Engineering Smart Grids: Applying Model-Driven Development from Use Case Design to Deployment

Abstract

:1. Introduction

2. Related Work

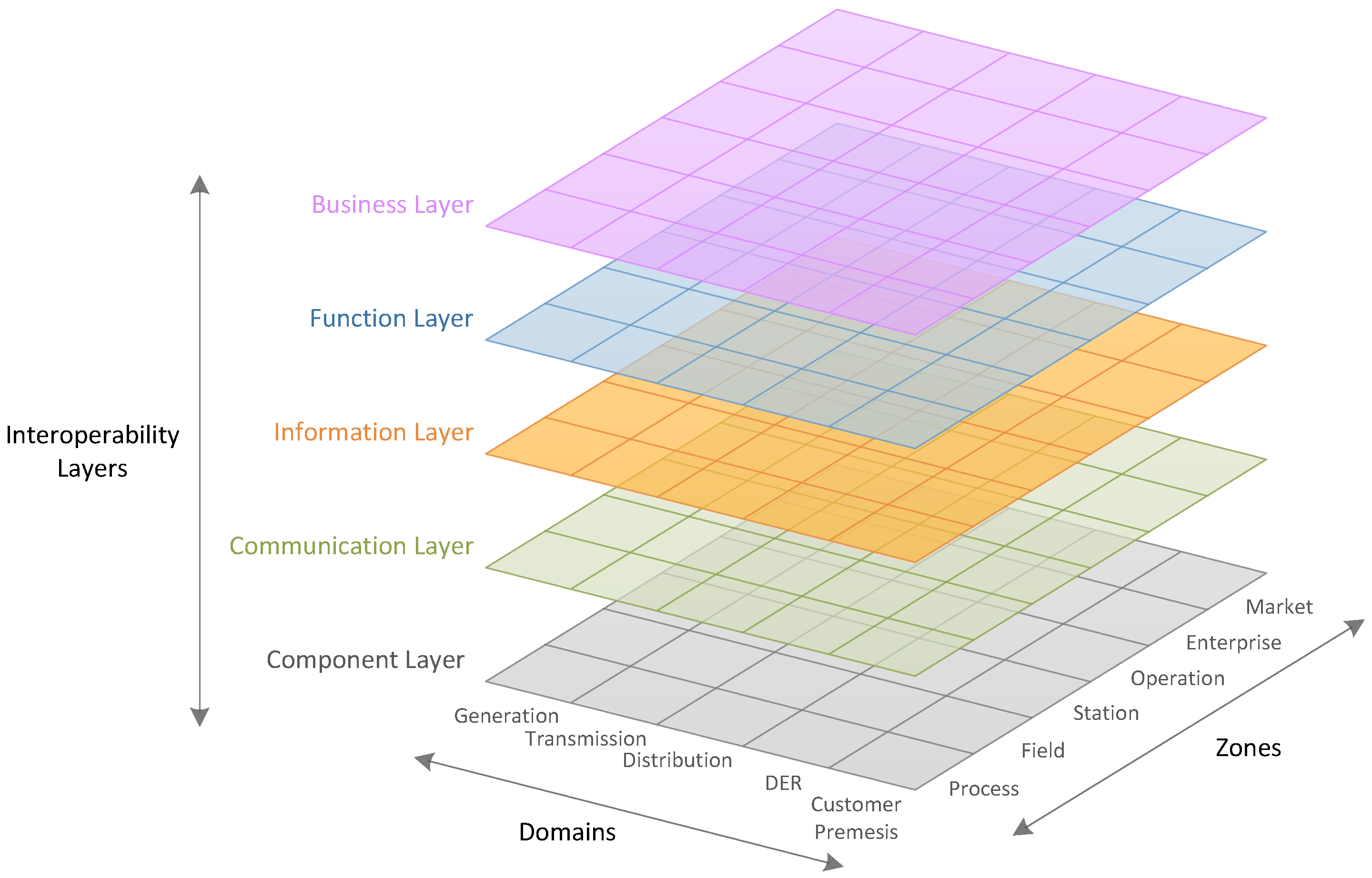

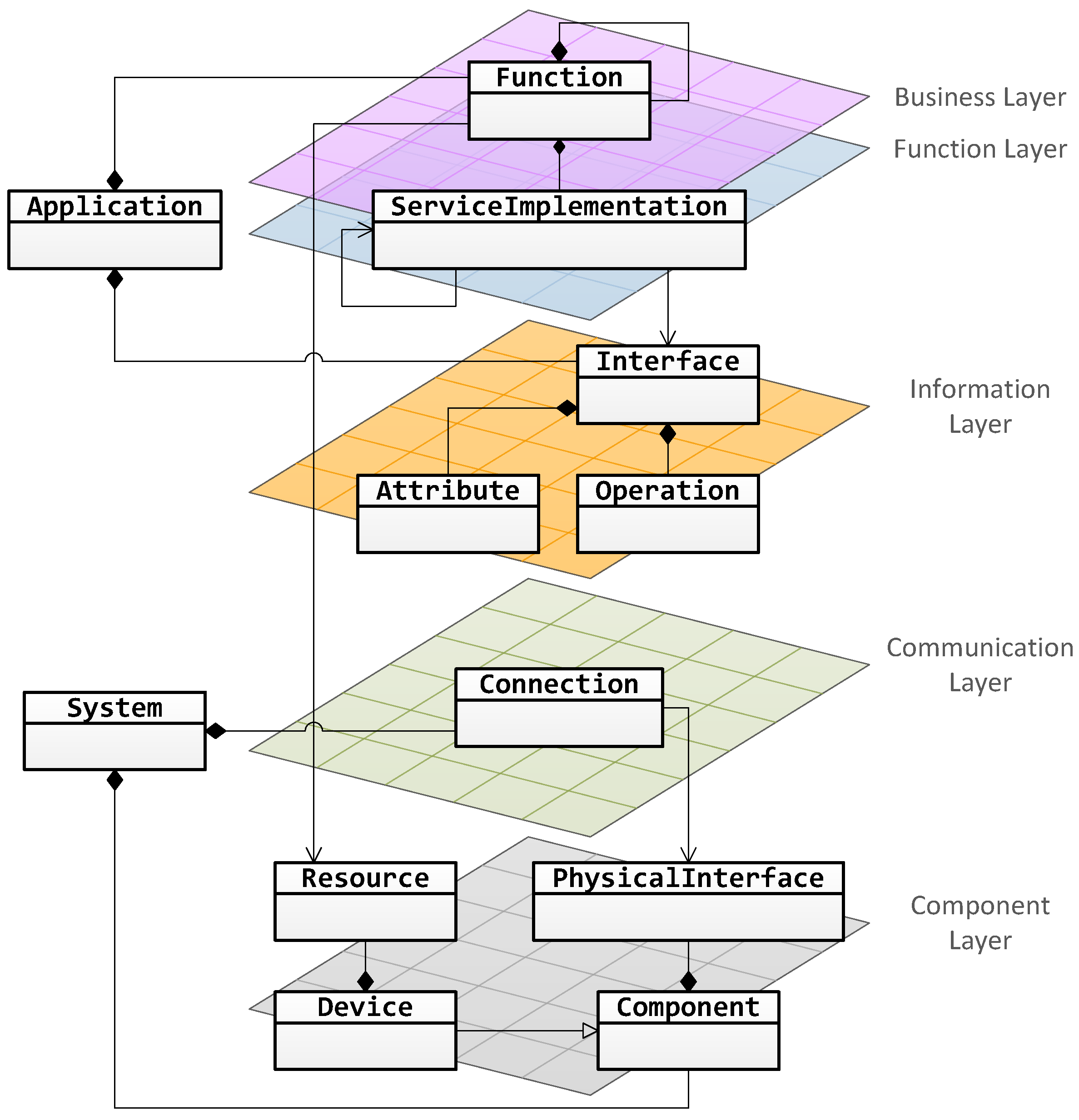

2.1. Use Case Descriptions According to the Smart Grid Architecture Model

- Use Case Analysis: The first step is an analysis of the use case. It is suggested to use the IEC 62559 template to create an initial use case description [16].

