Integrated BMS-MMC Balancing Technique Highlighted by a Novel Space-Vector Based Approach for BEVs Application

Abstract

:1. Introduction

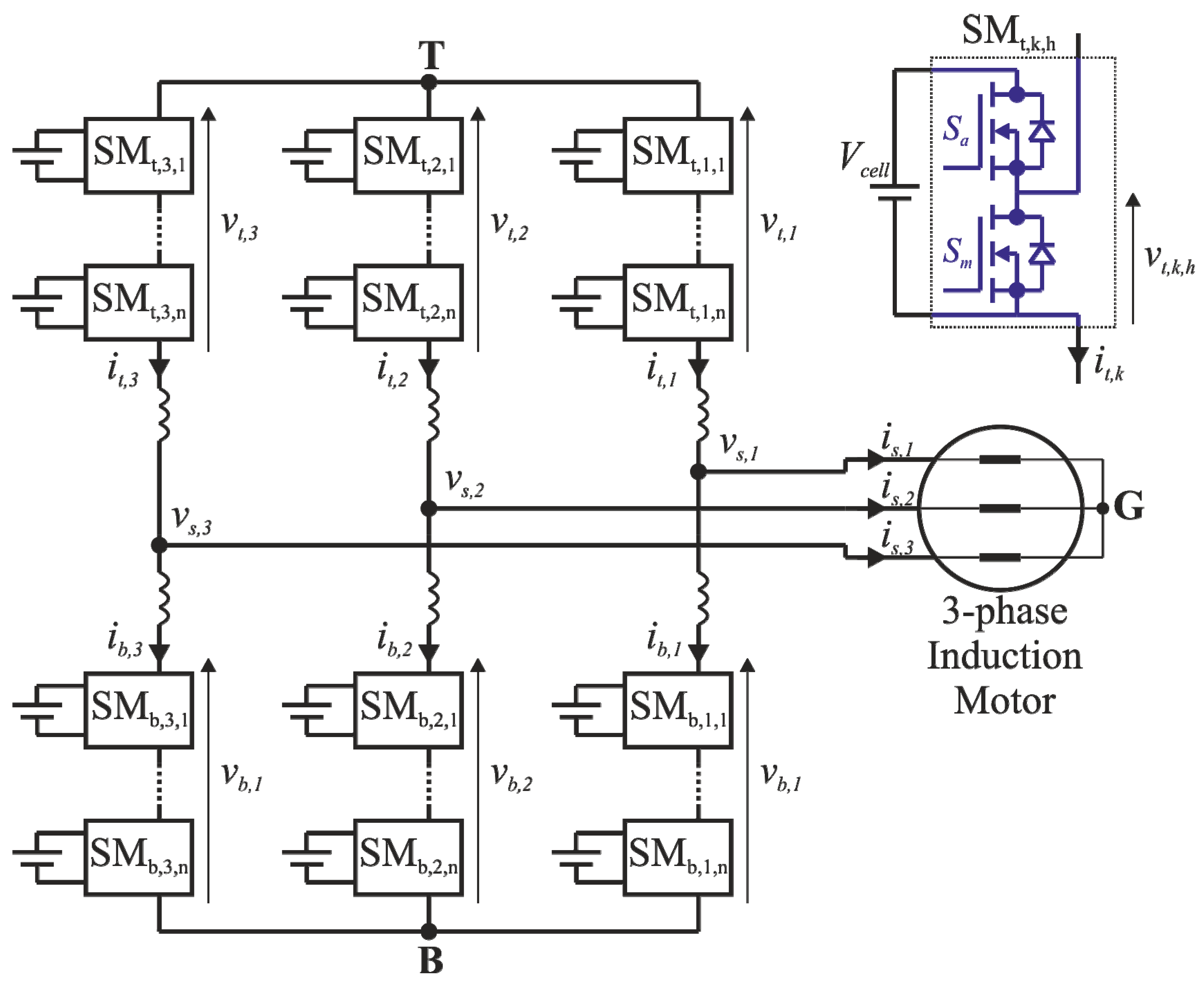

2. Description of the System

3. Traditional Approach to Cell Balancing

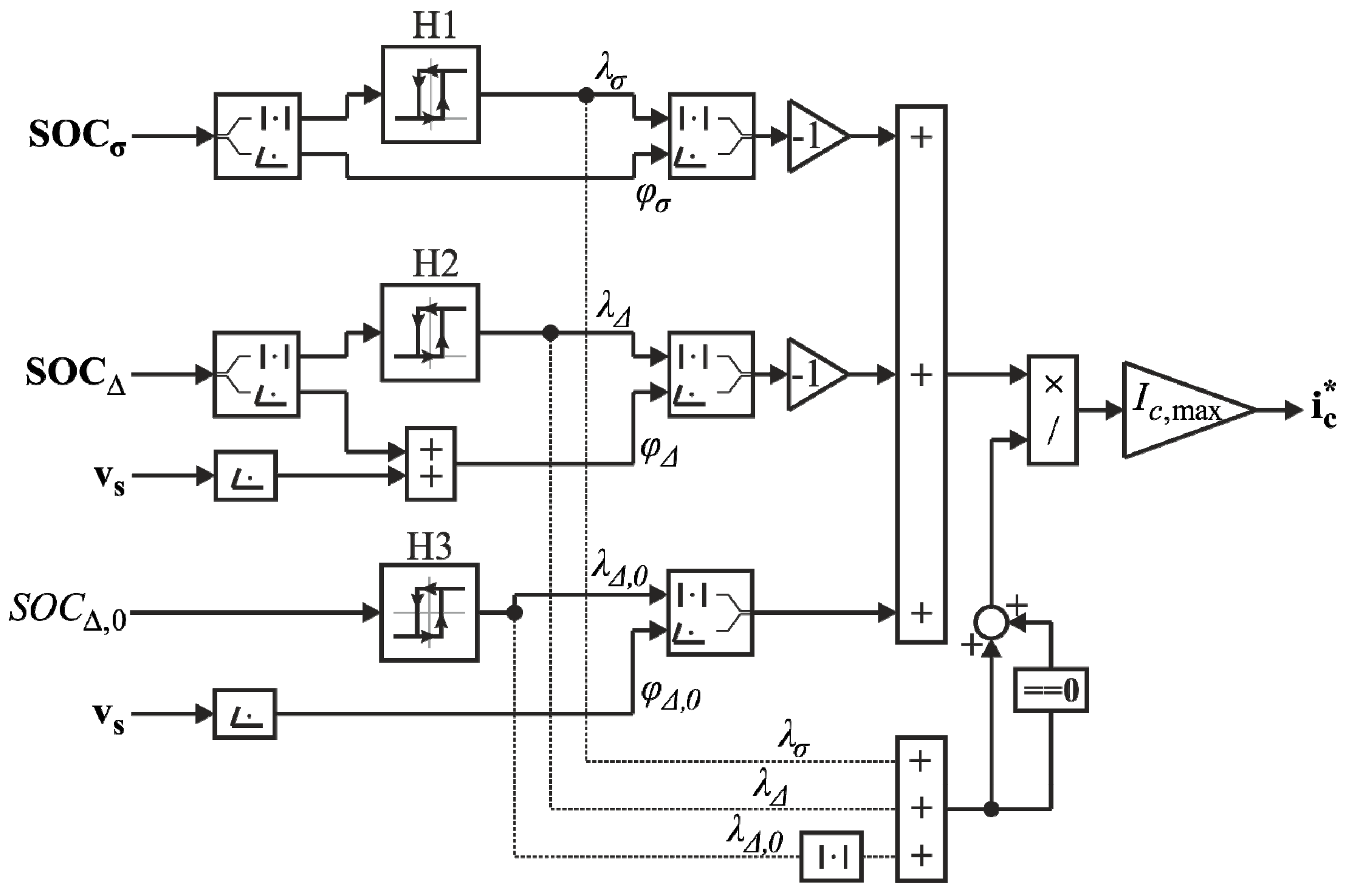

4. Generalized Mathematical Model

4.1. Main Definitions

4.2. Voltage Balance

4.3. Power Balance

5. Balancing Technique Derived from the Generalised Model

- -

- a DC component that, interacting with , controls ;

- -

- an inverse component at fundamental frequency that, interacting with , controls ;

- -

- a direct component at fundamental that, interacting with , controls ; this is indeed consistent with the traditional approach of Section 3.

