Research on the Common Rail Pressure Overshoot of Opposed-Piston Two-Stroke Diesel Engines

Abstract

:1. Introduction

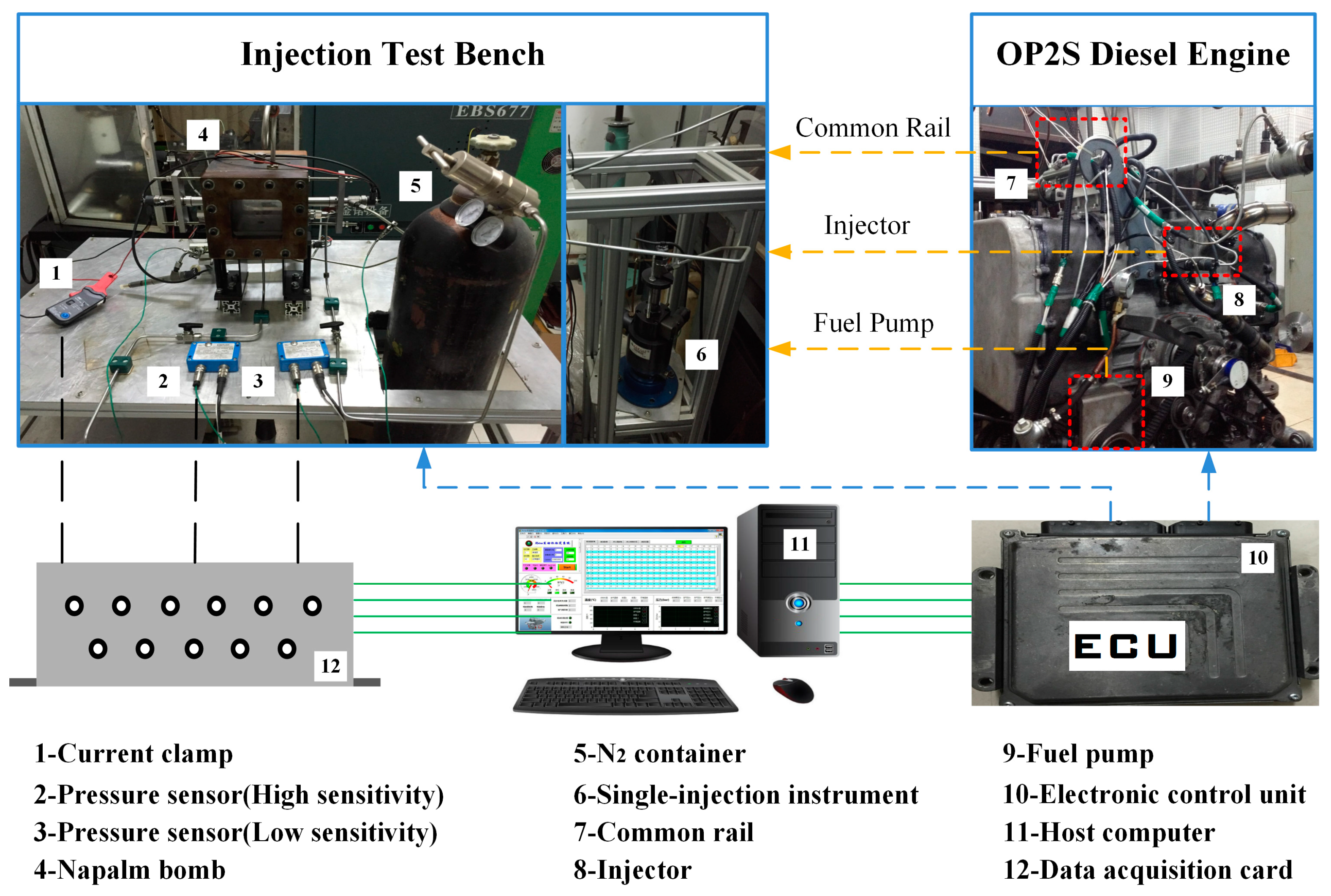

