Electric Field Simulations and Analysis for High Voltage High Power Medium Frequency Transformer

Abstract

:1. Introduction

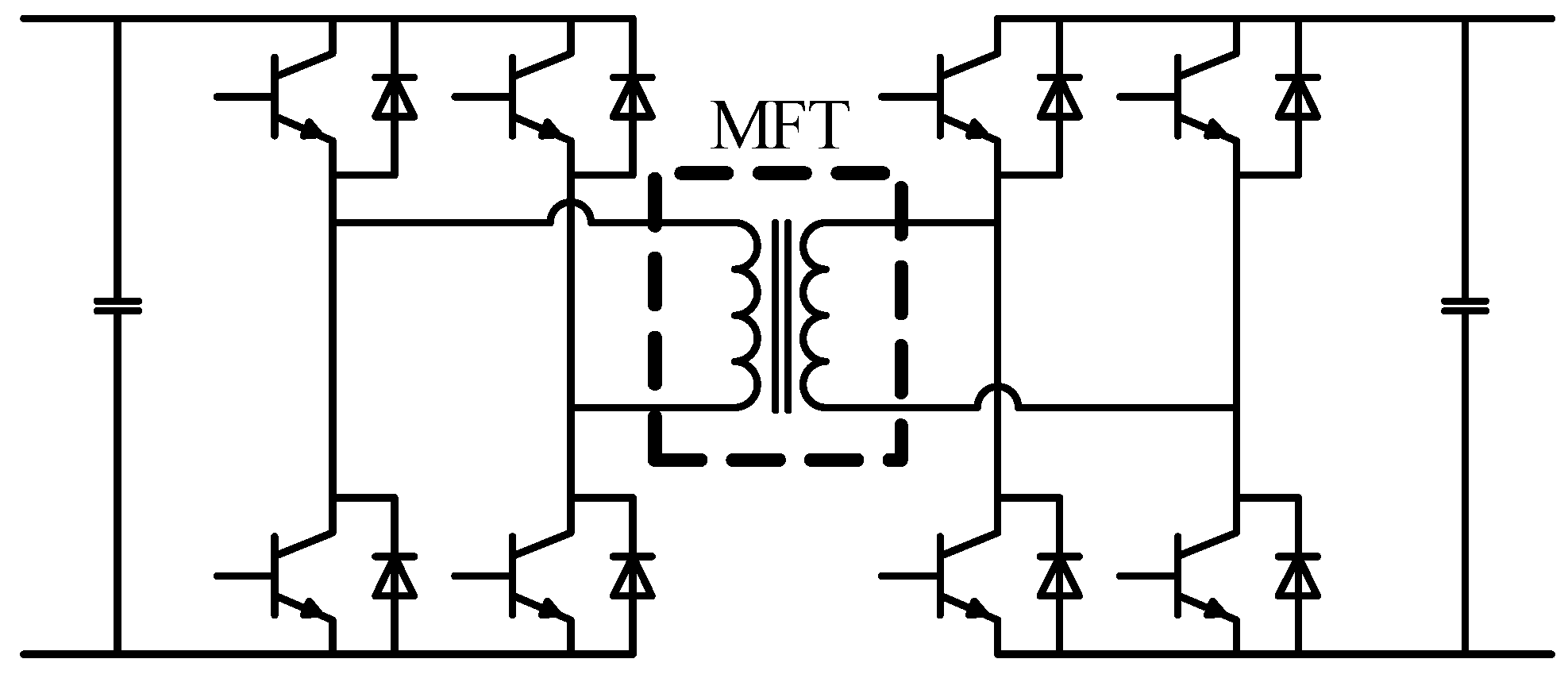

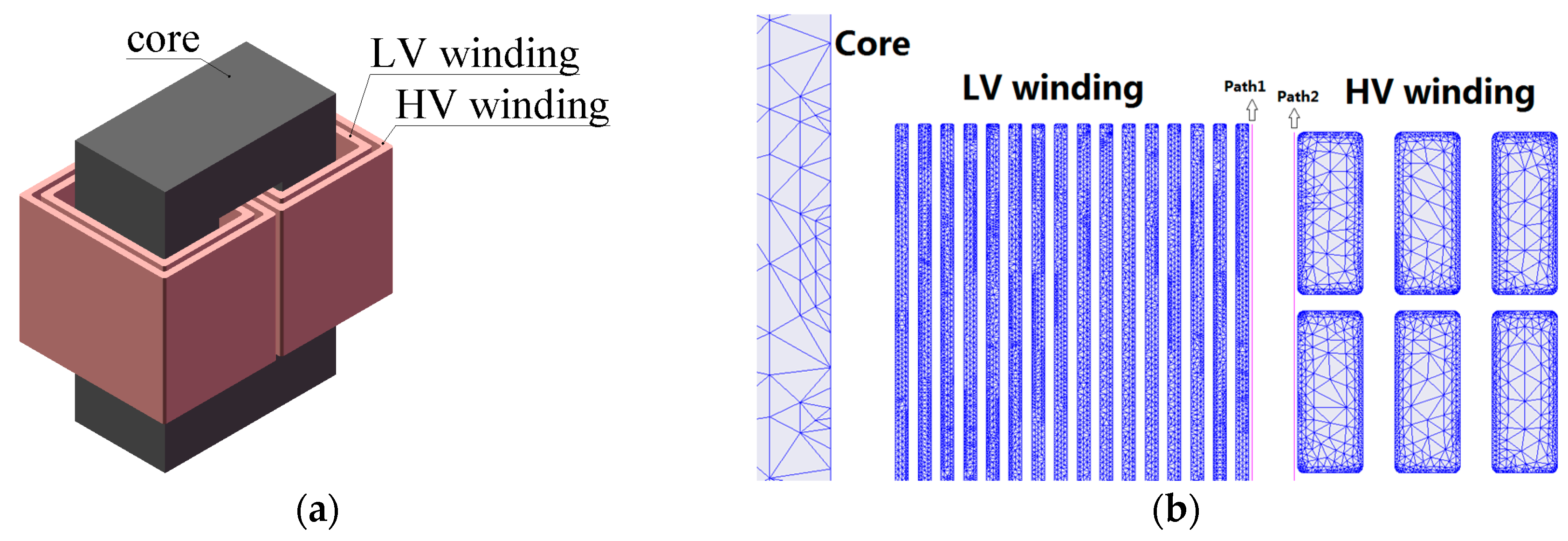

2. Finite Element Modeling of MFT

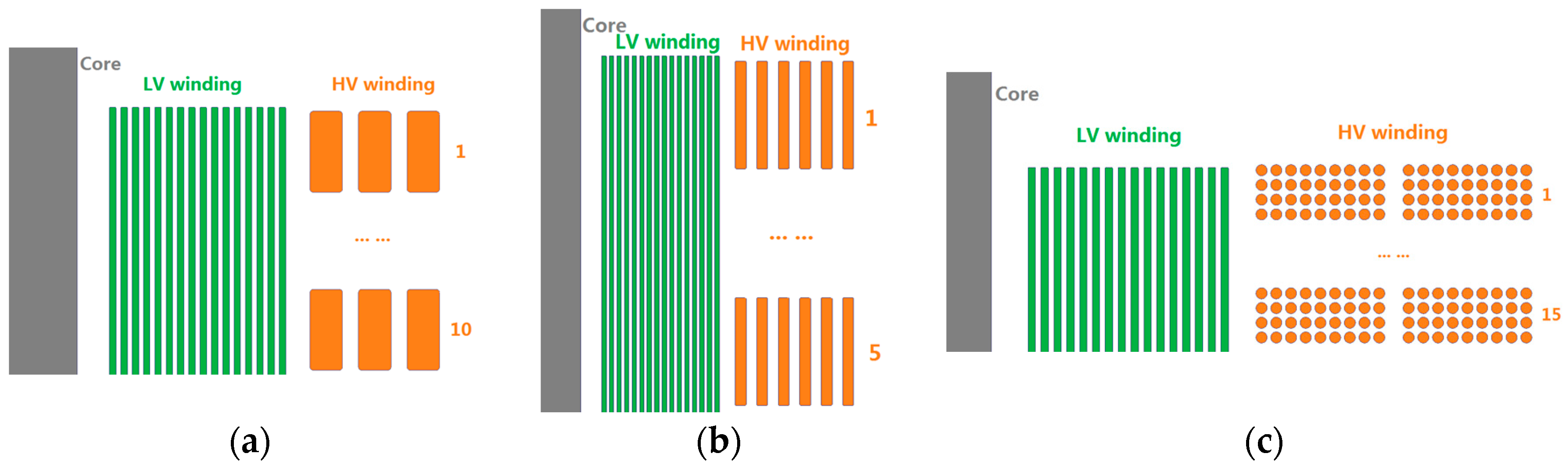

3. Windings with Different Wire Types

3.1. Windings with Different Wire Types

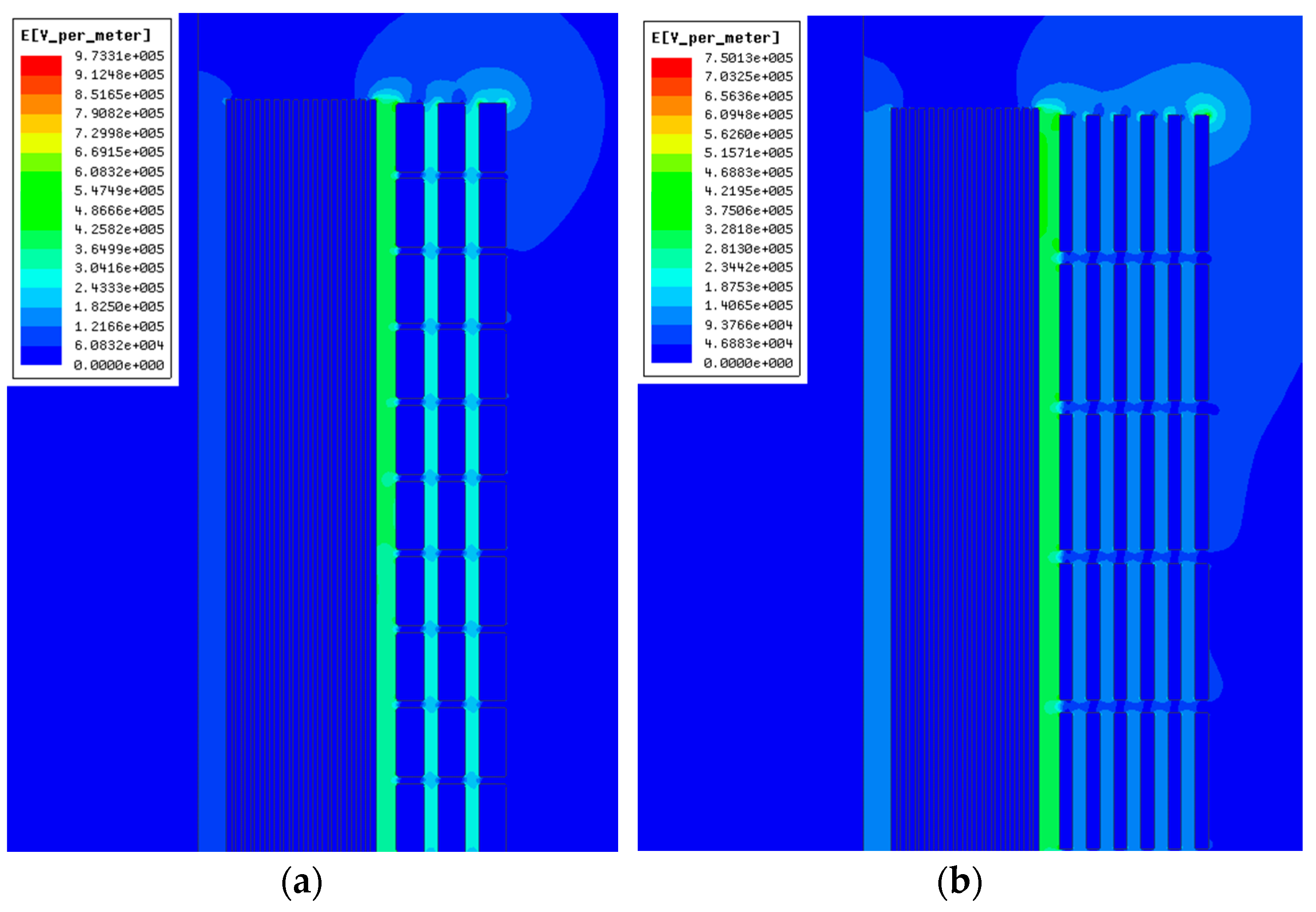

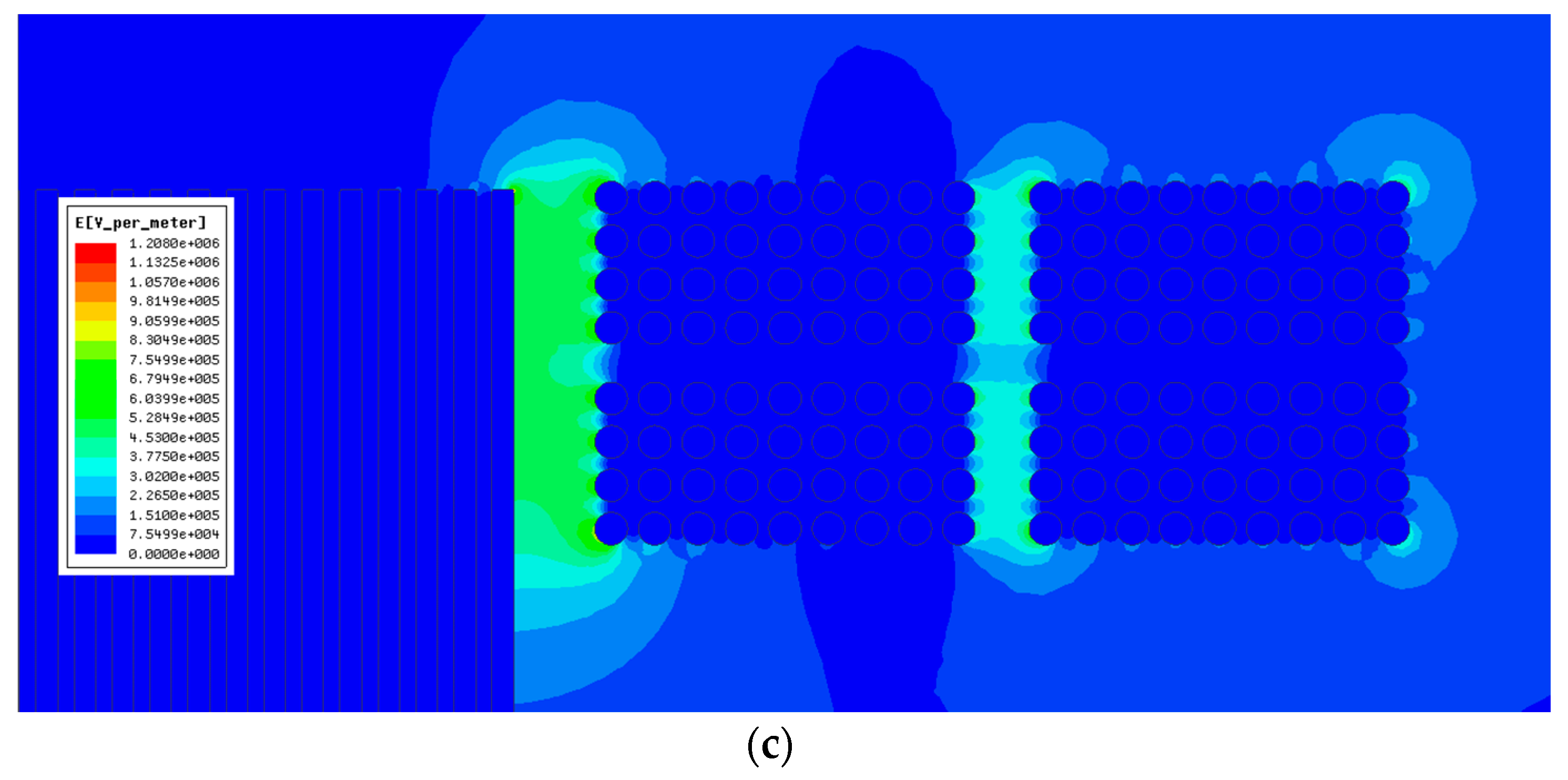

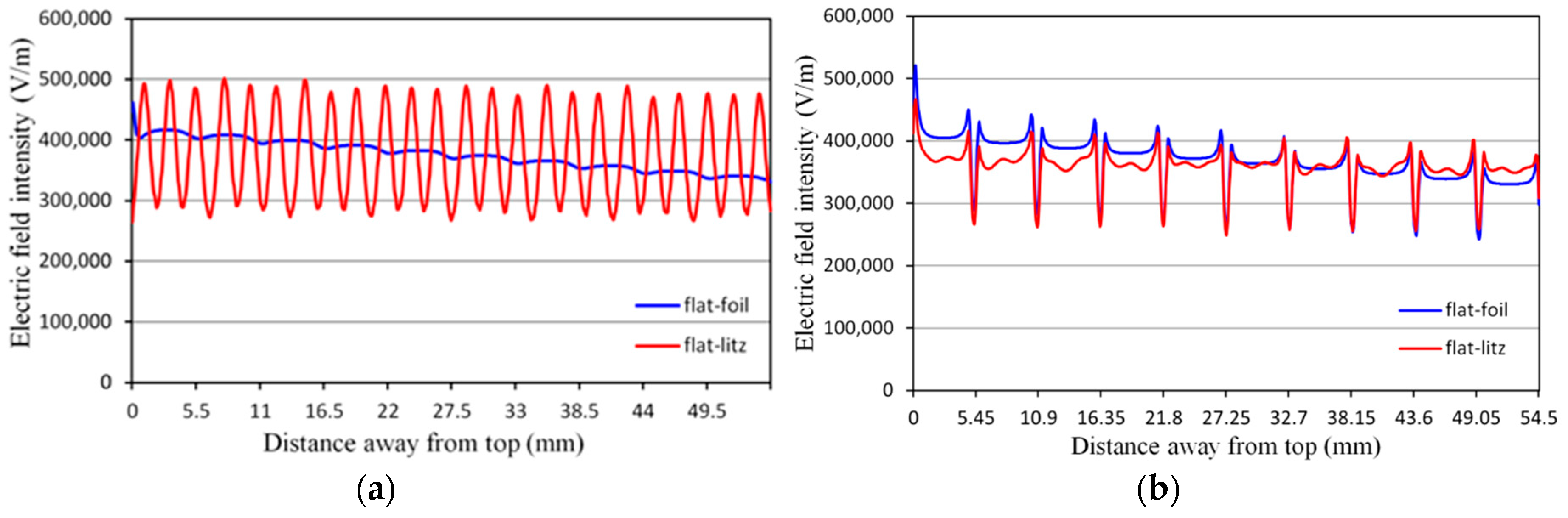

