1. Introduction

Islanded micro-grids are commonly settled in remote rural areas, which have a small population size and do not have large industrial plants. These areas are not connected to the electric grid because of the high connection, maintenance and operating costs.

The worst electrification rates are linked to Sub-Saharan Africa which has almost 620 million people (nearly a half of the total) living without access to electricity [

1]. Sub-Saharan Africa consists of 49 countries geographically situated below the Sahara Desert (some being intra-Saharan), 27 countries are among the top 36 world’s countries with the lowest incomes and with the highest number of people living in absolute poverty [

2]. Concerning Sub-Saharan Africa, the on-grid power generation capacity was 90 GW in 2012, with around half being in South Africa; 45% of this capacity is coal (mainly South Africa), 22% hydro, 17% oil (both more evenly spread) and 14% gas (mainly in Nigeria). The extension of the grid was limited only to a few areas, while most of the regions, especially the desert ones, were totally devoid of it [

3]. The actual scenario has not changed because of the high installation costs related to building generation, transmission and distribution networks. The costs for the grid extension to rural and remote Sub-Saharan regions increase since people live in dispersed clusters far from each other as well as from the utility grid, and can further rise in case natural boundaries are present [

4].

Nowadays, diesel generators (DGs) power most of the islanded micro-grids. Despite their many advantages like portability and flexibility, they do not represent a profitable solution from the economic point of view. For this reason, the integration of renewable energy systems within the DG micro-grids is a valid alternative for a more convenient management. This is possible since renewable energies sources (RES), like solar and wind, can be locally available, and these technologies are currently a low cost solution. Moreover, the electrification of remote areas and the improvement in power quality and energy cost in existing power plants is a very high potential market, especially in Africa.

The introduction of non-programmable renewable energy generators dramatically changes the management of the power flows into the micro-grids. To ensure the grid stability, the variability of the renewable sources requires an increase of the spinning reserve of the whole power plant [

5]. When the spinning reserve will be covered by the DGs, the benefits due to the installation of the RES will reduce. For this purpose, it is recommended to include other types of regulating generators, like storage systems provided by inverters with droop control, so that they can act as rotating generators and perform spinning reserve [

6]. Regulating generators performing primary and secondary regulation guarantees the power balance of the micro-grid, sharing the load power among the generating unit and restoring voltage and frequency levels after primary regulation intervention. The additional tertiary regulation can be introduced to controls the power flows pursuing power quality and economic benefits; usually a daily scheduling defines active generators’ generation curve in terms of hourly average values.

The control of a micro-grid is complex and crucial, even because there is no generally accepted benchmark test system; thus, in many countries of North America, Europe and Asia, experimental micro-grids have been realized in order to test the micro-grids’ topologies and their control logics [

7]. In particular, projects promoted by the European Union like the “EU Microgrids Research Project” and the “EU More Microgrids Research Project”, had the scopes to study the operation of micro-grids in parallel with the grid and islanded, to define and develop control strategies to ensure efficient, reliable, and economic operation and management of micro-grids and to simulate and demonstrate micro-grid operation on laboratory scales [

8]. As far as control logics are considered, decentralized energy management systems appear to be a viable solution for the control of autonomous micro-grid’s topologies [

9].

Micro-grids in rural and remote areas may comprehend even a potable water system or a hydrogen system, suitable for medium and long-term energy storage; the integration of these subsystems within the control logics increases the level of complexity of the control system, which can be managed with optimization tools [

10].

Many recent research works have been focused on optimization methods for grid-connected and islanded micro-grids [

11]. Generally, energy management optimization can be implemented as a dynamic problem. Therefore, it should apply the Dynamic Programming (DP) algorithms [

12]. However, due to their complexity, they are commonly addressed to small benchmark systems in short-term analysis. Some research works employed nonlinearity in optimization models to attempt applying Mixed Integer Non Linear Programming (MINLP) for energy mix. Usually, they approach the MINLP making use of the Benders decomposition [

13]. It allows for transformation of the typical MINLP problem into the Mixed Integer Linear Programming problem (MILP). This method ensures computational efficiency and guarantees a global solution (while the pure MINLP provides with only local ones). Because the MINLP models are often transformed to the MILP problems to facilitate model solving and to guarantee the local solution, some researchers have started to develop pure MILP model without the need for Benders decomposition application [

14]. A simplified representation of the power units applied to the optimization of energy power flow of limited systems, like for example a single battery storage [

15] or a combination of renewables and storage [

16], can be based on Linear Programming (LP).

