1. Introduction

Pulse width modulation (PWM) voltage source inverters (VSIs) have been widely used in power electronics, and their control has been extensively studied in the last decades. One of the most popular applications of VSIs is electric drives for speed control and electromagnetic torque regulation [

1]. Recently, inverter-interfaced distributed generation (DG) systems (wind turbines, photovoltaic (PV), wave generators, etc.) have raised concern. These DGs are either connected to a common bus to form a small isolated power system, or connected to the main utility grid. The power supplied by the DGs as well as the DG output voltage and current can be flexibly regulated by controlling VSIs in various operation conditions [

2,

3].

In the VSI applications mentioned above, generally two individual quantities are controlled in closed-loop strategies for inverters by means of switching. Traditionally the

d- and

q-axis current components are directly controlled in electric drives [

4]. Later on, direct torque control (DTC) was proposed and it eliminates the need for a current regulator and provides direct control of the motor electromagnetic torque [

5]. Derived from DTC, direct power control (DPC) was proposed to control rectifiers and inverters by using the active and reactive powers as control variables in DGs [

6]. Similarly, direct current control and direct voltage control were proposed for grid-connected or isolated VSI systems [

7,

8].

However, the torques (or active and reactive powers, currents and voltages) are not the only quantities that can be regulated directly by the inverter switching. The control of the inverter flux has raised concern in the last few years because the inverter flux is less sensitive to external disturbance for its voltage integral feature [

9,

10,

11]. Inverter flux control was first proposed by Chandorkar et al. [

9,

10] for inverter stand-alone operations. Nevertheless, it has not been applied in grid-connected inverters. Inverter flux was adopted in grid-connected converters [

11]. However, the inverter flux was just used to estimate the active and reactive powers in order to eliminate the instantaneous errors during measurement. In other words, the direct control variables of the inverters are active and reactive powers rather than the inverter flux. To the best of the authors’ knowledge, there are no existing papers working on direct flux control for grid-connected VSI systems. In addition, the magnitude of the inverter flux is related to the inverter voltage while the position of the inverter flux links to the voltage frequency. Therefore, inverter flux control could be a promising alternative for grid-connected renewable energy systems to performance grid support. Unfortunately, the existing inverter flux control strategies are still under development. The only approach reported in the literature is the switching table–based direct flux control, or SDFC [

9,

10]. In this scheme, the inverter switching is selected from a predefined switching table according to the position of the inverter flux. As a result, similar to conventional DTC and DPC, large flux ripples are the main drawback of SDFC. This leads to deteriorated power and current quality.

In order to address the disadvantages of SDFC, a new inverter control method is proposed in this paper by adopting predictive control to the inverter flux concept. The controller uses the system model and all the possible switching states to predict the behavior of the inverter flux, namely the flux amplitude and the flux position, at the next sampling instant. Then, a cost function is employed as a criterion to evaluate the inverter flux performance. Finally, the voltage vector or the switching state that minimizes the cost function will be applied during the next sampling interval. In this way, the inverter flux can be well controlled to track the reference. Also, it is necessary to point out that the proposed method in this paper falls into the category of model predictive control (MPC), while the method presented in [

11] belongs to the category of vector sequence–based predictive control. The cost function developed here presents totally different meanings to the cost function described in [

11]. In our work, the optimal voltage vector is selected according to the cost function, whereas the voltage vector sequences are selected according to a predefined switching table. The cost function is used to calculate the applied duration of the selected voltage vectors.

The rest of this paper is organized as follows. The VSI system configuration and the inverter flux concept are described in

Section 2. The conventional SDFC method is presented in

Section 3, while the new predictive direct flux control (PDFC) is introduced in

Section 4. The effectiveness of the proposed method is verified in

Section 5. The conclusion is presented in

Section 6.

