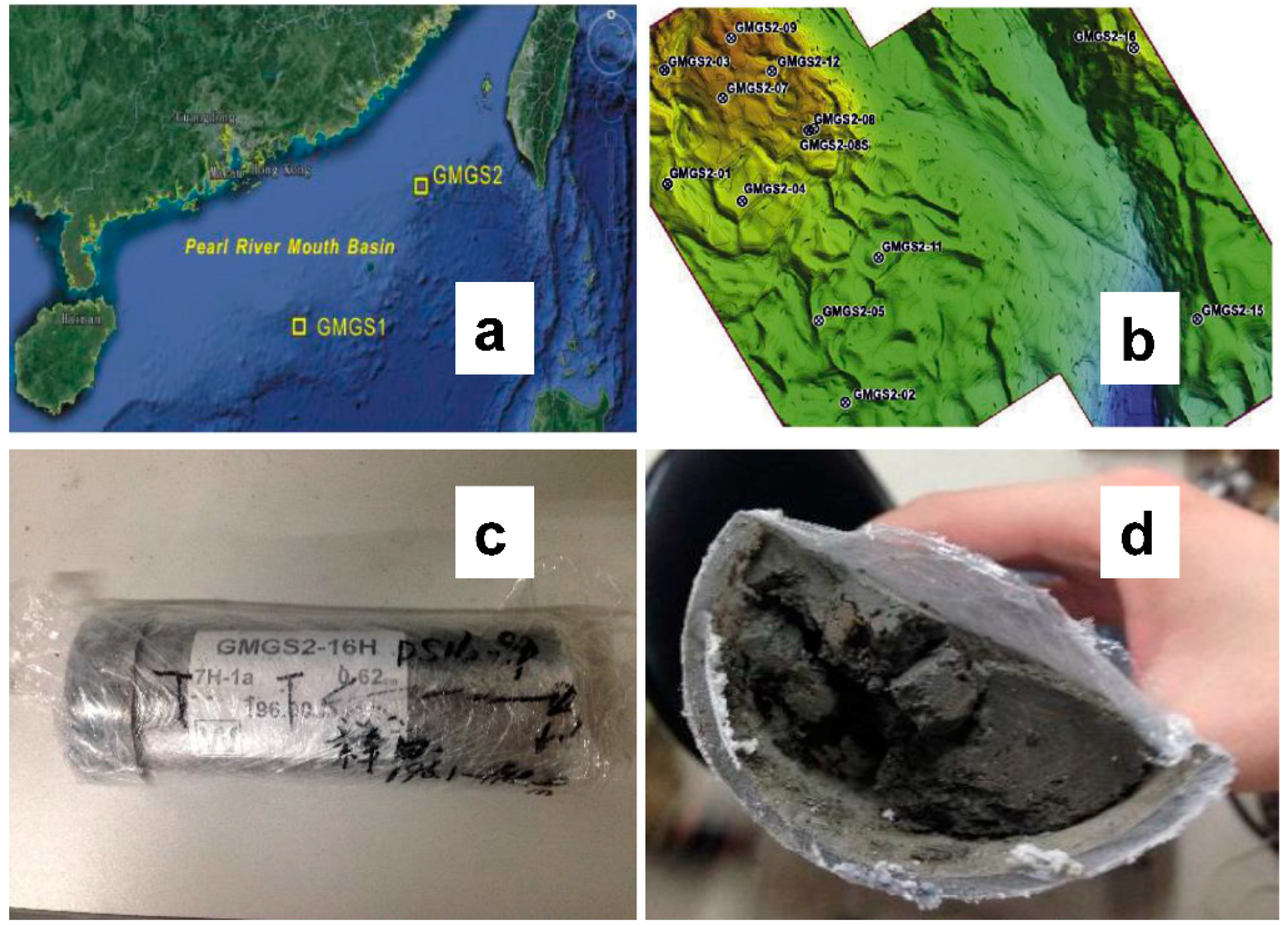

Analysis of the Physical Properties of Hydrate Sediments Recovered from the Pearl River Mouth Basin in the South China Sea: Preliminary Investigation for Gas Hydrate Exploitation