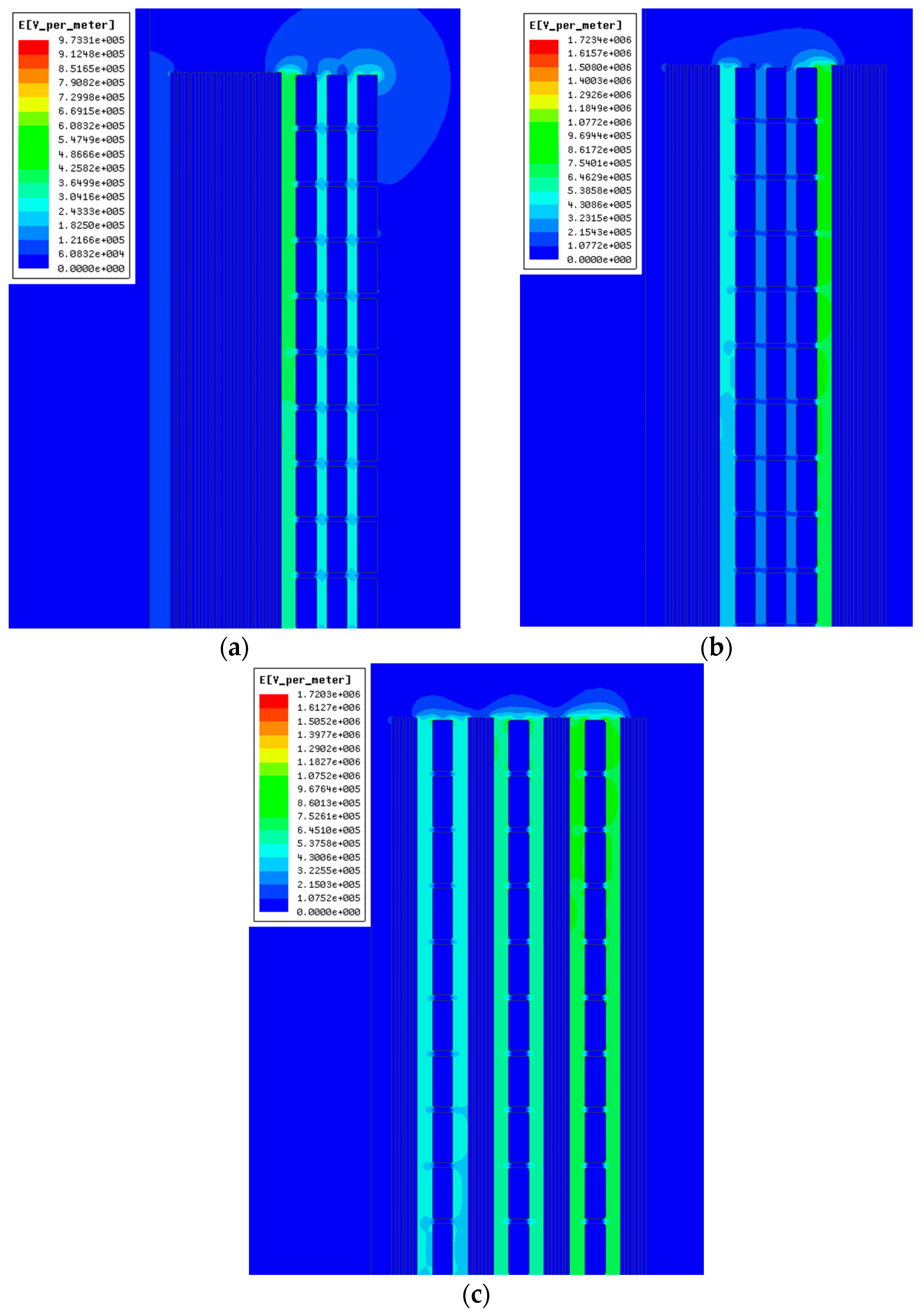

3.2. Electric Field Distribution of Different Windings

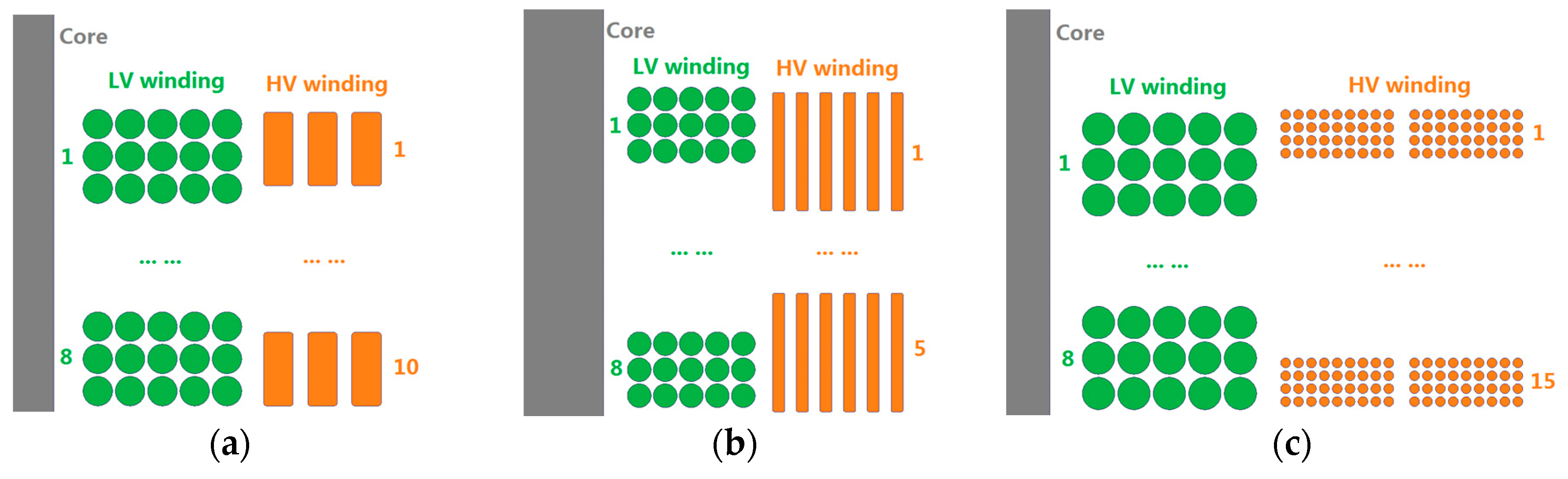

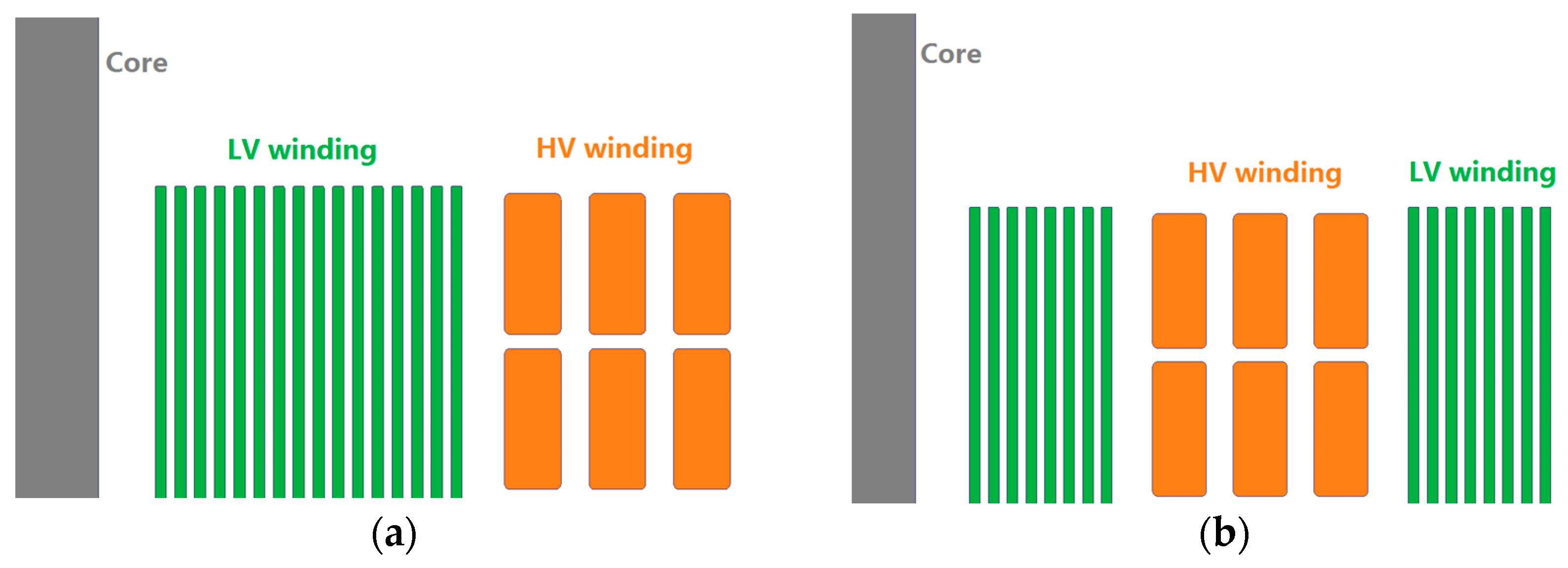

4. Interleaved and Non-Interleaved Windings

4.1. Interleaved and Non-Interleaved Windings

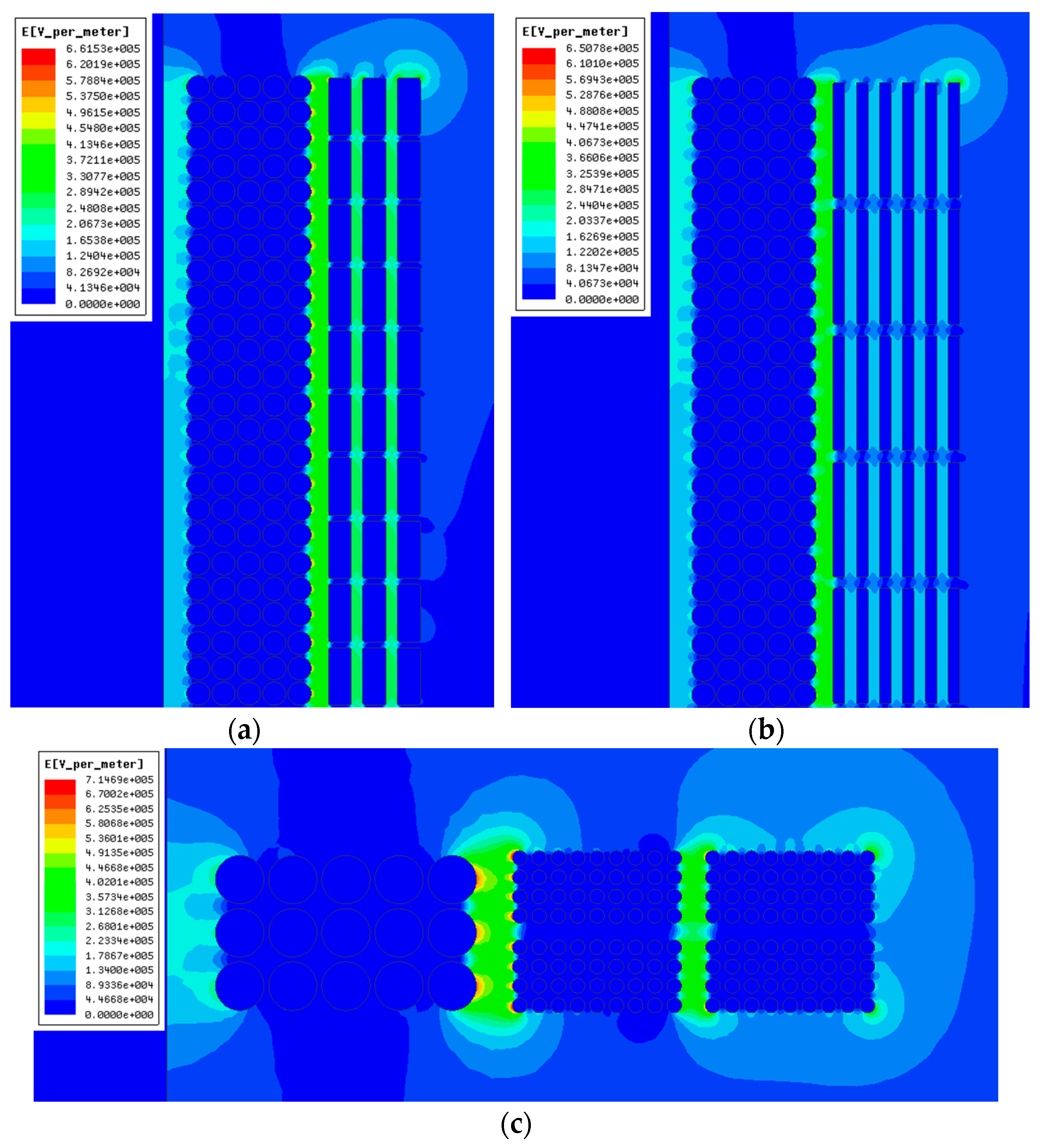

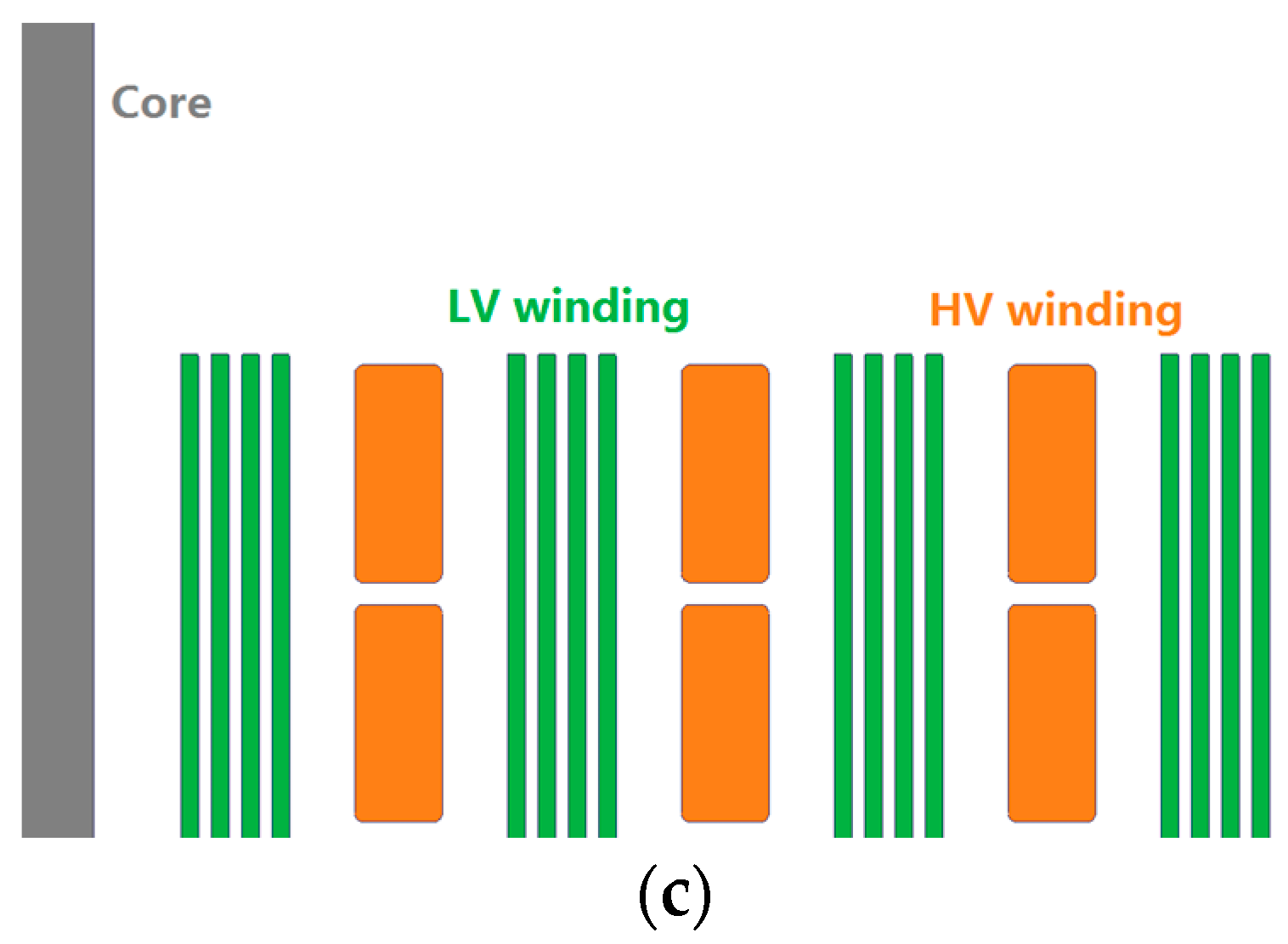

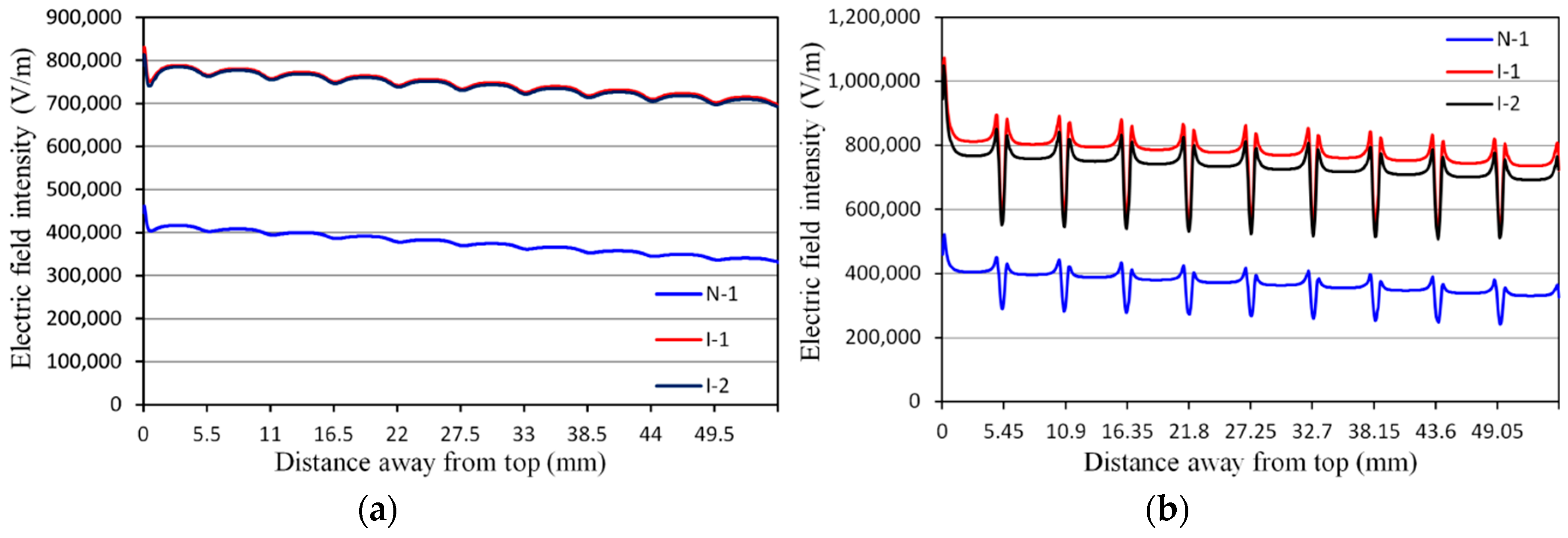

4.2. Electric Field Distribution of Different Windings