- Business Layer Design: The business processes, services, and organizations, which are linked to the use case, are mapped to the business layer. These business entities are placed in the appropriate domain and zone.

- Function Layer Design: In the function layer, functions and their interrelations should be represented. The functions are derived from the initial use case description. A use case can be hierarchically divided into sub use cases and functions.

- Component Layer Design: After the business layer and the function layer have been modeled, they have to be matched with a certain system. Thus, the next step is to model the component layer. Based on the actors involved in the use case, and any existing system components, the needed components for the use case can be derived and assigned to a domain and zone. Subsequently, the derived functions from the function layer can be assigned to a corresponding hardware.

- Information Layer Design: In the information layer, the information exchanged between functions, services, and components is represented. Information objects can be identified by analyzing the data exchanged between actors involved in the use case (e.g., using sequence and activity diagrams). Another important aspect of this layer is to represent which data models are used for the information exchange.

- Communication Layer Design: Taking the exchanged information and data models identified in the information layer into account, suitable communication protocols and ICT techniques have to be identified. These should be represented in the communication layer.

2.2. Power Utility Automation

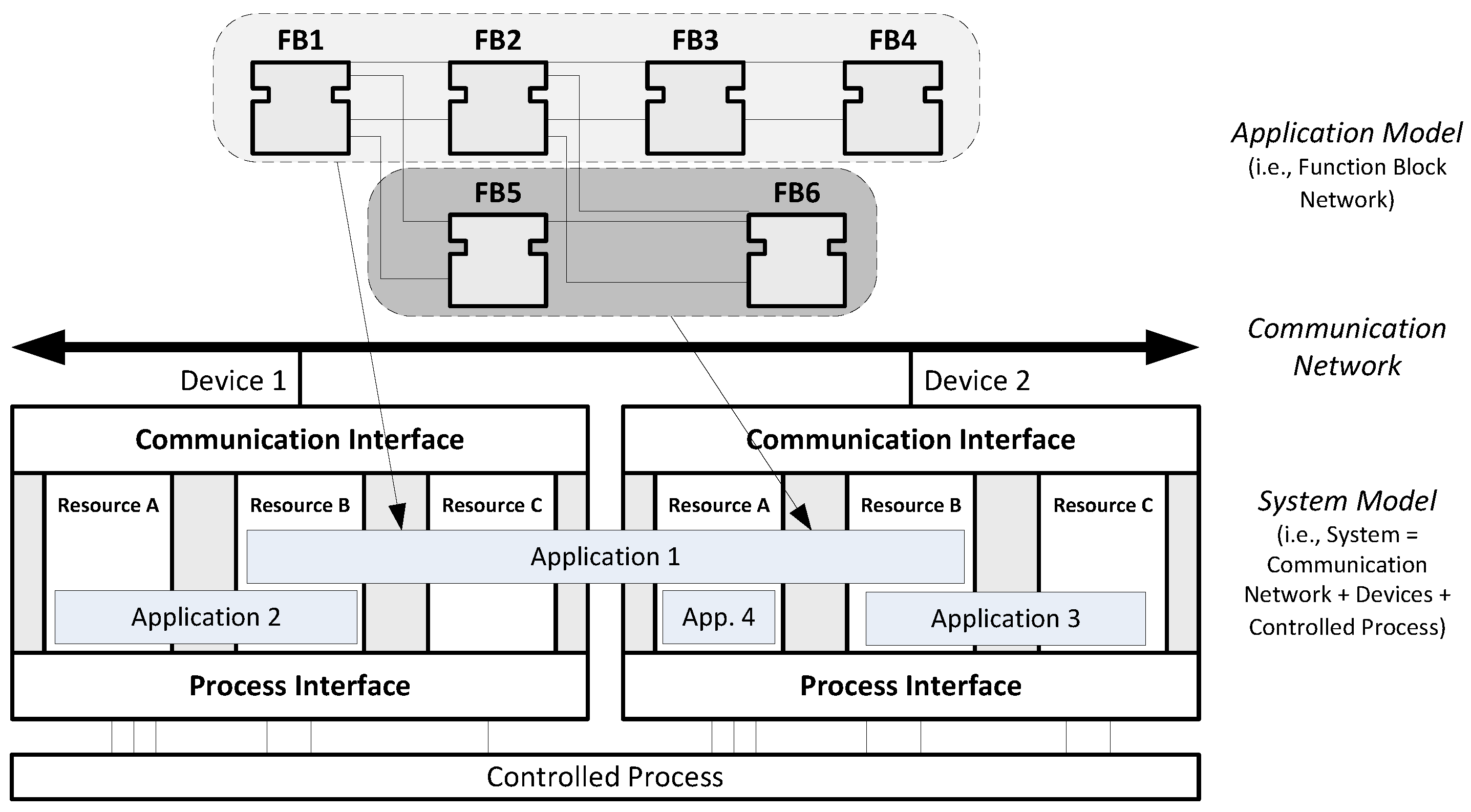

2.2.1. Distributed Control Reference Model—IEC 61499

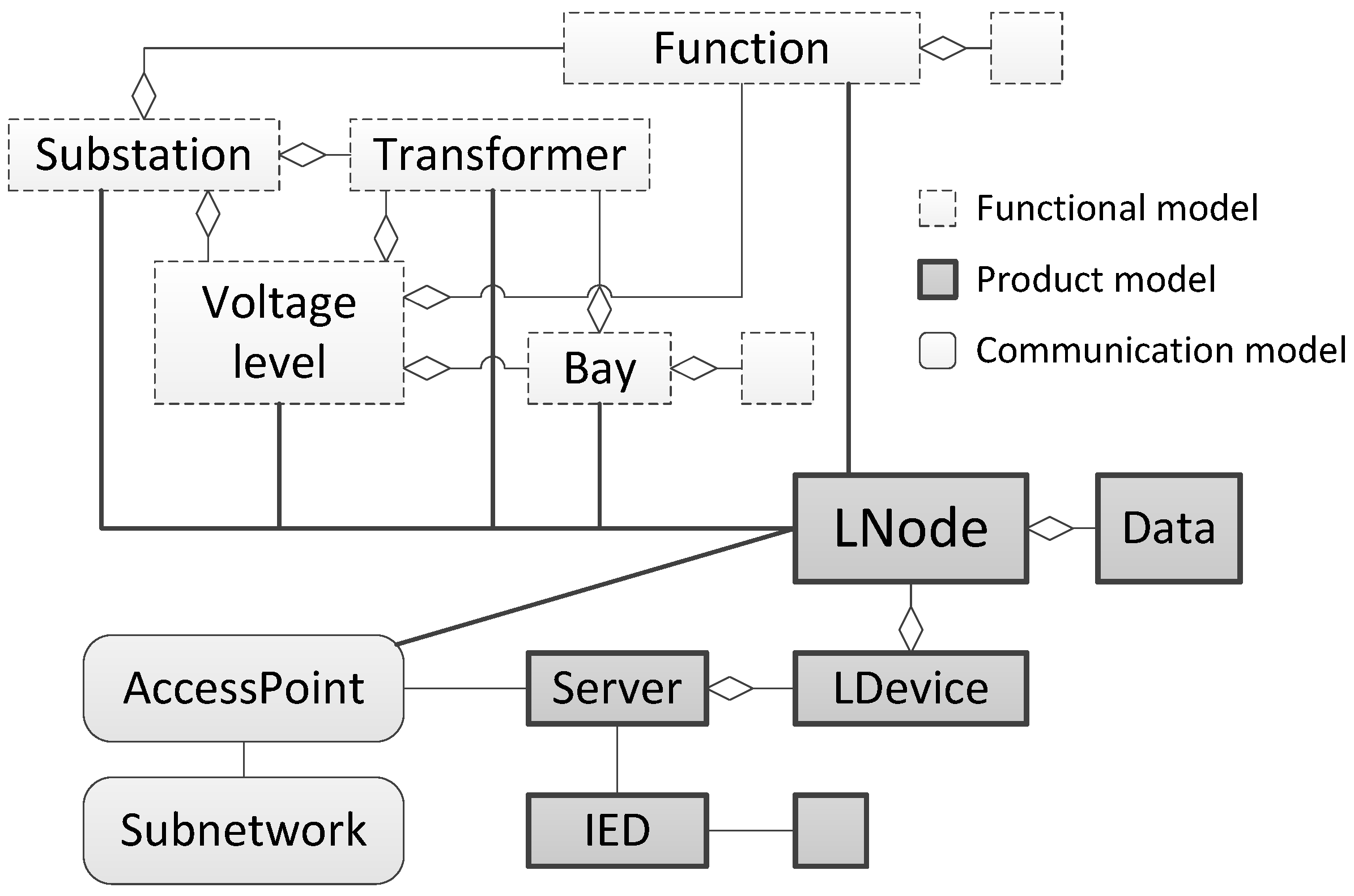

2.2.2. Interoperability in Power Systems—IEC 61850

2.3. Model-Driven Architectures & Domain-Specific Concepts

2.4. Model-Driven Engineering for Smart Grid Application Development

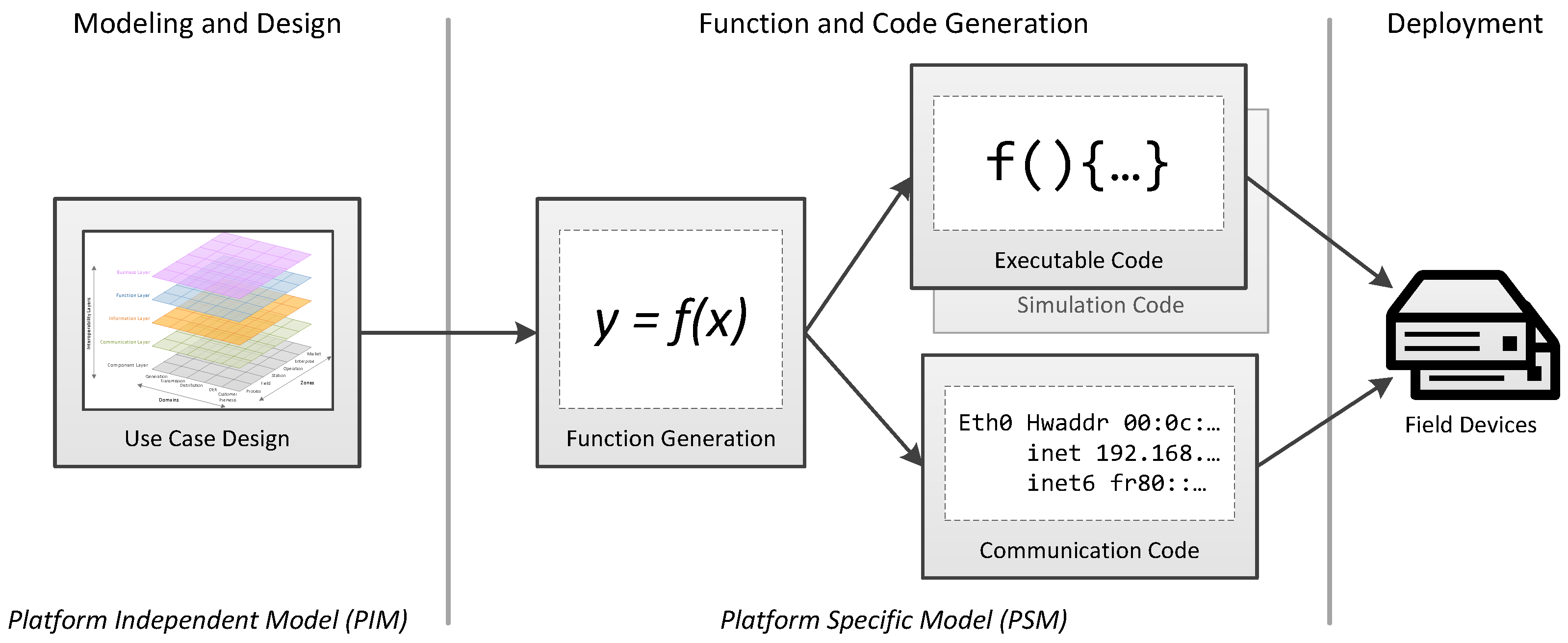

3. Creating a Rapid Engineering Methodology for Smart Grid Automation

