Design and Evaluation of an Efficient Three-Phase Four-Leg Voltage Source Inverter with Reduced IGBTs

Abstract

:1. Introduction

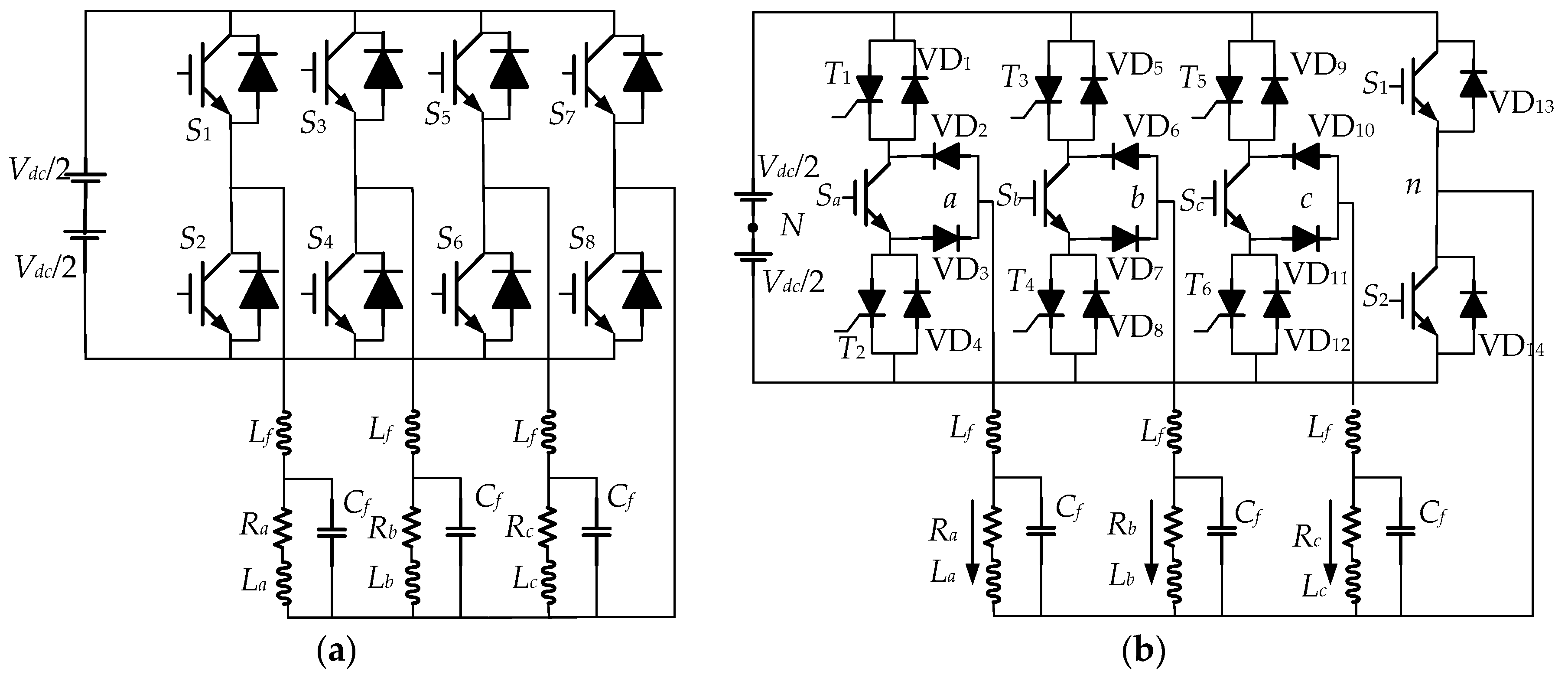

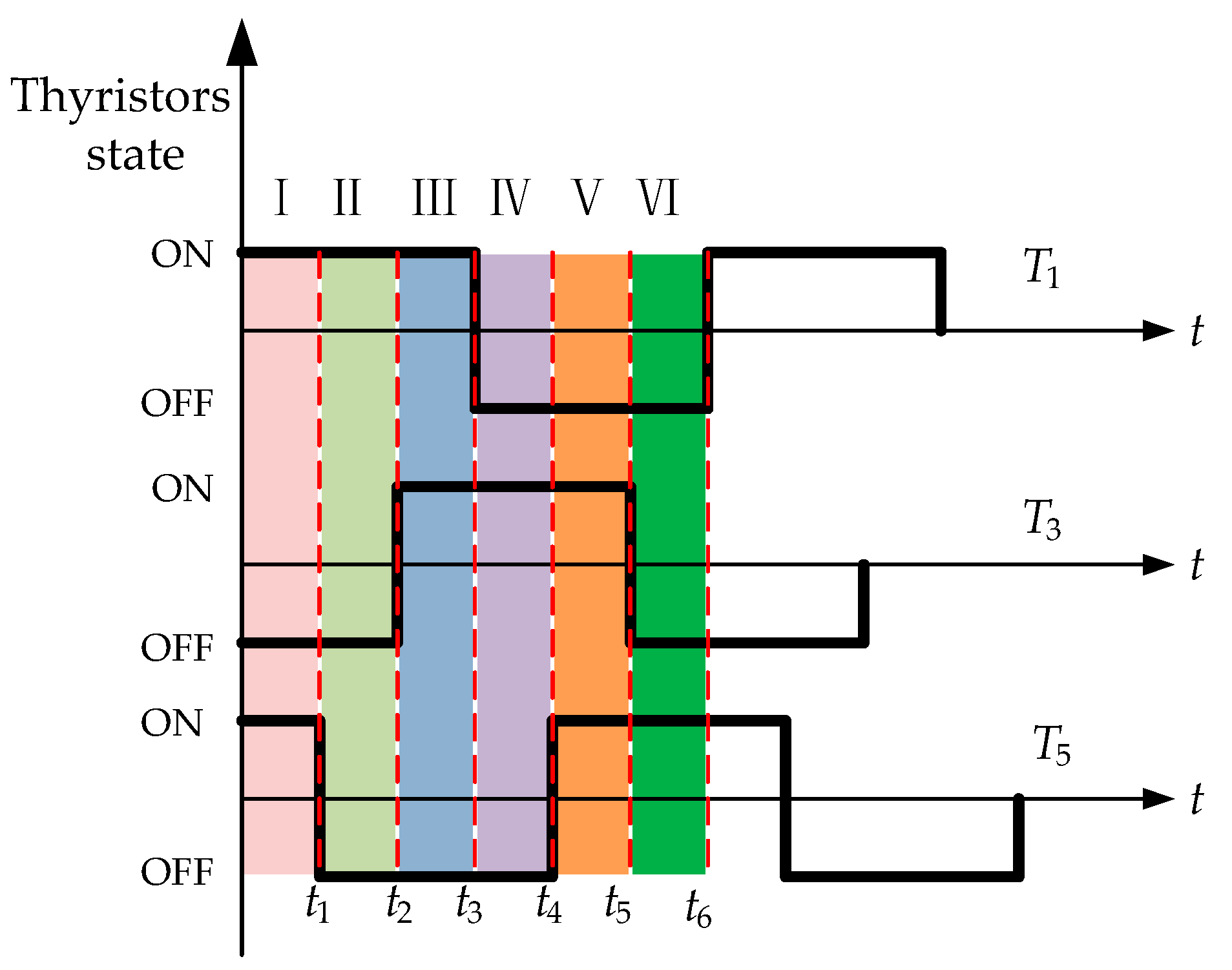

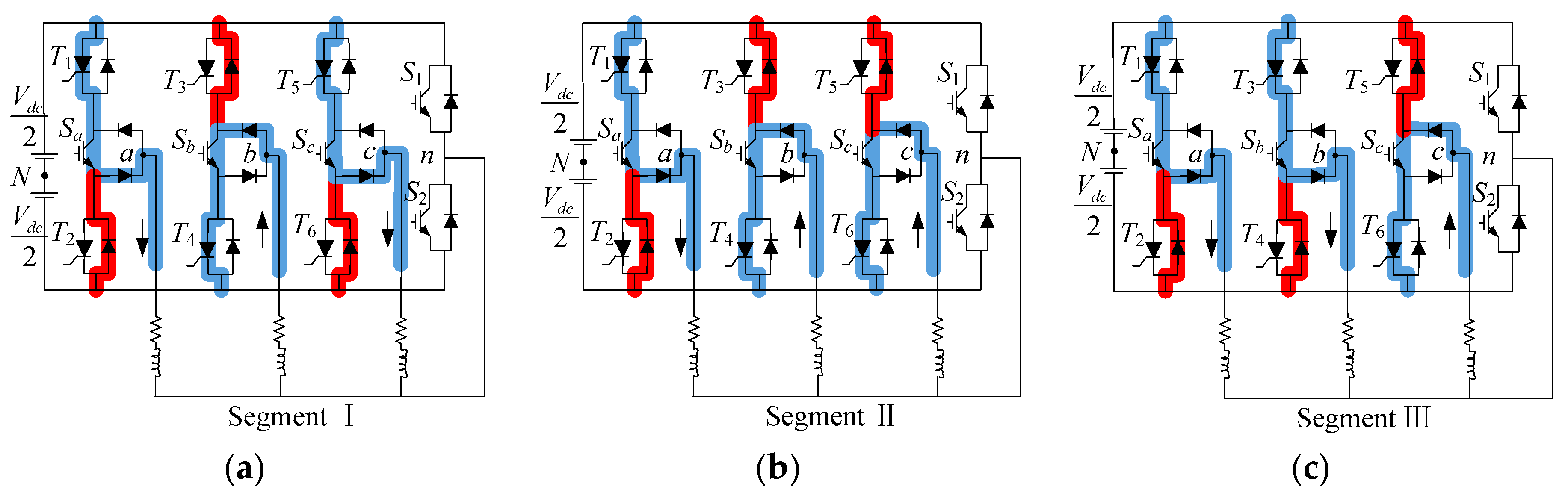

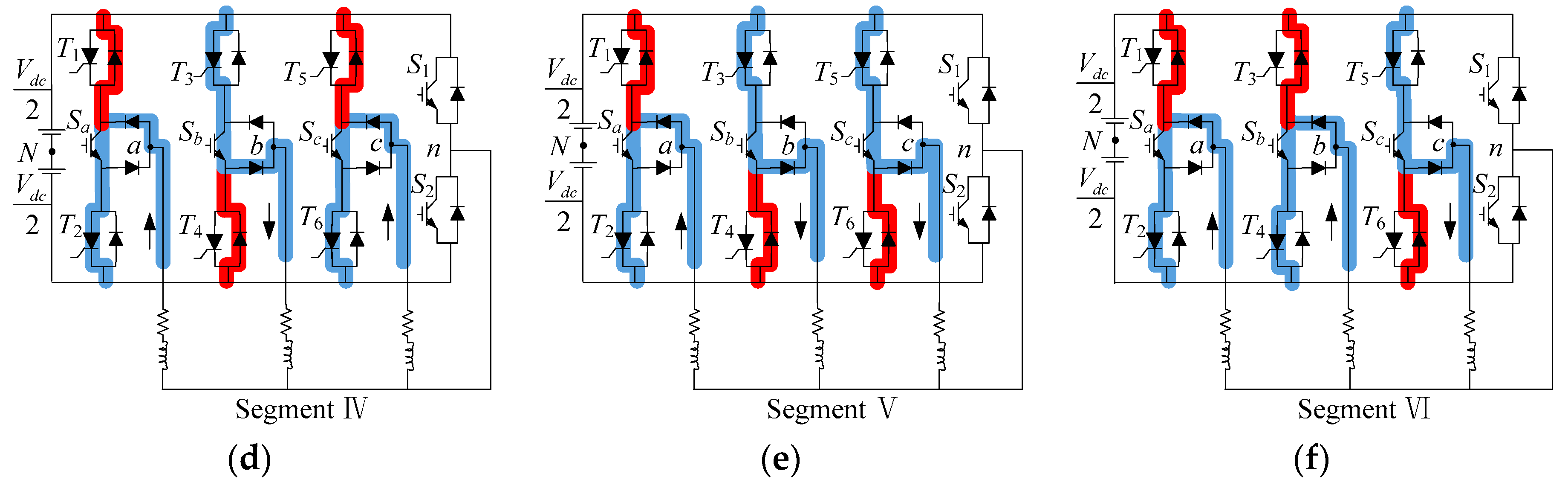

2. Topology and Operation Principle of the Proposed Inverter

