Voltage-Based Hot-Spot Detection Method for Photovoltaic String Using a Projector

Abstract

:1. Introduction

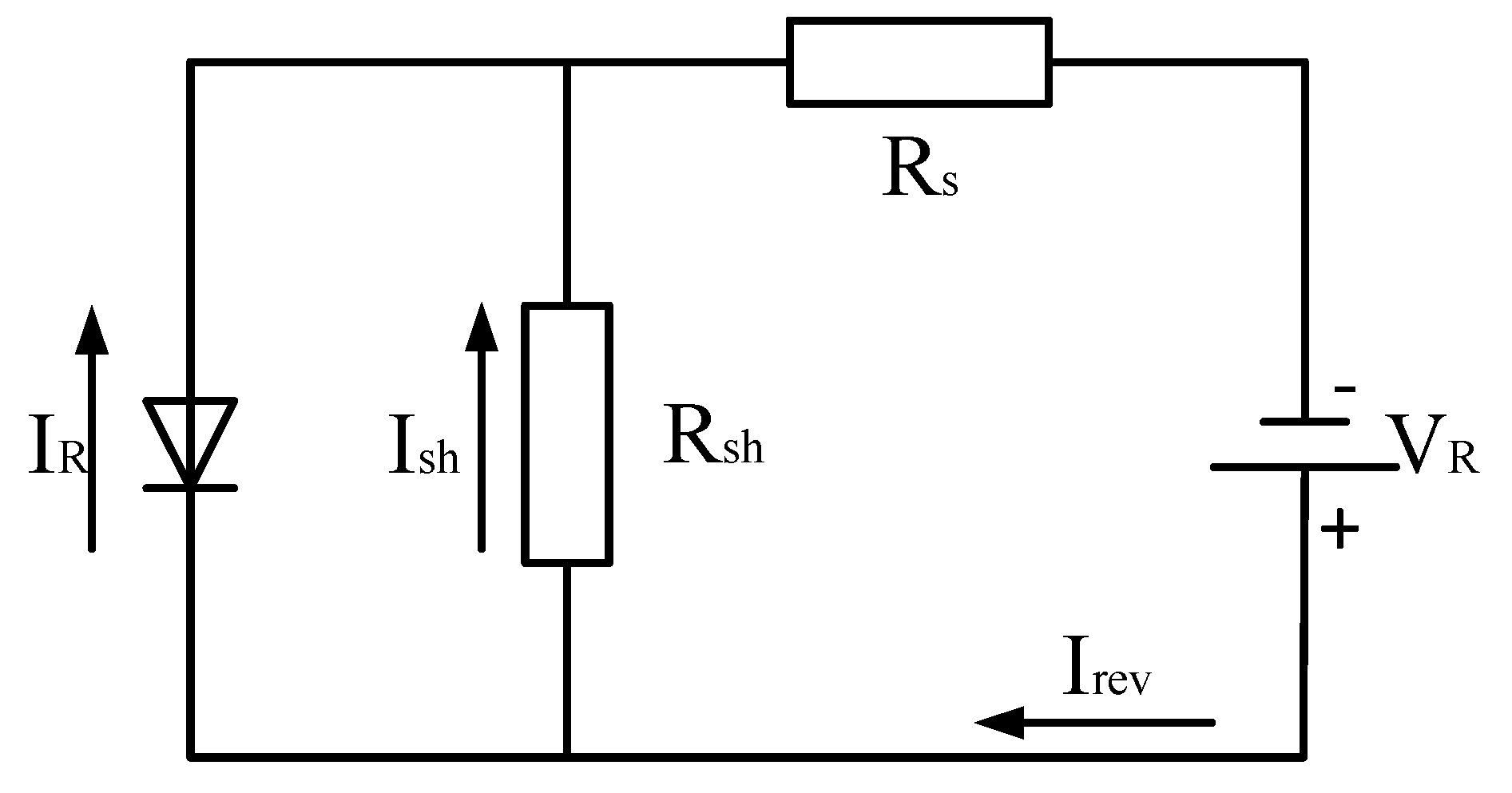

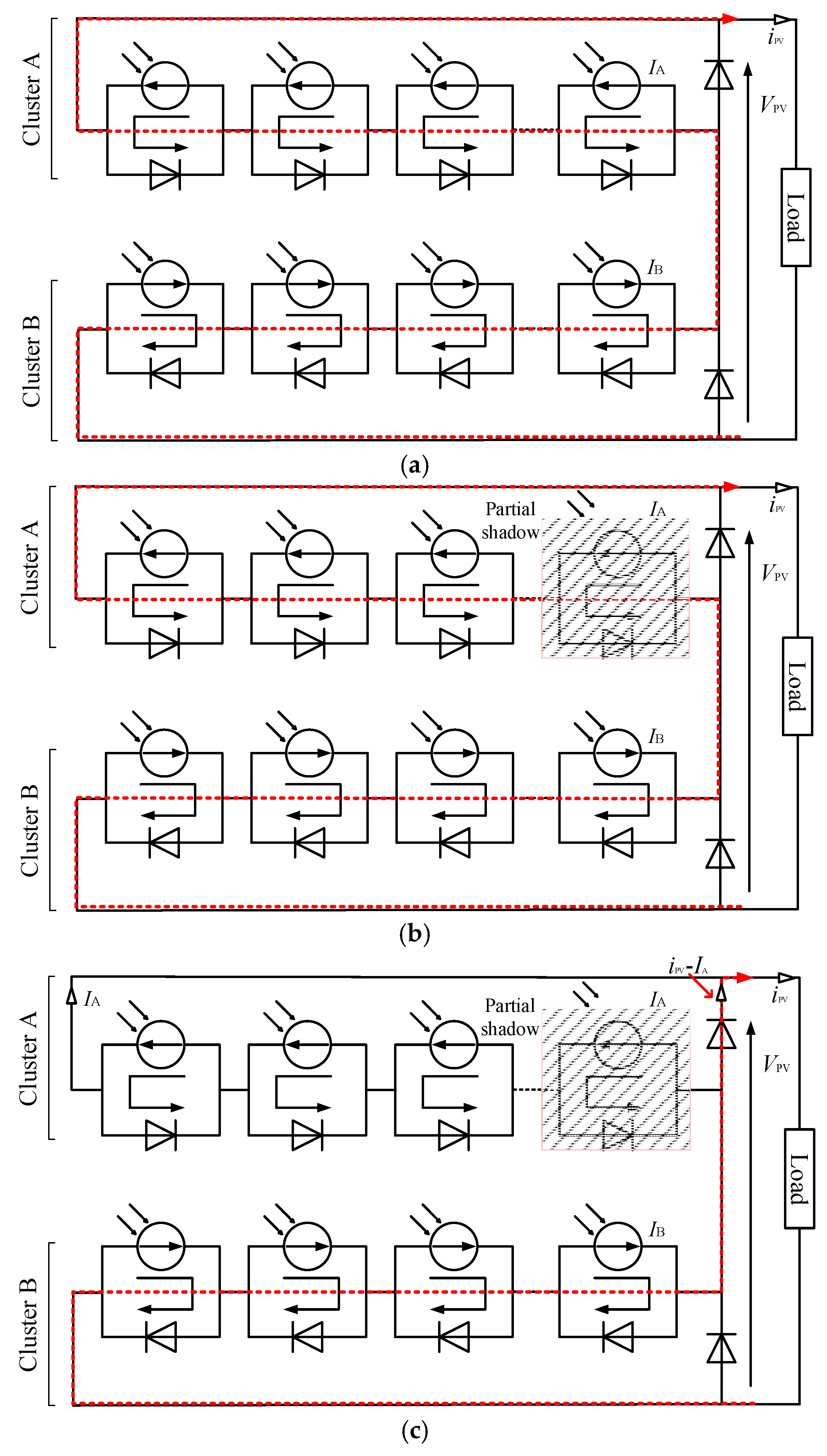

2. Theoretical Background

3. Proposed Voltage-Based Hot-Spot Detection Method

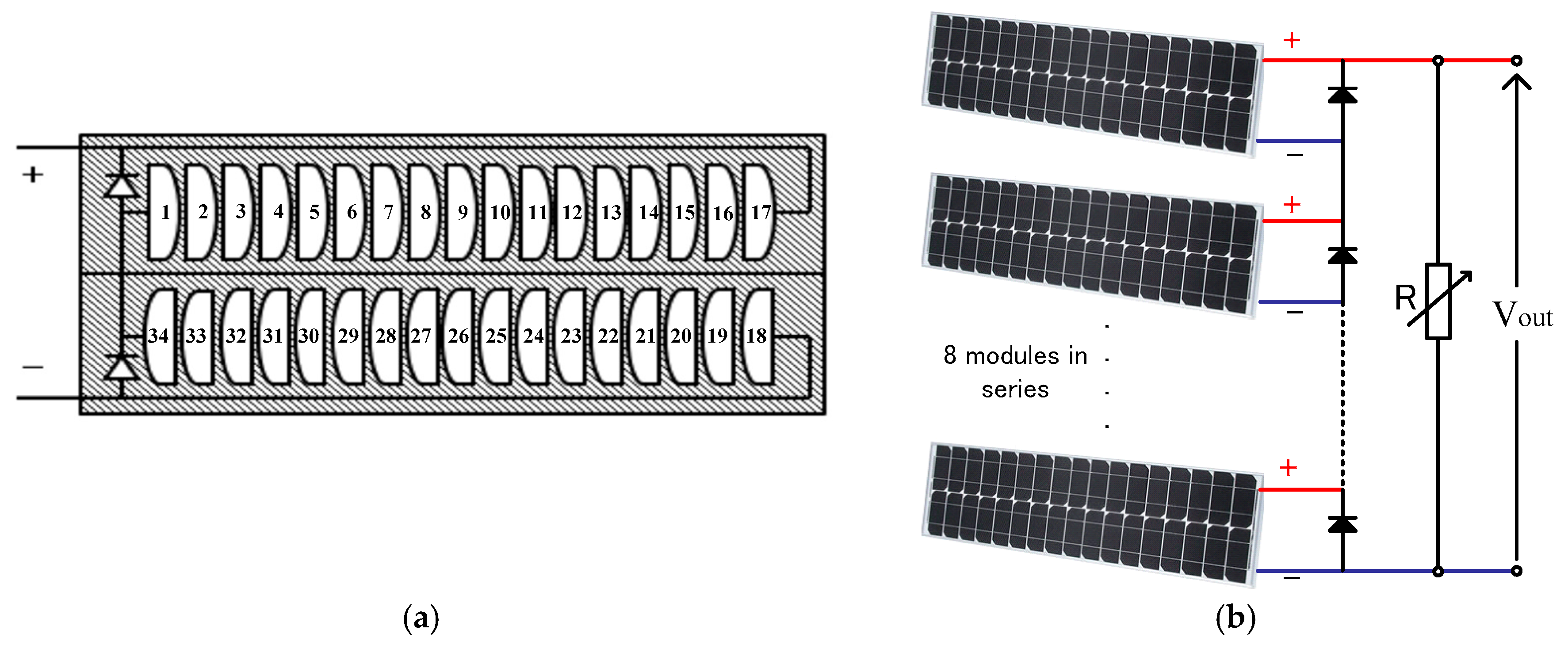

3.1. Specification of Experimental Module

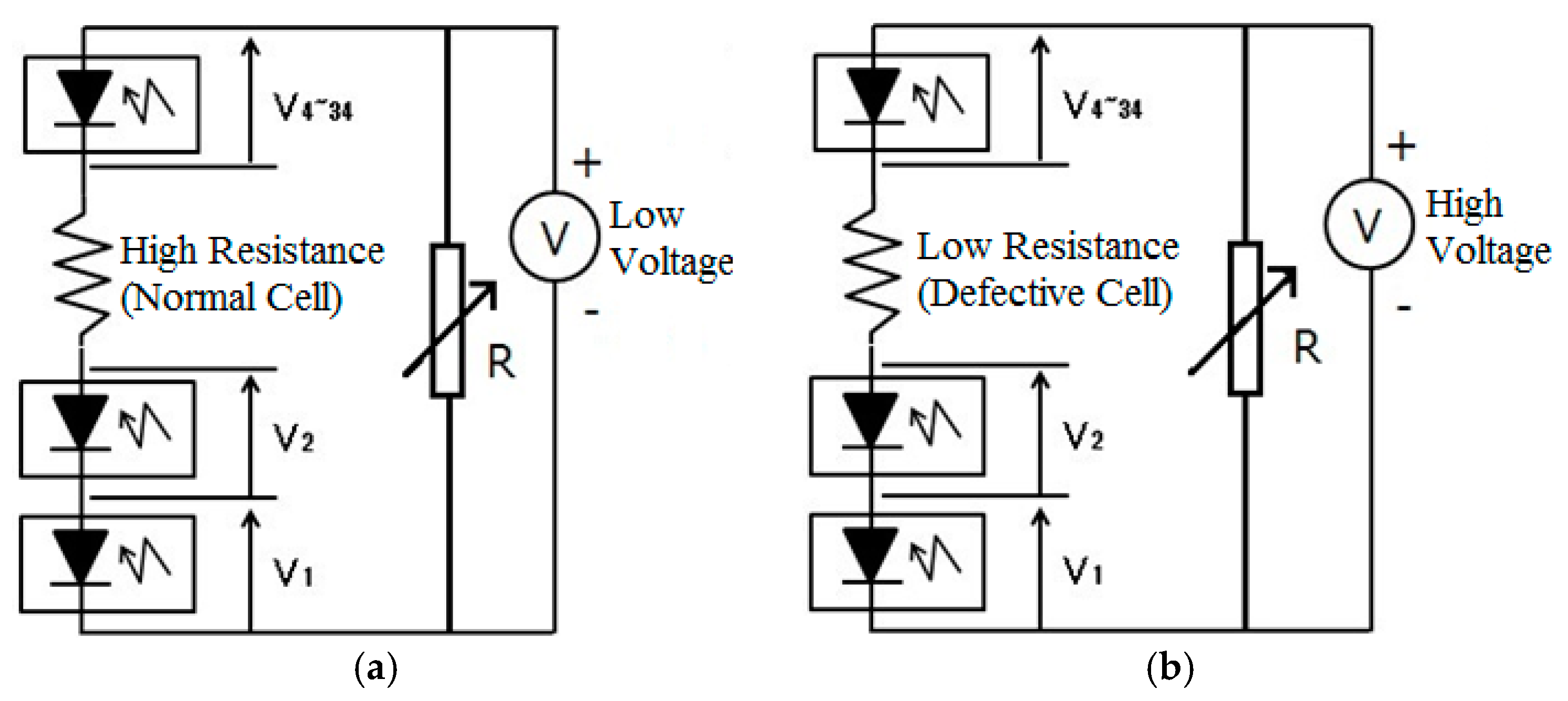

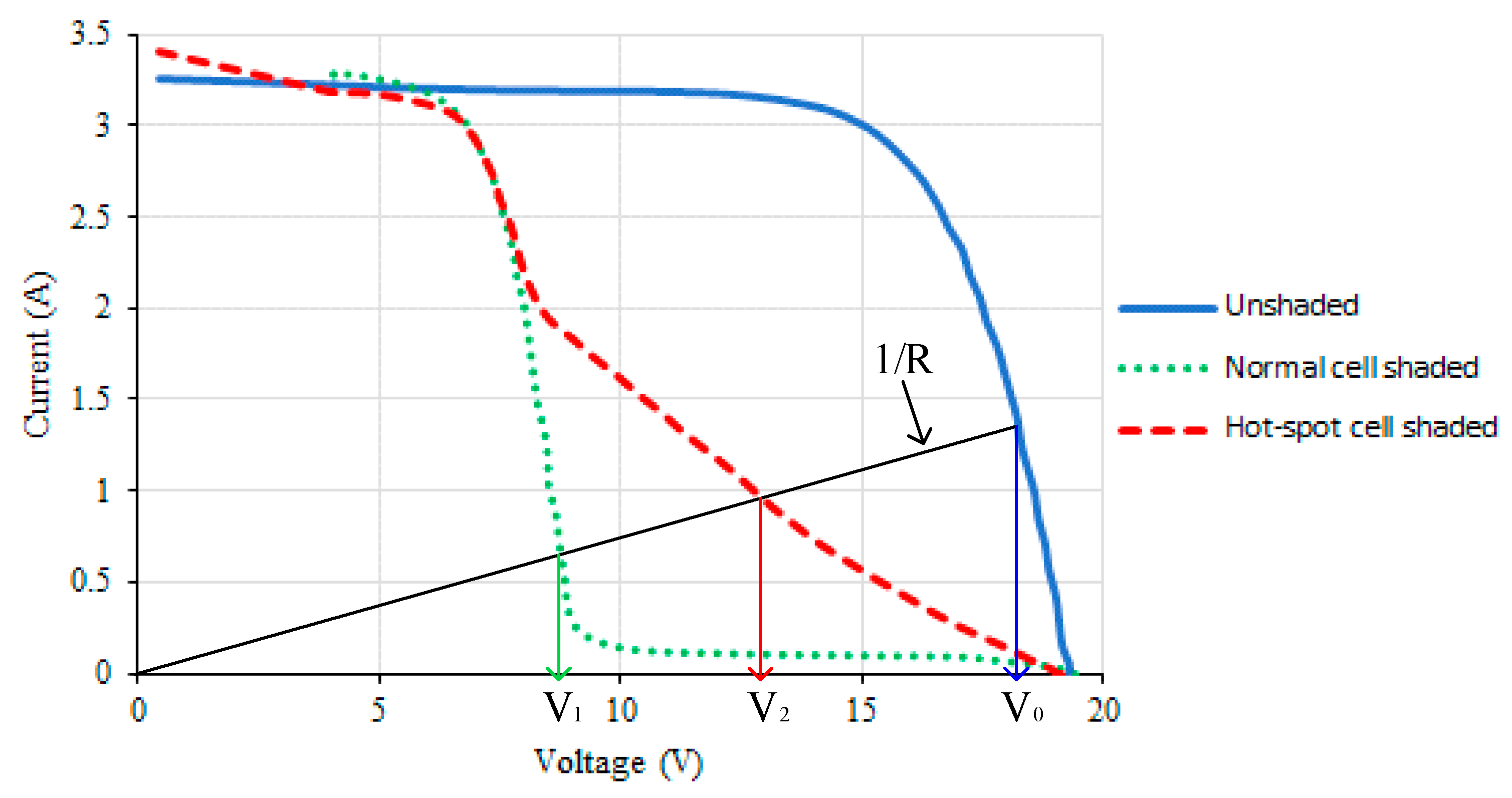

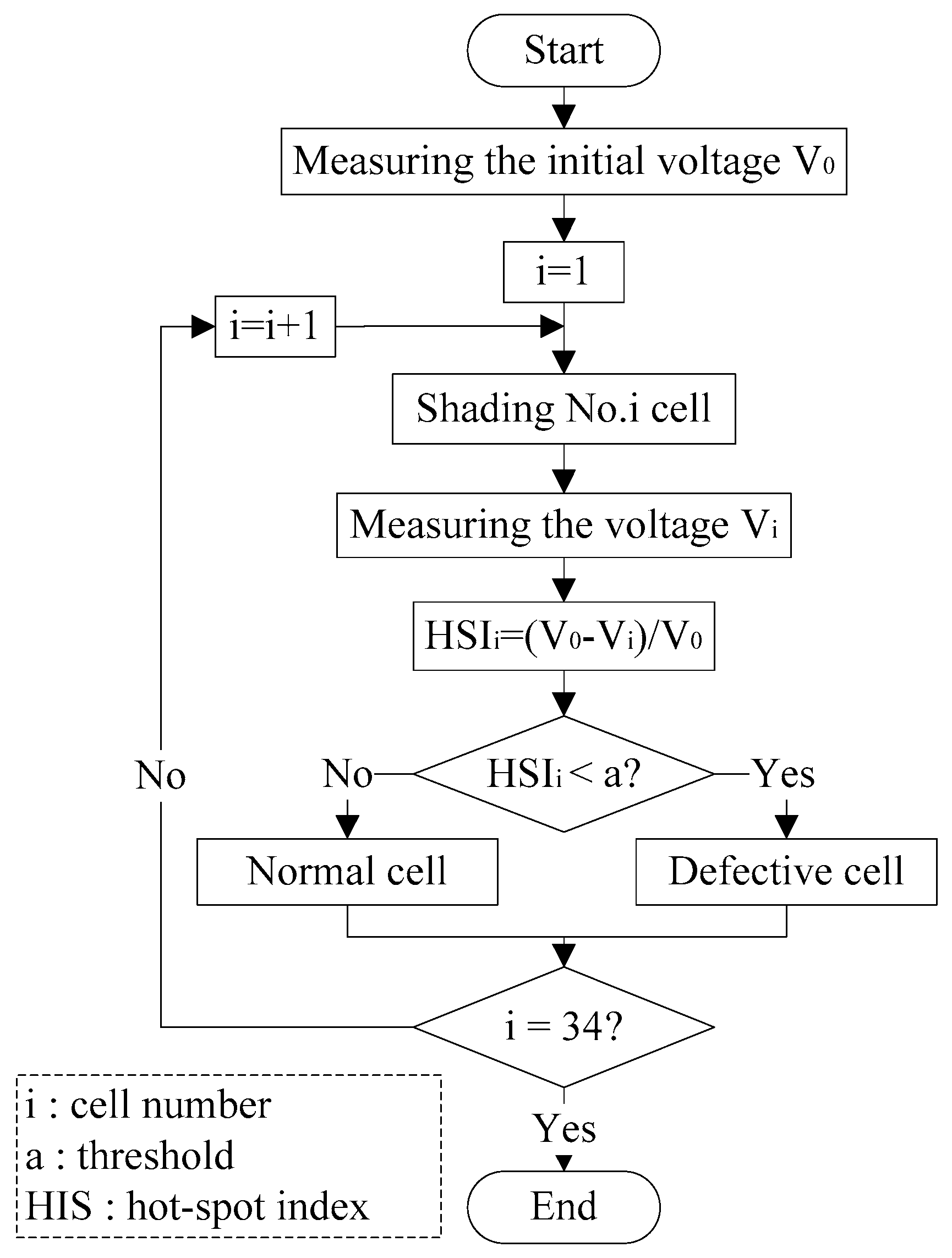

3.2. Detection Theory

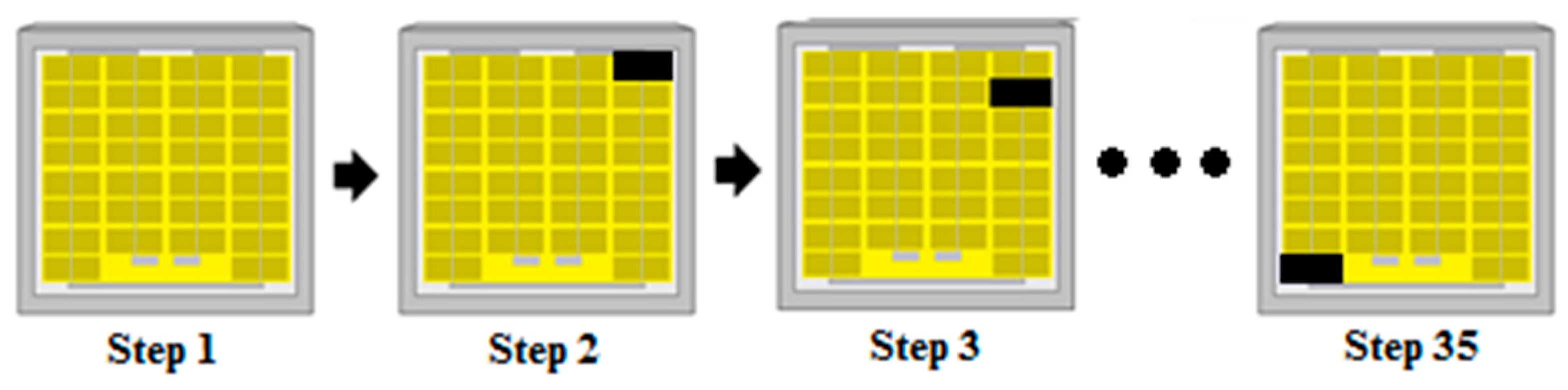

3.3. Operating Procedure

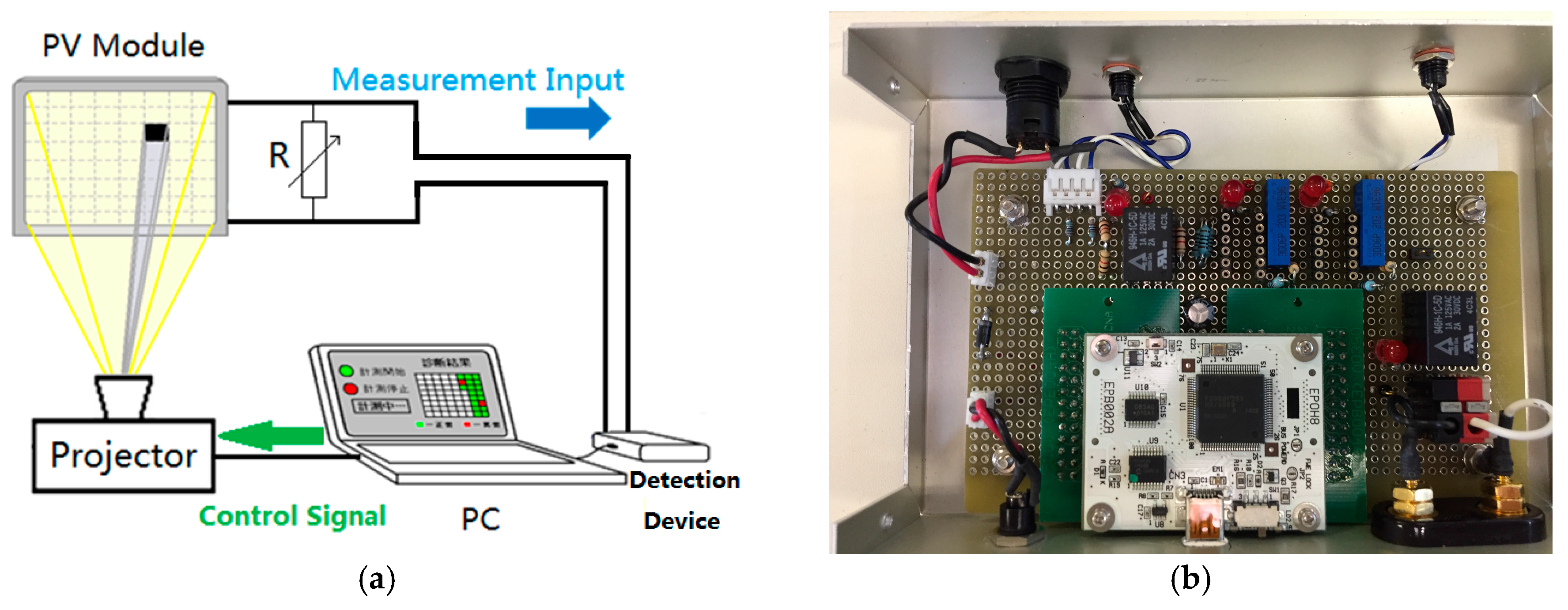

3.4. Proposed Voltage-Based Hot-Spot Detection System

4. Results

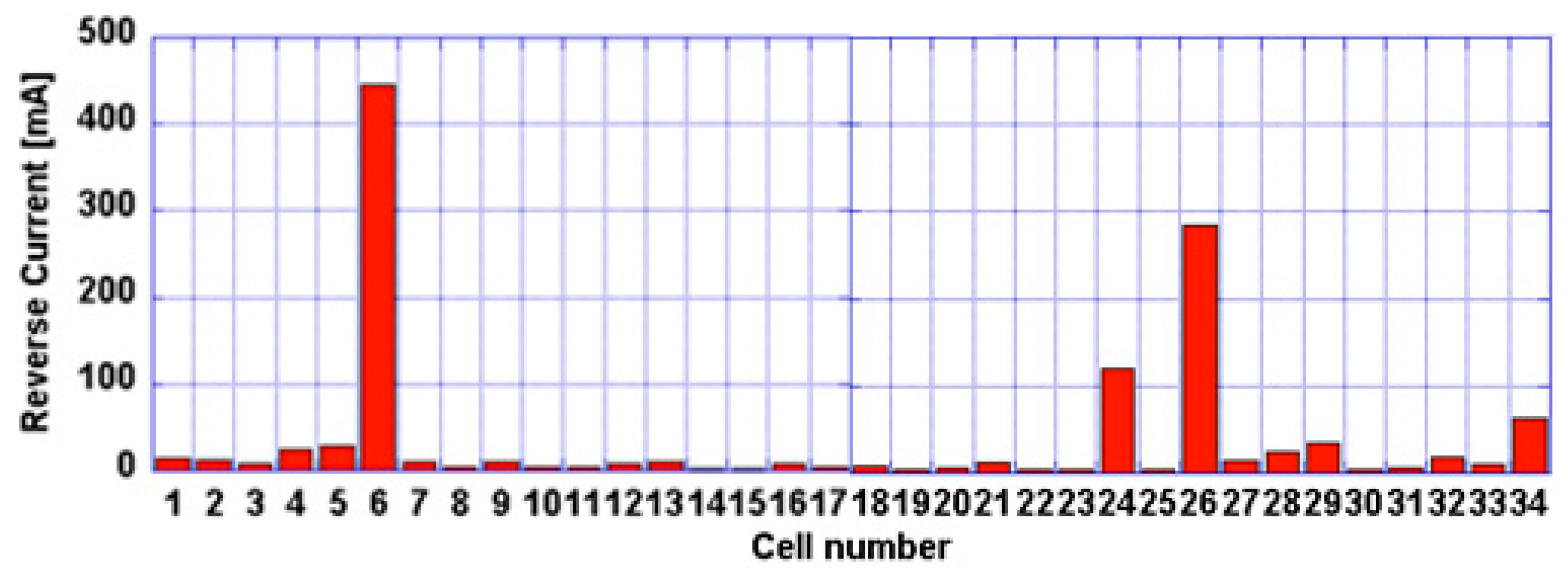