This paper develops two optimization models to set up a long-term schedule for tertiary regulation. The first one aims to maximize the energy harvesting from renewable energy sources, thus minimizing the energy production from DGs; it is based on Linear Programming (LP) method. The second one aims to minimize the operating costs, and it is based on Mixed Integer Programming (MIP). Both models have been applied, as a case study, to an islanded micro-grid composed of DGs, photovoltaic (PV) systems and a Battery Energy Storage System (BESS) operating in Somalia since November 2015.

This work is intended to present the application of these optimization methods to a real case study. The measurements obtained through a six-month monitoring period, in place of forecasted trends, have been used as the input of the models. Forecasting are intrinsically affected by errors, thus, using measurements allowed validating the models in a real case study. Results show that both the optimization methods led to some improvements with respect to the present and non-optimized control logics.

In the paper,

Section 2 is a technical description of the main components of the power plant, followed by a presentation of the main controls applied to the generators in order to regulate the power flows. A typical sunny day has been selected as a sample day to highlight the limits of the actual control logic.

Section 3 and

Section 4 describe the optimization models that have been developed by using the LP and MIP methods respectively. In both sections, the equations of the problem’s formulation are presented, and the results of the case study application of each model in the previously defined sample day are shown. In the end, the paper compares and discusses the outcomes of the LP model and of the MIP model.

2. The Case Study

2.1. Case Study Micro-Grid

This work takes into account an islanded micro-grid in Garowe City, in the North of Somalia, installed in 2015 [