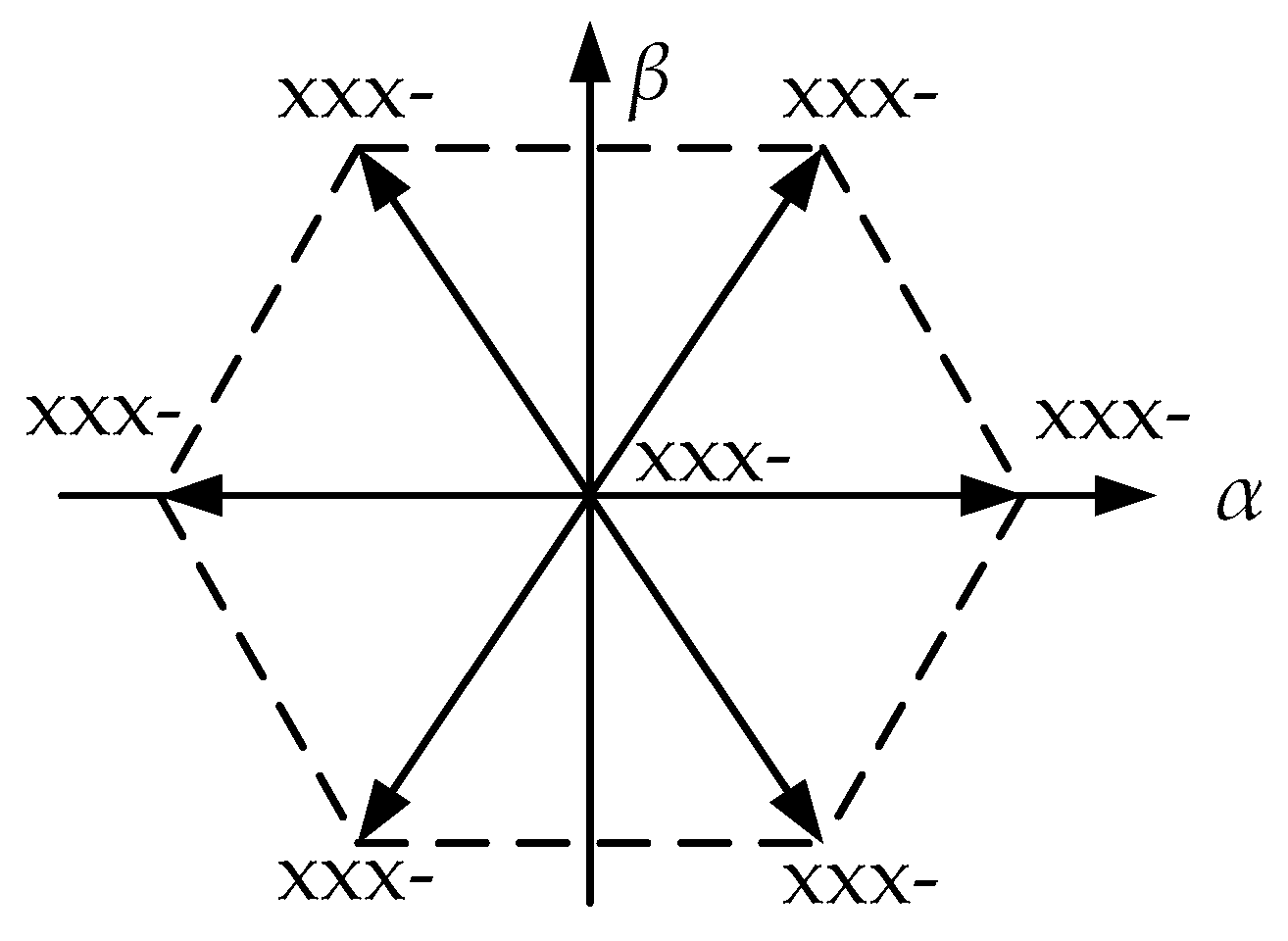

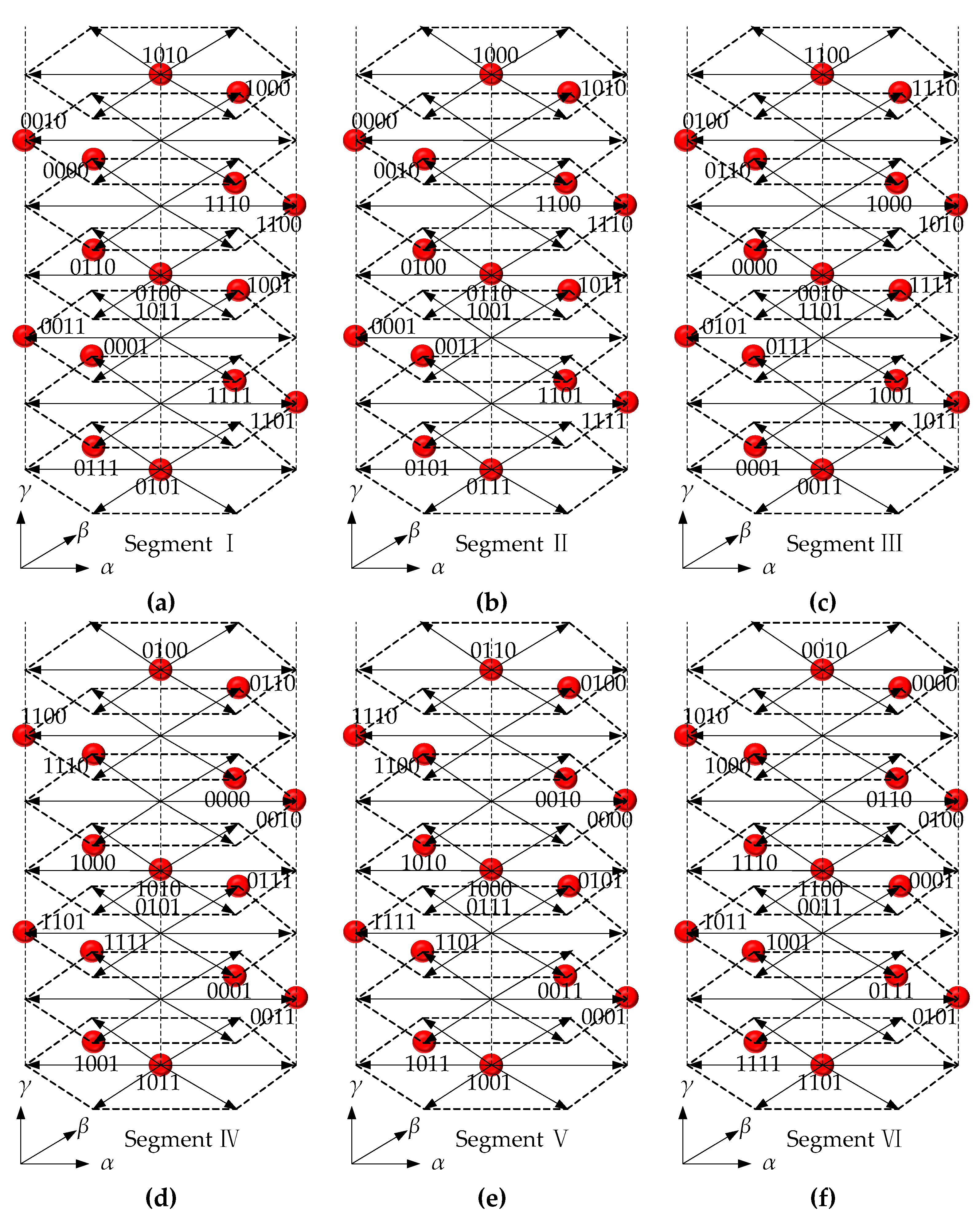

3. Mathematical Modelling

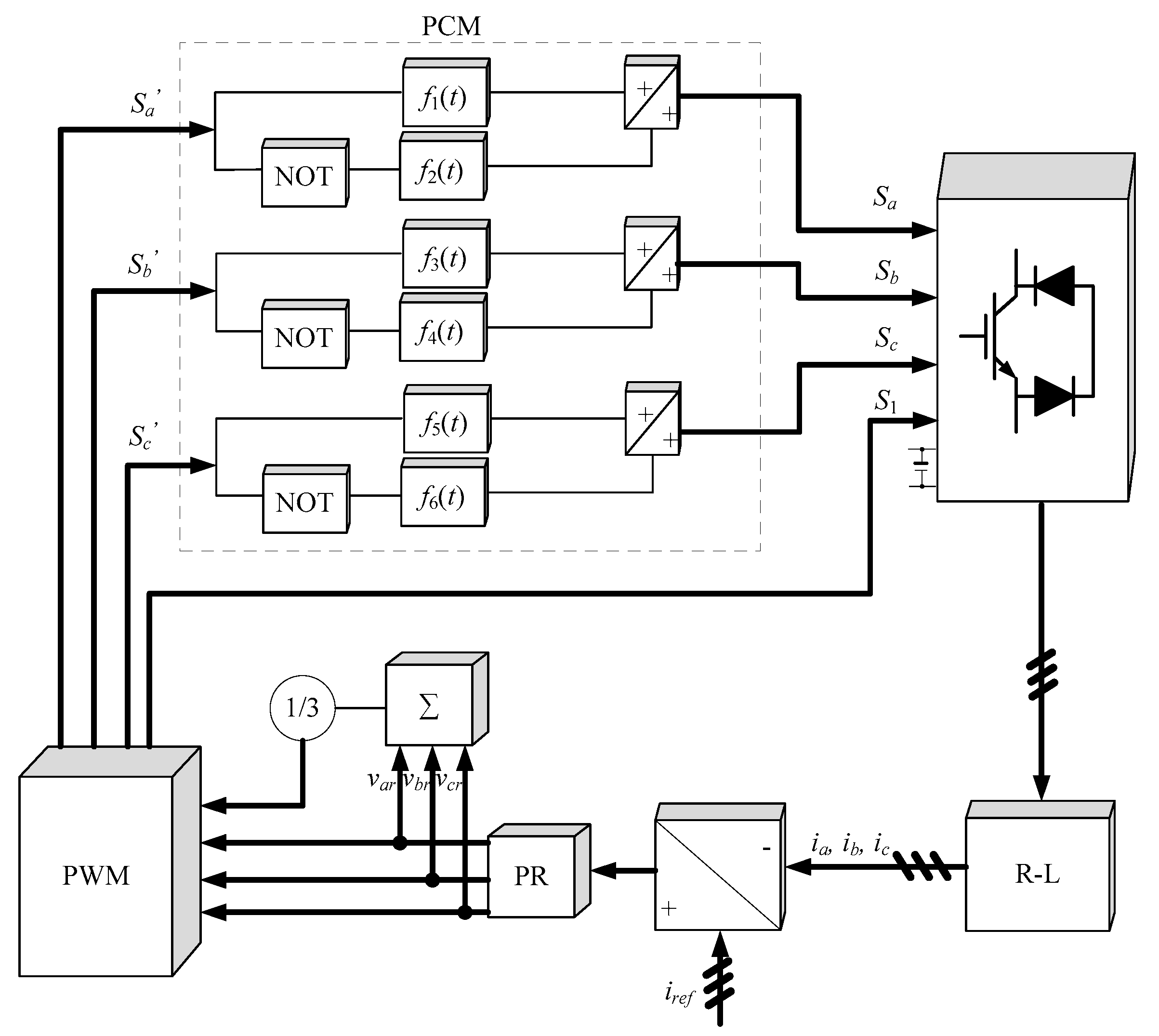

4. Current Control Algorithm for Proposed Inverter

5. Verification Results of Proposed Topology

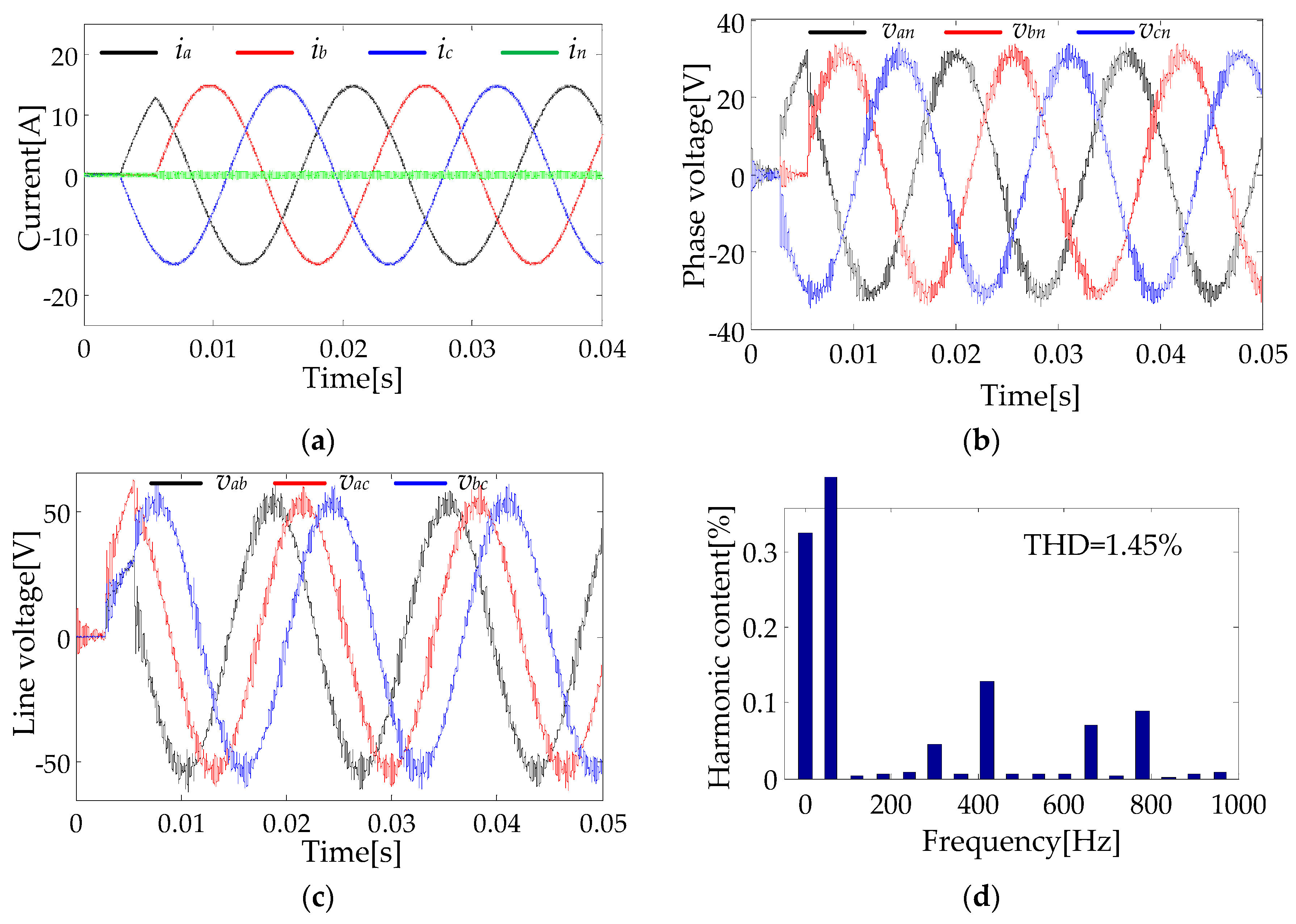

5.1. Simulation Results

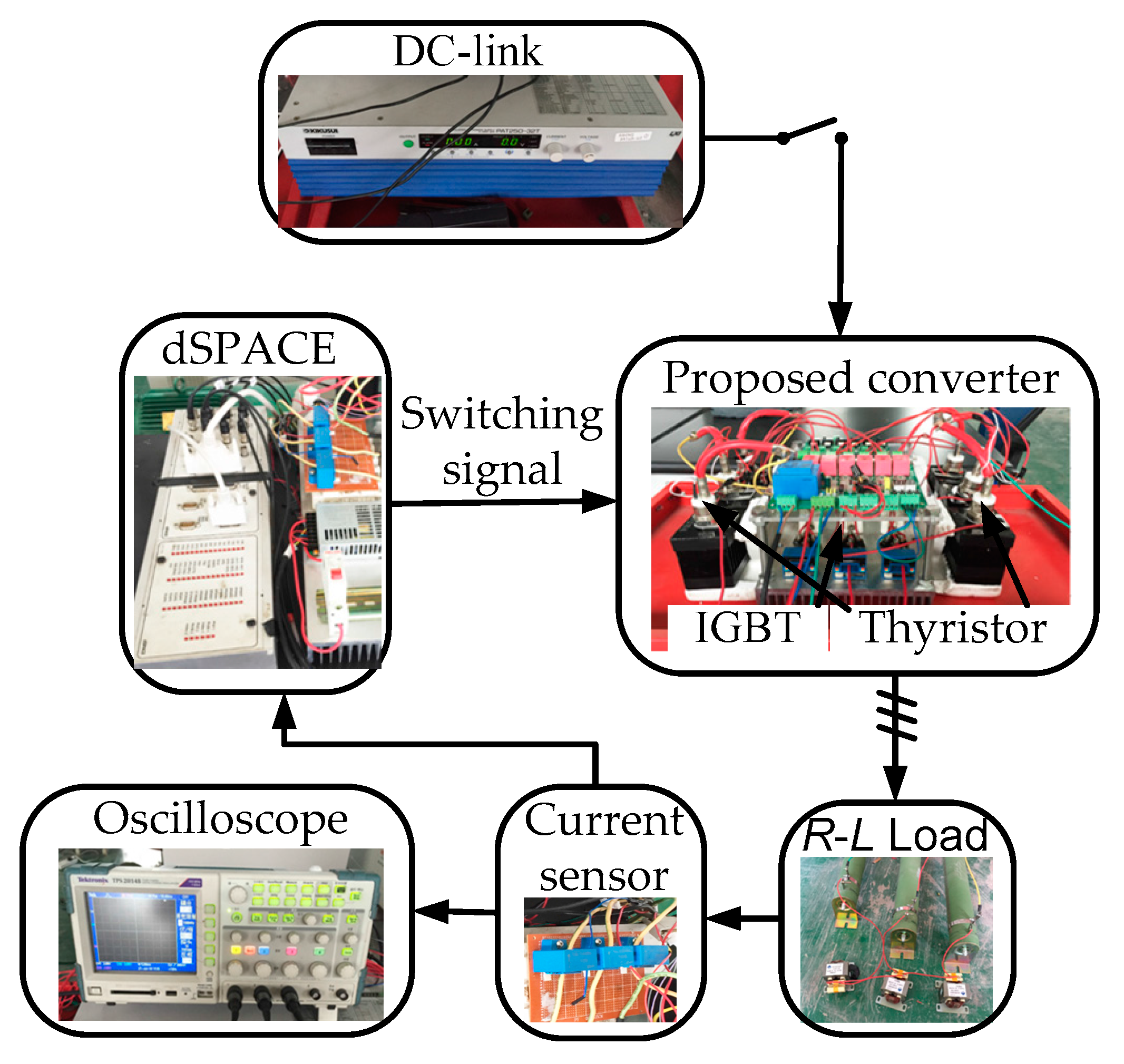

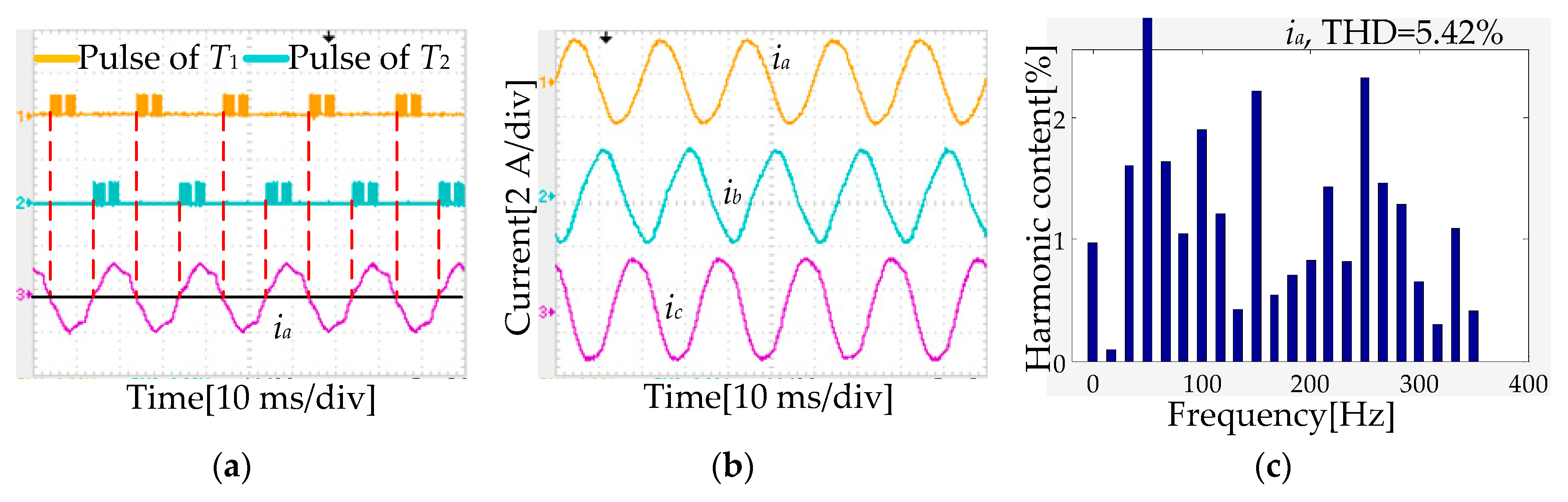

