Comparative Study on Uni- and Bi-Directional Fluid Structure Coupling of Wind Turbine Blades

Abstract

:1. Introduction

2. Mathematical Formulation

2.1. Flow Model

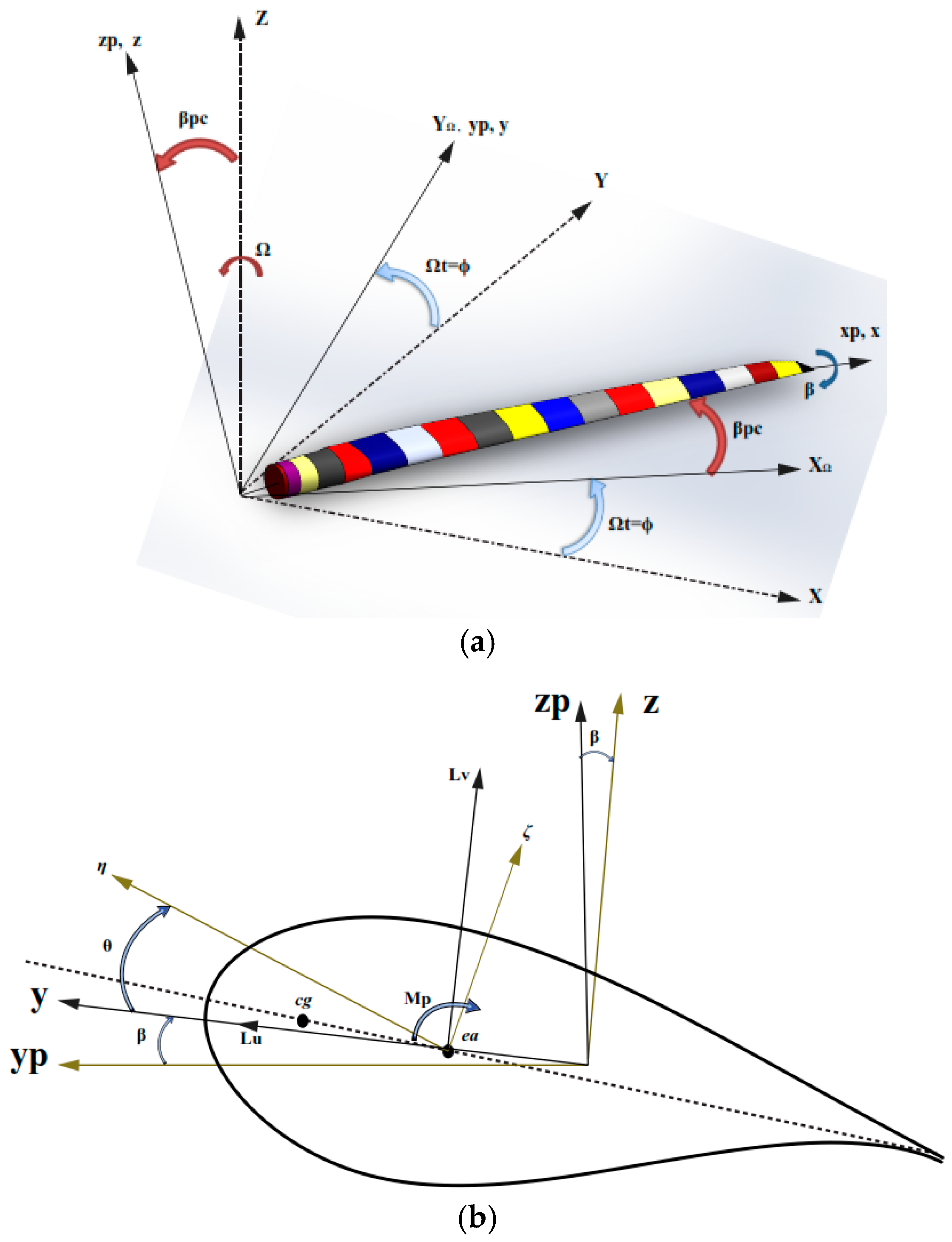

2.2. Structural Model

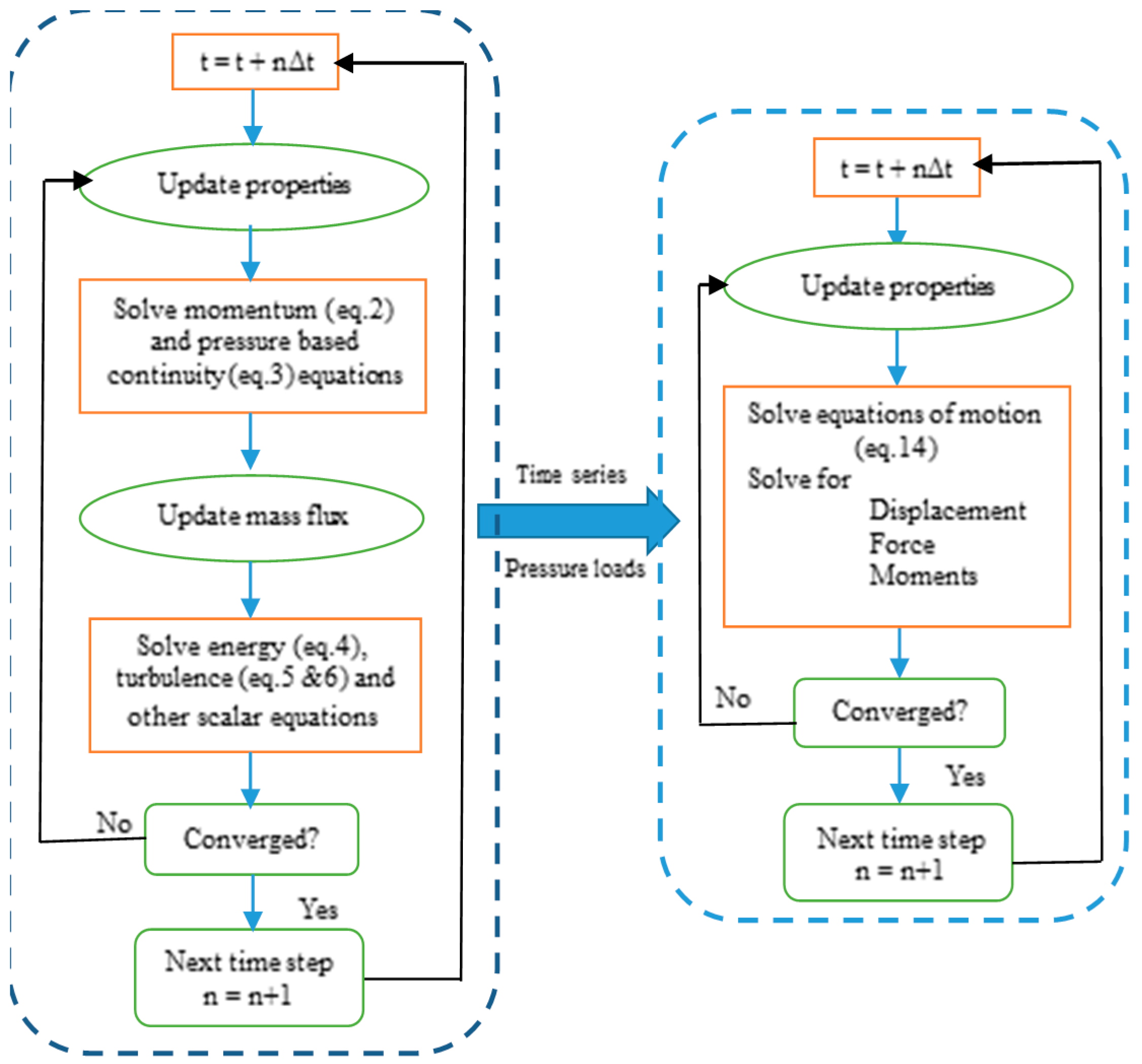

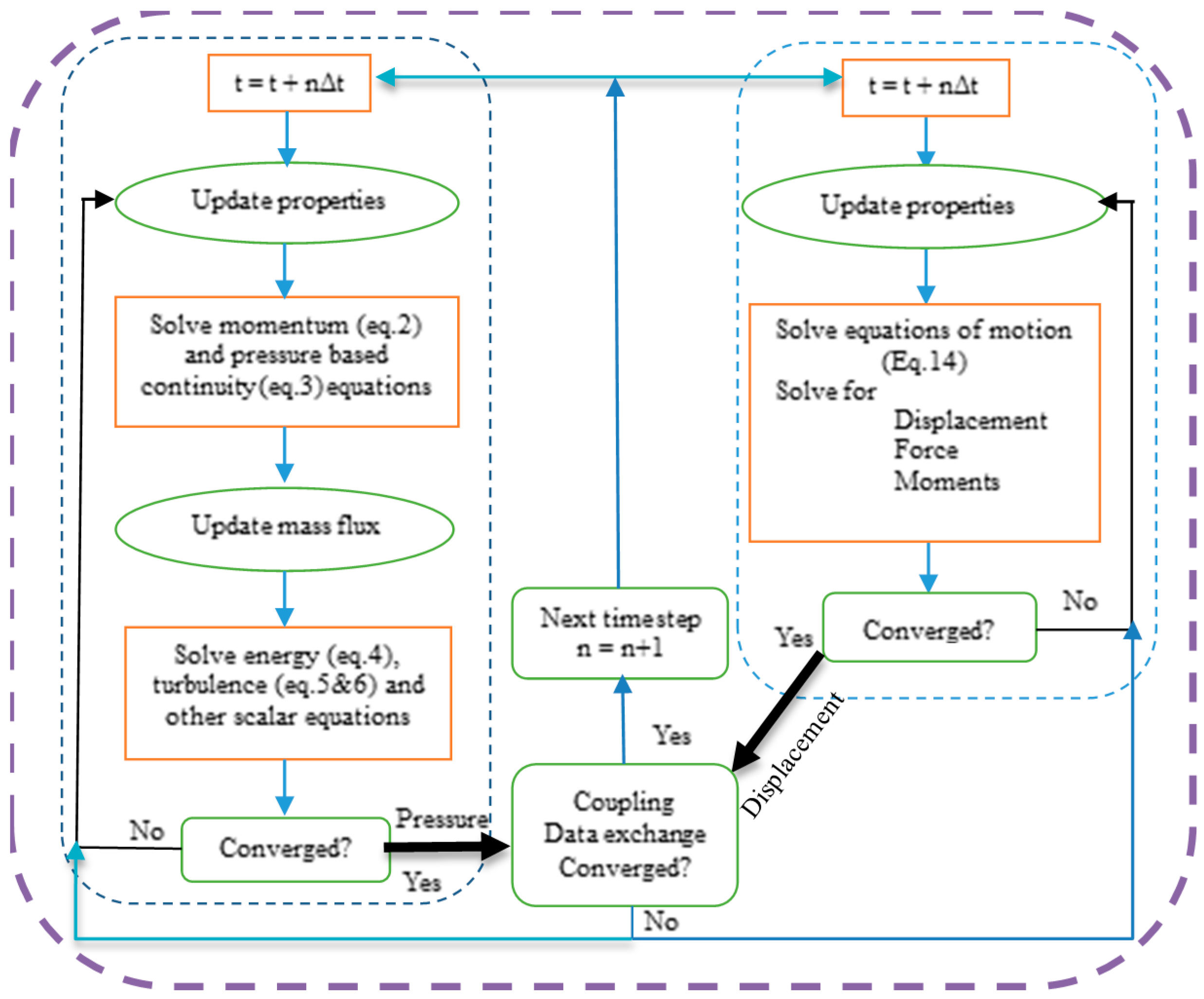

2.3. Coupling Methods and Algorithms

3. Computational Model

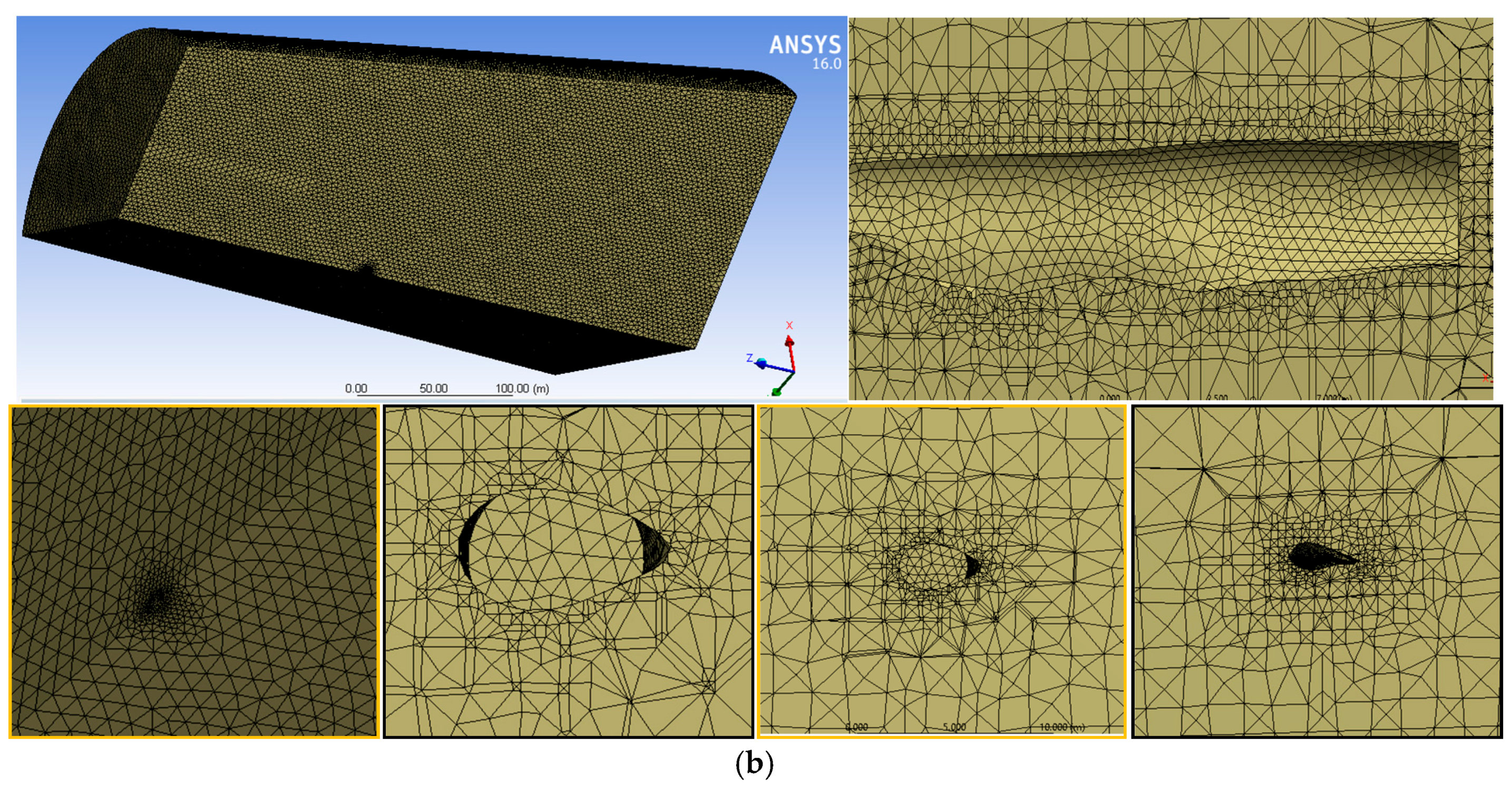

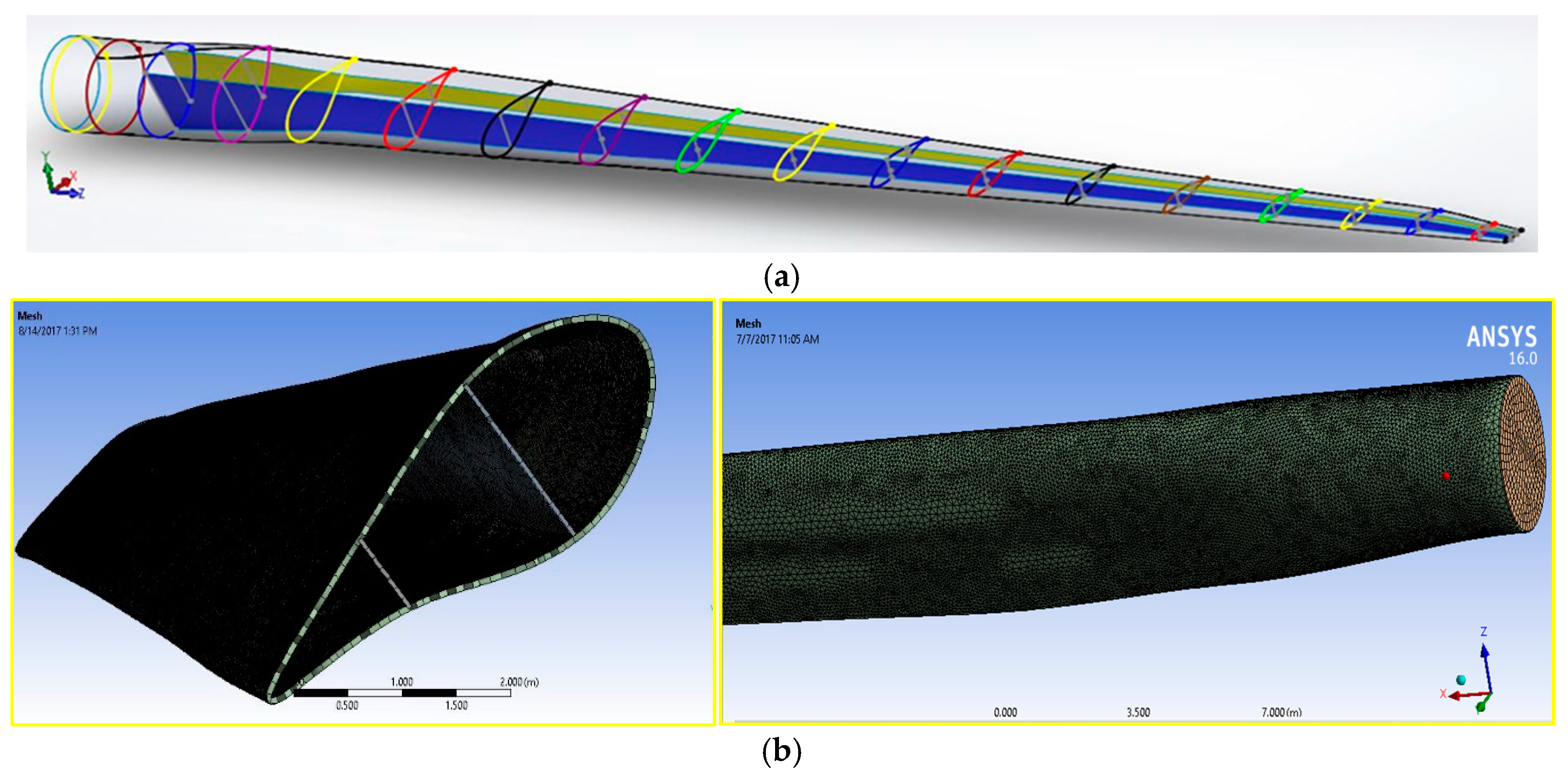

3.1. Computation Fluid Dynamics (CFD) Model

3.1.1. Computational Domain

3.1.2. Solver Settings and Turbulence Model

3.1.3. Boundary Conditions

3.2. Finite Element (FE) Model

3.2.1. Computational Domain

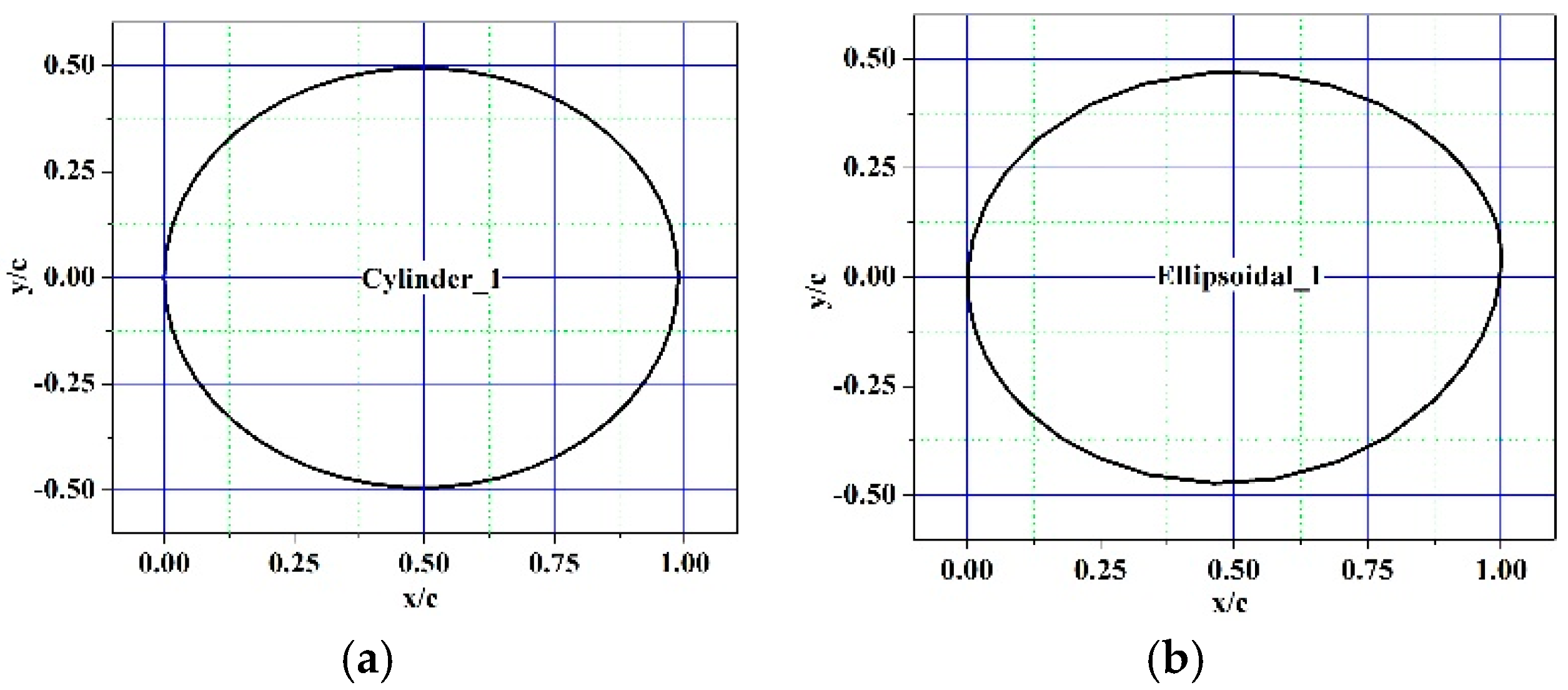

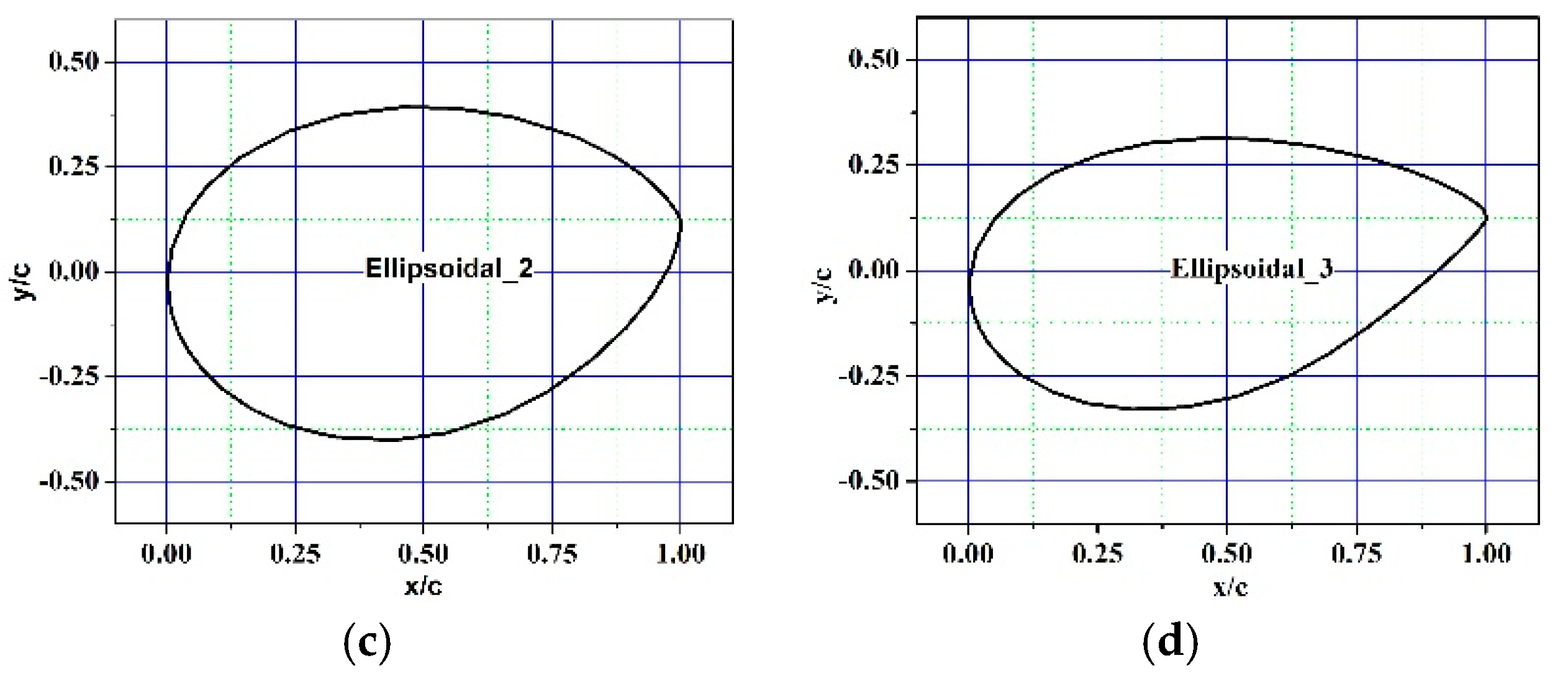

