1. Introduction

For many decades now, the certification procedure for new vehicles (or engines) around the world is accomplished by applying a driving (or engine) cycle. By doing so, a broad range of the engine’s speed and torque is under test, as well as its transient behavior. A certification test cycle is characterized by relatively long duration (of the order of 20–30 min) consisting of both speed and load changes under varying operating conditions, cold or hot starting, including (for highway engines/vehicles) urban as well as motorway driving. Applying a driving cycle for the certification of new vehicles/engines means that simulation of the most frequent daily driving (transient) conditions is encompassed in the certification procedure [

1].

When developing new engines/vehicles, internal combustion engine manufacturers are facing a two-fold challenge. Firstly, they must meet the stringent emission limits imposed by the regulations with respect to the legislated cycle; at the same time, they strive to address customer needs for vehicles with increased power and torque (good drivability) and low fuel consumption. In order to fulfill these often-conflicting tasks, the diesel engine has gradually surfaced as a rather promising alternative to the spark ignition (SI) engine. Contributing factors are its superior fuel efficiency and torque, its inherent capability to operate turbocharged as well as its reliability [

2]. However, there are certain aspects of a turbocharged diesel engine’s operation that might prove particularly demanding or even problematic. The most notable one is its transient behavior, being linked with off-design operation, owing to the turbocharger lag, and therefore non-optimum performance in terms of both drivability and engine-out emissions [

3,

4].

Since the early 1970s, the modeling and the experimental investigation of the thermodynamic and gas dynamic processes of diesel engines has furthered the study of their transient operation. Unfortunately, the vital issue of exhaust emissions, as well as the overall engine and vehicle performance during driving cycles, has not been investigated in a thorough and comprehensive manner, owing mainly to two reasons. Firstly, it is the inherent difficulties involved in developing and validating multi-zone simulation models that require huge computational time for the reproduction of a driving cycle. Secondly, costly and sophisticated facilities are needed for experimental validation of such simulations, particularly when larger/heavier vehicles are concerned.

