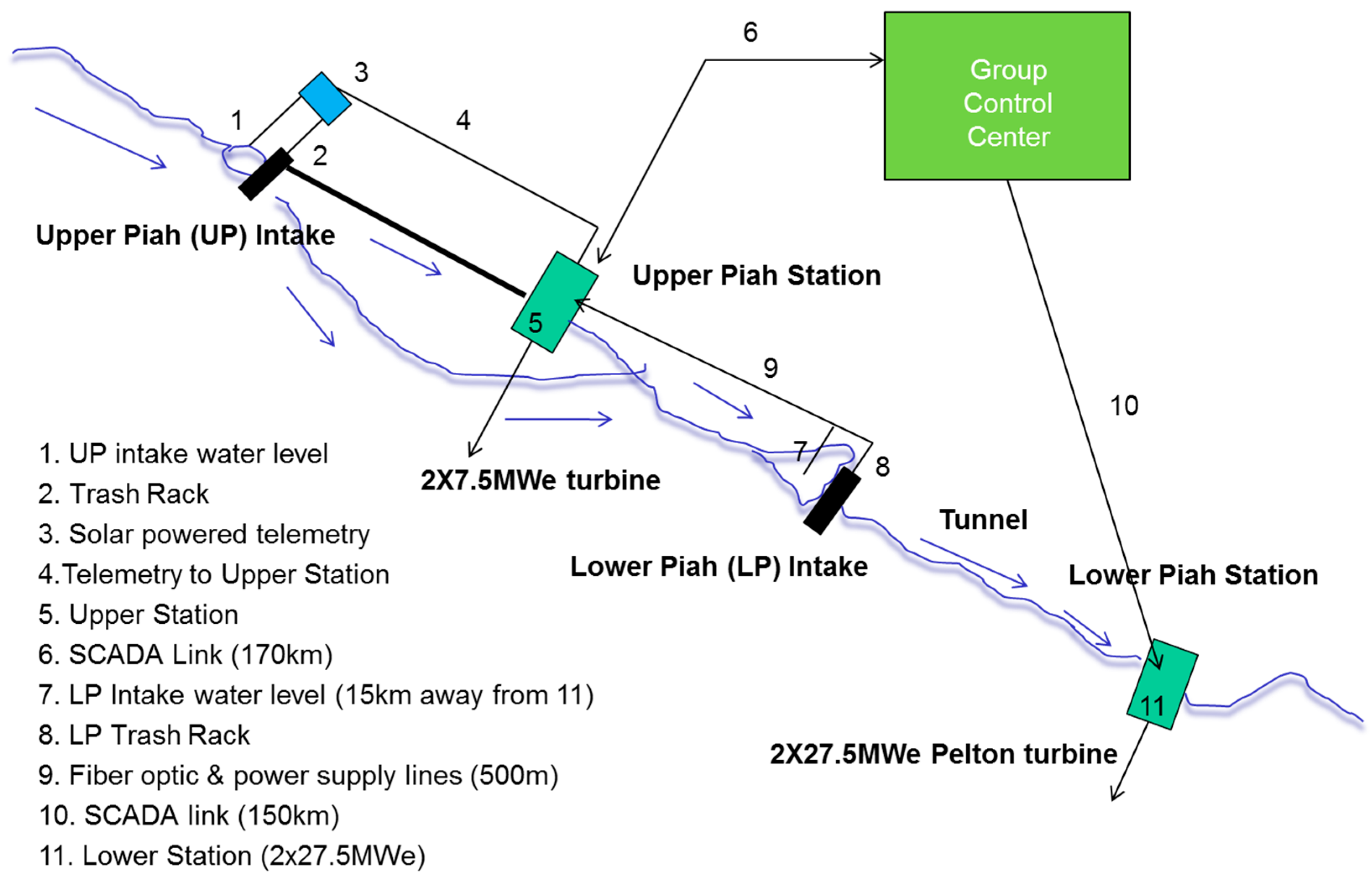

3.2. Proposed River Flow Estimation

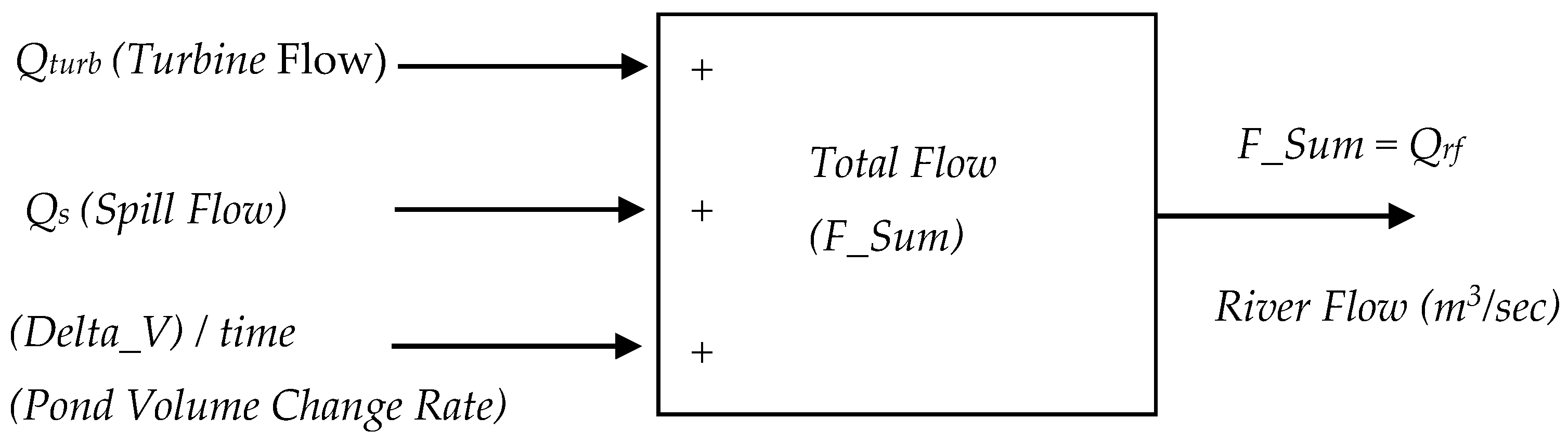

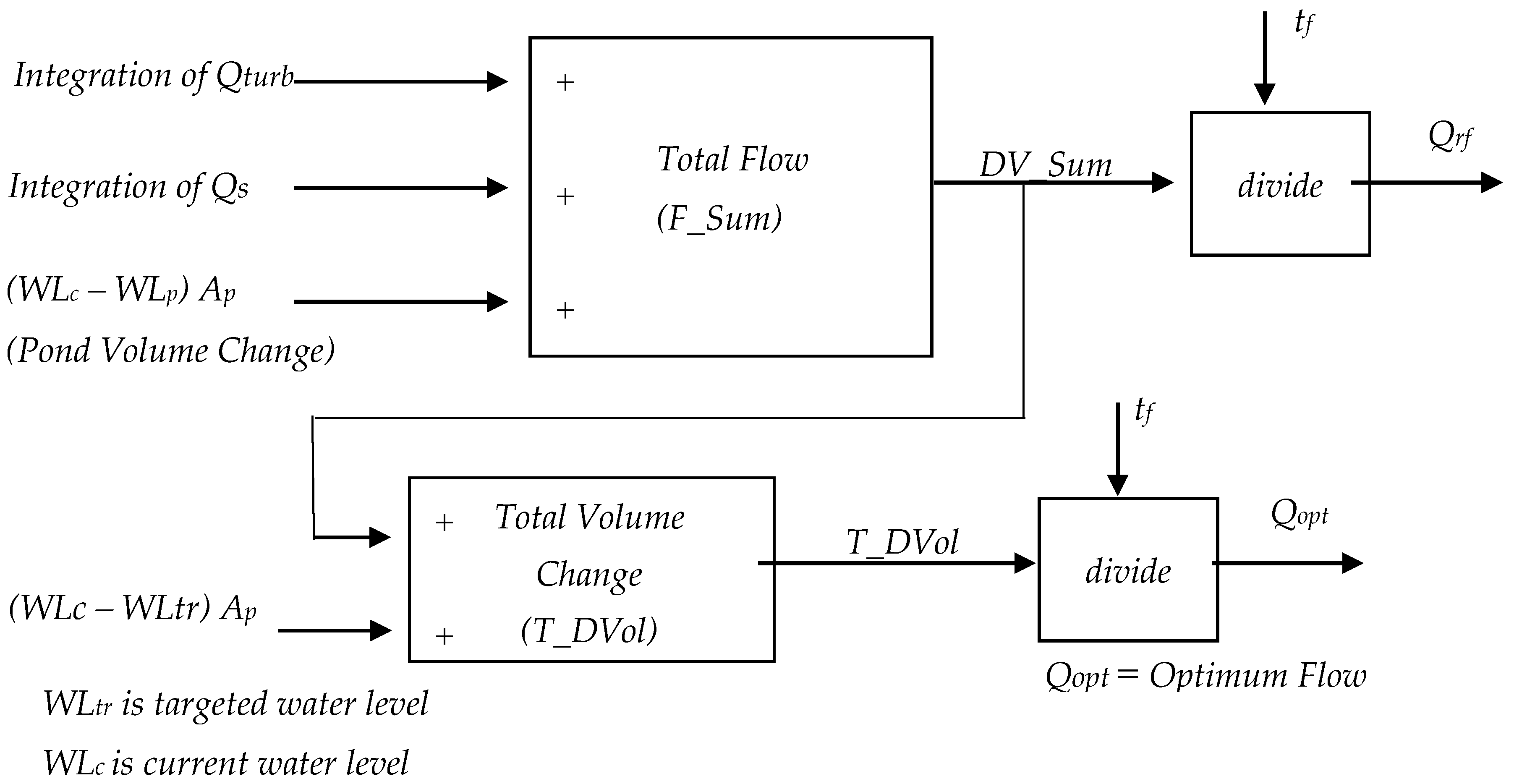

Instead of procuring expensive non-contactable type flow meters to measure the river flow, a new simple computing technique to estimate river flow is proposed. River flow can be computed by summing total turbine discharge flows, rate change of reservoir volumes and spillages. Let’s say the average river flow that feeds the lower station’s intake pond is