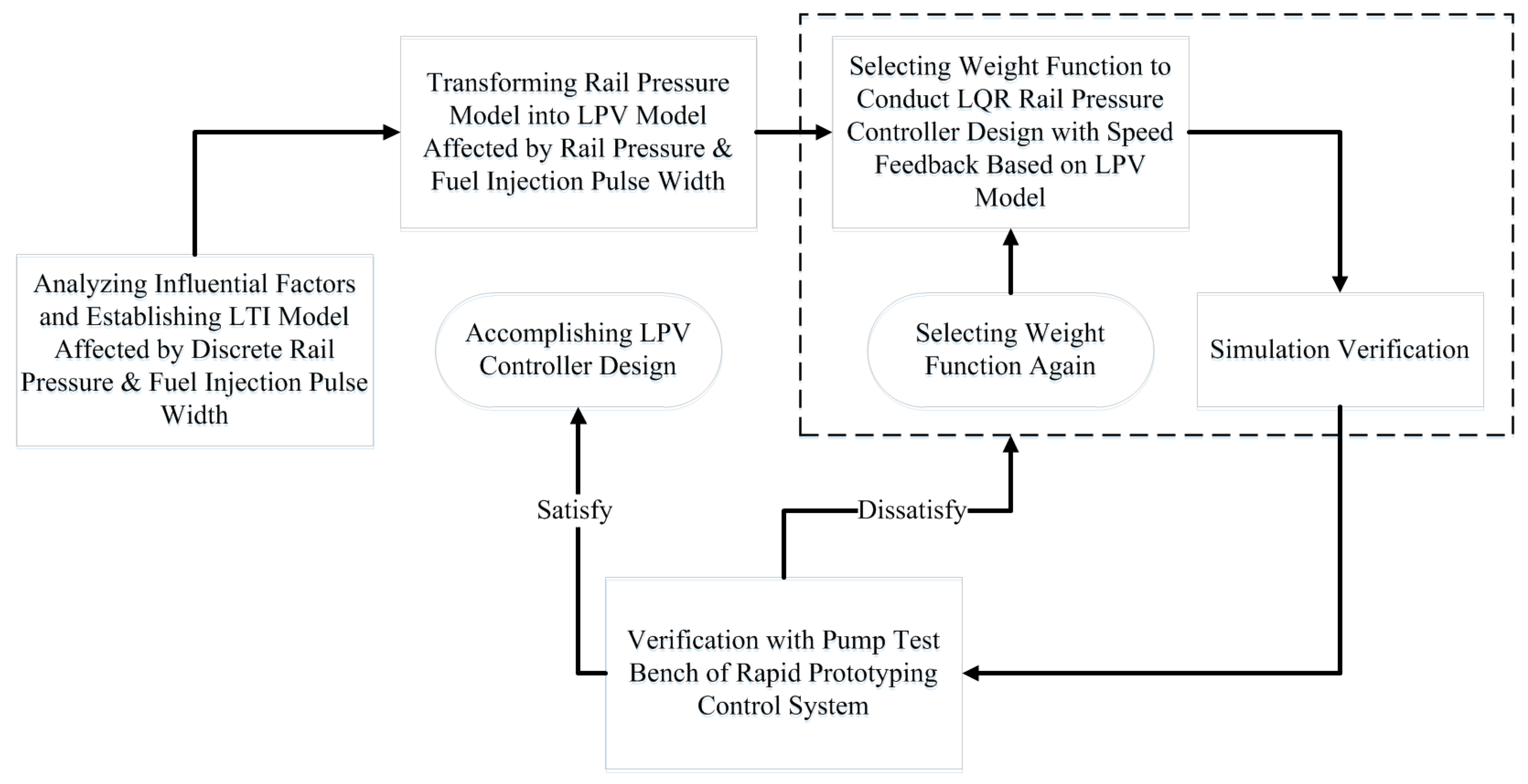

2. Experimental System

3. Common Rail System Model and Rail Pressure Control Algorithm

