A Study on the Optimization of Surfactants in the Main and Vice Slug in Weak Base ASP Flooding

Abstract

:1. Introduction

2. Numerical Simulation Model

2.1. Numerical Simulator

- (1)

- It includes a flexible component model, user can defined chemical reaction kinetics, phase equilibrium constant model, function model, saturation function model, and flexible good geological mechanics model of the simulator, and the user can simulate all kinds of chemical flooding processes based on this software;

- (2)

- It can fully characterize the physicochemical mechanism in the process of chemical flooding, it can simulate the change of molecular weight of the polymer, polymer shear, affect the degree of mineralization, adsorption, and retention, permeability decrease, inaccessible pore volume, non-Newtonian fluid, polymer degradation, capillary number equation, interfacial tension, components of the dispersion and diffusion, ion exchange reaction, emulsification, etc. It also can be used to simulate the scale of the laboratory to the scale of the mine, such as the choice of the chemical agent, the optimization of the development method, the research on the oil displacement mechanism, the chemical flooding simulation, and so on.

2.2. Geologic Characteristics

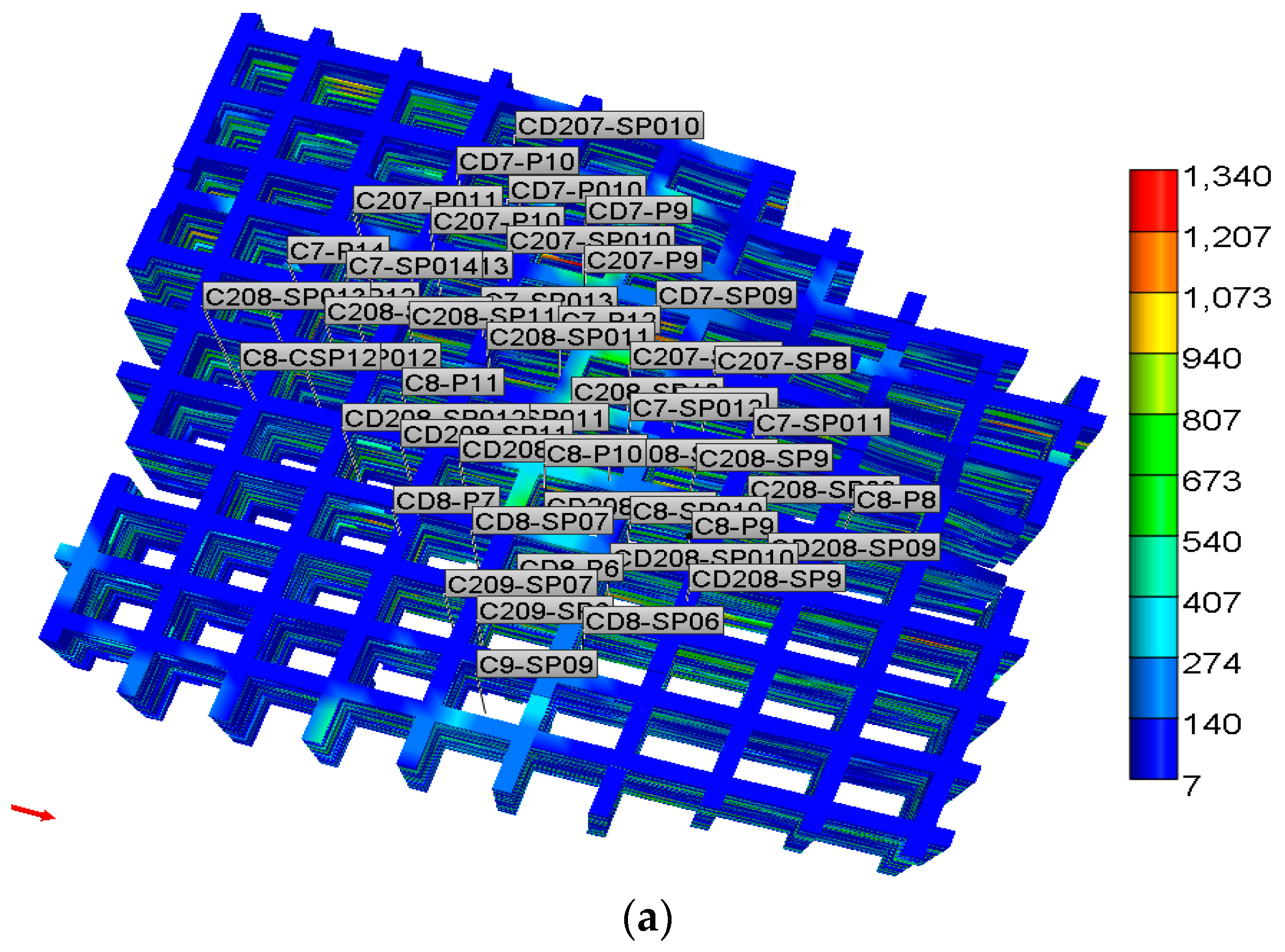

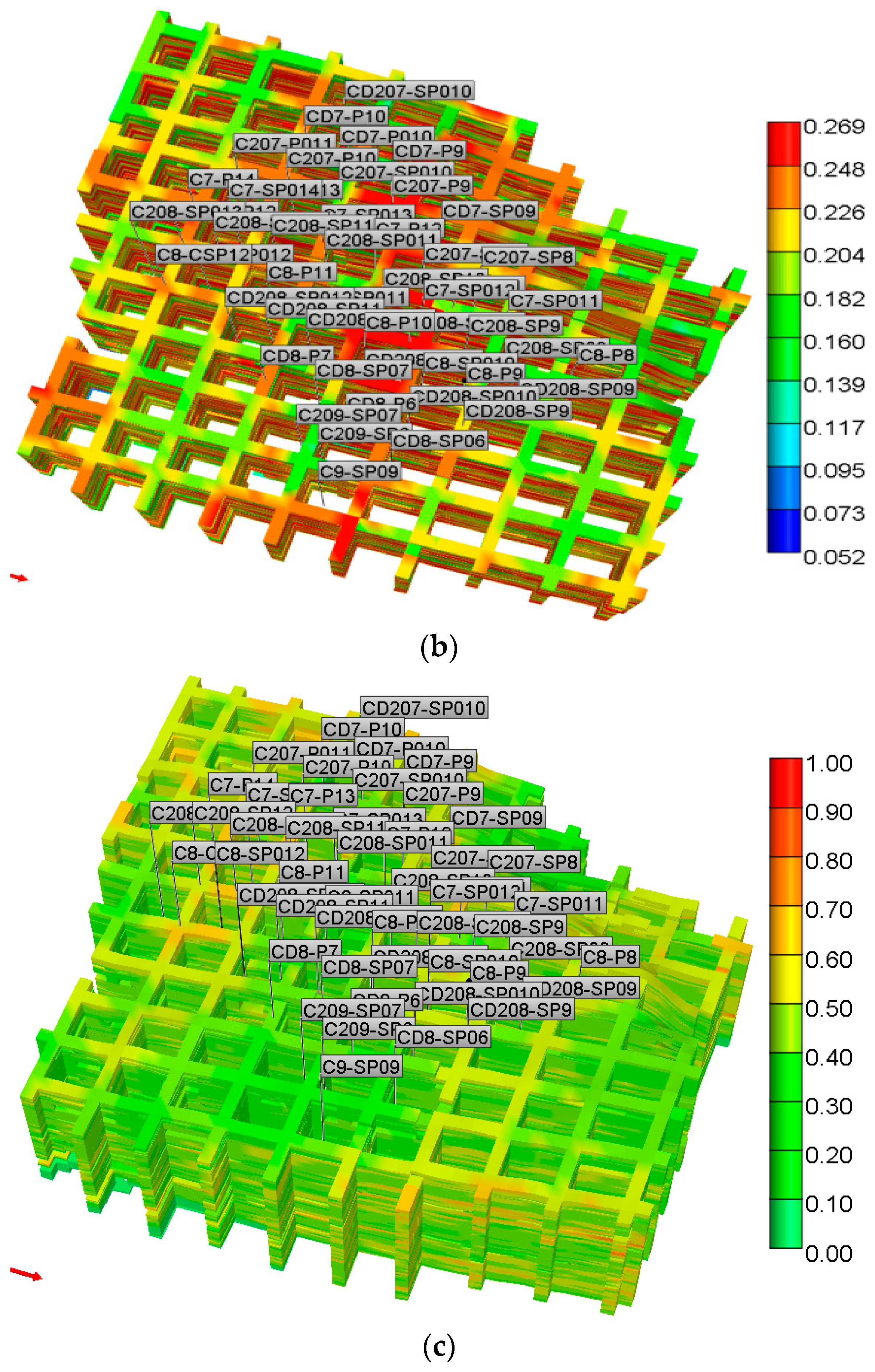

2.3. Geologic Models Characterization

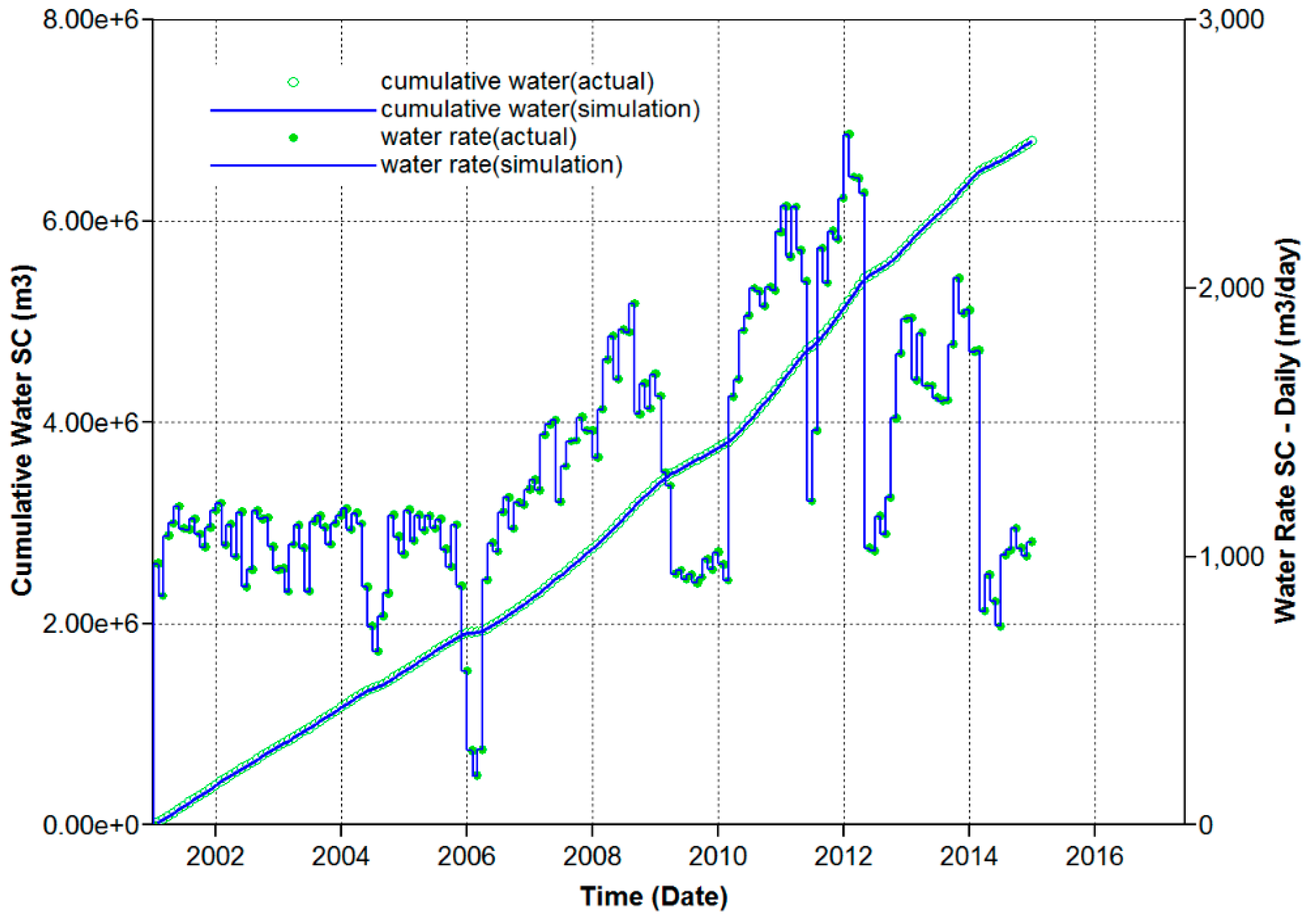

3. Dynamic Fitting of the Reservoir Water Flooding Production