Qrf. Using mass conservation, therefore the river flow should equal the summation of spillage (

Qs), intake pond volume change (

Delta_V/time) and discharge flows of turbines (

Qturb), as given in either Equation (2) or (3). The summation is further illustrated in

Figure 3 as a preliminary step prior to going into details of reasons that numerical integration is required to derive the river flow:

Also, the turbine flow Qturb (in both Equations (2) and (3)) should be the combination flows from all turbines that are in operation. Equation (2) or (3) demands multiple flow measurements or methods to calculate flow, as well a method to obtain intake pond volume change rates.

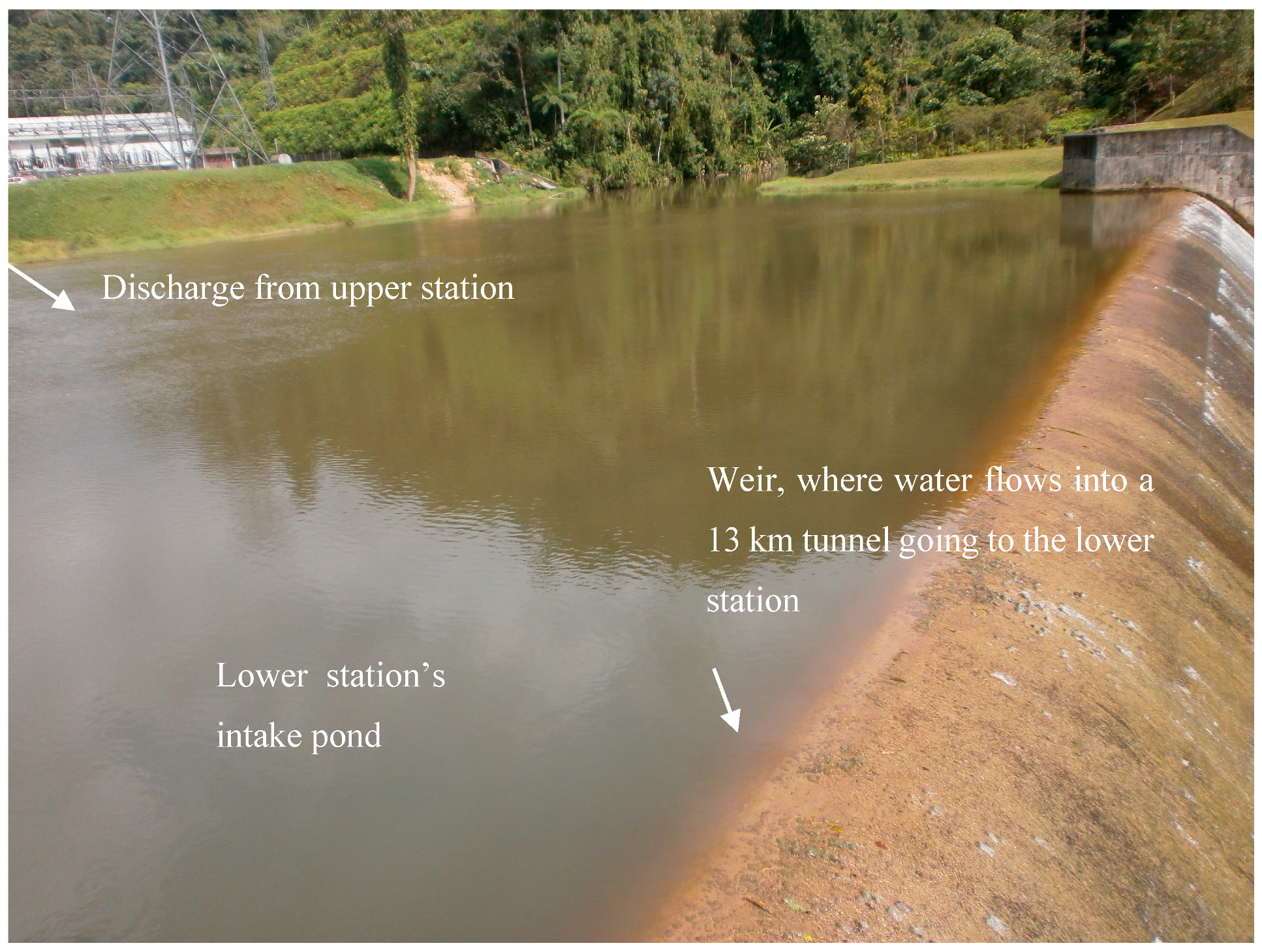

Referring to

Figure 3, it is not possible to measure the intake pond volume rate directly in order to obtain the river flow (