3.2.2. Geometry and Material Distribution

3.2.3. Boundary Conditions and Mesh

3.3. Fluid-Structure Interaction Model

3.4. Model Assessment

3.4.1. CFD Model

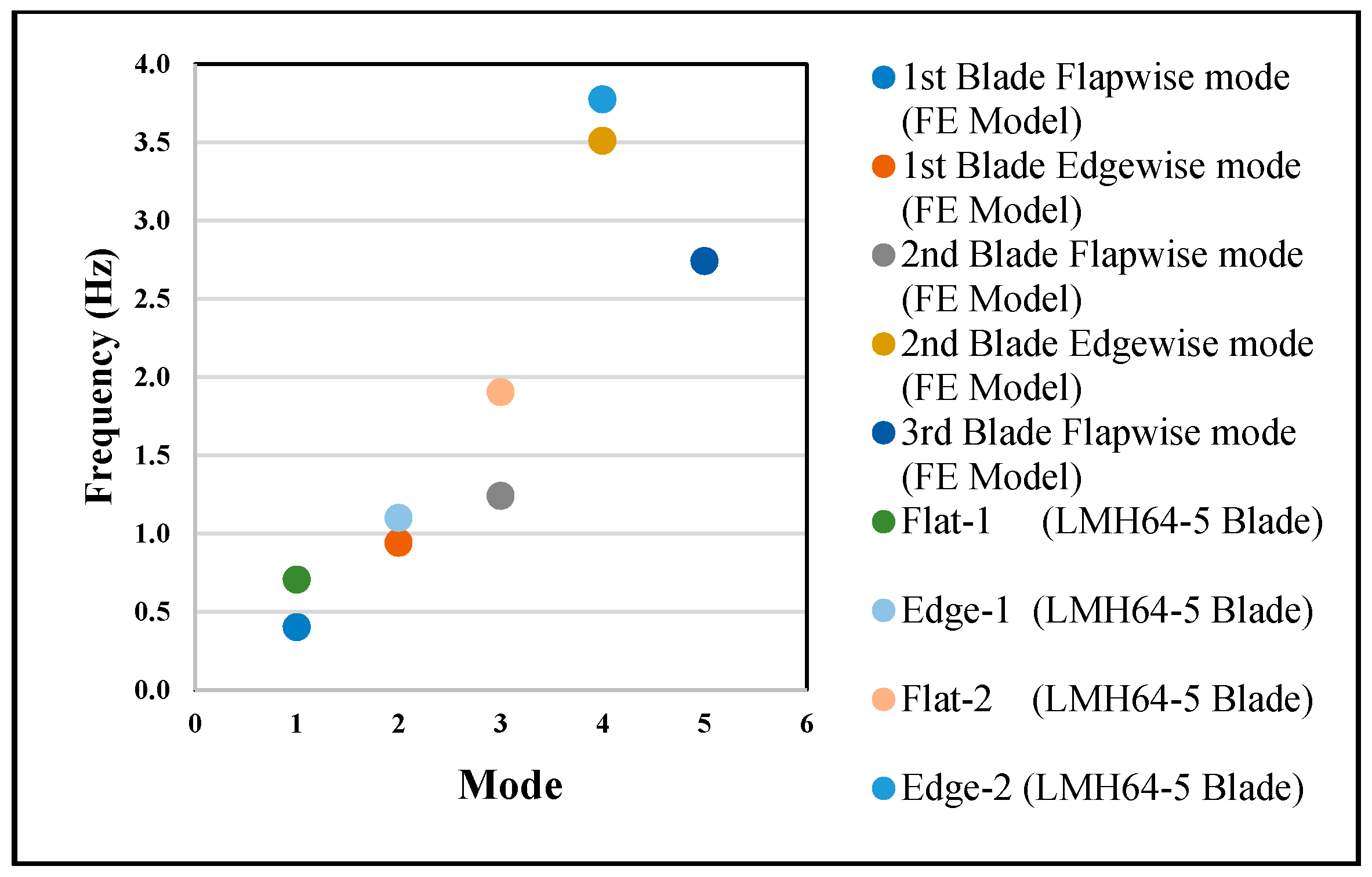

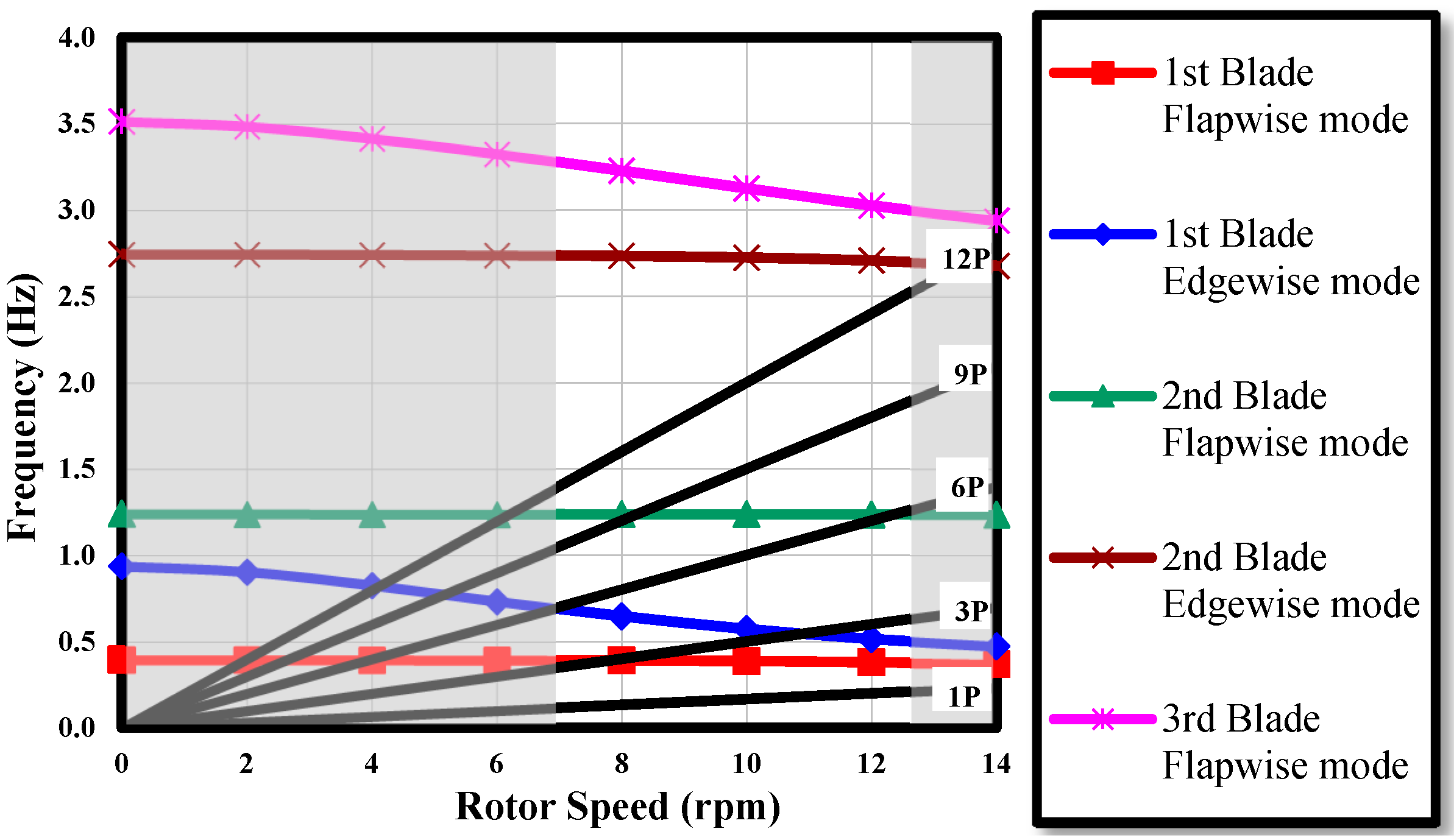

3.4.2. FE Model

4. Results and Discussion

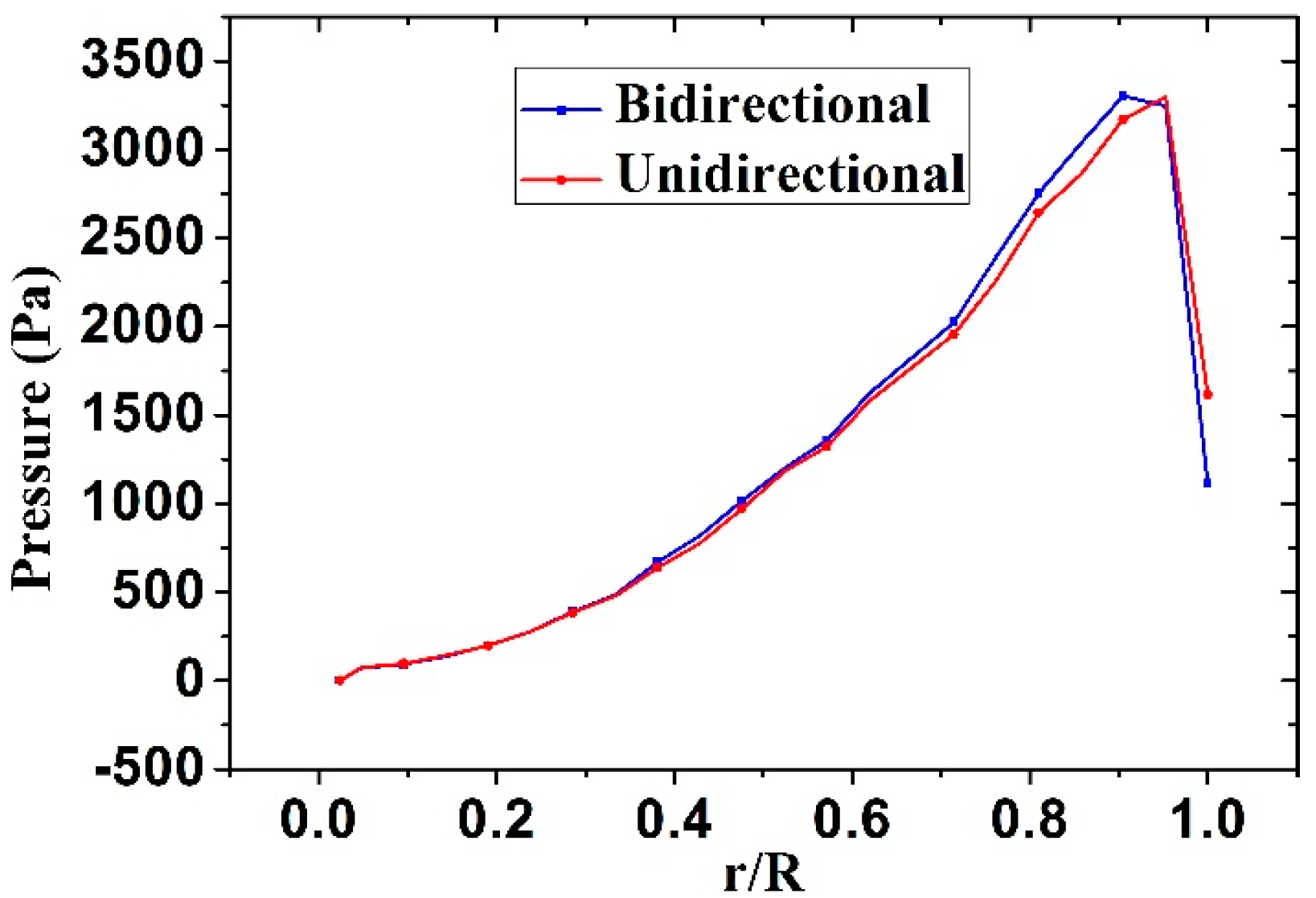

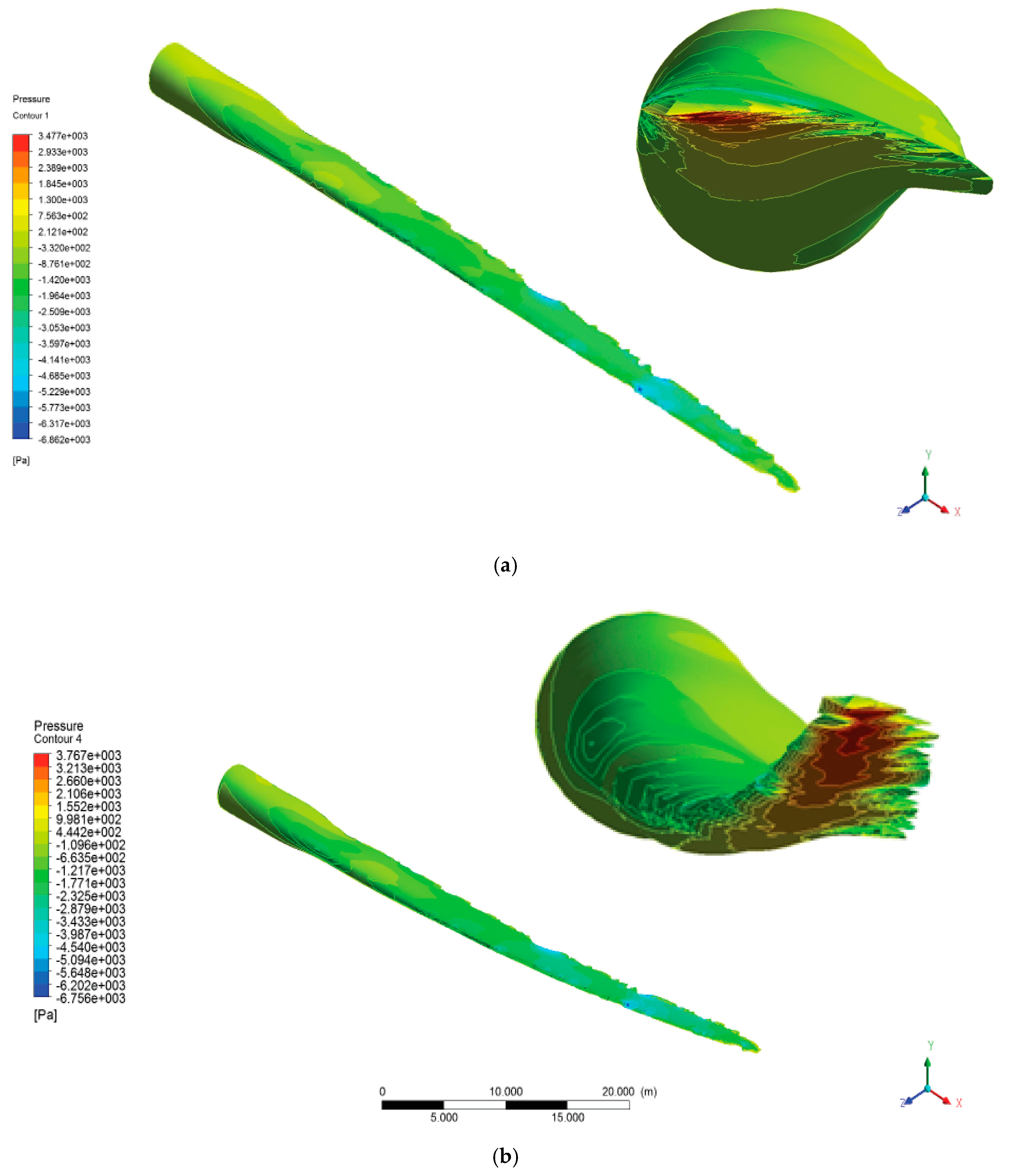

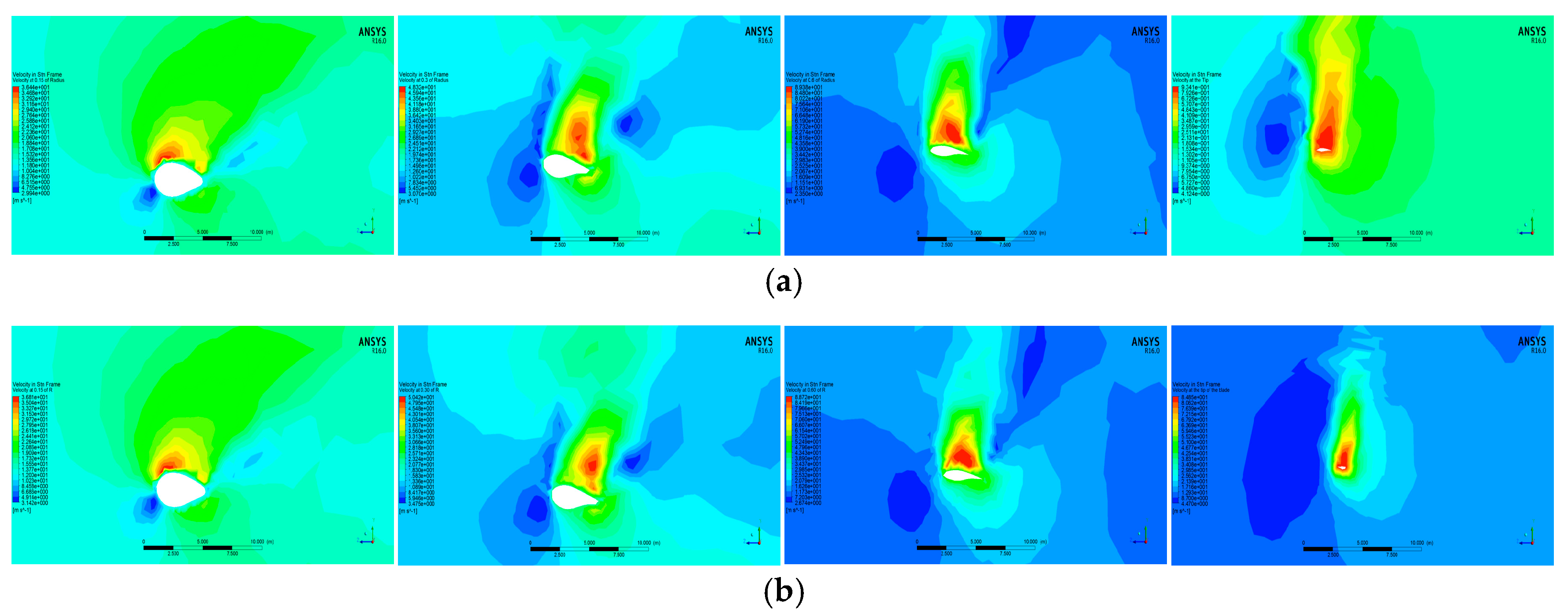

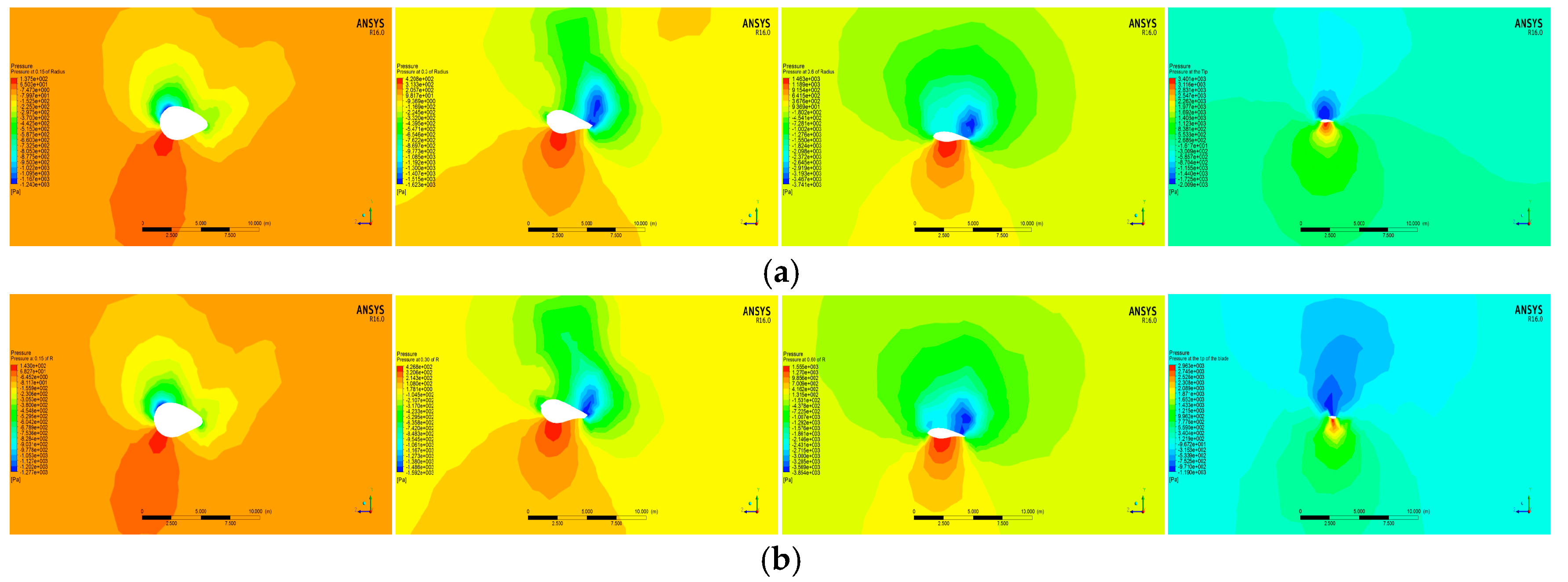

4.1. Aerodynamic Responses

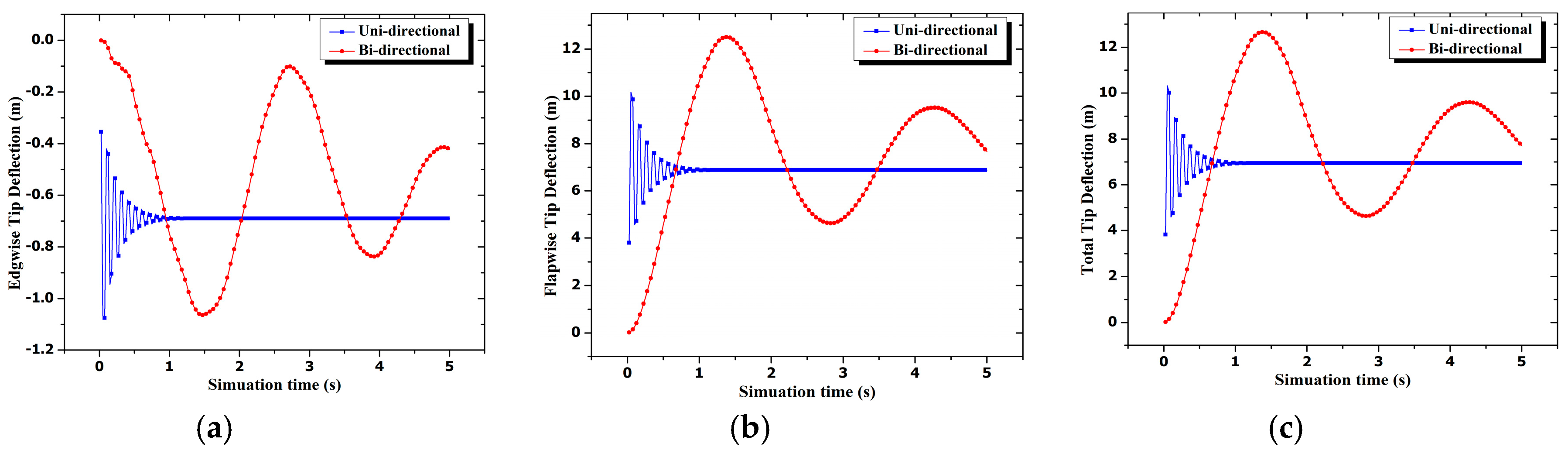

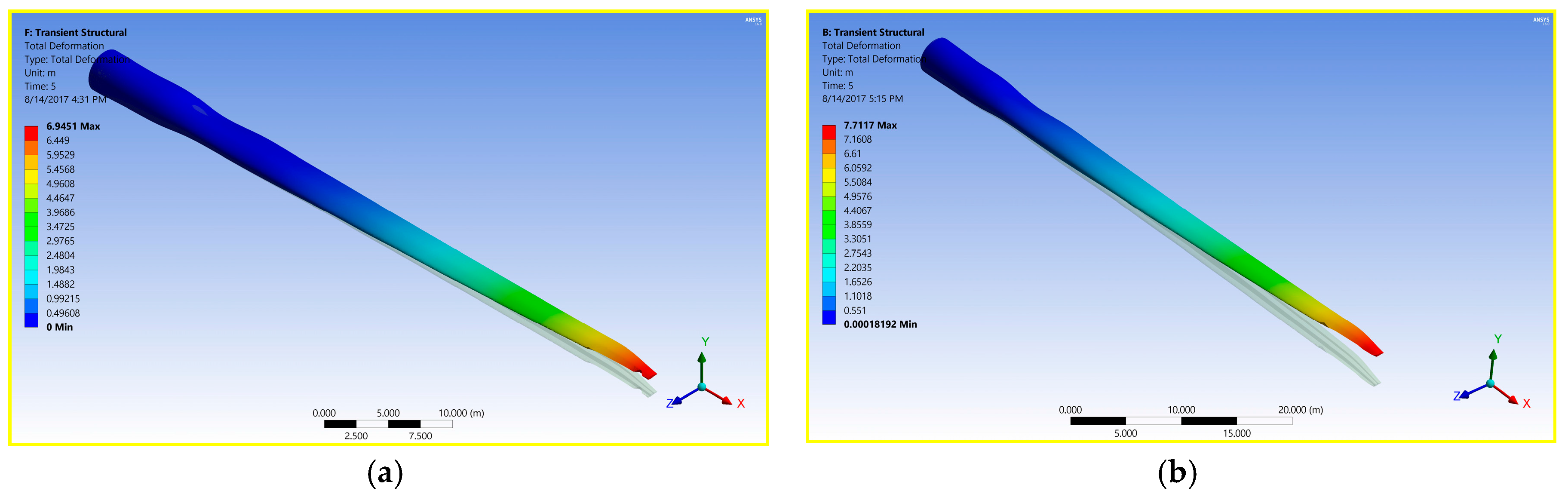

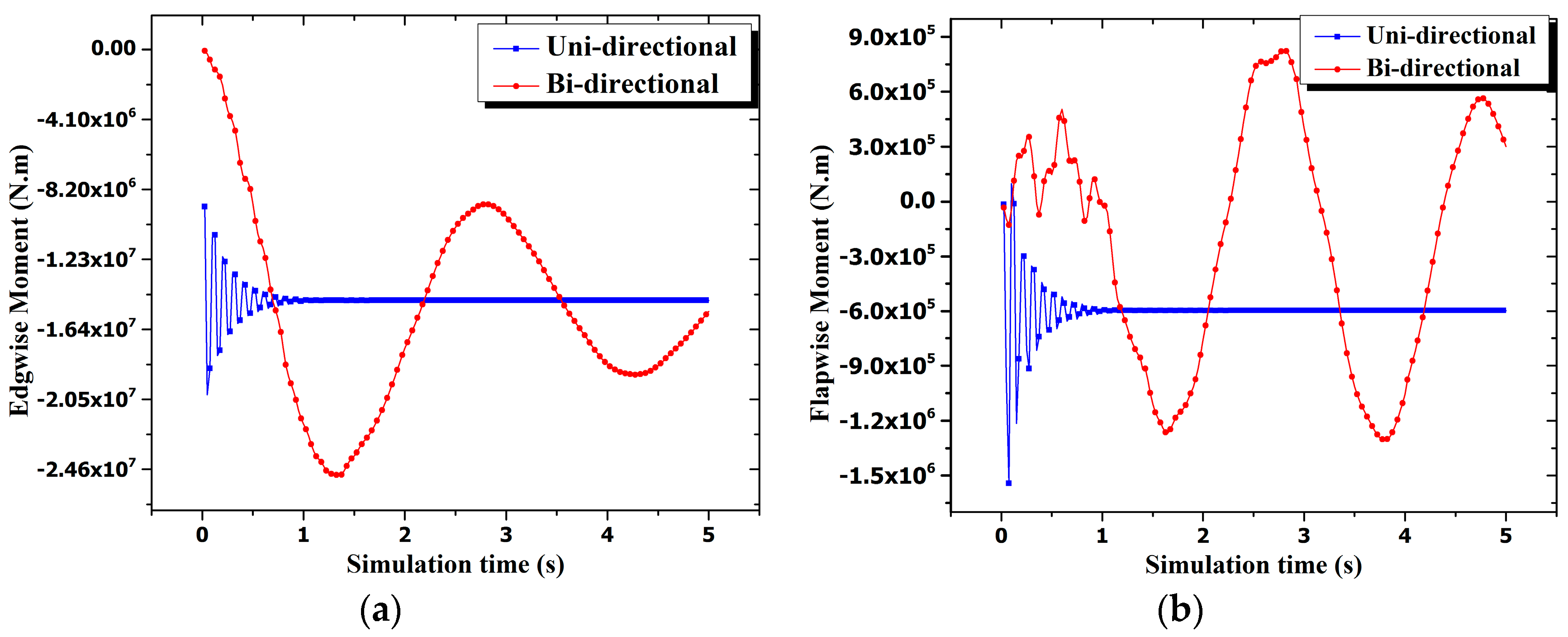

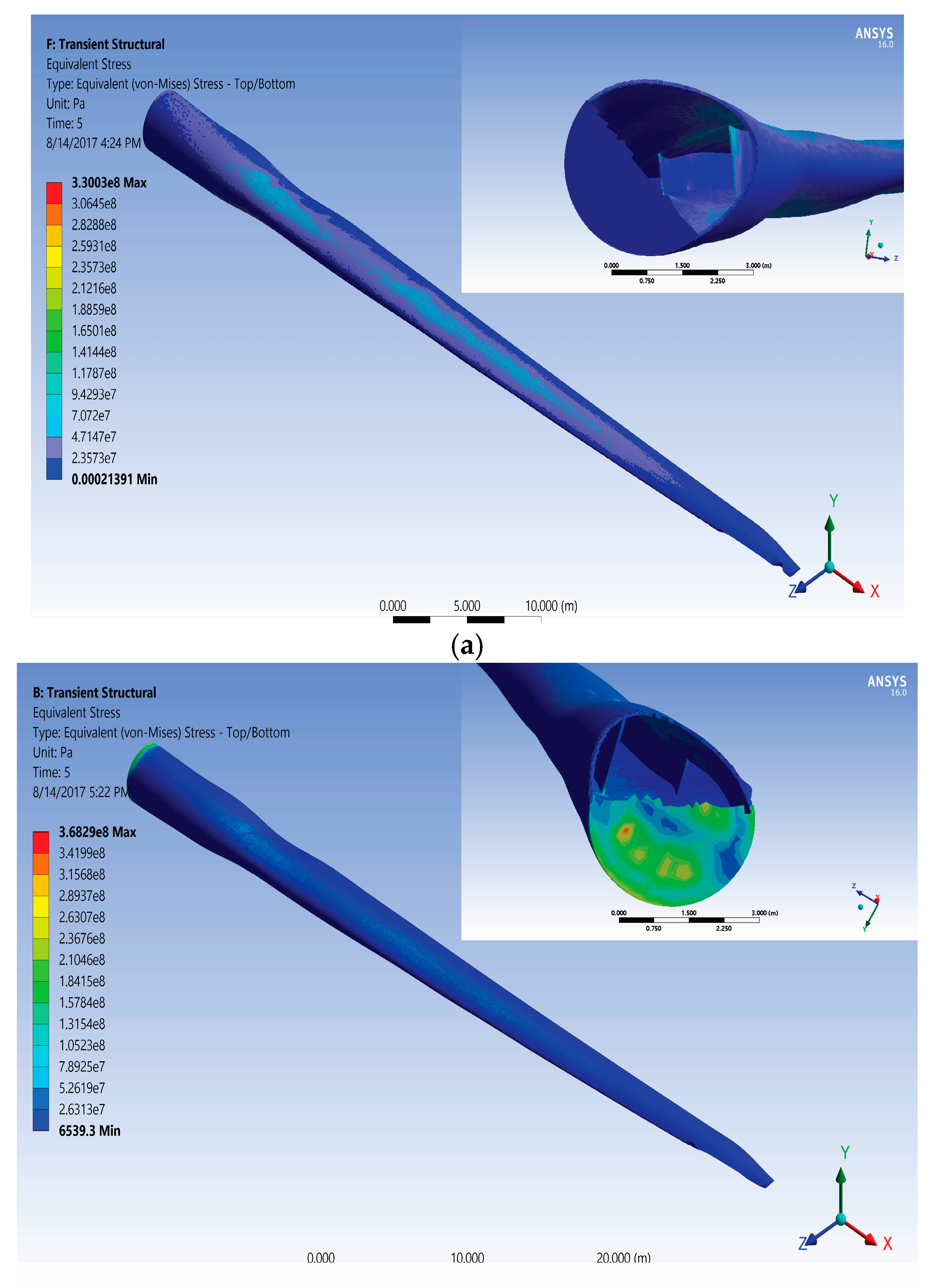

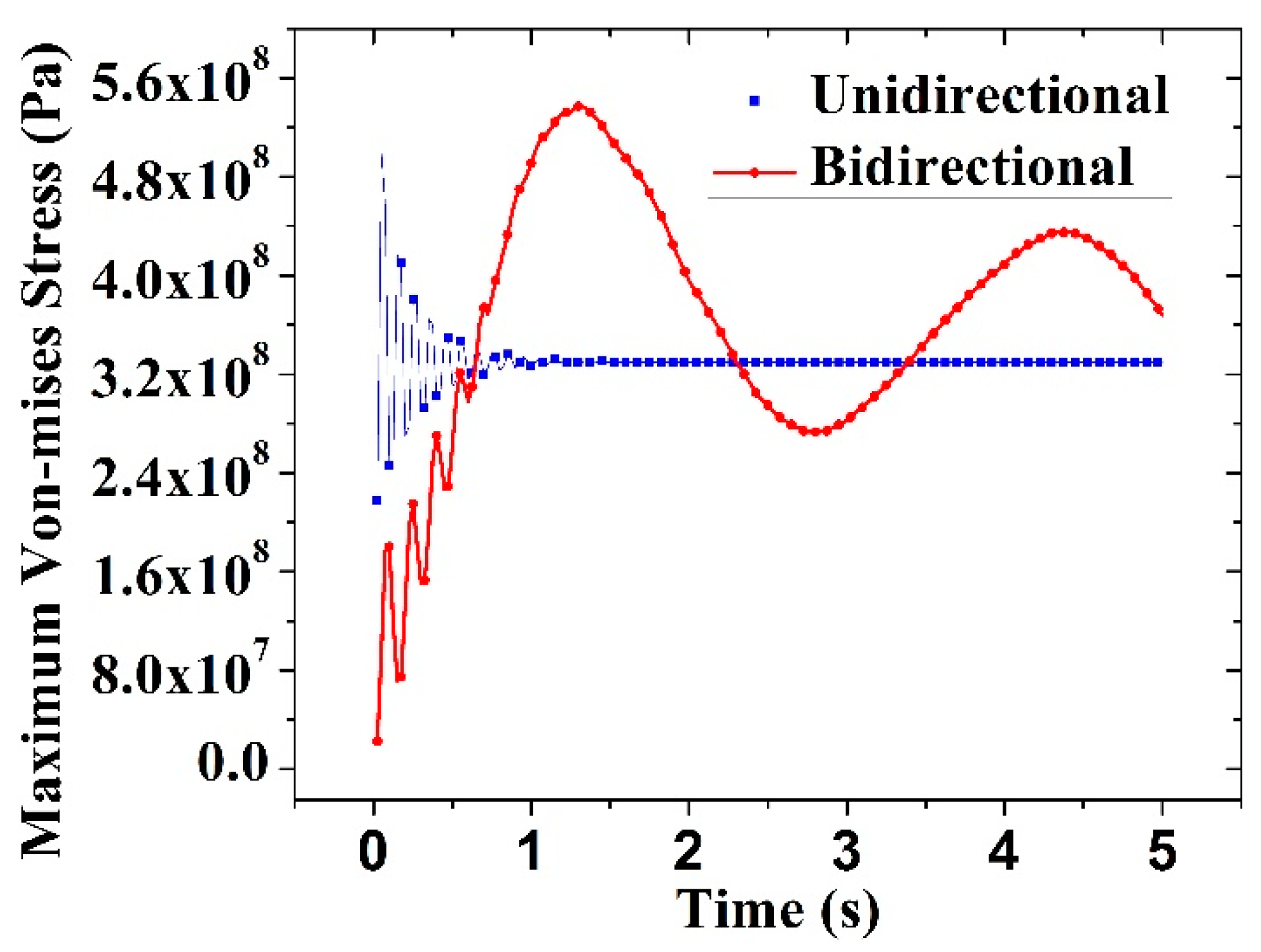

4.2. Structural Response

5. Conclusions