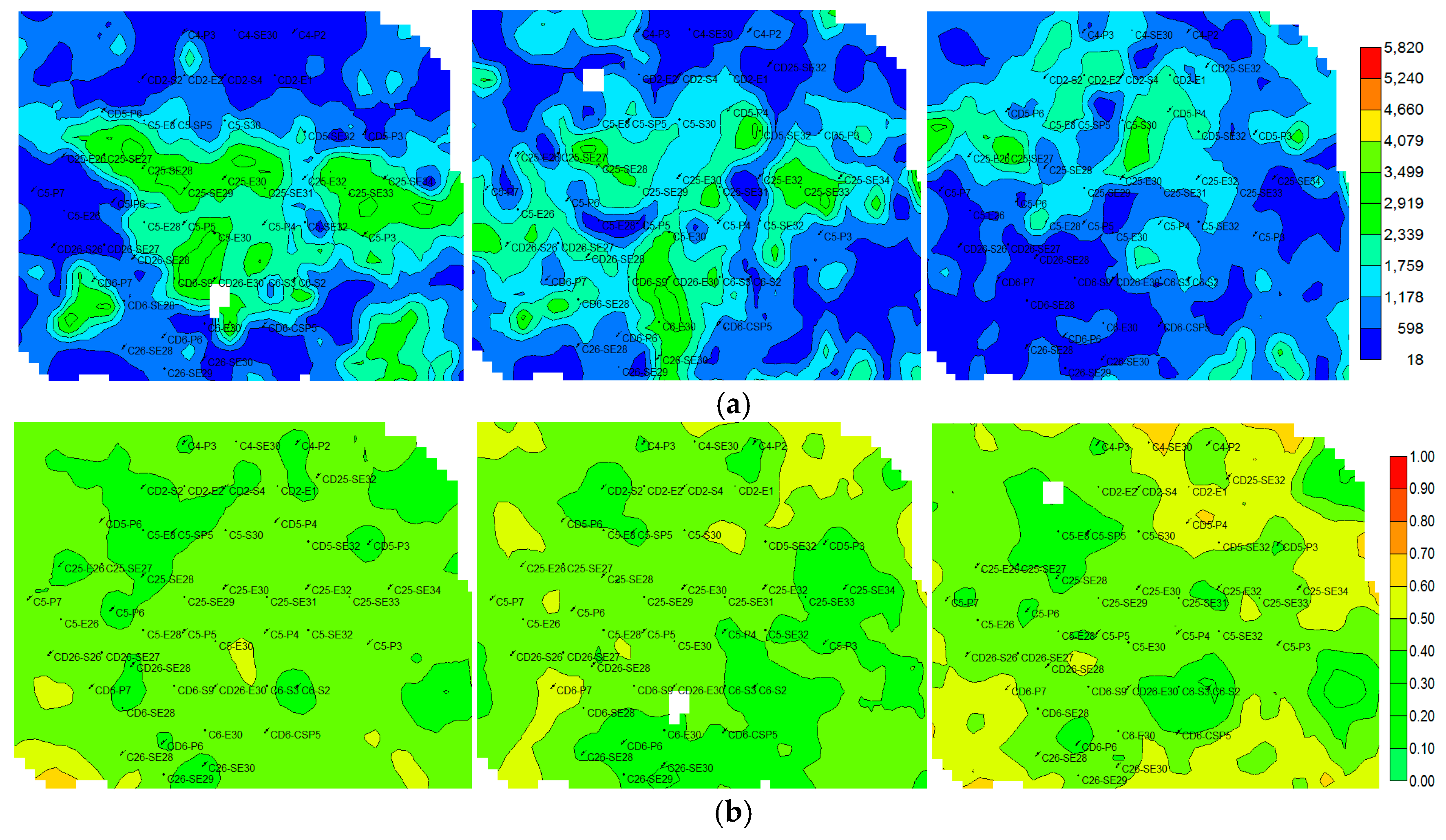

3.1. Dynamic History-Matching of Production in the Whole Block

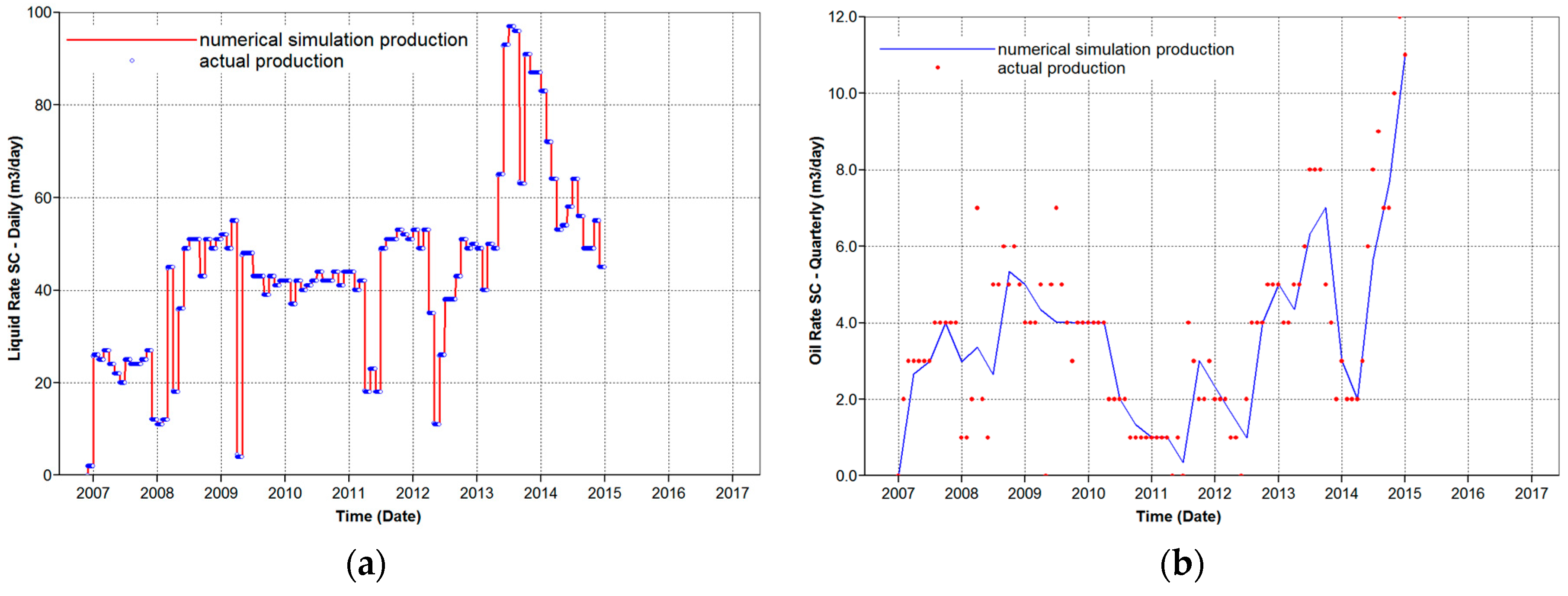

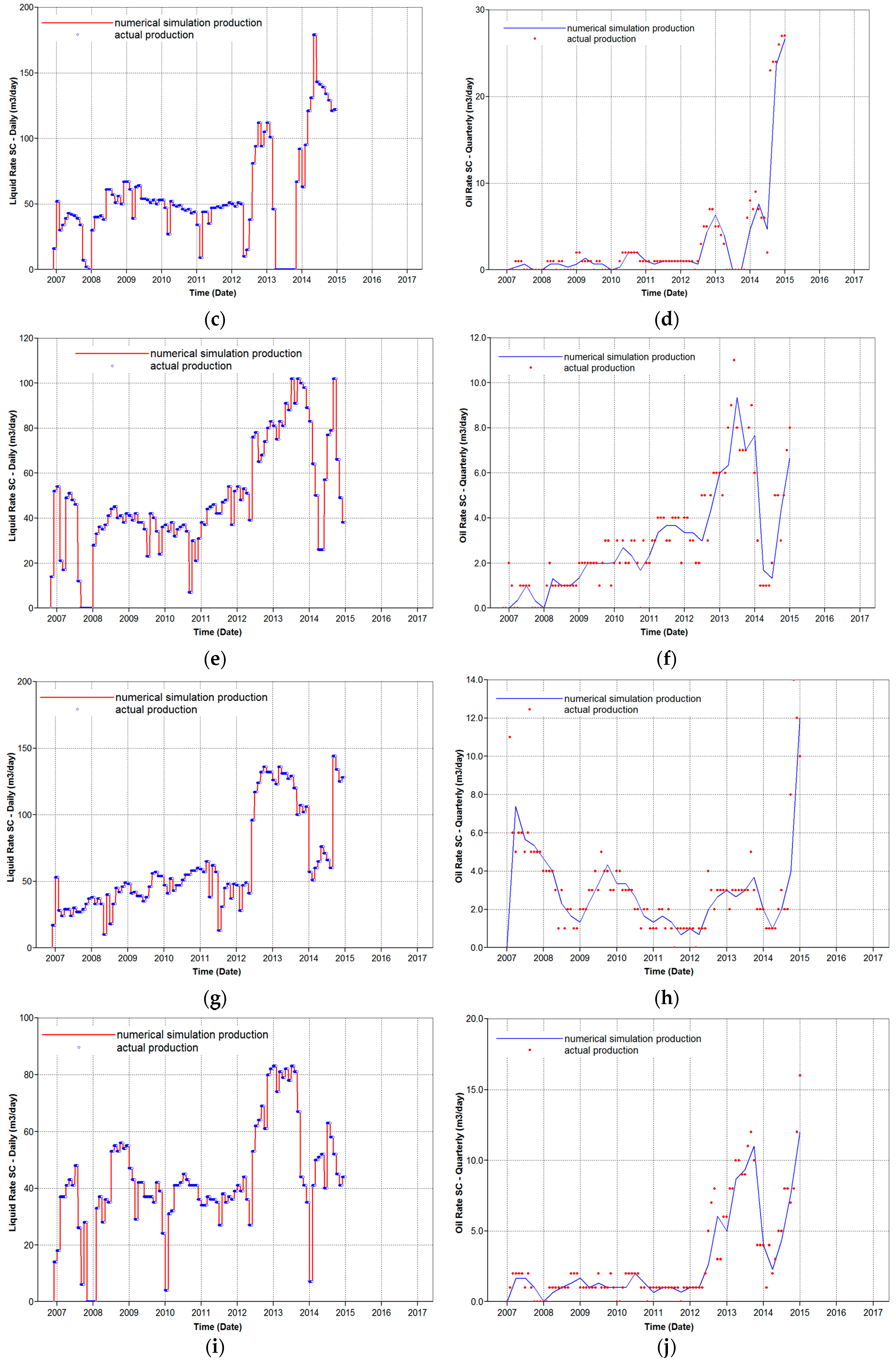

3.2. Dynamic History-Matching of Production in a Single Well

4. Numerical Simulation Results

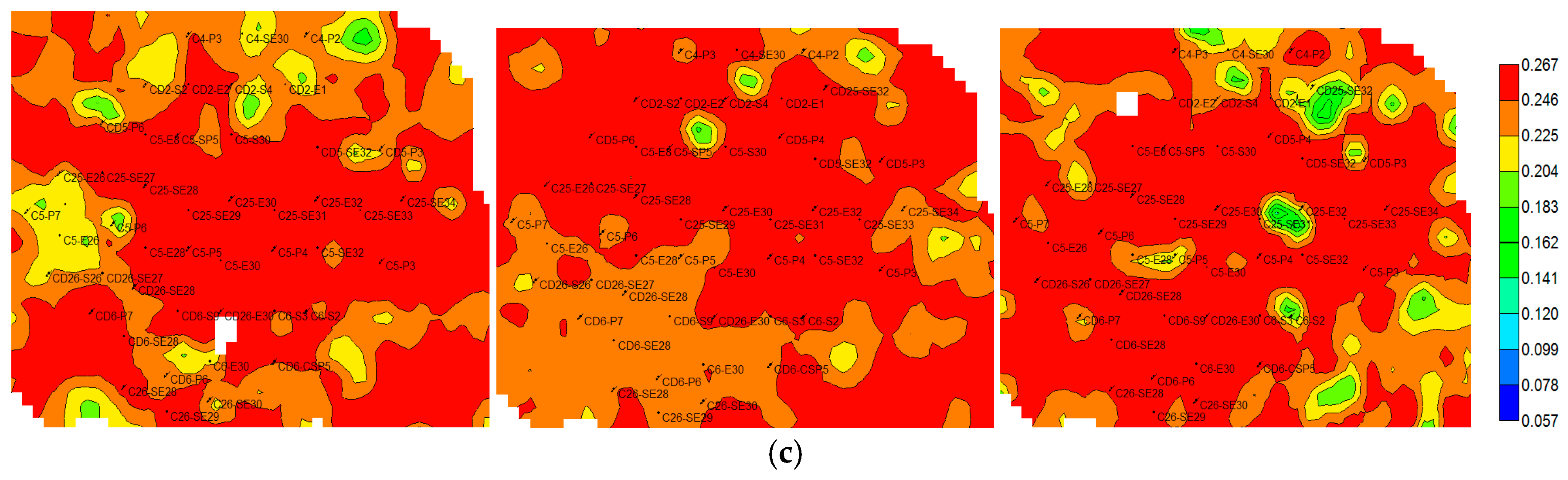

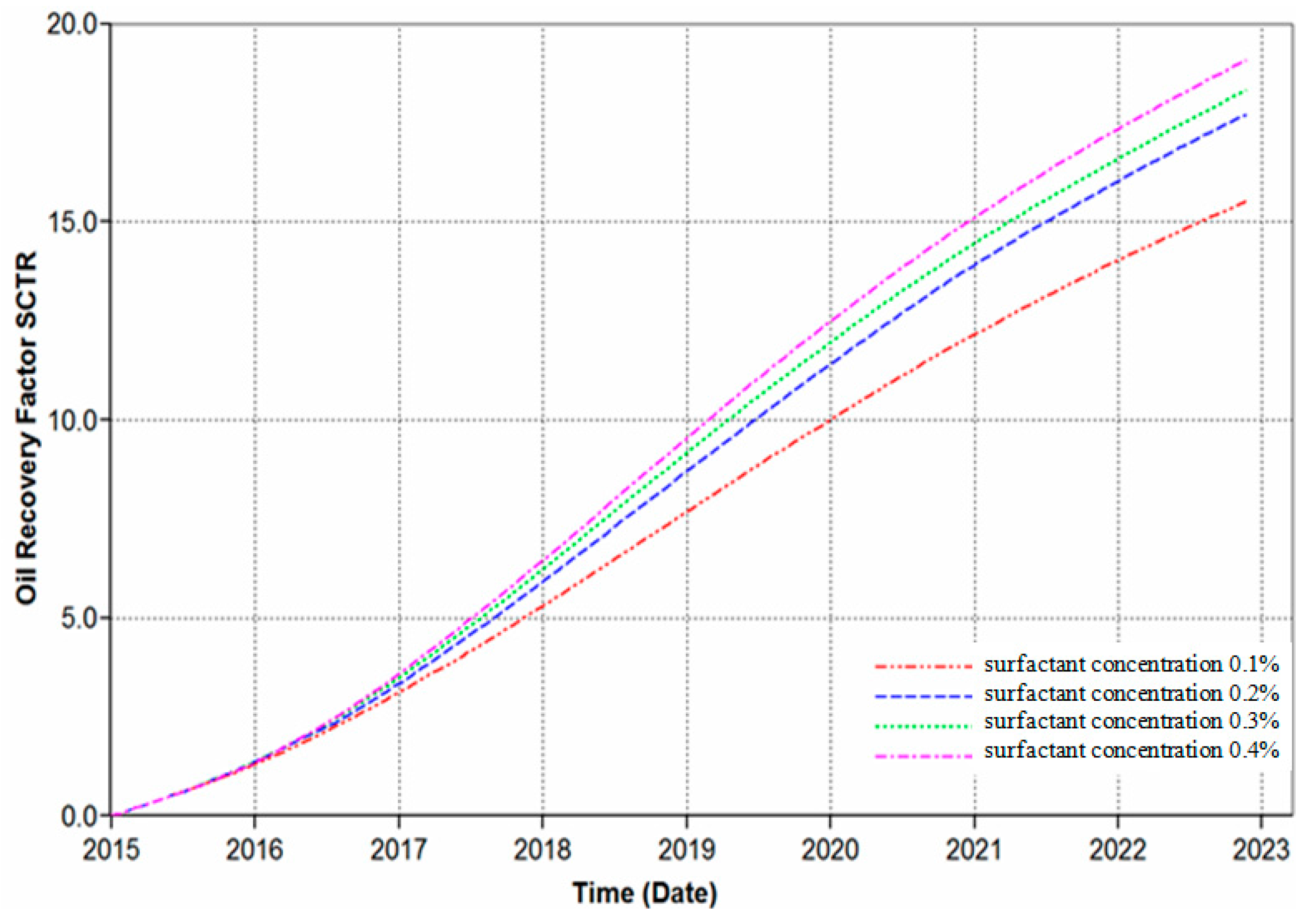

