1. Introduction

Along with the rapid development of global economy over the past several decades, the power demand has increased continuously, and a large amount of hydro and thermal plants have been successively built to supply sufficient energy [

1,

2,

3]. However, thermal plants inevitably produce emissions of pollutants like sulfur oxide and nitrogen oxide, which gives rise to a series of serious environmental problems and high social economic costs [

4,

5,

6]. Given to strong awareness about sustainable development, short-term economic environmental hydrothermal scheduling (SEEHTS) is becoming one of the most important optimization problems in modern electrical power systems [

7]. The main aim of SEEHTS is to choose the optimal operational process in a scheduling period to minimize the total fuel cost and pollutant emission cost simultaneously, while satisfying a group of equality and inequality constraints imposed on the system, including generation limits of hydro and thermal plants, storage and discharge limits and hydraulic balance of hydro plants, and load balance. Hence, due to the coupling characteristics in constraints and the competitiveness between objectives, SEEHTS becomes a high-dimensional multi-objective constrained optimization problem [

7,

8].

Many researchers have been applying every effort to develop efficient optimization algorithms to solve the SEEHTS problem. These methods can be roughly divided into two categories: one is single-objective optimization algorithms and the other is multi-objective optimization algorithms [

9]. The former methods usually use the method of weighting, target or constraints conversion to transform the SEEHTS into a single-objective problem, then use standard mathematical methods, like linear programming or nonlinear programming to solve it. Although a great deal of computation can be avoided in most cases, there are such issues as sensitivity to transformation coefficients, high memory requirements, and difficulty to obtain compromise solution sets in one trial [

10].

