Intermittent Smoothing Approaches for Wind Power Output: A Review

Abstract

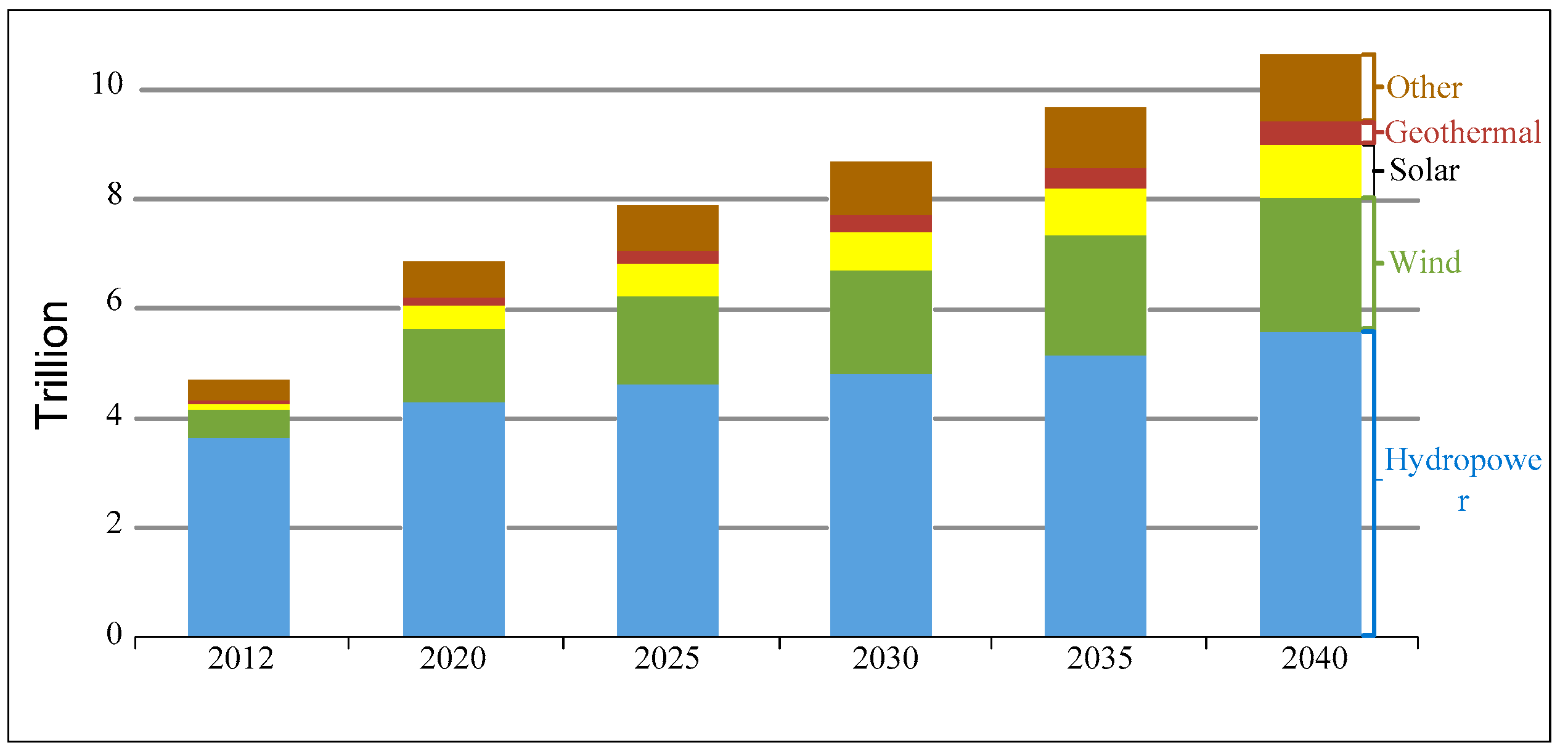

:1. Introduction

- (1)

- Fluctuations of wind power resulted in the change in grid frequency.

- (2)

- The reactive power of grid consumed by wind induction generator is related directly to the active power generation. Active power generation is varied by alteration in wind speed and hence absorbs reactive power, essential to voltage variation at the buses of the power grid.

- (3)

- Both voltage flicker and frequency fluctuation yield low quality of power generation and results in instability issues of power generation system, particularly when there are high sensitive loads that cannot tolerate frequent fluctuation of high voltage and frequency variations.