5.2. Experimental Results

6. Comparison

7. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Kim, E.-K.; Mwasilu, F.; Choi, H.H.; Jung, J.-W. An observer-based optimal voltage control scheme for three-phase UPS systems. IEEE Trans. Ind. Electron. 2015, 62, 2073–2081. [Google Scholar] [CrossRef]

- Hossain, R.; Lipo, T.; Kwon, B. A novel topology for a voltage source inverter with reduced transistor count and utilizing naturally commutated thyristors with simple commutation. In Proceedings of the 2014 International Symposium on Power Electronics Electrical Drives Automation and Motion (SPEEDAM), Ischia, Italy, 18–20 June 2014. [Google Scholar]

- Liu, C.; Chau, K.T.; Zhang, X. An efficient Wind–Photovoltaic hybrid generation system using doubly excited permanent-magnet brushless machine. IEEE Trans. Ind. Electron. 2010, 57, 831–839. [Google Scholar]

- Liu, C.; Chau, K.T.; Li, W. Loss analysis of permanent magnet hybrid brushless machines with and without HTS field windings. IEEE Trans. Appl. Supercond. 2010, 20, 1077–1080. [Google Scholar]

- Liu, C.; Chau, K.T.; Lee, C.H.T.; Lin, F.; Li, F.; Ching, T.W. Magnetic vibration analysis of a new DC-excited multitoothed switched reluctance machine. IEEE Trans. Magn. 2014, 50, 1–4. [Google Scholar] [CrossRef]

- Chen, W.; Liu, C.; Lee, C.H.T.; Shan, Z. Cost-effectiveness comparison of coupler designs of wireless power transfer for electric vehicle dynamic charging. Energies 2016, 9, 906. [Google Scholar] [CrossRef]