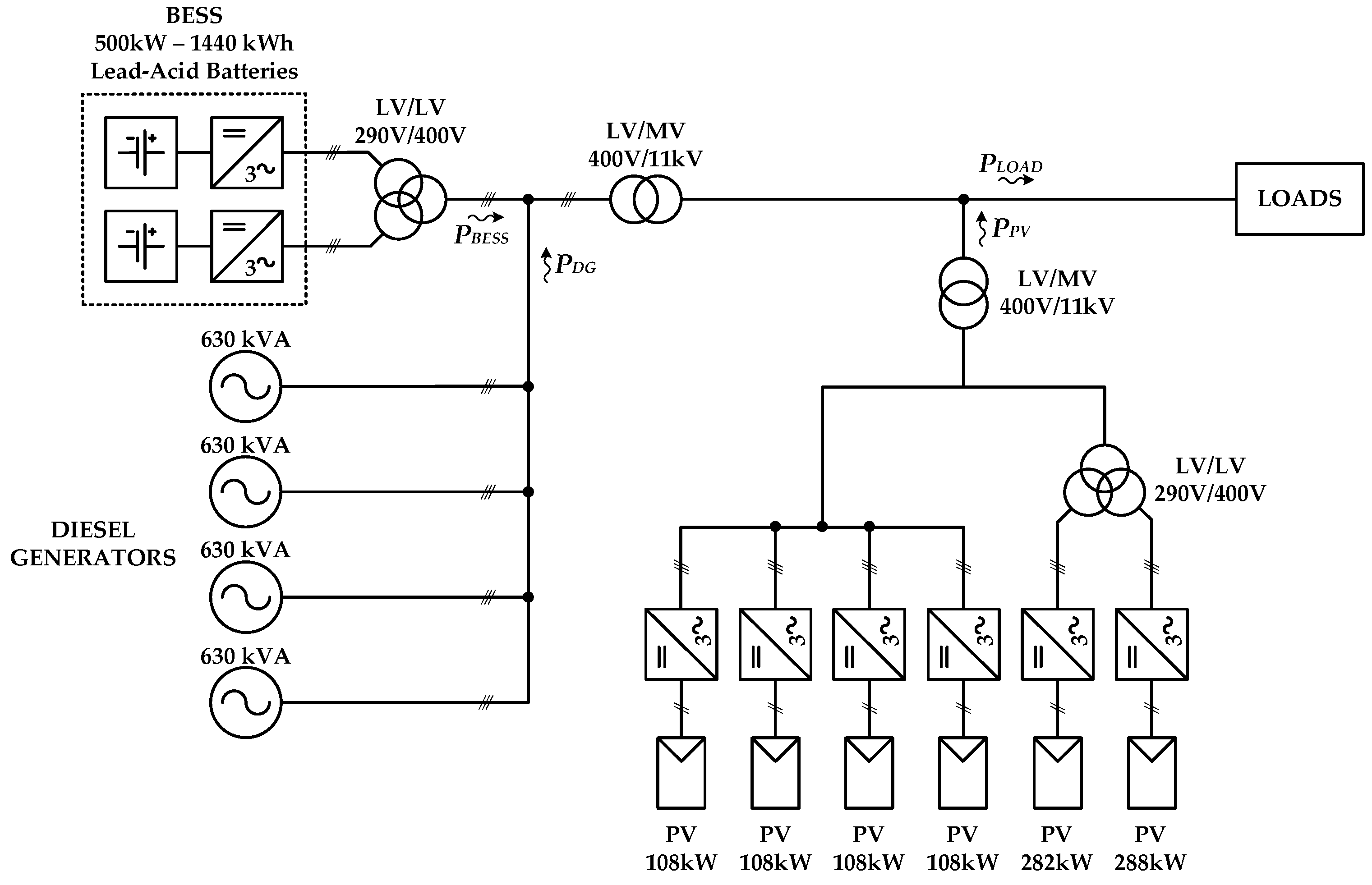

17]. The generation unit can be defined as a Hybrid Power Plant (HPP) because it consists of two different generation systems:

a conventional generation system, composed of four diesel units of 630 kVA/500kW each;

a renewable energy system, composed of six PV fields for a total of about 1 MWp.

The electrical system also includes a 2 × 250 kW–2 × 720 kWh BESS, made of two battery banks for a total of 600 lead-acid batteries; each battery is characterized by a rated voltage of 2 V and a rated capacity of 1200 Ah. Each battery bank is connected to the grid through a DC/AC 250 kVA bidirectional inverter. The main function of the BESS is the improvement of the stability of the power plant, with the aim of increasing the exploitation of RES, thereby leading to a substantial fuel economy compared to the solution with only DGs. The plant is designed to supply the city of Garowe through three overhead distribution lines, operating in medium voltage (11 kV, 50 Hz). Since the micro-grid is located in a rural area of Africa, the load is mainly domestic and related to lighting, thus concentrated in the evening hours.

Figure 1 shows the diagram of the micro-grid described above.

The HPP is controlled through a system based on Programmable Logic Controllers (PLCs). Normally, it is automatically managed through control logics based on power flow measurements, operational constraints and settings. The actual control logics regulate the power generated by the DGs and the PV and the power generated or absorbed by the BESS. Normally, in order to take the maximum advantage from the solar energy, PV plant is managed with the Maximum Power Point Tracking (MPPT) algorithm, using the Perturb and Observe (P&O) method. The P&O method adopted is based on a trial and error procedure in finding and tracking the MPP, even during variations of the irradiance and temperature [

18]. The P&O MPPT algorithm works well when the irradiance changes slowly and so, it should be the most appropriate method for the tropical, hot and dry weather of Somalia.

In case the power production, both from PV and DGs, exceeds the load demand and BESS is not available to store energy, PV is regulated by reducing the power with the algorithm of Regulated Power Point Tracking (RPPT). Anyway, DGs are regulated in order to guarantee an adequate spinning reserve.

The control logics are currently organized in a hierarchical order, based on the relevance and time of implementation of the actions. Functions with the maximum priority are related to safety operations, like prevention of anti-motoring of DG or rapid curtailment of generation. Then functions with medium priority manage the power flows to determine the stability of the micro-grid. In the end, functions with the lowest priority deal with the preservation of the main components, for instance by handling the number of starts and stops of DGs to exploit them in the same way.

2.2. Current Micro-Grid Control Logics

The current control logics do not lead to the best mix of power that allow one to take the maximum advantage from the RES. For that reason, this work aims to verify if an additional level of control, e.g., a tertiary regulation based on forecasting and an optimization method, will be useful to increase the amount of energy produced by RES. In this perspective, the optimized power flows would be inserted into the control logics, as medium-time control [

19].

The management of DGs is based on load demand, according to the operational constraints, as minimum and maximum power, and spinning reserve.