6. Numerical Analysis

- High speed: the reference speed is set for 90% of the rated speed.

- Low speed: the reference speed is set for 10% of the rated speed.

- Zero speed: the reference speed is set for zero.

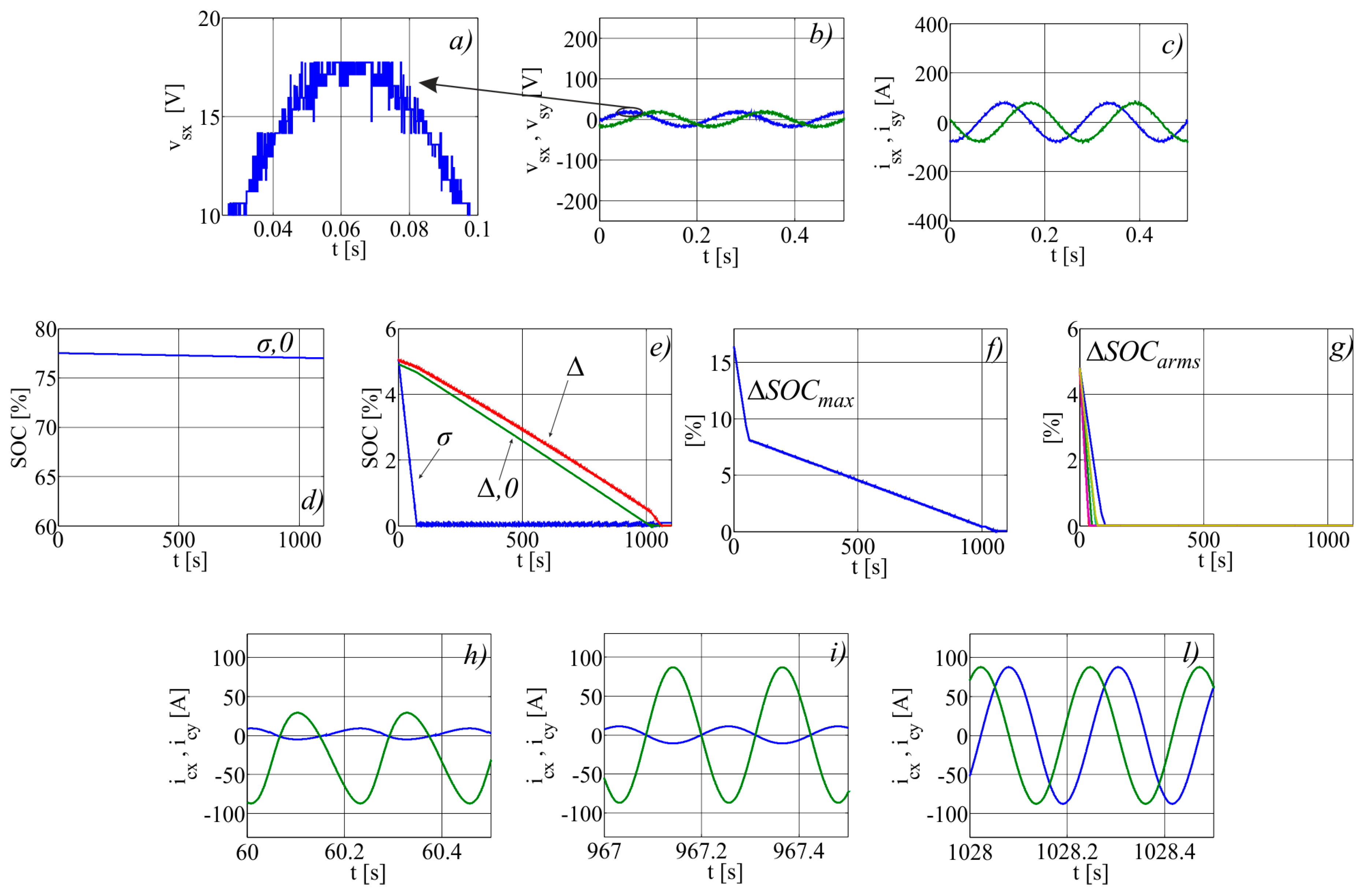

6.1. High Speed

- (h)

- all three hysteresis regulators are on: the circulating current has a DC component, a direct and an inverse component at fundamental frequency.

- (i)

- H1 is off, H2 and H3 are of: the circulating current has only a direct and an inverse component at fundamental frequency.

- (l)

- only H3 is ON: the circulating current only shows a direct component at fundamental frequency.

