Perforated Thermal Mass Shading: An Approach to Winter Solar Shading and Energy, Shading and Daylighting Performance

Abstract

:1. Introduction

2. Method

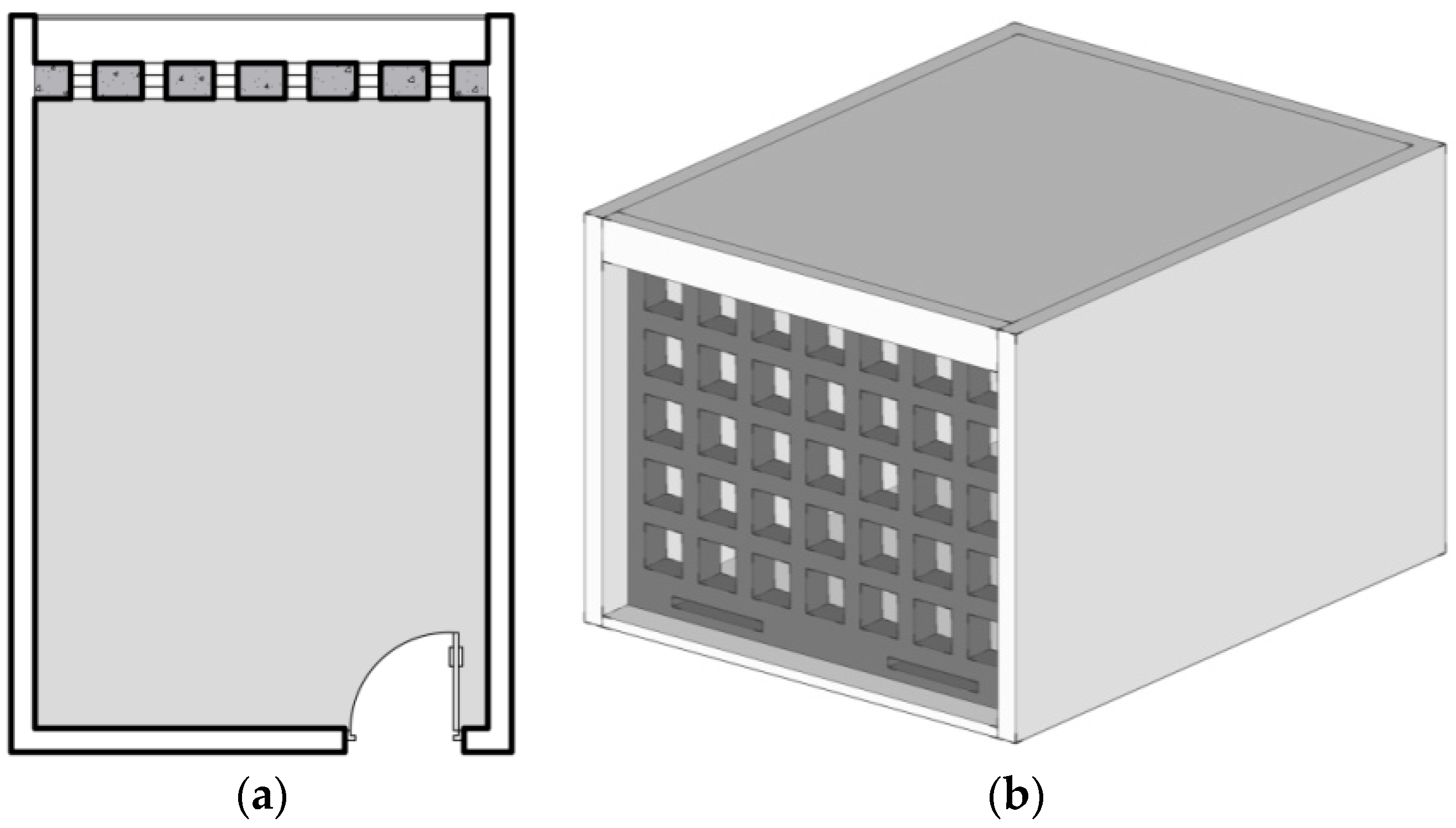

2.1. Design Approach to Winter Solar Shading