- The pressure on the blade, the total tip deflection and the blade root moments in the uni-directional model fluctuates for one second and maintains a constant value; however, in the bi-directional model the fluctuation continues.

- Comparing the tip vortex and the axial velocity gradient along the downwind side of the blade, the free stream velocity was attained faster in the bi-direction model than the uni-directional model.

- In the bi-directional model, the root of the blade is a highly stressed location with a magnitude of 368 MPa, and the leading edge is the most stressed part of the blade in the uni-directional model with a maximum of 330 MPa. In relation, the power developed would also fluctuate in the bi-directional model whereas it would have a constant value in the bi-directional coupling model.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- International Energy Agency. Long-Term Research and Development Needs for Wind Energy for the Time Frame 2012 to 2030; International Energy Agency: Paris, France, 2013. [Google Scholar]

- Tabassum, A.; Premalatha, M.; Abbasi, T.; Abbasi, S.A. Wind energy: Increasing deployment, rising environmental concerns. Renew. Sustain. Energy Rev. 2014, 31, 270–288. [Google Scholar] [CrossRef]

- Ageze, M.; Hu, Y.; Wu, H. Wind Turbine Aeroelastic Modeling: Basics and Cutting Edge Trends. Int. J. Aerosp. Eng. 2017, 2017, 5263897. [Google Scholar] [CrossRef]

- Hou, G.; Wang, J.; Layton, A. Numerical Methods for Fluid-Structure-Review. Commun. Comput. Phys. 2012, 12, 337–377. [Google Scholar] [CrossRef]