3.1. Common Rail System Model

3.1.1. OP2S Configuration

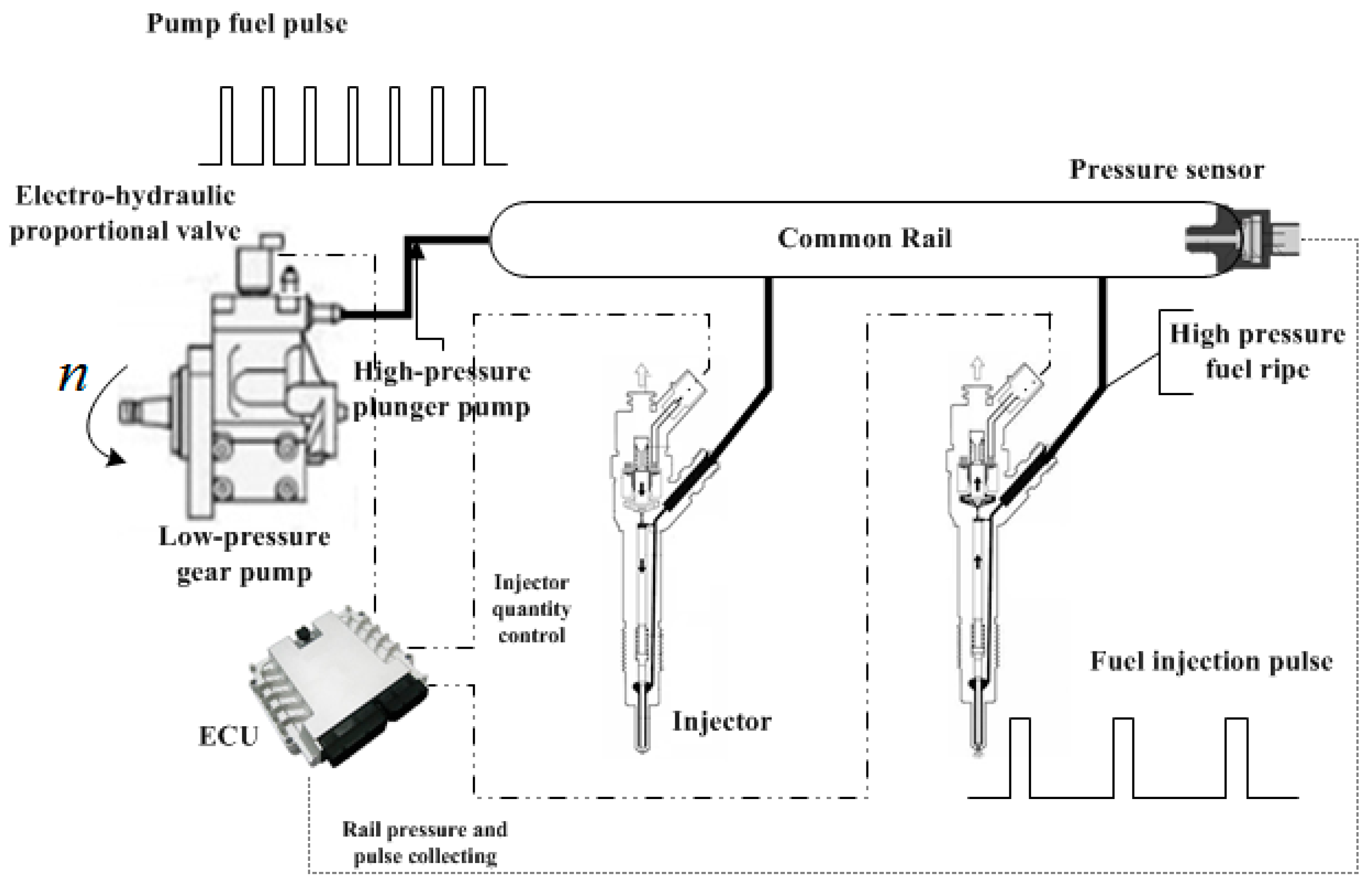

3.1.2. Fuel System Model

3.1.3. High-Pressure Pump Model