2.2. Experimental Approach

2.3. Simulation

2.3.1. Simulation Setup

2.3.2. Climate Data

2.4. Validation of Simulation Method

3. Results and Discussion

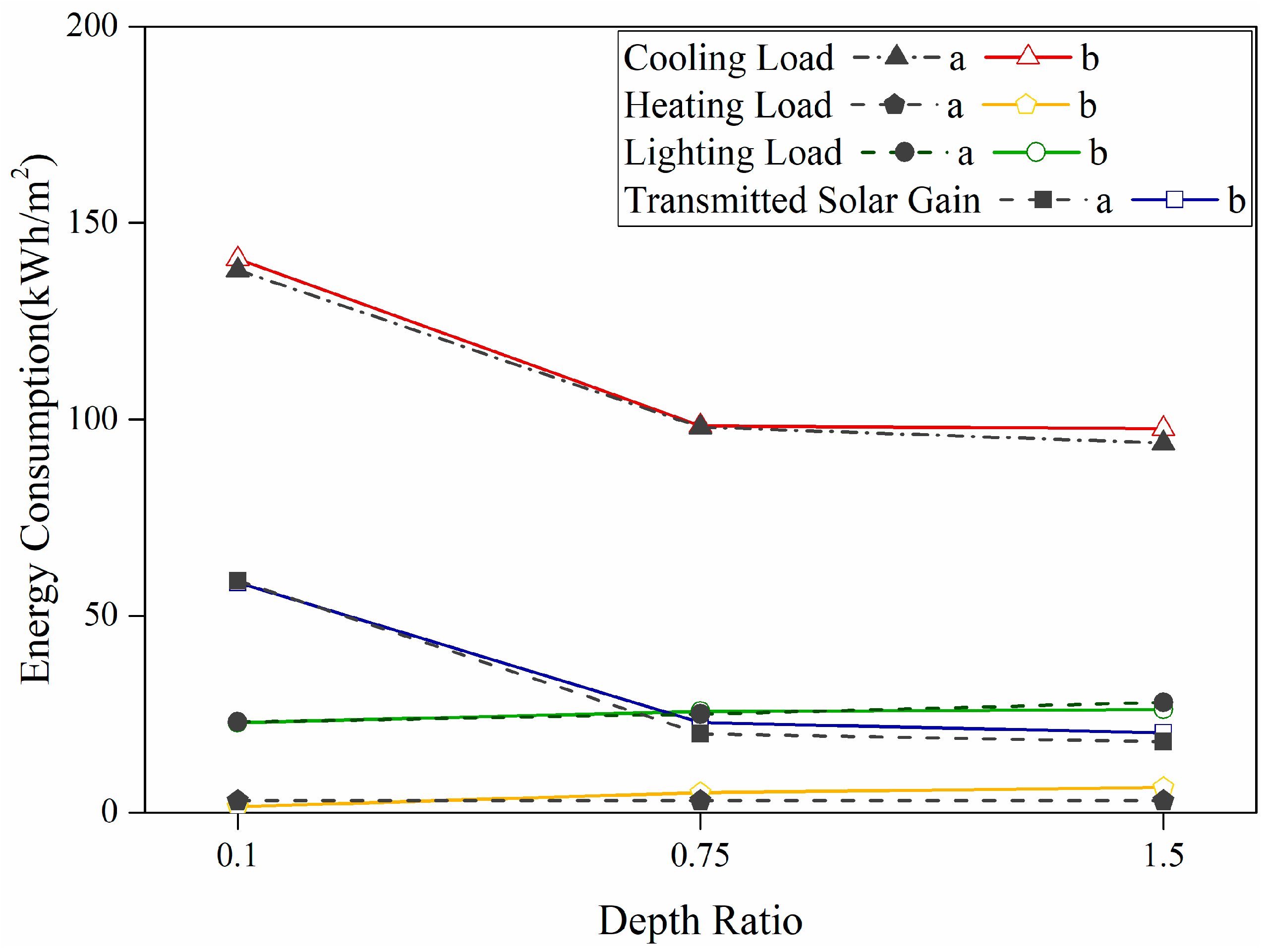

3.1. Benchmark of the Reference Model

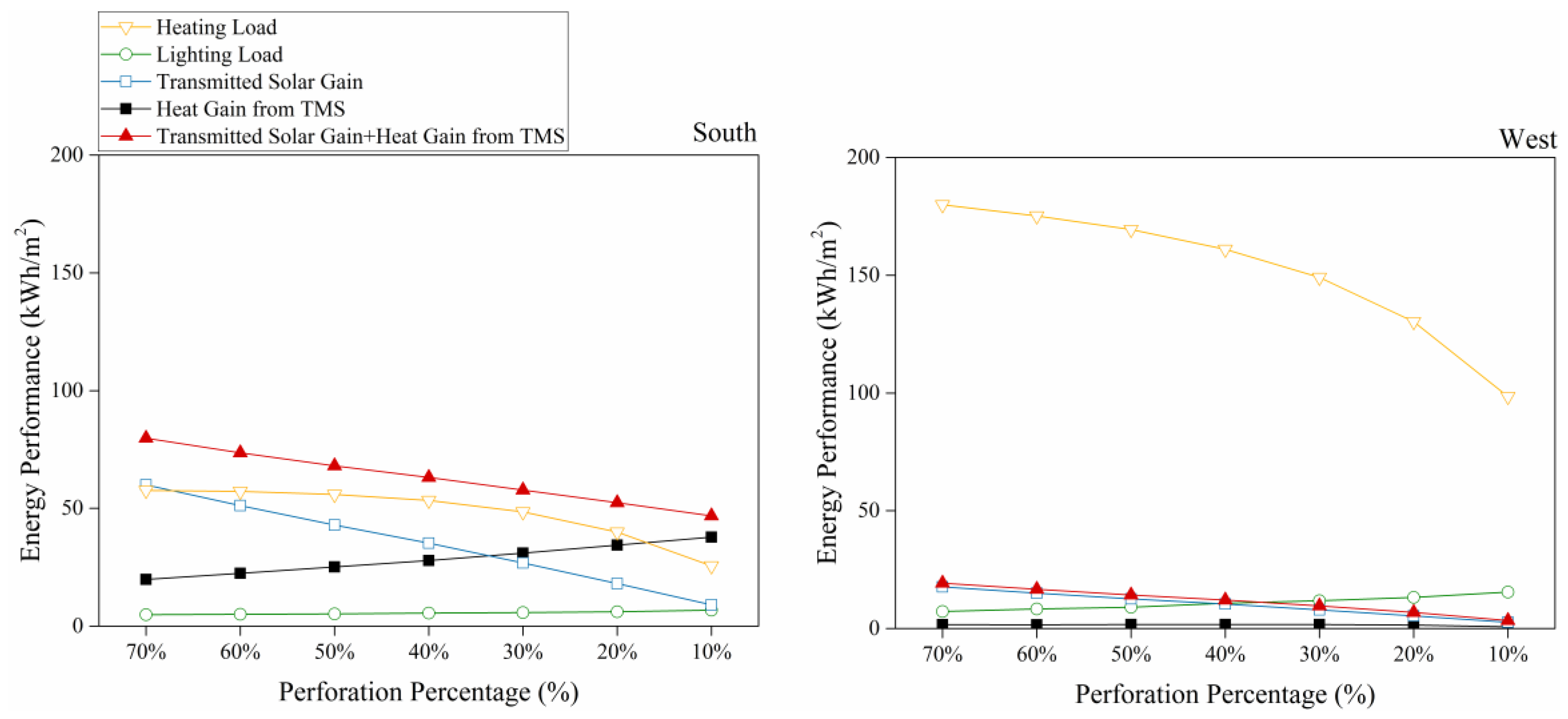