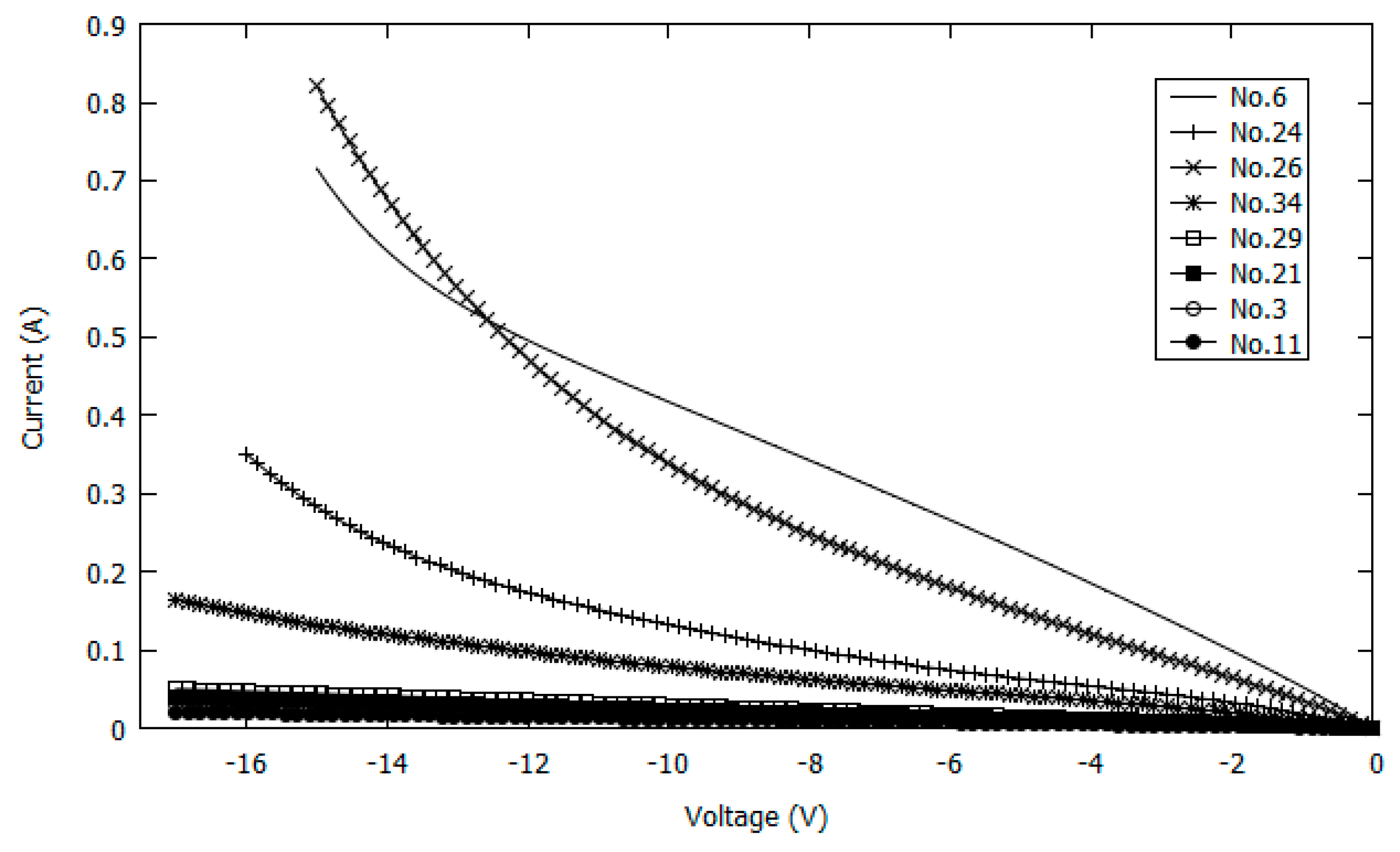

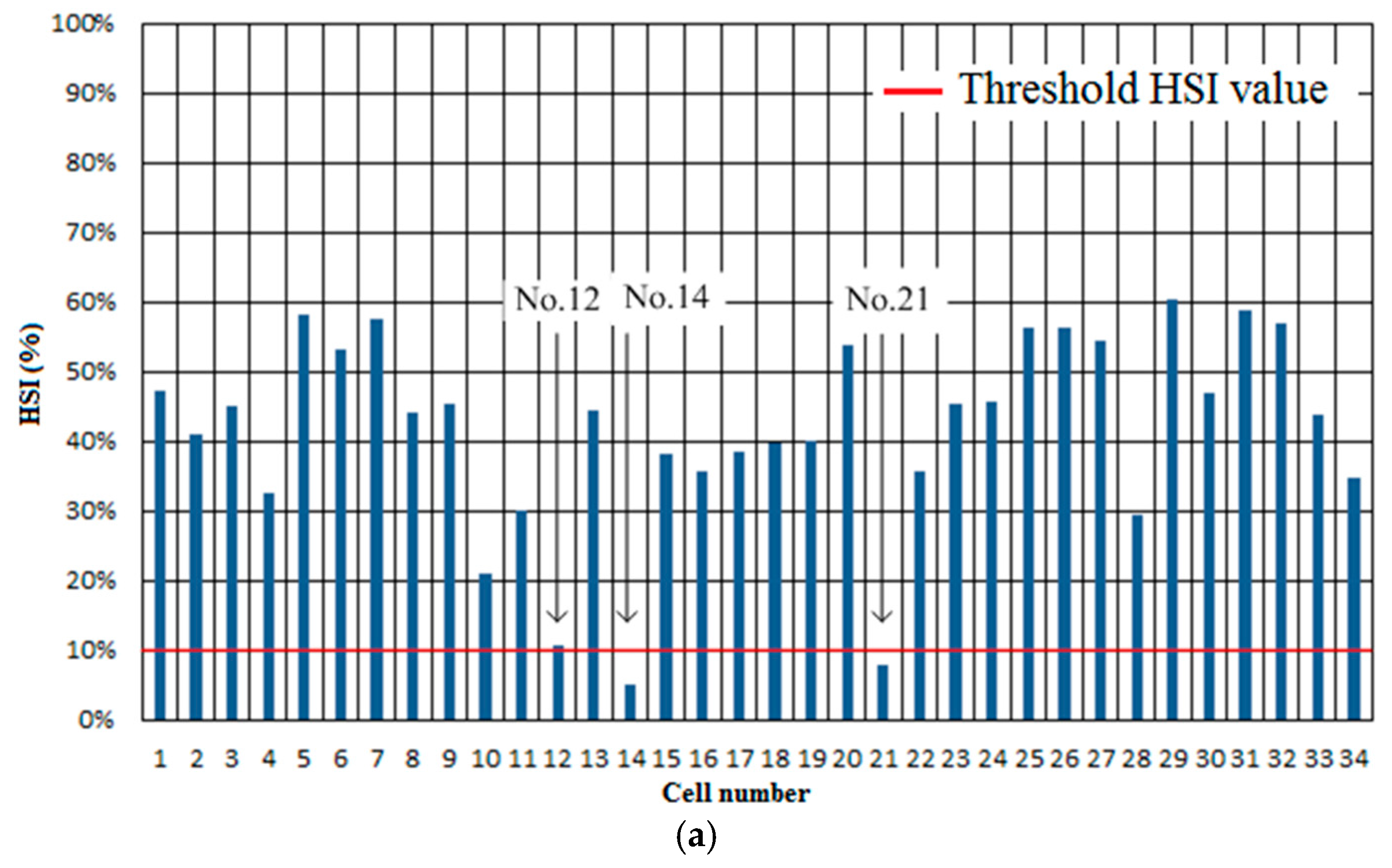

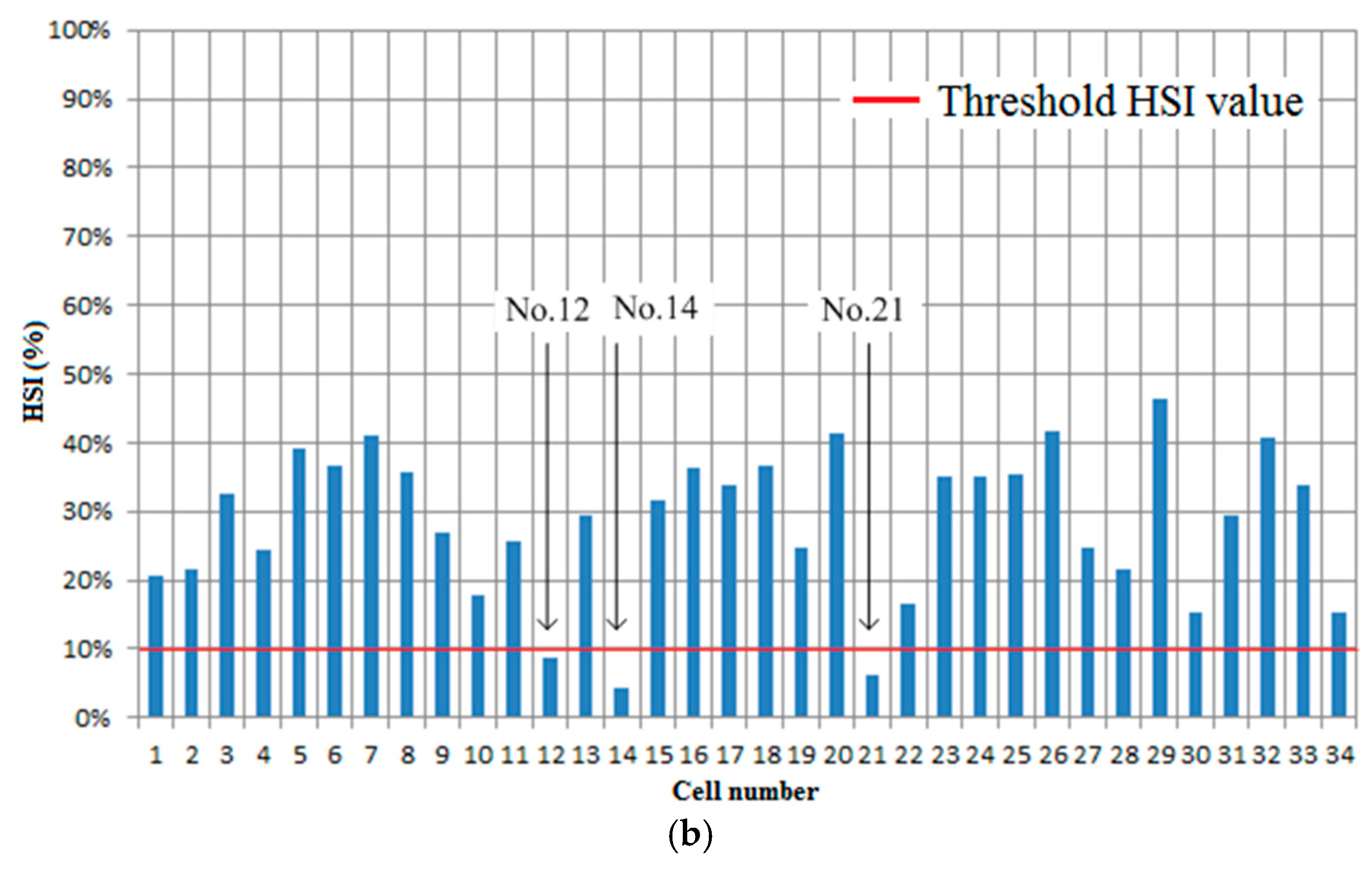

4.1. Resistance and Hot-Spot Index

4.2. Illuminance and Hot-Spot Index

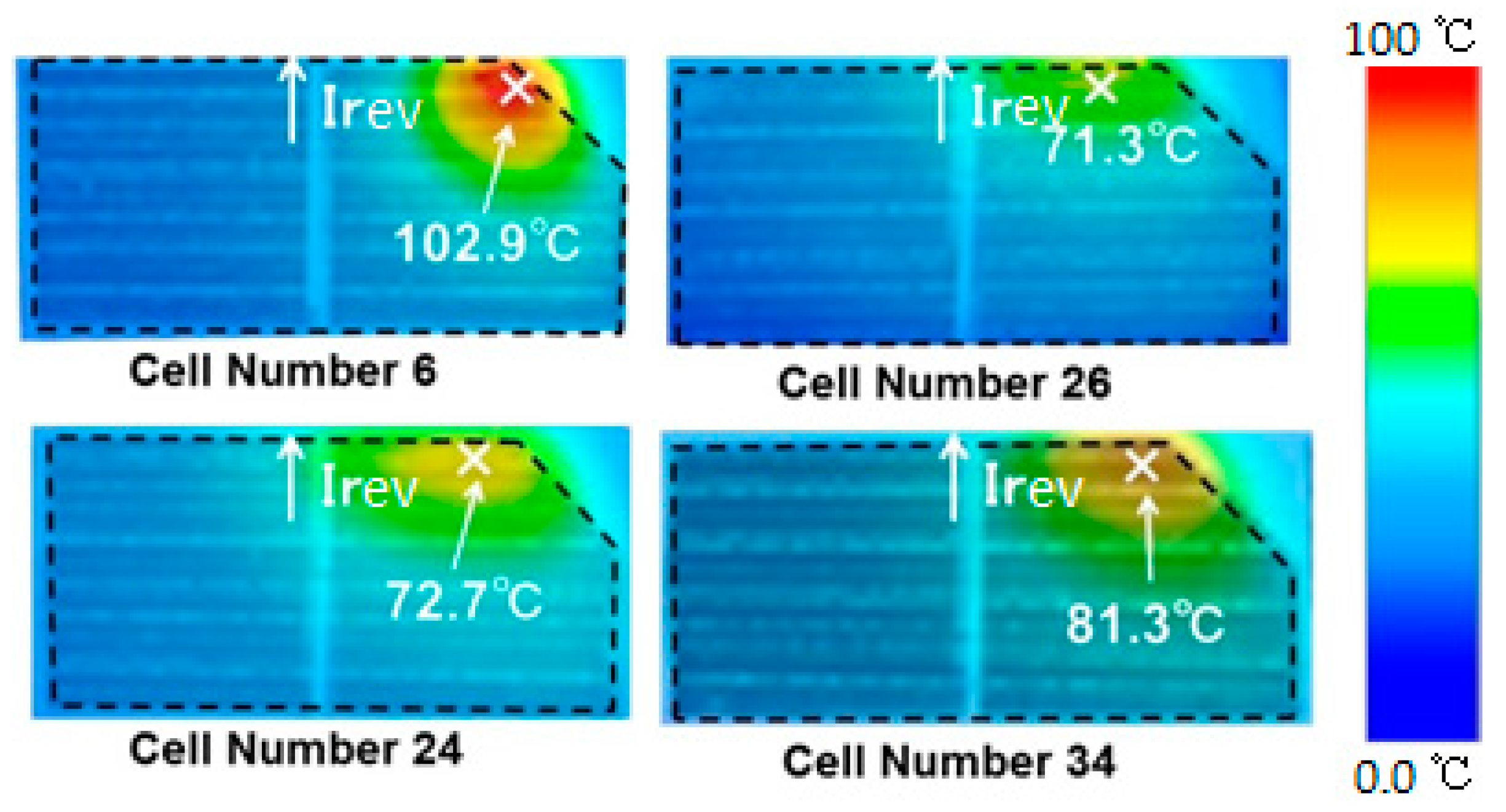

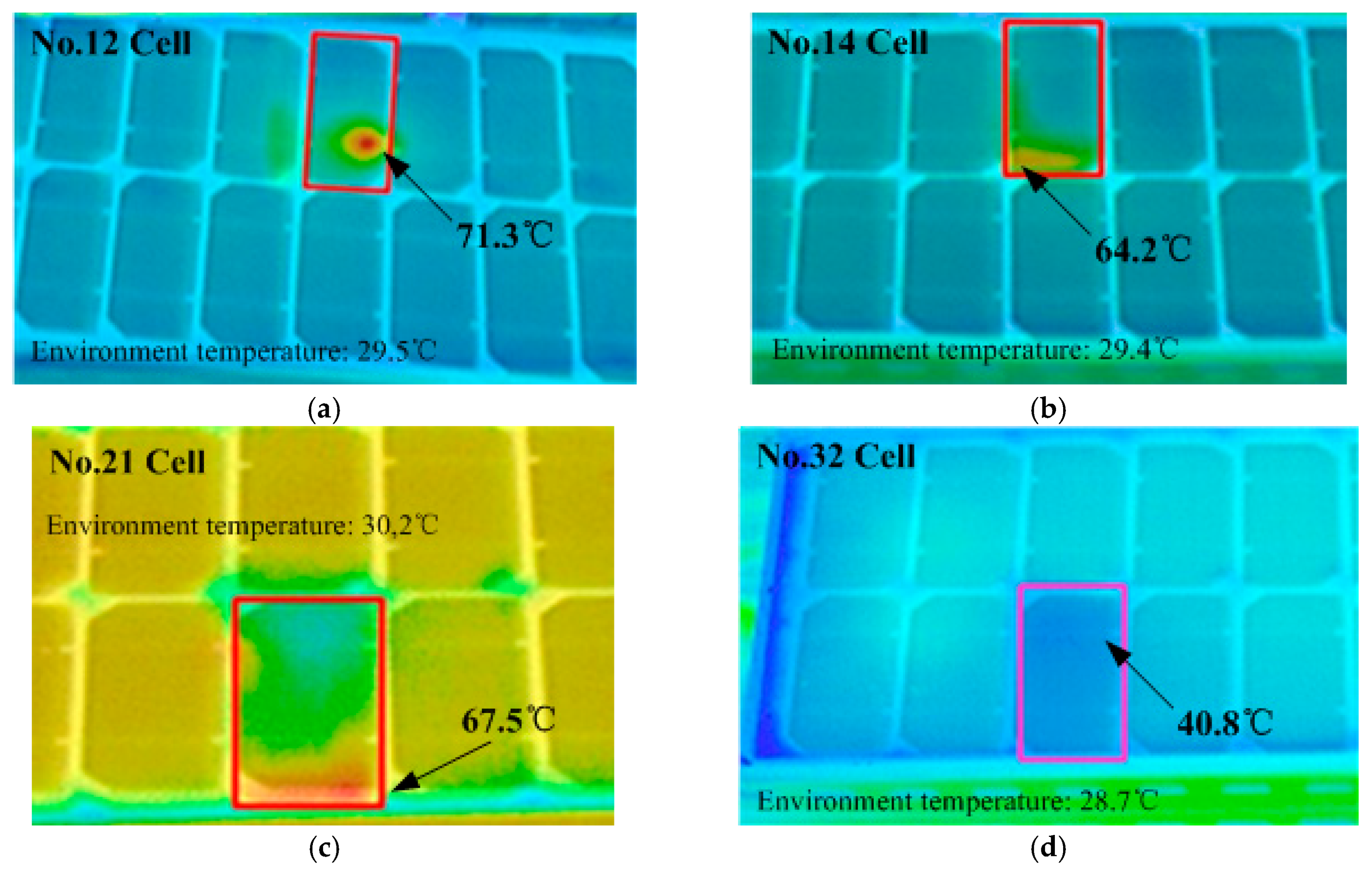

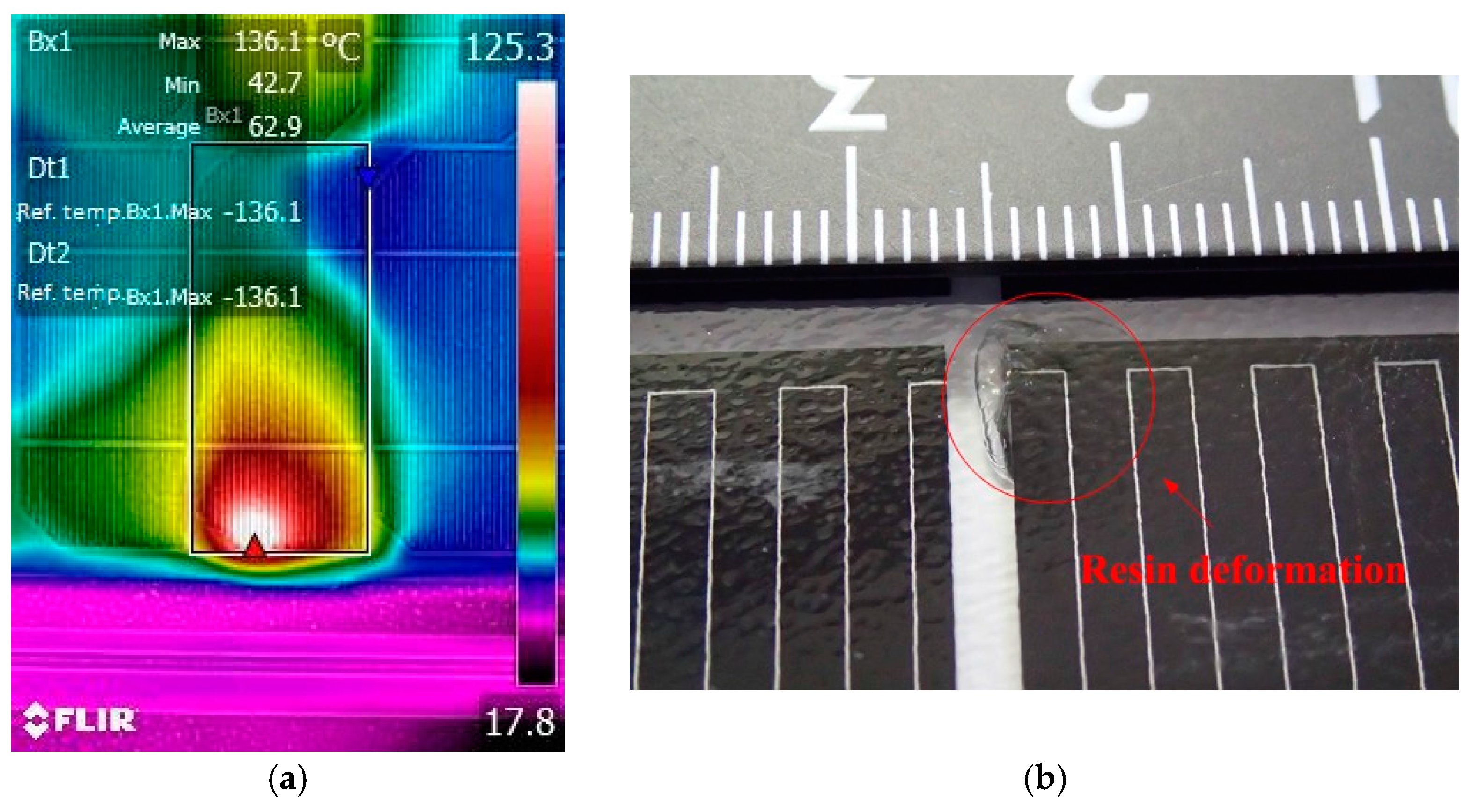

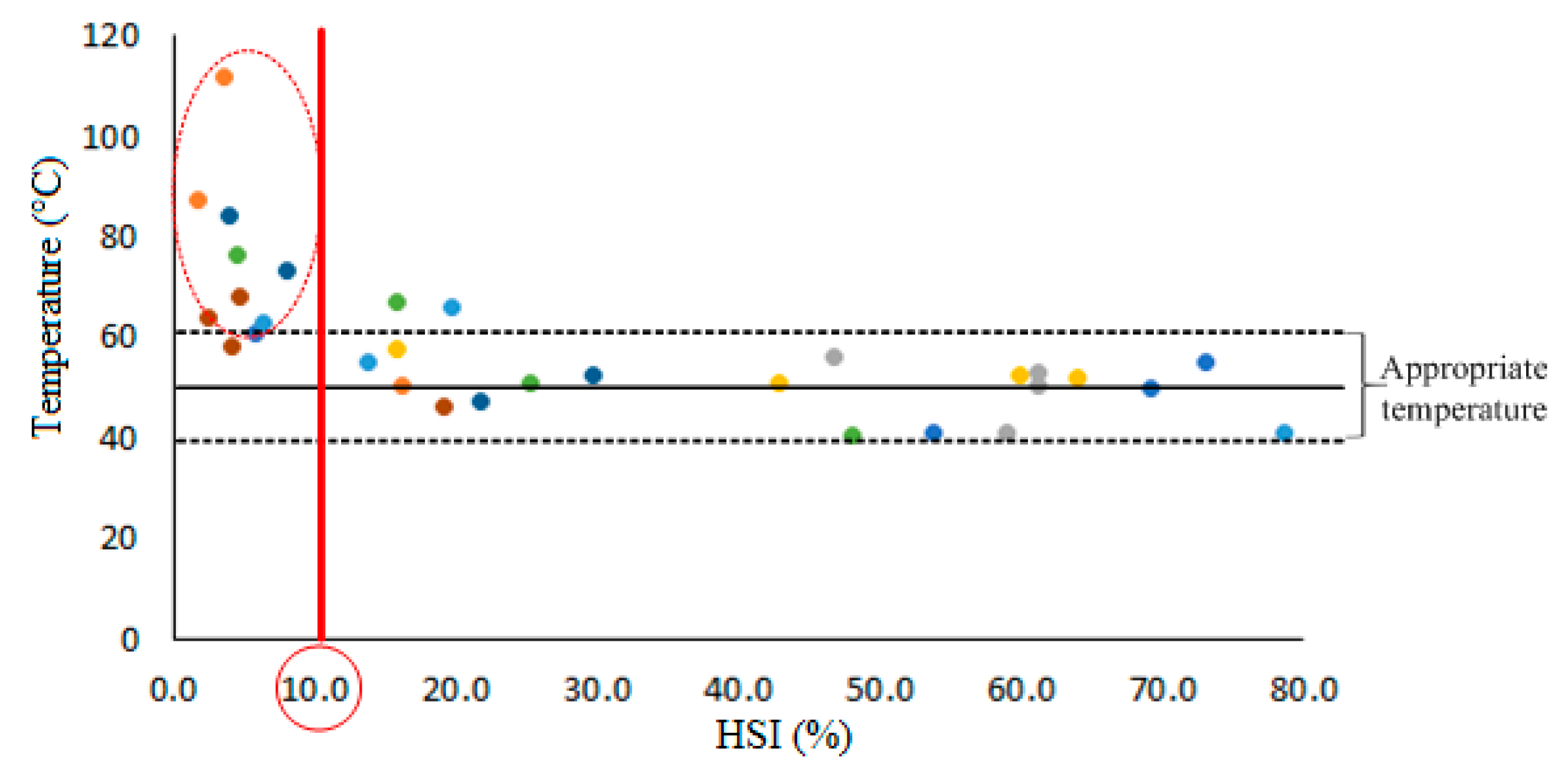

4.3. Thermal Analysis

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Yasushi, O.; Sanshiro, Y.; Daisuke, I. An investigation into hot-spot in PV module. In Proceedings of the Japan Solar Energy Society/Japan Wind Energy Association (JSES/JWEA) Joint Conference, Koriyama, Japan, 26–27 October 2010; pp. 535–538.