Abstract

:1. Introduction

2. Methods and Results

2.1. Index Properties

2.1.1. Specific Gravity

2.1.2. Water Content

2.1.3. Atterberg Limits

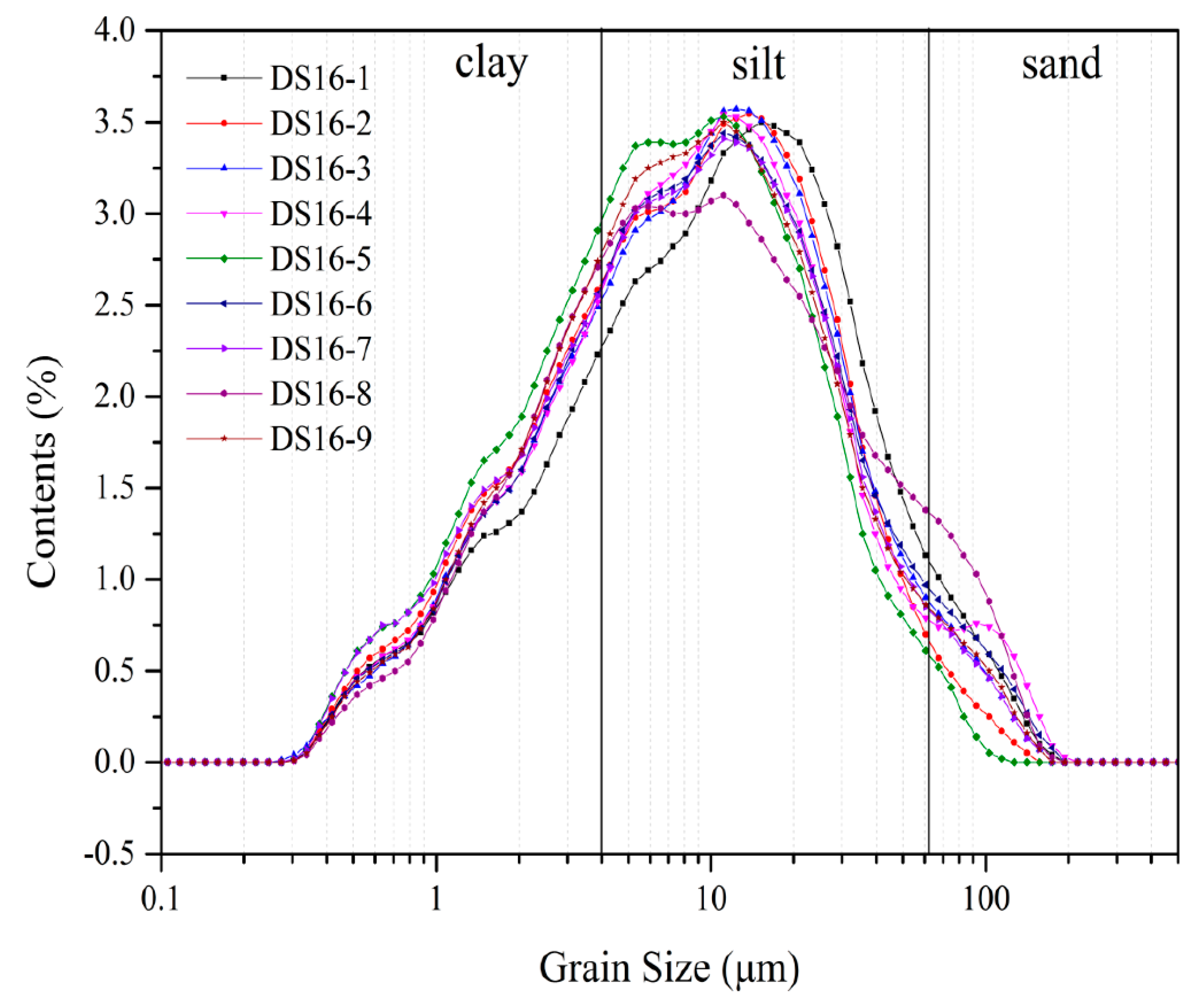

2.1.4. Grain Size Distribution

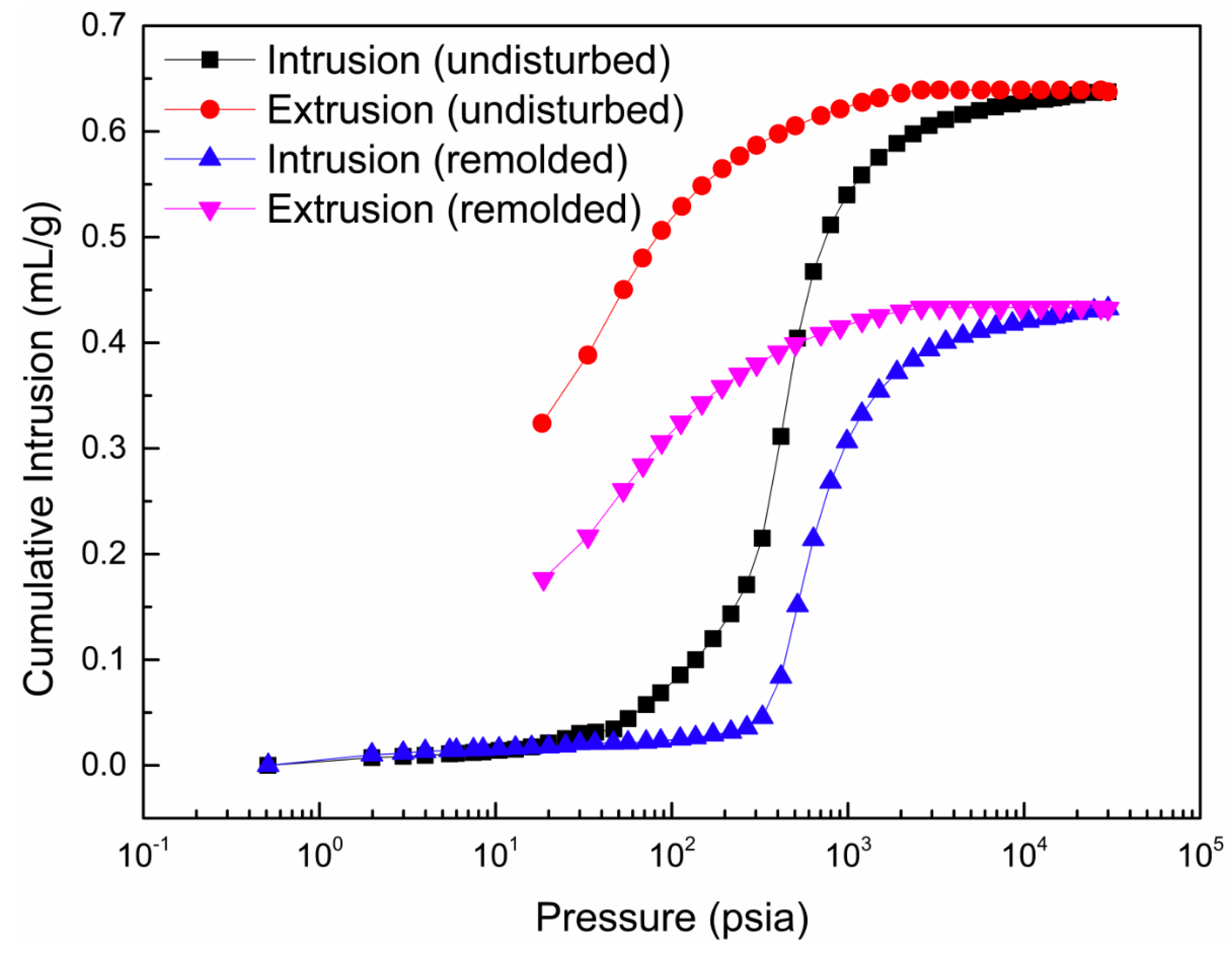

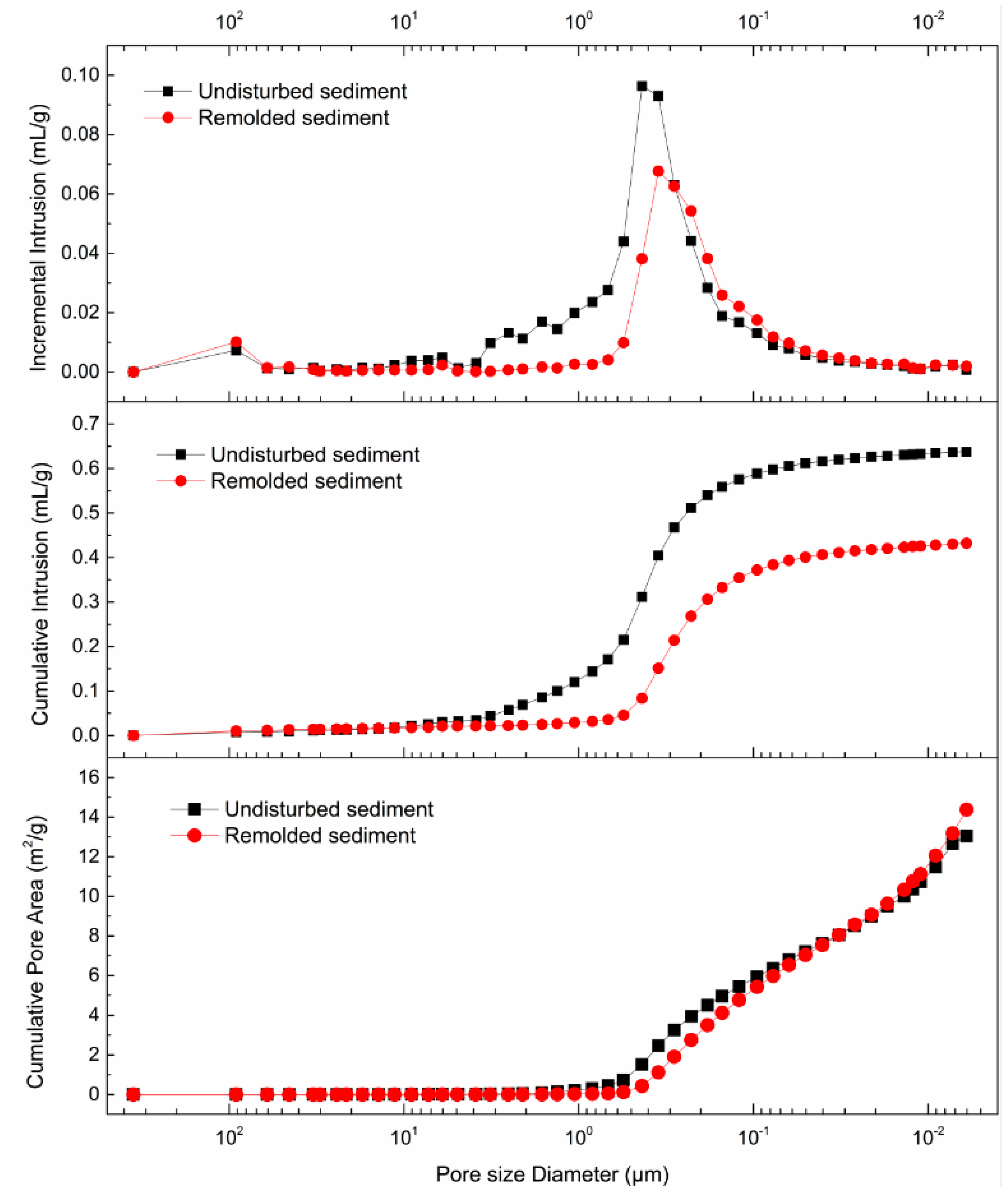

2.1.5. Pore Characteristics

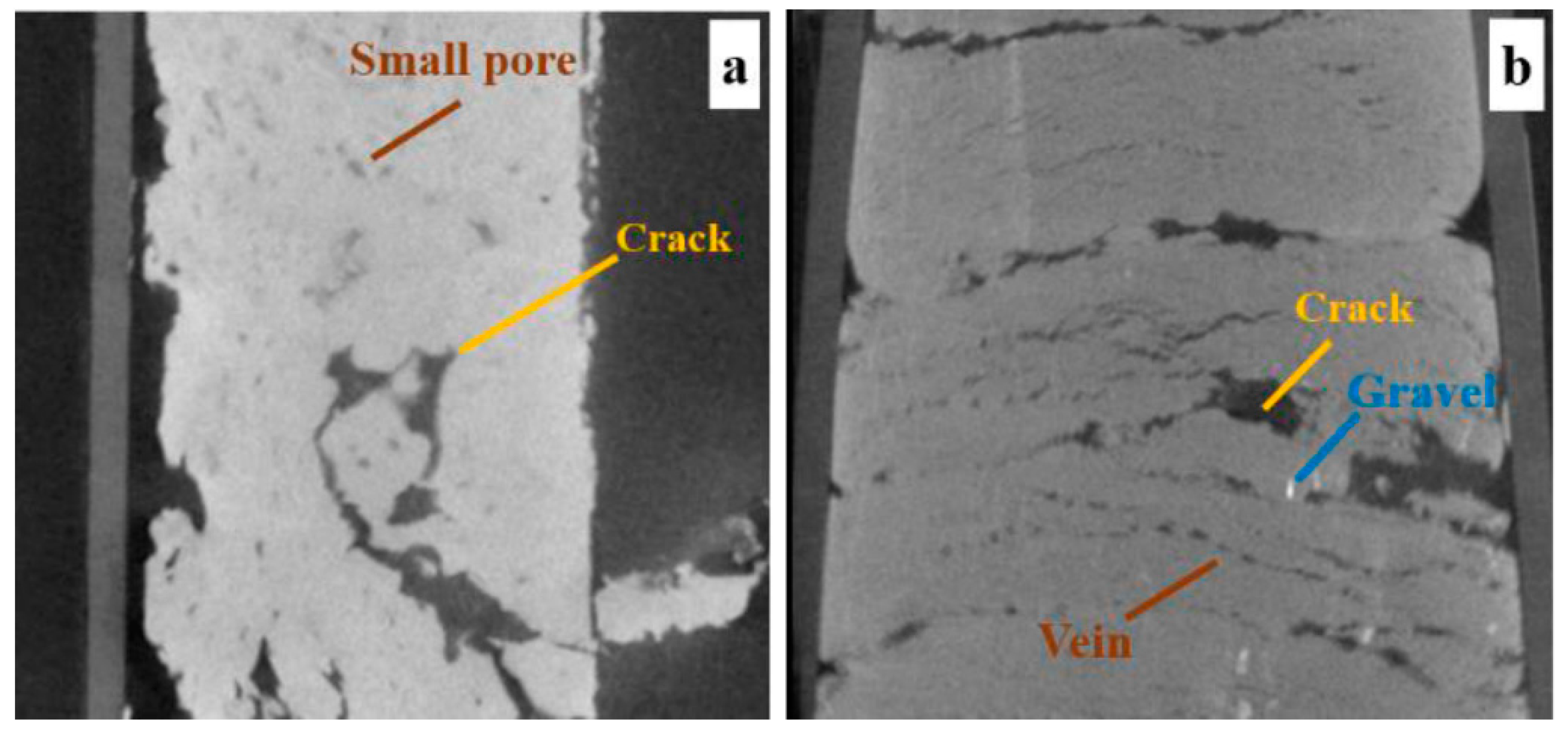

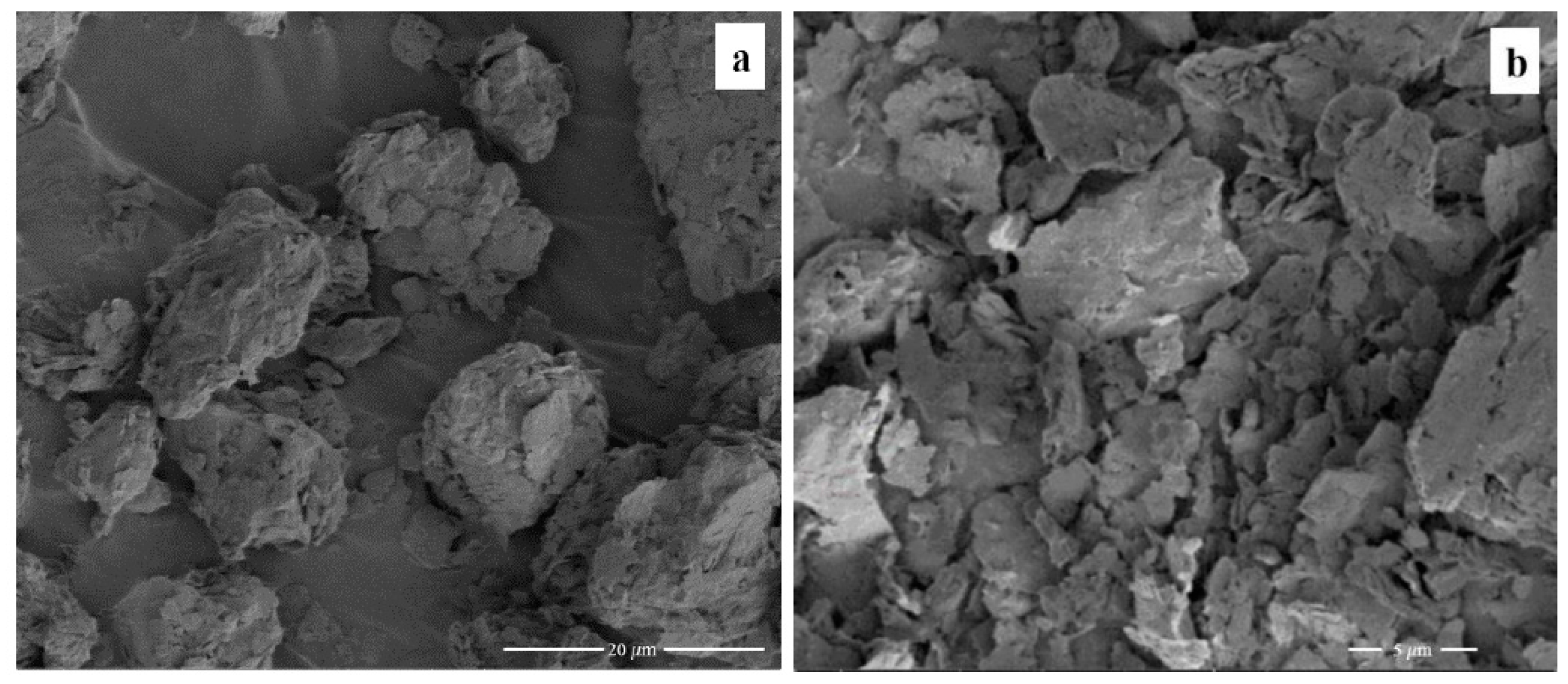

2.2. Microstructure Observation

2.3. Thermal Transport Properties

