1. Introduction

Nuclear power has a large unit capacity and requires high-level security. Nuclear power units are sensitive to system voltage and frequency fluctuations, because a sudden load rejection or cutting machine connected to the power grid may cause a big impact on the grid voltage and frequency stability [

1,

2]. The second-generation, or the improved second-generation nuclear technology were among the most effective methods being used, until the Fukushima nuclear accident in 2011. The newly constructed nuclear power plants (NPPs) worldwide are required to implement nuclear technology with higher security protection systems. For example, the third-generation nuclear reactor system, the AP1000 (i.e., Advanced Passive pressurized water reactor (PWR)) developed by Westinghouse Electric Corporation (USA), represents one of the important approaches for nuclear power development with unique, passive safety features, a relatively simplified plant layout design, as well as large unit capacity and high security requirements. However, it still lacks an applicable simulation model for third-generation PWR units. In addition, the primary loop system model parameters are still difficult to acquire. Furthermore, obtaining an effective model and the parameters of a PWR primary loop system is important for reactor safety, as well as for power system stabilization analysis and control.

A lot of research work has been done concerning second-generation nuclear power plant (NPP) modeling, including simulators, simulation software and user-defined modeling of various reactor types [

3,

4,

5,

6,

7,

8,

9]. The whole process simulator of the nuclear power could provide important training and accident simulation functions for NPP operators [

3]. The Westinghouse Electric Corporation (Pittsburgh, PA, USA) developed the high-fidelity Personal Computer Transient Analyzer (PCTRAN) simulation software based on a personal computer in 1985, which was selected as an advanced reactor simulation software by the International Atomic Energy Agency. It has been widely used for simulation and transient accident analysis with high simulation efficiency [

4], but the software expandibility for power system simulation analysis was hard. The approach of predictive control was applied to the NPP model [

10]. For current large-scale power system analysis, the established model was mainly aimed at second-generation PWR nuclear power units [

7,

8,

9]. There is an urgent need to perform more intensive studies on third-generation PWR unit models and parameters.

Much parameter identification work had been done on the excitation system and the prime mover speed control system model [

11,

12,

13], but there have only been a few studies about NPP parameter identification. The discrete sequence estimation method was applied for parameter identification of the nuclear reactor model [

14]. Based on the simplified PWR primary loop model, the simplex method was used for parameter identification with measured data [

15,

16]. The multidirectional search method was used for parameter identification based on the reduced PWR nuclear power plant model and for comparison of data from the Reactor Excursion and Leak Analysis Program (RELAP5) Software (Idaho National Engineering Laboratory, Idaho Falls, ID, USA) [

17]. The above NPP model parameter identification methods have the shortcoming of high requirements for identified models and initial parameter values, which is satisfactory for a nonlinear system or model signals with noise. The Monte-Carlo method was adopted for state estimation of a simplified third-order neutron flux dynamic model considering xenon poison feedback [

18].

The intelligent optimization algorithm is a good solution for the NPP identification problem. Neural networks were used for malfunction transient identification of the Hungarian Paks nuclear power plant simulator [

19]. The particle swarm optimization (PSO) algorithm has been used for nuclear engineering applications for fuel reloading, reactor core design, plant transient identification, maintenance scheduling and so on [

20,

21,

22,

23]. The PSO computational implementation is much simpler [

20]. PSO was also used for a mechanism model of a pressurizer in a PWR nuclear power plant [

24].

The NPP primary loop system model has a complex structure, including the following variables: electrical, temperature and pressure. The neutron flux density of a core neutron dynamic module changes rapidly, while the temperature and pressure changes of a steam generator module are slow. The different orders of magnitude for parameters also make it harder to identify parameters.

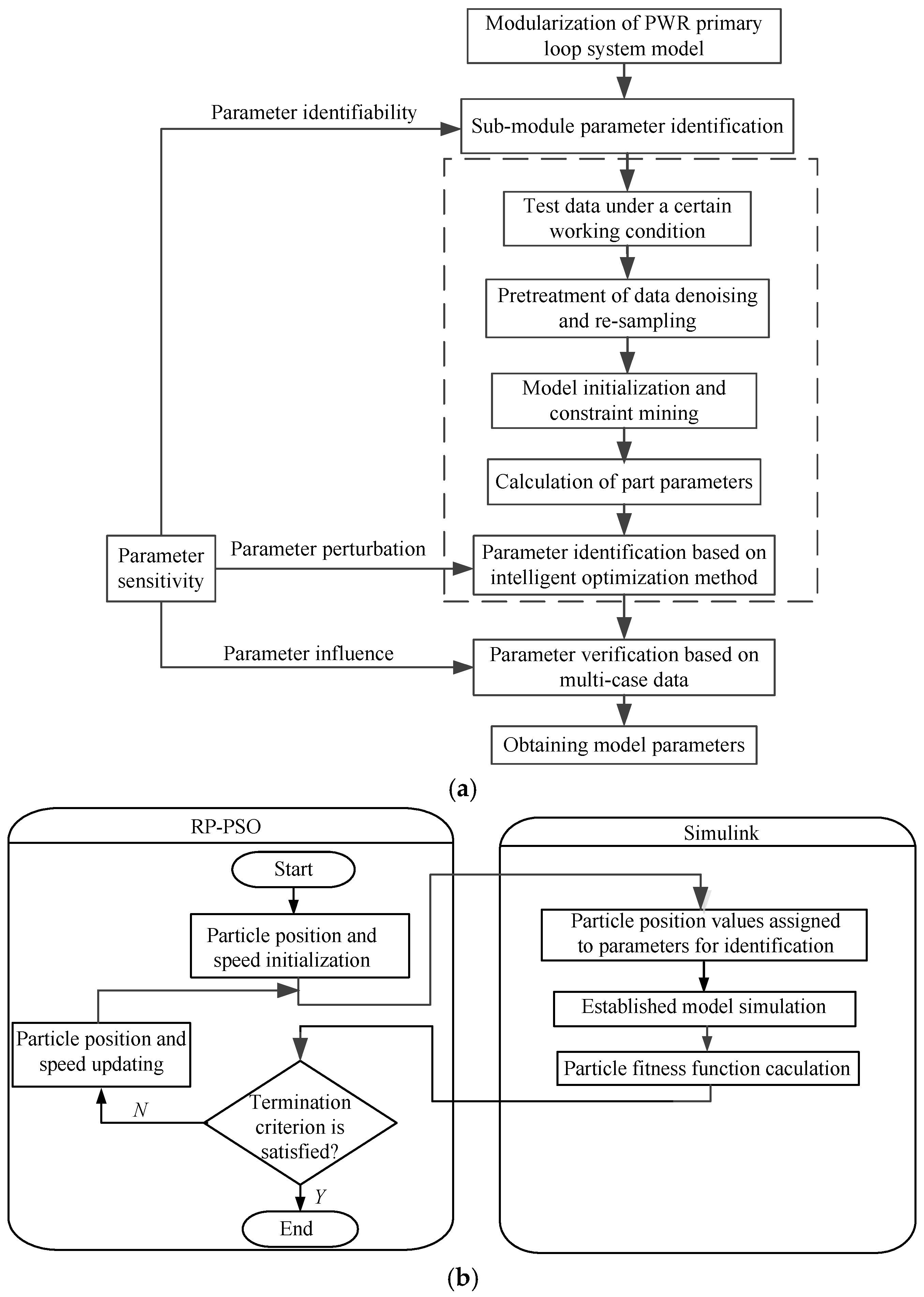

The organization of this paper is as follows. The advanced PWR nuclear power plant model was divided into several sub-modules for parameter identification and validation in

Section 2. The parameter identification method and process were developed in

Section 3. For each module, we selected appropriate tested data for input and output model variables, then preprocessed the noise reduction, data resampling and data normalization to get the disposed data for parameter identification. After obtaining the variable and parameter constraints, we calculated some parameters according to the operating characteristics and identified the other parameters.

Section 4 contains the model initialization through variable steady calculation based on differential equations and a program setting method. The parameters were identified under various conditions using the RP-PSO algorithm in

Section 4. The integrated model adaptation was checked in comparison with the PCTRAN software in

Section 5. Thus, the primary loop system model parameters of a third-generation PWR nuclear power plant suitable for power system analysis were obtained. The sensitivity analysis of parameters was performed in

Section 4 and

Section 5. The results and discussion were presented in

Section 5 as well.

Section 6 presents the conclusion drawn thereof.

2. Pressurized Water Reactor Nuclear Power Plant Mathematical Model

Considering the main equipment, subsystem boundary, operating characteristics and operational parameter testability, the PWR primary loop system model was divided into multiple sub-modules adopting modular modeling method. The established model should fully reflect the energy generation, transmission and transformation process in a NPP. The focus was on the subsystems that had a greater influence on the power plant physical process. The subsystems with lower impact were simplified.