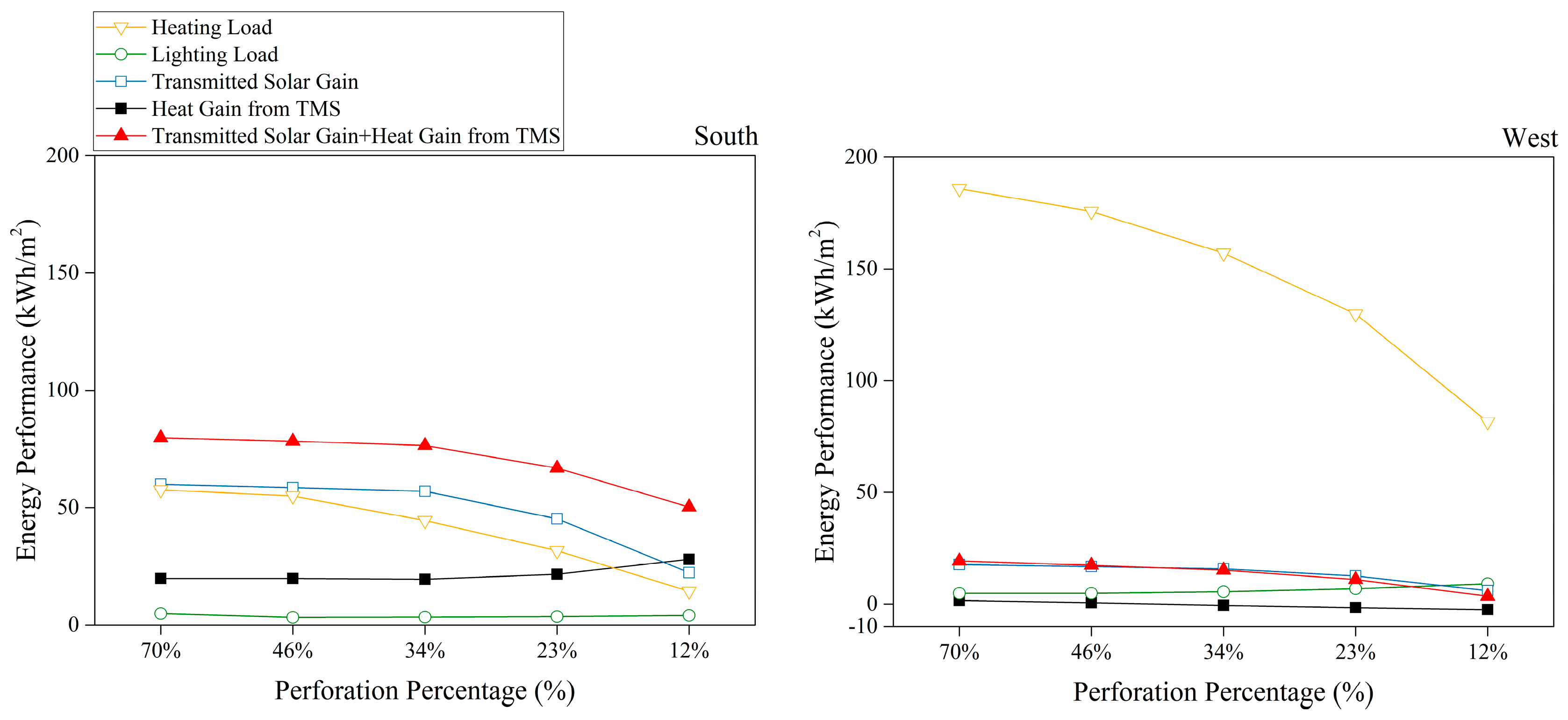

3.2. Effect of Perforation Percentage

3.2.1. Energy Performance

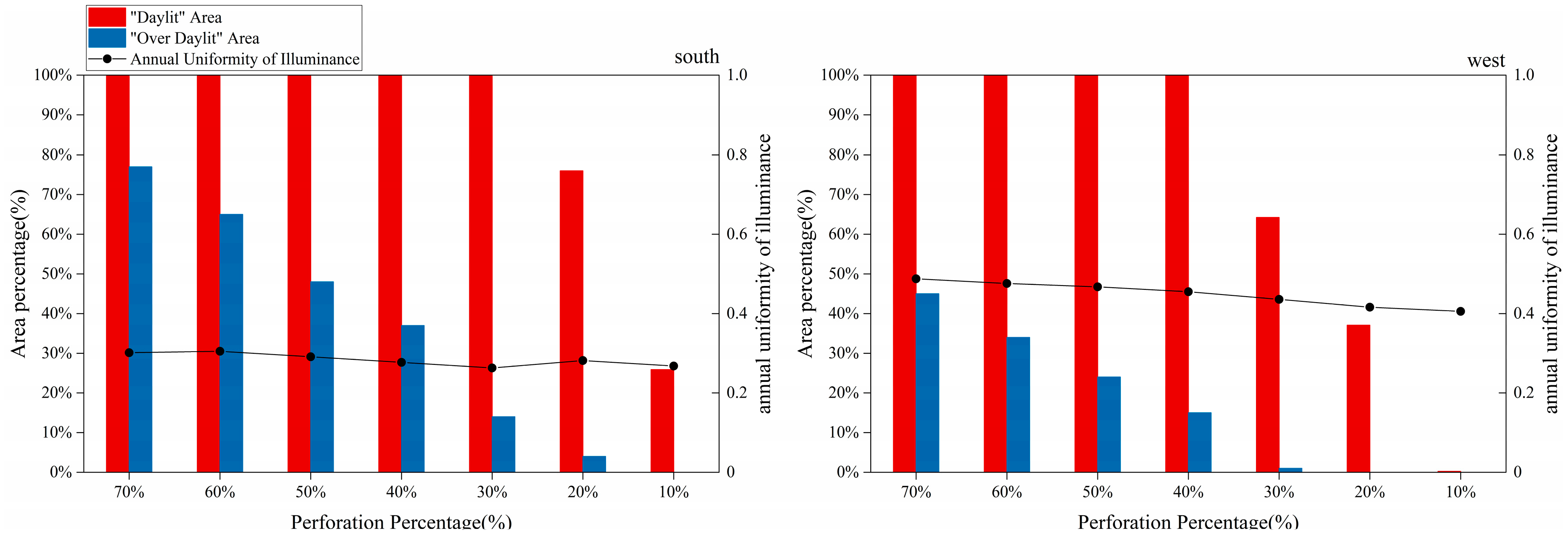

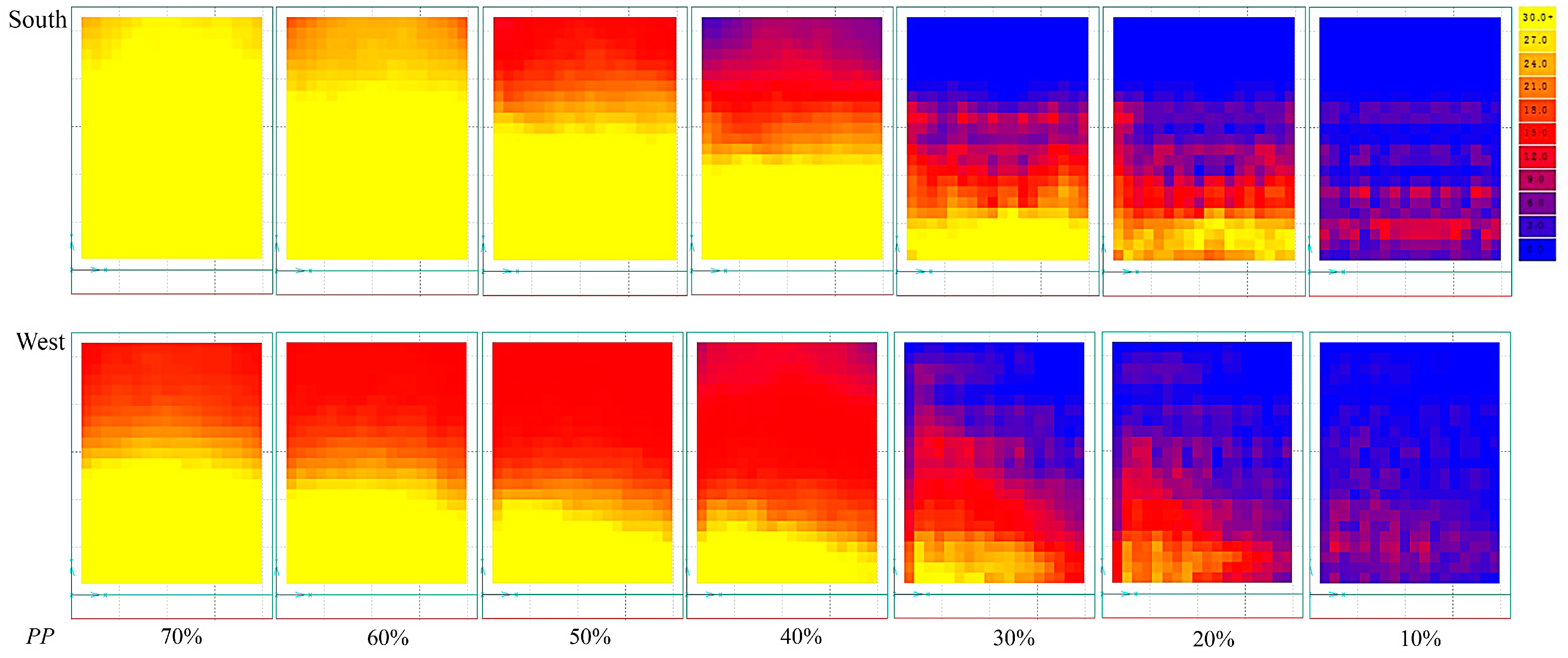

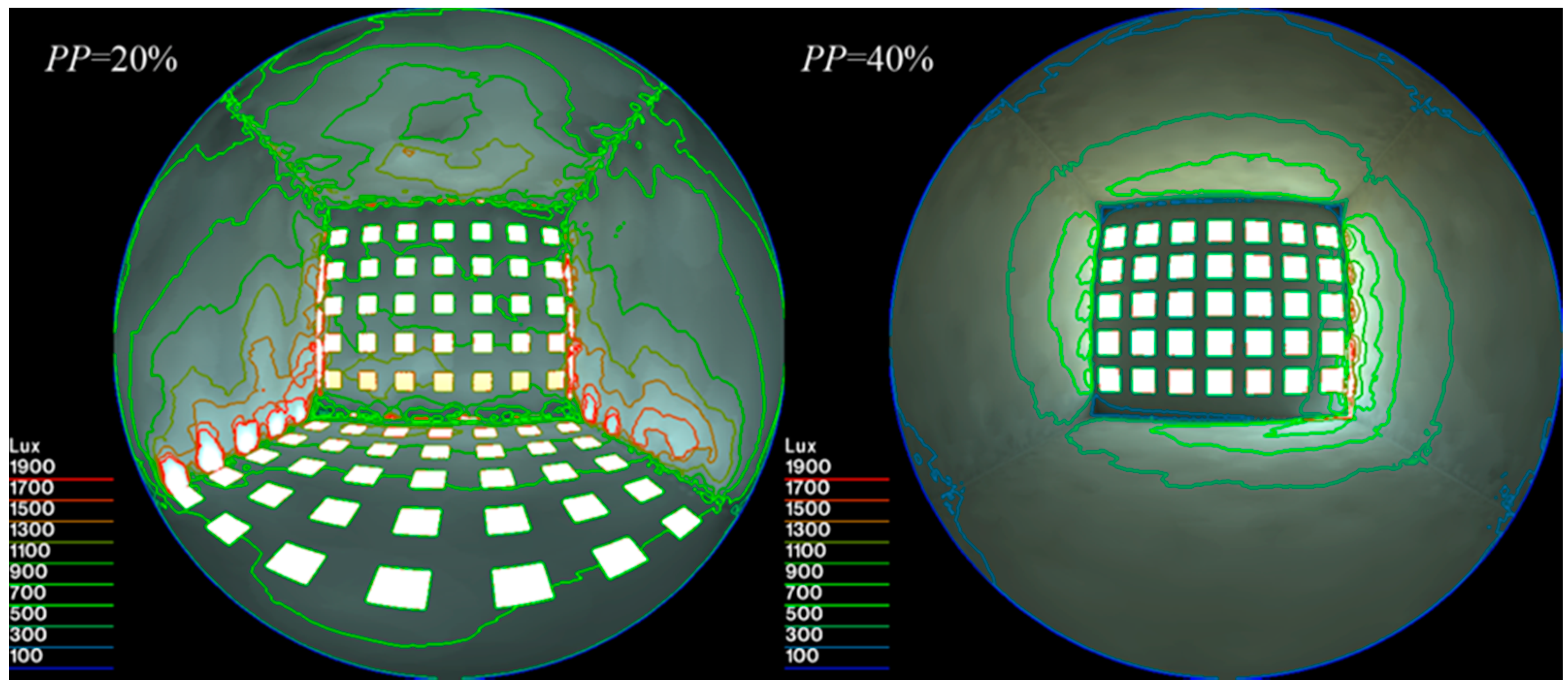