- Bao, L.N.; Kim, K. An Improved Current Control Strategy for a Grid-Connected Inverter under Distorted Grid Conditions. Energies 2016, 9, 190. [Google Scholar] [CrossRef]

- Wang, F.; Zhang, Z.; Ericsen, T.; Raju, R. Advances in Power Conversion and Drives for Shipboard Systems. IEEE Proc. 2015, 103, 2285–2311. [Google Scholar] [CrossRef]

- Pei, X.; Zhou, W.; Kang, Y. Analysis and calculation of DC-link current and voltage ripples for three-phase inverter with unbalanced load. IEEE Trans. Power Electron. 2015, 30, 5401–5412. [Google Scholar] [CrossRef]

- Jeong, C.Y.; Cho, J.G.; Kang, Y.; Rim, G.H.; Song, E.H. A 100 kVA power conditioner for three-phase four-wire emergency generators. In Proceedings of the IEEE PESC’98, Fukuoka, Japan, 22 May 1998; pp. 1906–1911. [Google Scholar]

- Zhang, R.; Boroyevich, D.; Prasad, V.H. A three-phase inverter with a neutral leg with space vector modulation. IEEE Proc. 1997, 2, 857–863. [Google Scholar]

- Ryan, M.J.; Lorenz, R.D.; de Doncker, R.W. Decoupled control of a four-leg inverter via a new 4×4 transformation matrix. IEEE Trans. Power Electron. 2001, 16, 694–701. [Google Scholar] [CrossRef]

- Zhang, R.; Prasad, V.H.; Boroyevich, D.; Lee, F.C. Three-dimensional space vector modulation for four-leg voltage source converters. IEEE Trans. Power Electron. 2002, 17, 314–325. [Google Scholar] [CrossRef]

- Perales, M.A.; Prats, M.M.; Portillo, R.; Mora, J.L.; Len, J.L.; Franquelo, L.G. Three-dimensional space vector modulation in abc coordinates for four-leg voltage source converters. IEEE Power Electron. Lett. 2003, 1, 104–109. [Google Scholar] [CrossRef]

- Depenbrock, M.; Staudt, V.; Wrede, H. A theoretical investigation of original and modified instantaneous power theory applied to four-wire systems. IEEE Trans. Ind. Appl. 2003, 39, 1160–1168. [Google Scholar] [CrossRef]

- Li, Y.W.; Vilathgamuwa, D.M.; Loh, P.C. Microgrid power quality enhancement using a three-phase four-wire grid-interfacing compensator. IEEE Trans. Ind. Appl. 2005, 41, 1707–1719. [Google Scholar] [CrossRef]

- Dong, G.; Ojo, O. Current regulation in four-leg voltage-source converters. IEEE Trans. Ind. Electron. 2007, 54, 2095–2105. [Google Scholar] [CrossRef]

- Escobar, G.; Valdez, A.A.; Torres-Olguin, R.E.; Martinez-Montejano, M.F. A model-based controller for a three-phase four-wire shunt active filter with compensation of the neutral line current. IEEE Trans. Power Electron. 2007, 22, 2261–2270. [Google Scholar] [CrossRef]

- Teodorescu, R.; Liserre, M.; Rodriguez, P.; Blaabjerg, F. Grid Converters for Photovoltaic and Wind Power Systems; Wiley: Chichester, UK, 2011. [Google Scholar]

- Dos Santos, E.; Jacobina, C.; Rocha, N.; Dias, J.; Correa, M. Single-phase to three-phase four-leg converter applied to distributed generation system. IET Power Electron. 2010, 3, 892–903. [Google Scholar] [CrossRef]

- Wu, B.; Lang, Y.; Zargari, N.; Kouro, S. Power Conversion and Control of Wind Energy Systems, 2nd ed.; IEEE Press Series on Power Engineering; Wiley: Hoboken, NJ, USA, 2011. [Google Scholar]

- Kim, J.-H.; Sul, S.-K. A carrier-based PWM method for three-phase four-leg voltage source converters. IEEE Trans. Power Electron. 2004, 19, 66–75. [Google Scholar] [CrossRef]

- Dai, N.-Y.; Wong, M.-C.; Ng, F.; Han, Y.-D. A FPGA-based generalized pulse width modulator for three-leg center-split and four-leg voltage source inverters. IEEE Trans. Power Electron. 2008, 23, 1472–1484. [Google Scholar] [CrossRef]

- Zhang, M.; Atkinson, D.J.; Ji, B.; Armstrong, M.; Ma, M. A near-state three-dimensional space vector modulation for a three-phase four-leg voltage source inverter. IEEE Trans. Power Electron. 2014, 29, 5715–5726. [Google Scholar] [CrossRef]

- Li, X.; Deng, Z.; Chen, Z.; Fei, Q. Analysis and simplification of three-dimensional space vector PWM for three-phase four-leg inverters. IEEE Trans. Ind. Electron. 2011, 58, 450–464. [Google Scholar] [CrossRef]

- Rivera, M.; Yaramasu, V.; Llor, A.; Rodriguez, J.; Wu, B.; Fadel, M. Digital predictive current control of a three-phase four-leg inverter. IEEE Trans. Ind. Electron. 2013, 60, 4903–4912. [Google Scholar] [CrossRef]

- Bayhan, S.; Abu-Rub, H.; Balog, R. Model predictive control of quasi-z source four-leg inverter. IEEE Trans. Ind. Electron. 2016, 63, 4506–4516. [Google Scholar] [CrossRef]

- Lohia, P.; Mishra, M.K.; Karthikeyan, K.; Vasudevan, K. A minimally switched control algorithm for three-phase four-leg VSI topology to compensate unbalanced and nonlinear load. IEEE Trans. Power Electron. 2008, 23, 1935–1944. [Google Scholar] [CrossRef]

- Zhang, F.; Yan, Y. Selective harmonic elimination PWM control scheme on a three-phase four-leg voltage source inverter. IEEE Trans. Power Electron. 2009, 24, 1682–1689. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, J.; Li, J. Modeling, analysis and mitigation of load neutral point voltage for three-phase four-leg inverter. IEEE Trans. Ind. Electron. 2013, 60, 2010–2021. [Google Scholar] [CrossRef]