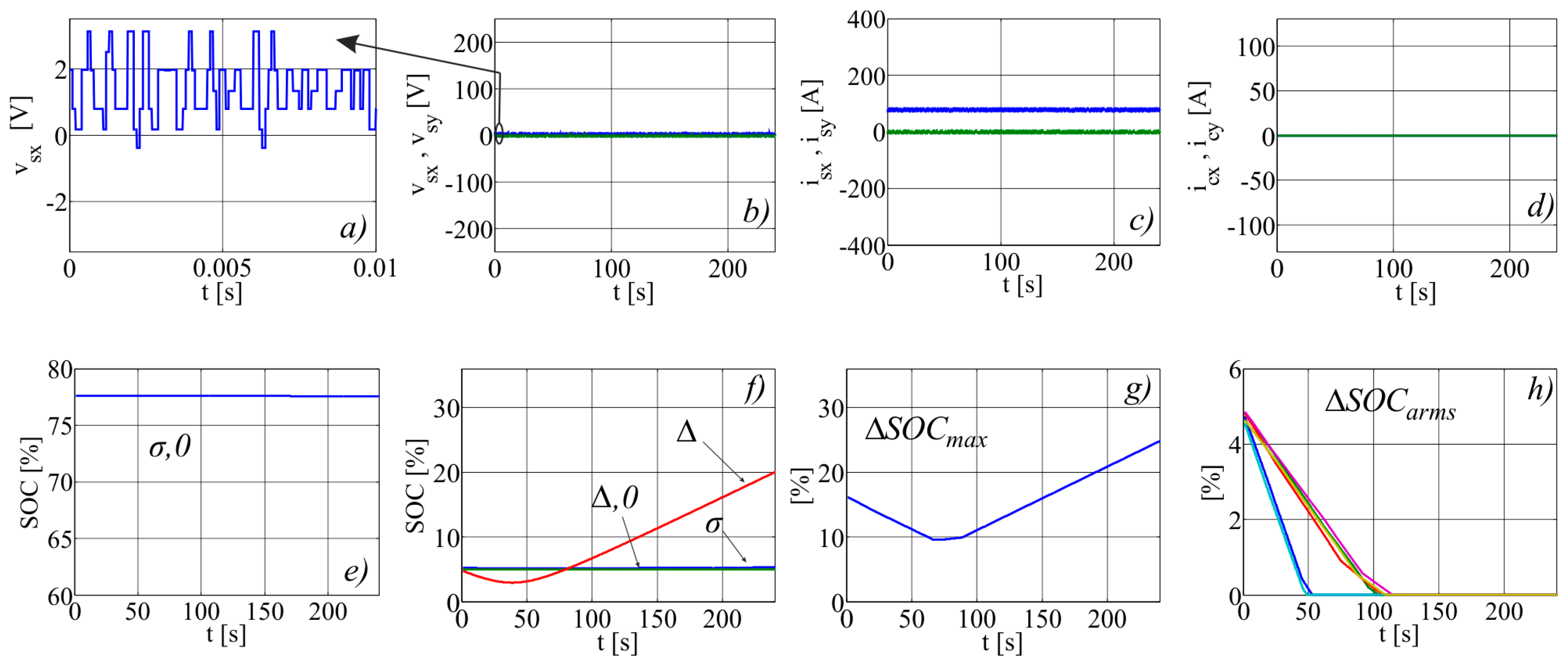

6.2. Low Speed

6.3. Zero Speed

7. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Statistical Office of the European Communities. Energy, Transport and Environment Indicators; Eurostat: Luxembourg, 2014; Available online: http://ec.europa.eu/eurostat (accessed on 27 September 2017).

- Stan, A.-I.; Swierczynski, M.; Stroe, D.-I.; Teodorescu, R.; Andreasen, S.J. Lithium ion battery chemistries from renewable energy storage to automotive and back-up power applications—An overview. In Proceedings of the 2014 International Conference on Optimization of Electrical and Electronic Equipment, OPTIM 2014, Bran, Romania, 22–24 May 2014; pp. 713–720. [Google Scholar]

- Yarlagadda, S.; Hartley, T.T.; Husain, I. A battery management system using an active charge equalization technique based on a dc/dc converter topology. IEEE Trans. Ind. Appl. 2013, 49, 2720–2729. [Google Scholar] [CrossRef]

- Gholizadeh, M.; Salmasi, F.R. Estimation of state of charge, unknown nonlinearities, and state of health of a lithium-ion battery based on a comprehensive unobservable model. IEEE Trans. Ind. Electron. 2014, 61, 1335–1344. [Google Scholar] [CrossRef]

- Kim, J.; Shin, J.; Chun, C.; Cho, B.H. Stable configuration of a Li-ion series battery pack based on a screening process for improved voltage/SOC balancing. IEEE Trans. Power Electron. 2012, 27, 411–424. [Google Scholar] [CrossRef]

- Panchal, S.; Dincer, I.; Agelin-Chaab, M.; Fowler, M.; Fraser, R. Uneven temperature and voltage distributions due to rapid discharge rates and different boundary conditions for series-connected LiFePO4 batteries. Int. Commun. Heat Mass Transf. 2017, 81, 210–217. [Google Scholar] [CrossRef]