3.1. Actors and Requirements

3.1.1. Actors and Stakeholders

3.1.2. Requirements

3.2. General Concept

- Rapidness and Effort: Smart grid solutions are becoming more and more complex resulting in increased engineering efforts and costs. Therefore, it is important to improve the rapidness of traditional engineering methods.

- Correctness: Due to the multidisciplinary character of smart grid applications this also requires the engineer to have an expert knowledge in each discipline [13]. This is often not the case, which increases the risk of human errors.

- Handling Legacy Systems: Grid operators expect a long service life of all components in their systems. Since not all devices are changed at the same time it must be possible to handle already existing legacy systems and corresponding units.

- Geographical Dispersion: The distribution of components over large geographical areas requires new ICT approaches and wide-area communication—also for the engineering.

- Interoperability: Interoperability is a critical issue in smart grid applications. This must be assured on all levels, from specifications over implementation, to deployment and finally during operation. Also components from different manufacturers must be handled, which requires a manufacturer independent method.

- Real-Time Constraints: Some applications may enforce real-time constraints on hardware and software. This may demand for special consideration during the whole engineering process.

3.3. Power System Automation Language

3.4. PSAL Definition

3.4.1. System Model

3.4.2. Application Model

4. Mapping a Selected Programming Technique to PSAL

- Choosing a programming technique

- Define how Functions are implemented using

- Define how ServiceImplementations are implemented using

4.1. Choosing a Suitable Programming Technique

- Software components: The Functions in PSAL are simple software components, which means that this concept should be supported. Components should also be able to contain other components, in order to model different levels of detail.