Based on the second-generation PWR nuclear power plant model [

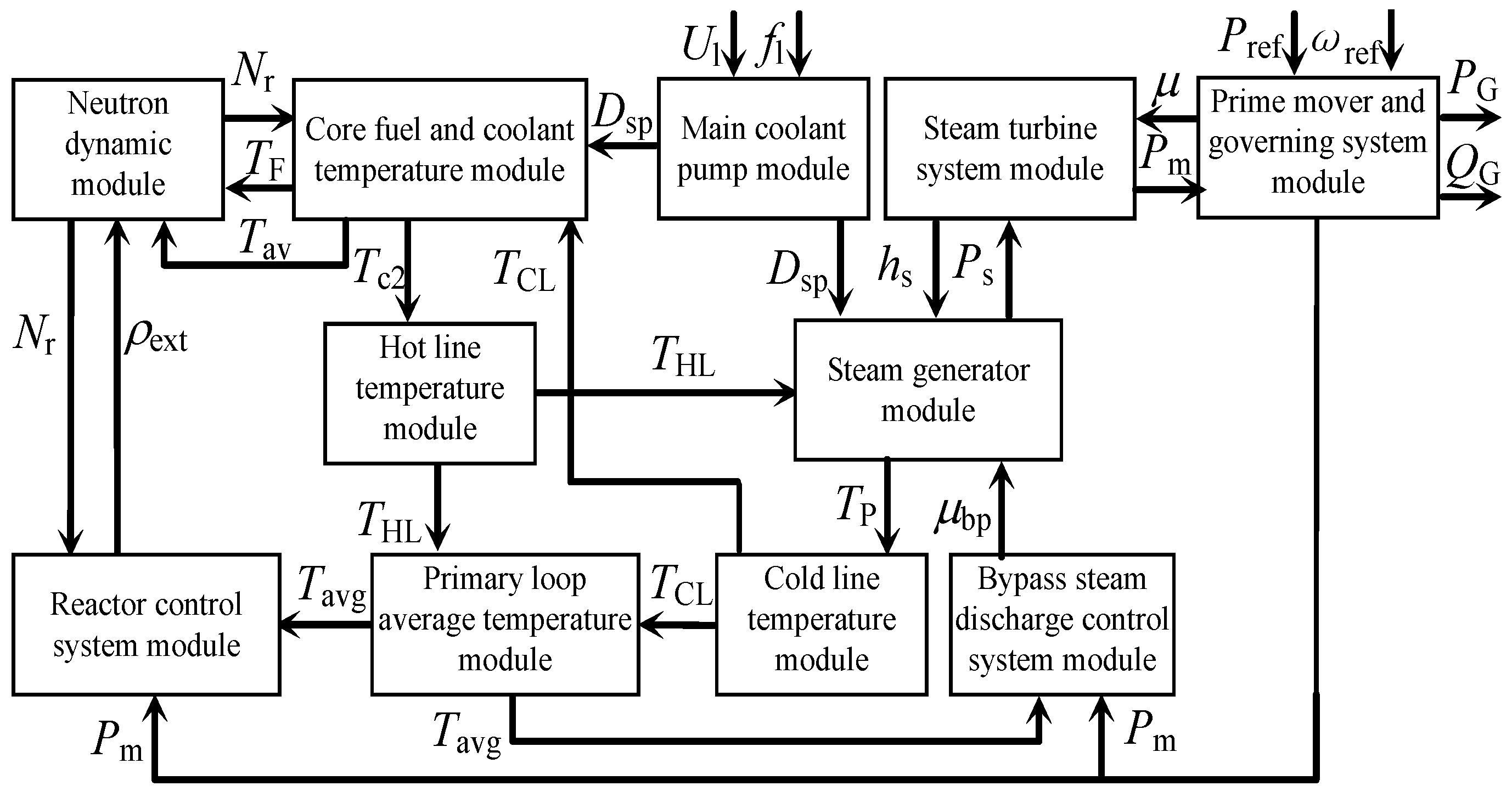

9] and the characteristics of the third-generation nuclear power plant, the dynamic AP1000 model of the primary loop system was established for power system simulation. It contains the core neutron dynamic module, the core fuel and coolant temperature module, the hot line and cold line temperature module, the primary loop average temperature module, the steam generator module, the reactor power control system module and the main coolant pump module.

Figure 1 shows each sub-module with multi-input multi-output (MIMO) characteristics that are coupled with each other to form an integrated system.

In this figure μ is the tone opening. Pref and ωref are the given unit power and speed, respectively. PG and QG are the generator output active power and reactive power, respectively. hs is the outlet steam specific enthalpy.

2.1. Reactor and Coolant System Model

Considering the effect of delayed neutrons, the neutron flux density is assumed in the same shape of the spatial distribution at different times. Considering the core and coolant system as a lumped parameter system to simulate normal operation as well as transient processes of the reactor and coolant system, the point reactor kinetics equations of the core neutron dynamic module are as follows:

where

l is the average neutron lifetime,

β is the total share of delayed neutron group and

λ is the time delay of equivalent delayed neutron group.

Cr is the precursor nuclear density of equivalent single set of delayed neutron.

αF and

αC are the reactivity coefficients of the fuel temperature and coolant temperature, respectively.

Considering the effect of nuclear fission energy on fuel temperature, as well as the heat energy transferred from the fuel to the core coolant, according to energy conservation law and volume balance, the mathematical model of core fuel and coolant temperature module is given by the following expression:

where

TF0 and

Tav0 are the initial temperature values within the fuel and core coolant, respectively.

P0 is the core thermal power.

Ff is the heating fuel share.

Ω is the heat transfer coefficient between fuel and coolant in the core.

μf and

μc are the heat capacities of fuel and core coolant, respectively.

M =

Dsp ×

Cpc ×

mCn, in which

Cpc is the coolant heat capacity and

mCn is the rated coolant mass flow.

Ignoring the heat loss of coolant in the pipeline, according to energy conservation law and volume balance, the hot line and cold line temperature module is given by the following equation:

where

τHL and

τCL are the coolant hotline and cold line time constants, respectively. Considering the coolant measuring sensor characteristics, the measured average temperature of the coolant loop circuit can be expressed using first-order inertial link as follows:

where

τc is the temperature measuring time constant of coolant.

2.2. Steam Generator Module

The AP1000 NPP uses two Δ125-type U-shaped natural circulation steam generators. Assuming the thermal power from the main pump transmitted to the primary circuit coolant can be neglected, the specific heat of the U-shaped heat transfer tube, the specific heat and density of the coolant are treated as constants. According to mass balance, volume balance and energy conservation law, a steam generator model with centralized parameters containing temperature and pressure equations is established as shown in Equation (5):

where

Tp is the average temperature of the primary coolant.

Tm denotes the U-shaped heat pipe temperature.

KPs is the steam pressure time constant.

KPs_Ts(

Ps) is the conversion relation between the main steam pressure and temperature of the secondary circuit.

Ωp is the heat transfer coefficient between coolant in steam generator and U-shaped heat pipe.

ΩS is the heat transfer coefficient between U-shaped heat pipe and secondary loop steam.

μp and

μm are the heat capacities of coolant in the steam generator and U-shaped heat pipe, respectively.

hfw is the inlet temperature specific enthalpy of secondary loop feed water.

2.3. Main Coolant Pump Module

The main coolant pump of the AP1000 is a shielded motor pump, mainly used to complete the circulation of the reactor coolant. The main coolant pump module is established considering the influence of auxiliary power supply voltage and frequency on the main coolant pump speed and flow rate, as shown in Equation (6):

where

Tpj is the inertia time constant of main coolant pump rotor.

and

are the electromagnetic torque and resistance moment per-unit values, respectively.

ke1 and

ke2 are the characteristic coefficients of the asynchronous motor.

and

are the speed and rated speed per-unit values of the asynchronous motor, respectively;

is the auxiliary power bus frequency per-unit value;

is the auxiliary power bus voltage per-unit value and

is the main coolant pump flow per-unit value.