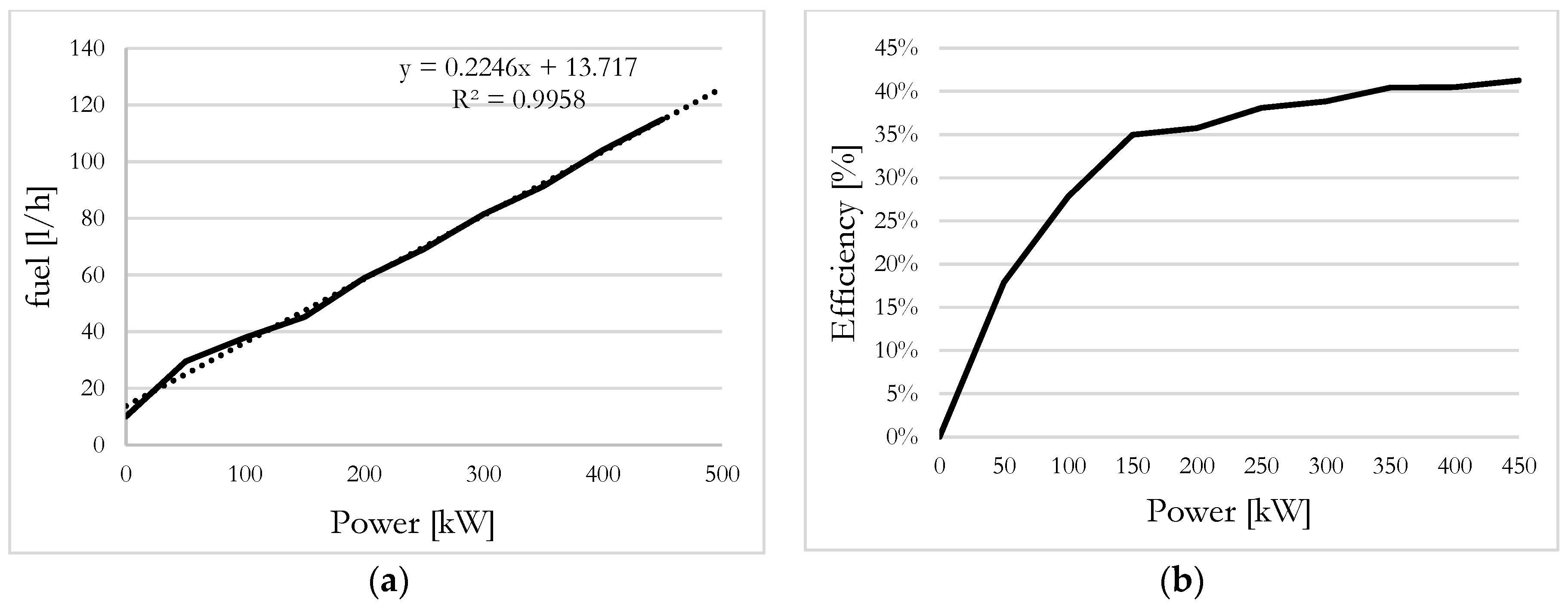

The fuel use has been computed from real measurements of this case study micro-grid. The pairs of experimental values of fuel consumption as a function of the output power have been fitted with a linear regression (

Figure 2a), thus the linear dependence between DG power and diesel consumption is:

where

A = 13.717 (L/h) and

B = 0.2246 (L/kWh) are the coefficients deduced from the linear regression,

ut,i is a binary variable that represents the on or off status of

DGi at time interval

t and

PDGt,i is the

DGi power at time interval

t.

By having collected the fuel consumption rates for different power levels of diesel generators, having assumed 40.9 MJ/kg of diesel heating value and 835 kg/m

3 for diesel density, it has been possible to calculate the input power for DGs and the corresponding efficiency (

Figure 2b).

The spinning reserve of a generator corresponds to its regulating capacity, such as the free power; it can be estimated as the difference between the maximum power of the generator and the power at which it is running at that moment. In order to guarantee a complete load coverage, the available spinning reserve of all the generators at any time must be greater than the required spinning reserve of the system. In this case study, the micro-grid spinning reserve,

PSR_TOT, is calculated as maximum the between a fixed term

SRload and a variable one,

PPV, that corresponds to the photovoltaic power produced;

SRload is estimated as the maximum load variation observed in the historical data available, corresponding to 250 kW.

In this way, during night time the HPP is regulated in order to cover the possible maximum load variation while, during day time the HPP is able to support the maximum generation oscillation.

This solution has been carried out since the demand is completely covered by residential loads, so that load variations compared to the HPP rated power are very limited, whereas a sudden lack of solar power can be responsible for a large oscillation. Moreover, a reduction in irradiation will affect all of the PV inverters, causing a sharp loss of produced power. Thus, it can be considered the worst condition, if compared to a breakdown of a single PV inverter. For this reason, while PV is generating power, the HPP spinning reserve corresponds to the whole PV generation at that moment.

The HPP spinning reserve is supplied by all the generators with regulating capacity, namely by DGs and BESS. BESS participation toward the spinning reserve is fixed at 200 kW. DGs power dedicated to the spinning reserve is calculated as the difference between the total requested spinning and the part of spinning reserve given by the batteries.

The BESS is normally regulated with droop control [

20] within a distributed control system [

21], in order to support the DGs in performing primary and secondary regulation, thus guaranteeing the power balance of the micro-grid. When BESS primary regulation is not working, the batteries perform a daily cycle of charge and discharge, from 35% to 100% of usable state of charge (SOC). Since the maximum Depth of Discharge (DOD) is 40% (corresponding to 60% of absolute SOC), the limit thresholds expressed in terms of absolute SOC are 74% and 100%. These thresholds have been selected according to the battery supplier’s recommendations and considering the best tradeoff for battery ageing, energy availability and power balance.