- Information services: Services must be representable by the programming technique. The services can be implemented in different ways, but important is that information can be exchanged between the software components.

- Software component mapping: Once a software component is described, it should be mappable to a system component. This mapping identifies on which hardware the software is executed.

- Deployment: Mapped software components should be easily deployable. This deployment can be either manual or (semi-)automatic.

- Support for multiple protocols: Different communication protocols should be supported by the technique. The more supported protocols, the higher the interoperability with other systems.

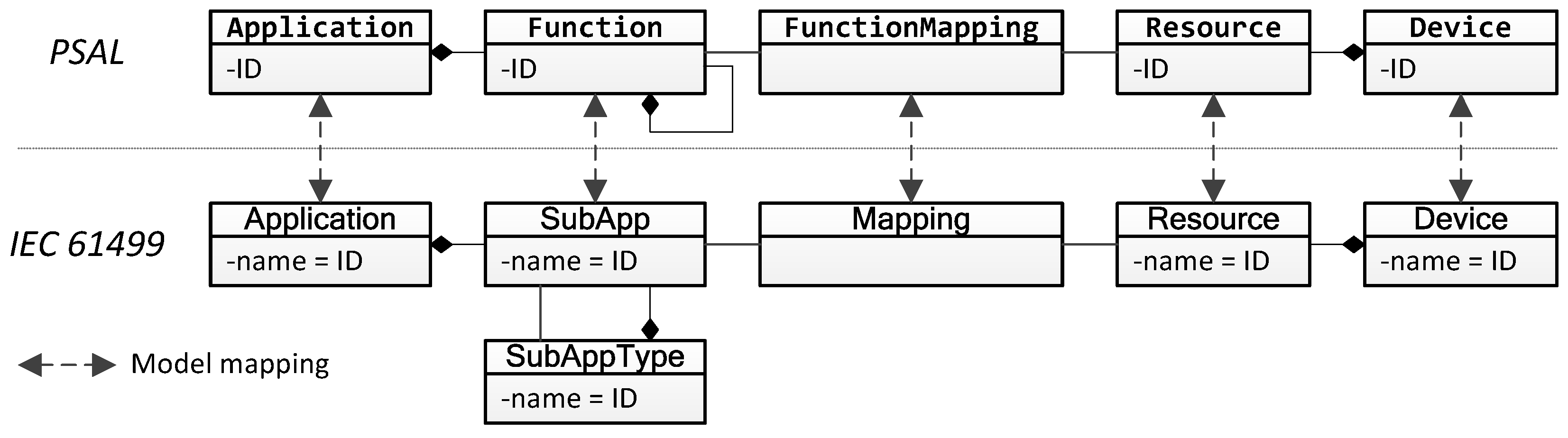

4.2. Mapping IEC 61499 to the Function Model of PSAL

4.3. Describing Service Implementations in PSAL Using IEC 61499

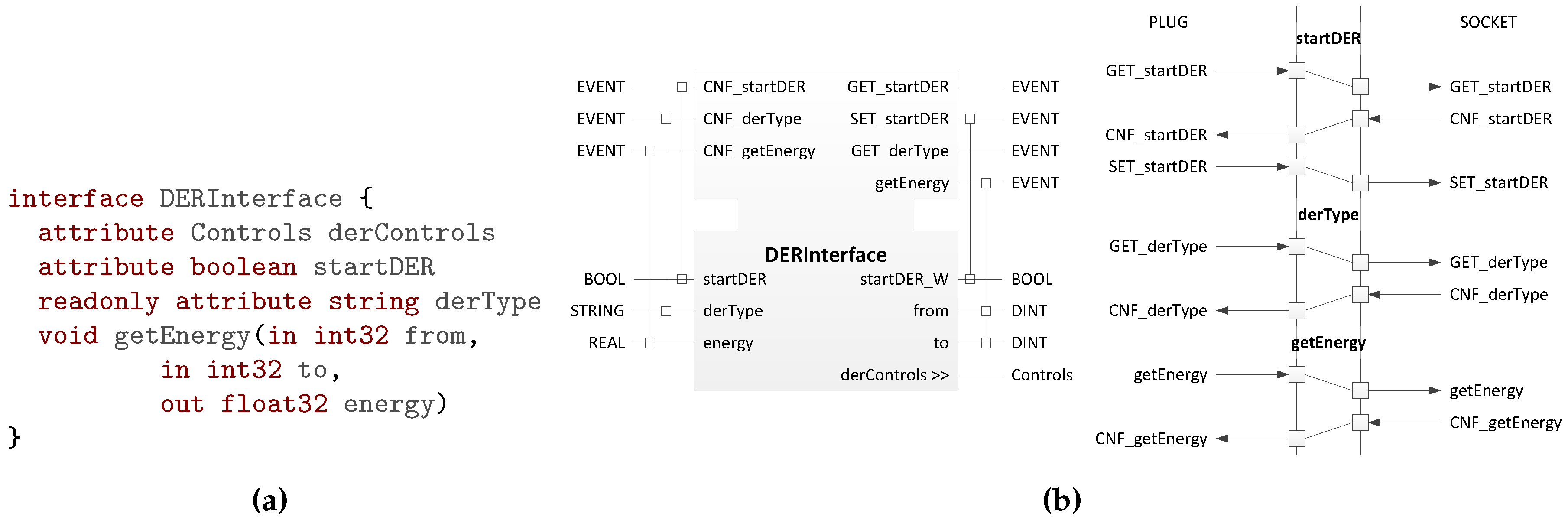

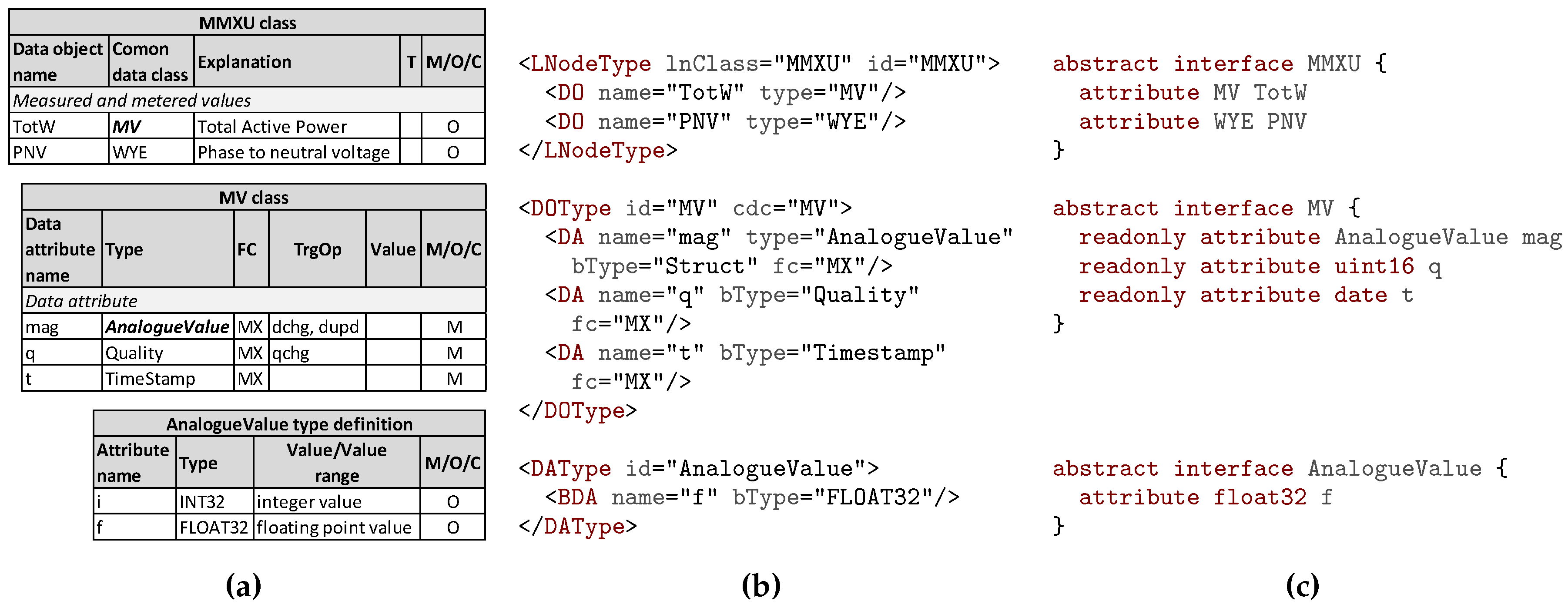

4.4. Mapping IEC 61850 to Interfaces and Events in PSAL

5. Use Case Example

5.1. Use Case Analysis

5.2. Business and Function Layers Design

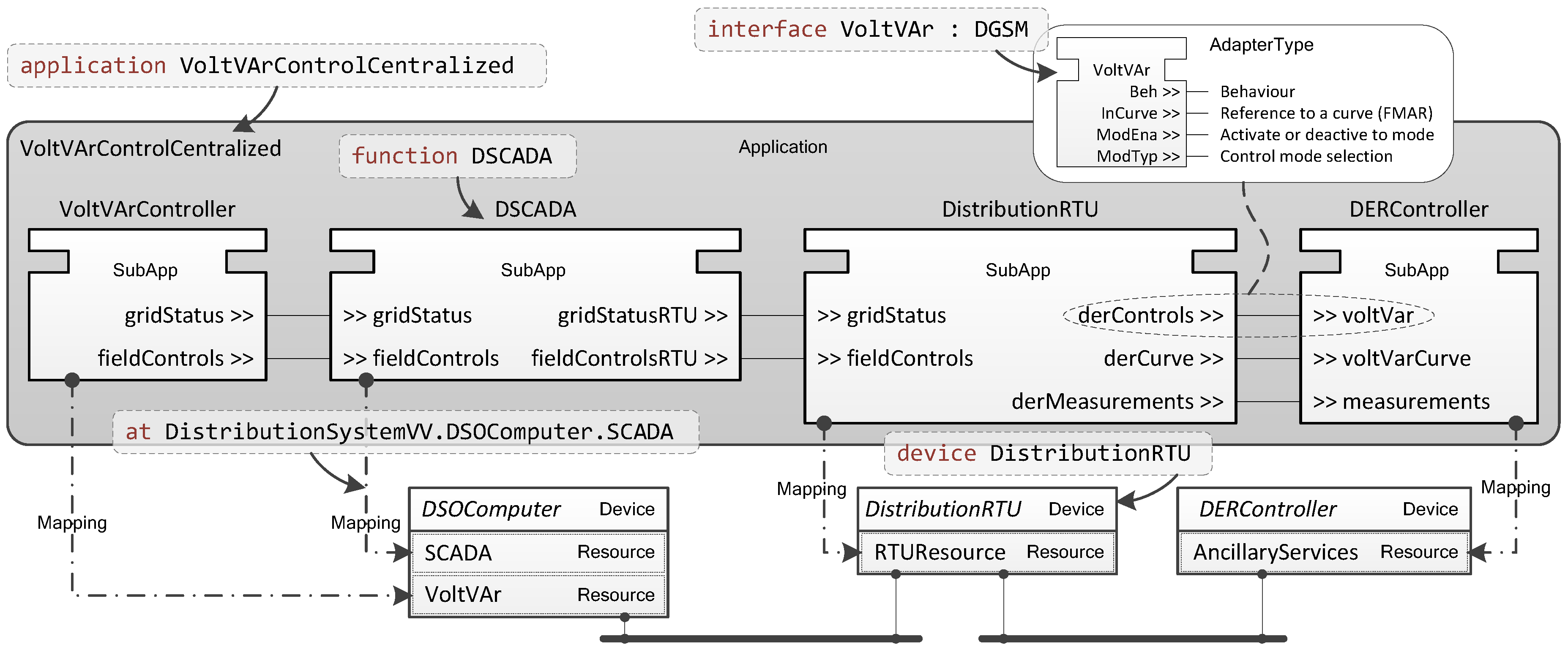

5.3. Component Layer Design

5.4. Information and Communication Layers Design

5.5. Business and Function Layers Revisited: Transformation to IEC 61499

6. Prototypical Implementation and Laboratory Validation

6.1. Prototypical Implementation

6.2. Validation Test Case

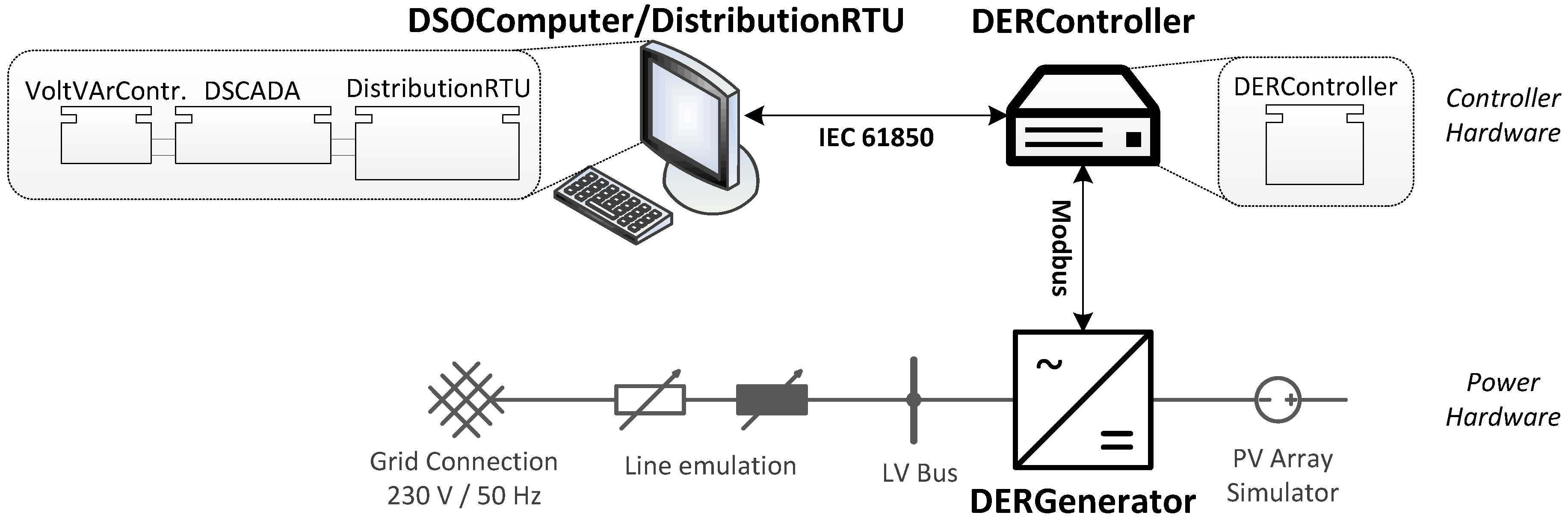

6.2.1. Laboratory Implementation

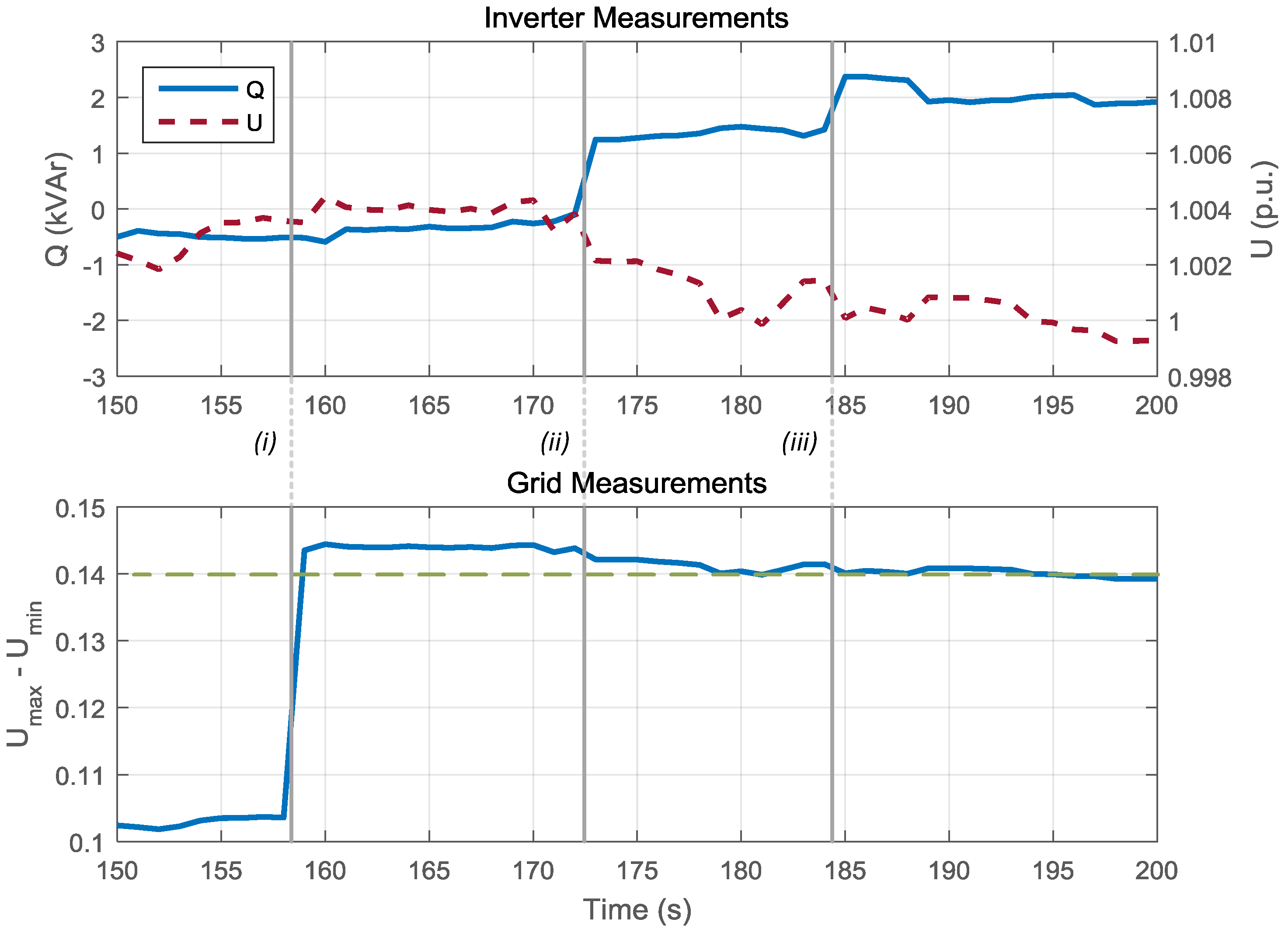