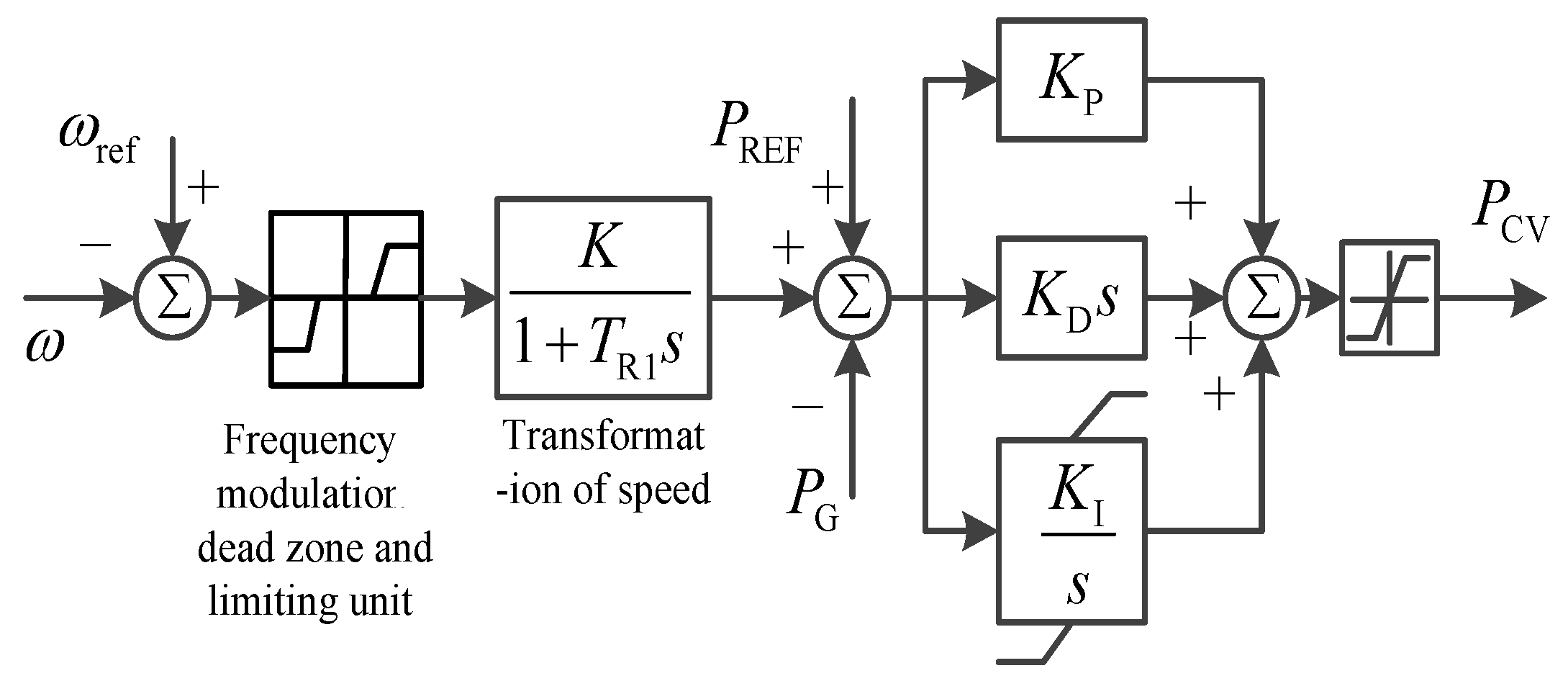

2.4. Reactor Power Control Module

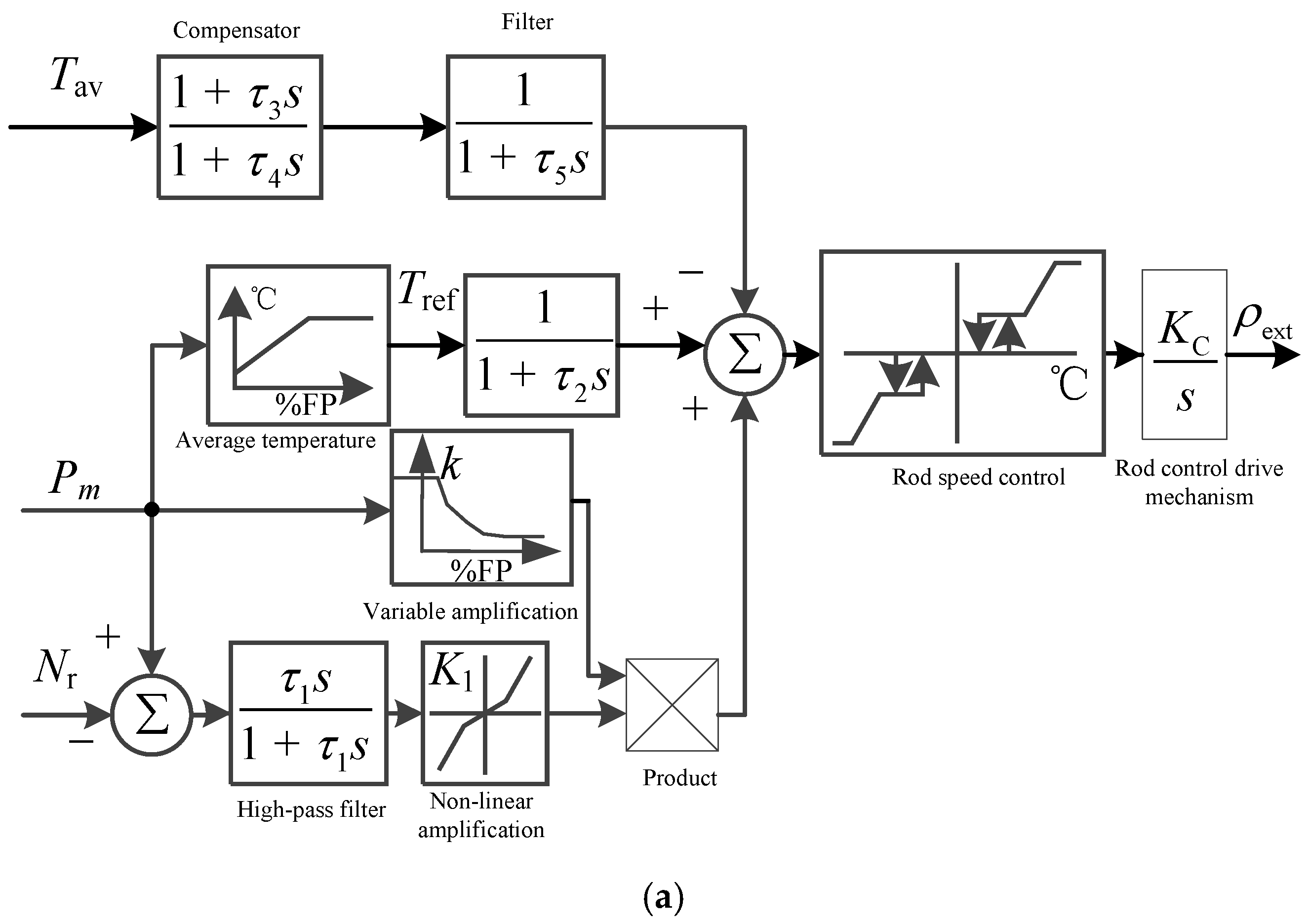

The PWR reactor power control module adjusts the reactor neutron flux density which reflects the core power by removing or inserting rods. The dead zone and hysteresis links are applied to maintain the average primary coolant temperature in the designed control band.

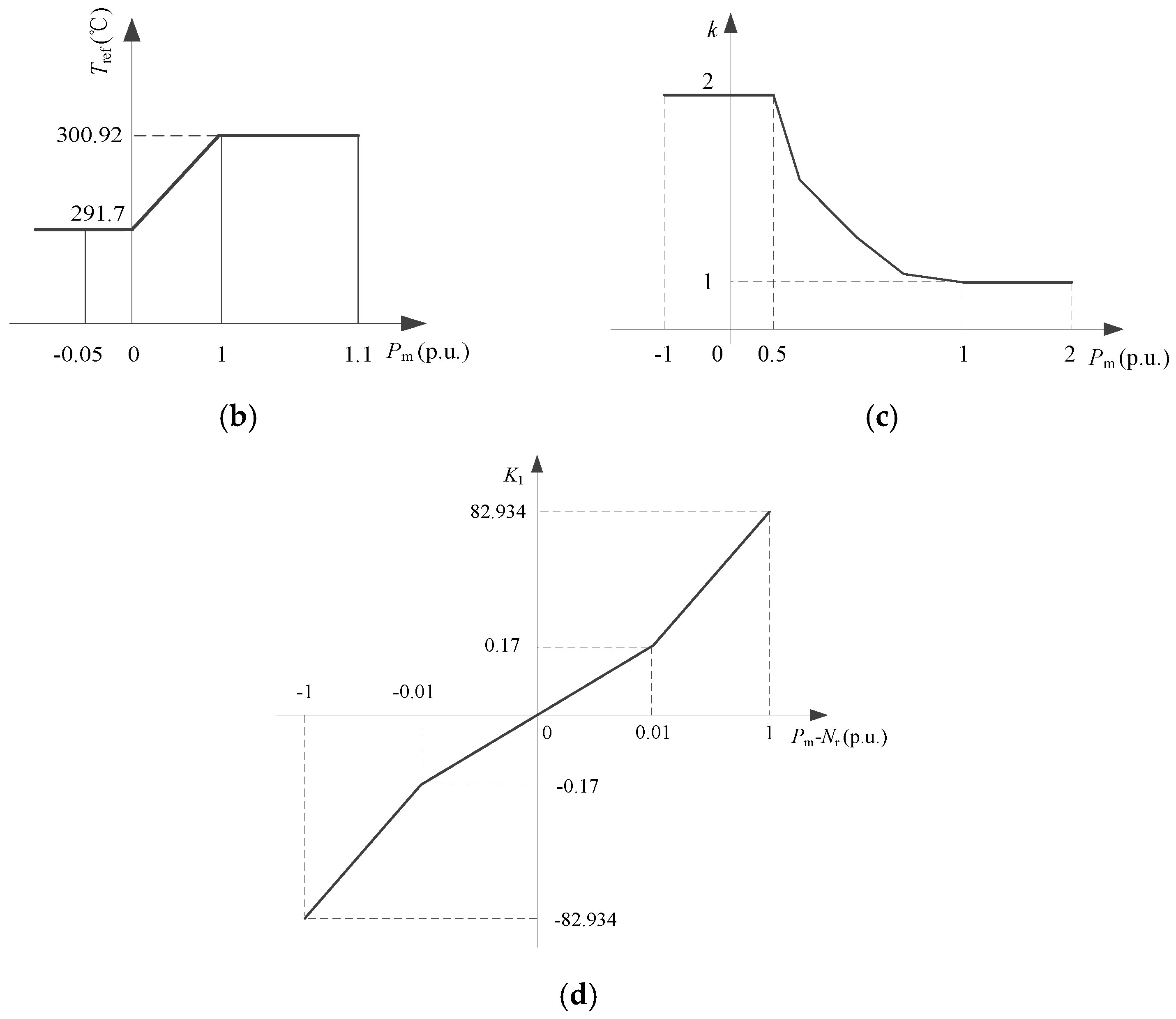

Figure 2 showed the third-generation reactor power control system module including the average temperature link, the variable amplification link, the nonlinear amplification link, the rod speed control link, the compensator and filter link. The variable measurement links were omitted. The rod speed varies over the range of 8–72 steps per minute depending on the input signal level.