3.1.4. Common Rail Pipe Model

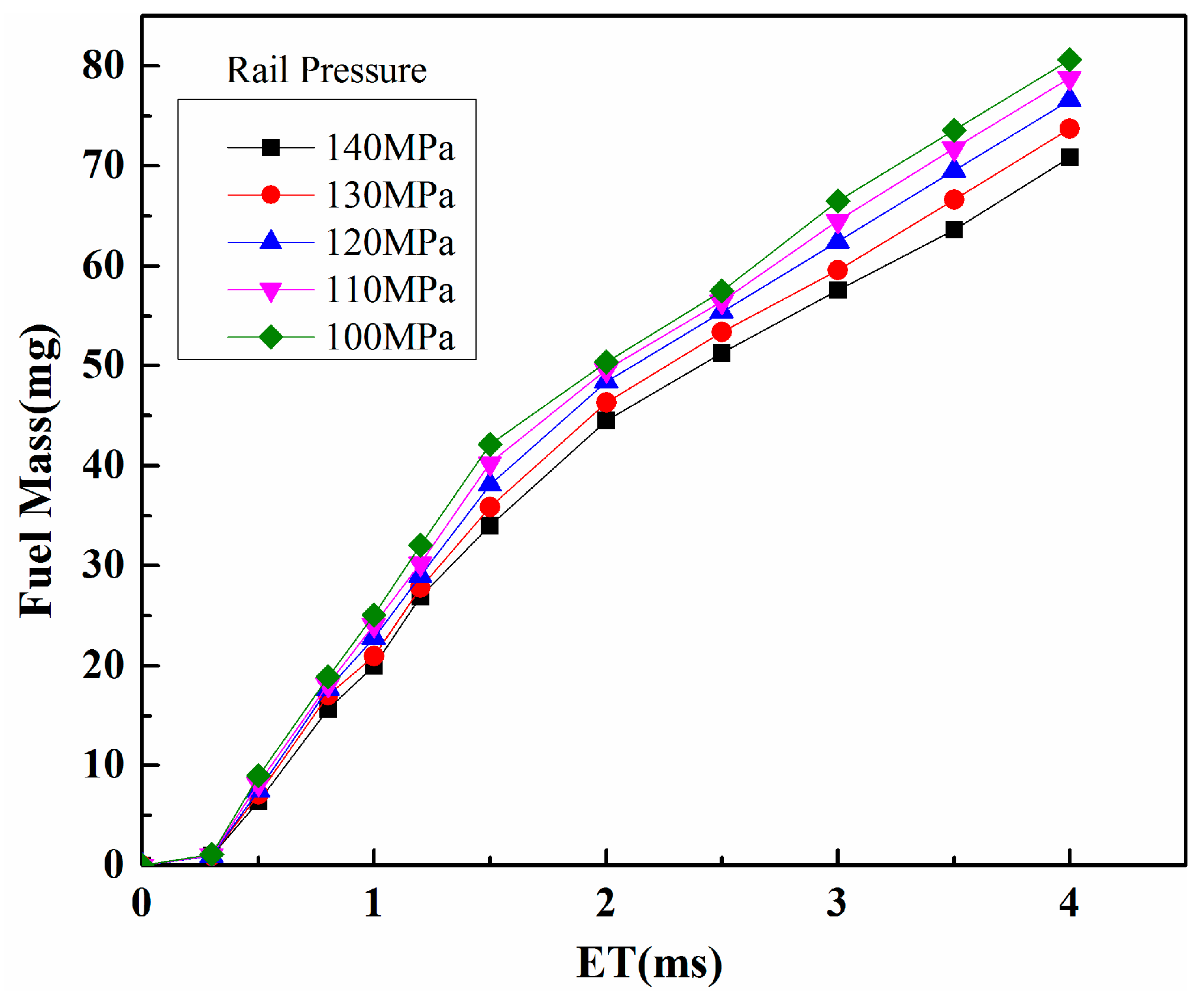

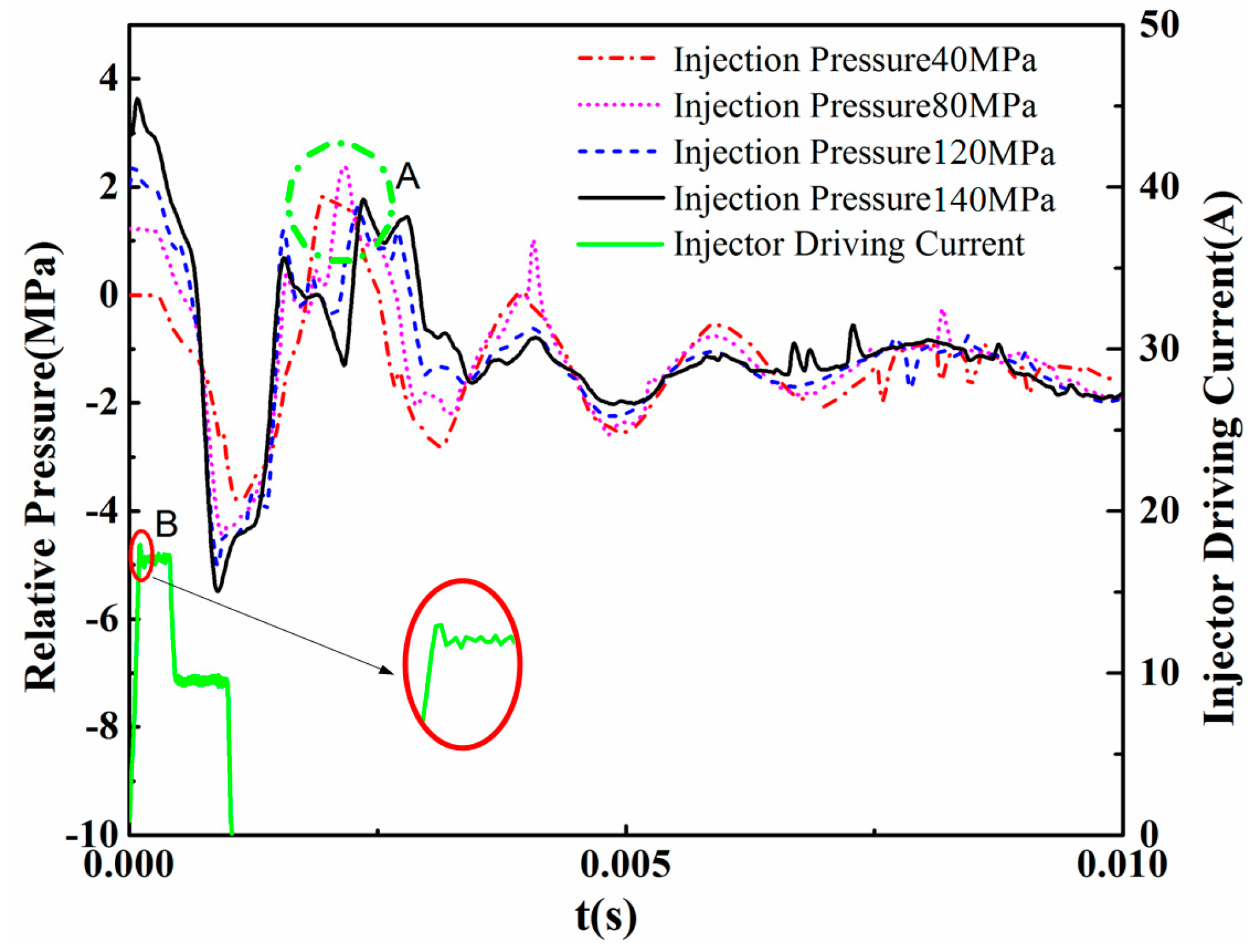

3.1.5. Fuel Injector Model