- Marshall, J.G.; Imregun, M. A review of aeroelasticity methods with emphasis on turbomachinery applications. J. Fluids Struct. 1996, 10, 237–267. [Google Scholar] [CrossRef]

- Carrión, M.; Steijl, R.; Woodgate, M.; Barakos, G.N.; Munduate, X.; Gomez-Iradi, S. Aeroelastic analysis of wind turbines using a tightly coupled CFD–CSD. J. Fluids Struct. 2014, 50, 392–415. [Google Scholar] [CrossRef]

- Hirt, C.W.; Amsden, A.A.; Cook, J.L. An Arbitrary Lagrangian–Eulerian Computing Method for All Flow Speeds. J. Comput. Phys. 1997, 135, 203–216. [Google Scholar] [CrossRef]

- Hu, H.H.; Patankar, N.A.; Zhu, M.Y. Direct Numerical Simulations of Fluid–Solid Systems Using the Arbitrary Lagrangian–Eulerian Technique. J. Comput. Phys. 2001, 169, 427–462. [Google Scholar] [CrossRef]

- Yuri, B.; Takizawa, K.; Tezduyar, T.E.; Hsu, M.; Kostov, N.; McIntyre, S. Aerodynamic and FSI Analysis of Wind Turbines with the ALE-VMS and ST-VMS Methods. Arch. Comput. Methods Eng. 2014, 21, 359–398. [Google Scholar]

- Tian, F.; Wang, Y.; Young, J.; Lai, J.C.S. An FSI solution technique based on the DSD/SST method and its applications. Math. Models Methods Appl. Sci. 2015, 25, 2257–2285. [Google Scholar] [CrossRef]

- Tian, F.-B. FSI modeling with the DSD/SST method for the fluid and finite difference method for the structure. Comput. Mech. 2014, 54, 581–589. [Google Scholar] [CrossRef]

- Benra, F.; Dohmen, H.J.; Pei, J.; Schuster, S.; Wan, B. A Comparison of One-Way and Two-Way Coupling Methods for Numerical Analysis of Fluid-Structure Interactions. J. Appl. Math. 2011, 2011, 853560. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, Z.; Tsai, G. Two-way Fluid-Structure Interaction Simulation of a Micro Horizontal Axis Wind Turbine. Int. J. Eng. Technol. Innov. 2015, 5, 33–44. [Google Scholar]

- Kumar, J.; Wurm, F. Bi-directional fluid-structure interaction for large deformation of layered composite propeller blades. J. Fluids Struct. 2015, 57, 32–48. [Google Scholar] [CrossRef]

- Jonkman, J.; Butterfield, S.; Musial, W.; Scott, G. Definition of a 5-Mw Reference Wind Turbine for Offshore System Development; Technical Report NREL/TP-500-38060; National Renewable Energy Laboratory: Golden, CO, USA, 2009.