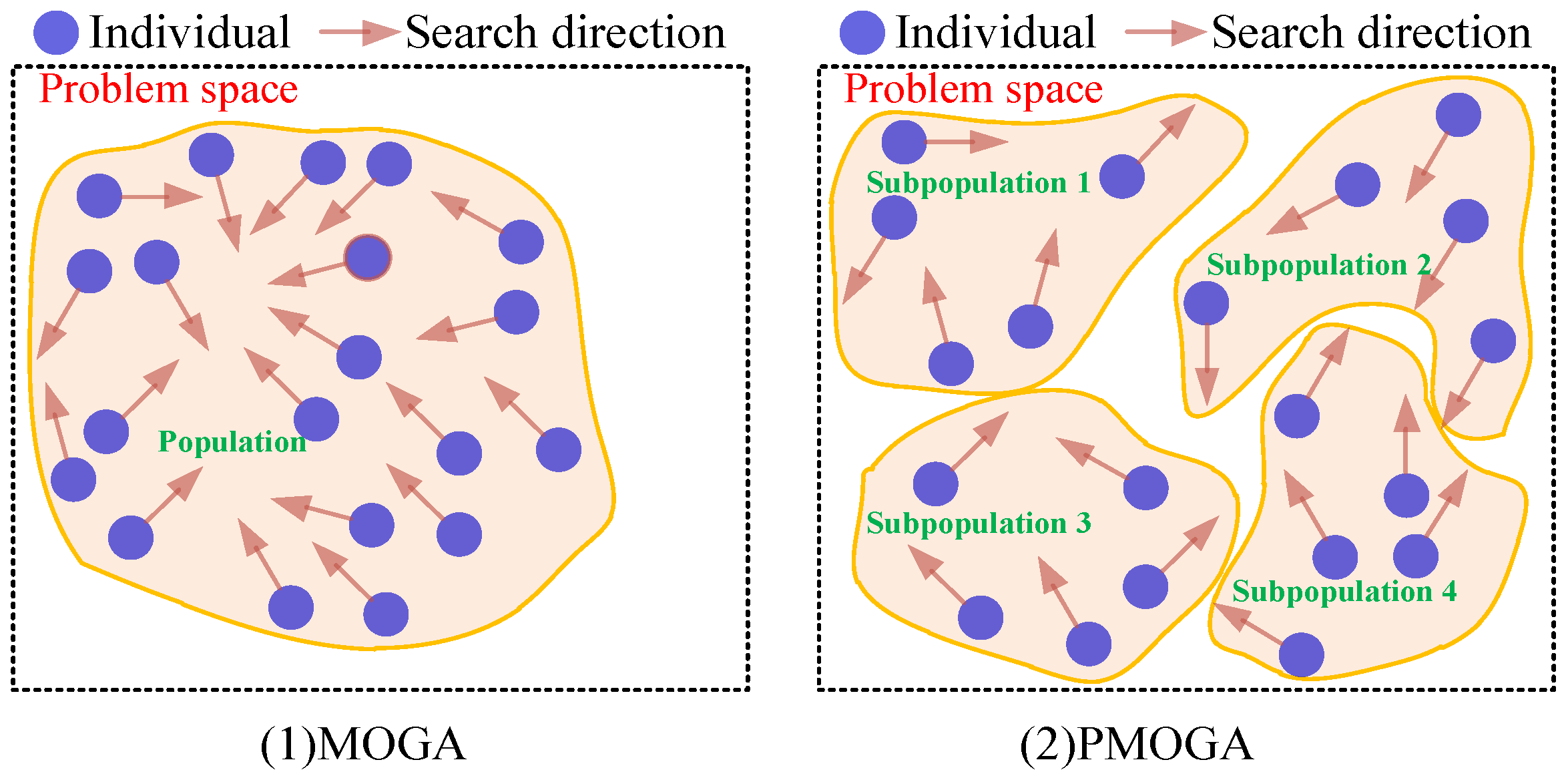

On the other hand, the latter mainly use multi-objective evolutionary algorithms (MOEAs) such as the multi-objective genetic algorithm (MOGA), multi-objective particle swarm optimization, multi-objective gravitational search algorithm, and multi-objective differential evolution to handle the SEEHTS problem [

11,

12]. The MOEAs have no strict requirements on the continuity and differentiability of optimization problems, and usually are able to obtain Pareto solution sets rather than one solution in a single run [

13]. However, due to the stochastic optimization mechanism, MOEAs may suffer from the problems of premature convergence and solution volatility [

14,

15,

16]. Sometimes, the satisfactory Pareto solutions cannot be obtained. In addition, when the problem scale reaches a certain large degree, the population diversity and computation cost will be intolerable [

17,

18,

19]. Thus, there is some space to improve MOEAs for the SEEHTS problem. In general, we can modify the search mechanism of MOEAs or use advanced computer technologies to alleviate these defects [

20,

21]. Here, parallel technologies are used to enhance the performance of MOEAs.

Recently, with the increasing popularity of multi-core technology, multi-core processors have become the standard configuration of personal computers, workstations and servers, providing the essential hardware conditions for the implementation of parallelization [

22,

23]. For parallel computation in multi-core computers, the large computational task is divided into several smaller subtasks to be concurrently executed in different cores [

20], which can help shorten the computing time and improve the resource utilization efficiency [

24]. Nowadays, multi-core parallel computing technology is a hot research area achieving great success in the fields of scientific research and engineering practice [

21,

25]. However, to our knowledge, there are a few reports about using the multi-core parallel technology to solve the SEEHTS problem. Therefore, it is of great importance to develop parallel optimization algorithms for the SEEHTS problem, and in the paper, we focus on the multi-core parallelization of MOEAs to solve the complicated SEEHTS problem.