2. Problems Related to Intermittent Wind Power Sources

2.1. Voltage Fluctuation

2.1.1. Reverse Power Flow Due to Voltage Rise

2.1.2. Voltage Flicker

2.2. Unintentional Islanding

2.3. Power Fluctuations in Grid

2.4. Influence on Grid Frequency

3. Intermittent Smoothing Approaches for Wind Output

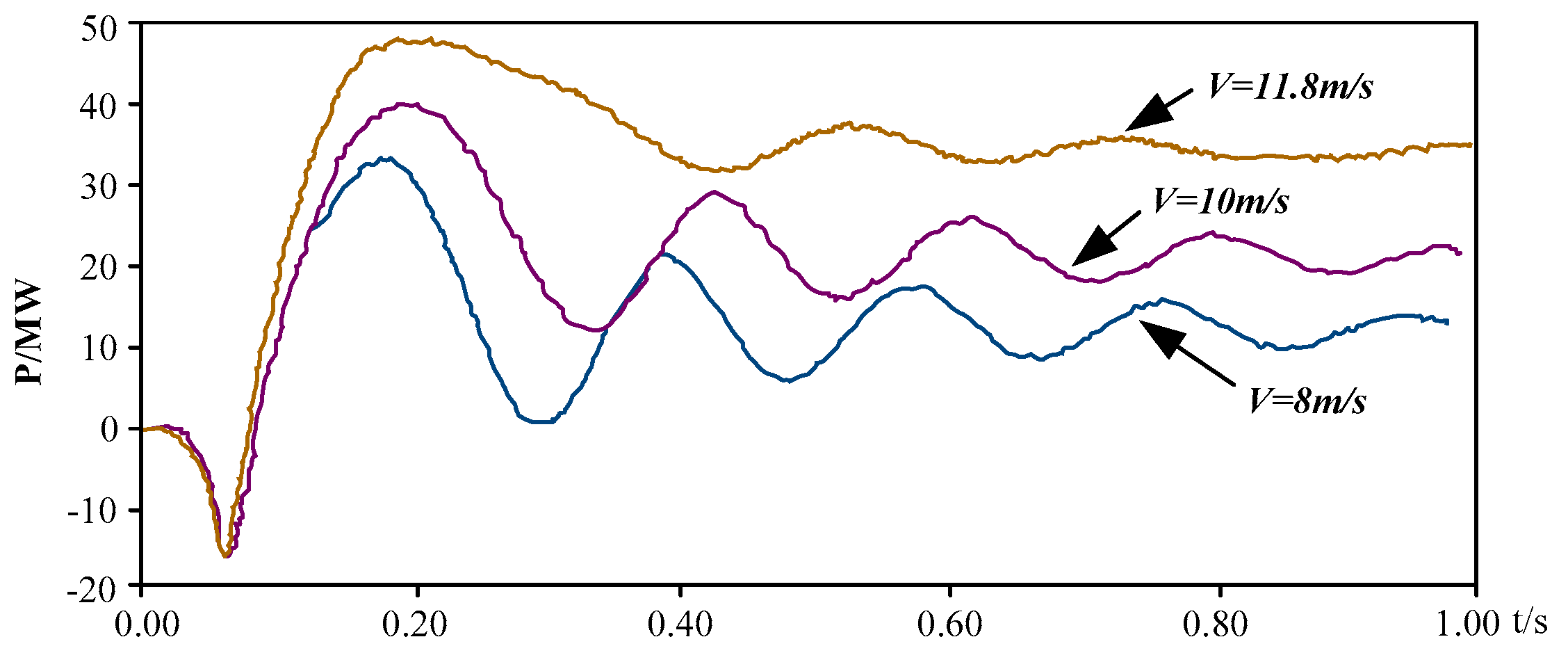

3.1. Smoothing by Using Pitch Control

3.2. Smoothing by Utilizing Energy Storage System

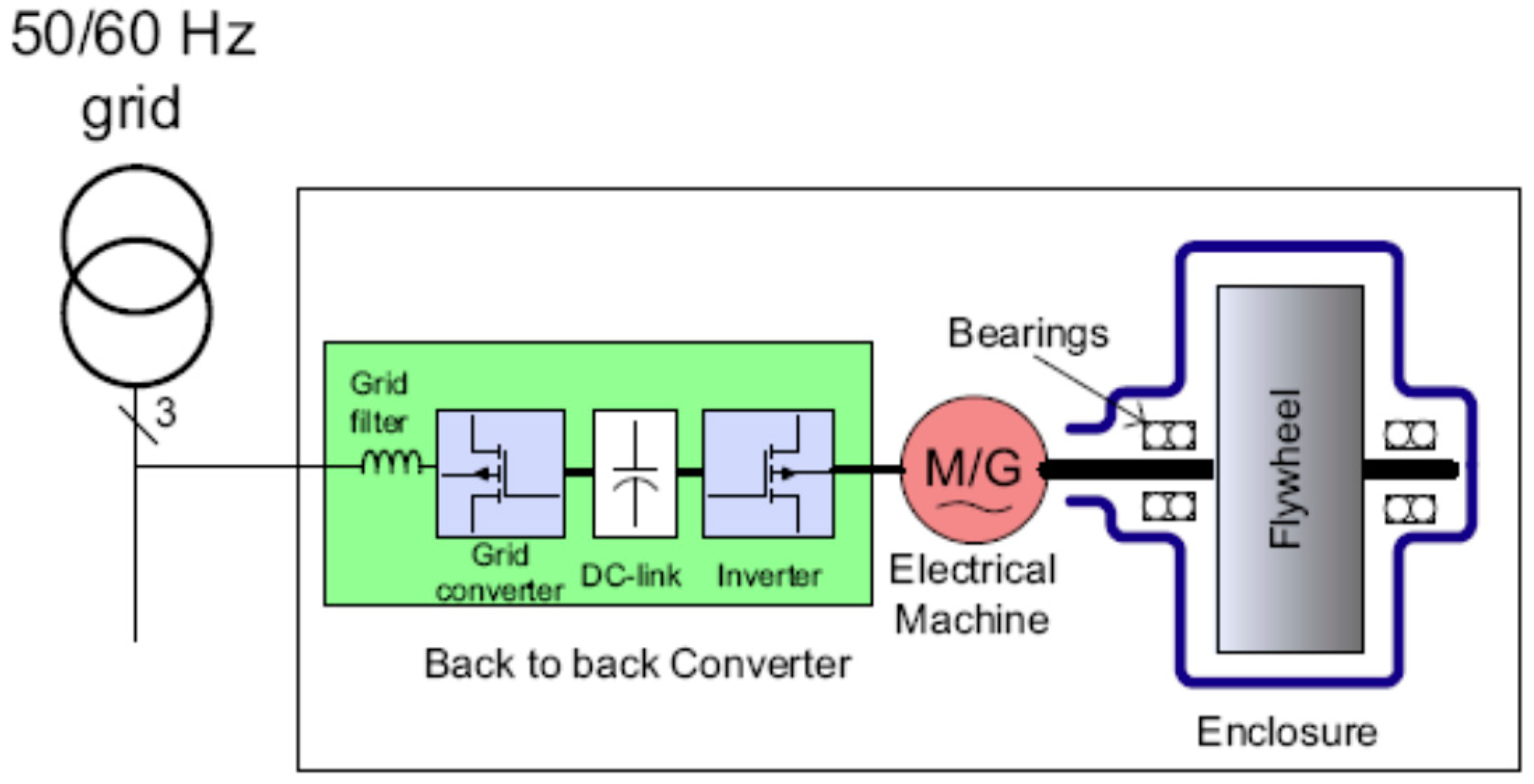

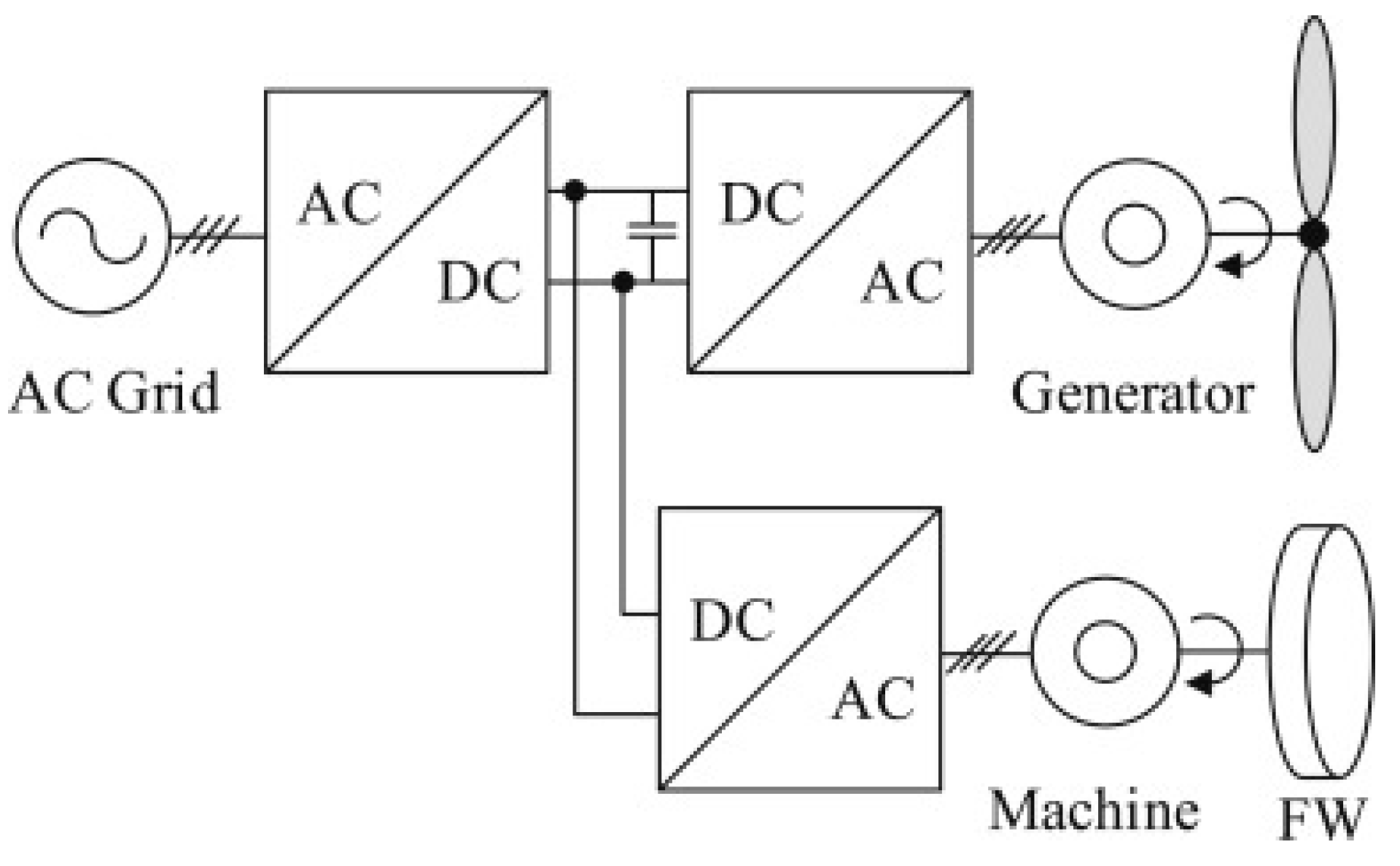

3.2.1. Flywheel Energy Storage System

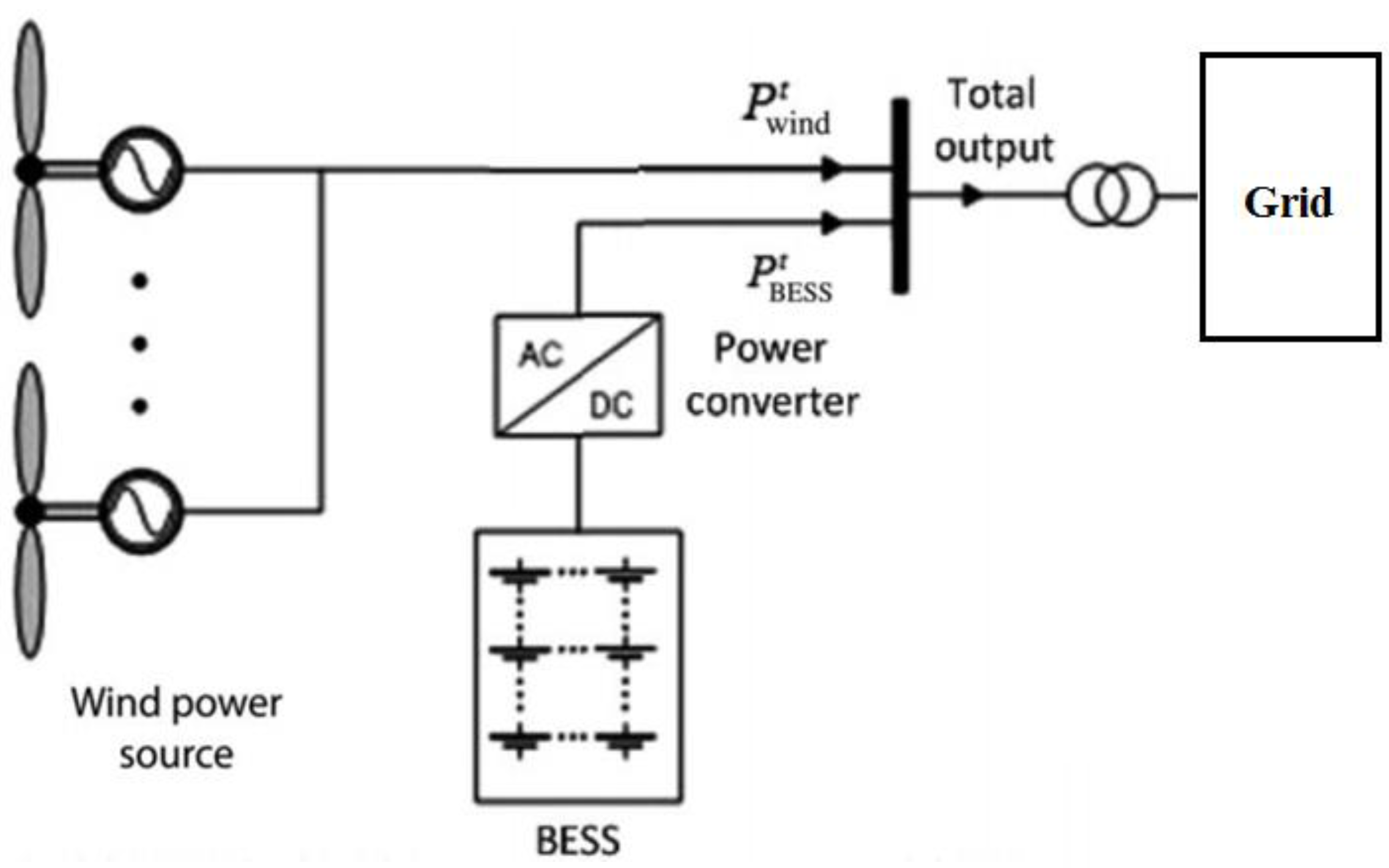

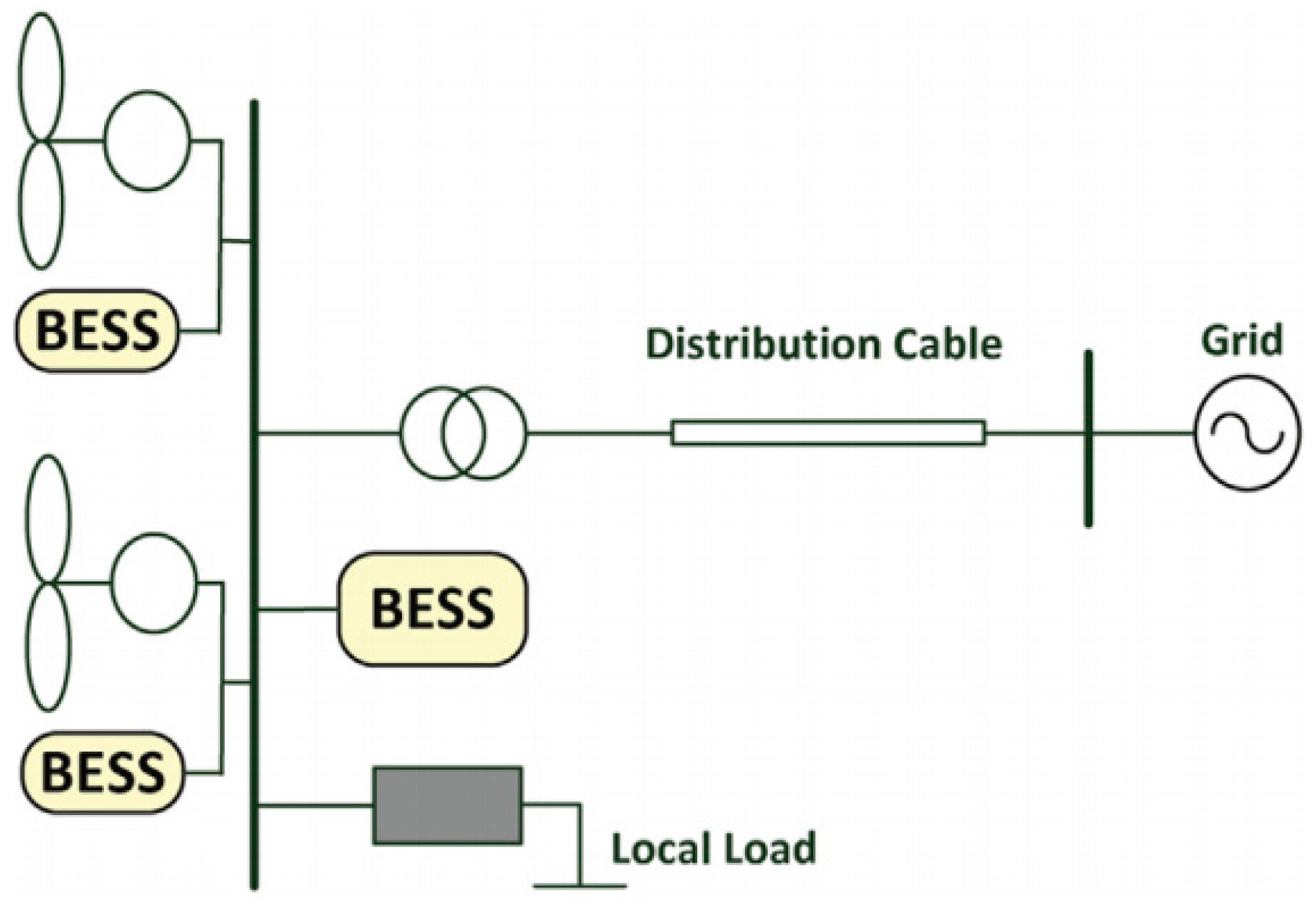

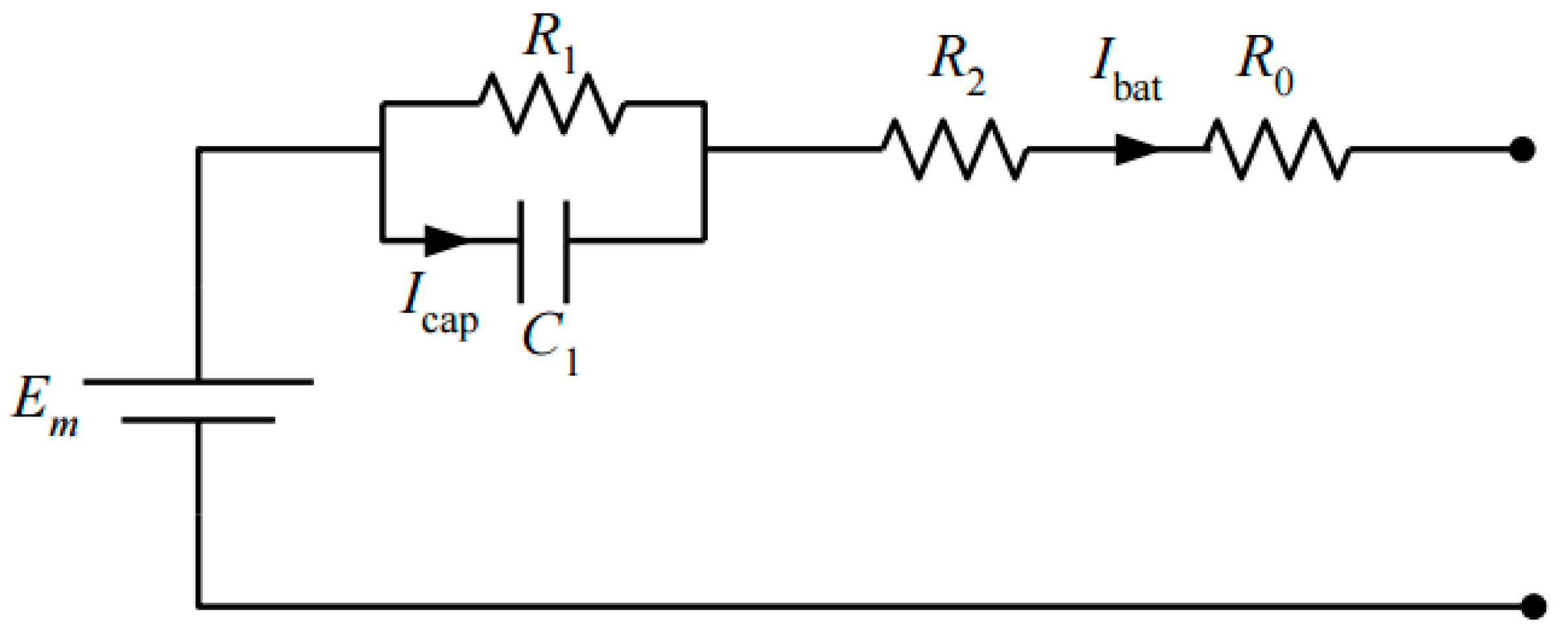

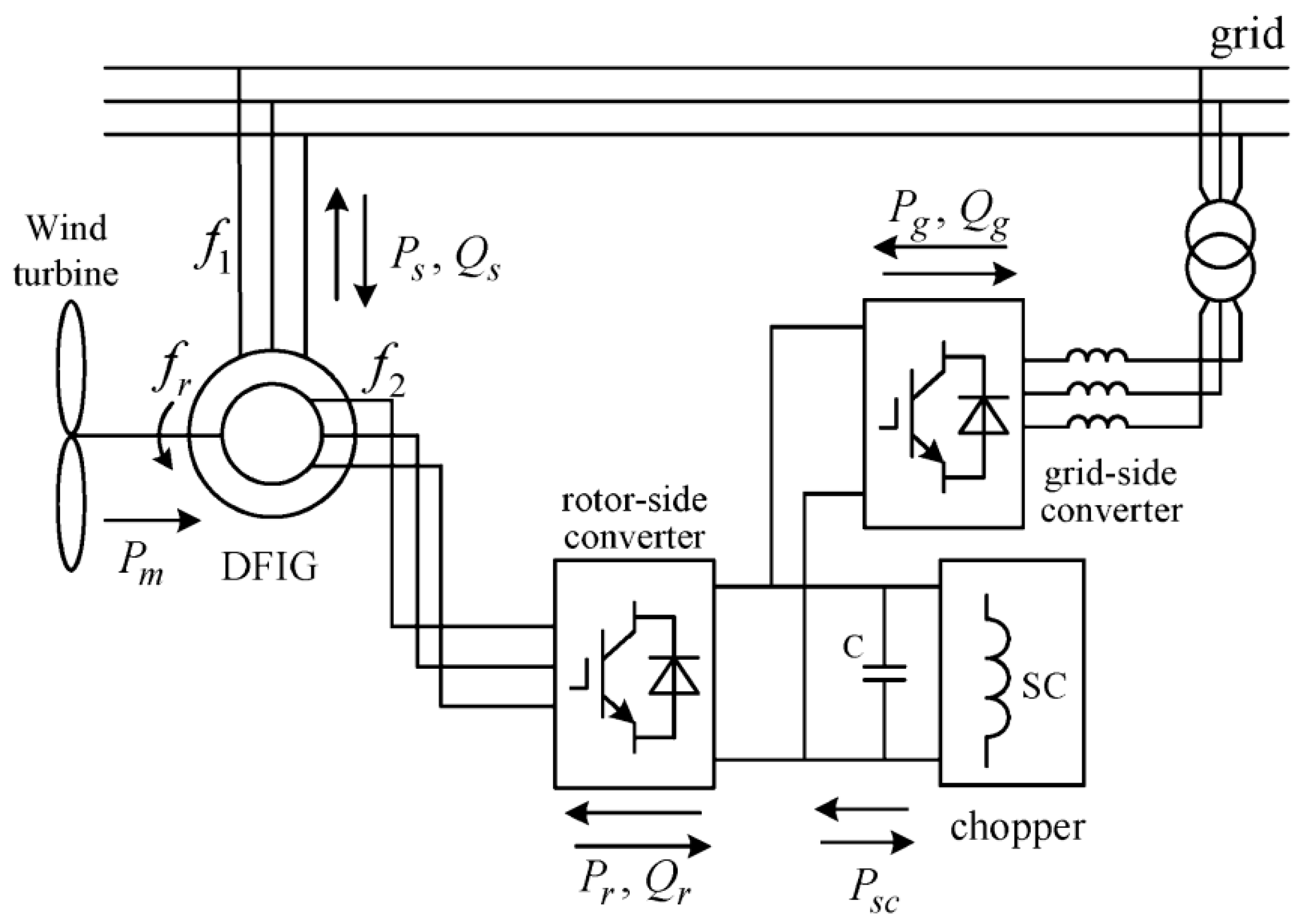

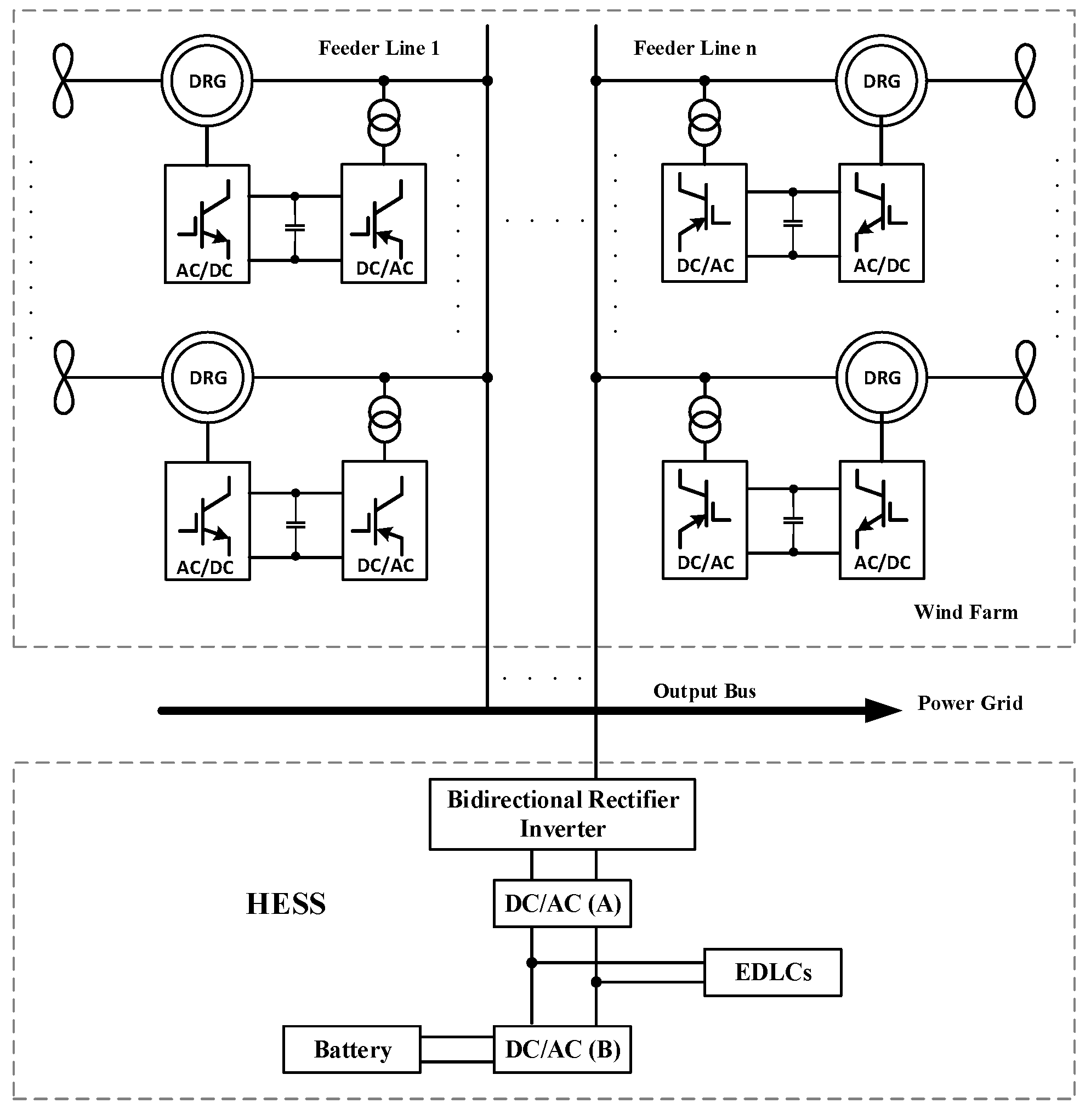

3.2.2. Battery Energy Storage System (BESS)

3.2.3. Superconductive Magnetic Energy Storage SYSTEM (SMESS)

3.2.4. Ultra-Capacitor

3.3. Curtailment of Active Power by maximum power point tracking (MPPT) Control

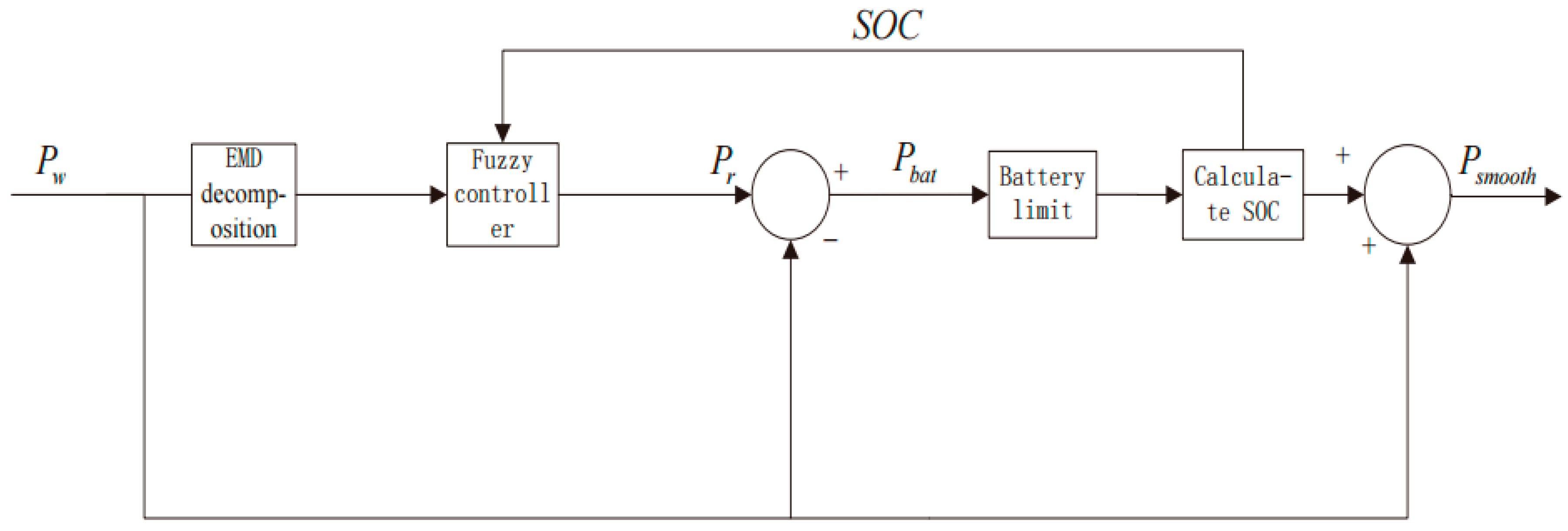