3.1.6. Fuel Quantity-Torque Transformation Model

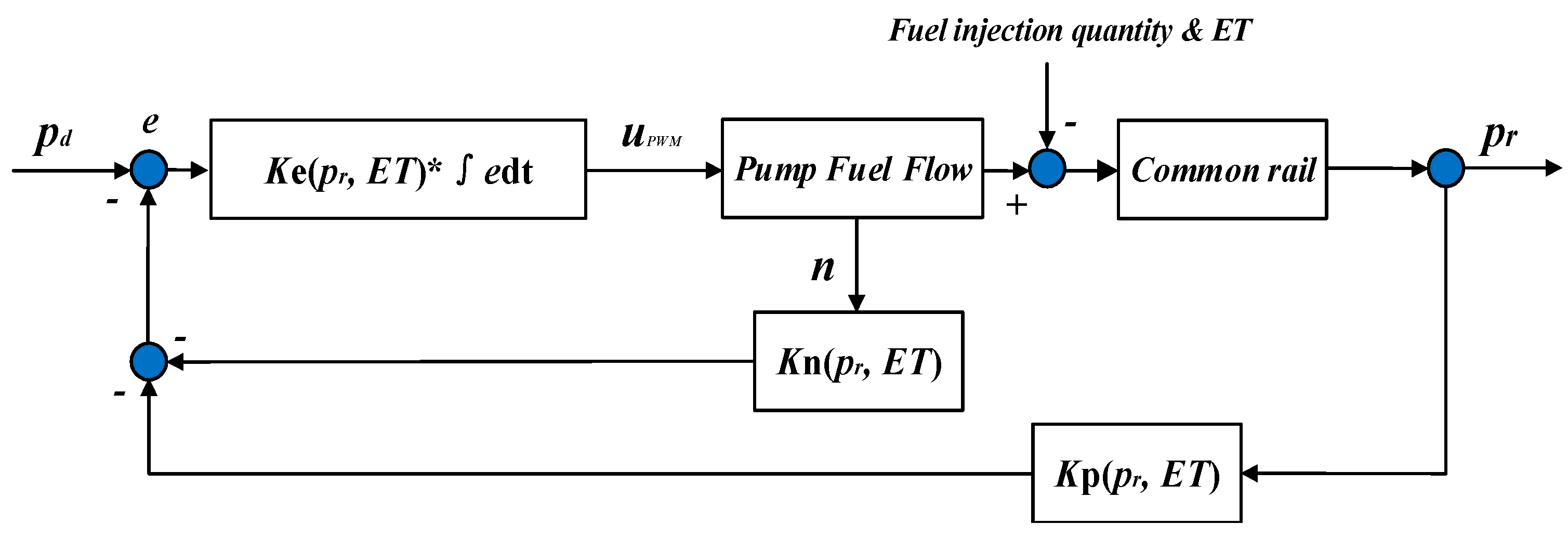

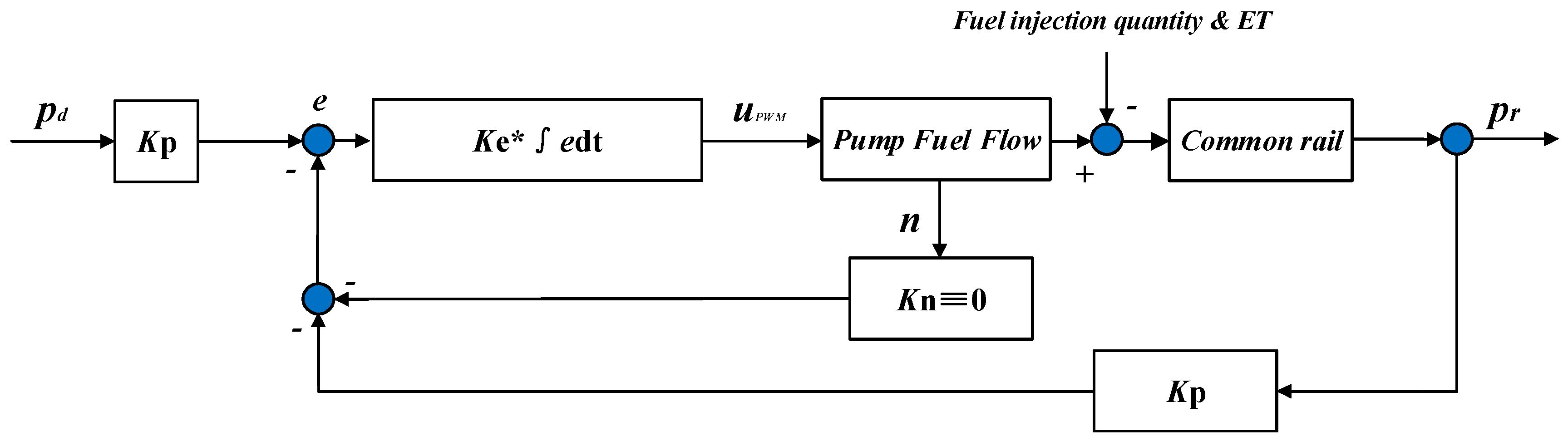

3.2. Rail Pressure Control Algorithm