2. Flux Concept in VSI Systems

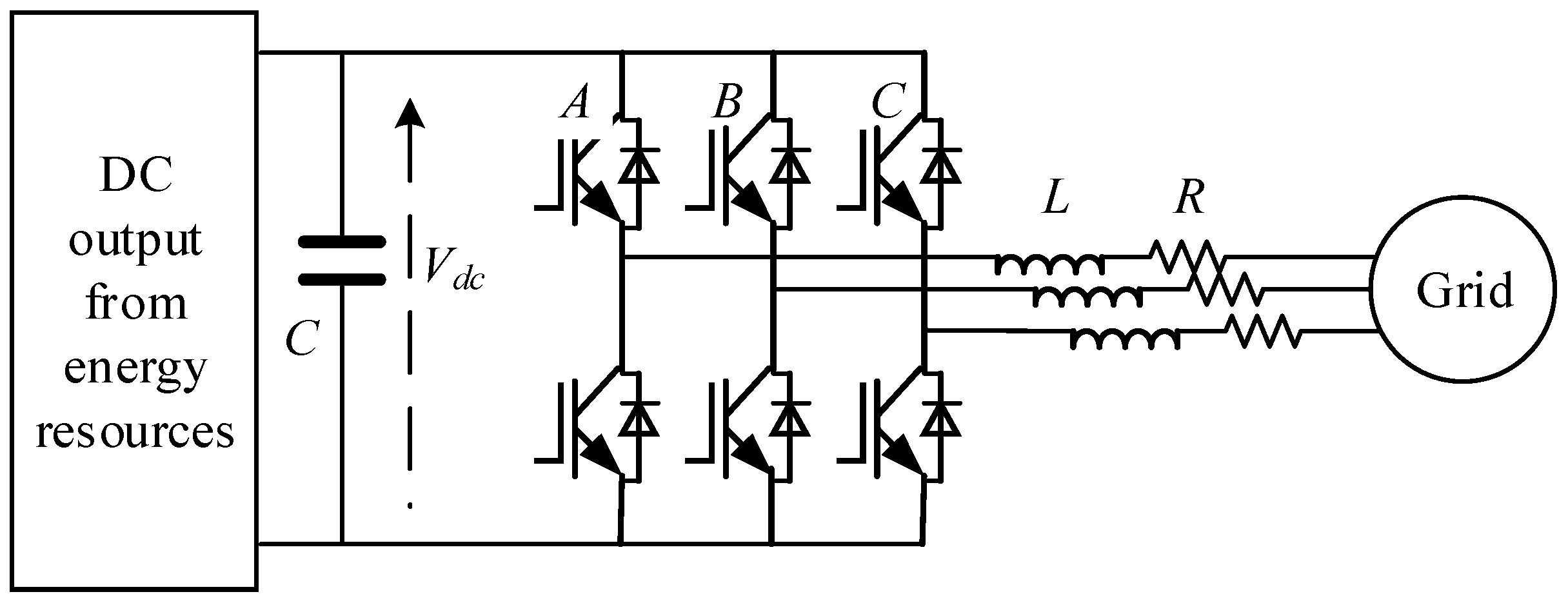

The power circuit considered is shown in

Figure 1. The energy resources are interfaced with the grid through the three-phase two-level VSI with six insulated gate bipolar transistors (IGBTs). The DC output from the energy resources could be from the solar PV panels, the permanent magnet synchronization wind generator with diode rectifiers, etc.

L and

R represent the line inductor and resistor, respectively. Depending on the switching states, the inverter can be controlled to generate eight possible output voltages including six active vectors and two null vectors. They can be expressed in complex space vectors as:

where

Vdc is the dc-link voltage.

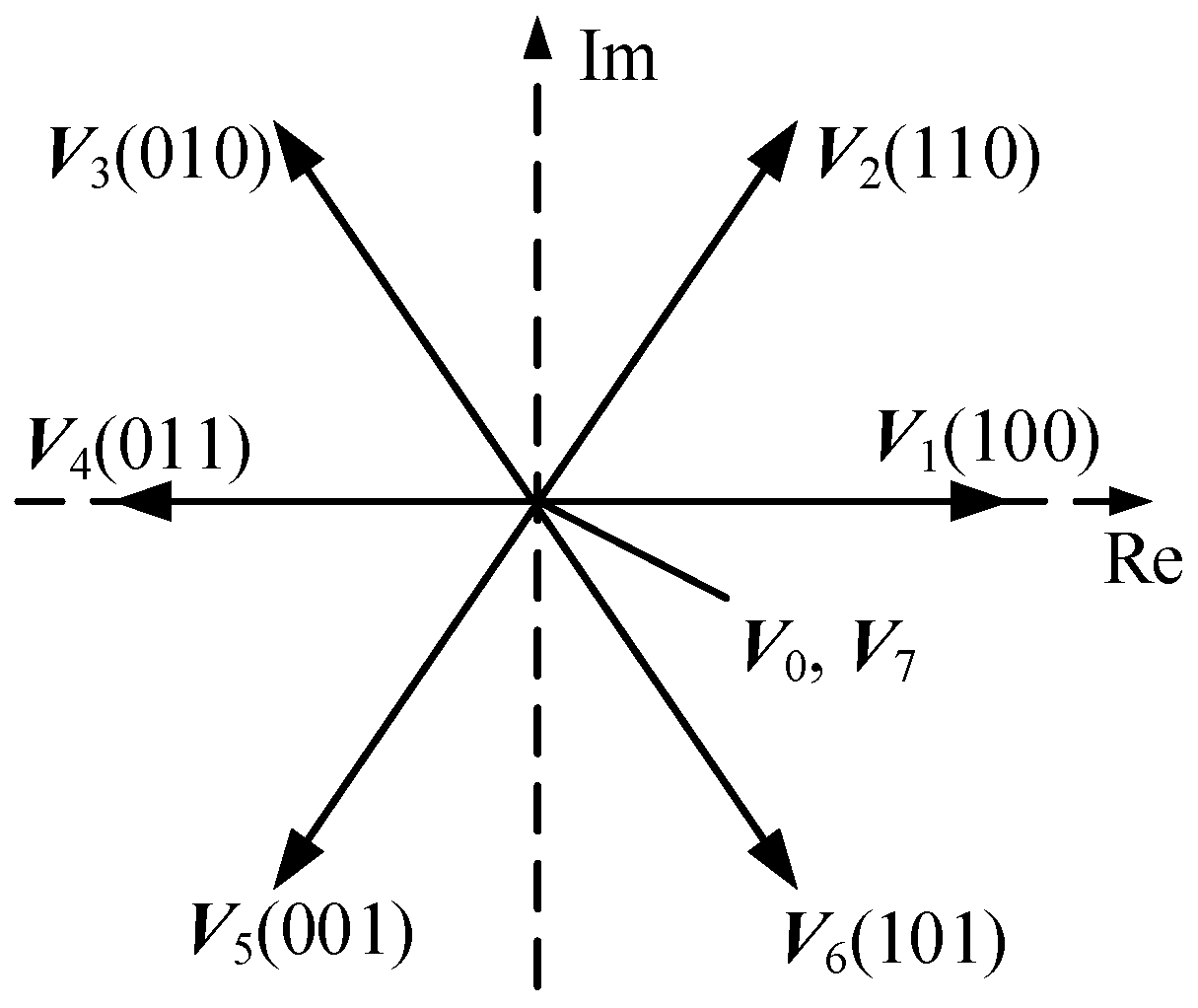

Figure 2 shows the inverter output voltages in terms of amplitude and position in the stationary α-β frame. For instance, if the upper switches of phases A and B are turned ON while the upper switch of phase C is turned OFF, voltage vector

V2 with an amplitude of 2/3

Vdc and a phase angle of 60° will be generated. It is noted that this two-dimensional plane can be divided into six sections, which will be explained and used in inverter flux control. The mathematical equations of the system equivalent circuit can be described as:

where

E and

I are the grid voltage vector and the line current vector, respectively.