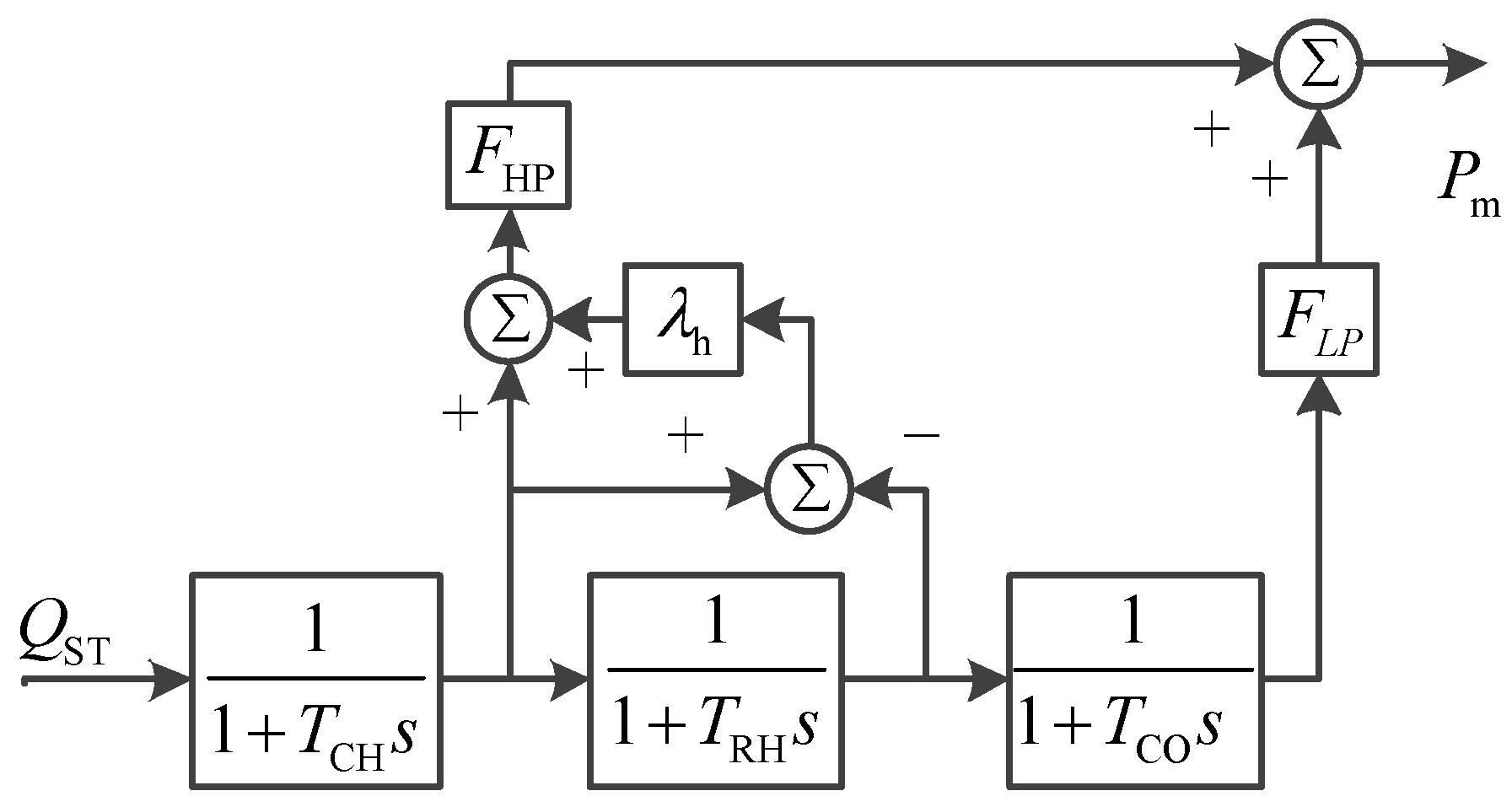

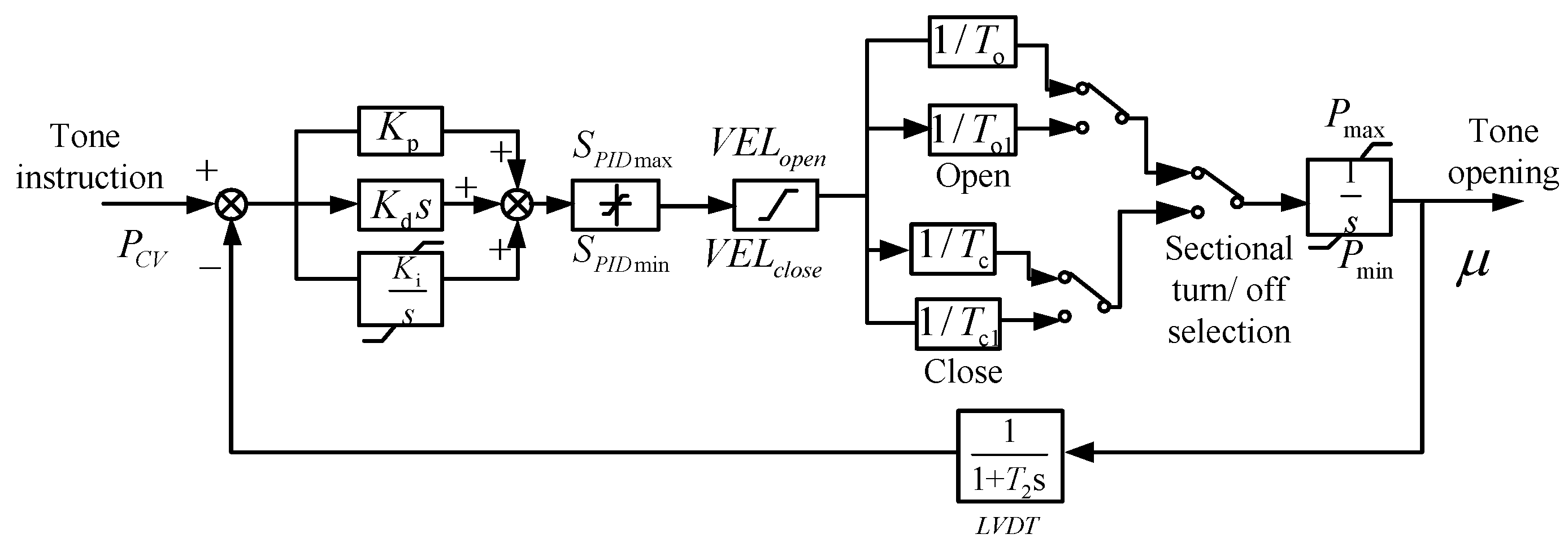

2.5. Steam Turbine and Its Control System Module

The steam turbine of the AP1000 has characteristics of a single-shaft with four-cylinder (i.e., a high-pressure cylinder and three low-pressure cylinders) reheat condensing steam turbine at half speed. A digital electric-hydraulic governor is used to respond to the frequency and power changes. The steam turbine module, speed control system module (i.e., the governor and electro-hydraulic servo system) and turbine bypass control system module suitable for the AP1000 are shown in

Figure 3,

Figure 4,

Figure 5 and

Figure 6, respectively, in which the main turbine steam flow is shown as follows:

where

Psn is the rated main steam pressure.

In

Figure 5,

Kp,

Ki and

Kd are the proportional, integral and differential coefficients, respectively.

SPIDmax and

SPIDmin are the upper and low limits, respectively.

VELopen and

VELclose are the rapid opening and rapid closing coefficients, respectively.

T2 is the time constant of oil motive stroke feedback link, usually taken as 0.02 s.

To and

Tc are defined as the main on/off time constants while

To1 and

Tc1 are defined as the auxiliary oil motive on/off time constants. The segmented opening and closing tone values are determined according to actual conditions.

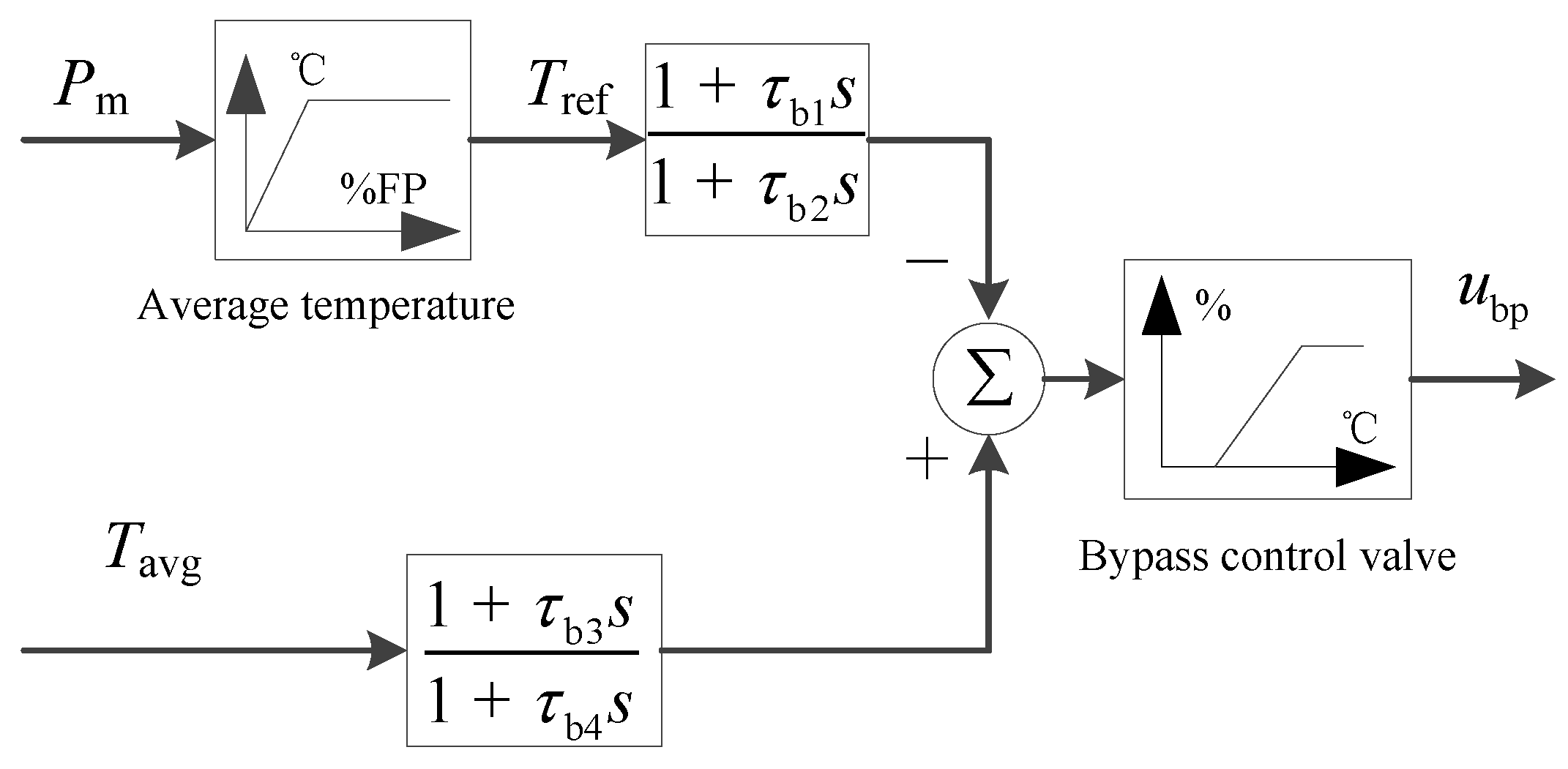

Figure 6 shows the steam turbine bypass control system diagram in the case that a large deviation between the turbine mechanical output power and the coolant average temperature equivalent to the core power appeared. The steam was discharged through the bypass valve to ensure reactor safety.