3.2.1. Simplification of Common Rail Mathematics Model

3.2.2. LPV Linearization of the Common Rail Space Model

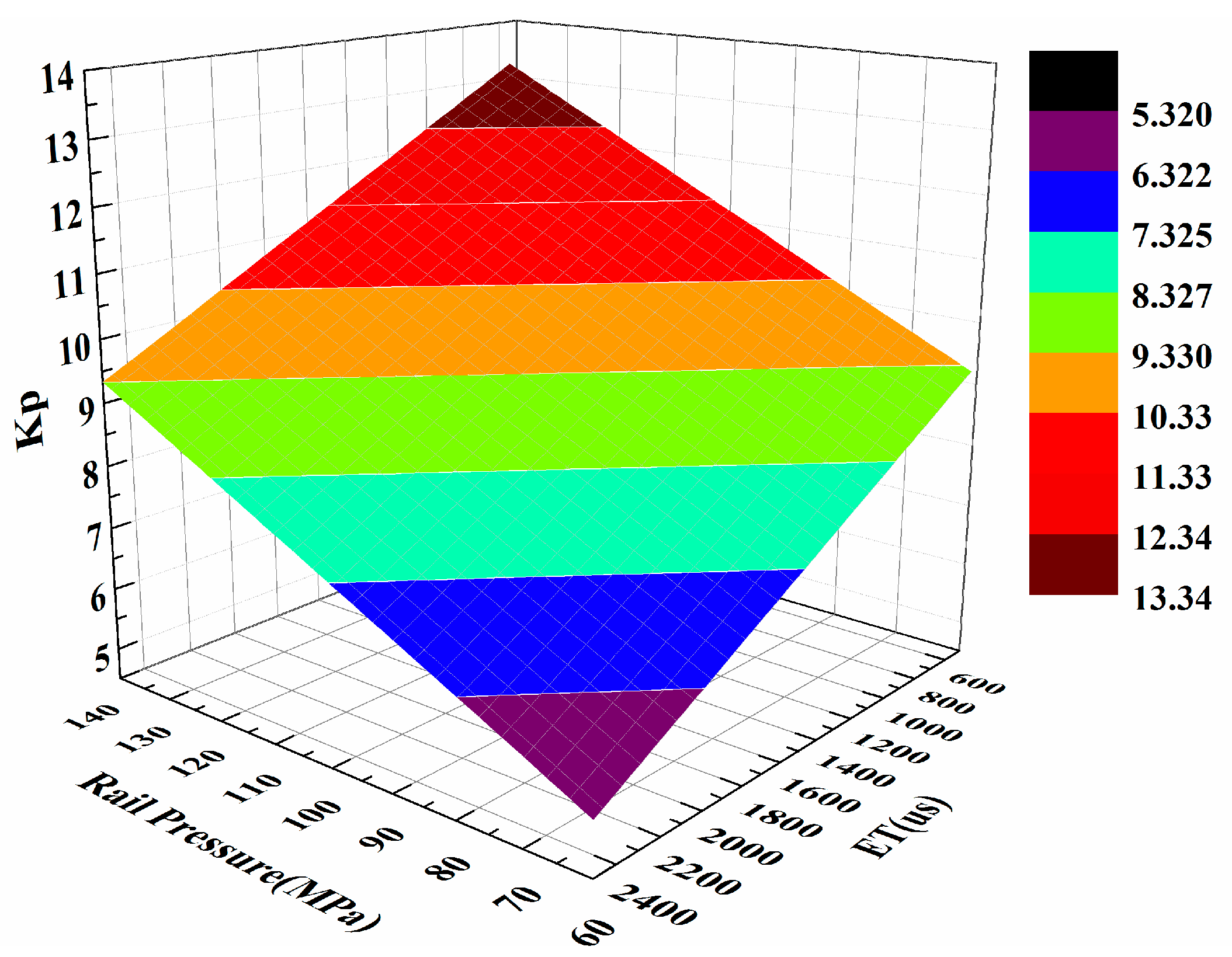