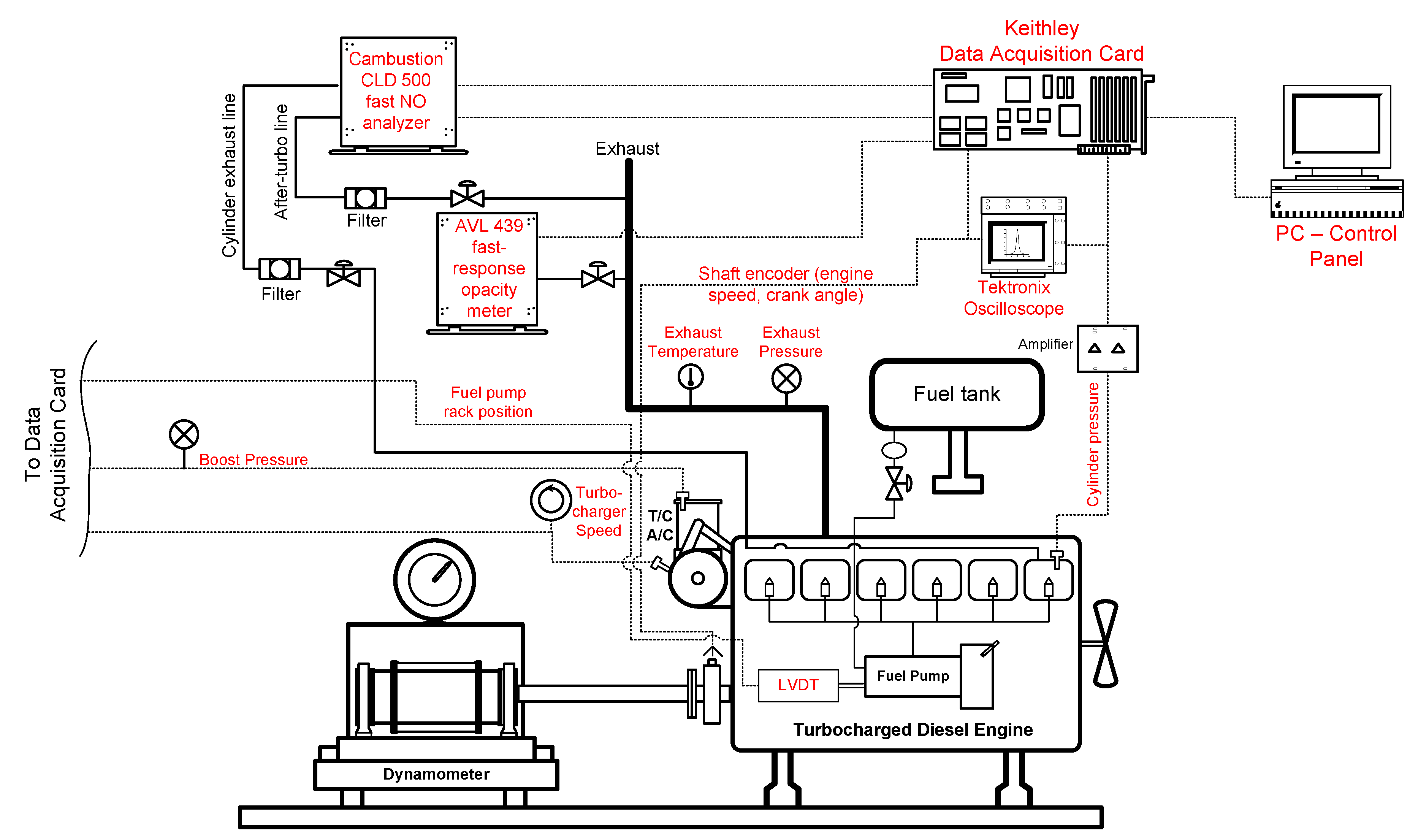

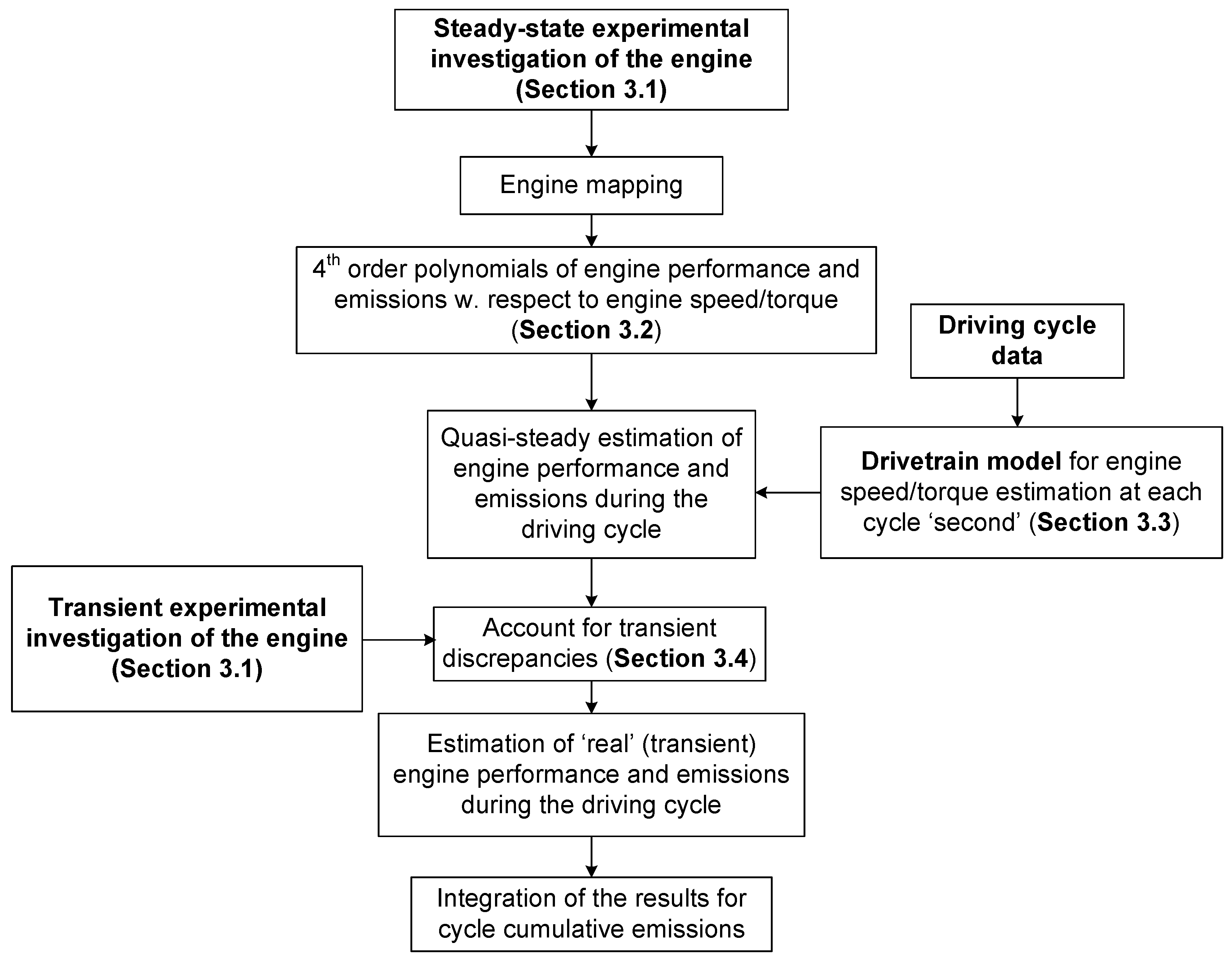

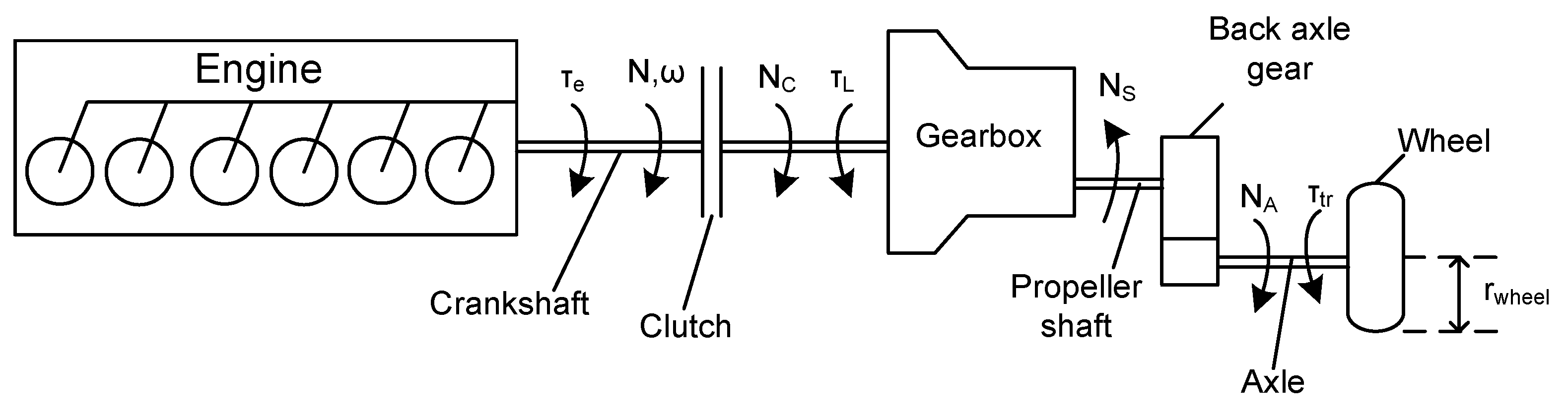

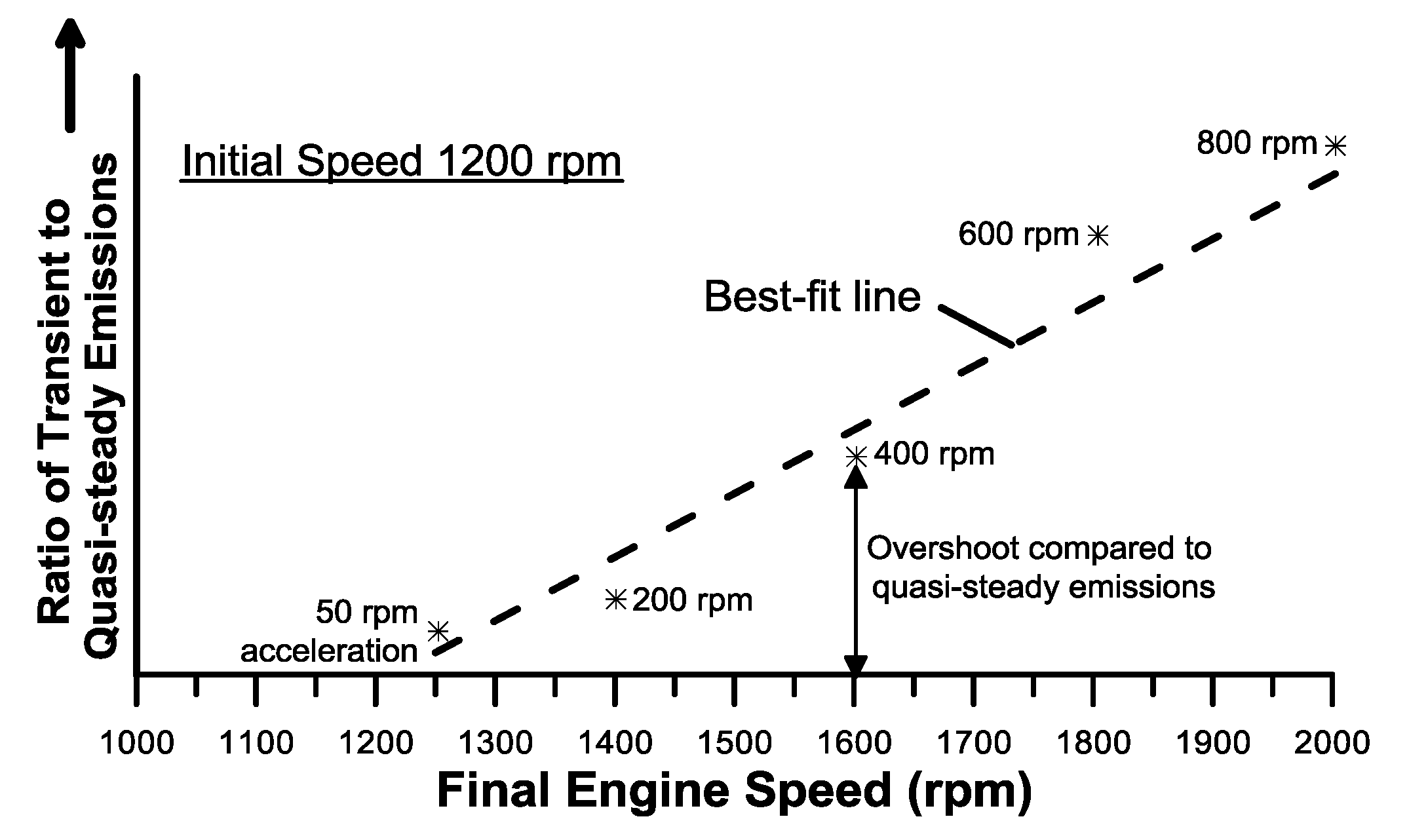

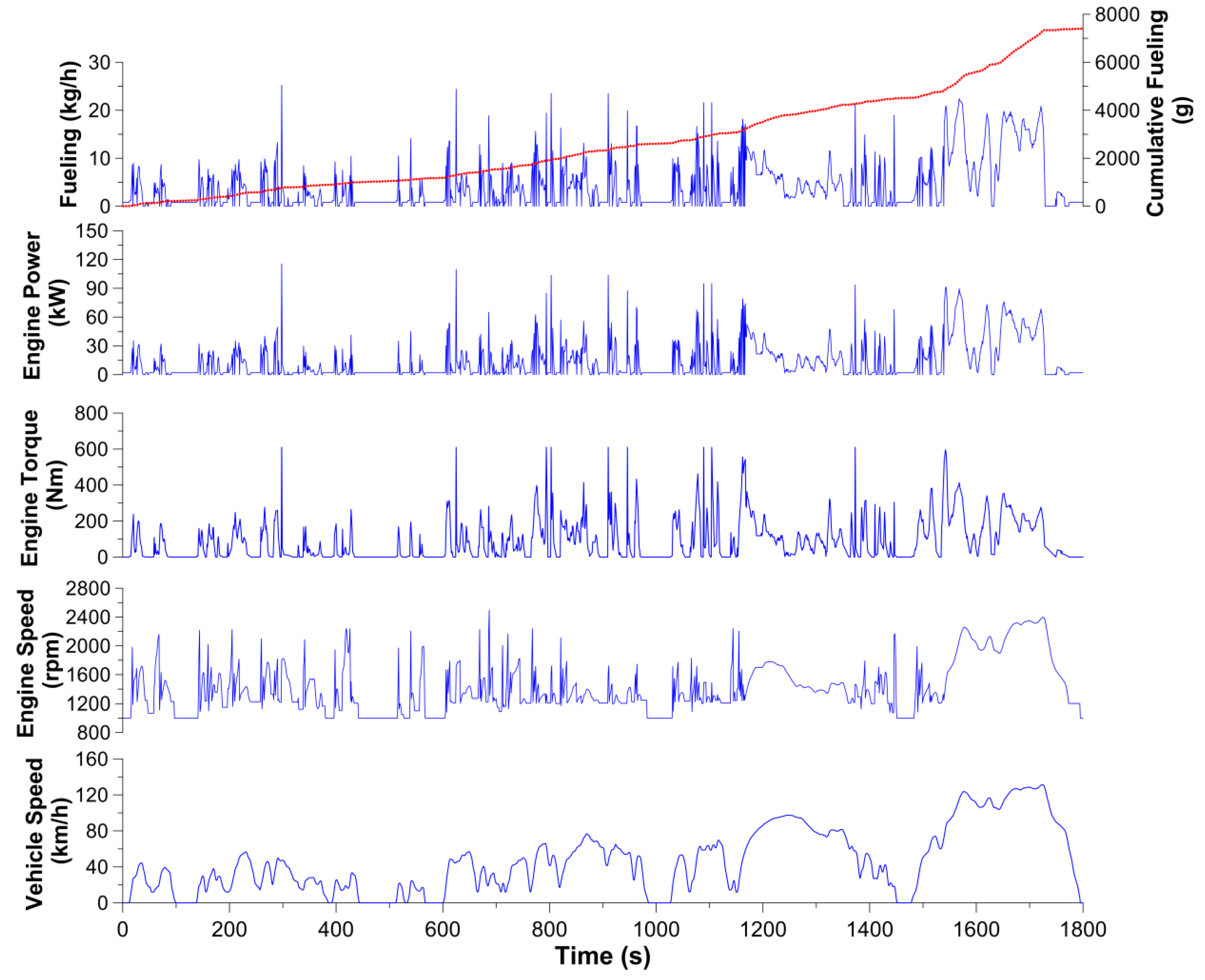

The work described in this paper aims to address the issues raised in the previous paragraph by applying an alternative procedure for the estimation of performance and emissions of a diesel-powered vehicle running on a driving cycle. The approach, which lies between simulation and experiment, is based on a steady-state experimental mapping of the engine in hand applying suitable correction coefficients to account for the significant discrepancies encountered during transients. These coefficients are derived from individual transient experiments (discrete accelerations), such as the ones experienced during the cycle. For the present study, the pollutants under consideration are nitrogen monoxide (NO) and soot, and the test schedule investigated is the newly developed worldwide harmonized light-duty driving test cycle (WLTC).