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Huang, H.; Mao, C.; Lu, J.; Wang, D. Electronic power transformer control strategy in wind energy conversion systems for low voltage ride-through capability enhancement of directly driven wind turbines with permanent magnet synchronous generators (D-PMSGs). Energies 2014, 7, 7330–7347. [Google Scholar] [CrossRef]

- Tian, J.; Mao, C.; Wang, D.; Lu, J.; Liang, X.; Liu, Y. Analysis and control of electronic power transformer with star-configuration under unbalanced conditions. IET Electr. Power Appl. 2015, 9, 358–369. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, D.; Wang, Y.; Wu, B.; Athab, H.S. Power and voltage balance control of a novel three-phase solid-state transformer using multilevel cascaded H-bridge inverters for microgrid applications. IEEE Trans. Power Electron. 2016, 31, 3289–3301. [Google Scholar] [CrossRef]

- Wang, X.; Liu, J.; Ouyang, S.; Xu, T.; Meng, F.; Song, S. Control and experiment of an H-bridge-based three-phase three-stage modular power electronic transformer. IEEE Trans. Power Electron. 2016, 31, 2002–2011. [Google Scholar] [CrossRef]

- Zhao, C.; Dujic, D.; Mester, A.; Steinke, J.K.; Weiss, M.; Lewdeni-Schmid, S.; Chaudhuri, T.; Stefanutti, P. Power electronic traction transformer—Medium voltage prototype. IEEE Trans. Ind. Electron. 2014, 61, 3257–3268. [Google Scholar] [CrossRef]

- Peng, S.; Biela, J. Design and optimization of medium frequency, medium voltage transformers. In Proceedings of the 2013 15th European Conference on Power Electronics and Applications (EPE), Lille, France; 2013; pp. 1–10. [Google Scholar]

- Bahmani, M.A. Design and Optimization Considerations of Medium-Frequency Power Transformers in High-Power dc-dc Applications. Ph.D. Thesis, Department of Energy and Environment, Chalmers University Technology, Gothenburg, Sweden, March 2016. [Google Scholar]

- Ortiz, G. High-Power DC-DC Converter Technologies for Smart Grid and Traction Applications. Ph.D. Dissertation, Swiss Federal Institute of Technology, ETH, Zürich, Switzerland, November 2013. [Google Scholar]

- Ortiz, G.; Biela, J.; Kolar, J.W. Optimized design of medium frequency transformers with high isolation requirements. In Proceedings of the IECON 2010—36th Annual Conference on IEEE Industrial Electronics Society, Glendale, AZ, USA, 7–10 November 2010; pp. 631–638.