Qrf). Instead the volume rate has to be computed using pond levels (water level sensor) measured at different times. Therefore a water level sensor needs to be installed to measure the water levels at the intake pond if the existing one is defective or does not possess appropriate resolution and accuracy; in our case a robust radar type sensor had been installed.

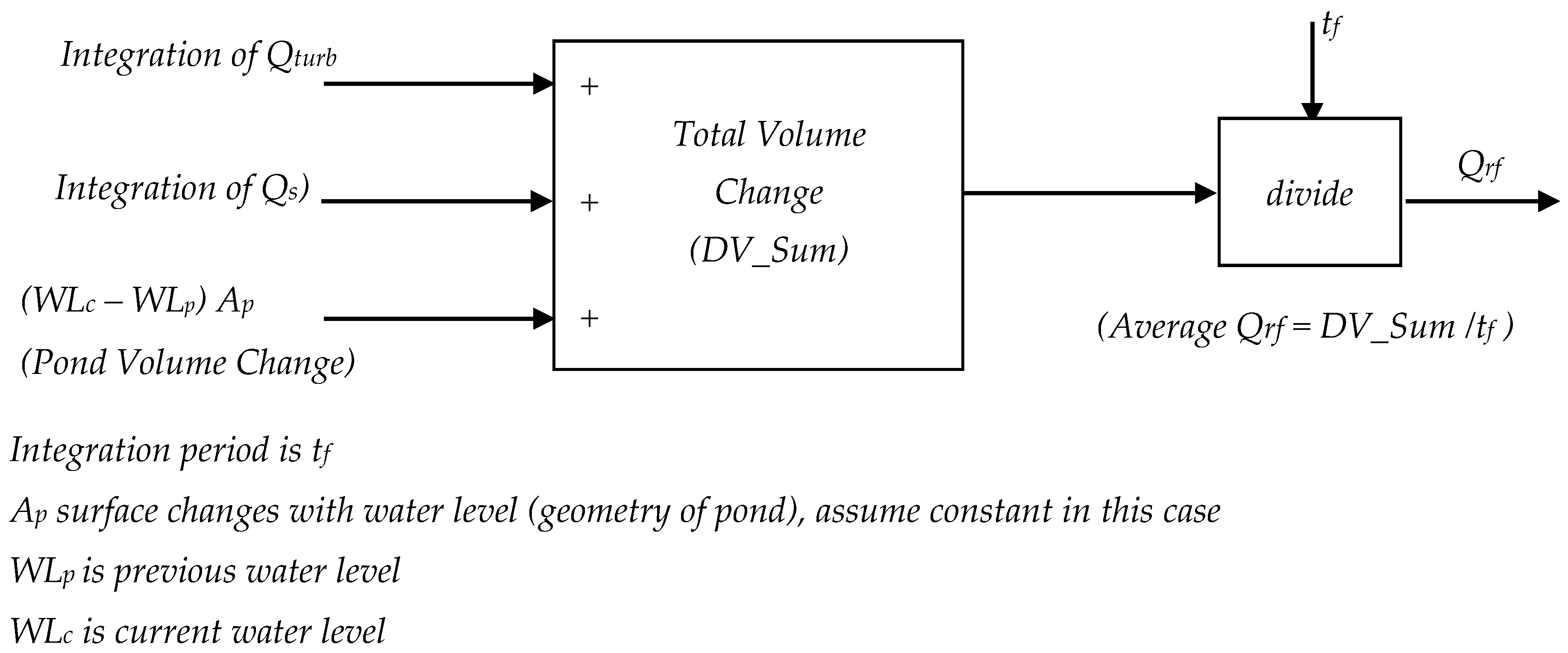

Integrating Equation (3) over time, we obtain Equation (4) which provides us with the information of fluid mass entering and exiting the system within time

tf. Therefore,

Figure 3 becomes

Figure 4 where an integration method is required since pond volume change rate cannot be measured directly. Also to eliminate noises and mitigate errors, multiple samplings of water level measurements are needed.

From

Figure 4, the average river flow (

Qrf) for a time interval (

tf) becomes Equation (4):

where

= spillage (m

3/s);

= turbine discharge (m

3/s) for both turbines;

= previous dam water level (mSLE is meter sea level elevation);

= current dam water level (mSLE) after

= average water surface area for intake pond (m

2);

= final time for control regulation interval (s); also

= integration period.