6.2.2. Performed Tests and Results

7. Reflection

- Initial specification of the Application and the System using PSAL

- Detailed specification of <interface>s and <event>s using protocol mappings

- Transformation into an IEC 61499 Application499 and System499 model

- Function design by implementation of SubAppTypes499

- Generating and downloading the communication configurations (e.g., SCL files)

- Downloading the Resources499 to their Devices499

8. Conclusions

- Modeling and design of the use case according to SGAM and a conceptual function design

- Function and code generation of executable code as well as communication configurations

- Deployment of the generated code to field devices

Acknowledgments

Author Contributions

Conflicts of Interest

Appendix A

References

- International Energy Agency. World Energy Outlook 2013; Technical Report; International Energy Agency: Paris, France, 2013. [Google Scholar]

- Liserre, M.; Sauter, T.; Hung, J. Future Energy Systems: Integrating Renewable Energy Sources into the Smart Power Grid Through Industrial Electronics. IEEE Ind. Electron. Mag. 2010, 4, 18–37. [Google Scholar] [CrossRef]

- Palensky, P.; Dietrich, D. Demand Side Management: Demand Response, Intelligent Energy Systems, and Smart Loads. IEEE Trans. Ind. Inform. 2011, 7, 381–388. [Google Scholar] [CrossRef]

- Gungor, V.; Sahin, D.; Kocak, T.; Ergut, S.; Buccella, C.; Cecati, C.; Hancke, G. Smart Grid Technologies: Communication Technologies and Standards. IEEE Trans. Ind. Inform. 2011, 7, 529–539. [Google Scholar] [CrossRef]