R is the line resistance, and

L is the line inductance.

P and

Q are the active and reactive power flow between the system and the utility grid. Similar to the flux definition in an electrical machine, the inverter flux vector and the grid flux vector can be defined as [

10]:

It is noted that the inverter flux and the grid flux are the rotating space vectors with a specified amplitude and angular speed. Here, the angle between

ΨV and

ΨE, indicated as the power angle, is defined as:

where δ

V and δ

E are the angles of

ΨV and

ΨE, respectively.

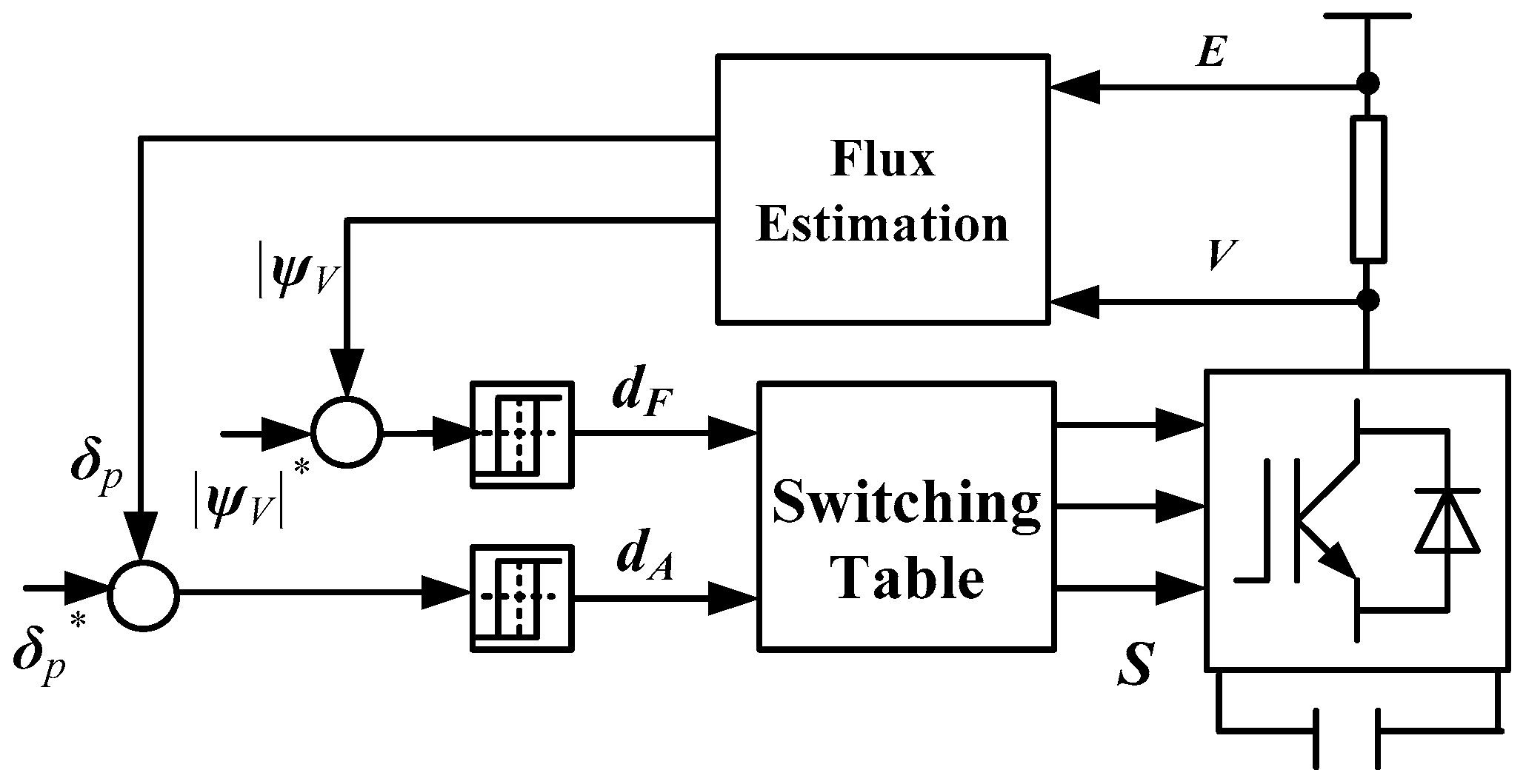

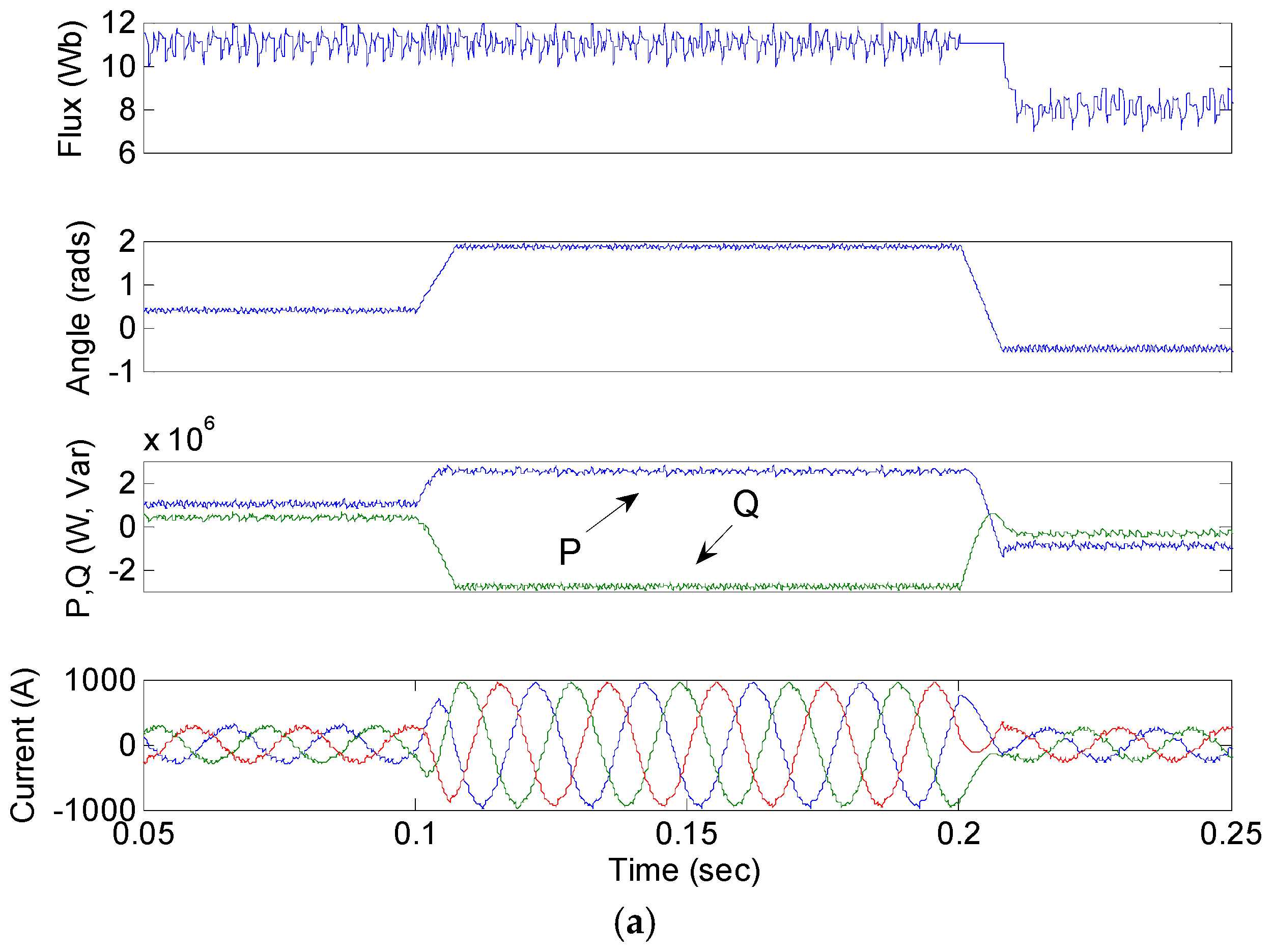

3. Conventional Switching Table–Based Direct Flux Control (SDFC)

Control of the flux vector has been found to show a good dynamic response and robustness. In conventional SDFC, two variables that are controlled directly by the inverter are |

ΨV| and δ

p. In other words, the vector

ΨV is controlled to have a specified magnitude and a specified position relative to the vector

ΨE, as shown in

Figure 3. The control strategy of the SDFC is depicted in

Figure 4. The signals

dF and

dA are first generated by two hysteresis comparators according to the tracking errors between the estimated and referenced values of the flux and power angle. The voltage vector is then selected from a look-up table (

Table 1) according to

dF,

dA and δ

V. Similar to the switching table–based DTC and DPC, the SDFC strategy is based on the fact that the effects of each inverter voltage vector on |

ΨV| and δ are different. This is summarized in

Table 1 [

9], where S

k is the sector number in the α-β plane given by the position of

ΨV, being

dF = 1 if |

ΨV|* > |

ΨV|,

dF = 0 if |

ΨV|* < |

ΨV|; and

dA = 1 if δ* > δ,

dA = 0 if δ* < δ.