- Moreton, R.; Lorenzo, E.; Narvarte, L. Dealing in practice with hot-spots. In Proceedings of the 29th European Photovoltaic Solar Conference and Exhibition, Amsterdam, The Netherlands, 22–26 September 2014; pp. 1–6.

- Bishop, J.W. Microplasma Breakdown and Hot-Spots in Silicon Solar Cells. Solar Cell 1989, 26, 335–349. [Google Scholar] [CrossRef]

- Blake, F.A.; Hanson, K.L. The hot-spot failure mode for solar arrays. In Proceedings of the 4th Intersociety Energy Conversion Engineering Conference, Washington, DC, USA, 22–26 September 1969; pp. 575–581.

- Yang, H.; Hu, W.; Wang, H.; Narayanan, M. Investigation of reverse current for crystalline silicon solar cells-new concept for a test standard about the reverse current. In Proceedings of the 35th IEEE Photovoltaic Specialists Conference (PVSC), Honolulu, HI, USA, 20–25 June 2010; pp. 2806–2810.

- Bishop, J.W. Computer simulation of the effects of electrical mismatches in photovoltaic cell interconnection circuits. Solar Cell 1988, 25, 73–79. [Google Scholar] [CrossRef]

- Alonso García, M.C.; Herrmann, W.; Bohmer, W.; Proisy, B. Thermal and electrical effects caused by outdoor hot-spot testing in associations of photovoltaic cells. Prog. Photovolt. 2003, 11, 293–307. [Google Scholar] [CrossRef]

- Hoyer, U.; Burkert, A.; Auer, R.; Lutz, C.B. Analysis of PV modules by electroluminescence and IR thermography. In Proceedings of the 24th European Photovoltaic Solar Energy Conference and Exhibition, Hamburg, Germany, 21–25 September 2009; pp. 3262–3266.