2.3. The Sample Day

The sample day that has been chosen among the first six months of operation of the power plant is 17 November 2015, as a representative day for the typical behavior of the case study micro-grid. In order to evaluate the solar production, a comparison between PV measured power and the maximum theoretical power that this PV plant could have generated, at the same ambient conditions of temperature and irradiance, has been carried out.

The maximum harvestable power from PV generators is the ideal power that derives from the MPPT fulfillment and it has been calculated according to [

22]:

where,

PMPP@STC is the maximum power at the Standard Test Conditions (STC) of the whole PV system, corresponding to 1 MW;

γ is the temperature coefficient corresponding to −0.42%/°C;

ΔT is the difference between measured ambient temperature and 25 °C;

G is the measured local irradiance (W/m

2);

GSTC is the irradiance at STC, namely 1000 W/m

2.

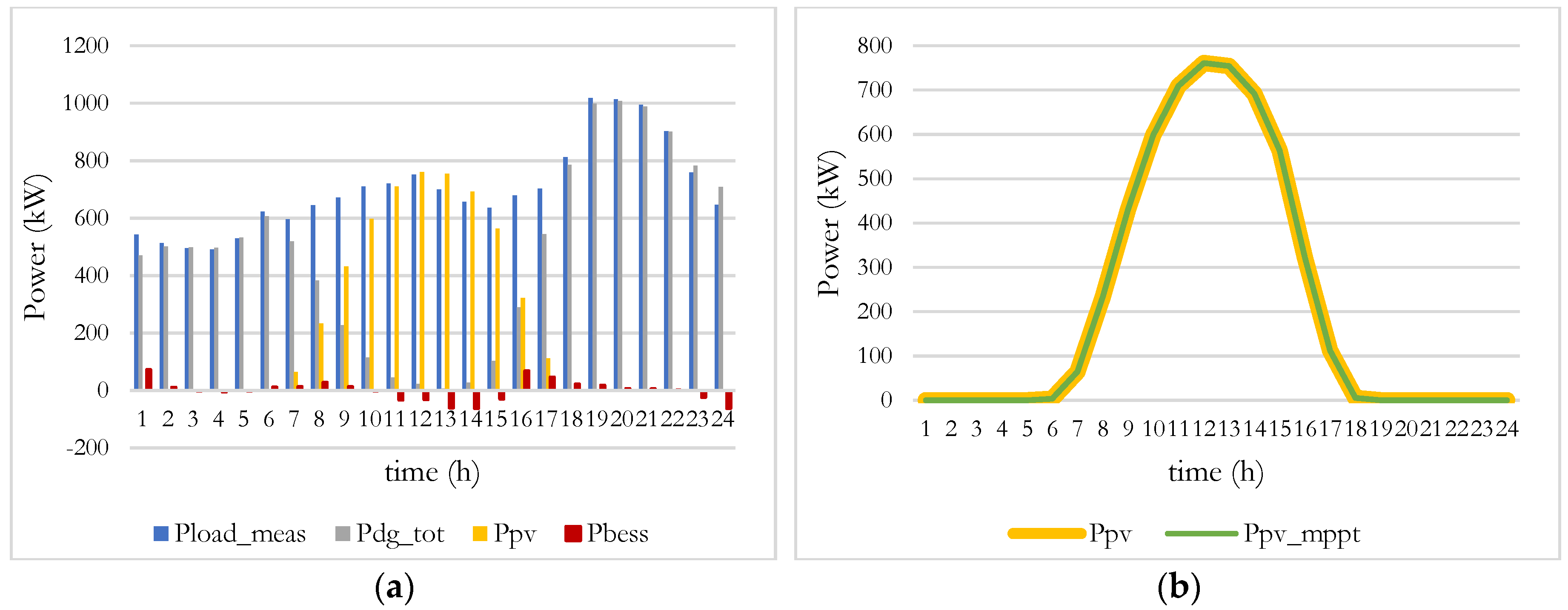

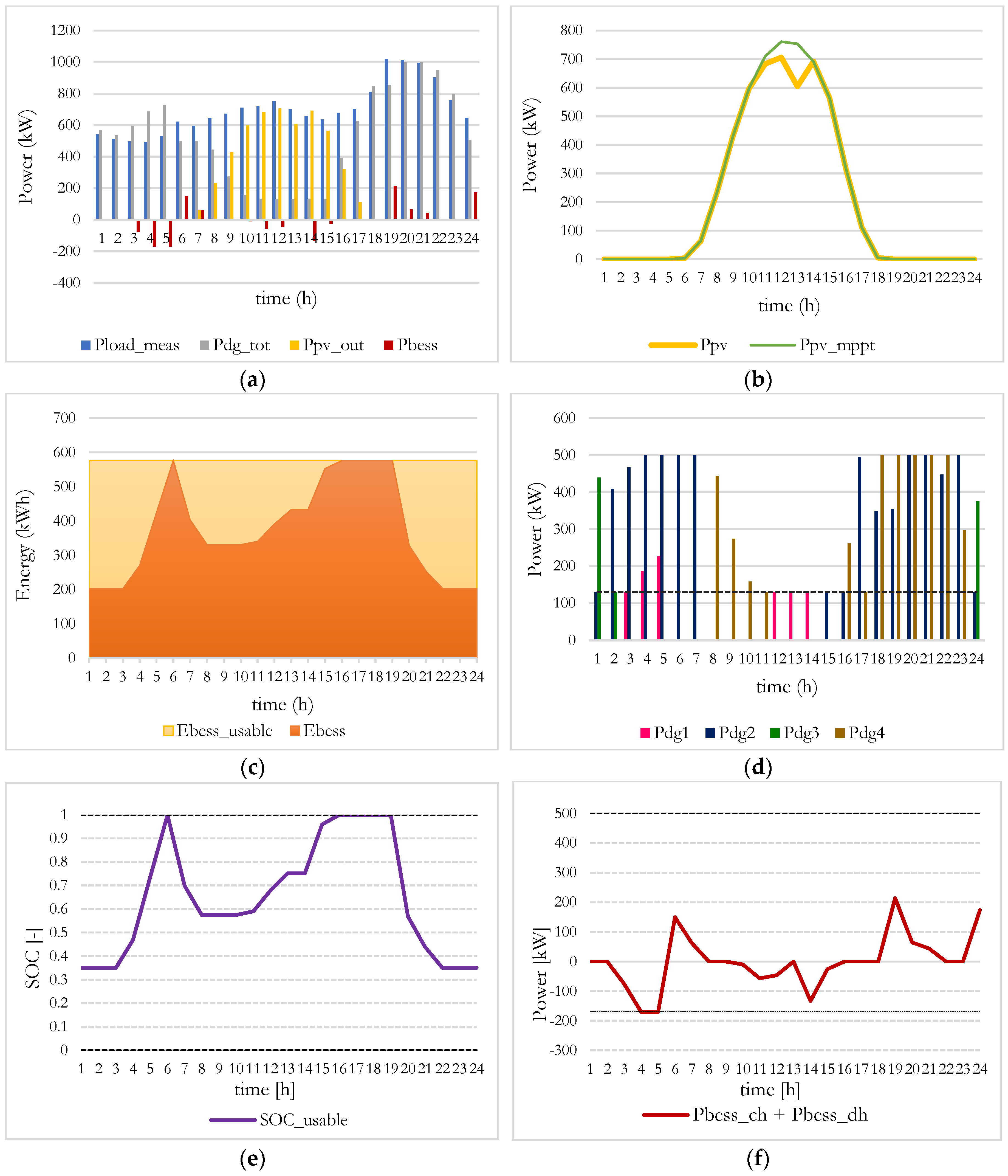

Figure 3a shows the main power flows into the micro-grid case study managed by the actual control logic in terms of power absorbed by the load (

Pload_meas), overall power produced by DGs (

P_dg_tot_meas), power produced by the PV system (

Ppv_meas) and power absorbed (negative values) or generated (positive values) by BESS (

Pbess_meas).

Figure 3b shows the comparison between the measured PV power (

Ppv_meas) and the maximum harvestable power (

Pmppt): it is evident that actual power has not reached the maximum possible (for the irradiance conditions of the day analyzed), but it has been curtailed in the central hours of the day.

The PV daily energy that has not been produced is 1131 kWh, corresponding to the 21.5% of the total harvestable PV energy.