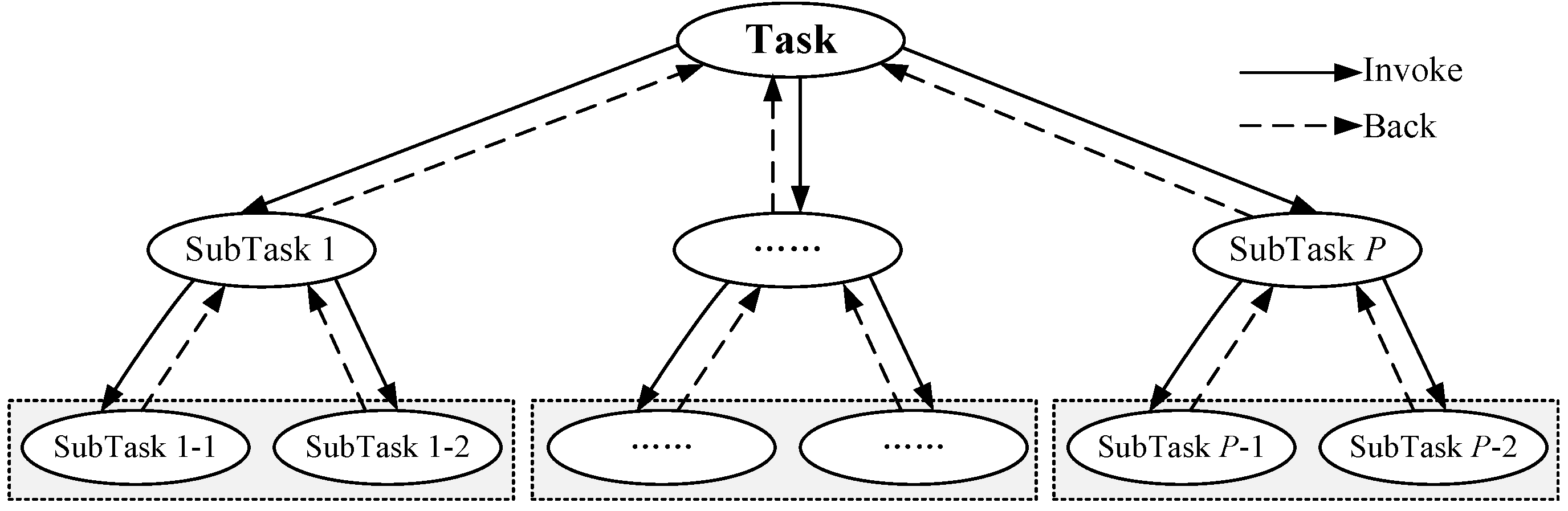

To achieve parallel computing, many parallel frameworks have been developed by different companies or institutions, such as Fork/Join, open multi-processing and message passing interface [

21]. Since the parallel framework can have a significant impact on the performance of parallel algorithms, we should take many factors into consideration when choosing the framework, such as programming language and operating environment [

26,

27]. Here, given that our algorithms are encoded in Java language, for the ease of implementation, the Fork/Join framework is used for the realization of algorithm parallelization [

24,

28]. As a standard Java parallel program platform, Fork/Join can help programmers design parallel optimization algorithms with cross-platform advantages. Based on the non-dominated sorting genetic algorithm-II (NSGA-II) [