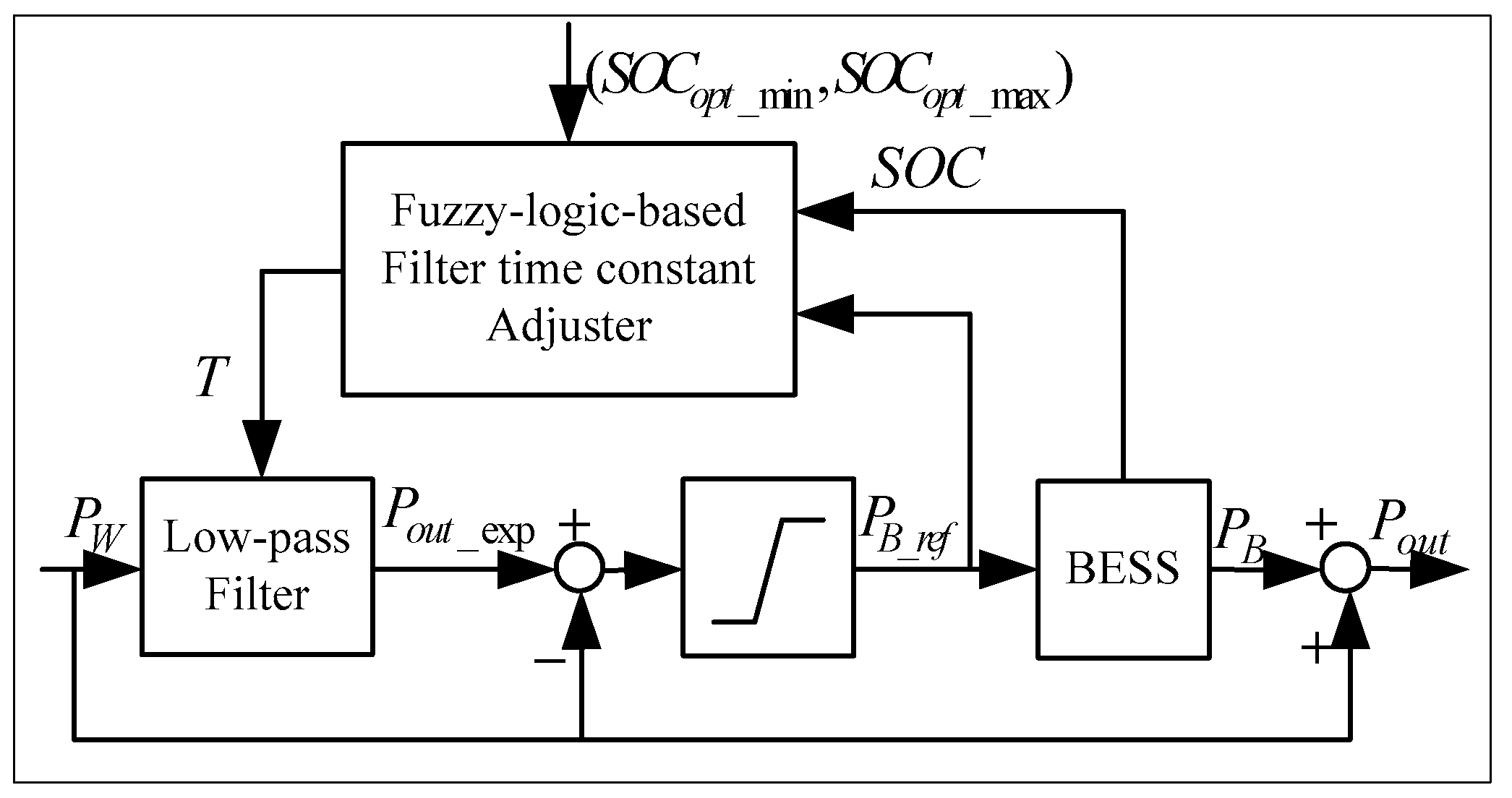

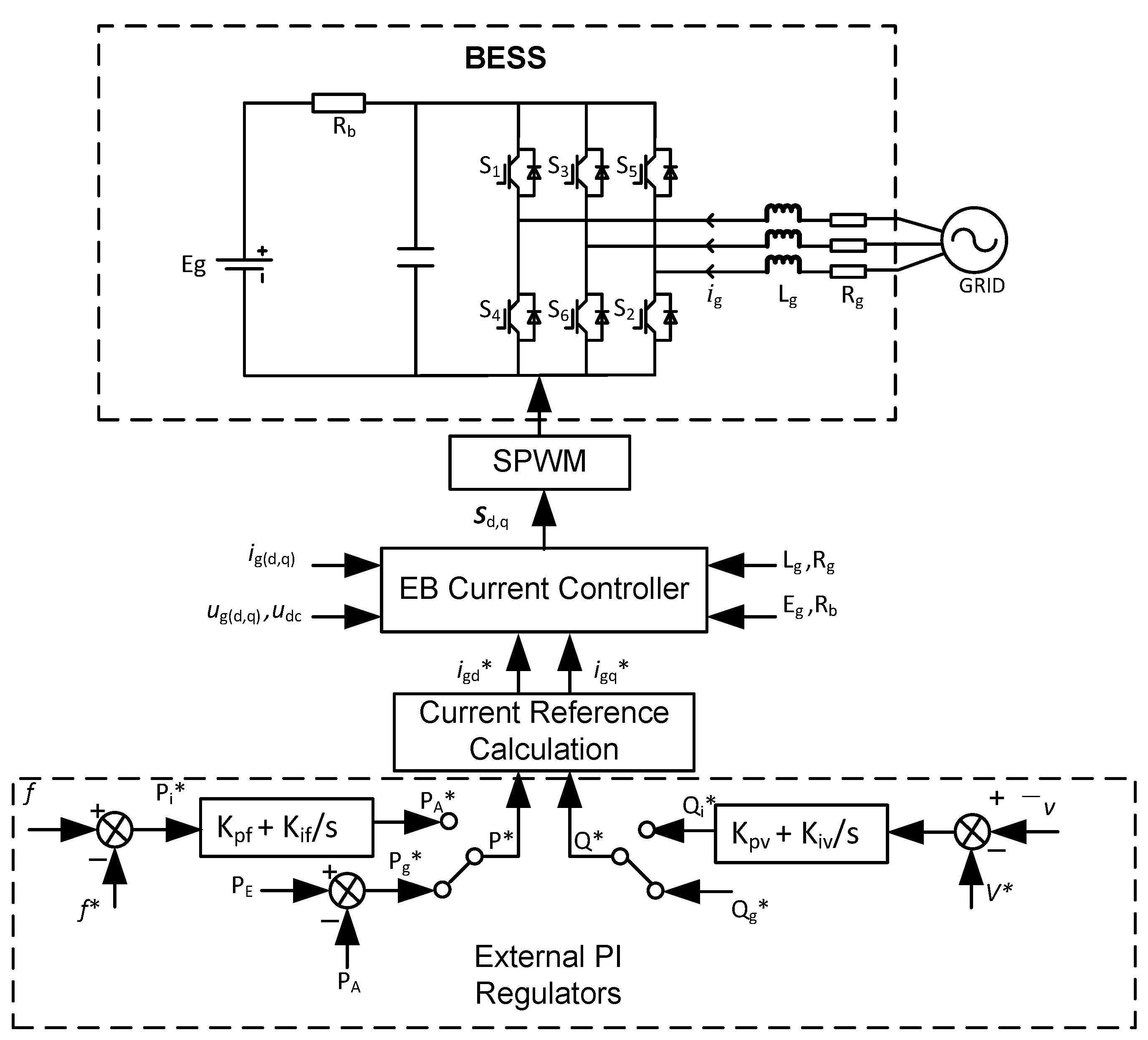

4. Control Strategy for BESS

5. Discussion

6. Conclusions and Future Recommendations

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ye, B.; Zhang, K.; Jiang, J.; Miao, L.; Li, J. Towards a 90% renewable energy future: A case study of an island in the South China Sea. Energy Convers. Manag. 2017, 142, 28–41. [Google Scholar] [CrossRef]

- International Energy Outlook. 2016. Available online: https://www.eia.gov/outlooks/ieo/electricity.php (accessed on 8 June 2017).

- Ye, B.; Yang, P.; Jiang, J.; Miao, L.; Shen, B.; Li, J. Feasibility and economic analysis of a renewable energy powered special town in China. Resour. Conserv. Recycl. 2017, 121, 40–50. [Google Scholar] [CrossRef]

- Islam, M.R.; Guo, Y.; Zhu, J. A High-Frequency Link Multilevel Cascaded Medium-Voltage Converter for Direct Grid Integration of Renewable Energy Systems. IEEE Trans. Power Electron. 2014, 29, 4167–4182. [Google Scholar] [CrossRef]