τb1,

τb2,

τb3 and

τb4 are compensator and filter time constants. The %FP symbol in

Figure 6 means the percentage of the rated full power.

2.6. Generator Mathematical Model

As the large-scale nuclear power plant uses a half-speed steam turbine generator unit, the PARK equation is adopted to establish the mathematical model of the six windings synchronous generator. The voltage and flux equations are shown in Equations (8) and (9):

where

u = [

ud,

uq,

uf, 0, 0, 0]

T,

Ψ = [

Ψd,

Ψq,

Ψf,

ΨD,

Ψg,

ΨQ]

T,

i = [

id,

iq,

if,

iD,

ig,

iQ]

T,

r = diag{

Rs,

Rs,

Rf,

RD,

Rg,

RQ},

.

x is a reactance matrix of size 6 × 6.

The motion equations of the generator rotor are shown in Equations (10) and (11):

where

Tj is the inertial time constant of generator.

Dω is the damping coefficient.

Tm is the mechanical torque.

Te =

Ψd ×

iq –

Ψq ×

id,

δ is the power angle and

ω0 is the rated speed (i.e.,

ω0 = 1).

The model parameters were obtained according to the AP1000 design manual, the test curves of second-generation operating PWR units and through comparison with the simulation curves from the PCTRAN software.

4. Model Parameter Identification and Validation

The tested data was obtained from a sub-module test, or the integrated model test. It required more than 300 s for the steam generator module. The main features of the PWR primary loop system model parameter identification were analyzed through the specific identification of each module. It is important to keep the model initially stable before parameter identification.

4.1. Model Initialization Based on Differential Equations and Program Setting

The rod position control is an integral part of the AP1000. When the input variable deviation is not within the dead band, there will be a rod position output, which works on another module. As a result, more variables are changed. The model initialization is needed to make the model initially stable, which is also conducive to the parameter identification work.

For the mathematical differential equations of each module given in

Section 2, let the derivative of the variables in the left sides of the equations equal zero. Then, the initial variable values can be calculated under a certain stable condition by the following expression:

where

Nr0 refers to a certain core power. It should be noted that

Cr, which is useful for identification analysis, is an intermediate variable whose value is difficult to be obtained. The initial variable values are closely related to the design parameters such as

Ω,

Ωs and

Ωp.

The initial values of some temperature variables set by the program were written as follows:

where

Pm0 is the given mechanical power value.

4.2. Parameter Identification Analysis

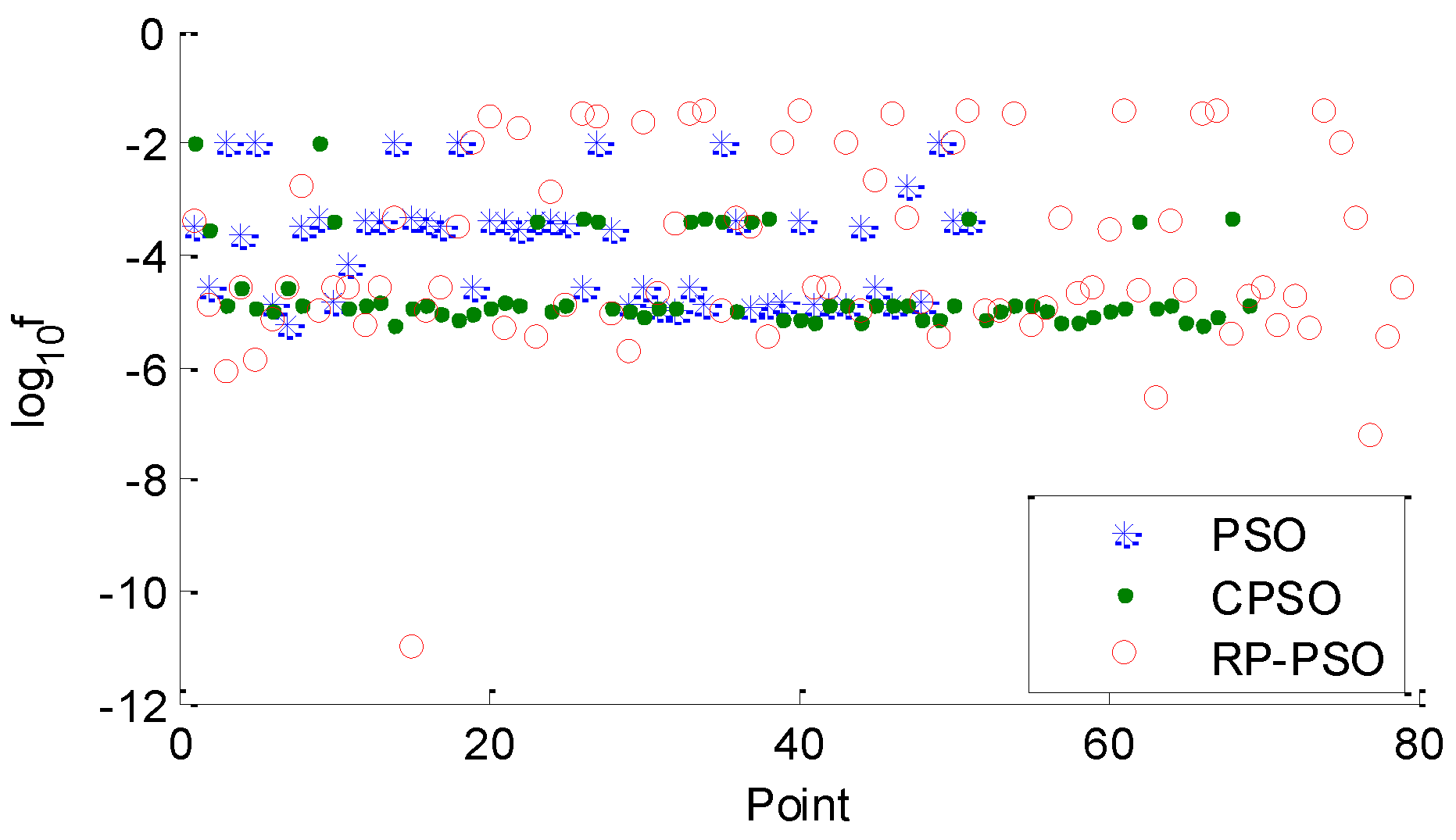

The model parameters were identified by the RP-PSO algorithm with the parameter identification process given in

Section 3.2. The parameters for the RP-PSO algorithm were set as

ωmax = 0.7,

ωmin = 0.01,

C1max = 2.5,

C1min = 0.5,

C2max = 2.5,

C2min = 0.5,

Vmax = 1,

Vmin = −1,

MI = 200. The population and iteration in the algorithm was set as 200. The largest iteration of 200 was the algorithm termination criterion. A large parameter range was given for the sake of objectivity. The parameter scope was given with a range of 0–1 for the parameters of the core neutron dynamic module, or there was a scope of 0–500 for the other parameters. When the parameter value exceeded 500, the parameter upper limit was set to a 2 order of magnitude larger than its actual value.

Next, it is important to get the model simulation curves under certain working conditions as tested curves with given appropriate parameter values. The data sampling frequency was 0.01 s per point. If the identified parameters were the same with the given values, the fitness function value of the algorithm should be infinitely close to zero.

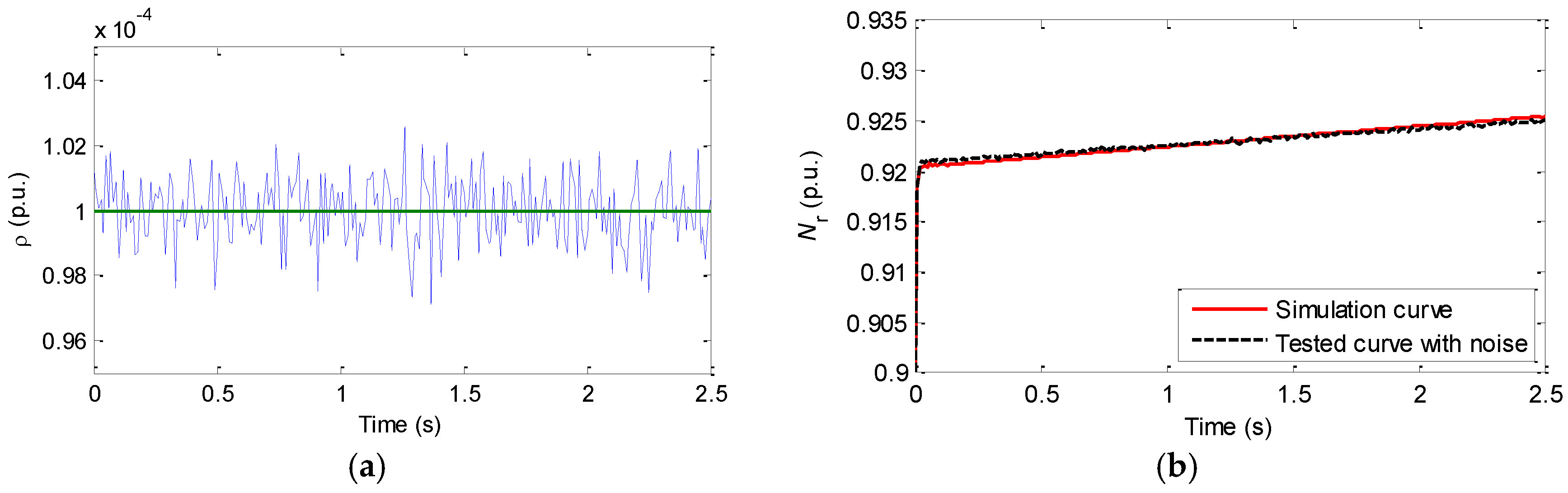

4.2.1. Core Neutron Dynamic Module Parameter Identification

Regardless of the temperature feedback, ρ and Nr are the input and output variables of the core neutron dynamic module, respectively. Supposing a step change of ρ from 0 to 0.0001 p.u. (i.e., per unit) at 1 s, the deviation of Nr was selected as the fitness function to identify l, λ and β.