The relatively few mapping-based approaches developed in the past, following a similar philosophy to the one developed in this study, are generally based on the context of quasi-linear modeling [

5]. For example, Berglund [

6] used tabulated data of brake torque vs. speed and fueling derived at steady-state conditions for vehicular accelerations and load acceptance transients. Rackmil et al. [

7] followed the same approach for load and speed increase transients, and also applied a correction coefficient to account for transient discrepancies based on an earlier phenomenological simulation code. Some researchers have applied the relevant analyses to transient cycle emission studies. For example, Jiang and van Gerpen [

8] focused on particulate matter during the American FTP cycle, Ericson et al. [

9] investigated all regulated pollutants during the European heavy-duty engines ETC, and the present research group focused on NO and soot emissions for light-duty [

10] and heavy-duty [

11] vehicles. In parallel, Kirchen et al. [

12] developed a mean value model for soot and showed the effectiveness with tip-in operations employing empirical correlations between engine-out emissions and engine operating conditions. Furthermore, artificial neural networks have been employed by various researchers (e.g., [

13,

14]) to determine transient emissions based on steady-state test results used to generate the training data. On the other hand, a different prediction approach was followed by Bishop et al. [

15], who, based on data collected from on-board diagnostics (OBD) and portable emissions measurement systems (PEMS) when driving under real-world conditions, created fuel consumption and emission engine maps of real-world driving.

The scope of the present work is to apply the proposed methodology to the newly finalized WLTC driving cycle, which is scheduled to be implemented in the European Union (EU) as of September 2017. Due to its recent development and finalization [

16,

17], the research endeavors focused on performance and emission results during the cycle are rather limited. For example in [

18] and [

19], three Euro 5 certified gasoline direct injection cars, two Euro 6 diesel cars, and one Euro 5 non-plug-in gasoline hybrid car were tested on the WLTC, New European Driving Cycle (NEDC), and the Common Artemis cycle; one important conclusion derived was that the new WLTP test procedure may bring more realistic carbon dioxide (CO

2) emissions from the higher vehicle inertia included in the test procedure (being closer to the real mass of vehicle) but most likely not from the drive cycle pattern, even if this is more transient (as will be discussed later in the text). The same research group studied the emissions from two Euro 6 diesel cars over several laboratory test cycles and on the road, with the aim to evaluate the emissions performance of the vehicles when using PEMS systems in real-life driving, and to identify the differences in emissions that may arise between the various test procedures [

20]. Marotta et al. [

21] tested gaseous emissions of 21 Euro 4–6 gasoline and diesel-powered vehicles on the WLTP and the NEDC, with the results indicating rather small differences of CO

2 emissions between the two test procedures. In [

22], the comparison regarding CO

2 and fuel consumption was expanded to also include the U.S. FTP-75 certification cycle, again suggesting rather small differences between the compared cycles. Tsokolis et al. [

23], recently measured 20 vehicles on both the WLTP and the NEDC test procedure, again with the aim of identifying differences in the reported CO

2 emissions.

The present analysis aims to shed light into the relevant phenomena and underlying mechanisms of pollutants and CO2 emissions production during a transient cycle, based on its fundamental procedure and the fact that only vehicle speed profile effects will be taken under consideration, without the need for either costly experimental facilities or huge computational times as all the previous studies. Since the WLTC will replace the NEDC from September 2017, a comparative analysis between the two test schedules will also be performed for the engine/vehicle under study for all three examined emissions.