- Ardito, L.; Procaccianti, G.; Menga, G.; Morisio, M. Smart Grid Technologies in Europe: An Overview. Energies 2013, 6, 251–281. [Google Scholar] [CrossRef]

- Santodomingo, R.; Uslar, M.; Göring, A.; Gottschalk, M.; Nordström, L.; Saleem, A.; Chenine, M. SGAM-based methodology to analyse Smart Grid solutions in DISCERN European research project. In Proceedings of the 2014 IEEE International Energy Conference (ENERGYCON), Cavtat, Croatia, 13–16 May 2014; pp. 751–758.

- Frascella, A.; Swiderski, J.; Proserpio, G.; Rikos, E.; Temiz, A.; Babs, A.; Uslar, M.; Branchetti, S.; Graditi, G. Looking for the unified classification and evaluation approach of SG interface standards for the purposes of ELECTRA IRP. In Proceedings of the International Symposium on Smart Electric Distribution Systems and Technologies (EDST), Vienna, Austria, 8–11 September 2015.

- CEN-CENELEC-ETSI Smart Grid Coordination Group. Reference Architecture for the Smart Grid; Technical Report; CEN-CENELEC-ETSI Smart Grid Coordination Group: Brussels, Belgium, 2012. [Google Scholar]

- International Electrotechnical Commission. IEC 62559: Use Case Methodology; International Electrotechnical Commission: Geneva, Switzerland, 2015. [Google Scholar]

- Andrén, F.; Strasser, T.; Rohjans, S.; Uslar, M. Analyzing the need for a common modeling language for Smart Grid applications. In Proceedings of the 11th IEEE International Conference on Industrial Informatics (INDIN), Bochum, Germany, 29–31 July 2013.