Figure 8 shows the simulation comparison. The identified parameter values changed with iteration increase until they reached their true values after 80 iterations. The fitness function value reached a negative 9 order of magnitude with the identified parameter values in full compliance with their actual values. The simulation curve was consistent with the tested curve as

Nr changed from the initial value of 0.9 p.u. (i.e., per unit) with a suddenly steep change to about 0.92 in about 0.03 s, followed by a slower linear growth (see

Figure 8e).

4.2.2. Core Fuel and Coolant Temperature Module Parameter Identification

Nr and

Tθ1 are the input variables.

TF,

Tθ2 and

Tav are the output variables. Given a step change of

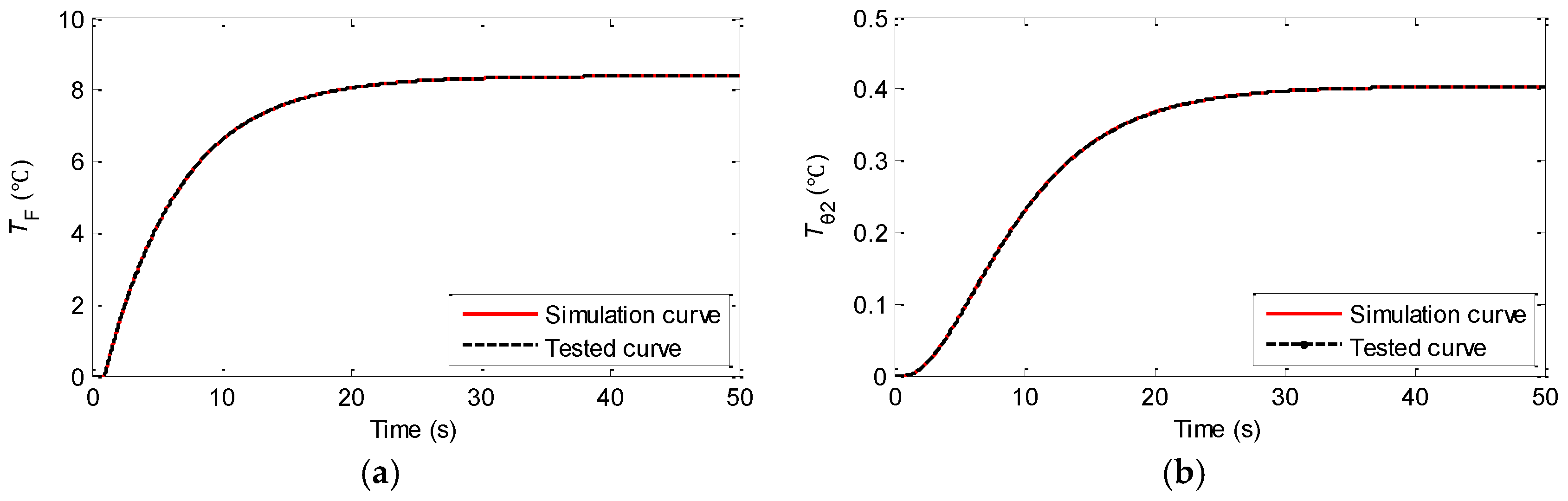

Nr from 0 to 0.01 at 1 s with all the initial variable values of 0, the parameters identified were fit with their real values as the fitness function value reached negative a 11 order of magnitude.

Figure 9 showed the simulation results, proving the effectiveness of the parameter identification. Each output variable raised to a steady-state value with no overshoot.

