4 | 761.7 | 511.9 |

| Gross additional power generated (MWe) | 10.4 | 11.7 | 11.9 |

| Standard coal consumption rate (g/kWh) | 259.40 | 261.11 | 267.48 |

| Standard coal consumption rate decrease (g/kWh) | 2.68 | 4.05 | 6.31 |

| Items | 100% (High Load) | 75% (Medium Load) | 50% (Low Load) |

|---|---|---|---|

| SCR de-NOx temperature of the referenced unit (°C) | 350.0 | 330.0 | 311.0 |

| SCR de-NOx temperature of the proposed SAPG (°C) | 350.0 | 350.0 | 350.0 |

| SCR de-NOx temperature increase (°C) | - | 20.0 | 39.0 |

| SCR de-NOx efficiency of the original case unit (%) | 82.9 | 79.8 | 75.0 |

| SCR de-NOx efficiency of the proposed SAPG (%) | 82.9 | 82.9 | 82.9 |

| SCR de-NOx efficiency increase (%) | - | 3.1 | 7.9 |

| Items | Proposed SAPG |

|---|---|

| FCI of the additional equipment | |

| Solar collector (million USD) | 11.95 |

| OFGH (million USD) | 1.08 |

| OWH (million USD) | 0.21 |

| FGAH (million USD) | 1.06 |

| Total additional FCI (million USD) | 14.3 |

| Additional operation and maintenance cost (million USD) | 0.57 |

| Additional solar electricity output (GWh) | 48.5 |

| COE of solar generated electricity (USD/kWh) | 0.040 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, Y.; Xu, C.; Xu, G.; Zhang, Y.; Yang, Y. An Improved Flexible Solar Thermal Energy Integration Process for Enhancing the Coal-Based Energy Efficiency and NOx Removal Effectiveness in Coal-Fired Power Plants under Different Load Conditions. Energies 2017, 10, 1485. https://doi.org/10.3390/en10101485

Han Y, Xu C, Xu G, Zhang Y, Yang Y. An Improved Flexible Solar Thermal Energy Integration Process for Enhancing the Coal-Based Energy Efficiency and NOx Removal Effectiveness in Coal-Fired Power Plants under Different Load Conditions. Energies. 2017; 10(10):1485. https://doi.org/10.3390/en10101485

Chicago/Turabian StyleHan, Yu, Cheng Xu, Gang Xu, Yuwen Zhang, and Yongping Yang. 2017. "An Improved Flexible Solar Thermal Energy Integration Process for Enhancing the Coal-Based Energy Efficiency and NOx Removal Effectiveness in Coal-Fired Power Plants under Different Load Conditions" Energies 10, no. 10: 1485. https://doi.org/10.3390/en10101485