- Shahbazi, M.; Poure, P.; Saadate, S.; Zolghadri, M.R. Five-leg converter topology for wind energy conversion system with doubly fed induction generator. Renew. Energy 2011, 36, 3187–3194. [Google Scholar] [CrossRef] [Green Version]

- Bouzgou, H.; Benoudjit, N. Multiple architecture system for wind speed prediction. Appl. Energy 2011, 88, 2463–2471. [Google Scholar] [CrossRef]

- Sideratos, G.; Hatziargyriou, N.D. Probabilistic Wind Power Forecasting Using Radial Basis Function Neural Networks. IEEE Trans. Power Syst. 2012, 27, 1788–1796. [Google Scholar] [CrossRef]

- Chow, T.W.S.; Xiao-Dong, L.; Yong, F. A real-time learning control approach for nonlinear continuous-time system using recurrent neural networks. IEEE Trans. Ind. Electron. 2000, 47, 478–486. [Google Scholar] [CrossRef]

- Santamaría-Bonfil, G.; Reyes-Ballesteros, A.; Gershenson, C. Wind speed forecasting for wind farms: A method based on support vector regression. Renew. Energy 2016, 85, 790–809. [Google Scholar] [CrossRef]

- Cassola, F.; Burlando, M. Wind speed and wind energy forecast through Kalman filtering of Numerical Weather Prediction model output. Appl. Energy 2012, 99, 154–166. [Google Scholar] [CrossRef]

- Amjady, N.; Keynia, F.; Zareipour, H. Wind Power Prediction by a New Forecast Engine Composed of Modified Hybrid Neural Network and Enhanced Particle Swarm Optimization. IEEE Trans.Sustain. Energy 2011, 2, 265–276. [Google Scholar] [CrossRef]

- Shukur, O.B.; Lee, M.H. Daily wind speed forecasting through hybrid KF-ANN model based on ARIMA. Renew. Energy 2015, 76, 637–647. [Google Scholar] [CrossRef]

- Shi, J.; Ding, Z.; Lee, W.J.; Yang, Y.; Liu, Y.; Zhang, M. Hybrid Forecasting Model for Very-Short Term Wind Power Forecasting Based on Grey Relational Analysis and Wind Speed Distribution Features. IEEE Trans. Smart Grid 2014, 5, 521–526. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, N.; Wu, L.; Wang, Y. Wind speed forecasting based on the hybrid ensemble empirical mode decomposition and GA-BP neural network method. Renew. Energy 2016, 94, 629–636. [Google Scholar] [CrossRef]