2. The WLTC and the NEDC Driving Cycles

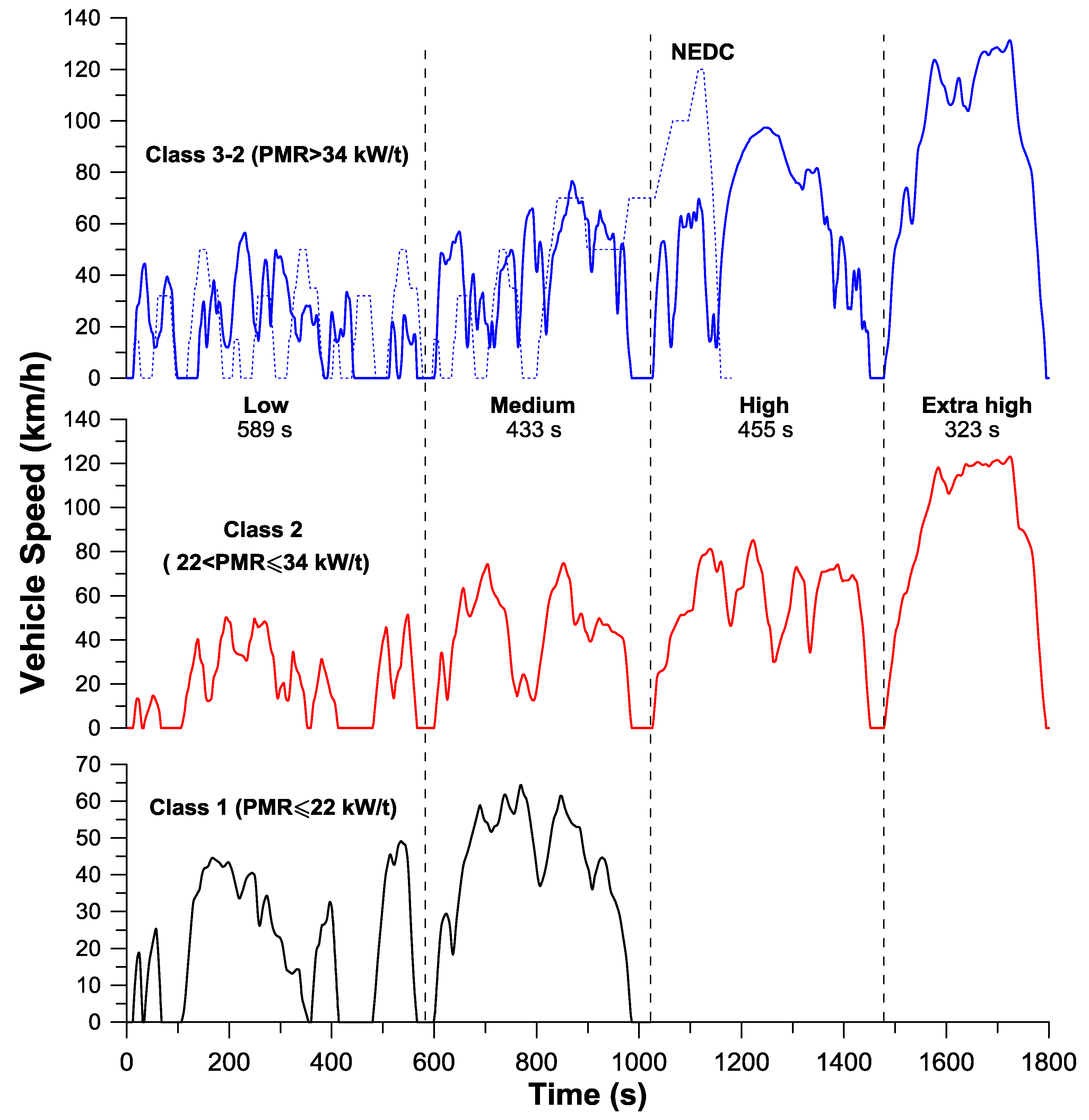

Passenger cars and light-duty trucks/vans (collectively referred to as light-duty vehicles), were the first vehicle types for which emission standards and test cycles were legislated in the late 1960s. With Directive 70/220/EEC, the first driving cycle, the ECE-15, was legislated in Europe. This was a modal, “repetitive” cycle, exclusively urban oriented. Beginning with the Euro 1 emission standard in 1992, a motorway segment was added (modal too), the EUDC (extra-urban driving cycle), with the entire cycle known from 2000 (Euro 3 emission standard) as the New European Driving Cycle or NEDC, of 1180 s duration. Owing to the simplified and stylized form of the NEDC (see the upper sub-diagram of

Figure 1), the European authorities, with considerable delay, have decided to adopt a true transient cycle from September 2017. This is going to be the worldwide harmonized light-duty vehicles test cycle WLTC, together with the corresponding test procedure WLTP [

24]. The WLTC is actually a suite of cycles, with different speed/time schedules depending on the tested vehicle’s power to mass ratio (PMR); the corresponding speed/time traces for the three classes are illustrated in

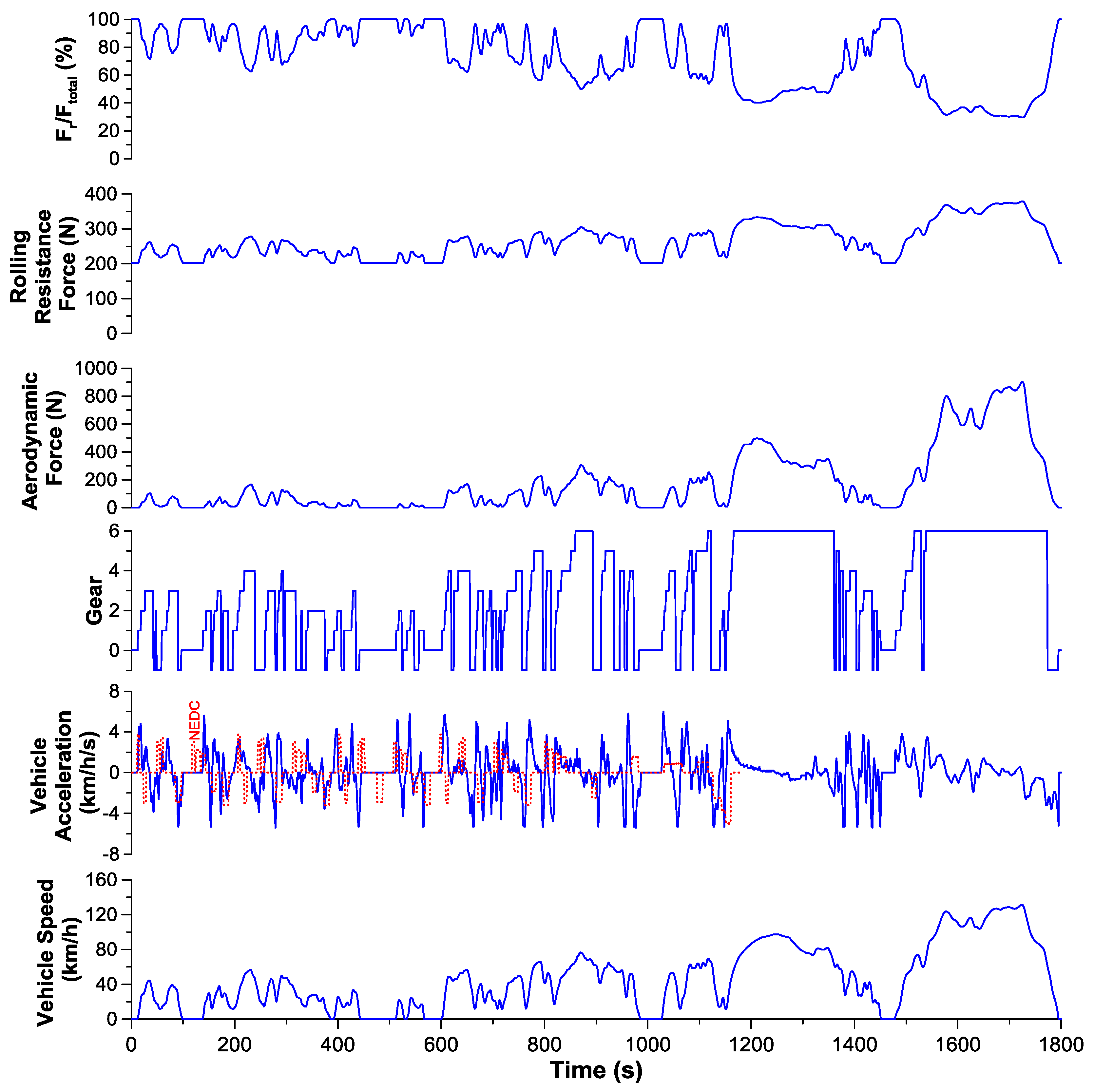

Figure 1. Particularly for Europe, the concerned class is mostly Class 3-2, which is appropriate for the power to mass ratio of the majority of European cars.

Duration of the WLTC is 1800 s, which was believed to represent an acceptable compromise between statistical representativeness on the one hand and test feasibility in the laboratory on the other. The duration of each cycle segment was set in a way that reflected the mileage distribution among the phases, thus no weighting factors were necessary for the final result. Specifically, the low segment lasts 589 s (five micro-trips), the medium 433 s (only one micro-trip), the high 455 s (one micro-trip), and the extra high 323 s (one micro-trip).