2.4. Mechanical Properties

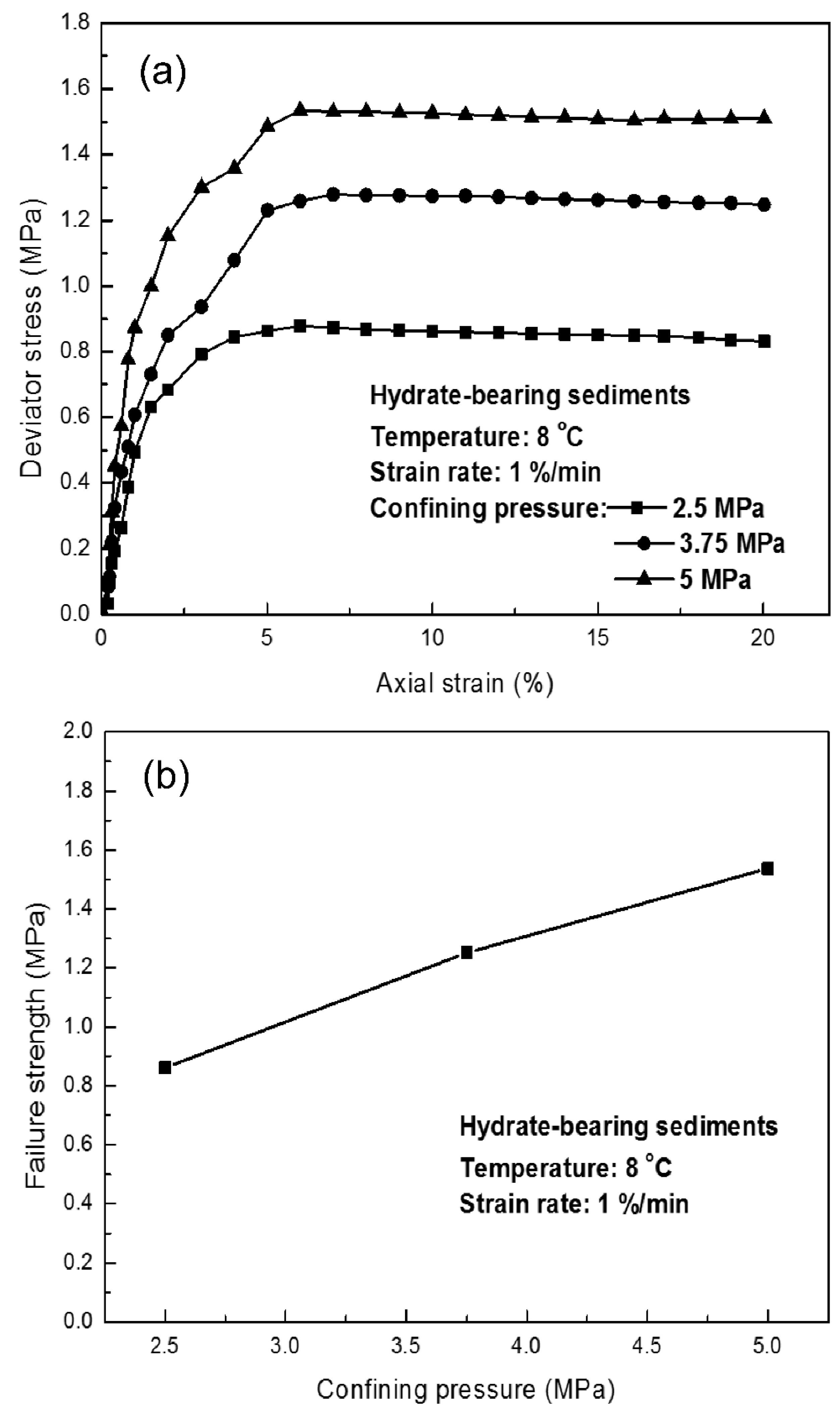

2.4.1. Mechanical Properties of Remolding Methane Hydrate-Bearing Sediments by Marine Soil

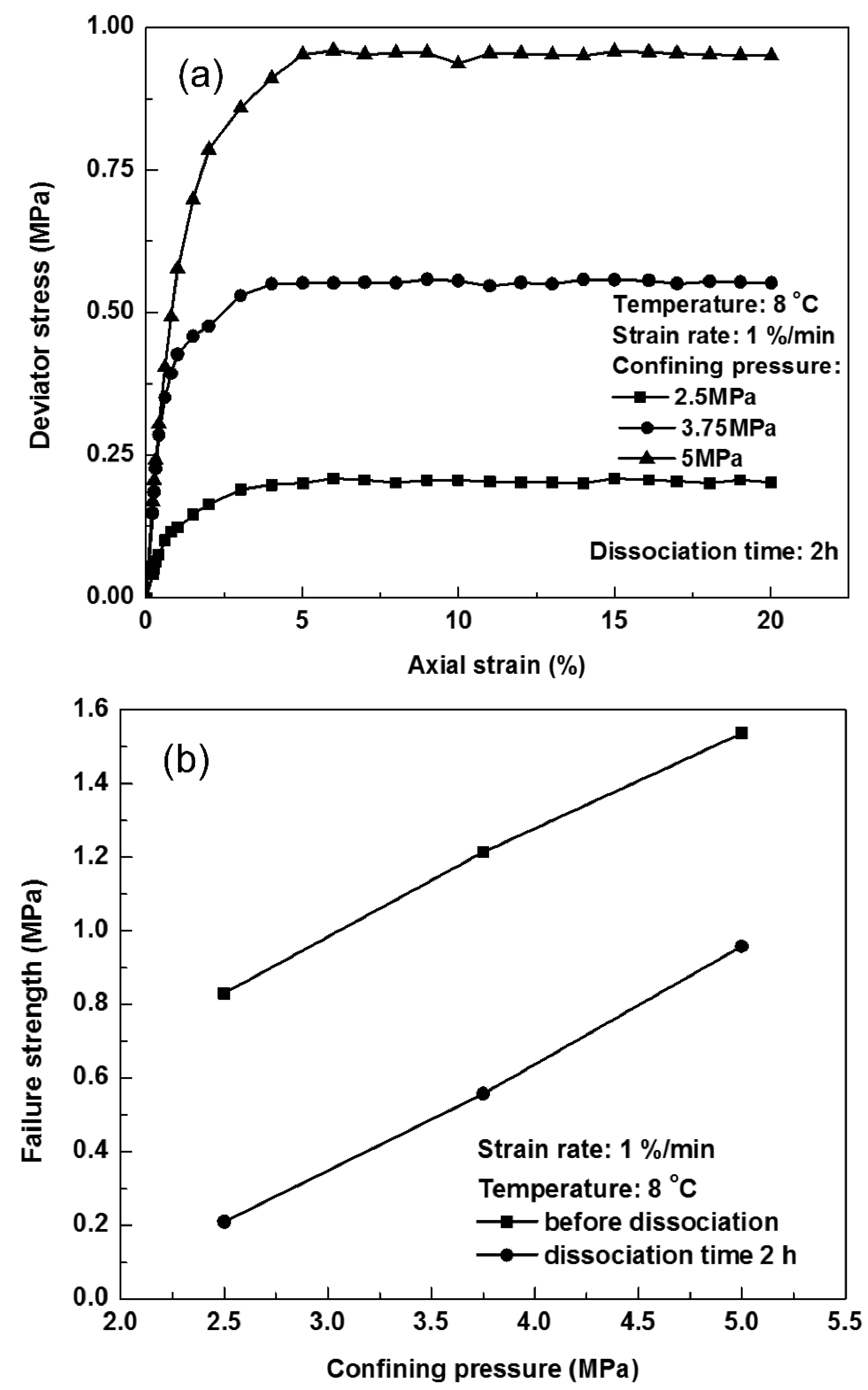

2.4.2. Effect of Hydrate Dissociation on the Strength Property of the Methane Hydrate-Bearing Sediment

3. Discussion

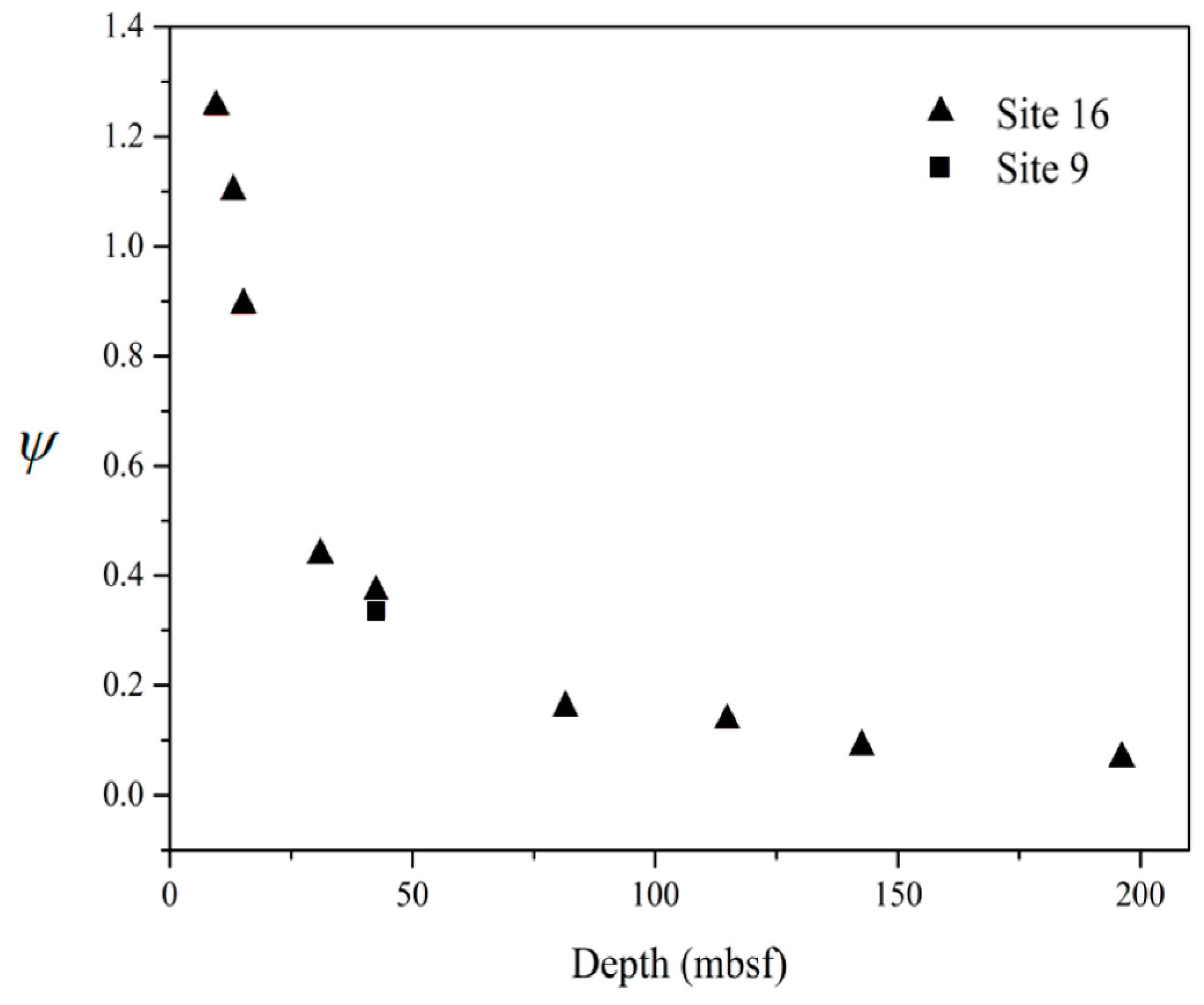

3.1. Grain Migration Behavior

3.2. Soil Types and Classification

4. Conclusions

- (1)

- The mean grain size mostly ranges from 7 to 11 μm throughout all intervals. Additionally, we conclude that fine-grained layers are mostly self-filtering.

- (2)

- From the computed tomography of X-ray and SEM, bioclasts have not been found, although the identified flaky clay increases the contact area of the gas-water two-phase; this may be conducive to hydrate formation in pore spaces.

- (3)

- The measured thermal conductivities range from 1.3 to 1.45 W/(m·K), except for the GMGS2-16-8 and GMGS2-16-9 samples which have values of 0.841 and 1.038 W/(m·K), respectively. The relatively low thermal conductivity in the PRM basin suggests that thermal stimulation might not be a good option for gas production from hydrate-bearing sediments at the PRM basin, and depressurization could exacerbate the problem about ice generation and/or gas hydrate reformation. Heat transfer enhancement is an important aspect for the establishment of an efficient production method.