- Liu, H.; Tian, H.; Liang, X.; Li, Y. New wind speed forecasting approaches using fast ensemble empirical model decomposition, genetic algorithm, Mind Evolutionary Algorithm and Artificial Neural Networks. Renew. Energy 2015, 83, 1066–1075. [Google Scholar] [CrossRef]

- Chowdhury, M.A.; Hosseinzadeh, N.; Shen, W.X. Smoothing wind power fluctuations by fuzzy logic pitch angle controller. Renew. Energy 2012, 38, 224–233. [Google Scholar] [CrossRef]

- Gevorgian, V.; Booth, S. Review of PREPA Technical Requirements for Interconnecting Wind and Solar Generation; National Renewable Energy Laboratory: Golden, CO, USA, 2013. [Google Scholar]

- Carvalho, P.M.S.; Correia, P.F.; Ferreira, L.A.F.M. Distributed Reactive Power Generation Control for Voltage Rise Mitigation in Distribution Networks. IEEE Trans. Power Syst. 2008, 23, 766–772. [Google Scholar] [CrossRef]

- Guerrero, J.X.S.; Escriva, G. Simulation Model for Energy Integration of Distributed Resources in Buildings. IEEE Lat. Am. Trans. 2015, 13, 166–171. [Google Scholar] [CrossRef]

- Ghorbanian, M.J.; Ahmadian, J.; Shams, S.; Goodarzvand, F.; Mahadi, W.N.L. Overview of grid connected doubly fed induction generator power quality. In Proceedings of the 2013 IEEE Conference on Clean Energy and Technology (CEAT), Langkawi TBD, Malaysia, 18–20 November 2013; pp. 146–151. [Google Scholar]

- Barahona, B.; Sorensen, P.; Christensen, L.; Sorensen, T.; Nielsen, H.K.; Larsen, X.G. Validation of the Standard Method for Assessing Flicker From Wind Turbines. IEEE Trans. Energy Convers. 2011, 26, 373–378. [Google Scholar] [CrossRef]

- Hu, W.; Chen, Z.; Wang, Y.; Wang, Z. Flicker Mitigation by Active Power Control of Variable-Speed Wind Turbines With Full-Scale Back-to-Back Power Converters. IEEE Trans. Energy Convers. 2009, 24, 640–649. [Google Scholar] [CrossRef]

- Elnaggar, A.K.; Rueda, J.L.; Erlich, I. Comparison of short-circuit current contribution of Doubly-Fed induction generator based wind turbines and synchronous generator. In Proceedings of the 2013 IEEE Grenoble Conference, Grenoble, France, 16–20 June 2013; pp. 1–6. [Google Scholar]

- Howlader, A.M.; Urasaki, N.; Yona, A.; Senjyu, T.; Saber, A.Y. A review of output power smoothing methods for wind energy conversion systems. Renew. Sustain. Energy Rev. 2013, 26, 135–146. [Google Scholar] [CrossRef]

- Ould Amrouche, S.; Rekioua, D.; Rekioua, T.; Bacha, S. Overview of energy storage in renewable energy systems. Int. J. Hydrog. Energy 2016, 41, 20914–20927. [Google Scholar] [CrossRef]

- Kinjo, T.; Senjyu, T.; Urasaki, N.; Fujita, H. Terminal-voltage and output-power regulation of wind-turbine generator by series and parallel compensation using SMES. IEE Proc. Gener. Transm. Distrib. 2006, 153, 276–282. [Google Scholar] [CrossRef]

- Díaz-González, F.; Sumper, A.; Gomis-Bellmunt, O.; Villafáfila-Robles, R. A review of energy storage technologies for wind power applications. Renew. Sustain. Energy Rev. 2012, 16, 2154–2171. [Google Scholar] [CrossRef]

- Alnasir, Z.; Kazerani, M. A dump load-less standalone wind energy conversion system supplying a generic load. In Proceedings of the 2016 IEEE Electrical Power and Energy Conference (EPEC), Ottawa, ON, Canada, 12–14 October 2016; pp. 1–7. [Google Scholar]

- Șerban, I. Small wind turbine control with frequency support for integration in microgrids. Bull. Transilv. Univ. Braşov Ser. I Eng. Sci. 2013, 6, 55. [Google Scholar]

- Sudhakar, P.; Malaji, S.; Sarvesh, B. Power Flow Analysis in a Wind Turbine Based Distributed Generation for Protection of a Power System. Int. J. Adv. Res. Technol. 2014, 3, 82. [Google Scholar]

- Saad-Saoud, Z.; Jenkins, N. Models for predicting flicker induced by large wind turbines. IEEE Trans. Energy Convers. 1999, 14, 743–748. [Google Scholar] [CrossRef]

- Petrone, G.; Spagnuolo, G.; Teodorescu, R.; Veerachary, M.; Vitelli, M. Reliability Issues in Photovoltaic Power Processing Systems. IEEE Trans. Ind. Electron. 2008, 55, 2569–2580. [Google Scholar] [CrossRef]

- Shi, R.-J.; Fan, X.-C.; He, Y. Comprehensive evaluation index system for wind power utilization levels in wind farms in China. Renew. Sustain. Energy Rev. 2017, 69, 461–471. [Google Scholar] [CrossRef]

- Lara-Jimenez, J.D.; Ramirez, J.M. Inertial frequency response estimation in a power system with high wind energy penetration. In Proceedings of the 2015 IEEE Eindhoven PowerTech, Eindhoven, The Netherlands, 29 June–2 July 2015; pp. 1–6. [Google Scholar]

- Yoldaş, Y.; Önen, A.; Muyeen, S.M.; Vasilakos, A.V.; Alan, İ. Enhancing smart grid with microgrids: Challenges and opportunities. Renew. Sustain. Energy Rev. 2017, 72, 205–214. [Google Scholar] [CrossRef]

- Zhao, J.; Abedi, S.; He, M.; Du, P.; Sharma, S.; Blevins, B. Quantifying Risk of Wind Power Ramps in ERCOT. IEEE Trans. Power Syst. 2017, PP, 1. [Google Scholar] [CrossRef]

- Sruthi, M.A.; Sai, C.P.; Kumar, M.V. Controlling flicker caused due to power fluctuations by using individual pitch control for a variable speed dfig based wind turbine. Int. Res. J. Eng. Technol. 2017, 4, 286–293. [Google Scholar]

- Abedini, A.; Mandic, G.; Nasiri, A. Wind power smoothing using rotor inertia aimed at reducing grid susceptibility. Int. J. Power Electron. 2008, 1, 227–247. [Google Scholar] [CrossRef]

- Kawakami, N.; Iijima, Y.; Fukuhara, M.; Bando, M.; Sakanaka, Y.; Ogawa, K.; Matsuda, T. Development and field experiences of stabilization system using 34MW NAS batteries for a 51MW wind farm. In Proceedings of the 2010 IEEE International Symposium on Industrial Electronics, Bari, Italy, 4–7 July 2010; pp. 2371–2376. [Google Scholar]

- Burton, T.; Sharpe, D.; Jenkins, N. Handbook of Wind Energy; John Wiley & Sons: Hoboken, NJ, USA, 2001. [Google Scholar]

- Senjyu, T.; Sakamoto, R.; Urasaki, N.; Funabashi, T.; Fujita, H.; Sekine, H. Output power leveling of wind turbine Generator for all operating regions by pitch angle control. IEEE Trans. Energy Convers. 2006, 21, 467–475. [Google Scholar] [CrossRef]

- Ledesma, P.; Usaola, J. Doubly fed induction generator model for transient stability analysis. IEEE Trans. Energy Convers. 2005, 20, 388–397. [Google Scholar] [CrossRef]

- Kanna, O.; Hanba, S.; Asato, S.; Yamashita, K. A method of stabilization of a wind generator power using backstepping algorithm. IEEJ Trans. Power Energy 1997, 117, 1513–1519. [Google Scholar] [CrossRef]

- Matsuzaka, T.; Tuchiya, K. Study on stabilization of a wind generator power fluctuation. IEEJ Trans. Power Energy 1997, 117, 625–633. [Google Scholar] [CrossRef]

- Belghazi, O.; Douiri, R.; Cherkaoui, M. Power control of a wind energy based on a DFIG by sliding mode approach and pitch angle optimal control by genetic algorithm. J. Achiev. Mater. Manuf. Eng. 2016, 74, 78–85. [Google Scholar] [CrossRef]

- Lakshmi, K.V.; Srinivas, P. Fuzzy adaptive PID control of pitch system in variable speed wind turbines. In Proceedings of the 2014 International Conference on Issues and Challenges in Intelligent Computing Techniques (ICICT), Ghaziabad, India, 7–8 February 2014; pp. 52–57. [Google Scholar]

- Jiang, Z.; Karimirad, M.; Moan, T. Dynamic response analysis of wind turbines under blade pitch system fault, grid loss, and shutdown events. Wind Energy 2014, 17, 1385–1409. [Google Scholar] [CrossRef]

- Geng, H.; Yang, G. Linear and nonlinear schemes applied to pitch control of wind turbines. Sci. World J. 2014, 2014, 406382. [Google Scholar] [CrossRef] [PubMed]

- Lu, M.S.; Chang, C.L.; Lee, W.J.; Wang, L. Combining the Wind Power Generation System with Energy Storage Equipments. In Proceedings of the 2008 IEEE Industry Applications Society Annual Meeting, Edmonton, AB, Canada, 5–9 October 2008; pp. 1–6. [Google Scholar]

- Chen, H.; Cong, T.N.; Yang, W.; Tan, C.; Li, Y.; Ding, Y. Progress in electrical energy storage system: A critical review. Prog. Nat. Sci. 2009, 19, 291–312. [Google Scholar] [CrossRef]