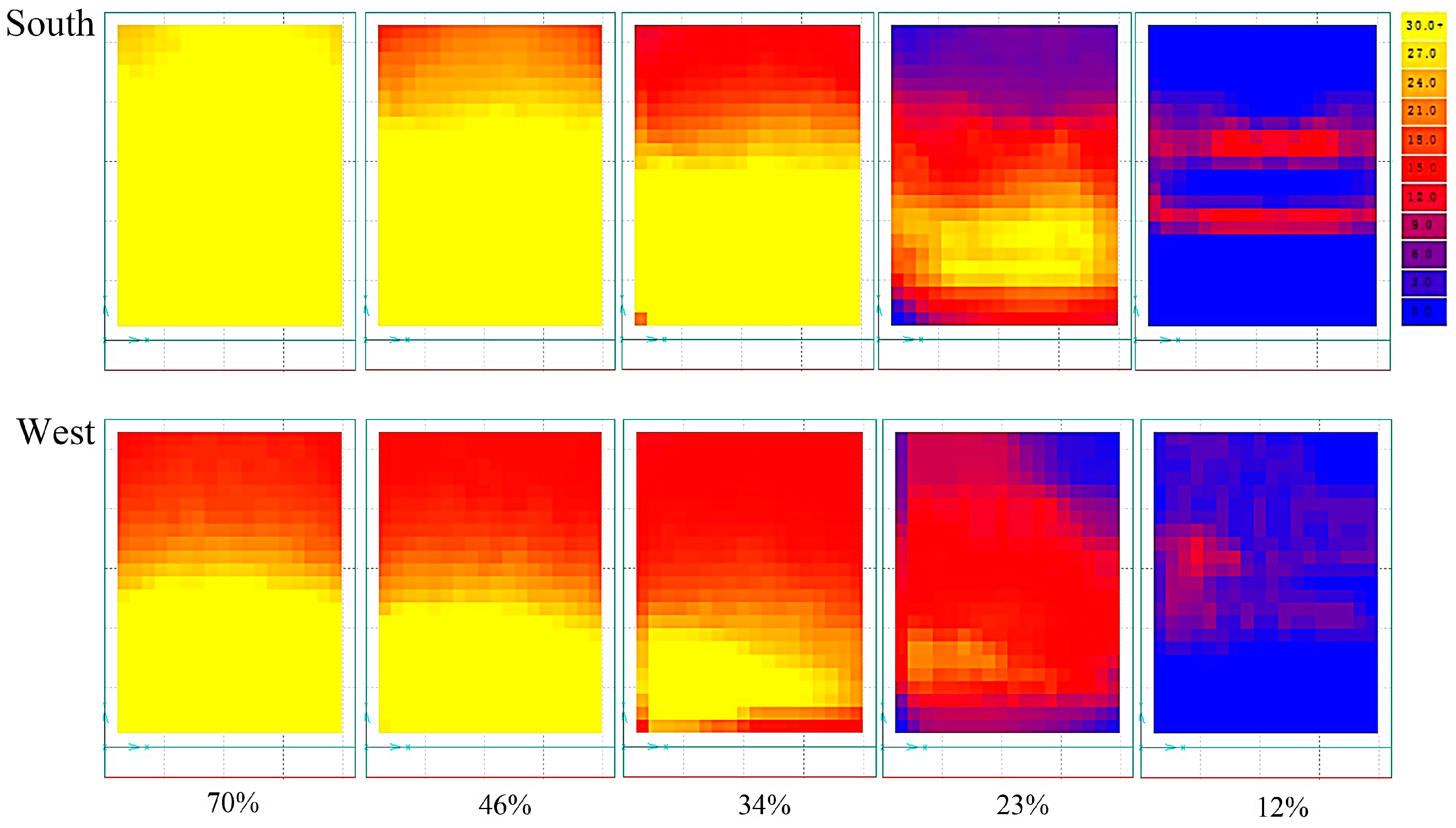

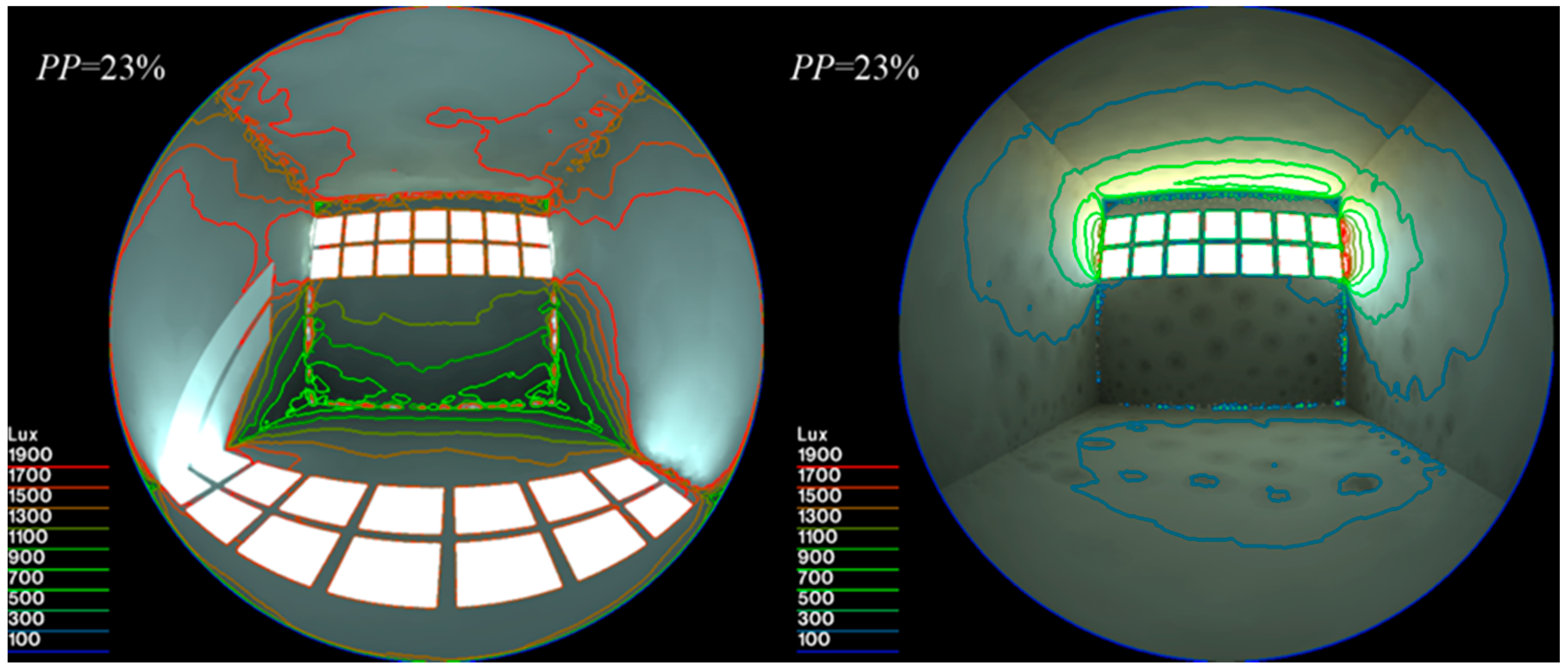

3.2.2. Shading and Daylighting Performance

3.3. Effect of the Opening Position

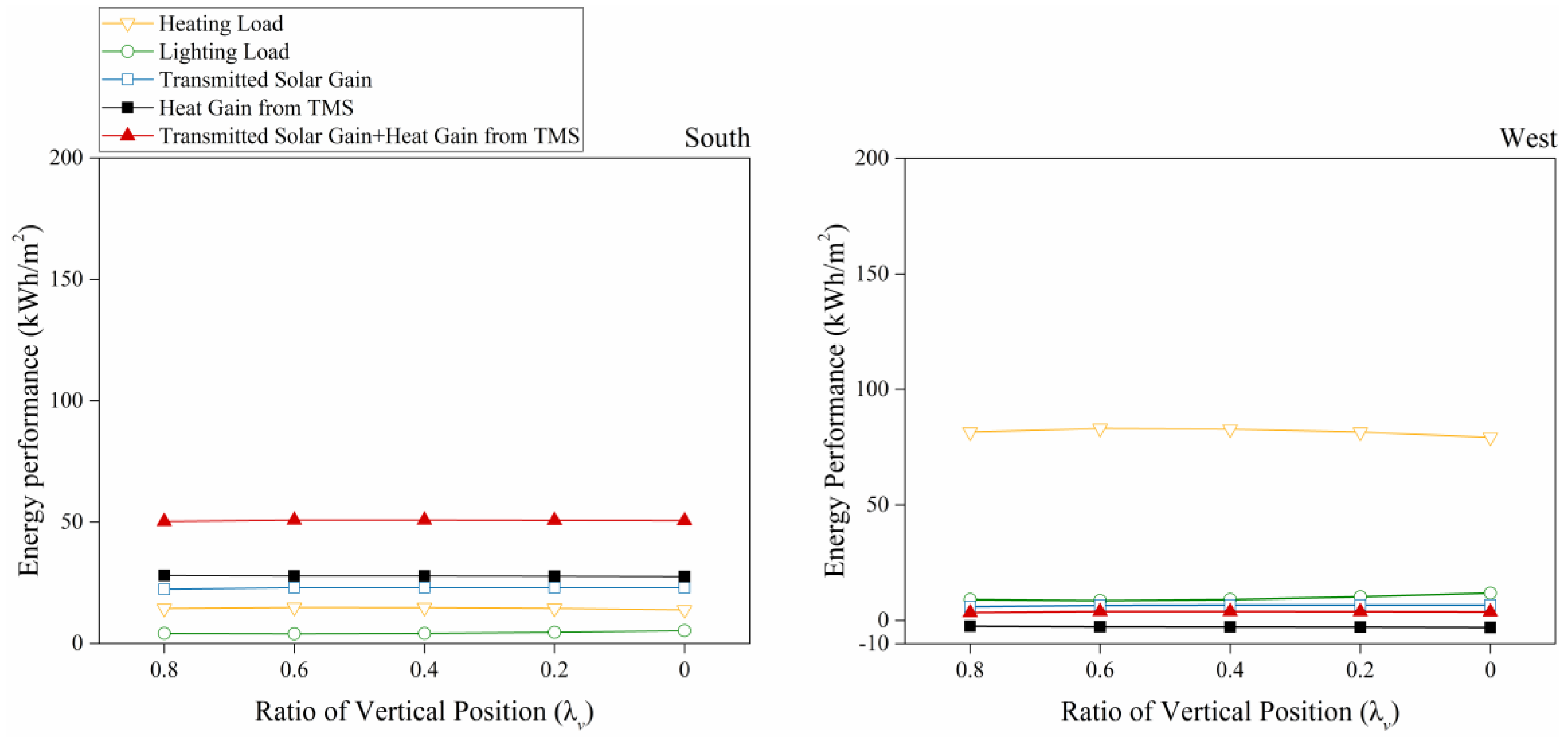

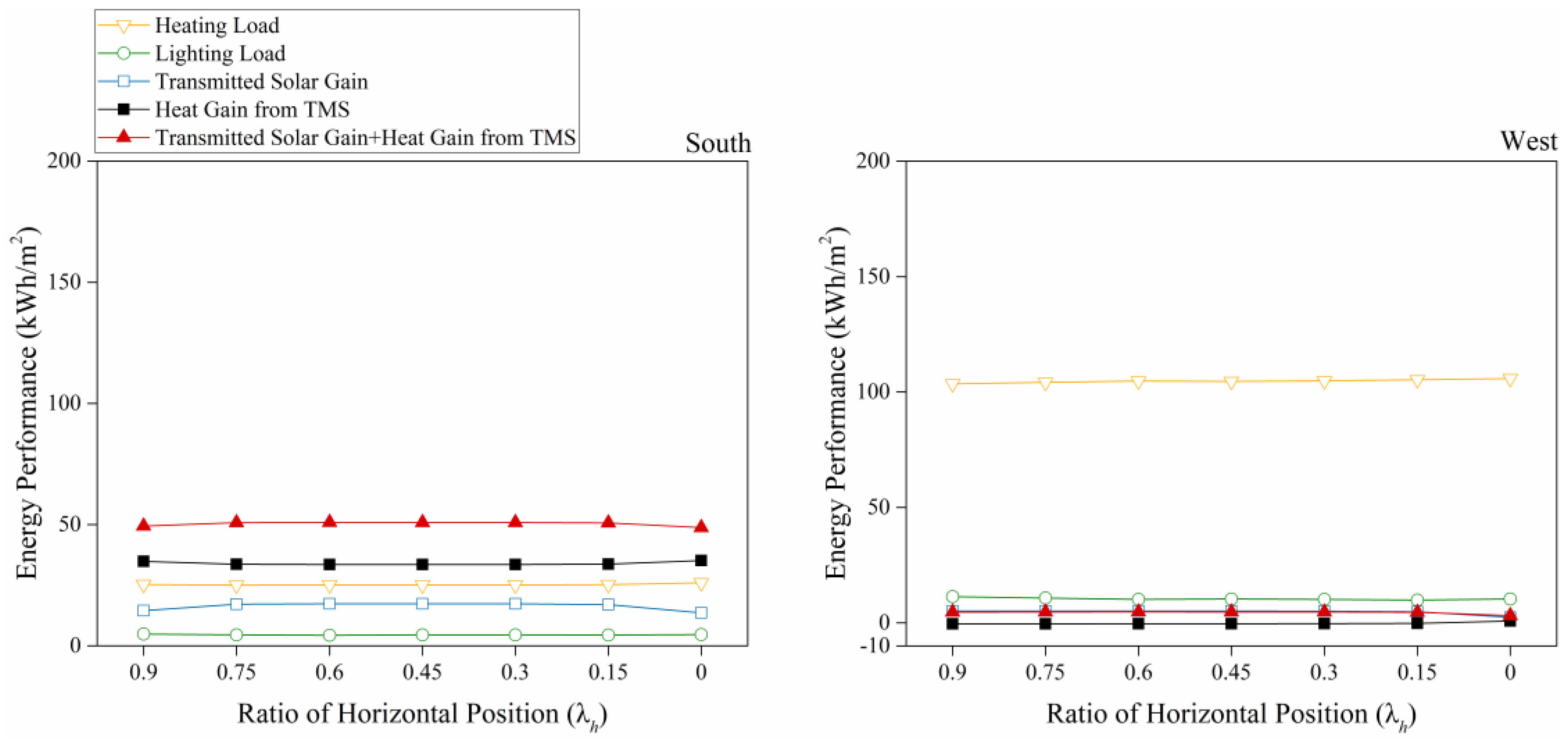