- Panchal, S.; Dincer, I.; Agelin-Chaab, M.; Fraser, R.; Fowler, M. Experimental and simulated temperature variations in a LiFePO4–20Ah battery during discharge process. Appl. Energy 2016, 180, 504–515. [Google Scholar] [CrossRef]

- Deng, F.; Chen, Z. Voltage-Balancing Method for Modular Multilevel Converters Switched at Grid Frequency. IEEE Trans. Ind. Electron. 2015, 62, 2835–2847. [Google Scholar] [CrossRef]

- D’Arco, S.; Piegari, L.; Tricoli, P. Power and balancing control considerations on modular multilevel converters for battery electric vehicles. In Proceedings of the 2013 15th European Conference on Power Electronics and Applications (EPE), Lille, France, 2–6 September 2013; pp. 1–9. [Google Scholar]

- D’Arco, S.; Piegari, L.; Quraan, M.S.; Tricoli, P. Battery charging for electric vehicles with modular multilevel traction drives. In Proceedings of the 7th IET International Conference on Power Electronics, Machines and Drives (PEMD 2014), Manchester, UK, 8–10 April 2014; pp. 1–6. [Google Scholar]

- Maharjan, L.; Inoue, S.; Akagi, H.; Asakura, J. State-of-Charge (SOC)-balancing Control of a battery energy storage system based on a Cascade PWM Converter. IEEE Trans. Power Electron. 2009, 24, 1628–1636. [Google Scholar] [CrossRef]

- D’Arco, S.; Piegari, L.; Tricoli, P. A modular converter with embedded battery cell balancing for electric vehicles. In Proceedings of the Electrical Systems for Aircraft, Railway and Ship Propulsion (ESARS), Bologna, Italy, 16–18 October 2012; pp. 1–6. [Google Scholar]