- Rekioua, D. Wind Power Electric Systems—Modeling, Simulation and Control; Springer: Bejaia, Algeria, 2014. [Google Scholar]

- Nguyen, T.D.; Tseng, K.J.; Zhang, S.; Nguyen, H.T. A Novel Axial Flux Permanent-Magnet Machine for Flywheel Energy Storage System: Design and Analysis. IEEE Trans. Ind. Electron. 2011, 58, 3784–3794. [Google Scholar] [CrossRef]

- Faraji, F.; Majazi, A.; Al-Haddad, K. A comprehensive review of Flywheel Energy Storage System technology. Renew. Sustain. Energy Rev. 2017, 67, 477–490. [Google Scholar] [CrossRef]

- Cimuca, G.O.; Saudemont, C.; Robyns, B.; Radulescu, M.M. Control and Performance Evaluation of a Flywheel Energy-Storage System Associated to a Variable-Speed Wind Generator. IEEE Trans. Ind. Electron. 2006, 53, 1074–1085. [Google Scholar] [CrossRef]

- Awadallah, M.A.; Venkatesh, B. Energy Storage in Flywheels: An Overview. Can. J. Electr. Comput. Eng. 2015, 38, 183–193. [Google Scholar] [CrossRef]

- Cao, Q.; Song, Y.D.; Guerrero, J.M.; Tian, S. Coordinated Control for Flywheel Energy Storage Matrix Systems for Wind Farm Based on Charging/Discharging Ratio Consensus Algorithms. IEEE Trans. Smart Grid 2016, 7, 1259–1267. [Google Scholar] [CrossRef]

- Díaz-González, F.; Bianchi, F.D.; Sumper, A.; Gomis-Bellmunt, O. Control of a Flywheel Energy Storage System for Power Smoothing in Wind Power Plants. IEEE Trans. Energy Convers. 2014, 29, 204–214. [Google Scholar] [CrossRef]

- Sebastián, R.; Peña-Alzola, R. Control and simulation of a flywheel energy storage for a wind diesel power system. Int. J. Electr. Power Energy Syst. 2015, 64, 1049–1056. [Google Scholar] [CrossRef]

- Capp, F.W.; Lazarewicz, M.L.; Arseneaux, A.J.; Dresens, P.; Rojas, H.A. Methods, Systems and Apparatus for Regulating Frequency of Generated Power using Flywheel Energy Storage Systems with Varying Load and/or Power Generation. Patents EP2887485 A1, 24 June 2015. [Google Scholar]

- Takahashi, R.; Tamura, J. Frequency control of isolated power system with wind farm by using Flywheel Energy Storage System. In Proceedings of the 2008 18th International Conference on Electrical Machines, Vilamoura, Portugal, 6–9 September 2008; pp. 1–6. [Google Scholar]

- Deepak, M.; Abraham, R.J.; Gonzalez-Longatt, F.M.; Greenwood, D.M.; Rajamani, H.-S. A novel approach to frequency support in a wind integrated power system. Renew. Energy 2017, 108, 194–206. [Google Scholar] [CrossRef]

- Suvire, G.O.; Mercado, P.E. Improvement of power quality in wind energy applications using a DSTATCOM coupled with a Flywheel Energy Storage System. In Proceedings of the 2009 Brazilian Power Electronics Conference, Bonito-Mato Grosso do Sul, Brazil, 27 September–1 October 2009; pp. 58–64. [Google Scholar]

- Suvire, G.; Mercado, P. Combined control of a distribution static synchronous compensator/flywheel energy storage system for wind energy applications. IET Gener. Transm. Distrib. 2012, 6, 483–492. [Google Scholar] [CrossRef]

- Suvire, G.; Mercado, P. Active power control of a flywheel energy storage system for wind energy applications. IET Renew. Power Gener. 2012, 6, 9–16. [Google Scholar] [CrossRef]

- Islam, F.; Al-Durra, A.; Muyeen, S.M. Smoothing of Wind Farm Output by Prediction and Supervisory-Control-Unit-Based FESS. IEEE Trans. Sustain. Energy 2013, 4, 925–933. [Google Scholar] [CrossRef]

- Lai, J.; Song, Y.; Du, X. Hierarchical Coordinated Control of Flywheel Energy Storage Matrix Systems for Wind Farms. IEEE/ASME Trans. Mechatron. 2017, PP, 99. [Google Scholar] [CrossRef]

- Ghosh, S.; Kamalasadan, S. An Integrated Dynamic Modeling and Adaptive Controller Approach for Flywheel Augmented DFIG Based Wind System. IEEE Trans. Power Syst. 2017, 32, 2161–2171. [Google Scholar] [CrossRef]

- Hadjipaschalis, I.; Poullikkas, A.; Efthimiou, V. Overview of current and future energy storage technologies for electric power applications. Renew. Sustain. Energy Rev. 2009, 13, 1513–1522. [Google Scholar] [CrossRef]

- Divya, K.C.; Østergaard, J. Battery energy storage technology for power systems—An overview. Electr. Power Syst. Res. 2009, 79, 511–520. [Google Scholar] [CrossRef]

- Liu, Y.; Du, W.; Xiao, L.; Wang, H.; Cao, J. A Method for Sizing Energy Storage System to Increase Wind Penetration as Limited by Grid Frequency Deviations. IEEE Trans. Power Syst. 2016, 31, 729–737. [Google Scholar] [CrossRef]

- Teleke, S.; Baran, M.E.; Huang, A.Q.; Bhattacharya, S.; Anderson, L. Control Strategies for Battery Energy Storage for Wind Farm Dispatching. IEEE Trans. Energy Convers. 2009, 24, 725–732. [Google Scholar] [CrossRef]

- Luo, F.; Meng, K.; Dong, Z.Y.; Zheng, Y.; Chen, Y.; Wong, K.P. Coordinated Operational Planning for Wind Farm With Battery Energy Storage System. IEEE Trans. Sustain. Energy 2015, 6, 253–262. [Google Scholar] [CrossRef]

- Khalid, M.; Savkin, A.V. Minimization and control of battery energy storage for wind power smoothing: Aggregated, distributed and semi-distributed storage. Renew. Energy 2014, 64, 105–112. [Google Scholar] [CrossRef]

- Luo, Y.; Shi, L.; Tu, G. Optimal sizing and control strategy of isolated grid with wind power and energy storage system. Energy Convers. Manag. 2014, 80, 407–415. [Google Scholar] [CrossRef]

- Jiang, Q.; Gong, Y.; Wang, H. A Battery Energy Storage System Dual-Layer Control Strategy for Mitigating Wind Farm Fluctuations. IEEE Trans. Power Syst. 2013, 28, 3263–3273. [Google Scholar] [CrossRef]

- Deng, Z.; Xu, Y.; Gu, W.; Fei, Z. Finite-time convergence robust control of battery energy storage system to mitigate wind power fluctuations. Int. J. Electr. Power Energy Syst. 2017, 91, 144–154. [Google Scholar] [CrossRef]

- Teleke, S.; Baran, M.E.; Bhattacharya, S.; Huang, A.Q. Optimal Control of Battery Energy Storage for Wind Farm Dispatching. IEEE Trans. Energy Convers. 2010, 25, 787–794. [Google Scholar] [CrossRef]

- Savkin, A.V.; Khalid, M.; Agelidis, V.G. A Constrained Monotonic Charging/Discharging Strategy for Optimal Capacity of Battery Energy Storage Supporting Wind Farms. IEEE Trans. Sustain. Energy 2016, 7, 1224–1231. [Google Scholar] [CrossRef]

- Miranda, I.; Silva, N.; Leite, H. A Holistic Approach to the Integration of Battery Energy Storage Systems in Island Electric Grids With High Wind Penetration. IEEE Trans. Sustain. Energy 2016, 7, 775–785. [Google Scholar] [CrossRef]

- Nguyen, C.L.; Lee, H.H. A Novel Dual-Battery Energy Storage System for Wind Power Applications. IEEE Trans. Ind. Electron. 2016, 63, 6136–6147. [Google Scholar] [CrossRef]

- Oh, U.; Choi, J.; Kim, H.-H. Reliability Contribution Function considering Wind Turbine Generators and Battery Energy Storage System in Power System. IFAC-PapersOnLine 2016, 49, 301–306. [Google Scholar] [CrossRef]

- Sulaeman, S.; Yuting, T.; Benidris, M.; Mitra, J. Quantification of Storage Necessary to Firm up Wind Generation. IEEE Trans. Ind. Appl. 2017, PP. [Google Scholar] [CrossRef]

- Acuña, L.G.; Padilla, R.V.; Mercado, A.S. Measuring reliability of hybrid photovoltaic-wind energy systems: A new indicator. Renew. Energy 2017, 106, 68–77. [Google Scholar] [CrossRef]

- Shi, N.; Luo, Y. Energy storage system sizing based on a reliability assessment of power systems integrated with wind power. Sustainability 2017, 9, 395. [Google Scholar] [CrossRef]

- Nielsen, K.E.; Molinas, M. Superconducting Magnetic Energy Storage (SMES) in power systems with renewable energy sources. In Proceedings of the 2010 IEEE International Symposium on Industrial Electronics, Bari, Italy, 4–7 July 2010; pp. 2487–2492. [Google Scholar]

- Vitale, G. Frequency Stability Improvement in Weak Grids by Storage Systems. In Smart Energy Grid Design for Island Countries; Springer: Suva, Fiji, 2017; pp. 223–258. [Google Scholar]