3.3.1. Energy Performance

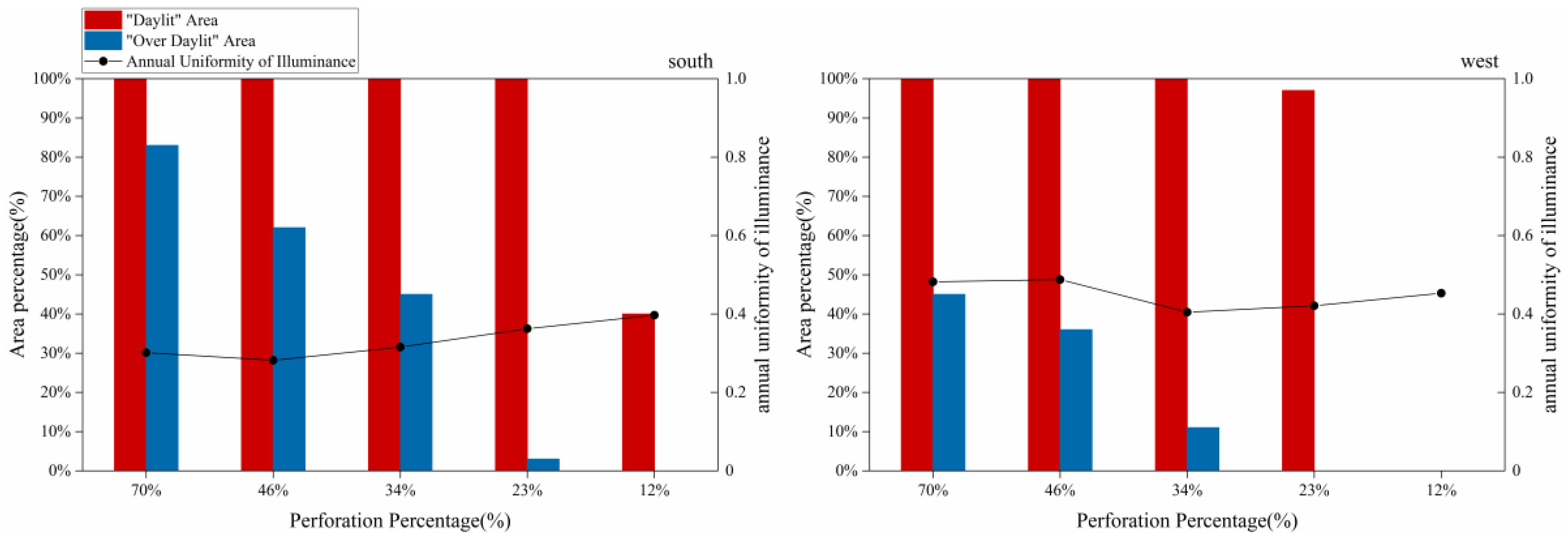

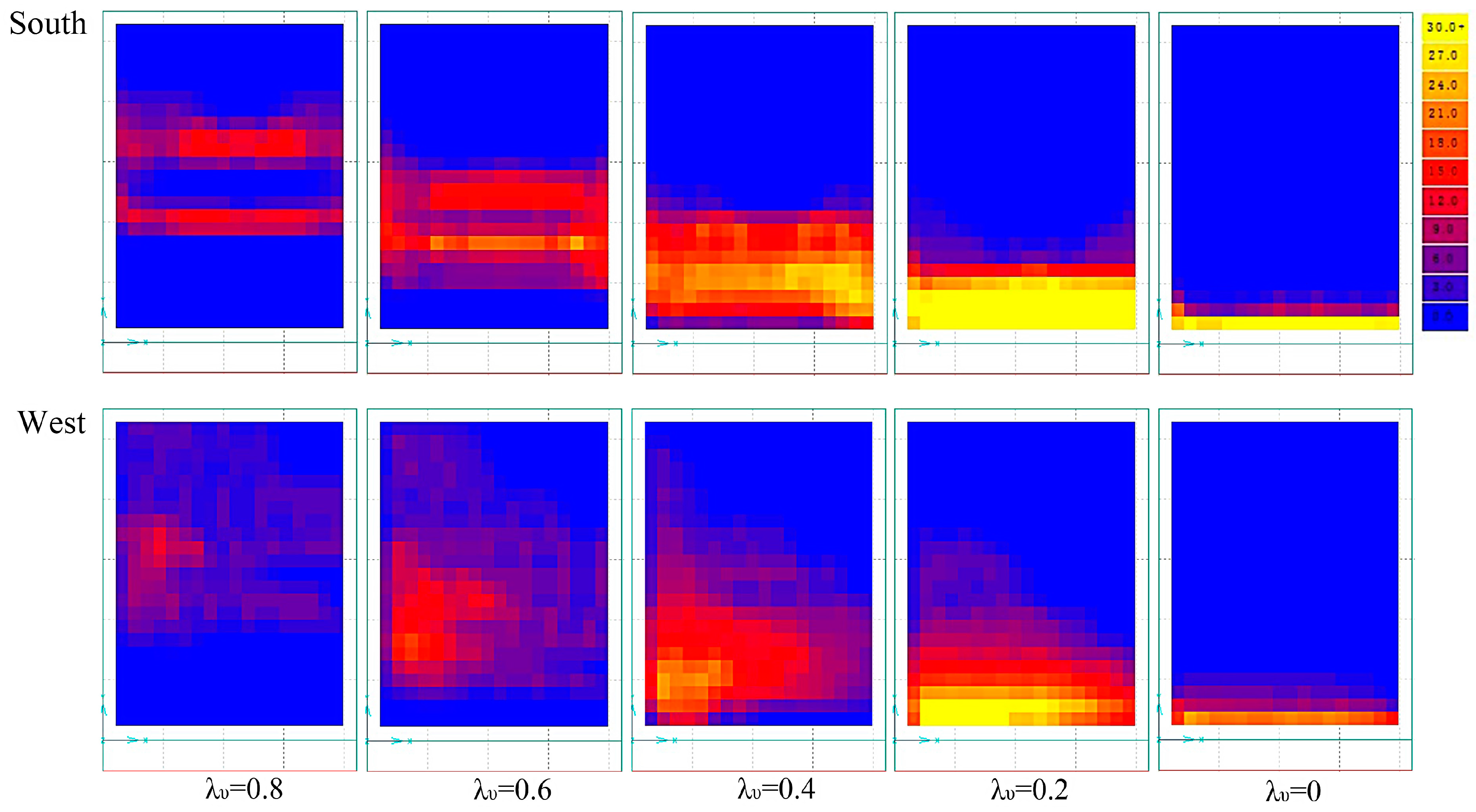

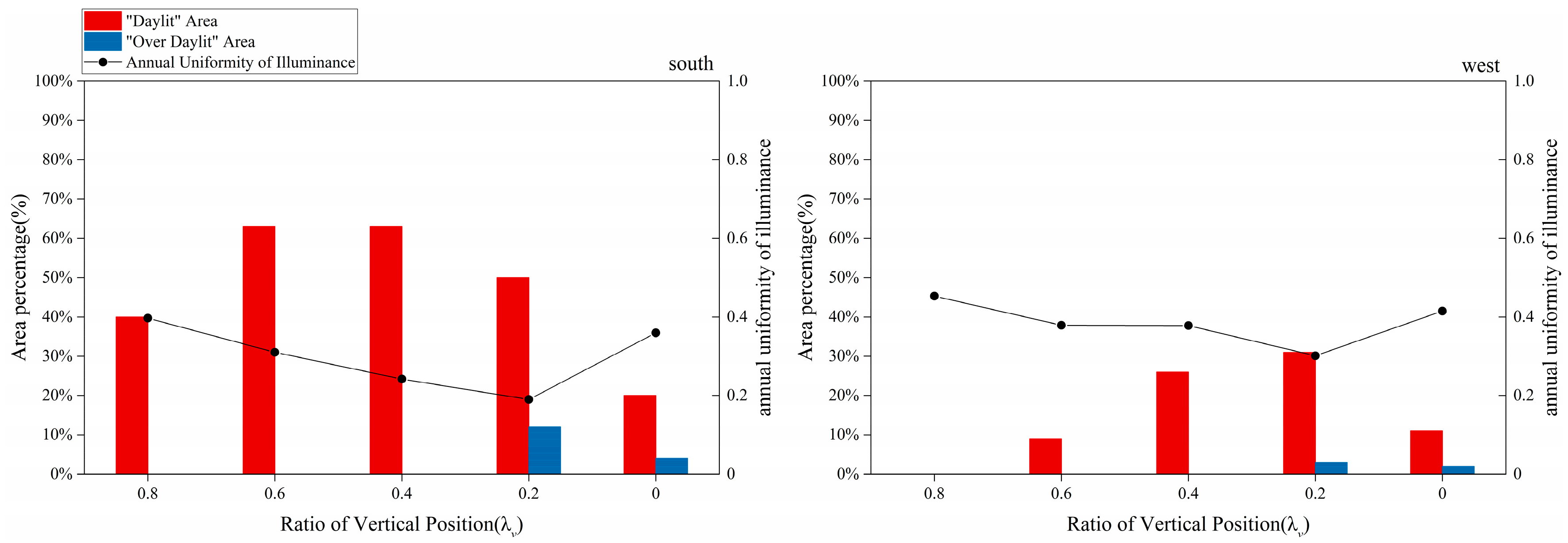

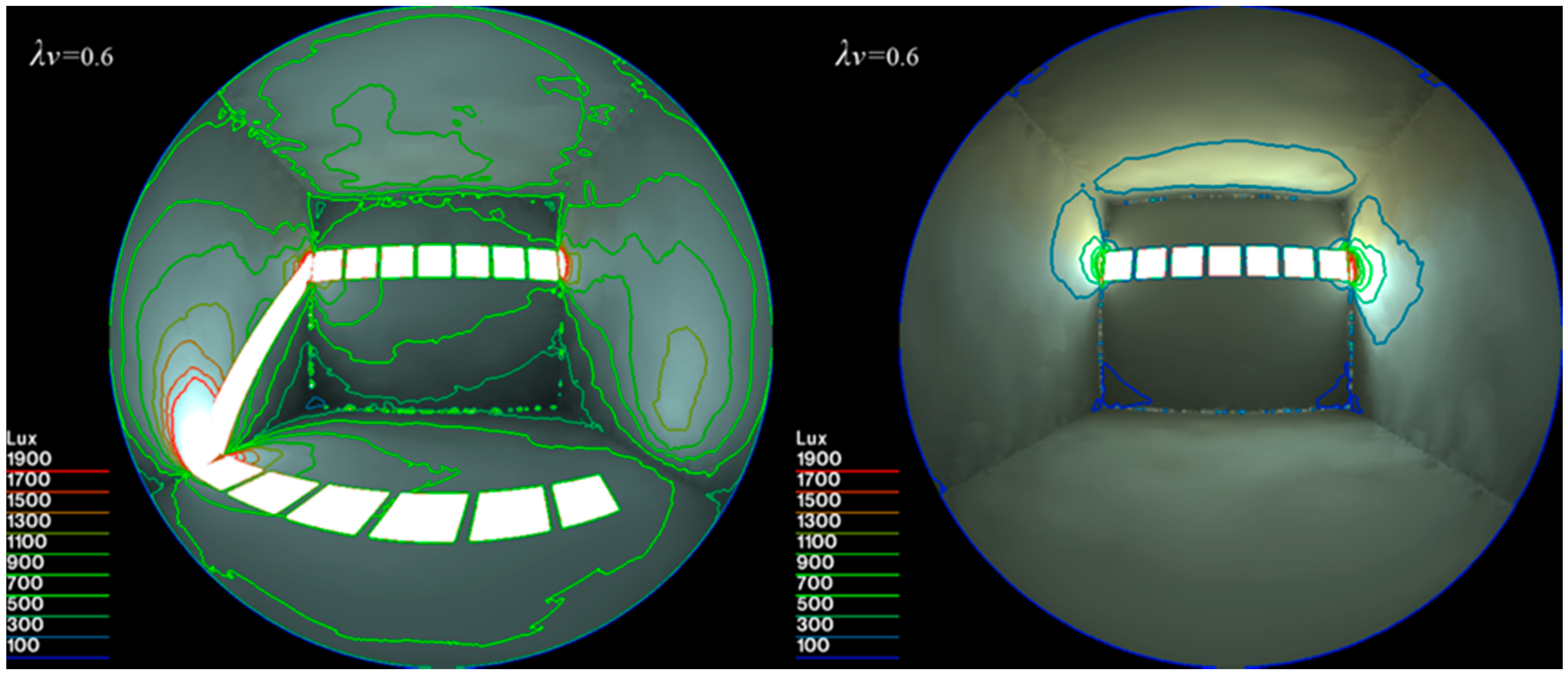

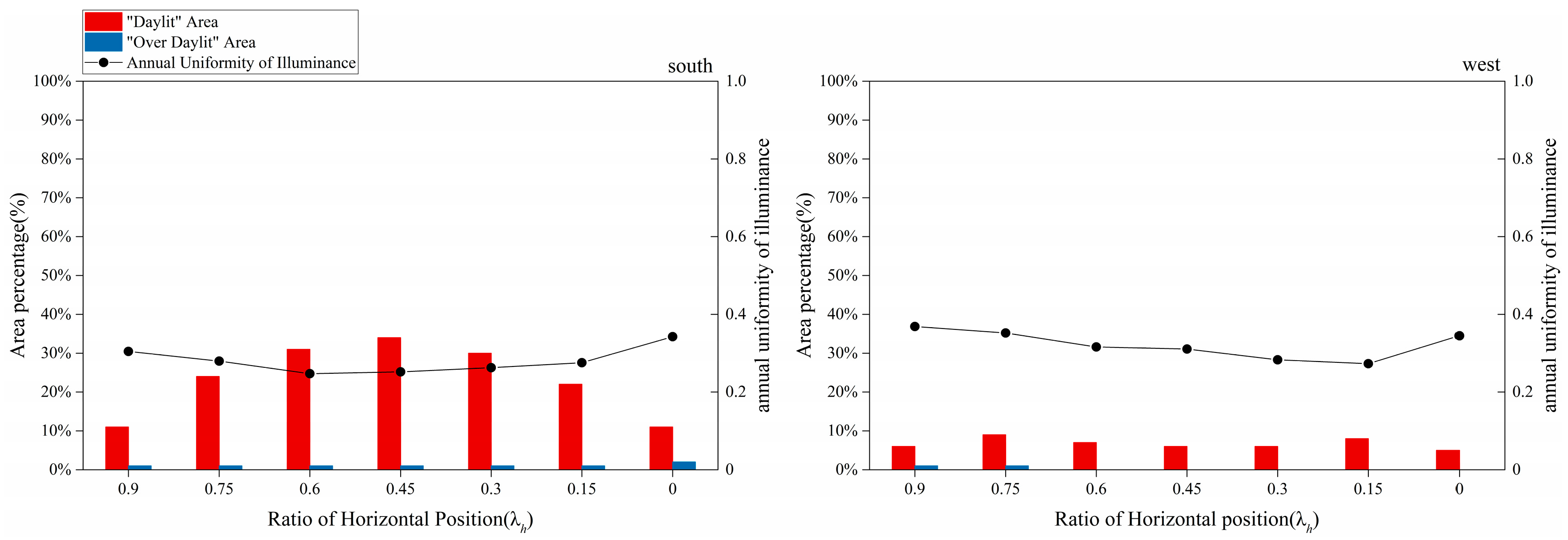

3.3.2. Shading and Daylighting Performance

3.4. Overall Performance

4. Conclusions

5. Future Work

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Lyons, P.R.; Arasteh, D.; Huizenga, C. Window performance for human thermal comfort. Ashrae Trans. 2000, 106, 4–20. [Google Scholar]

- American Society of Heating, Refrigerating and Air-Conditioning Engineers. 2009 ASHRAE Handbook: Fundamentals. Available online: http://shop.iccsafe.org/media/wysiwyg/material/8950P217-toc.pdf (accessed on 22 November 2017).