- (4)

- The results of testing the mechanical properties indicate that Kaolin clay and sediments from the GMGS2 Gas Hydrate Drilling Expedition have the same stress-strain properties, and the stability of hydrate-bearing sediments decreases with hydrate dissociation, further causing the risk of sediment deformation, production platform collapse, and submarine slope.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Francisca, F.; Yun, T.S.; Ruppel, C.; Santamarina, J.C. Geophysical and geotechnical properties of near-seafloor sediments in the northern Gulf of Mexico gas hydrate province. Earth Planet. Sci. Lett. 2005, 237, 924–939. [Google Scholar] [CrossRef]

- Han, H.; Wang, Y.; Li, X.S.; Yu, J.X.; Feng, J.C.; Zhang, Y. Experimental study on sediment deformation during methane hydrate decomposition in sandy and silty clay sediments with a novel experimental apparatus. Fuel 2016, 182, 446–453. [Google Scholar] [CrossRef]

- Liu, C.L.; Ye, Y.G.; Meng, Q.G.; He, X.L.; Lu, H.L.; Zhang, J.; Liu, J.; Yang, S.X. The Characteristics of Gas Hydrates Recovered from Shenhu Area in the South China Sea. Mar. Geol. 2012, 307, 22–27. [Google Scholar] [CrossRef]

- Koh, C.A.; Sum, A.K.; Sloan, E.D. State of the art: Natural gas hydrates as a natural resource. J. Natl. Gas Sci. Eng. 2012, 8, 132–138. [Google Scholar] [CrossRef]

- Rossi, F.; Filipponi, M.; Castellani, B. Investigation on a novel reactor for gas hydrate production. Appl. Energy 2012, 99, 167–172. [Google Scholar] [CrossRef]

- Sloan, E.D. Fundamental principles and applications of natural gas hydrates. Nature 2003, 426, 353–363. [Google Scholar] [CrossRef] [PubMed]

- Castellani, B.; Rossi, F.; Filipponi, M.; Nicolini, A. Hydrate-based removal of carbon dioxide and hydrogen sulphide from biogas mixtures: Experimental investigation and energy evaluations. Biomass Bioenergy 2014, 70, 330–338. [Google Scholar] [CrossRef]

- Castellani, B.; Rossetti, G.; Tupsakhare, S.; Rossi, F.; Nicolini, A.; Castaldi, M.J. Simulation of CO2 storage and methane gas production from gas hydrates in a large scale laboratory reactor. J. Pet. Sci. Eng. 2016, 147, 515–527. [Google Scholar] [CrossRef]

- Yun, T.S.; Fratta, D.; Santamarina, J.C. Hydrate-bearing sediments from the Krishna—Godavari Basin: Physical characterization, pressure core testing, and scaled production monitoring. Energy Fuels 2010, 24, 5972–5983. [Google Scholar] [CrossRef]

- Shipley, T.H.; Houston, M.H.; Buffler, R.T.; Shaub, F.J.; McMillen, K.J.; Ladd, J.W.; Worzel, J.L. Seismic evidence for widespread possible gas hydrate horizons on continental slopes and rises. AAPG Bull. 1979, 63, 2204–2213. [Google Scholar]

- Ecker, C.; Dvorkin, J.; Nur, A.M. Estimating the amount of gas hydrate and free gas from marine seismic data. Geophysics 2000, 65, 565–573. [Google Scholar] [CrossRef]

- Collett, T.S.; Lee, M.W. Downhole well log characterization of gas hydrates in nature—A review. In Proceedings of the 7th International Conference on Gas Hydrates (ICGH 2011), Edinburgh, UK, 17–21 July 2011. [Google Scholar]

- Waite, W.F.; Kneafsey, T.J.; Winters, W.J.; Mason, D.H. Physical property changes in hydrate-bearing sediment due to depressurization and subsequent repressurization. J. Geophys. Res. Solid Earth 2008, 113, B7. [Google Scholar] [CrossRef]

- Nixon, M.F.; Grozic, J.L. Submarine slope failure due to gas hydrate dissociation: A preliminary. Can. Geotech. J. 2011, 44, 314–325. [Google Scholar] [CrossRef]

- Yun, T.S.; Santamarina, J.C.; Ruppel, C. Mechanical properties of sand, silt, and clay containing tetrahydrofuran hydrate. J. Geophys. Res. Solid Earth 2007, 112, B4. [Google Scholar] [CrossRef]

- Wu, Q.; Jiang, G. Assessing the permafrost temperature, thickness conditions favorable for the occurrence of gas hydrate in the Qinghai-Tibet Plateau. Energy Convers. Manag. 2010, 51, 783–787. [Google Scholar]

- Zhu, Y.; Zhang, Y. Gas hydrates in the Qilian Mountain permafrost, Qinghai, Northwest China. Acta Geol. Sin. Engl. Ed. 2010, 84, 1–10. [Google Scholar] [CrossRef]

- Wang, X.; Wu, S. Gas hydrate saturation from acoustic impedance and resistivity logs in the Shenhu area, South China Sea. Mar. Pet. Geol. 2011, 28, 1625–1633. [Google Scholar] [CrossRef]

- Zhang, G.X.; Yang, S.X.; Zhang, M.; Liang, J.Q.; Lu, J.G.; Holland, M.; Schultheiss, P.; Team, G.S. GMGS2 expedition investigates rich and complex gas hydrate environment in the South China Sea. Methane Hydrate Newsl. 2014, 14, 1–5. [Google Scholar]

- Liu, C.L.; Meng, Q.G.; He, X.L.; Li, C.F.; Ye, Y.G.; Zhang, G.X.; Liang, J.Q. Characterization of natural gas hydrate recovered from Pearl River Mouth basin in South China Sea. Mar. Pet. Geol. 2015, 61, 14–21. [Google Scholar] [CrossRef]

- Wang, Y.; Feng, J.-C.; Li, X.-S.; Zhang, Y.; Li, G. Evaluation of Gas Production from Marine Hydrate Deposits at the GMGS2-Site 8, Pearl River Mouth Basin, South China Sea. Energies 2016, 9, 222. [Google Scholar] [CrossRef]

- Dai, S.; Lee, C.; Carlos Santamarina, J. Formation history and physical properties of sediments from the Mount Elbert Gas Hydrate Stratigraphic Test Well, Alaska North Slope. Mar. Pet. Geol. 2011, 28, 427–438. [Google Scholar] [CrossRef]

- Lee, J.Y.; Kim, G.Y.; Kang, N.K.; Yi, B.Y.; Jung, J.W.; Im, J.H.; Son, B.K.; Bahk, J.J.; Chun, J.H.; Ryu, B.J.; et al. Physical properties of sediments from the Ulleung Basin, East Sea: Results from Second Ulleung Basin Gas Hydrate Drilling Expedition, East Sea (Korea). Mar. Pet. Geol. 2013, 47, 43–55. [Google Scholar] [CrossRef]

- Song, Y.C.; Zhu, Y.M.; Liu, W.G.; Zhao, J.F.; Li, Y.H.; Chen, Y.F.; Shen, Z.T.; Lu, Y.; Ji, C.M. Experimental research on the mechanical properties of methane hydrate-bearing sediments during hydrate dissociation. Mar. Pet. Geol. 2014, 51, 70–78. [Google Scholar] [CrossRef]

- Lee, C.; Yun, T.S.; Lee, J.-S.; Bahk, J.J.; Santamarina, J.C. Geotechnical characterization of marine sediments in the Ulleung Basin, East Sea. Eng. Geol. 2011, 117, 151–158. [Google Scholar] [CrossRef]

- Waite, W.F.; Santamarina, J.C.; Cortes, D.D.; Dugan, B.; Espinoza, D.N.; Germaine, J.; Jang, J.; Jung, J.W.; Kneafsey, T.J.; Shin, H.; et al. Physical Properties of Hydrate-Bearing Sediments. Rev. Geophys. 2009, 47, 38. [Google Scholar] [CrossRef]