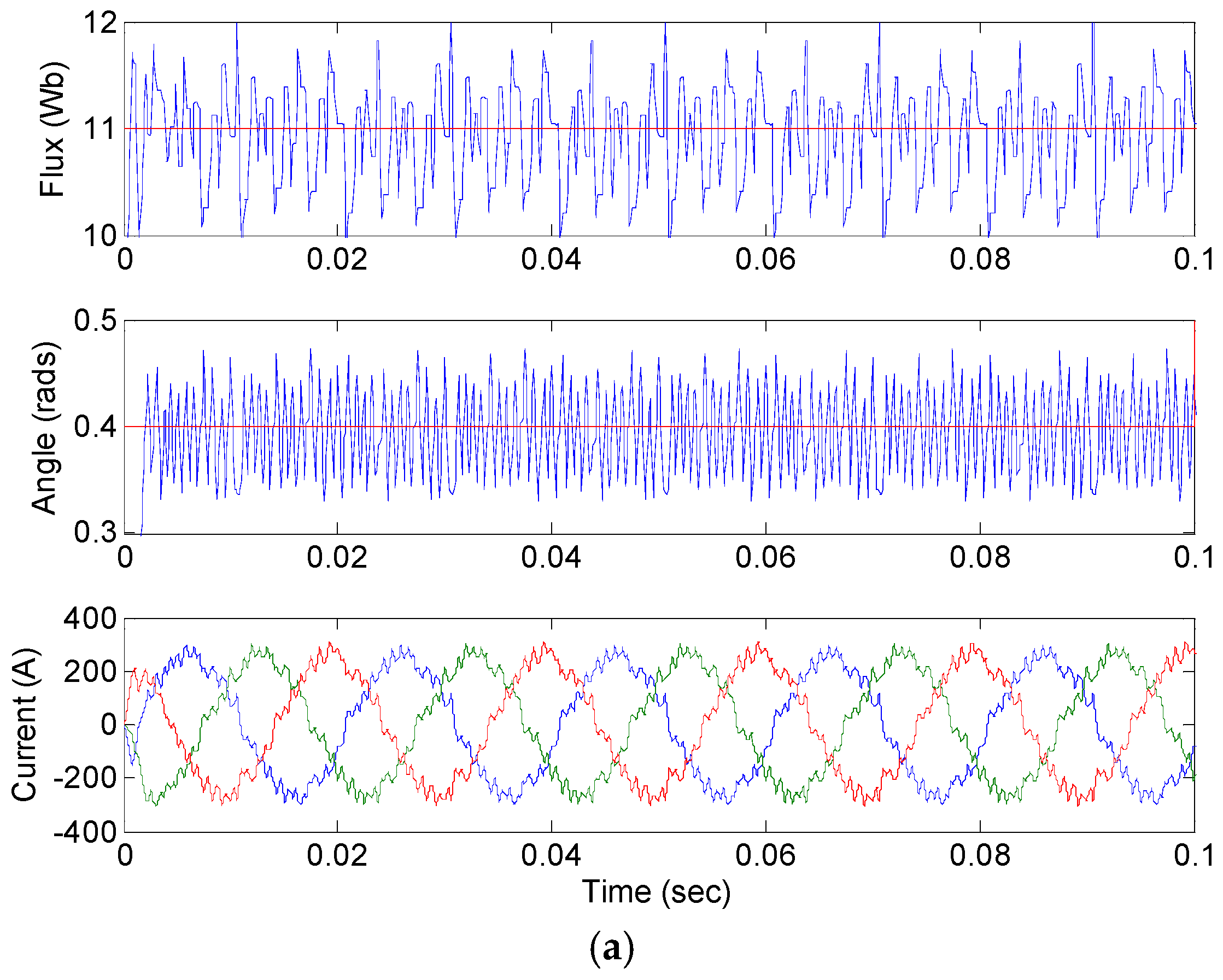

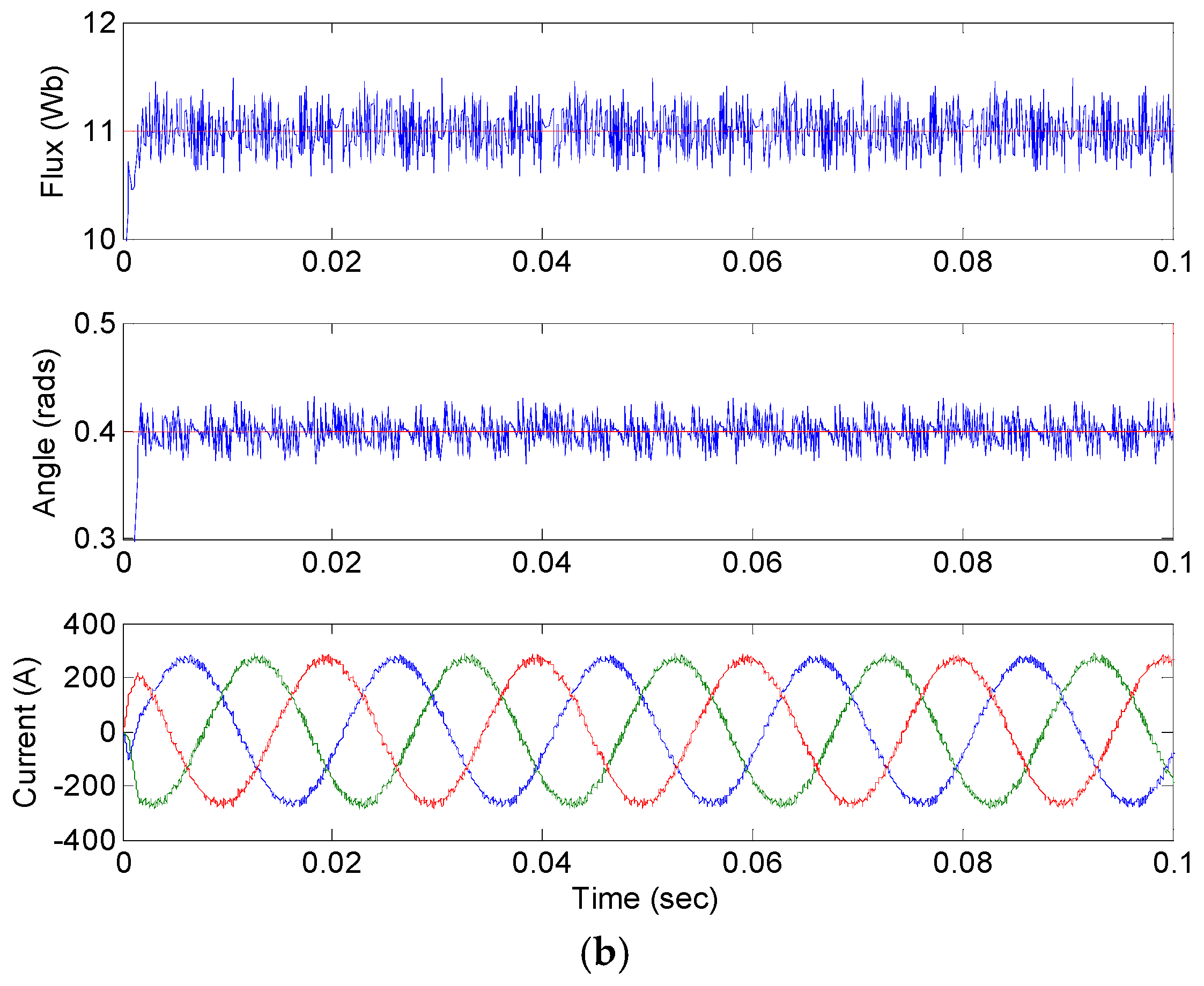

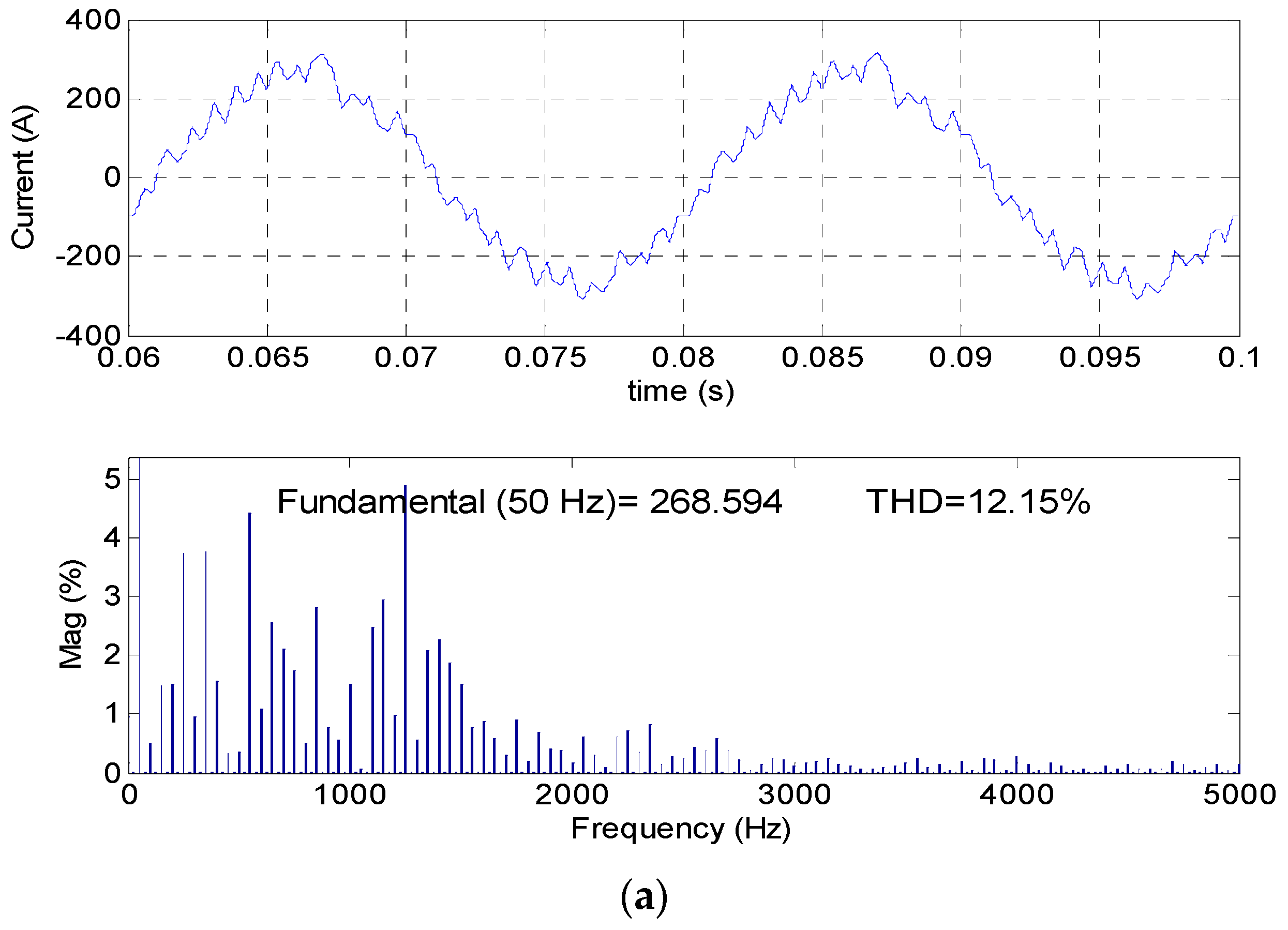

For instance, assuming that at the kth sampling instant, ΨV is within sector S1, |ΨV|* > |ΨV| and > δ, so that dF = 1 and dA = 1. Therefore, V2(110) will be selected to increase both |ΨV| and δp. After that, V2(110) will be applied during the kth and (k + 1)th sampling instants. In a similar manner to DTC and DPC, this voltage vector can be generated simply by turning on the upper switches and turning off the lower switches of the inverter legs of phases A and B, while turning off the upper switch and turning on the lower switch of phase C. In this way, ΨV is controlled around an approximate circular path within specified hysteresis bands through the inverter switching, which will be demonstrated in the test results.