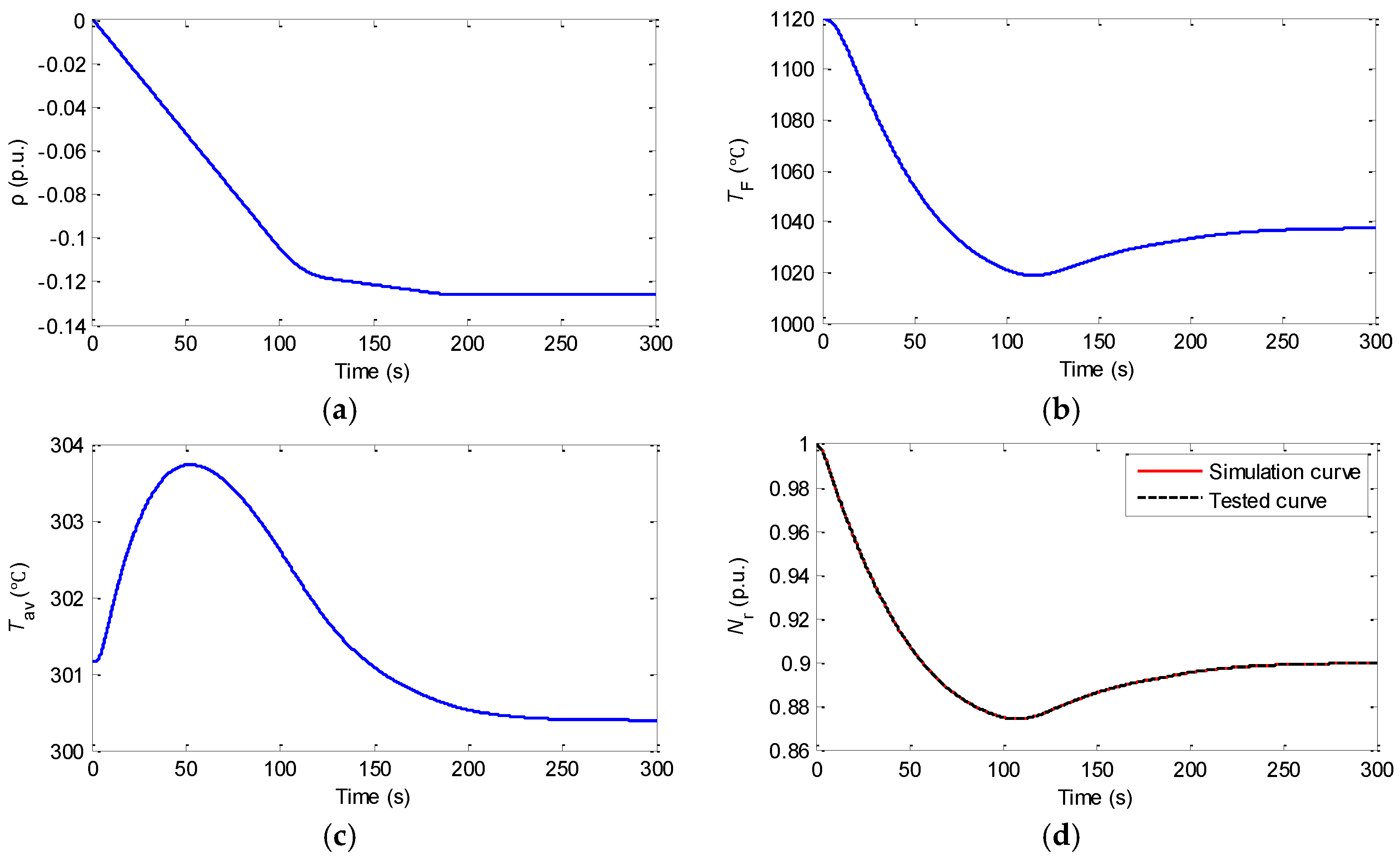

4.2.3. Reactor Power Control System Module Parameter Identification

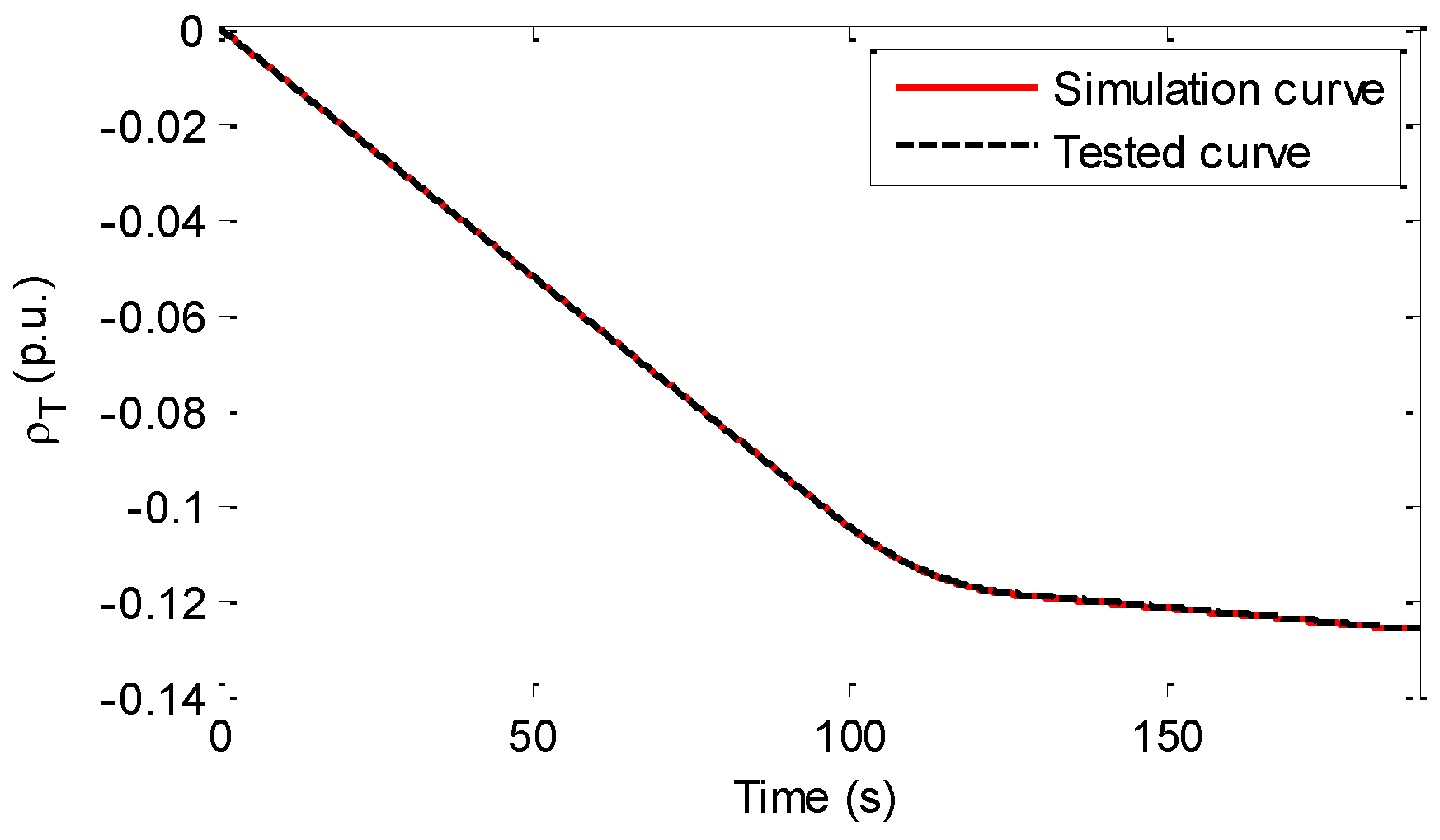

The input variables are Tavg, and, Pm and Nr. ρT is the output variable. Since the transfer function was the lead link, τ3 was larger than τ4.

For the reactor power control system module, the tested data were obtained under a nuclear power change from the rated power of 1–0.9 based on the whole PWR primary loop system model. Furthermore, the turbine bypass control system module was omitted due to its smaller effect when the power changed to 0.1. As the fitness function value reached a negative 14 order of magnitude, the parameters identified were almost the same as their actual values.

Figure 10 showed the simulation result after identification.

ρT declined approximately linearly from 0 before 110 s, followed by a slower decline, until eventually it reached a steady level. The simulation curve fitted the tested curve well.

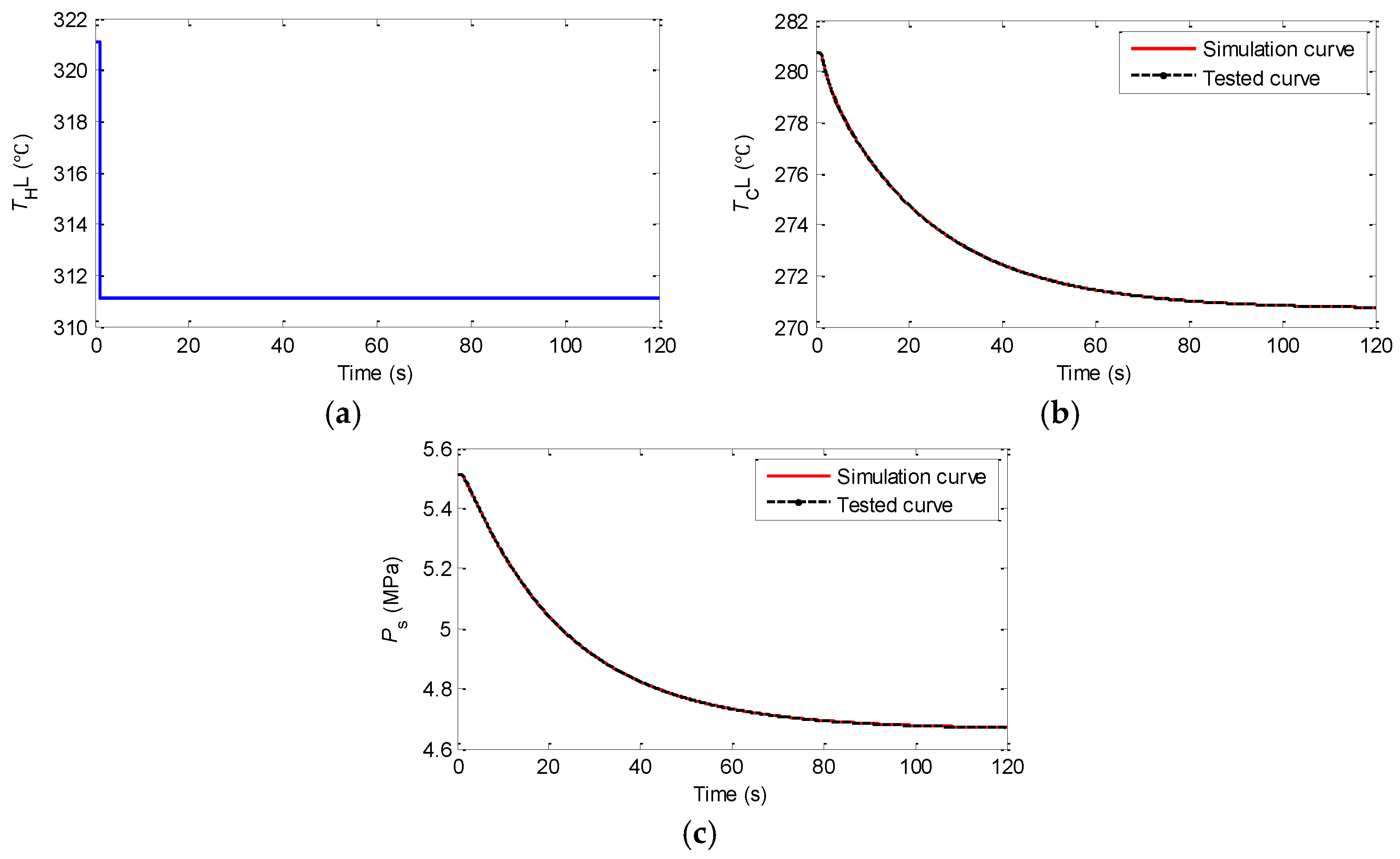

4.2.4. Steam Generator Module Parameter Identification

The input variables are

THL and

Qsg. Besides some other intermediate variables,

TCL and

Ps are the main output variables. The steam generator parameters are mainly related to design parameters with different order magnitudes large to a 7 order of magnitude. Supposing that

Qsg was constant at 1, it gave

THL a step change of 10 °C from the rated value of 321.1 °C at 1 s. Both the simulation and tested deviation values of

TCL and

Ps were used in the fitness function.

Figure 8 shows the input

THL change and output variable simulation comparison.

The simulation result could basically fit with the tested curve (see

Figure 11). The variable curves of another condition with

Qsg that were given a step change from 1 to 0.9 were more complex. The identification result using single variable deviation (i.e., the deviation of

TCL or

Ps) as the fitness function could not match multiple output variable curves. Thus, the identified parameters might only fit several output variables or parts of the tested curves, if the output variables and tested curves chosen for identification are unable to completely reflect the variable transition process.

Moreover, the parameters of the turbine bypass control system module and the time constants of the cold line, hot line and primary loop average temperature module were easy to be identified, which were omitted in details due to space limitations. Besides the designed parameters,

Table 1 lists the main sub-module parameters.

Table 2 lists partial parameters with their actual and identified values. The index of relative error was applied to judge the identified results that deviated from their true values. Through the caculation of relative error given in

Table 2, the identification precision is basically higher than 95%.