As WLc and WLp are readings that originate from the same water level sensor, measurement times should be appropriately apart with multiple samples taken to reduce measurement errors. Also, as turbine discharge flow and spillages fluctuate over time, therefore their summation to derive river flow necessitates integration methods.

As illustrated in

Figure 4, the intake pond volume changes (either the increment or decrement rate) is the product of pond water surface average area by the water height difference over a selected time interval T as in Equation (5). T is equals to integration period. The height difference of water level is obtained by deducting the previous water level (

WLp) from the current water level (

WLc). Both water levels are readings from the same water level sensor with appropriate measurement times apart (

WLp and

WLc are measured at start and end of integration period, respectively). The pond surface area differs at different water levels, however as water variation within our case was less than 0.75 m, its average of 9000 m

2 was used for simplification:

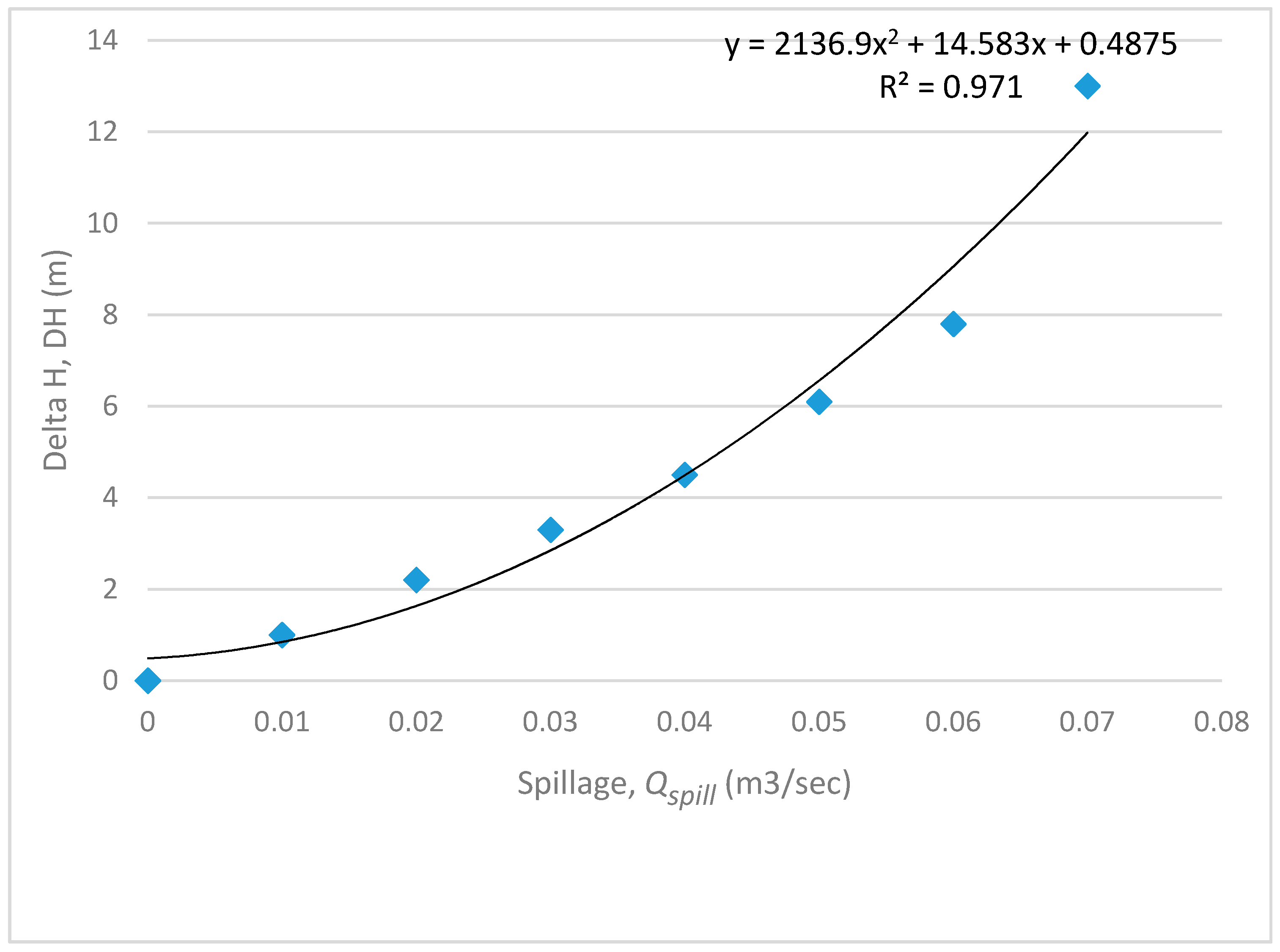

As for the spill flow, its relation with water level above dam crest is tabulated in

Table 1. Spillage flow is

Qs, while the height difference between water level and the dam crest is

Delta_H or

DH. Using values tabulated in

Table 1 that had been obtained by measurements, using quadratic curve fitting, yielding Equation (6). The plot of spillage versus

DH is shown in

Figure 5:

where the regression (

R2) value is 0.971.