4. Predictive Direct Flux Control

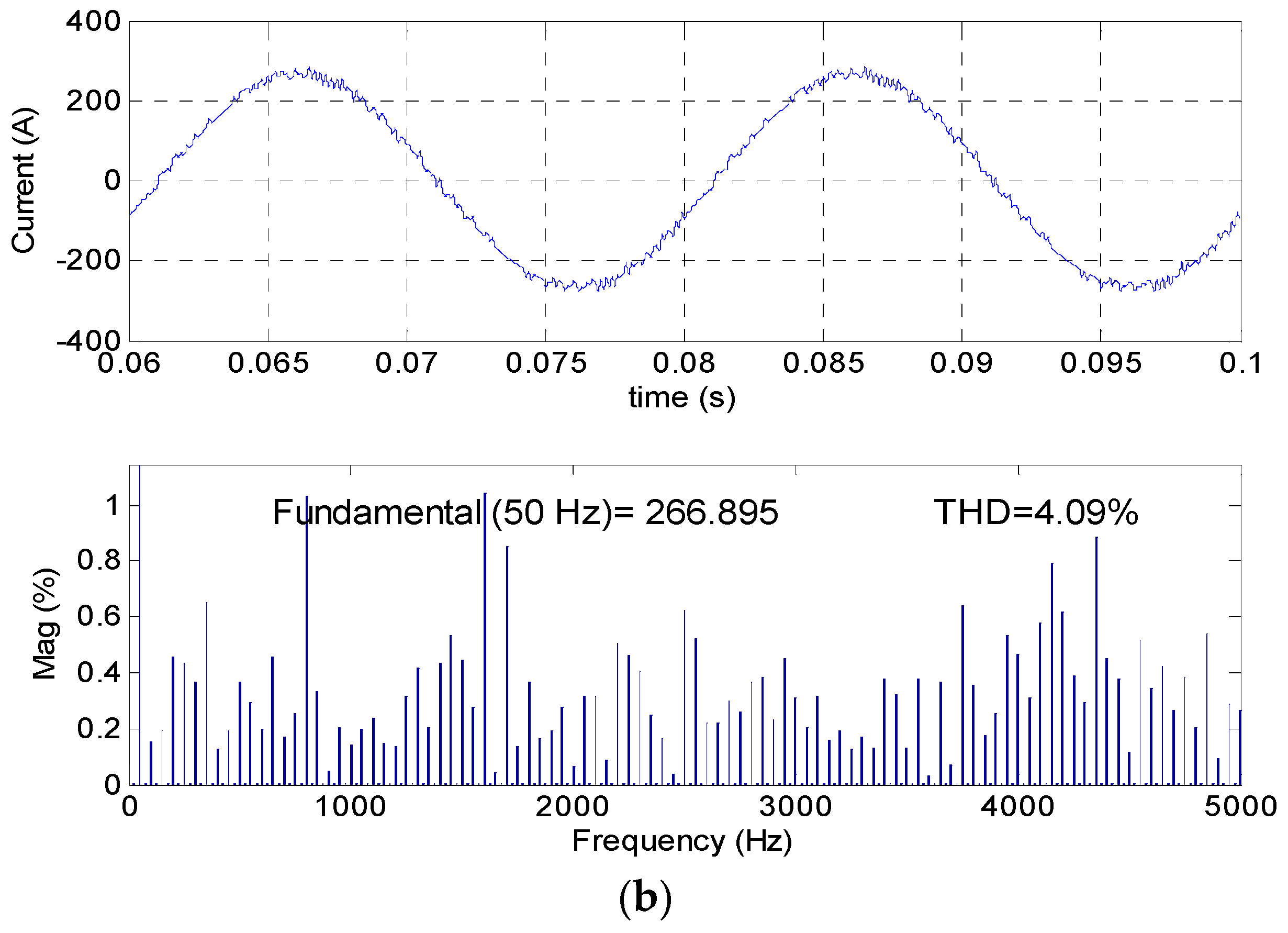

As explained before, in SDFC, the position of the inverter flux is identified according to an α-β plane divided into six sectors. There is one voltage vector and only that one selected within a whole sector. In fact, the vector selected according to the switching table is not necessarily the best one for controlling the inverter flux amplitude and power angle, especially when the inverter flux position is located near the edge of the sectors. Therefore, it is expected that the voltage vectors are always chosen according to some specified criteria regardless of the inverter flux position.

Based on the above discussion, a PDFC is proposed for VSIs in this paper. In fact, several kinds of control schemes have been developed under the name of predictive control, such as deadbeat predictive control, hysteresis-based predictive control, trajectory-based predictive control, MPC, etc. Due to its flexible control scheme that allows the easy inclusion of system constraints and nonlinearities of the system, MPC has raised much concern in the last few years [

12,

13]. In MPC, different definitions of the cost function are possible, considering different norms and including several variables and weighting factors [

14,

15,

16]. Taking the advantages of MPC, a new PDFC strategy is developed. Different from the use of hysteresis comparators and the switching table in SDFC, the selection of voltage vectors of the proposed PDFC is based on evaluating a defined cost function.