- Hansen, M.; Sørensen, J.; Voutsinas, S.; Sørensen, N.; Madsen, H. State of the art in wind turbine aerodynamics and aeroelasticitys. Prog. Aerosp. Sci. 2006, 42, 285–330. [Google Scholar] [CrossRef]

- Menter, F.R. Two-equation eddy-viscosity turbulence models for engineering applications. AIAA J. 1994, 32, 1598–1605. [Google Scholar] [CrossRef]

- Villalpando, F.; Reggio, M.; Ilinca, A. Assessment of Turbulence Models for Flow Simulation around a Wind Turbine Airfoil. Model. Simul. Eng. 2011, 2011, 714146. [Google Scholar] [CrossRef]

- Menter, F.R. Zonal two-equation model k–w models for aerodynamic flows. In Proceedings of the 23rd Fluid Dynamics, Plasmadynamics, and Lasers Conference, Orlando, FL, USA, 6–9 July 1993. [Google Scholar]

- Hodges, D.H.; Dowell, E.H. Nonlinear Equations of Motion for the Elastic Bending and Torsion of Twisted Nonuniform Rotor Blades; National Aeronautics and Space Administration: Washington, DC, USA, 1974.

- Kaza, K. Nonlinear Aeroelastic Equations of Motion of Twisted, Nonuniform, Flexible Horizontal-Axis Wind Turbine Blades; Toledo University: Toledo, OH, USA, 1980. [Google Scholar]

- Kallesøe, B.S. Equations of motion for a rotor blade, including gravity, pitch action and rotor speed variations. Wind Energy 2007, 10, 209–230. [Google Scholar] [CrossRef]

- Kooijman, H.J.T.; Lindenburg, C.; Winkelaar, D.; van der Hooft, E.L. Dowec 6 MW Pre-Design: Aero-Elastic Modelling of the DOWEC 6 MW Pre-Design in Phatas; ECN Wind Energy: Amsterdam, The Netherland, 2003. [Google Scholar]

- Martin, H.R. Development of a Scale Model Wind Turbine for Testing of Offshore Floating Wind Turbine Systems; The University of Maine: Orono, ME, USA, 2011. [Google Scholar]

- Griffin, D. WindPACT Turbine Design Scaling Studies Technical Area 1-Composite Blades for 80- to 120-Meter Rotor; National Renewable Energy Laboratory: Golden, CO, USA, 2001.

- Jonkman, J.M.; Jonkman, B.J. FAST modularization framework for wind turbine simulation: Full-system linearization. J. Phys. Conf. Ser. 2016, 753. [Google Scholar] [CrossRef]

- Stol, K.A.; Moll, H.G.; Bir, G.; Namik, H. A Comparison of Multi-Blade Coordinate Transformation and Direct Periodic Techniques for Wind Turbine Control Design. In Proceedings of the 47th AIAA Aerospace Sciences Meeting Including the New Horizons Forum and Aerospace Exposition, Orlando, FL, USA, 5–8 January 2009. [Google Scholar]

- Lindenburg, C. Aeroelastic Modelling of the LMH64–5; Energy Research Centre of the Netherlands: Petten, The Netherlands, 2002. [Google Scholar]

- Bir, G.; Jonkman, J. Aeroelastic Instabilities of Large Offshore and Onshore Wind Turbines. J. Phys. Conf. Ser. 2007, 75. [Google Scholar] [CrossRef]

| Station No. ** | Radius | Aerofoil | Chord (m) | Twist (°) | Principal Moment of Inertia at the Section Centroid | Solid Cross-Sectional Area (m2) | Section Centroid (m) * | ||

|---|---|---|---|---|---|---|---|---|---|

| IXX (m4) | IYY (m4) | J (m4) | |||||||

| 1 | 1.5000 | Cyclinder1 | 3.5420 | 13.3080 | 1.05 | 1.07 | 2.12 | 0.671 | (1.7, 0.402, 1.5) |

| 2 | 1.9530 | Cyclinder1 | 3.5420 | 13.3080 | 1.04 | 1.07 | 2.11 | 0.668 | (1.7, 0.402, 1.95) |

| 3 | 3.4020 | Ellipsoidal_1 | 3.5726 | 13.3080 | 0.96 | 1.06 | 2.02 | 0.651 | (1.73, 0.416, 3.4) |

| 4 | 5.5440 | Ellipsoidal_2 | 3.8060 | 13.3080 | 0.951 | 1.24 | 2.19 | 0.959 | (1.8, 0.448, 5.54) |

| 5 | 8.6330 | Ellipsoidal_3 | 4.0997 | 13.3080 | 0.626 | 1.27 | 1.9 | 0.874 | (1.89, 0.502, 8.63) |

| 6 | 11.7500 | DU40_A17 | 4.5570 | 13.3080 | 0.27 | 1.23 | 1.5 | 0.728 | (2.05, 0.486, 11.7) |

| 7 | 15.8500 | DU35_A17 | 4.6520 | 11.4800 | 0.179 | 1.2 | 1.37 | 0.675 | (2.13, 0.413, 15.9) |

| 8 | 19.9500 | DU35_A17 | 4.4580 | 10.1620 | 0.15 | 1.0 | 1.15 | 0.617 | (2.05, 0.349, 19.9) |

| 9 | 24.0500 | DU30_A17 | 4.2490 | 9.0110 | 0.103 | 0.771 | 0.873 | 0.528 | (2, 0.309, 24.1) |

| 10 | 28.1500 | DU25_A17 | 4.0070 | 7.7950 | 0.0528 | 0.601 | 0.653 | 0.458 | (1.9, 0.3, 28.1) |

| 11 | 32.2500 | DU25_A17 | 3.7480 | 6.5440 | 0.0411 | 0.466 | 0.507 | 0.406 | (1.79, 0.241,32.3) |

| 12 | 36.3500 | DU21_A17 | 3.5020 | 5.3610 | 0.0229 | 0.35 | 0.373 | 0.347 | (1.68, 0.223,36.4) |

| 13 | 40.4500 | DU21_A17 | 3.2560 | 4.1880 | 0.0171 | 0.265 | 0.282 | 0.304 | (1.57, 0.176, 40.5) |

| 14 | 44.5500 | NACA64_A17 | 3.0100 | 3.1250 | 0.00884 | 0.191 | 0.2 | 0.256 | (1.46, 0.15, 44.6) |

| 15 | 48.6500 | NACA64_A17 | 2.7640 | 2.3190 | 0.00648 | 0.138 | 0.145 | 0.219 | (1.34, 0.119, 48.6) |

| 16 | 52.7500 | NACA64_A17 | 2.5180 | 1.5260 | 0.00462 | 0.0973 | 0.102 | 0.186 | (1.22, 0.091, 52.7) |

| 17 | 56.1667 | NACA64_A17 | 2.3130 | 0.8630 | 0.00338 | 0.0708 | 0.0742 | 0.16 | (1.12, 0.0704, 56.2) |

| 18 | 58.9000 | NACA64_A17 | 2.0860 | 0.3700 | 0.00237 | 0.0493 | 0.0517 | 0.137 | (1.01, 0.0543, 58.9) |

| 19 | 61.6333 | NACA64_A17 | 1.4190 | 0.1060 | 0.000773 | 0.0149 | 0.0157 | 0.088 | (0.691, 0.0332, 61.6) |

| 20 | 63 | NACA64_A17 | 1.0870 | 0 | 0.000368 | 0.00663 | 0.007 | 0.0658 | (0.529, 0.0233, 63) |

| Material | Lay-up | EL(GPa) | ET(GPa) | GLT(GPa) | Poisson’s Ratio (νLT) | Density (kg/m3) |

|---|---|---|---|---|---|---|

| E-LT-5500/EP-3 | 0 | 41.8 | 14 | 2.63 | 0.28 | 1920 |

| Saertex/EP-3 | 45 | 13.6 | 13.3 | 11.8 | 0.51 | 1780 |

| Properties | NREL 5MW | FE Model |

|---|---|---|

| Length (w.r.t. Root Along Preconed Axis) | 61.5 m | 61.5 m |

| Overall (Integrated) Mass | 17,740 kg | 48,122 kg |

| CM Location (w.r.t. Root along Preconed Axis) | 20.475 m | 23.397 m |

| Pre-cone | 2.5° | 0 |

| Sub-Domain | Mass Flow Rate (kg/s) | |

|---|---|---|

| Uni-Directional | Bi-Directional | |

| Inlet | 232,138.22 | 232,138.22 |

| Inlet top (far field ) | 265,637.39 | 265,637.39 |

| Outlet | −497,775.5 | −497,775.96 |

| Net | 0.10900877 | −0.34917137 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ageze, M.B.; Hu, Y.; Wu, H. Comparative Study on Uni- and Bi-Directional Fluid Structure Coupling of Wind Turbine Blades. Energies 2017, 10, 1499. https://doi.org/10.3390/en10101499

Ageze MB, Hu Y, Wu H. Comparative Study on Uni- and Bi-Directional Fluid Structure Coupling of Wind Turbine Blades. Energies. 2017; 10(10):1499. https://doi.org/10.3390/en10101499

Chicago/Turabian StyleAgeze, Mesfin Belayneh, Yefa Hu, and Huachun Wu. 2017. "Comparative Study on Uni- and Bi-Directional Fluid Structure Coupling of Wind Turbine Blades" Energies 10, no. 10: 1499. https://doi.org/10.3390/en10101499