- Herrmann, W.; Alonso, M.C.; Wambach, K. Effective hot-spot protection of PV modules characteristics of crystalline silicon cells and consequences for cell production. In Proceedings of the 17th European Photovoltaic Solar Energy Conference, Munich, Germany, 22–26 October 2001; pp. 1646–1649.

- Alonso-Garcia, M.; Ruiz, J.; Chenlo, F. Experimental study of mismatch and shading effects in the I–V characteristic of a photovoltaic module. Sol. Energy Mater. Sol. Cells 2006, 90, 329–340. [Google Scholar] [CrossRef]

- Kim, K.A.; Seo, G.S.; Cho, B.H.; Krein, P.T. Photovoltaic hot-spot detection for solar panel substrings using AC parameter characterization. IEEE Trans. Power Electron. 2016, 31, 1121–1130. [Google Scholar] [CrossRef]

- Watanabe, S.; Iijima, T.; Ohya, H.; Kudoh, T.; Itako, K. Study on temperature and fundamental characteristic of hot-spot of single-crystal photovoltaic cell by the amount of solar radiation. In Proceedings of the JSES/JWEA Joint Conference, Naha, Japan, 26–27 November 2013; pp. 315–318.

- Kudou, H.; Sugiyama, T.; Kudoh, T.; Itako, K. Prototype of the hot-spot rough-diagnosis equipment using projector for PV module. In Proceedings of the JSES/JWEA Joint Conference, Naha, Japan, 26–27 November 2013; pp. 49–52.

- Itako, K.; Kudoh, T. Study on hotspot of a single-crystal photovoltaic module. J. Inst. Electr. Install. Eng. Jpn. 2014, 34, 140–146. [Google Scholar]