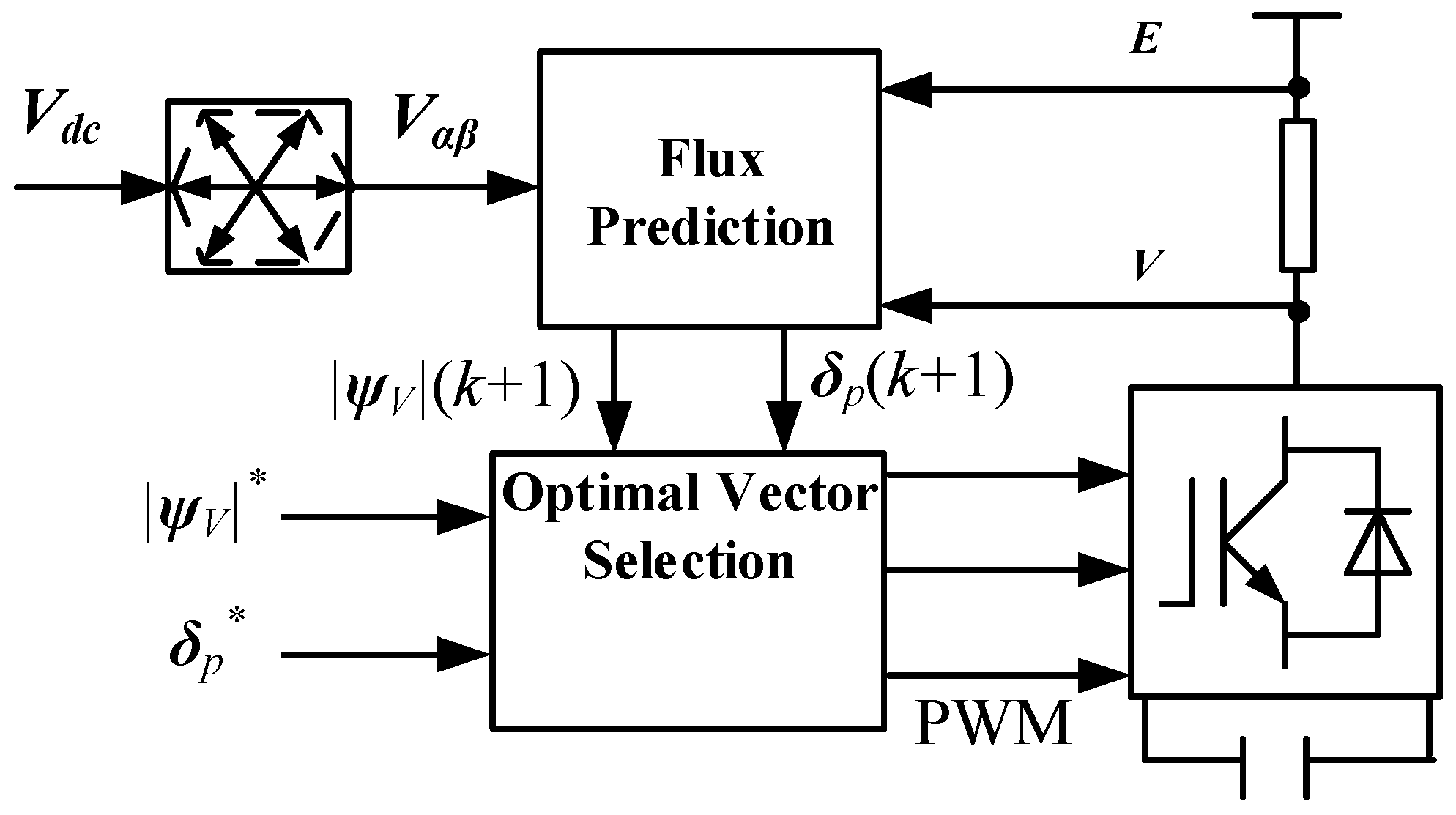

Generally, the proposed controller consists of three main steps, namely flux prediction, optimal voltage vector selection and weighting factor tuning, as illustrated in

Figure 5.

Step 1: Flux prediction

The system variables that need to be predicted are the inverter flux amplitude |

ΨV| and the power angle δ

p. According to Equation (5), we have

=

+

VTs, where

Ts is the sampling period and

V is the possible inverter voltage vectors. As explained before,

V can be controlled to eight space voltage vectors, depending on the switching states. The inverter flux vector can be predicted using α and β components as:

Subsequently, the inverter flux amplitude at the next (

k + 1)

th sampling instant can be expressed as:

For the inverter flux angle, it can be predicted by:

Since the grid is a stiff AC power system, the grid voltage vector rotates at a constant angular speed. Therefore, the grid flux angle can be simply predicted as:

where ω is the angular speed of the grid voltage in radians per second, i.e., the angular speed of the grid flux. Now that the future states of the inverter flux angle and the grid flux angle have been obtained, the power angle can thus be calculated as:

Substitute Equations (12) and (13) into Equation (8), and the vector that produces the minimum J will be selected to control |ΨV| and δp.

Step 2: Optimal inverter voltage vector selection

After the future behavior of the system is predicted, the next step is to design a cost function (or selection criteria) to evaluate all the possible switching states. Actually, different formulations of the cost function are possible, depending on which variables need to be controlled [

15]. In this paper, the cost function is chosen in such a way that both the flux and angle are as close as possible to the referenced values, which is defined as:

where

k1 and

k2 are the weighting factors, |

ΨV|* and

are the referenced inverter flux amplitude and power angle, respectively. In this paper, weighting factors are obtained with the purpose of getting a trade-off between the flux and power angle. As there are eight possible voltage vectors, there will be eight possible values of the cost function. Next, the voltage vector that can minimize the cost function will be selected to control the inverter.

Step 3: Weighting factor determination

In grid-connected inverters where active power and reactive power are the control objectives, the weighting factors of the cost function can be decided in a simple way by equalizing

k1 and

k2, because the active power and reactive power show the same control priority and they have the same order of magnitude. However, the control objectives in this paper are the flux magnitude |

ΨV| and the power angle δ

p. The first term in Equation (14) reduces the flux ripples, while the second term contributes to power angle ripple reduction. For example, a larger value for

k1 implies a higher priority for the flux regulation. Now it can be seen that the unit of |

ΨV| is Webers while the unit of the δ

p is radians, and they show different orders of magnitude. Therefore, it is necessary to design a suitable weighting factor determination approach in this case. Here, a two-step tuning method is developed. In coarse tuning, the preliminary ratio of

k1/

k2 can be obtained according to the nominal values of the power angle and the flux. For instance, if the nominal power angle is 0.7 radians and the nominal flux amplitude is 12 Wb for a grid-connected inverter, then

k1:

k2 can be set as 0.7:12. In this way, both the flux and the power angle can be controlled in a balance. After that,

k1 and

k2 will be adjusted slightly in fine tuning until a satisfactory performance is obtained. Actually there is some specified research focused on weighting factor optimization [

17,

18]. However, the topic of weighting factor optimization is out of the scope of this paper.