5. Conclusions

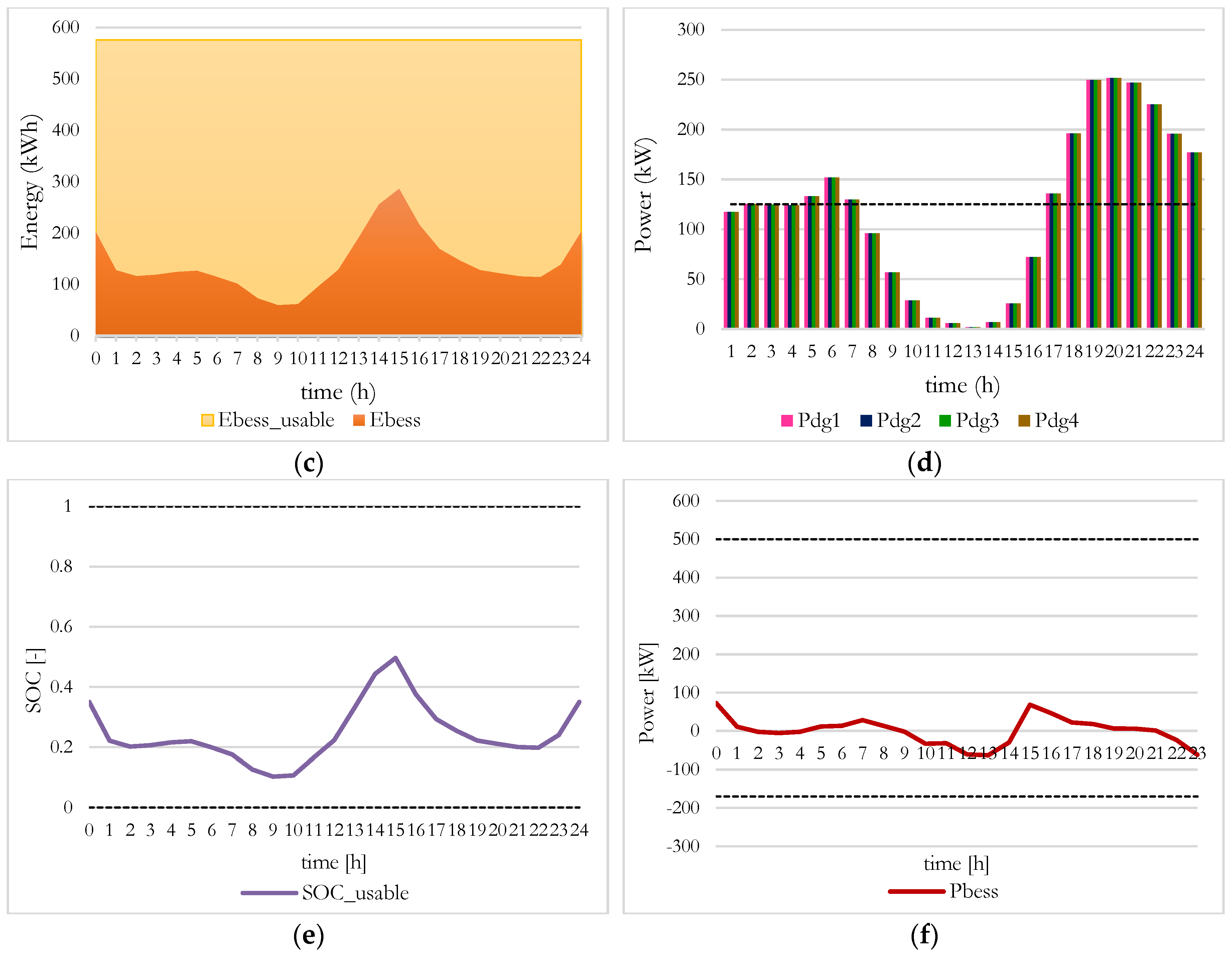

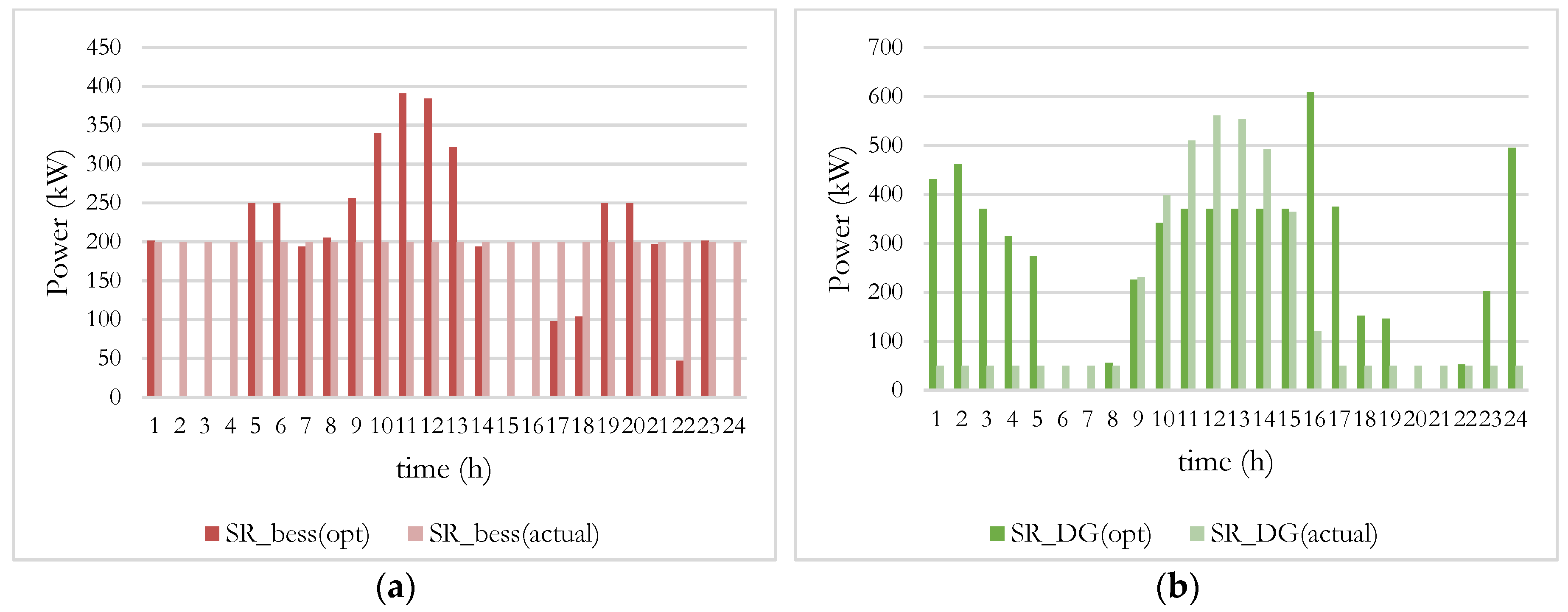

This paper developed and compared two optimization methods intended to define the power flows into an islanded micro-grid including DGs, PV systems and BESS. The LP method has been applied to set up the model to maximize the energy harvesting from renewable energy sources, while the MIP method has allowed to set up the model to minimize the micro-grid operating costs.

An islanded micro-grid, placed in Somalia and running since November 2015, has been identified as case study for this research. It emerged that load profile, with peaks concentrated during evening hours mainly due to lighting and domestic appliances, does not match with the PV generation curve. Since battery storage capacity has not been sized for time-shift function, it cannot store all the excess PV power produced during the day. Moreover, in order to guarantee the required spinning reserve, the actual control logics keep the DGs working close to their minimum power also in case of high PV production. In these conditions, to comply with the power balance, PV power has to be curtailed during the central hours of the day. In the sample day, it appeared that a large part of PV daily energy, equal to 21.5%, cannot be produced due to spinning reserve constraints.

Optimization models allow to improve the actual management by minimizing PV curtailment or operating costs, namely the fuel consumption. The optimization model developed using LP has been formulated in order to minimize the DGs’ energy produced during the day. As a result of the LP model, it can be noticed that the daily electric energy produced by DGs can be reduced by 13.5% and PV energy produced corresponds to the maximum feasible, but overall costs are 4% higher than in the real case study. The LP model imposes the DGs to operate in the range between zero and the minimum operating power, thus with an extremely low efficiency, for several hours per day, resulting in an increase of the fuel consumption. The optimization model developed using MIP has been formulated to overcome this problem, setting the objective function as the minimization of the operating costs. As a result of the MIP model, it can be noticed that the daily fuel cost saving is 12.3%, corresponding to a 5.8% of DG energy saving. The curtailed PV energy reduces from 21.5% to 4.4% of the maximum harvestable solar energy.