- Du, S.B.Y.; Gangyao, W.; Bhattacharya, S. Design considerations of high voltage and high frequency transformer for solid state transformer application. In Proceedings of the IECON 2010—36th Annual Conference on IEEE Industrial Electronics Society, Glendale, AZ, USA, 7–10 November 2010; pp. 421–426.

- Guillod, T.; Huber, J.E.; Ortiz, G.; De, A.; Franck, C.M.; Kolar, J.W. Characterization of the voltage and electric field stresses in multi-cell solid-state transformers. In Proceedings of the 2014 IEEE Energy Conversion Congress and Exposition (ECCE), Pittsburgh, PA, USA, 14–18 September 2014; pp. 4726–4734.

- Qi, B.; Zhao, X.; Li, C.; Wu, H. Transient electric field characteristics in oil-pressboard composite insulation under voltage polarity reversal. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 2148–2155. [Google Scholar] [CrossRef]

- Faiz, J.; Ebrahimi, B.M.; Noori, T. Three- and two-dimensional finite-element computation of inrush current and short-circuit electromagnetic forces on windings of a three-phase core-type power transformer. IEEE Trans. Magn. 2008, 44, 590–597. [Google Scholar] [CrossRef]

- González, E.; Gomez, P.; Espino-Cortés, F.P. Analysis of the electric field distribution on insulating supports of dry-type transformers under high temperature. IET Electr. Power Appl. 2013, 7, 331–337. [Google Scholar] [CrossRef]

- Khaligh, A.; Vakilian, M. Power transformers internal insulation design improvements using electric field analysis through finite-element methods. IEEE Trans. Magn. 2008, 44, 273–278. [Google Scholar] [CrossRef]

- Smajic, J.; Steinmetz, T.; Cranganu-Cretu, B.; Nogues, A.; Murillo, R.; Tepper, J. Analysis of near and far stray magnetic fields of dry-type transformers: 3-D simulations versus measurements. IEEE Trans. Magn. 2011, 47, 1374–1377. [Google Scholar] [CrossRef]

- Yamashita, H.; Cingoski, V.; Nakamae, E.; Namera, A.; Kitamura, H. Design improvements on graded insulation of power transformers using transient electric field analysis and visualization technique. IEEE Trans. Energy Convers. 1999, 14, 1379–1384. [Google Scholar] [CrossRef]

- Lesniewska, E. The use of 3-D electric field analysis and the analytical approach for improvement of a combined instrument transformer insulation system. IEEE Trans. Magn. 2002, 38, 1233–1236. [Google Scholar] [CrossRef]

- Salihu Mustafa, S.; Misron, N.; Mariun, N.; Othman, M.; Hanamoto, T. Torque distribution characteristics of a novel double-stator permanent magnet generator integrated with a magnetic gear. Energies 2017, 10, 2. [Google Scholar] [CrossRef]

- Barrios, E.L.; Urtasun, A.; Ursua, A.; Marroyo, L.; Sanchis, P. High-frequency power transformers with foil windings: Maximum interleaving and optimal design. IEEE Trans. Power Electron. 2015, 30, 5712–5723. [Google Scholar] [CrossRef]

- Wang, D.; Mao, C.; Lu, J. Modelling of electronic power transformer and its application to power system. IET Gener. Transm. Distrib. 2007, 1, 887–895. [Google Scholar] [CrossRef]

| Parameter | Symbol | Value |

|---|---|---|

| Number of Phase | N | 1 |

| Operation frequency | f | 1 kHz |

| Power | P | 35 kW |

| Maximum primary voltage | Upmax | 1.5 kV |

| Maximum secondary voltage | Usmax | 385 V |

| Rms primary current | Ip | 26.3 A |

| Rms secondary current | Is | 102 A |

| Primary/secondary turn numbers | Np/Ns | 120/32 |

| Size of the foil conductor | Width/Length | 0.4 mm/110 mm |

| Size of the flat copper wire | Width/Length | 2 mm/5 mm |

| Max. length of elements for core | null | 30 mm |

| Max. length of elements for winding | null | 0.1 mm |

| Winding Type | HV Winding | LV Winding |

|---|---|---|

| N-1 (flat-foil) | Flat copper wire | Foil conductor |

| N-2 (foil-foil) | Foil conductor | Foil conductor |

| N-3 (litz-foil) | Litz wire | Foil conductor |

| N-4 (flat-litz) | Flat copper wire | Litz wire |

| N-5 (foil-litz) | Foil conductor | Litz wire |

| N-6 (litz-litz) | Litz wire | Litz wire |

| Winding Type | Emax (V/m) | Winding Type | Emax (V/m) |

|---|---|---|---|

| N-1 (flat-foil) | 9.7331 × 105 | N-4 (flat-litz) | 6.6153 × 105 |

| N-2 (foil-foil) | 7.5013 × 105 | N-5 (foil-litz) | 6.5078 × 105 |

| N-3 (litz-foil) | 1.2080 × 106 | N-6 (litz-litz) | 7.1469 × 105 |

| Winding Type | Emax (V/m) |

|---|---|

| Non-interleaved N-1 | 9.7331 × 105 |

| Interleaved I-1 | 1.7234 × 106 |

| Interleaved I-2 | 1.7203 × 106 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, P.; Mao, C.; Wang, D. Electric Field Simulations and Analysis for High Voltage High Power Medium Frequency Transformer. Energies 2017, 10, 371. https://doi.org/10.3390/en10030371

Huang P, Mao C, Wang D. Electric Field Simulations and Analysis for High Voltage High Power Medium Frequency Transformer. Energies. 2017; 10(3):371. https://doi.org/10.3390/en10030371

Chicago/Turabian StyleHuang, Pei, Chengxiong Mao, and Dan Wang. 2017. "Electric Field Simulations and Analysis for High Voltage High Power Medium Frequency Transformer" Energies 10, no. 3: 371. https://doi.org/10.3390/en10030371