17,

29,

30,

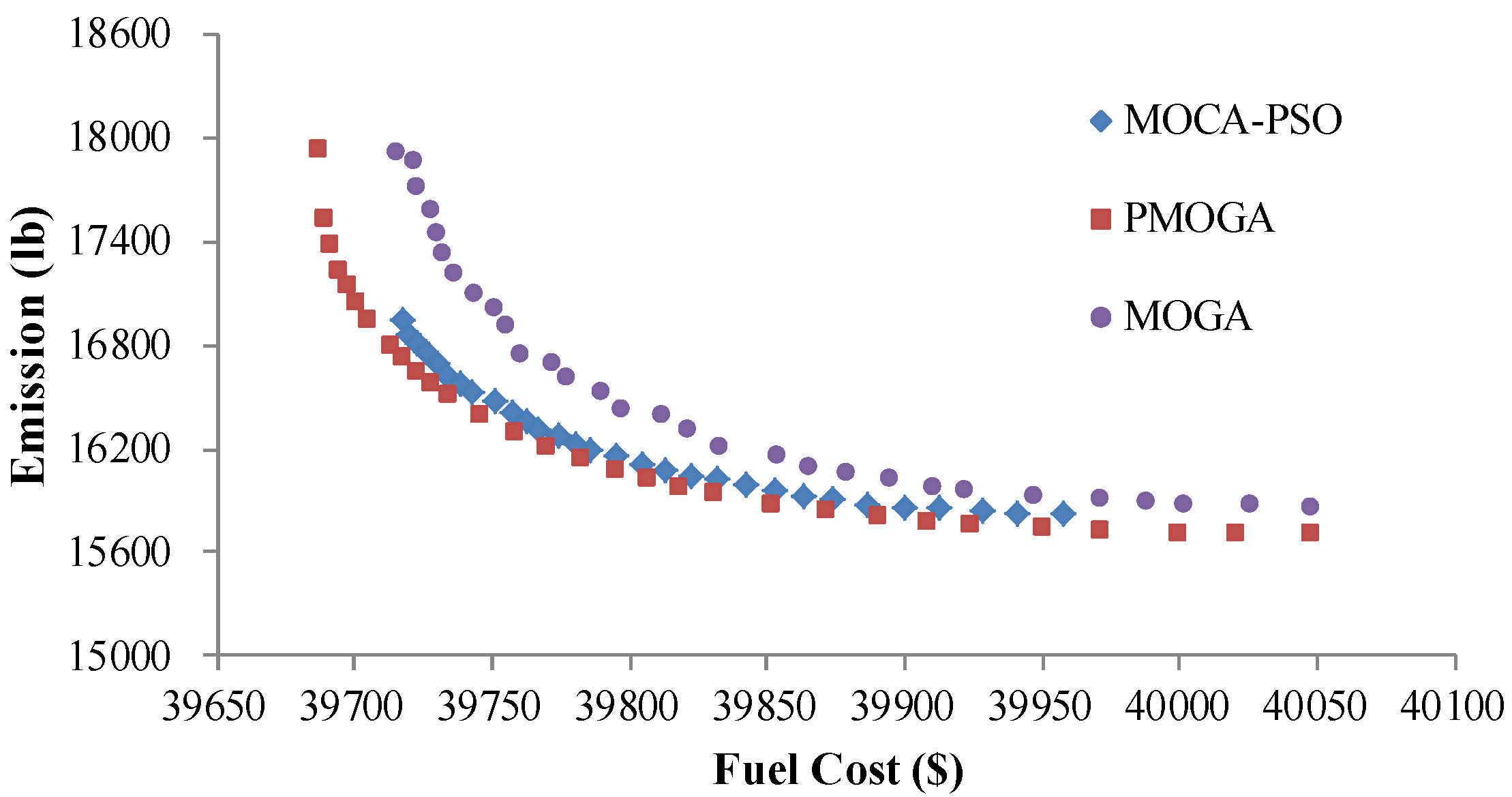

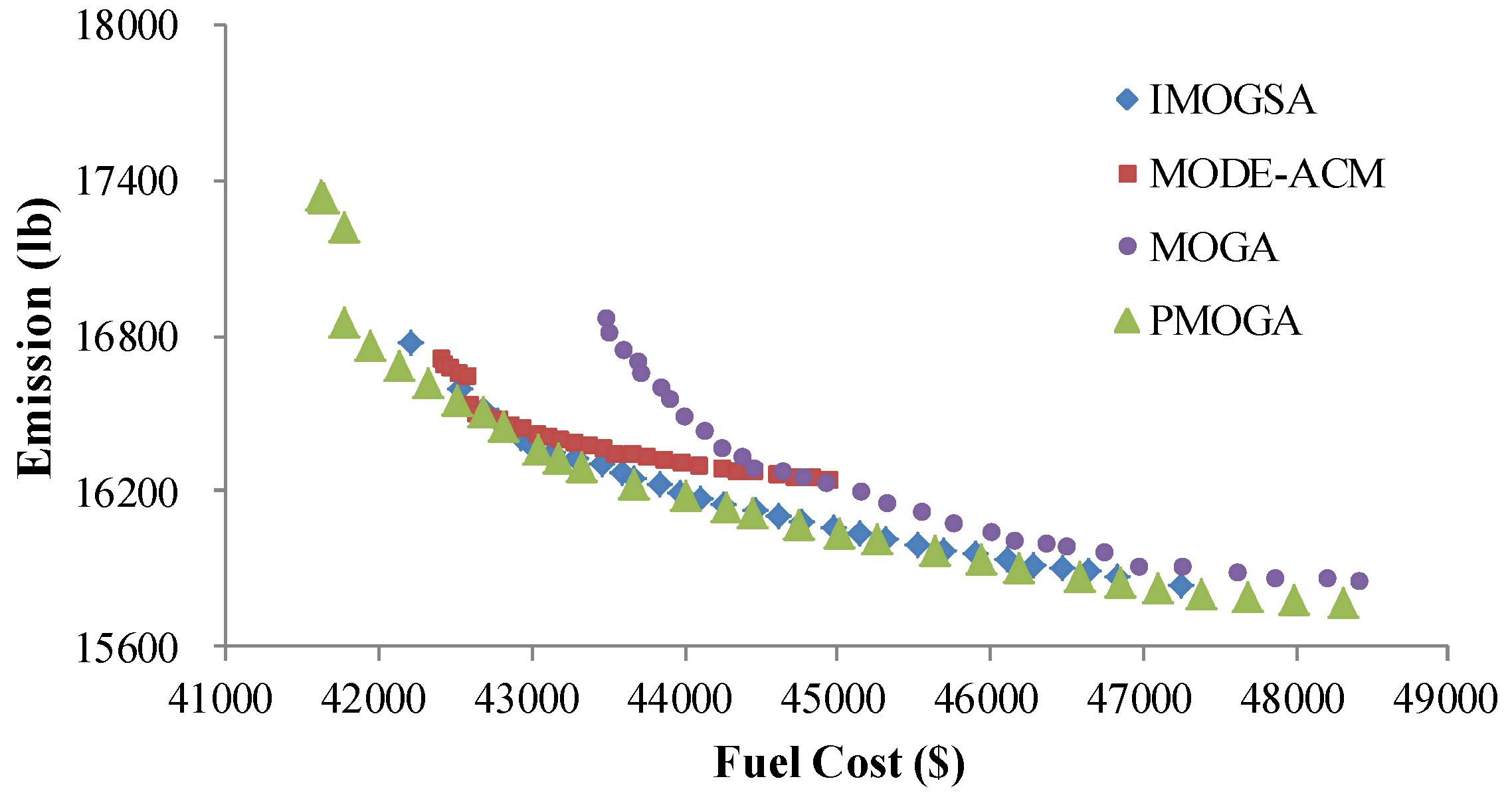

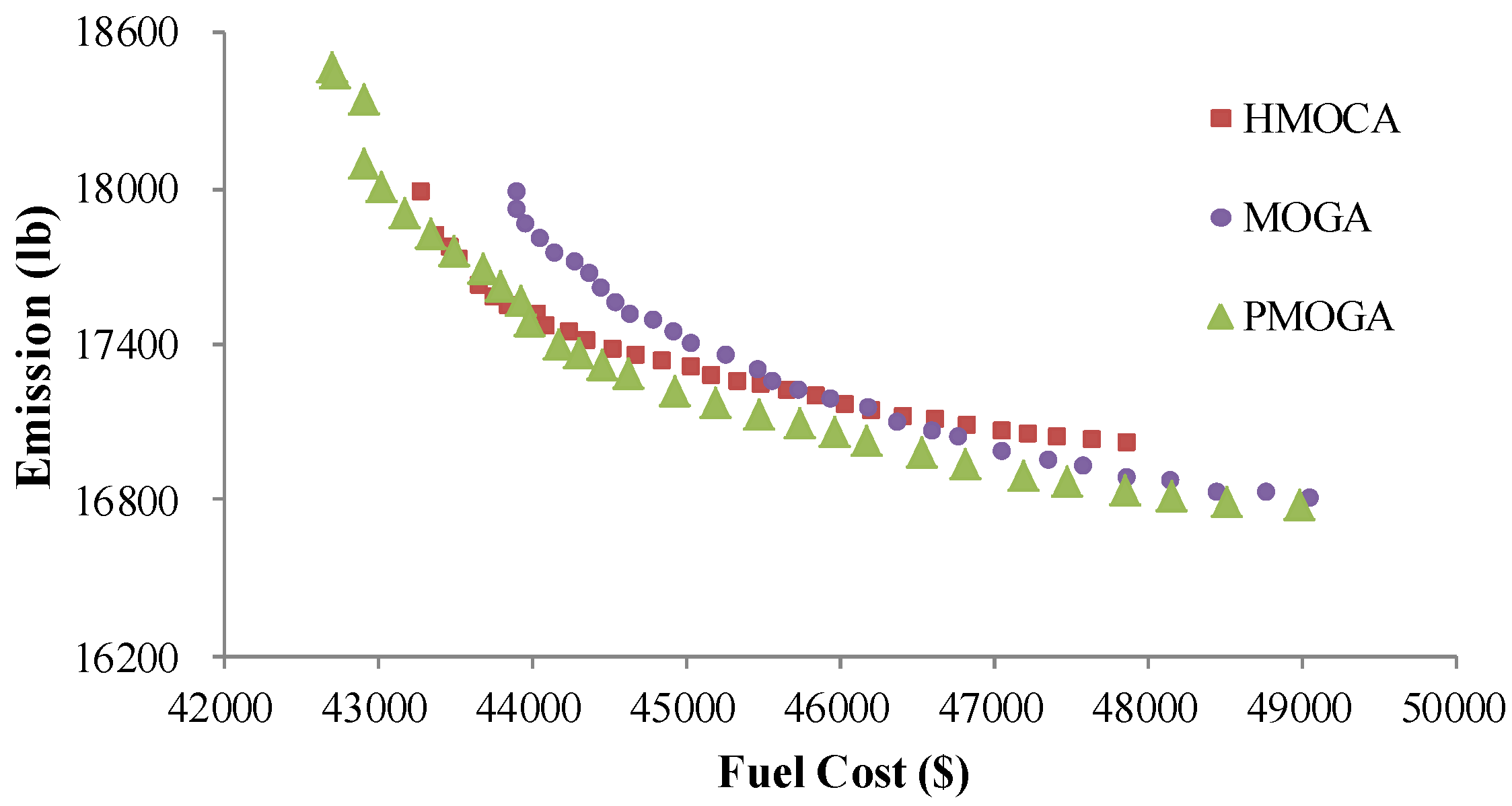

31], the parallel multi-objective genetic algorithm (PMOGA) which combines the merits of NSGA-II and parallel computing is proposed. Finally, PMOGA is applied to a mature hydrothermal system consisting of four hydro plants and three thermal plants. The results from different cases show that the proposed approach has better convergence speed and Pareto optimal front performance than traditional methods, demonstrating the effectiveness of our methods.

Moreover, to clearly understand our work, the contributions of this paper can be summarized as: (1) an optimization model is presented for SEEHTS; (2) a novel PMOGA combining the advantages of MOGA and parallel techniques is proposed to enhance the computational efficiency and population diversity simultaneously; (3) a new heuristic constraint handling method based on the two-stage proportional adjustment idea is proposed to ensure the feasibility of solutions; and (4) our method outperforms several other methods, which proves to be an alternative tool for the SEEHTS problem.

The rest of this paper is organized as follows.

Section 2 introduces the mathematical model for the SEEHTS problem.