- International Standard IEC 61215:2005, Crystalline Silicon Terrestrial Photovoltaic (PV) Modules—Design Qualification and Type Approval; International Electrotechnical Commission: Geneva, Switzerland, 2005.

- International Standard ASTM E2481–12, Standard Test Method for Hot Spot Protection Testing of Photovoltaic Modules; ASTM International: West Conshohocken, PA, USA, 2012.

| Item | Specification |

|---|---|

| PV solar panel model number | GT133 |

| Maximum power (Pm) | 50 W |

| Maximum voltage (Voc) | 20.5 V |

| Maximum current (Isc) | 3.35 A |

| Operation voltage (Vpm) | 16.4 V |

| Operation current (Ipm) | 3.05 A |

| Module Number | Connection Status | Insertion Resistor | Surface Illuminance | Initial Voltage (V0) |

|---|---|---|---|---|

| No. 2 | String (8 in series) | 910 Ω | 6000 Lux (24.6 W/m2) | 18.61 V |

| No. 2 | String (8 in series) | 910 Ω | 600 Lux (2.49 W/m2) | 8.49 V |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Itako, K.; Kudoh, T.; Koh, K.; Ge, Q. Voltage-Based Hot-Spot Detection Method for Photovoltaic String Using a Projector. Energies 2017, 10, 230. https://doi.org/10.3390/en10020230

Wang Y, Itako K, Kudoh T, Koh K, Ge Q. Voltage-Based Hot-Spot Detection Method for Photovoltaic String Using a Projector. Energies. 2017; 10(2):230. https://doi.org/10.3390/en10020230

Chicago/Turabian StyleWang, Yadong, Kazutaka Itako, Tsugutomo Kudoh, Keishin Koh, and Qiang Ge. 2017. "Voltage-Based Hot-Spot Detection Method for Photovoltaic String Using a Projector" Energies 10, no. 2: 230. https://doi.org/10.3390/en10020230