4.1. Effect of Surfactant Concentration in the Main Slug on the Oil Displacement Results

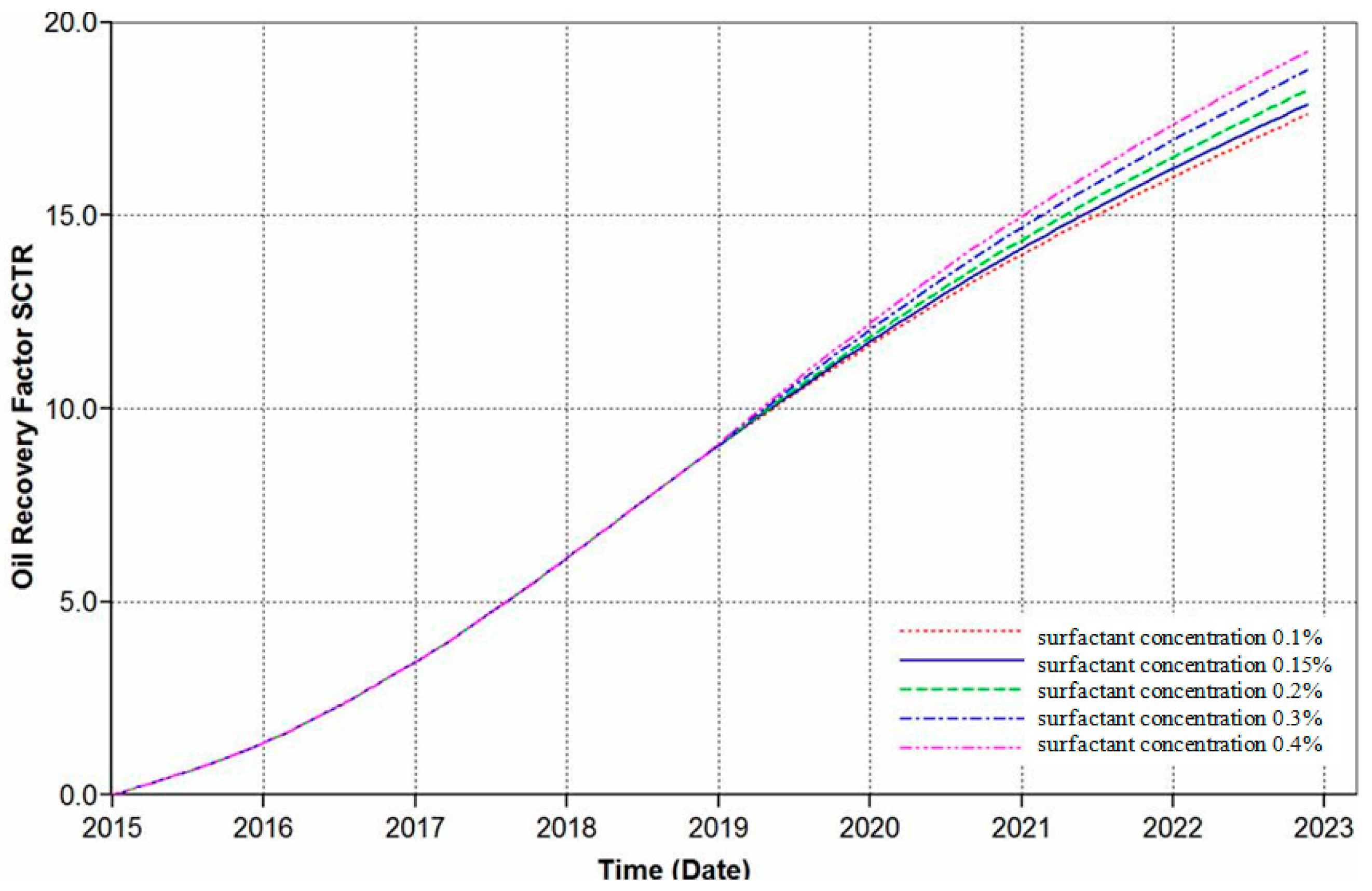

4.2. Effect of Surfactant Concentration in the Vice Slug on the Oil Displacement Results

5. Oil displacement Experiment

5.1. Experimental Materials and Equipment

- (1)

- Core: artificial epoxy resin cementation heterogeneous cores, 4.5 cm × 4.5 cm × 30 cm;