Section 3 presents the proposed PMOGA method.

Section 4 gives the details of PMOGA for the SEEHTS problem.

Section 5 provides the experimental results and discussions.

Section 6 presents the conclusions.

4. PMOGA for Short-Term Economic Environmental Hydrothermal Scheduling

In this section, some practical strategies are proposed to deal with complicated constraints in the SEEHTS problem.

4.1. Structure of Individuals

For convenience, the water discharge of hydro plants and power generation of thermal plants are selected as decision variables for evolution. The structure of an individual is expressed by the following real-coded matrix consisted of some decision variables:

Thus, each individual contains the detailed scheduling decision information of all the NH + NT generators in T periods, and the total dimension of the population is NP·(NH + NT)·T, where NP denotes the number of individuals in the population.

4.2. Initialization of Individuals

During the initialization phase, the elements of all the

NP individuals are generated randomly in the feasible range of water discharge in hydro plants and power output in thermal plants, which is as follows:

where

U(0,1) denotes the number distributed uniformly in the range of [0,1].

4.3. Constraint Handling Method

Since the SEEHTS involves a number of complex constraints, the newly generated individuals in the initialization phase and evolution process may not satisfy all the necessary constraints, which will influence the convergence speed of algorithms [

29,

33]. Thus, a heuristic strategy for repairing infeasible solutions is proposed in this section to enhance the computing efficiency of algorithms. Moreover, the equality constraints (power and water balances) are solved through an iterative scheme for each set of values of decision variables given by the optimizer, and they are not handled as part of the optimization algorithm, while only bounds and inequality constraints are handled by the optimizer.

4.3.1. Inequality Constraints Handling Method

When the elements of the newly generated individuals do not satisfy the boundary constraints, the following formula will be used to modify the infeasible values:

4.3.2. Water Balance Constraints Handling Method

To deal with the water balance constraints, a two stage proportional adjustment method is proposed. This method first calculates the total water discharge volume, and then adjusts the water discharge sequence by the relative weight which is gotten by the original water discharge rate in the total left water discharge volume. The procedure is as follows:

- Step 1:

Set the hydro plant index k = 1.