- Li, B.; Jia, J.; Xue, S. Study on the Current-Limiting-Capable Control Strategy for Grid-Connected Three-Phase Four-Leg Inverter in Low-Voltage Network. Energies 2016, 9, 726. [Google Scholar] [CrossRef]

- Zmood, D.N.; Holmes, D.G. Stationary Frame Current Regulation of PWM Inverters with Zero Steady-State Error. IEEE Trans. Power Electron. 2003, 18, 814–822. [Google Scholar] [CrossRef]

| Switching States | Phase a | |||||||

|---|---|---|---|---|---|---|---|---|

| S1 | 1 | 0 | ||||||

| UT | 1 | 0 | 1 | 0 | ||||

| Sa | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 |

| van | 0 | −Vdc | −Vdc | 0 | Vdc | 0 | 0 | Vdc |

| Vectors | States | van, vbn, vcn | |||||

|---|---|---|---|---|---|---|---|

| I | II | III | IV | V | VI | ||

| V0 | 0000 | 0, 1, 0 | 0, 1, 1 | 0, 0, 1 | 1, 0, 1 | 1, 0, 0 | 1, 1, 0 |

| V1 | 0001 | −1, 0, −1 | −1, 0, 0 | −1, −1, 0 | 0, −1, 0 | 0, −1, −1 | 0, 0, −1 |

| V2 | 0010 | 0, 1, 1 | 0, 1, 0 | 0, 0, 0 | 1, 0, 0 | 1, 0, 1 | 1, 1, 1 |

| V3 | 0011 | −1, 0, 0 | −1, 0, −1 | −1, −1, −1 | 0, −1, −1 | 0, −1, 0 | 0, 0, 0 |

| V4 | 0100 | 0, 0, 0 | 0, 0, 1 | 0, 1, 1 | 1, 1, 1 | 1, 1, 0 | 1, 0, 0 |

| V5 | 0101 | −1, −1, −1 | −1, −1, 0 | −1, 0, 0 | 0, 0, 0 | 0, 0, −1 | 0, −1, −1 |

| V6 | 0110 | 0, 0, 1 | 0, 0, 0 | 0, 1, 0 | 1, 1, 0 | 1, 1, 1 | 1, 0, 1 |

| V7 | 0111 | −1, −1, 0 | −1, −1, −1 | −1, 0, −1 | 0, 0, −1 | 0, 0, 0 | 0, −1, 0 |

| V8 | 1000 | 1, 1, 0 | 1, 1, 1 | 1, 0, 1 | 0, 0, 1 | 0, 0, 0 | 0, 1, 0 |

| V9 | 1001 | 0, 0, −1 | 0, 0, 0 | 0, −1, 0 | −1, −1, 0 | −1, −1, −1 | −1, 0, −1 |

| V10 | 1010 | 1, 1, 1 | 1, 1, 0 | 1, 0, 0 | 0, 0, 0 | 0, 0, 1 | 0, 1, 1 |

| V11 | 1011 | 0, 0, 0 | 0, 0, −1 | 0, −1, −1 | −1, −1, −1 | −1, −1, 0 | −1, 0, 0 |

| V12 | 1100 | 1, 0, 0 | 1, 0, 1 | 1, 1, 1 | 0, 1, 1 | 0, 1, 0 | 0, 0, 0 |

| V13 | 1101 | 0, −1, −1 | 0, −1, 0 | 0, 0, 0 | −1, 0, 0 | −1, 0, −1 | −1, −1, −1 |

| V14 | 1110 | 1, 0, 1 | 1, 0, 0 | 1, 1, 0 | 0, 1, 0 | 0, 1, 1 | 0, 0, 1 |

| V15 | 1111 | 0, −1, 0 | 0, −1, −1 | 0, 0, −1 | −1, 0, −1 | −1, 0, 0 | −1, −1, 0 |

| Parameters | Values |

|---|---|

| DC link voltage | 100 V |

| AC filter inductor for each phase | 5 mH |

| Ac filter capacitor for each phase | 1.5 µF |

| Switching frequency | 5 kHz |

| Load inductor | 1.5 mH |

| Load resistor | 3-phase variable resistors |

| Item | IGBT Module (Single Switch) | IGBT Module (Dual Switch) | Thyristor | Diode |

|---|---|---|---|---|

| Model | FZ1800R16KF4 | FF1800R17IP5 | Y60KPE | ZP2000A |

| Cost (USD) | 550 | 965 | 50 | 30 |

| Size (H × W × D, cm) | 3.81 × 19.0 × 14.0 | 3.8 × 23.4 × 8.9 | 6.0 × 15 × 5.0 | 3.2 × 9.9 × 9.9 |

| Weight (kg) | 2.31 | 1.4 | 0.85 | 0.52 |

| Ir (Amps) | 1800 | 1800 | 1800 | 2000 |

| Vr (Volts) | 1600 | 1700 | 1800 | 5000 |

| Item | Proposed Inverter | Conventional Inverter |

|---|---|---|

| Overall size (cm3) | 8268.4 | 3165.56 |

| Overall weight (kg) | 15.05 | 5.6 |

| Cost (USD) | 2766 | 3860 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, Y.; Liu, C.; Yu, F.; Lee, C.H.T. Design and Evaluation of an Efficient Three-Phase Four-Leg Voltage Source Inverter with Reduced IGBTs. Energies 2017, 10, 530. https://doi.org/10.3390/en10040530

Luo Y, Liu C, Yu F, Lee CHT. Design and Evaluation of an Efficient Three-Phase Four-Leg Voltage Source Inverter with Reduced IGBTs. Energies. 2017; 10(4):530. https://doi.org/10.3390/en10040530

Chicago/Turabian StyleLuo, Yixiao, Chunhua Liu, Feng Yu, and Christopher H.T. Lee. 2017. "Design and Evaluation of an Efficient Three-Phase Four-Leg Voltage Source Inverter with Reduced IGBTs" Energies 10, no. 4: 530. https://doi.org/10.3390/en10040530