- Xu, C.; Dai, K.; Chen, X.; Kang, Y. Unbalanced PCC voltage regulation with positive- and negative-sequence compensation tactics for MMC-DSTATCOM. IET Power Electron. 2016, 9, 2846–2858. [Google Scholar] [CrossRef]

- Ben-Brahim, L.; Gastli, A.; Trabelsi, M.; Ghazi, K.A.; Houchati, M.; Abu-Rub, H. Modular Multilevel Converter Circulating Current Reduction Using Model Predictive Control. IEEE Trans. Ind. Electron. 2016, 63, 3857–3866. [Google Scholar] [CrossRef]

- Saad, H.; Guillaud, X.; Mahseredjian, J.; Dennetière, S.; Nguefeu, S. MMC Capacitor Voltage Decoupling and Balancing Controls. IEEE Trans. Power Deliv. 2015, 30, 704–712. [Google Scholar] [CrossRef]

- Moon, J.-W.; Kim, C.-S.; Park, J.-W.; Kang, D.-W.; Kim, J.-M. Circulating current control in MMC under the unbalanced voltage. IEEE Trans. Power Deliv. 2013, 28, 1952–1959. [Google Scholar] [CrossRef]

- Quraan, M.; Yeo, T.; Tricoli, P. Design and Control of Modular Multilevel Converters for Battery Electric Vehicles. IEEE Trans. Power Electron. 2016, 31, 507–517. [Google Scholar] [CrossRef]

- Quraan, M.; Tricoli, P.; D’Arco, S.; Piegari, L. Efficiency Assessment of Modular Multilevel Converters for Battery Electric Vehicles. IEEE Trans. Power Electron. 2017, 32, 2041–2051. [Google Scholar] [CrossRef]

| Subscript | Description |

| Arm module | |

| Converter leg | |

| Converter output electrical quantities | |

| Top arms, bottom arms | |

| Top-bottom difference | |

| Top+bottom addition | |

| Zero-sequence component | |

| Symbol | Description |

| Frequency | |

| Circulating current | |

| Maximum circulating current reference value | |

| Buffer inductance | |

| Number of arm sub-modules | |

| Not compensated power term | |

| Rated capacity of the cells | |

| State of charge | |

| Voltage, Current, Power | |

| Cells voltage | |

| Load voltage and current amplitude | |

| Generic space vector and its conjugate | |

| Hysteresis regulator output | |

| Modulation Index | |

| Load current phase delay | |

| Angular frequency |

| Symbol | Quantity | Value |

|---|---|---|

| - | Rated motor power | 80 kW |

| - | Rated motor speed | 2975 rpm |

| - | Rated motor frequency | 50 Hz |

| - | Rated motor voltage | 230 V |

| n | Number of cells per arm | 108 |

| Vcell | Cell voltage | 3.2–4.2 V |

| - | Cell energy | 38 Wh |

| - | Sampling frequency | 10 kHz |

| L | Recirculating inductance | 50 µH |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brando, G.; Dannier, A.; Spina, I.; Tricoli, P. Integrated BMS-MMC Balancing Technique Highlighted by a Novel Space-Vector Based Approach for BEVs Application. Energies 2017, 10, 1628. https://doi.org/10.3390/en10101628

Brando G, Dannier A, Spina I, Tricoli P. Integrated BMS-MMC Balancing Technique Highlighted by a Novel Space-Vector Based Approach for BEVs Application. Energies. 2017; 10(10):1628. https://doi.org/10.3390/en10101628

Chicago/Turabian StyleBrando, Gianluca, Adolfo Dannier, Ivan Spina, and Pietro Tricoli. 2017. "Integrated BMS-MMC Balancing Technique Highlighted by a Novel Space-Vector Based Approach for BEVs Application" Energies 10, no. 10: 1628. https://doi.org/10.3390/en10101628