- Step 2:

Calculate the total water discharge of the

kth hydro plant. According to Equations (11) and (12), the terminal reservoir storage volume

can be expressed as follows:

Thus, the possible total discharge rate Wk of the k-th hydro plant during the whole scheduling periods is as follows:

- Step 3:

Use the following formula to adjust the water discharge rate to be feasible value at any periods, and then the modified water discharge sequence

is used to calculate the corresponding storage volumes of the

kth hydro plant in the scheduling periods.

- Step 4:

Set , and if , go to Step 2; otherwise, the process to adjust water balance constraints is done.

4.3.3. Power Balance Constraints Handling Method

In this section, to satisfy the power balance constraints, the output of thermal plants is adjusted without changing the output of hydro plants in the previous adjustment. The procedure is as follows:

- Step 1:

Set the period index j = 1.

- Step 2:

Calculate the power transmission loss by Equation (5) and the total power output

Dj left for thermal plants by Equation (21).

- Step 3:

Use the following formula to adjust the power output of all thermal plants to be feasible value at the current period:

- Step 4:

Set j = j + 1, and if j ≤ T, go back to Step 2; otherwise, the process for handling load balance constraints is done.

4.4. Selection Strategy Based on Constraint Violation

In theory, the individuals modified by the above constraint handling process can satisfy all the constraints imposed on hydrothermal systems. However, it is possible that some infeasible solutions still exist because of various problems. Thus, after the elements are modified to be feasible values during the constraint handling process, the total violation of individual X will be calculated by summing the violation of storage volume, power output and system balance, which is as follows:

From the above equation, it can be found that TV will be zero and a positive number for feasible solutions and infeasible solutions, respectively. Here, to make full use of the constraint violation information, the dominance relationship between any two solutions X1 and X2 is modified as below: (1) the feasible individual always dominates the infeasible one; (2) between two feasible individuals, the dominance relationship is determined by the objectives and crowding distance; (3) between two infeasible candidates, the one with smaller violation value is chosen.

4.5. Outline of PMOGA for the SEEHTS Problem

The outline of PMOGA for solving the SEEHTS problem is presented as below:

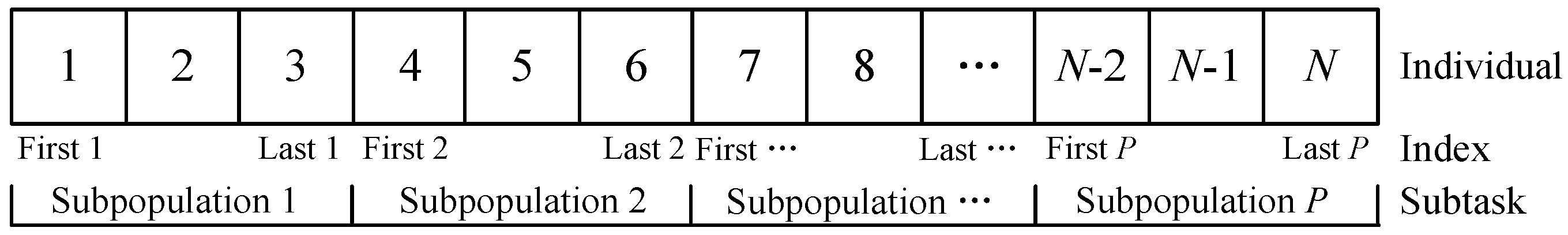

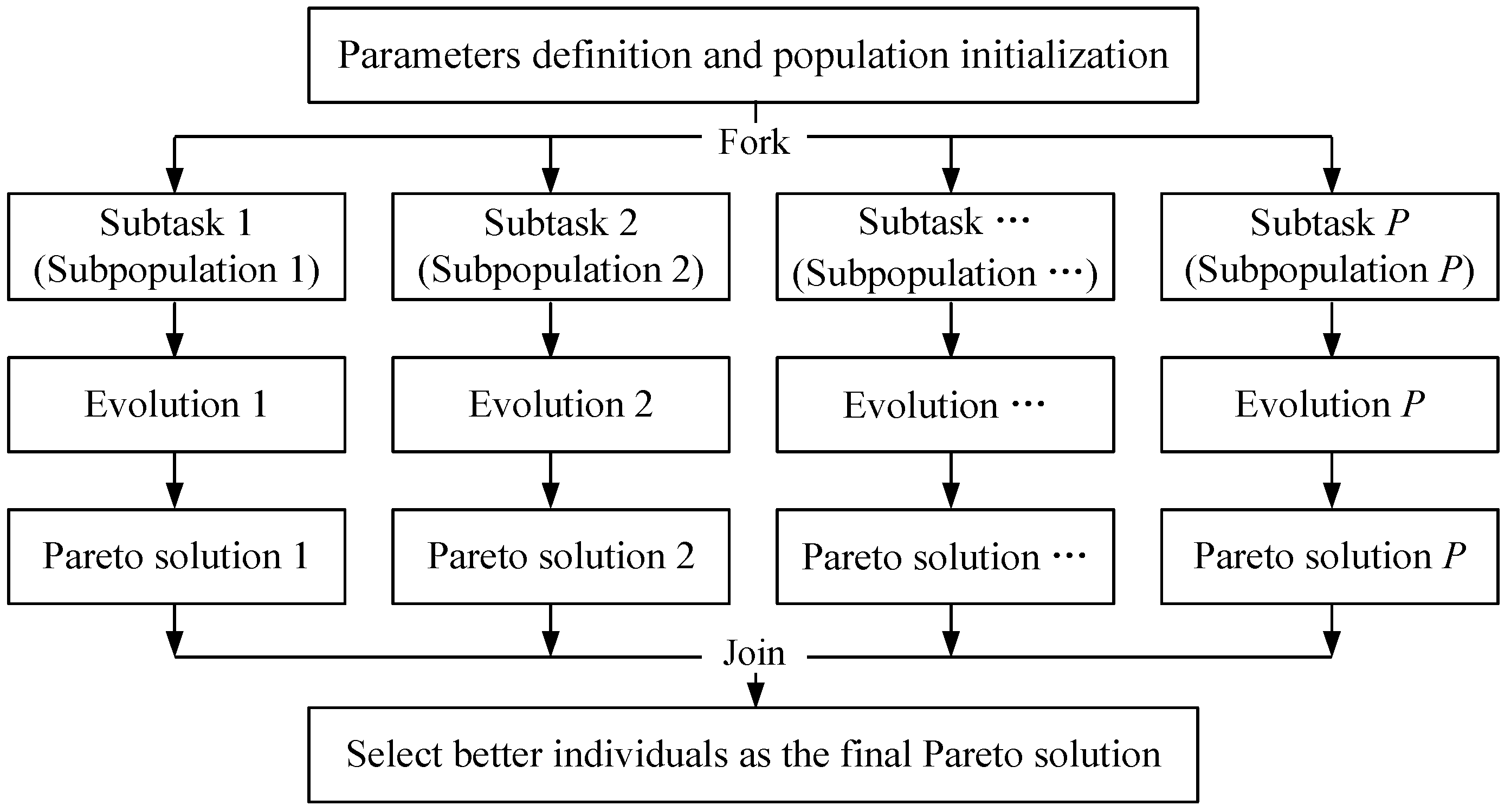

- Step 1:

Preparation. Set the computing parameters, such as the population size, the maximum iteration and the worker threads for parallelization.

- Step 2:

Initialization. Use the method in

Section 4.2 to initialize all the individuals randomly in the problem space. Then, the main thread creates a thread pool and divides the whole population into several subpopulations to be concurrently optimized.

- Step 3:

Subpopulation evolution. For any one subpopulation, use the corresponding crossover, mutation and selection operators to generate the members for the next cycle, and the whole iterative process will not be stopped until the maximum iteration is reached. To be mentioned, for the target subpopulation, the constraint handling method in

Section 4.3 is used to repair infeasible solutions, while the method in

Section 4.4 is employed to verify the performance of solutions.

- Step 4:

Stop the calculation. The main thread will shut down the thread pool when all the subpopulations finish the calculation. Meanwhile, the results of each subpopulation are collected to form up the optimal Pareto solution set that will be exported as the final solutions for the problem.