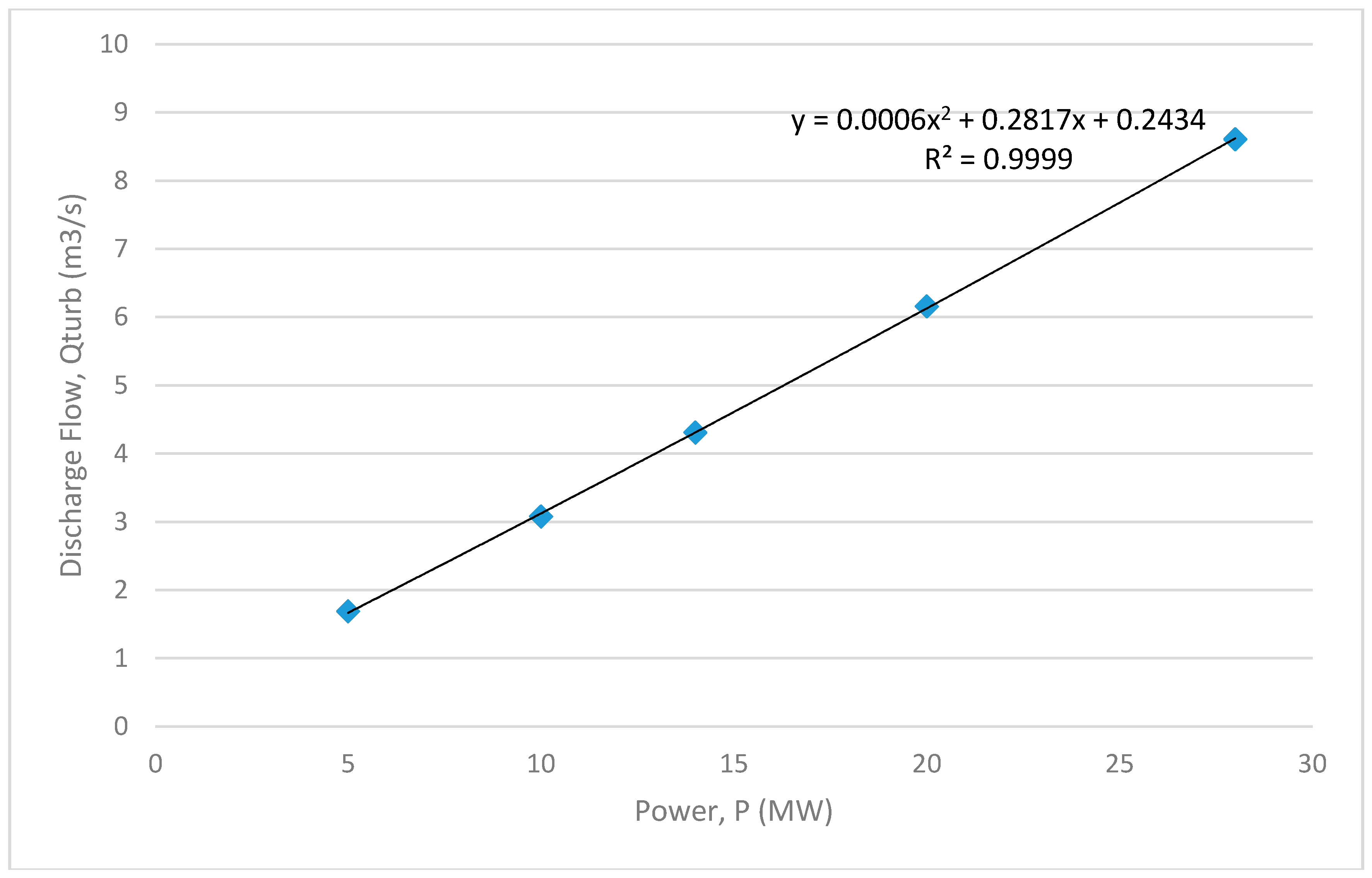

As for the turbine discharge flow,

Qturb for each turbine can be computed if the power output of generator unit is known. The turbine discharge had been obtained by studying the turbine characteristics provided by manufacturers and recent performance tests. The relationship between turbine discharge flows versus power outputs is as given in

Table 2. Using

Table 2, one can plot a relationship curve between turbine discharges versus generator power outputs (as in

Figure 6), also to find their relationship, as in Equation (7):

P is power output in MW driven by the turbine. In Equation (7), turbine discharge flow is a function of generated power as gross head and efficiency remain almost constant when the generator output is greater than 10 MW, as tabulated in

Table 2.