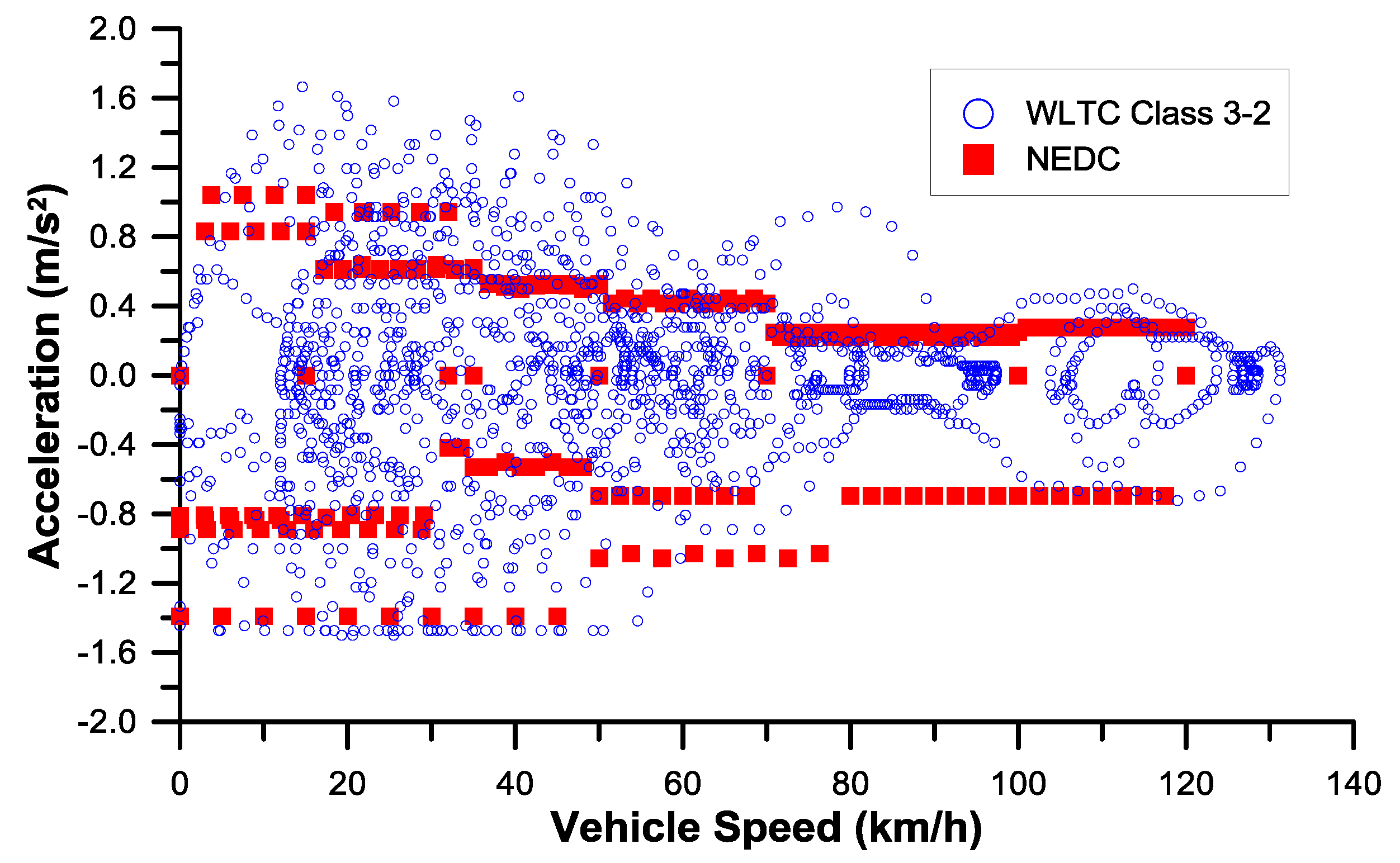

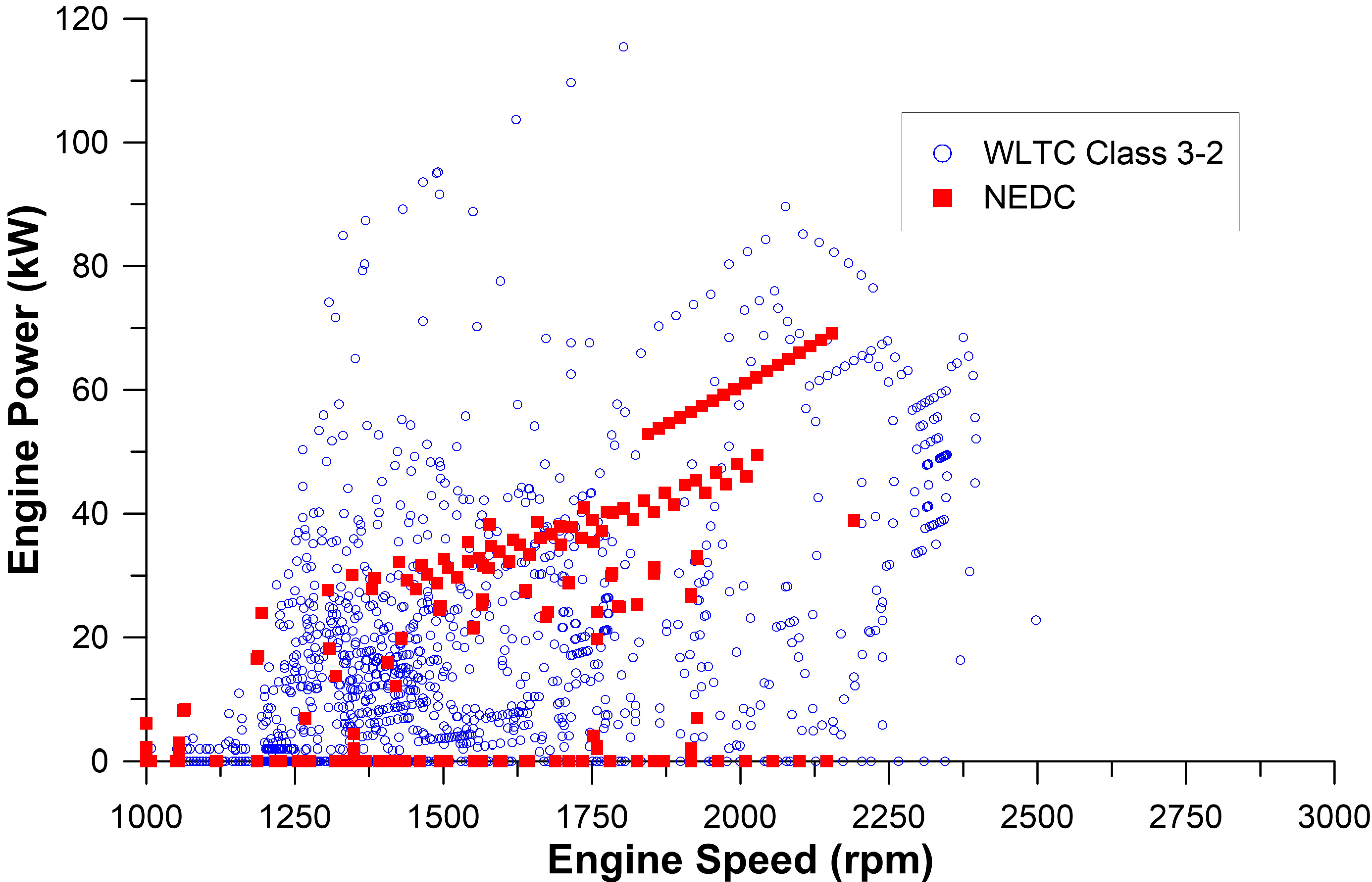

Figure 2 demonstrates the speed/acceleration distribution for Class 3-2 which is under study in this work; the corresponding NEDC speed/acceleration points are also provided in this figure needed for the comparison that will be presented later in the text. Further,

Table 1 lists the main technical specifications of each segment and of the entire WLTC that will be useful for discussion later in the text.

Further, the corresponding UNECE Global Technical Regulation (GTR) No. 15 provides gear selection and shift point determination (the gear shift strategy being vehicle dependent and not fixed as is the case with the European NEDC), reference fuels, road-load and dynamometer setting, test equipment such as analyzers and their calibrations, and test procedure and conditions to be followed during the certification [

24].

Comparison between the WLTC and the NEDC

Since the WLTC will replace from September 2017 the NEDC in the European Union for the certification of new passenger cars and light-duty trucks, the following paragraphs provide a direct comparison between the two cycles as regards their technical specifications (comparison of the respective engine emission results will be presented in

Section 4.2).

The NEDC is quite simple to drive and thus easily repeatable as

Figure 1 demonstrates. However, as already argued, it does not account for real driving behavior in actual traffic, containing many constant-speed and constant-acceleration segments. In fact, from several observations it has been shown that in Europe the gap between fuel consumption and emissions experienced by the vehicle on the road and those measured at type approval is higher compared to other areas of the world [

1]. The overall simplistic pattern of the NEDC and the exact gear-shift schedule make it easy for the manufacturers to implement cycle-beating techniques. Moreover, since it is only run once, cold started, its short distance might over-emphasize cold-starting emission effects. Oddly for its outdated structure, the encountered speeds are relatively high, at least compared to its Japanese (JC08 and earlier J10-15) and U.S. (FTP-75 and HFET) counterparts.

The WLTC, compared to the NEDC, lasts longer and covers more than double distance (see

Table 2 that compares some important technical attributes of the two cycles). This is then reflected into cold-start emission effects being relatively lower. From a purely measurement/experimental point of view, the longer duration of the WLTC poses a burden on the test-bed capacity (e.g., sampling bags). Furthermore, the WLTC has higher maximum, average, and driving speeds, and almost half the idling period (although the single stop with the longest duration is 66 s in the WLTC and only 27 s in the NEDC).

5. Summary and Conclusions

A mapping methodology was proposed and developed to estimate engine and vehicle performance and emissions during the recently developed worldwide WLTC driving cycle. The procedure is based on a steady-state experimental investigation of the engine in hand for the formulation of polynomial expressions of all interesting engine parameters with respect to rotational speed and torque. Correction coefficients were then applied to account for transient discrepancies based on various discrete transient events conducted and analyzed for the engine under study in a specially developed transient test bed. The obvious advantage of the methodology is that neither costly and sophisticated experimental facilities nor huge computational times are required.