- Wang, L.; Chen, S.S.; Lee, W.J.; Chen, Z. Dynamic Stability Enhancement and Power Flow Control of a Hybrid Wind and Marine-Current Farm Using SMES. IEEE Trans. Energy Convers. 2009, 24, 626–639. [Google Scholar] [CrossRef]

- Shi, J.; Tang, Y.; Xia, Y.; Ren, L.; Li, J. SMES Based Excitation System for Doubly-Fed Induction Generator in Wind Power Application. IEEE Trans. Appl. Supercond. 2011, 21, 1105–1108. [Google Scholar] [CrossRef]

- Ali, M.H.; Tamura, J.; Wu, B. SMES strategy to minimize frequency fluctuations of wind generator system. In Proceedings of the 2008 34th Annual Conference of IEEE Industrial Electronics, Orlando, FL, USA, 10–13 November 2008; pp. 3382–3387. [Google Scholar]

- Sheikh, M.R.I.; Mondol, N. Wind power smoothing scheme using SMES with reduced capacity. In Proceedings of the 2012 International Conference on Informatics, Electronics & Vision (ICIEV), Dhaka, Bangladesh, 18–19 May 2012; pp. 404–410. [Google Scholar]

- Saejia, M.; Ngamroo, I. Alleviation of Power Fluctuation in Interconnected Power Systems With Wind Farm by SMES With Optimal Coil Size. IEEE Trans. Appl. Supercond. 2012, 22, 5701504. [Google Scholar] [CrossRef]

- Hasanien, H.M. A Set-Membership Affine Projection Algorithm-Based Adaptive-Controlled SMES Units for Wind Farms Output Power Smoothing. IEEE Trans. Sustain. Energy 2014, 5, 1226–1233. [Google Scholar] [CrossRef]

- Kang, J.; Ko, T.K.; Al-Ammar, E.A.; Hur, K. Jointless Pancake Coil Winding for Minimizing Electrical Loss in HTS SMES for Wind Power. IEEE Trans. Appl. Supercond. 2015, 25, 1–5. [Google Scholar] [CrossRef]

- Payman, A.; Pierfederici, S.; Meibody-Tabar, F. Energy control of supercapacitor/fuel cell hybrid power source. Energy Convers. Manag. 2008, 49, 1637–1644. [Google Scholar] [CrossRef]

- Helwig, A.; Ahfock, T. Ultra-capacitor assisted battery storage for remote area power supplies: A case study. In Proceedings of the 2009 Australasian Universities Power Engineering Conference, Adelaide, Australia, 27–30 September 2009; pp. 1–6. [Google Scholar]

- Aranizadeh, A.; Vahidi, B.; Rahiminejad, A. Wind turbine power output smoothing in microgrid using ultra-capacitor with continuous wind speed forecasting and online supervisory control. J. Renew. Sustain. Energy 2016, 8, 3. [Google Scholar] [CrossRef]

- Islam, M.M.; Islam, A.; Shaikh, S.M.; Sheikh, M.R.I. Stability enhancement of wind power system by using energy capacitor system. In Proceedings of the 2015 International Conference on Electrical & Electronic Engineering (ICEEE), Ankara, Turkey, 4–6 November 2015; pp. 85–88. [Google Scholar]

- Muyeen, S.M.; Takahashi, R.; Ali, M.H.; Murata, T.; Tamura, J. Transient Stability Augmentation of Power System Including Wind Farms by Using ECS. IEEE Trans. Power Syst. 2008, 23, 1179–1187. [Google Scholar] [CrossRef]

- Sun, B.; Liu, Z.; Yang, S.; Zhang, B. A Method in Smoothing Fluctuation of Wind Power with Wavelet Threshold Filtering and Mean-value Intervals by HESS. In Proceedings of the 2016 5th International Conference on Civil, Architectural and Hydraulic Engineering, Zhuhai, China, 30–31 July 2016. [Google Scholar]

- Han, X.; Zhao, Z.; Li, J.; Ji, T. Economic evaluation for wind power generation–hybrid energy storage system based on game theory. Int. J. Energy Res. 2017, 41, 49–62. [Google Scholar] [CrossRef]

- Abeywardana, D.B.W.; Hredzak, B.; Agelidis, V.G.; Demetriades, G.D. Supercapacitor Sizing Method for Energy-Controlled Filter-Based Hybrid Energy Storage Systems. IEEE Trans. Power Electron. 2017, 32, 1626–1637. [Google Scholar] [CrossRef]

- Kusko, A.; DeDad, J. Short-term, long-term, energy storage methods for standby electric power systems. In Proceedings of the Fourtieth IAS Annual Meeting, Conference Record of the 2005 Industry Applications Conference, Hong Kong, China, 2–6 October 2005; Volume 2674, pp. 2672–2678. [Google Scholar]

- Kumar, A.S.; Ramakrishna, E.; Haq, S.S. A non-linear model predictive control (nmpc) energy management control strategy for standalone dc microgrids. Int. J. Core Eng. Manag. 2017, 135–147. [Google Scholar]

- Koustas, G.; Van der Sluis, L.; Ummels, B.C.; Papaefthymiou, G. Stochastic assessment of opportunities for wind power curtailment. In Proceedings of the Nordic Wind Power Conference (NWPC2007), Roskilde, Denmark, 1–2 November 2007. [Google Scholar]

- Nasiri, M.; Milimonfared, J.; Fathi, S.H. Modeling, analysis and comparison of TSR and OTC methods for MPPT and power smoothing in permanent magnet synchronous generator-based wind turbines. Energy Convers. Manag. 2014, 86, 892–900. [Google Scholar] [CrossRef]

- Esmaili, A.; Nasiri, A. Power smoothing and power ramp control for wind energy using energy storage. In Proceedings of the 2011 IEEE Energy Conversion Congress and Exposition, Phoenix, AZ, USA, 17–22 September 2011; pp. 922–927. [Google Scholar]

- Alanazi, A.; Khodaei, A.; Babazadeh, H. Power fluctuation reduction in wind turbine generator systems. In Proceedings of the 2016 North American Power Symposium (NAPS), Denver, CO, USA, 18–20 September 2016; pp. 1–5. [Google Scholar]

- Shivashankar, S.; Mekhilef, S.; Mokhlis, H.; Karimi, M. Mitigating methods of power fluctuation of photovoltaic (PV) sources—A review. Renew. Sustain. Energy Rev. 2016, 59, 1170–1184. [Google Scholar] [CrossRef]

- Teleke, S.; Baran, M.E.; Bhattacharya, S.; Huang, A.Q. Rule-Based Control of Battery Energy Storage for Dispatching Intermittent Renewable Sources. IEEE Trans. Sustain. Energy 2010, 1, 117–124. [Google Scholar] [CrossRef]

- Xiyun, Y.; Chao, C.; Xiangjun, L.; Tingting, Y. Control method of smoothing wind power output using battery energy storage system based on empirical mode decomposition. In Proceedings of the 2015 34th Chinese Control Conference (CCC), Hangzhou, China, 28–30 July 2015; pp. 304–308. [Google Scholar]

- Zou, J.; Peng, C.; Shi, J.; Xin, X.; Zhang, Z. State-of-charge optimising control approach of battery energy storage system for wind farm. IET Renew. Power Gener. 2015, 9, 647–652. [Google Scholar] [CrossRef]

- Hou, R.; Nguyen, T.-T.; Kim, H.-M.; Song, H.; Qu, Y. An Energy-Based Control Strategy for Battery Energy Storage Systems: A Case Study on Microgrid Applications. Energies 2017, 10, 215. [Google Scholar] [CrossRef]

- Li, X.; Hui, D.; Lai, X. Battery Energy Storage Station (BESS)-Based Smoothing Control of Photovoltaic (PV) and Wind Power Generation Fluctuations. IEEE Trans. Sustain. Energy 2013, 4, 464–473. [Google Scholar] [CrossRef]

- Kim, S.K.; Kim, J.Y.; Cho, K.H.; Byeon, G. Optimal Operation Control of Multiple BESSs for a Large-Scale Customer under Time-Based Pricing. IEEE Trans. Power Syst. 2017, PP, 1. [Google Scholar] [CrossRef]

| Characteristics | Pitch Control | Flywheel | Battery | Capacitors/SMES/EDLC | MPPT Method |

|---|---|---|---|---|---|

| Response time of Intermittent smoothing approach | Fast | Fast | Fast | Very Fast | Fast |

| Energy Density | N/A | Low | High | Low | N/A |

| Power Density | N/A | High | High | High | N/A |

| Life Period | Large | Very Large | Large | Large | Large |

| Ability to smooth fast ups ramp and downs ramp | Yes (ups ramp only) | Yes | Yes | Yes very fast | Yes |

| Efficiency in mitigating short term wind variation | High | High | High | High | High |

| Ability to mitigate voltage/frequency variations | Yes | Yes | Yes | Yes | Yes |

| Reliability | High | High | High | Very High | High |

| Cost | Low | High | High | Very High | Low |

| Size of wind farm | few MW to large MW scale | Large MW scale | 0 to large MW scale | 0 to few MW scale | 0 to few KW scale |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jabir, M.; Azil Illias, H.; Raza, S.; Mokhlis, H. Intermittent Smoothing Approaches for Wind Power Output: A Review. Energies 2017, 10, 1572. https://doi.org/10.3390/en10101572

Jabir M, Azil Illias H, Raza S, Mokhlis H. Intermittent Smoothing Approaches for Wind Power Output: A Review. Energies. 2017; 10(10):1572. https://doi.org/10.3390/en10101572

Chicago/Turabian StyleJabir, Muhammad, Hazlee Azil Illias, Safdar Raza, and Hazlie Mokhlis. 2017. "Intermittent Smoothing Approaches for Wind Power Output: A Review" Energies 10, no. 10: 1572. https://doi.org/10.3390/en10101572