- Mellor, S.J.; Kendall, S.; Uhl, A.; Weise, D. MDA Distilled; Addison Wesley Longman Publishing Co., Inc.: Redwood City, CA, USA, 2004. [Google Scholar]

- Siegel, J. Developing in OMG’s New Model-Driven Architecture; Technical Report; Object Management Group (OMG): Needham, MA, USA, 2001. [Google Scholar]

- Strasser, T.; Pröstl Andrén, F.; Lauss, G.; Bründlinger, R.; Brunner, H.; Moyo, C.; Seitl, C.; Rohjans, S.; Lehnhoff, S.; Palensky, P.; et al. Towards holistic power distribution system validation and testing—An overview and discussion of different possibilities. E I Elektrotech. Informationstech. 2016, 134, 71–77. [Google Scholar] [CrossRef]

- European Commission (EC). M/490 Standardization Mandate to European Standardisation Organisations (ESOs) to Support European Smart Grid Deployment; Technical Report; European Commission (EC): Brussels, Belgium, 2012. [Google Scholar]

- CEN-CENELEC-ETSI Smart Grid Coordination Group. SG-CG/M490/F Overview of SG-CG Methodologies; Technical Report; CEN-CENELEC-ETSI Smart Grid Coordination Group: Brussels, Belgium, 2014. [Google Scholar]

- CEN-CENELEC-ETSI Smart Grid Coordination Group. Use Case Collection, Management, Repository, Analysis and Harmonization; Technical Report; CEN-CENELEC-ETSI Smart Grid Coordination Group: Brussels, Belgium, 2012. [Google Scholar]

- Dänekas, C.; Neureiter, C.; Rohjans, S.; Uslar, M.; Engel, D. Towards a Model-Driven-Architecture Process for Smart Grid Projects. In Digital Enterprise Design & Management; Advances in Intelligent Systems and Computing; Benghozi, P.J., Krob, D., Lonjon, A., Panetto, H., Eds.; Springer: Cham, Switzerland, 2014; Volume 261, pp. 47–58. [Google Scholar]

- International Electrotechnical Commission. IEC 61499: Function Blocks; International Electrotechnical Commission (IEC): Geneva, Switzerland, 2012. [Google Scholar]

- International Electrotechnical Commission. IEC 61131-3: Programmable Controllers—Part 3: Programming Languages; International Electrotechnical Commission (IEC): Geneva, Switzerland, 2012. [Google Scholar]

- Lewis, R.W. Modeling Control Systems Using IEC 61499; The Institution of Engineering and Technology: Stevenage, UK, 2001. [Google Scholar]

- International Electrotechnical Commission. IEC 61850: Communication Networks and Systems for Power Utility Automation; International Electrotechnical Commission (IEC): Geneva, Switzerland, 2010. [Google Scholar]

- Colak, I.; Sagiroglu, S.; Fulli, G.; Yesilbudak, M.; Covrig, C.F. A survey on the critical issues in smart grid technologies. Renew. Sustain. Energy Rev. 2016, 54, 396–405. [Google Scholar] [CrossRef]

- Kurtev, I. State of the art of QVT: A model transformation language standard. In Applications of Graph Transformations with Industrial Relevance; Springer: Cham, Switzerland, 2008; pp. 377–393. [Google Scholar]

- Fowler, M. Domain-Specific Languages; Pearson Education: London, UK, 2010. [Google Scholar]

- Parr, T. The Definitive ANTLR Reference: Building Domain-Specific Languages; Pragmatic Bookshelf: Raleigh, NC, USA, 2007. [Google Scholar]

- Petre, M. Why Looking Isn’t Always Seeing: Readership Skills and Graphical Programming. Commun. ACM 1995, 38, 33–44. [Google Scholar] [CrossRef]

- Shin, I.J.; Song, B.K.; Eom, D.S. Auto-Mapping and Configuration Method of IEC 61850 Information Model Based on OPC UA. Energies 2016, 9, 901. [Google Scholar] [CrossRef]

- International Electrotechnical Commission. IEC 61970: Energy Management System Application Program Interface (EMS-API); International Electrotechnical Commission (IEC): Geneva, Switzerland, 2004. [Google Scholar]

- Lefrançois, M.; Habault, G.; Ramondou, C.; Françon, E. Outsourcing Electric Vehicle Smart Charging on the Web of Data. In Proceedings of the First International Conference on Green Communications, Computing and Technologies, (GREEN 2016), Nice, France, 24–28 July 2016.

- Broy, M. Model-driven architecture-centric engineering of (embedded) software intensive systems: Modeling theories and architectural milestones. Innov. Syst. Softw. Eng. 2007, 3, 75–102. [Google Scholar] [CrossRef]

- Paulo, R.; Carvalho, A. Towards model-driven design of substation automation systems. In Proceedings of the 2005 18th International Conference and Exhibition on Electricity Distribution, (CIRED 2005), Lyon, France, 6–9 June 2005.

- Yang, C.W.; Vyatkin, V.; Mousavi, A.; Dubinin, V. On automatic generation of IEC61850/IEC61499 substation automation systems enabled by ontology. In Proceedings of the 40th Annual Conference of the IEEE Industrial Electronics Society (IECON), Dallas, TX, USA, 29 October–1 November 2014.

- Blair, S.M.; Coffele, F.; Booth, C.D.; Burt, G.M. An Open Platform for Rapid-Prototyping Protection and Control Schemes With IEC 61850. IEEE Trans. Power Deliv. 2013, 28, 1103–1110. [Google Scholar] [CrossRef] [Green Version]

- Andrén, F.; Stifter, M.; Strasser, T. Towards a Semantic Driven Framework for Smart Grid Applications: Model-Driven Development using CIM, IEC 61850 and IEC 61499. Informatik-Spektrum 2013, 36, 58–68. [Google Scholar] [CrossRef]

- Pröstl Andrén, F.; Strasser, T.; Kastner, W. Applying the SGAM Methodology for Rapid Prototyping of Smart Grid Applications. In Proceedings of the 42nd Annual Conference of the IEEE Industrial Electronics Society (IECON), Florence, Italy, 24–27 October 2016.

- Pröstl Andrén, F.; Strasser, T.; Langthaler, O.; Veichtlbauer, A.; Kasberger, C.; Felbauer, G. Open and Interoperable ICT Solution for Integrating Distributed Energy Resources into Smart Grids. In Proceedings of the 21th IEEE International Conference on Emerging Technologies and Factory Automation (ETFA’2016), Berlin, Germany, 6–9 September 2016.

- Schwalbe, R.; Einfalt, A.; Abart, A.; Radauer, M.; Brunner, H. DG DemoNet Smart LV Grid—Robust Control Architecture to Increase DG Hosting Capacity. In Proceedings of the 23rd International Conference and Exhibition on Electricity Distribution, CIRED 2015, Lyon, France, 6–18 June 2015.