MIP model is a more complex and more complete model with respect to the LP model, able to represent real operating management scenarios of the HPP without any limitations. In particular, the modeling of the start and stop of DGs and their independent management is crucial in defining power flows that minimize the use of fossil fuels. Moreover, MIP model allows to point out the limitations of the actual control logics of the case study micro-grid. The improvements in the control logic, related to the optimized approach, can be summarized as:

let the amount of spinning reserve dedicated to BESS free to be calculated by the optimal solution;

do not equally share power among DGs, but take care to the best mix of power in order to have the maximum efficiency.

In order to apply further improvements to the management of the micro-grid, two possible solutions can be followed: the first one is the increment of the storage capacity installed, to increase the quantity of RES energy that can be stored in case it exceeds load demand. This could be an effective solution; however, it will not be the least expensive one. The second alternative is the identification of different spinning reserve margins that could lead to an additional reduction in fuel consumption. A possible further development of this work will consider the latter scenario.

Moreover, in order to take into account the benefits of both LP and MIP methods, the design of a new multi-objective model can be implemented, combining the maximization of RES energy harvesting and minimizing the operating costs. However, this approach necessarily requires using specific multi-objective optimization algorithms. A second option can be the definition in the MIP model of a weighted objective function representing a tradeoff of the previous goals.