The relationship as plotted in

Figure 6 seems to be linear, but it is not, as the coefficient for the (

P)

2 term in Equation (7) is not zero but 0.0006. The nonlinear characteristic of the plot can be shown by investigating the same correlation in dimensionless form, i.e., overall efficiencies as in Equation (8); (the overall efficiency depends on relationships between generator power, gross head and turbine discharge flow):

where

generator load (W);

water density (kg/m

3);

gravitational acceleration (m/s

2);

gross head (m);

turbine discharge (m

3/s).

As an example, using the data for 5 MW in

Table 2, and let

= 997 kg/m

3,

Hg = 403 m,

g = 9.781 m/s

2 (is typical value of

g for Malaysia), with turbine discharge equals to 1.69 (

Qturb = 1.69 m

3/s), yields the following efficiency:

The remaining computed efficiency results are tabulated in

Table 2. Overall efficiency at 5 MW is significantly low since the number of operating nozzles is either two or four. While each nozzle was designed to work best at values between 5 and 7.5 MW, utilizing two nozzles for generator output as low as 5 MW made each nozzle to operate at 2.5 MW, which is far below its best design load. As the load per nozzle exceeds 5 MW, its efficiency reaches almost the flat zone. This is the important contributing factor why overall efficiency has achieved almost a constant value beyond this load.

Though the two generating units in this plant do not have identical turbine discharge and overall efficiency characteristics, however for a purpose of simplification, in this project they have been considered similar (turbine discharge versus generator output and overall efficiency versus generator outputs curves).