- (2)

- Polymer: the polymer is partially hydrolyzed polyacrylamide, with an average relative molecular weight of 16–19 million and 25 million, and a solid content of 88%, from Daqing Refining and Chemical Company in China. The alkali is Na2CO3 of analytical grade; the surfactant is alkyl benzene sulfonate with a solid content of 50%, from Daqing Refining and Chemical Company in China;

- (3)

- Experiment water: the injected water was from injection allocation station II of factory one from the Daqing oilfield. The injection and formation water contains sodium bicarbonate and includes high concentrations of Na+ and K+ and relatively low concentrations of Mg2+ and SO42− ions. The average total salinity of the injection water and formation water were 4012.7 and 8025.4, respectively. The composition of the injected water and formation water are shown in Table 5;

- (4)

- Experimental oil: the synthetic oil used in the displacement experiment was compounded with the crude oil sampled (degassed and dehydrated) from Daqing Oilfield and the aviation kerosene. The viscosity of the synthetic oil was 7.0 mPa·s at 45 °C.

5.2. Experimental Procedure

- (1)

- The pore volume was measured by vacuum and then saturating it with underground water. All steps were conducted at room temperature;

- (2)

- At 45 °C, the core was saturated with 1.2 PV (Pore Volume) oil, and was then stopped when the oil saturation was larger than 70%;

- (3)

- At 45 °C, the core was flooded with water until the water cut was 98%. The pressure change, liquid producing capacity, water rate, and oil rate in each period were recorded, and then the recovery factor was calculated;

- (4)

- At 45 °C, the chemical flooding was conducted. Each slug was injected according to the experimental scheme. The pressure change value, liquid producing capacity, water rate, and oil rate in each period were recorded, and then the recovery factor was calculated. The experimental process diagram is shown in Figure 8 [14].

5.3. Experimental Results

6. Conclusions

- (1)

- According to the numerical simulation, the oil recovery increases gradually with the surfactant concentration in the main slug. The optimal concentration of the surfactant in main slug is 0.3%;

- (2)

- According to the numerical simulation, the oil recovery factor increases gradually with the surfactant concentration in the vice slug. The optimal concentration of surfactant in the vice slug is 0.15%;

- (3)

- Compared to increasing the mass fraction of surfactant in the vice slug, the recovery factor increased more when increasing the mass fraction of surfactant in the main slug. This demonstrates that the amount of surfactant in the main slug plays a more important role in displacing oil from the formation than in the vice slug.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Wang, J.L.; Sun, Y.; Wei, Y.X. Research and outlook of the ASP flooding. Foreign Oilfield 2001, 8, 15–19. [Google Scholar]

- Cheng, J.C.; Wu, G.Z.; Hu, J.Q. The key theory and technology of ASP flooding in improving oil recovery. Acta Petrol. Sin. 2014, 2, 310–318. [Google Scholar]

- Wu, W.X.; Zhang, D.; Lang, L.Y. Surfactant agent on the properties of recognition system optimization. FAU Oil Gas Field 2013, 6, 772–774. [Google Scholar]

- Niu, L.W.; Jiang, G.P.; Lu, X.G.; Li, J.B.; Su, Y.C.; You, H.L.; Yuan, S.W. The performance of ASP system and its effect on oil displacement efficiency. Oil Field Chem. 2014, 2, 290–294. [Google Scholar]

- Lu, X.G.; Qi, L.Q.; Niu, J.G. Laboratory evaluation of flooding efficiency for ASP solution of lower surfactant and alkaline concentration in the Daqing Oil field. Acta Petrol. Sin. 2002, 5, 59–63. [Google Scholar]

- Xie, Y.Y.; Hou, J.R.; Zhang, J.Z.; Xie, D.H.; Ren, F.; Zhang, Y. Evaluation of low-concentration surfactant system for chemical flooding. Pet. Geol. Recover. Effic. 2014, 1, 74–77. [Google Scholar]

- Yan, W.H.; Yao, Z.J.; Shi, X.B.; Wu, A.D.; Pan, W.H. Experimental Study on the Displacement of Oil by ASP Weak Alkali System in Class III Reservoirs. Spec. Oil Gas Reserv. 2013, 2, 102–104. [Google Scholar]

- Zhang, T.K.; Li, Y.H.; Zhao, F.L. Laboratory research of oil displacement compound system for layer IV5–11, Shuanghe oilfield. Pet. Geol. Recovery Effic. 2012, 1, 62–65. [Google Scholar]

- Yu, H.W.; Chen, T.P.; Gao, M.; Liu, J.S.; Liu, J.L. Estimates of surfactant concentration used for EOR in Daqing oil field low permeability oil reservoir. In Proceedings of the SPE Enhanced Oil Recovery Conference, Kuala Lumpur, Malaysia, 19–21 July 2011.

- Lashgari, H.R.; Sepehrnoori, K.; Delshad, M. A four-phase chemical/gas model in an implicit-pressure/explicit-concentration reservoir simulator. SPE J. 2016, 21, 1086–1105. [Google Scholar] [CrossRef]

- Zhang, F.S.; Zhang, Y.P.; Xie, H.Z.; Zhang, H.B. Alkali/surfactant/polymer effects on the emulsion stability. J. Oil Gas 2005, S6, 925–927. [Google Scholar]

- Yang, C.L.; Zhang, Q.C.; Hu, X.H.; Wang, G.X.; Zhou, Z.X. Numerical simulation of Alkalescence-surfactant-polymer flooding in the test area of the North-Two-West, Saertu Oil Field. J. Daqing Pet. Insur. 2008, 5, 41–44. [Google Scholar]

- Han, P.H.; Me, S.C.; Zhang, S.Y.; Li, Z.P.; Wang, Y. Numerical simulation of Daqing oil field south area of polymer and surfactant/surfactant alternating injection. Daqing Pet. Geol. Dev. 2006, 2, 75–77. [Google Scholar]