- Hailong, L.; Kawasaki, T.; Ukita, T.; Moudrakovski, I.; Fujii, T.; Noguchi, S.; Shimada, T.; Nakamizu, M.; Ripmeester, J.; Ratcliffe, C. Particle size effect on the saturation of methane hydrate in sediments—Constrained from experimental results. Mar. Pet. Geol. 2011, 28, 1801–1805. [Google Scholar]

- Wang, J.Q.; Zhao, J.F.; Zhang, Y.; Wang, D.Y.; Li, Y.H.; Song, Y.C. Analysis of the effect of particle size on permeability in hydrate-bearing porous media using pore network models combined with CT. Fuel 2016, 163, 34–40. [Google Scholar] [CrossRef]

- Oyama, H.; Konno, Y.; Suzuki, K.; Nagao, J. Depressurized dissociation of methane-hydrate-bearing natural cores with low permeability. Chem. Eng. Sci. 2012, 68, 595–605. [Google Scholar] [CrossRef]

- Cheng, C.; Zhao, J.; Yang, M.; Liu, W.; Wang, B.; Song, Y. Evaluation of gas production from methane hydrate sediments with heat transfer from over-underburden layers. Energy Fuels 2015, 29, 1028–1039. [Google Scholar] [CrossRef]

- Oyama, H.; Konno, Y.; Masuda, Y.; Narita, H. Dependence of depressurization-induced dissociation of methane hydrate bearing laboratory cores on heat transfer. Energy Fuels 2009, 23, 4995–5002. [Google Scholar] [CrossRef]

- Pooladi-Darvish, M.; Hong, H. Effect of Conductive and Convective Heat Flow on Gas Production from Natural Hydrates by Depressurization; Kluwer Academic/Plenum Publishing Corporation: New York, NY, USA, 2004; pp. 43–65. [Google Scholar]

- Zhao, J.; Wang, B.; Yang, L.; Cheng, C.; Song, Y. A novel apparatus for in situ measurement of thermal conductivity of hydrate-bearing sediments. Rev. Sci. Instrum. 2015, 86, 085110. [Google Scholar] [CrossRef] [PubMed]

- Ning, F.; Yu, Y.; Kjelstrup, S.; Vlugt, T.J.; Glavatskiy, K. Mechanical properties of clathrate hydrates: Status and perspectives. Energy Environ. Sci. 2012, 5, 6779–6795. [Google Scholar] [CrossRef]

- Li, Y.H.; Liu, W.G.; Zhu, Y.M.; Chen, Y.F.; Song, Y.C.; Li, Q.P. Mechanical behaviors of permafrost-associated methane hydrate-bearing sediments under different mining methods. Appl. Energy 2015, 162, 1627–1632. [Google Scholar] [CrossRef]

- Flemings, P.B. Generation of overpressure and compaction—driven fluid flow in a Plio—Pleistocene growth—Faulted basin, Eugene Island 330, offshore Louisiana. Basin Res. 1998, 10, 177–196. [Google Scholar]

- Yun, T.S.; Narsilio, G.A.; Carlos Santamarina, J. Physical characterization of core samples recovered from Gulf of Mexico. Mar. Pet. Geol. 2006, 23, 893–900. [Google Scholar] [CrossRef]

- Mitchell, J.K.; Soga, K. Fundamentals of Soil Behavior; Wiley: New York, NY, USA, 1976. [Google Scholar]

- Shepard, F.P.; Moore, D.G. Sedimentary environments differentiated by coarse-fraction studies. AAPG Bull. Am. Assoc. Pet. Geol. 1954, 38, 1792–1802. [Google Scholar]

- Chen, F.; Su, X.; Zhou, Y.; Lu, H.F.; Liu, G.H.; Chen, Z.X.; Chen, C.Y. Variations in biogenic components of late Miocene-Holocene sediments from Shenhu Area in the northern South China Sea and their geological implication. Mar. Geol. Quat. Geol. 2009, 29, 1–8. [Google Scholar]

- Gustafsson, S.; Karawacki, E.; Khan, M.N. Transient hot-strip method for simultaneously measuring thermal conductivity and thermal diffusivity of solids and fluids. J. Phys. D Appl. Phys. 1979, 12, 1411. [Google Scholar] [CrossRef]

- Kim, Y.-G.; Lee, S.-M.; Matsubayashi, O. New heat flow measurements in the Ulleung Basin, East Sea (Sea of Japan): Relationship to local BSR depth, and implications for regional heat flow distribution. Geo-Mar. Lett. 2010, 30, 595–603. [Google Scholar] [CrossRef]

- Zhao, J.F.; Zhu, Z.H.; Song, Y.C.; Liu, W.G.; Zhang, Y.; Wang, D.Y. Analyzing the process of gas production for natural gas hydrate using depressurization. Appl. Energy 2015, 142, 125–134. [Google Scholar] [CrossRef]

- Terzaghi, K. Soil Mechanics in Engineering Practice; John Wiley & Sons: New York, NY, USA, 1996. [Google Scholar]

- Jansen, R.B. Advanced Dam Engineering for Design, Construction, and Rehabilitation; Springer: Berlin/Heidelberg, Germany, 1988. [Google Scholar]

- Dai, S.; Santamarina, J.C.; Waite, W.F.; Kneafsey, T.J. Hydrate morphology: Physical properties of sands with patchy hydrate saturation. J. Geophys. Res. Solid Earth 2012, 117, B11. [Google Scholar] [CrossRef]

| Core Number | Interval and Length (mbsf) | Water Content (%) | Specific Gravity, Gs | Liquid Limit, WL (%) | Plastic Limit, Wp (%) |