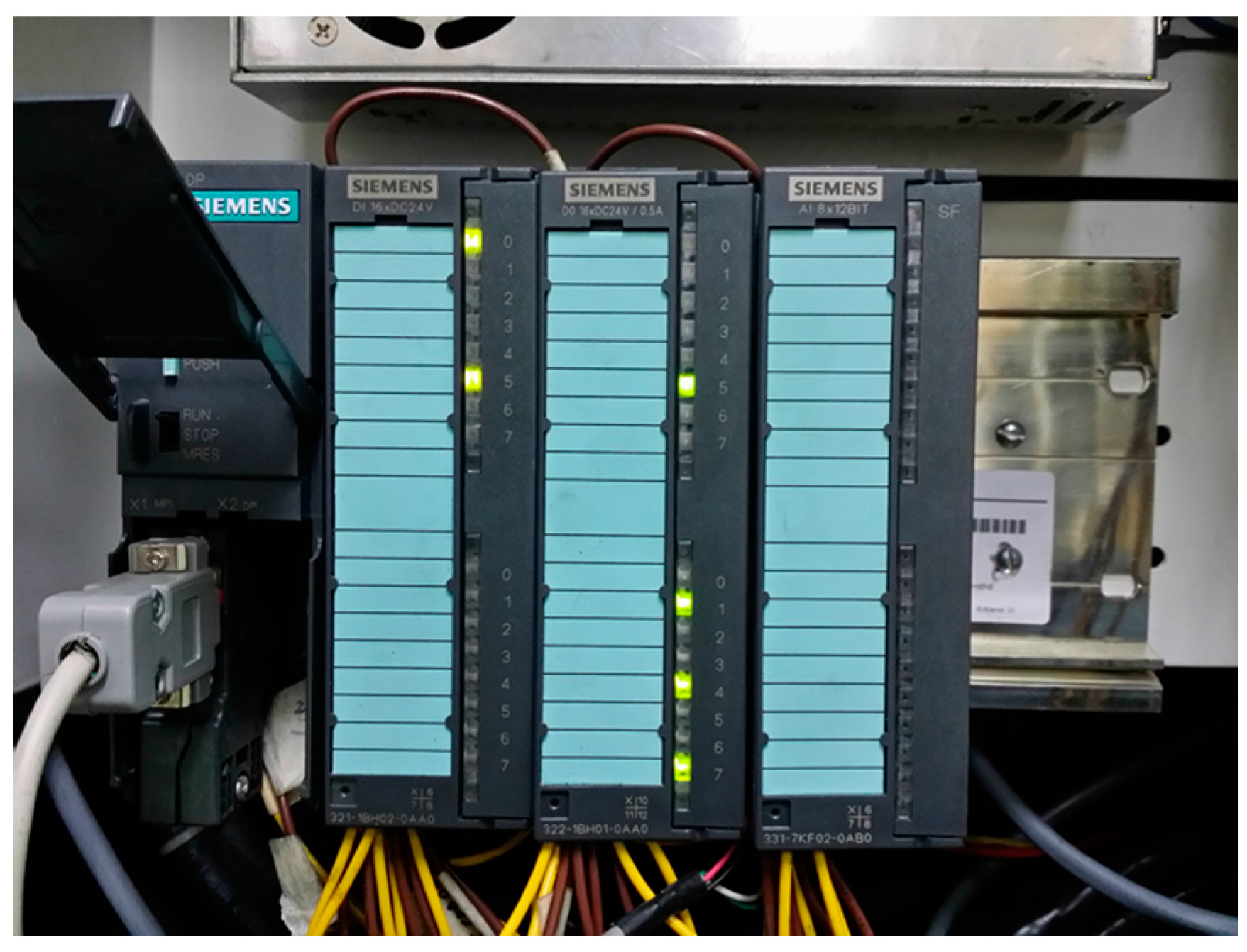

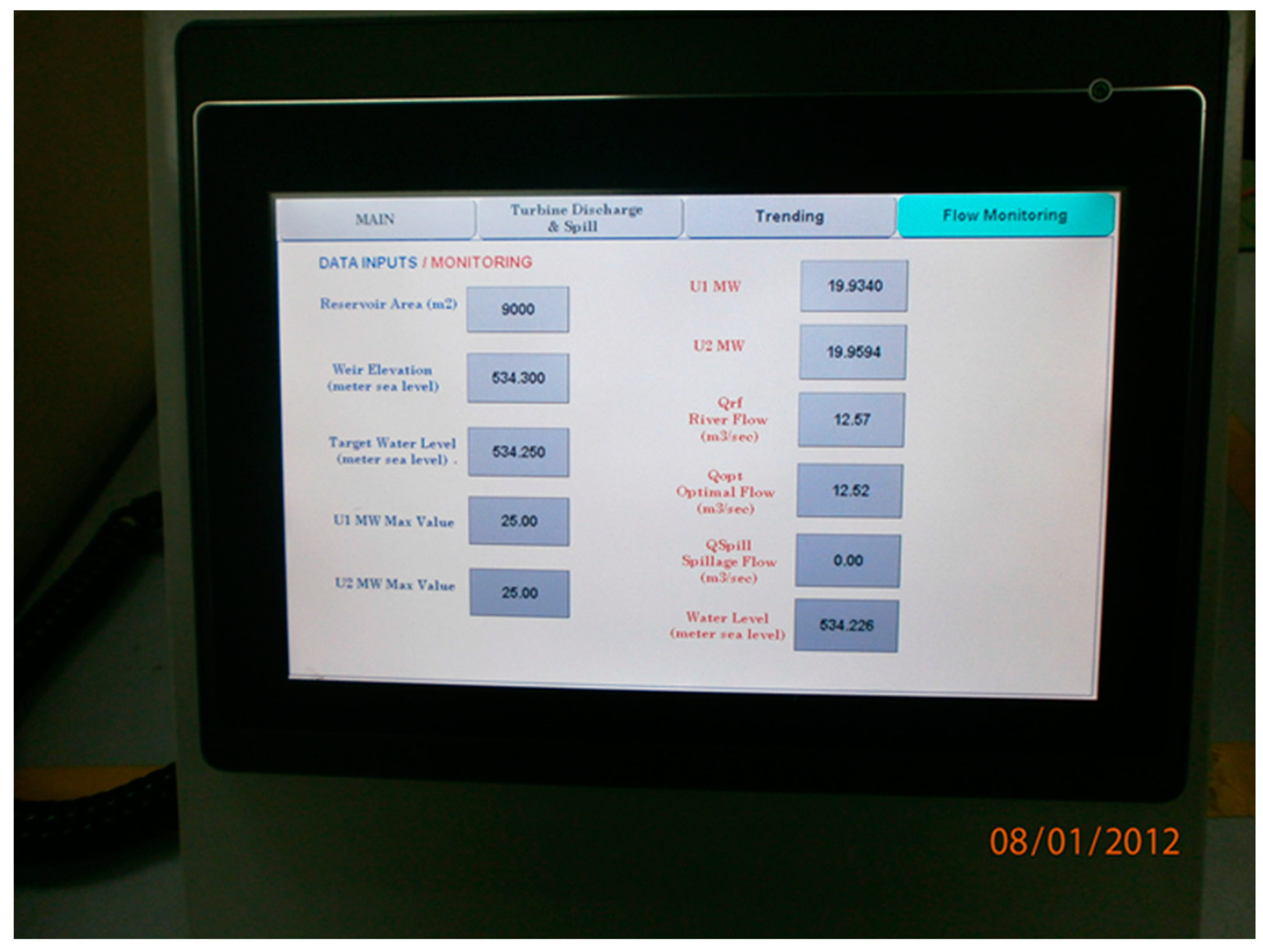

All these computations has been realized in the form of ladder logic rungs on a programmable logic controller (PLC). In summary, the average river flow is the right hand-side component of Equation (4) divided by time integration interval.