- Arens, E.; Hoyt, T.; Zhou, X.; Huang, L.; Zhang, H.; Schiavon, S. Modeling the comfort effects of short-wave solar radiation indoors. Build. Environ. 2015, 88, 3–9. [Google Scholar] [CrossRef]

- La Gennusa, M.; Nucara, A.; Pietrafesa, M.; Rizzo, G. A model for managing and evaluating solar radiation for indoor thermal comfort. Sol. Energy 2007, 81, 594–606. [Google Scholar] [CrossRef]

- Haldi, F.; Robinson, D. On the behaviour and adaptation of office occupants. Build. Environ. 2008, 43, 2163–2177. [Google Scholar] [CrossRef]

- Yun, G.Y.; Steemers, K. Time-dependent occupant behaviour models of window control in summer. Build. Environ. 2008, 43, 1471–1482. [Google Scholar] [CrossRef]

- Huang, L.; Hamza, N.; Lan, B.; Zahi, D. Climate-responsive design of traditional dwellings in the cold-arid regions of Tibet and a field investigation of indoor environments in winter. Energy Build. 2016, 128, 697–712. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, J.; Yang, L.; Li, J. Measureing study of passive solar house for traditional dewlling building in lhasa area. Acta Energiae Sol. Sin. 2008, 29, 391–394. [Google Scholar]

- Si, P.; Feng, Y.; Lv, Y.; Rong, X.; Pan, Y.; Liu, X.; Yan, J. An optimization method applied to active solar energy systems for buildings in cold plateau areas—The case of Lhasa. Appl. Energy 2017, 194, 487–498. [Google Scholar] [CrossRef]

- Blumthaler, M.; Ambach, W.; Ellinger, R. Increase in solar UV radiation with altitude. J. Photochem. Photobiol. B Biol. 1997, 39, 130–134. [Google Scholar] [CrossRef]

- Blumthaler, M. Solar Radiation of the high Alps. In Plants in Alpine Regions; Springer: Vienna, Austria, 2012; pp. 11–20. [Google Scholar]

- Huang, L. Impacts of Solar Radiation on Winter Indoor Thermal Comfort in Lhasa in: 12th National Building Physics Conference; China Building Industry Press: Wenzhou, China, 2016; pp. 575–579. [Google Scholar]

- Aldawoud, A. Conventional fixed shading devices in comparison to an electrochromic glazing system in hot, dry climate. Energy Build. 2013, 59, 104–110. [Google Scholar] [CrossRef]

- Cho, J.; Yoo, C.; Kim, Y. Viability of exterior shading devices for high-rise residential buildings: Case study for cooling energy saving and economic feasibility analysis. Energy Build. 2014, 82, 771–785. [Google Scholar] [CrossRef]

- Grynning, S.; Time, B.; Matusiak, B. Solar shading control strategies in cold climates—Heating, cooling demand and daylight availability in office spaces. Sol. Energy 2014, 107, 182–194. [Google Scholar] [CrossRef]

- David, M.; Donn, M.; Garde, F.; Lenoir, A. Assessment of the thermal and visual efficiency of solar shades. Build. Environ. 2011, 46, 1489–1496. [Google Scholar] [CrossRef]

- Sherif, A.; El-Zafarany, A.; Arafa, R. External perforated window Solar Screens: The effect of screen depth and perforation ratio on energy performance in extreme desert environments. Energy Build. 2012, 52, 1–10. [Google Scholar] [CrossRef]

- Sherif, A.; Sabry, H.; Rakha, T. External perforated Solar Screens for daylighting in residential desert buildings: Identification of minimum perforation percentages. Sol. Energy 2012, 86, 1929–1940. [Google Scholar] [CrossRef]

- Sabry, H.; Sherif, A.; Gadelhak, M.; Aly, M. Balancing the daylighting and energy performance of solar screens in residential desert buildings: Examination of screen axial rotation and opening aspect ratio. Sol. Energy 2014, 103, 364–377. [Google Scholar] [CrossRef]

- Chi, D.A.; Moreno, D.; Navarro, J. Design optimisation of perforated solar façades in order to balance daylighting with thermal performance. Build. Environ. 2017, 125, 383–400. [Google Scholar] [CrossRef]

- Vadiee, A.; Yaghoubi, M.; Martin, V.; Bazargan-Lari, Y. Energy analysis of solar blind system concept using energy system modelling. Sol. Energy 2016, 139, 297–308. [Google Scholar] [CrossRef]

- O’Hegarty, R.; Kinnane, O.; McCormack, S.J. Review and analysis of solar thermal facades. Sol. Energy 2016, 135, 408–422. [Google Scholar] [CrossRef]

- Peng, J.; Lin, L.; Yang, H. An experimental study of the thermal performance of a novel photovoltaic double-skin facade in Hong Kong. Sol. Energy 2013, 97, 293–304. [Google Scholar] [CrossRef]

- Chan, H.Y.; Riffat, S.B.; Zhu, J. Review of passive solar heating and cooling technologies. Renew. Sustain. Energy Rev. 2010, 14, 781–789. [Google Scholar] [CrossRef]

- Lee, K.S.; Han, K.J.; Lee, J.W. The Impact of Shading Type and Azimuth Orientation on the Daylighting in a Classroom–Focusing on Effectiveness of Façade Shading, Comparing the Results of DA and UDI. Energies 2017, 10, 635. [Google Scholar] [CrossRef]

- Reinhart, C.F.; Walkenhorst, O. Validation of dynamic RADIANCE-based daylight simulations for a test office with external blinds. Energy Build. 2001, 33, 683–697. [Google Scholar] [CrossRef]

- Nabil, A.; Mardaljevic, J. Useful daylight illuminances: A replacement for daylight factors. Energy Build. 2006, 38, 905–913. [Google Scholar] [CrossRef]

- Nguyen, A.T.; Reiter, S.; Rigo, P. A review on simulation-based optimization methods applied to building performance analysis. Appl. Energy 2014, 113, 1043–1058. [Google Scholar] [CrossRef]

- Reinhart, C.F.; Herkel, S. The simulation of annual daylight illuminance distributions—A state-of-the-art comparison of six RADIANCE-based methods. Energy Build. 2000, 32, 167–187. [Google Scholar] [CrossRef]

- Meteorological Data Set for Building Thermal Environment Analysis of China; China Building Industry Press: Beijing, China, 2005.

| Group 1—PP Changes with a Fixed Number of Openings |

|

| Group 2—PP Changes with a Decreased Number of Openings |

|

| Group 3—Changes in Vertical Position with a Constant PP of 14% |

|

| Group 4—Changes in Horizontal Position with a Constant PP of 10% |

|

| Components | Material | Properties |

|---|---|---|

| Exterior wall | Brickwork, XPS extruded polystyrene, concrete block, gypsum plastering | U-value: 0.35 W/(m2·K) |

| Reflectivity: 0.753 | ||

| Floor | Concrete slab | U-value: Set as adiabatic |

| Reflectivity: 0.592 | ||

| Ceiling | Suspended plaster insulation | U-value: Set as adiabatic |

| Reflectivity: 0.702 | ||

| Glazing | Single; clear (6 mm) | U-value: 5.78 W/(m2·K) |

| Total solar transmission: 0.819 | ||

| Direct solar transmission: 0.775 | ||

| Light transmission: 0.881 | ||

| Partition | Concrete block plaster | U-value: Set as adiabatic |

| Reflectivity: 0.753 | ||

| Perforated Thermal Mass | Black cast concrete (dense) | U-value: 2.11 W/(m2·K) |

| Reflectivity: 0.753 |

| Evaluating Indicators | Average Error (kWh/m2) | Maximum Error (kWh/m2) |

|---|---|---|

| Annual Lighting Load | 0.89 | 1.79 |

| Annual Heating Load | 2.2 | 3.3 |

| Annual Cooling Load | 1.9 | 2.79 |

| Annual Transmitted Solar Gain | 1.8 | 2.8 |

| Evaluating Indicators | Group 1 | Group 2 | Group 3 | Group 4 |

|---|---|---|---|---|

| PP 20% | PP 23% | λv 0.6 | λh 0.45 | |

| Heating Load | 41.1% | 53.2% | 78.1% | 63.0% |

| “Day Lit” Area | 76% | 100% | 63% | 34% |

| “Over-day Lit” Area | 4% | 3% | 0% | 1% |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, L.; Zhao, S. Perforated Thermal Mass Shading: An Approach to Winter Solar Shading and Energy, Shading and Daylighting Performance. Energies 2017, 10, 1955. https://doi.org/10.3390/en10121955

Huang L, Zhao S. Perforated Thermal Mass Shading: An Approach to Winter Solar Shading and Energy, Shading and Daylighting Performance. Energies. 2017; 10(12):1955. https://doi.org/10.3390/en10121955

Chicago/Turabian StyleHuang, Lingjiang, and Shuangping Zhao. 2017. "Perforated Thermal Mass Shading: An Approach to Winter Solar Shading and Energy, Shading and Daylighting Performance" Energies 10, no. 12: 1955. https://doi.org/10.3390/en10121955