|---|---|---|---|---|---|

| DS16-1 | 9.62–9.78 | 31.57 | 2.841 | 45.77 | 20.35 |

| DS16-2 | 12.73–12.89 | 35.56 | 2.754 | 55.69 | 27.26 |

| DS16-3 | 15.00–15.16 | 42.93 | 2.726 | - | - |

| DS16-4 | 30.88–31.04 | 35.63 | 2.722 | - | - |

| DS16-5 | 42.50–42.66 | 31.89 | 2.719 | - | - |

| DS16-6 | 81.45–81.53 | 29.42 | 2.795 | 51.20 | 27.63 |

| DS16-7 | 114.65–114.73 | 31.47 | 2.717 | - | - |

| DS16-8 | 142.60–142.76 | 16.84 | 2.708 | - | - |

| DS16-9 | 196.10–196.18 | 23.76 | 2.719 | - | - |

| DS09-1 | 42.50–42.90 | 40.42 | 2.824 | 56.20 | 31.10 |

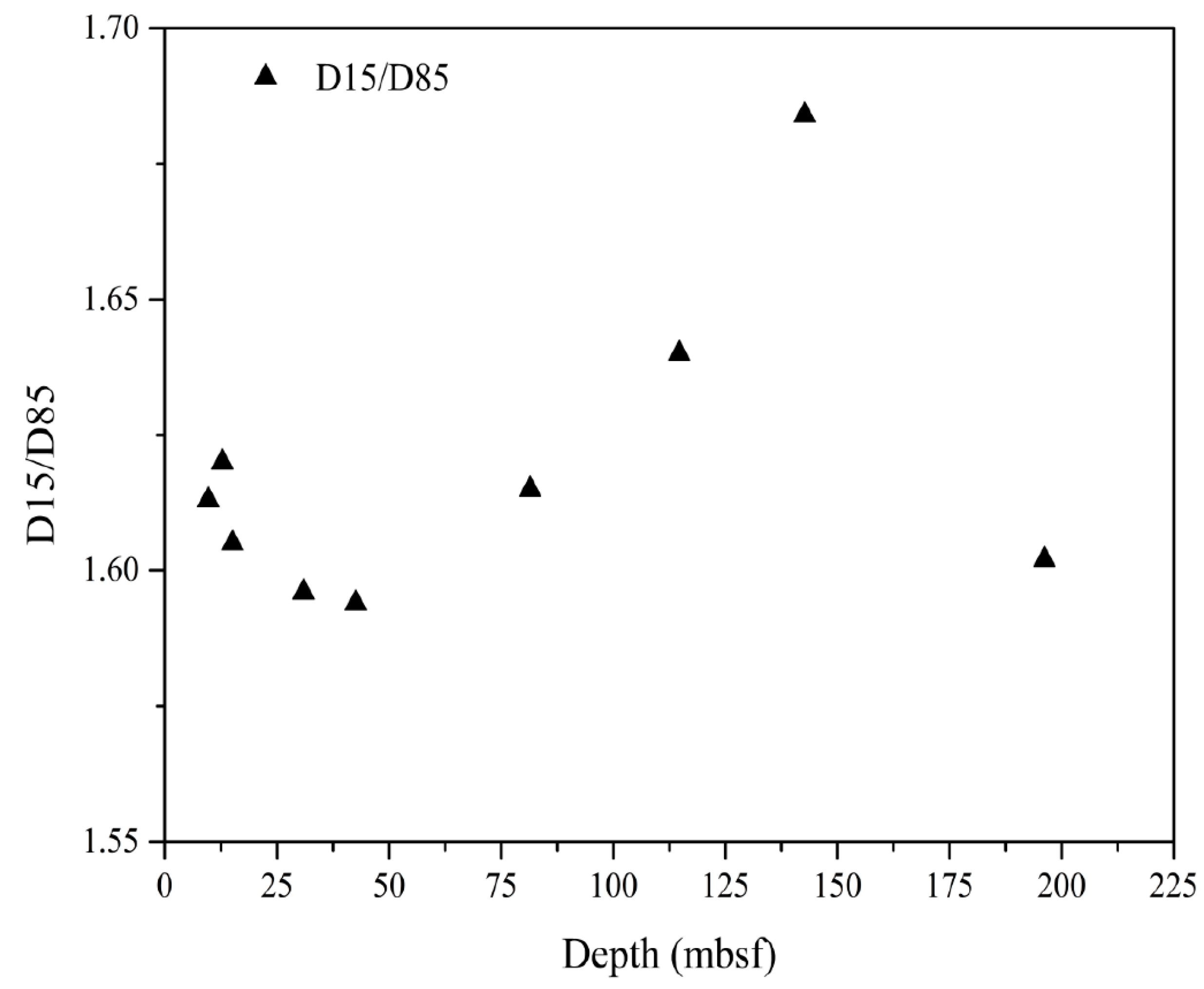

| Core Number | D50 (μm) | D3 (μm) | D10 (μm) | D25 (μm) | D75 (μm) | D90 (μm) | D97 (μm) | D15/D85 |

|---|---|---|---|---|---|---|---|---|

| DS16-1 | 10.69 | 0.739 | 1.620 | 4.123 | 23.22 | 43.75 | 81.44 | 1.613 |

| DS16-2 | 8.560 | 0.714 | 1.468 | 3.426 | 18.47 | 32.65 | 57.63 | 1.620 |

| DS16-3 | 9.132 | 0.750 | 1.564 | 3.676 | 19.57 | 37.17 | 72.91 | 1.605 |

| DS16-4 | 8.905 | 0.743 | 1.561 | 3.689 | 19.36 | 39.76 | 94.80 | 1.596 |

| DS16-5 | 7.071 | 0.656 | 1.337 | 3.016 | 15.30 | 27.62 | 49.73 | 1.594 |

| DS16-6 | 8.926 | 0.749 | 1.577 | 3.672 | 19.87 | 40.80 | 83.79 | 1.615 |

| DS16-7 | 8.283 | 0.658 | 1.368 | 3.297 | 18.51 | 35.93 | 72.12 | 1.640 |

| DS16-8 | 8.950 | 0.830 | 1.679 | 3.647 | 22.46 | 51.48 | 91.87 | 1.684 |

| DS16-9 | 8.271 | 0.761 | 1.572 | 3.518 | 18.23 | 36.34 | 75.00 | 1.602 |

| DS09-1 | 7.156 | 0.671 | 1.376 | 3.091 | 15.67 | 30.21 | 66.46 | 1.591 |

| Samples | Median Volume Pore Diameter (nm) | Median Area Pore Diameter (nm) | Average Pore Diameter (nm) | Apparent (Skeletal) Density (g/mL) | Porosity (%) |

|---|---|---|---|---|---|

| Undisturbed sediment | 426.1 | 71.3 | 195.4 | 3.29 | 67.73 |

| Remolded sediment | 281.8 | 47.0 | 120.2 | 3.19 | 57.98 |

| Core Number | Thermal Conductivity (W/(m·K)) | Thermal Diffusivity (mm2/s) | Specific Heat (MJ/m3K) |

|---|---|---|---|

| DS16-1 | 1.450 | 0.500 | 2.901 |

| DS16-2 | 1.366 | 0.520 | 2.630 |

| DS16-3 | 1.329 | 0.466 | 2.852 |

| DS16-4 | 1.401 | 0.488 | 2.871 |

| DS16-5 | 1.353 | 0.473 | 2.858 |

| DS16-6 | 1.447 | 0.551 | 2.627 |

| DS16-7 | 1.383 | 0.474 | 2.915 |

| DS16-8 | 0.841 | 0.414 | 2.032 |

| DS16-9 | 1.038 | 0.429 | 2.422 |

| DS09-1 | 1.294 | 0.455 | 2.846 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, B.; Huo, P.; Luo, T.; Fan, Z.; Liu, F.; Xiao, B.; Yang, M.; Zhao, J.; Song, Y. Analysis of the Physical Properties of Hydrate Sediments Recovered from the Pearl River Mouth Basin in the South China Sea: Preliminary Investigation for Gas Hydrate Exploitation. Energies 2017, 10, 531. https://doi.org/10.3390/en10040531

Wang B, Huo P, Luo T, Fan Z, Liu F, Xiao B, Yang M, Zhao J, Song Y. Analysis of the Physical Properties of Hydrate Sediments Recovered from the Pearl River Mouth Basin in the South China Sea: Preliminary Investigation for Gas Hydrate Exploitation. Energies. 2017; 10(4):531. https://doi.org/10.3390/en10040531

Chicago/Turabian StyleWang, Bin, Peng Huo, Tingting Luo, Zhen Fan, Fanglan Liu, Bo Xiao, Mingjun Yang, Jiafei Zhao, and Yongchen Song. 2017. "Analysis of the Physical Properties of Hydrate Sediments Recovered from the Pearl River Mouth Basin in the South China Sea: Preliminary Investigation for Gas Hydrate Exploitation" Energies 10, no. 4: 531. https://doi.org/10.3390/en10040531