- Xie, K.; Lu, X.G.; Li, Q.; Jiang, W.D.; Yu, Q. Analysis of reservoir applicability of hydrophobically associating polymer. SPE J. 2015, 21. [Google Scholar] [CrossRef]

| Items | Cumulative Oil Production (104 m3) | Cumulative Liquid Production (104 m3) | Cumulative Water Injection (104 m3) |

|---|---|---|---|

| Simulation | 26.64 | 327.76 | 678.967 |

| Actual | 27.09 | 329.40 | 682.362 |

| Scheme | Pre-Polymer Slug | Main Slug | Vice Slug | Rear-Polymer Slug | Surfactant Concentration in Main Slug/% |

|---|---|---|---|---|---|

| 1 | 0.04 PV (Pore Volume) (1600 mg/L, 25 million P a) | 0.35 PV (1.2% A b + S c + 1900 mg/L, 16–19 million P) | 0.15 PV (1% A + 0.15% S + 1800 mg/L, 16–19 million P) | 0.2 PV (1600 mg/L, 16–19 million P) | 0.1 |

| 2 | 0.2 | ||||

| 3 | 0.3 | ||||

| 4 | 0.4 |

| Scheme | Surfactant Concentration/% | Recovery Factor/% | Increased Value of Recovery Factor/% |

|---|---|---|---|

| 1 | 0.1 | 15.53 | -- |

| 2 | 0.2 | 17.72 | 2.19 |

| 3 | 0.3 | 18.53 | 0.81 |

| 4 | 0.4 | 19.08 | 0.55 |

| Scheme | Surfactant Concentration/% | Recovery Factor/% | Increased Value of Recovery Factor/% |

|---|---|---|---|

| 1 | 0.1 | 17.74 | -- |

| 2 | 0.15 | 18.53 | 0.79 |

| 3 | 0.2 | 18.90 | 0.37 |

| 4 | 0.3 | 19.15 | 0.25 |

| 5 | 0.4 | 19.33 | 0.18 |

| Component Water Type | Cations | Anions | Total Salinity | |||||

|---|---|---|---|---|---|---|---|---|

| Na+ + K+ | Mg2+ | Ca2+ | CO32− | HCO3− | Cl− | SO42− | ||

| Injection water | 1265 | 7.3 | 32.06 | 210.07 | 1708.56 | 780.12 | 9.61 | 4012.7 |

| Formation water | 2530 | 14.6 | 64.12 | 420.14 | 3417.12 | 1560.24 | 19.22 | 8025.4 |

| Scheme | Pre-Polymer Slug | Main Slug | Vice Slug | Surfactant Concentration in Main Slug/% | Post-Polymer Slug |

|---|---|---|---|---|---|

| 1 | 0.04 PV (1600 mg/L, 25 million P a) | 0.35 PV (1.2% A b + S c + 1900 mg/L, 16–19 million P) | 0.15 PV (1% A + 0.15% S + 1800 mg/L, 16–19 million P) | 0.25 | 0.2 PV (1600 mg/L, 16–19 million P) |

| 2 | 0.3 | ||||

| 3 | 0.35 |

| Scheme | Oil Saturation/% | Water Flooding Recovery Factor/% | Chemical Flooding Recovery Factor/% | Added Value by Chemical Flooding/% | Amplification of Recovery Factor/% |

|---|---|---|---|---|---|

| 1 | 74.1 | 56.5 | 80.07 | 23.57 | -- |

| 2 | 73.5 | 56.8 | 80.97 | 24.17 | 0.60 |

| 3 | 73.8 | 57.0 | 81.56 | 24.56 | 0.39 |

| Scheme | Pre-Polymer Slug | Main Slug | Vice Slug | Surfactant Concentration in Vice Slug/% | Post-Polymer Slug |

|---|---|---|---|---|---|

| 1 | 0.04 PV (1600 mg/L, 25 million P a) | 0.35 PV (1.2% A b + 0.3% S c + 1900 mg/L, 16–19 million P | 0.15 PV (1% A + S + 1800 mg/L, 16–19 million P) | 0.05 | 0.2 PV (1600 mg/L, 16–19 million P) |

| 2 | 0.10 | ||||

| 3 | 0.15 | ||||

| 4 | 0.2 |

| Scheme | Oil Saturation/% | Water Flooding Recovery Factor/% | Chemical Flooding Recovery Factor/% | Added Value by Chemical Flooding/% | Amplification of Recovery Factor/% |

|---|---|---|---|---|---|

| 1 | 73.6 | 57.2 | 80.23 | 23.03 | -- |

| 2 | 73.8 | 56.5 | 80.10 | 23.60 | 0.57 |

| 3 | 73.5 | 56.6 | 80.97 | 24.37 | 0.77 |

| 4 | 73.4 | 56.4 | 81.28 | 24.88 | 0.51 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, B.; Zhang, W.; Liu, H.; Fu, C.; Feng, P.; Wang, Y. A Study on the Optimization of Surfactants in the Main and Vice Slug in Weak Base ASP Flooding. Energies 2017, 10, 304. https://doi.org/10.3390/en10030304

Huang B, Zhang W, Liu H, Fu C, Feng P, Wang Y. A Study on the Optimization of Surfactants in the Main and Vice Slug in Weak Base ASP Flooding. Energies. 2017; 10(3):304. https://doi.org/10.3390/en10030304

Chicago/Turabian StyleHuang, Bin, Wei Zhang, Huan Liu, Cheng Fu, Pengxin Feng, and Ying Wang. 2017. "A Study on the Optimization of Surfactants in the Main and Vice Slug in Weak Base ASP Flooding" Energies 10, no. 3: 304. https://doi.org/10.3390/en10030304