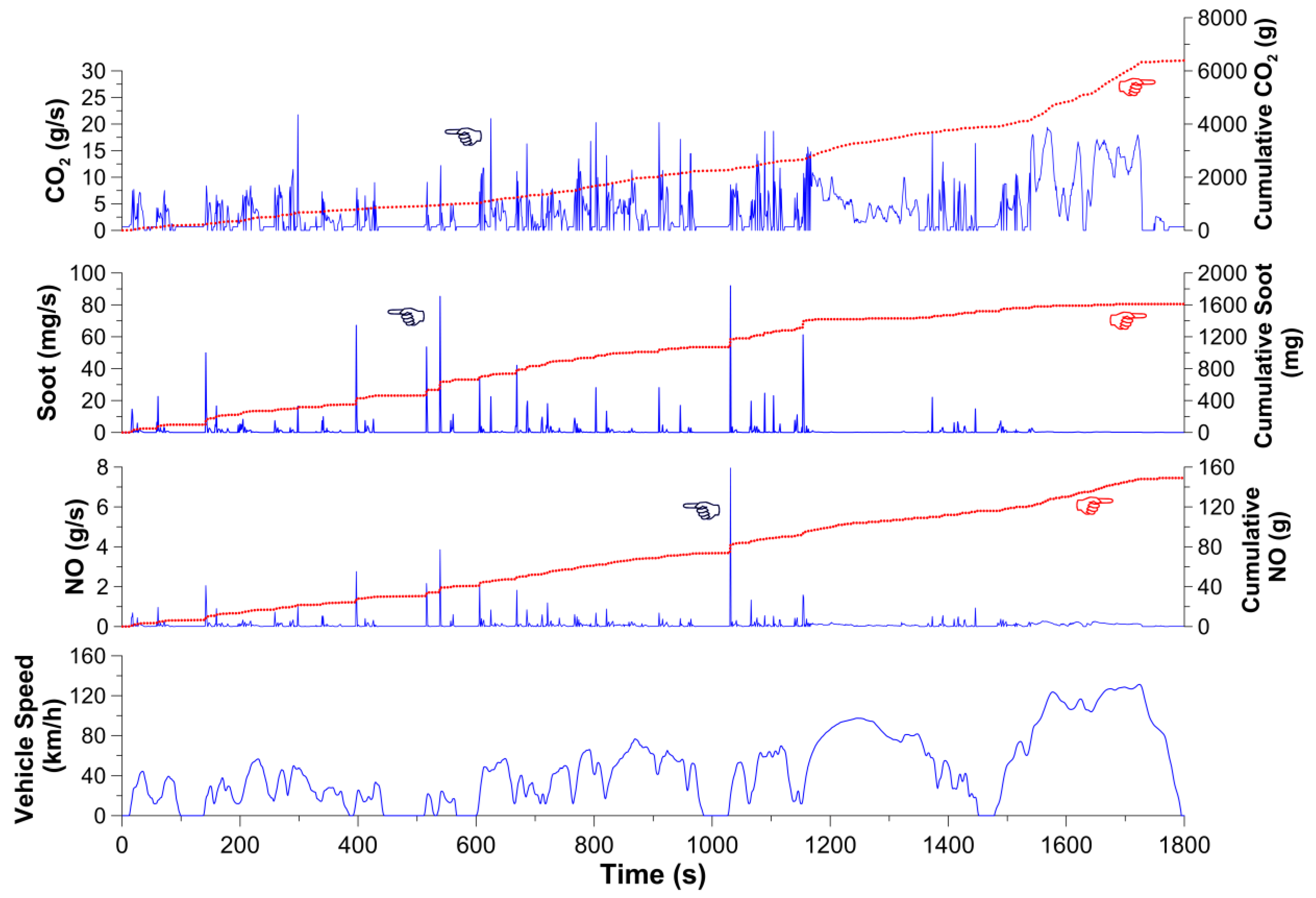

Vehicle speed was identified as the dominant property affecting almost all vehicle parameters and performance in general. A significant differentiation was observed between urban and motorway segments in this respect. As regards the engine, it was the rotational speed fluctuations (initiated by the respective vehicle accelerations) that decisively influenced the engine performance and emissions. At each point in the cycle where an (abrupt) increase in the vehicle speed was experienced, an overshoot in emissions (particularly soot) was noticed; the culprit here was the turbocharger lag.

It was further revealed that the first section (urban driving) of the WLTC is responsible for the biggest amount of emissions (g/km) owing to the most frequent and abrupt accelerations from no load conditions due to its many stops and increased RPA.

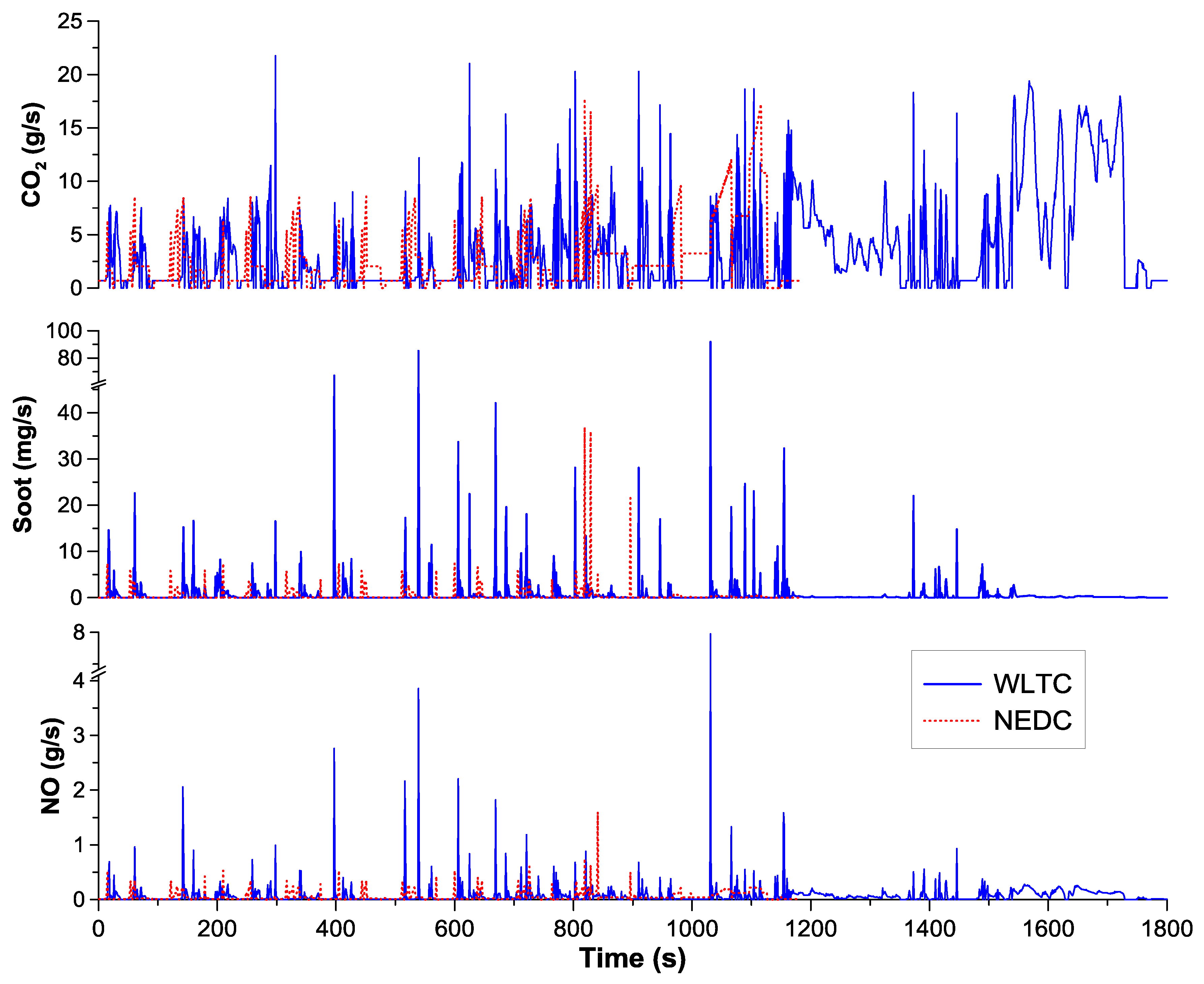

A comparison between the WLTC and the NEDC driving schedules was also performed applying the same vehicle test mass and gear-shift strategy. For the engine/vehicle in hand, it was shown that the WLTC, owing to its truly transient profile (in contrast to the NEDC’s modal form), captures much wider vehicle and engine operating activity, with obvious benefits in terms of real-world driving representativeness. At the same time, the WLTC exhibits higher specific energy and higher pollutant (NO and soot) emissions. On the other hand, owing to the engine operating at a slightly higher load level during the WLTC, the corresponding CO2 emissions were found somewhat lower compared to the NEDC.