- World Wide Web Consortium (W3C). EBNF for XML; World Wide Web Consortium (W3C): Cambridge, MA, USA, 2004. [Google Scholar]

- Object Management Group. Interface Definition Language Version 3.5; Technical Report; Object Management Group (OMG): Needham, MA, USA, 2014. [Google Scholar]

- Slee, M.; Agarwal, A.; Kwiatkowski, M. Thrift: Scalable Cross-Language Services Implementation; Technical Report; Facebook: California, CA, USA, 2007. [Google Scholar]

- Vyatkin, V.; Zhabelova, G.; Higgins, N.; Ulieru, M.; Schwarz, K.; Nair, N. Standards-enabled Smart Grid for the future Energy Web. In Proceedings of the Innovative Smart Grid Technologies (ISGT), Gaithersburg, MD, USA, 19–21 January 2010; pp. 1–9.

- Strasser, T.; Andrén, F.; Vyatkin, V.; Zhabelova, G.; Yang, C.W. Towards an IEC 61499 compliance profile for smart grids review and analysis of possibilities. In Proceedings of the 38th Annual Conference on IEEE Industrial Electronics Society (IECON), Montreal, QC, Canada, 25–28 October 2012; pp. 3750–3757.

- Andrén, F.; Bründlinger, R.; Strasser, T. IEC 61850/61499 Control of Distributed Energy Resources: Concept, Guidelines, and Implementation. IEEE Trans. Energy Convers. 2014, 29, 1008–1017. [Google Scholar] [CrossRef]

- Andren, F.; Strasser, T.; Kastner, W. Model-driven engineering applied to Smart Grid automation using IEC 61850 and IEC 61499. In Proceedings of the Power Systems Computation Conference (PSCC), Wroclaw, Poland, 18–22 August 2014; pp. 1–7.

- Hegny, I.; Strasser, T.; Melik-Merkumians, M.; Wenger, M.; Zoitl, A. Towards an increased reusability of distributed control applications modeled in IEC 61499. In Proceedings of the 2012 IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), Krakow, Poland, 17–21 September 2012.

- Green, B.D. Integrated Volt VAR Control Centralized; Technical Report; American Electric Power: Columbus, OH, USA, 2011. [Google Scholar]

- International Electrotechnical Commission. IEC/TR 61850-90-7—Communication Networks and Systems for Power Utility Automation—Part 90-7: Object Models for Power Converters in Distributed Energy Resources (DER) Systems; International Electrotechnical Commission (IEC): Geneva, Switzerland, 2013. [Google Scholar]

- Efftinge, S.; Völter, M. oAW xText: A framework for textual DSLs. In Proceedings of the Workshop on Modeling Symposium at Eclipse Summit, Esslingen, Germany, 11–12 October 2006; Volume 32.

- Zoitl, A.; Strasser, T.; Valentini, A. Open source initiatives as basis for the establishment of new technologies in industrial automation: 4DIAC a case study. In Proceedings of the 2010 IEEE International Symposium on Industrial Electronics (ISIE), Bari, Italy, 4–7 Juli 2010.

- Lednicki, L.; Carlson, J. A framework for generation of inter-node communication in component-based distributed embedded systems. In Proceedings of the 2014 IEEE Emerging Technology and Factory Automation (ETFA), Barcelona, Spain, 16–19 September 2014; pp. 1–8.

- Strasser, T.; Andrén, F.; Bründlinger, R.; Garabandic, D. Integrating PV into the Smart Grid—Implementation of an IEC 61850 Interface for Large Scale PV Inverters. In Proceedings of the 28th European Photovoltaic Solar Energy Conference and Exhibition (EUPVSEC), Paris, France, 30 September–4 October 2013.

| # | Actor Name and Description |

|---|---|

| A1 | Utility Operator |

| The operator of the power grid and its corresponding assets. A common activity for the utility operator is the specification of a certain use case or functionality before implementation. The utility operator may also be directly involved in the implementation and validation of applications. | |

| A2 | System Integrator |

| The system integrator delivers and integrates a whole or part of a system (e.g., a substation) to a utility operator. Commonly the utility operator specifies an application that is implemented by one or more system integrators. | |

| A3 | Manufacturer/Device Vendor |

| The manufacturer of grid components. This actor must have the possibility to implement functionality on all levels of a component (i.e., low-level as well as high-level functionality). | |

| A4 | Third-Party Service Provider |

| The third-party service provider may be interested in implementing services for smart grid components (e.g., implementing direct-marketing services for smart inverters). | |

| A5 | Plant Operator |

| The operator of a power plant or a flexible load (e.g., a building or an energy storage unit). This could, for example, be a virtual power plant operator who needs to optimize the usage of the involved plants. It may also be an aggregator for ancillary services or flexibility. | |

| A6 | Plant Owner |

| The owner of a power plant or a flexible load. This may in many cases be the same actor as the plant operator. The owner may want to install certain monitoring functionality, or connect the plant to a building automation system. |

| # | Requirement Name and Description |

|---|---|

| ER1 | Business Case Specification Usually as the first step, before any other specifications are made, it must be clear what the benefit and drawbacks are for the involved actor. This is the definition of business cases and their related goals. |

| ER2 | Functional Specification From the business cases, one or more functions are derived. For each distinct function, its inputs, outputs, and goals are specified. This work focuses on automation functions (e.g., control, monitoring, supervisory control). |

| ER3 | Functional Implementation The specified functions that are owned by the business actor need to be implemented using a formal software specification (e.g., UML, IEC 61499). |

| ER4 | System Specification The system specification specifies the architecture of the execution hardware and the system upon it will operate. This includes power system equipment, ICT equipment, and field devices. It should be possible to model already existing as well as new smart grid system infrastructure. |

| ER5 | Function-System Mapping In order to know where a function should be executed it must be mapped to an execution platform. This is done with a function-system mapping where one or more functions are assigned to a specific hardware platform. |

| ER6 | Information Model Specification Data that is exchanged between functions must be assigned to an information model, with the purpose to define semantics for the data. It must also be possible to use existing information models (e.g., IEC 61850, SunSpec). |

| ER7 | Communication Specification Although an information model is already defined for a certain exchange, it should also be possible to define what kind of protocol is used for the communication. This must also be possible on different OSI (Open Systems Interconnection) layers. |

| ER8 | Application Implementation After specification, the use case must be implemented for the specified system (see ER4). This means that functions are ported to their host platform and all communication interfaces must be properly configured. |

| ER9 | Validation and Testing With the validation, the functionality of the system is tested before it is deployed. The validation can either be simulative and/or with real components (e.g., hardware-in-the-loop experiments, laboratory tests). |

| ER10 | Field Deployment To operate the implemented application, it must first be deployed to the field. This includes installation of new hardware components, software functions, and configuration of the communication and ICT system. |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Andrén, F.P.; Strasser, T.I.; Kastner, W. Engineering Smart Grids: Applying Model-Driven Development from Use Case Design to Deployment. Energies 2017, 10, 374. https://doi.org/10.3390/en10030374

Andrén FP, Strasser TI, Kastner W. Engineering Smart Grids: Applying Model-Driven Development from Use Case Design to Deployment. Energies. 2017; 10(3):374. https://doi.org/10.3390/en10030374

Chicago/Turabian StyleAndrén, Filip Pröstl, Thomas I. Strasser, and Wolfgang Kastner. 2017. "Engineering Smart Grids: Applying Model-Driven Development from Use Case Design to Deployment" Energies 10, no. 3: 374. https://doi.org/10.3390/en10030374