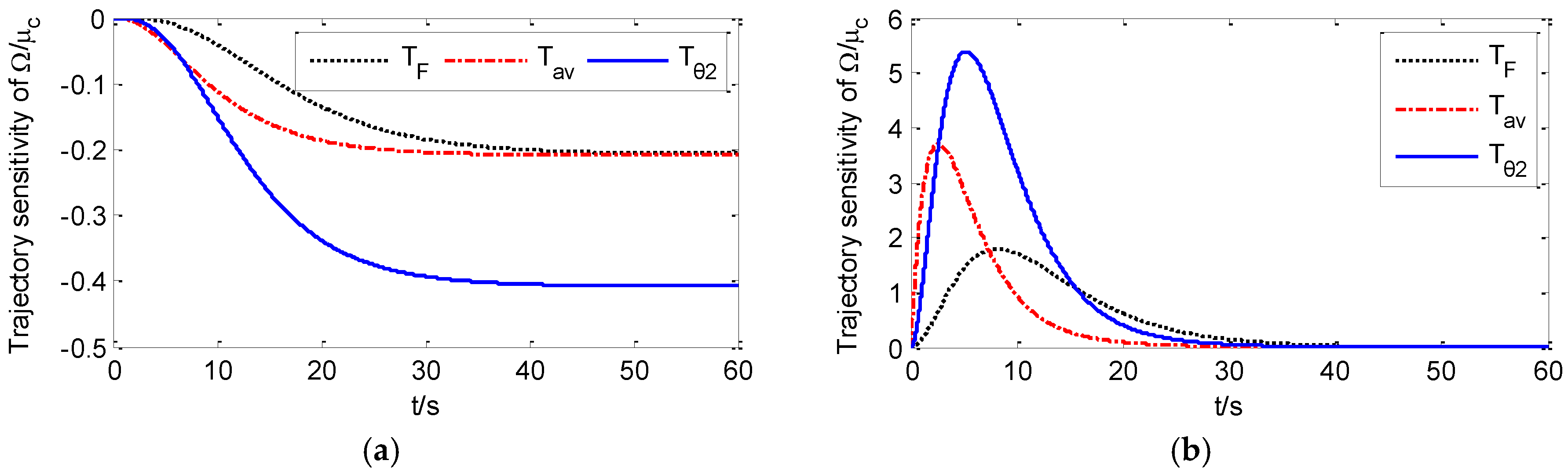

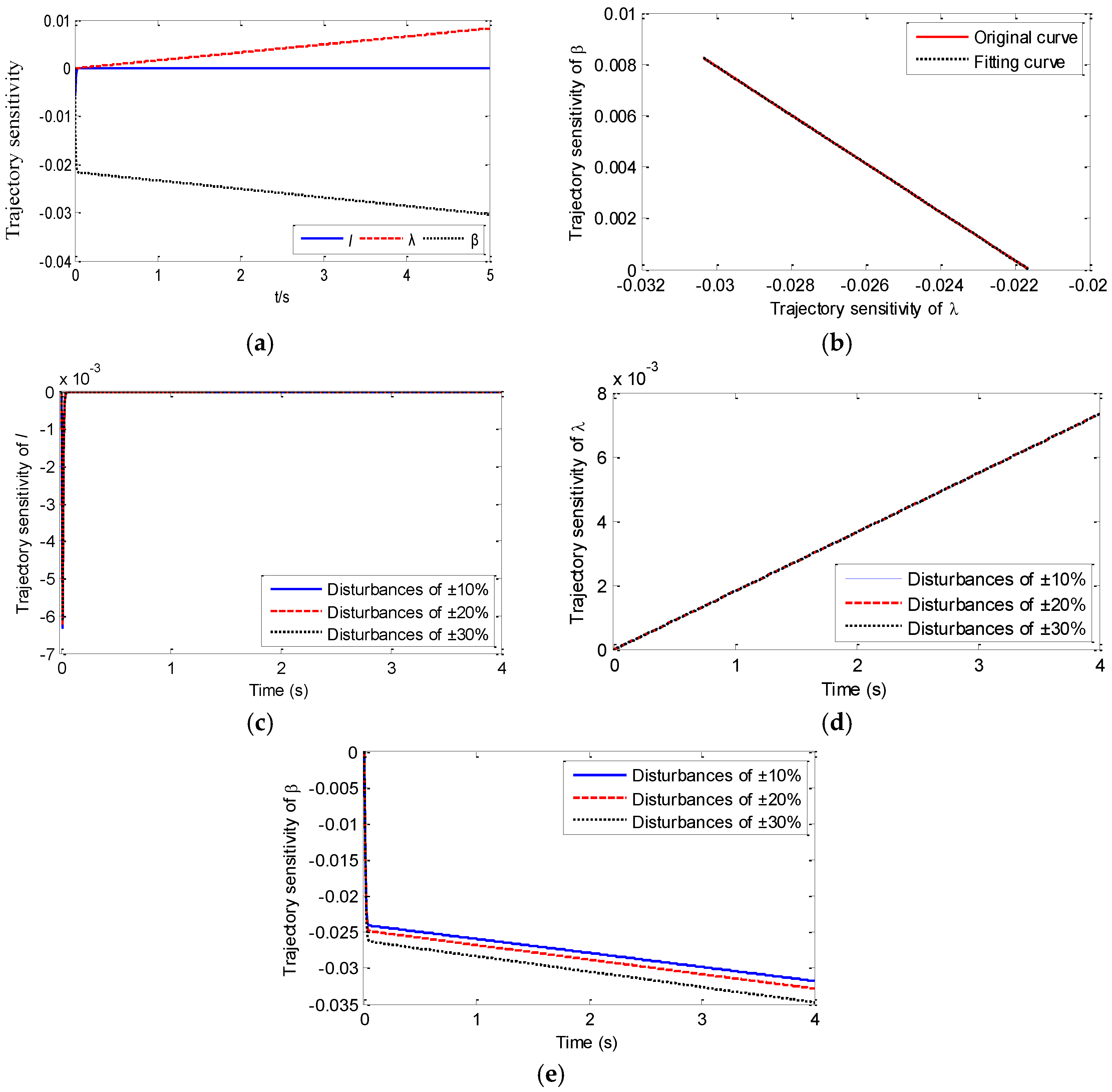

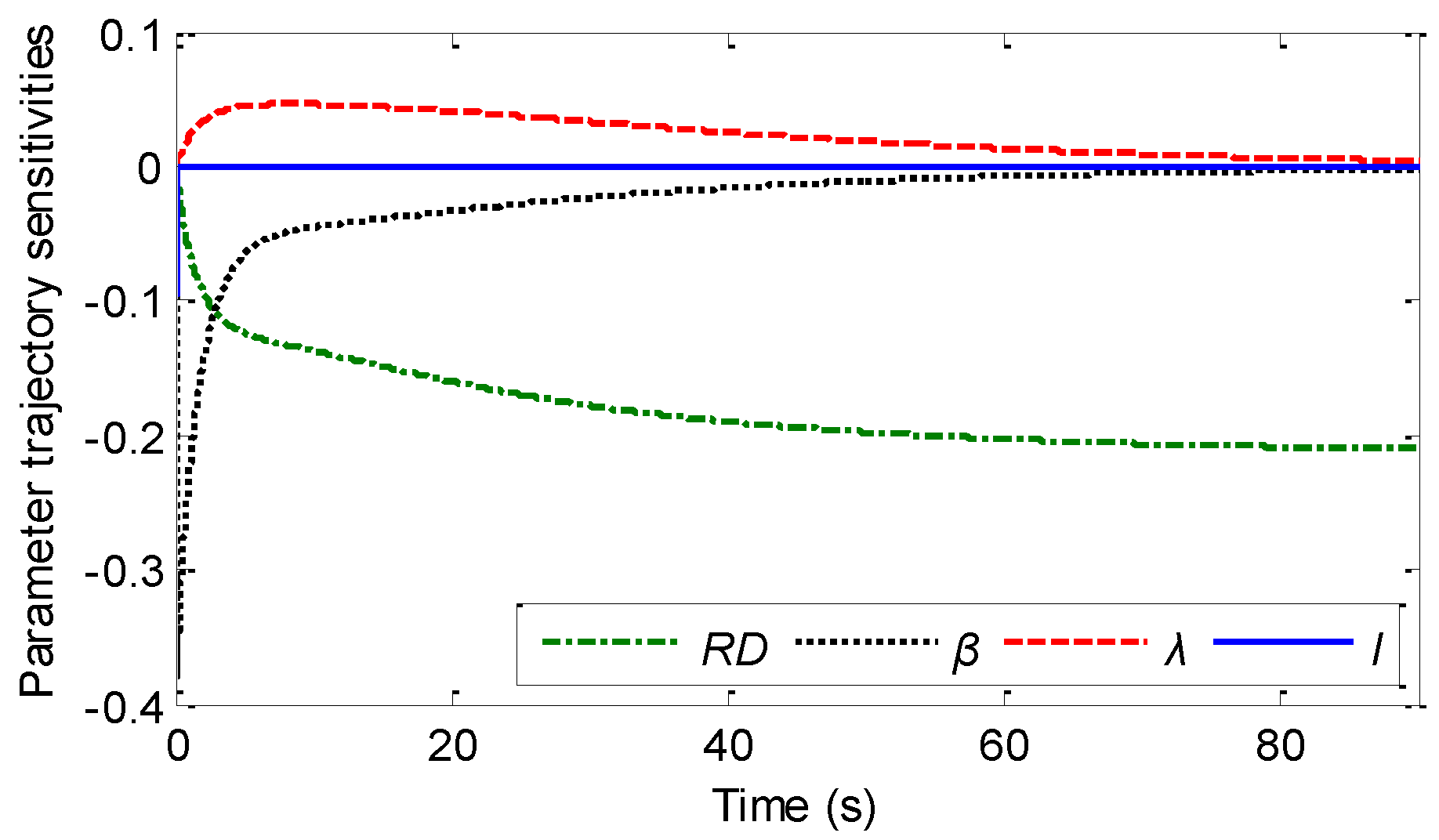

4.3. Parameter Sensitivity Analysis

The parameters should be kept in a suitable range to ensure system transient stability. The parameter influence on the system dynamic response was revealed through the sub-module parameter sensitivity analysis under different input conditions, which gave reference for parameter identification.

Taking the core fuel and coolant temperature module for example,

Figure 12 shows the trajectory sensitivity analysis results with changes of ±10% to

Ω/

μc under a step change of 0.01 for

Nr, or a positive step change of 10 degrees for

.

The parameter influence of

Ω/

μc on output variables (i.e.,

TF,

Tav and

) existed constantly as

Nr changed. The trajectory sensitivities eventually dropped to zero after about 30 s under step change of

(see

Figure 12). Thus, there was a significant difference in the sensitivity of

Ω/

μc to each output variable under two cases. The change of

Nr was more beneficial for the parameter identification of

Ω/

μc. Similarly, some other structural and thermal parameters for the steam generator module also had a constant effect on the model output variables under given input conditions.

6. Conclusions

The electrical, temperature and pressure variables with clear physical meaning were integrated in the primary loop system model using a modular modeling method, which reflected the actual operating characteristics. The PWR primary loop system had the characteristics of orders of magnitude that ranged from −5 to 7 for parameters and variables with a time scale of more than 300 s, which increased the parameter identification difficulty. The sampling frequency should be increased to record the rapid transition process in actual tests. Different disturbance depths under multiple conditions should be applied to get the test data, especially in case of signals with noise. The model practicability was increased by the variable initialization based on the differential equation and program setting method. The parameters were obtained from calculation or identification with the RP-PSO algorithm and were checked under various working conditions.

The trajectory sensitivities of the same parameter to the output variables under various input disturbances might be quite different for a MIMO system. Thus, the design of the appropriate test conditions was beneficial to parameter identification. The linear correlation between the trajectory sensitivities of different parameters made the parameter identifiability worse. However, the relevance parameters did not affect the identification of other parameters that were not associated with them. The parameters that changed the model gain, like the reactor temperature feedback coefficients and some other design parameters, had a more significant effect on the simulation results. These parameters needed to be obtained properly, since large deviations from their real values changed the output variable steady-state values. Meanwhile, the effects of some other parameters were only reflected in the variation process.

The parameter identification features of the advanced PWR primary loop system and the parameter identifiability difficulty degree through sensitivity analysis was helpful for the test-work design. It also laid the foundation for the calculation and identification of the model parameters based on measured data.