3.2.3. LQR Scheduling Control Algorithm Based on LPV Model

3.2.4. Optimal Control PID Control Algorithm

3.3. Analysis of Rail Pressure Overshoot

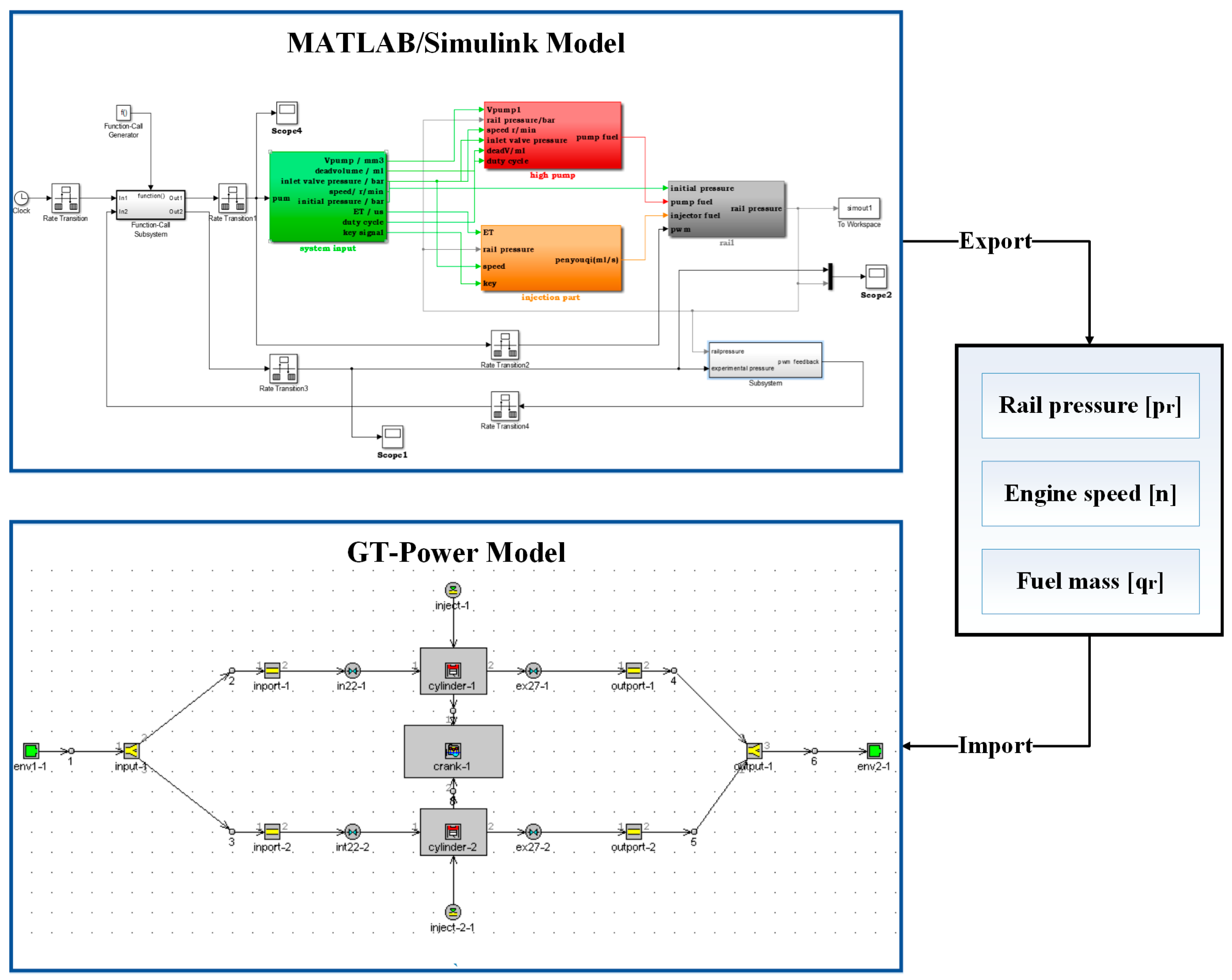

3.3.1. Co-Simulation Model

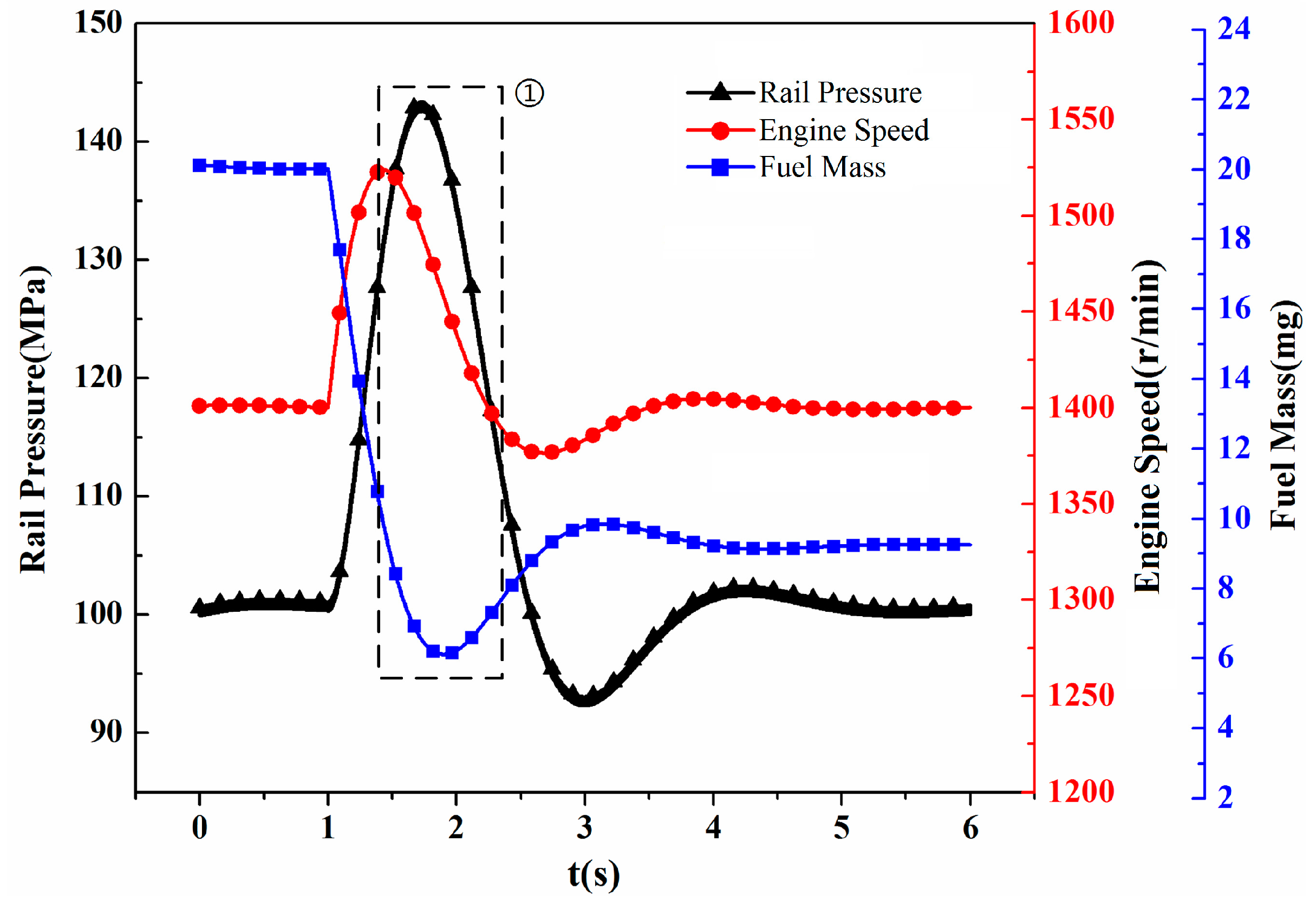

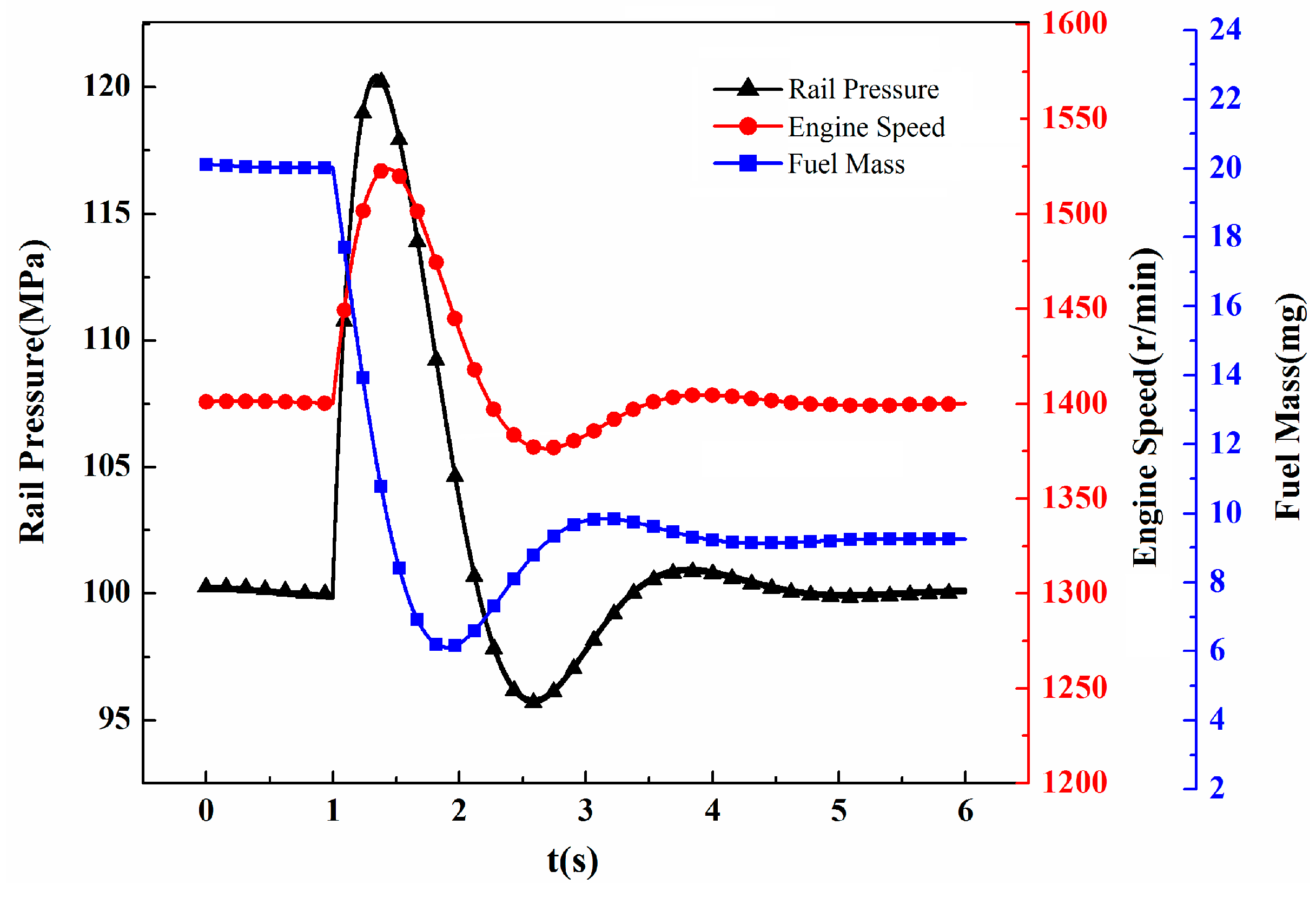

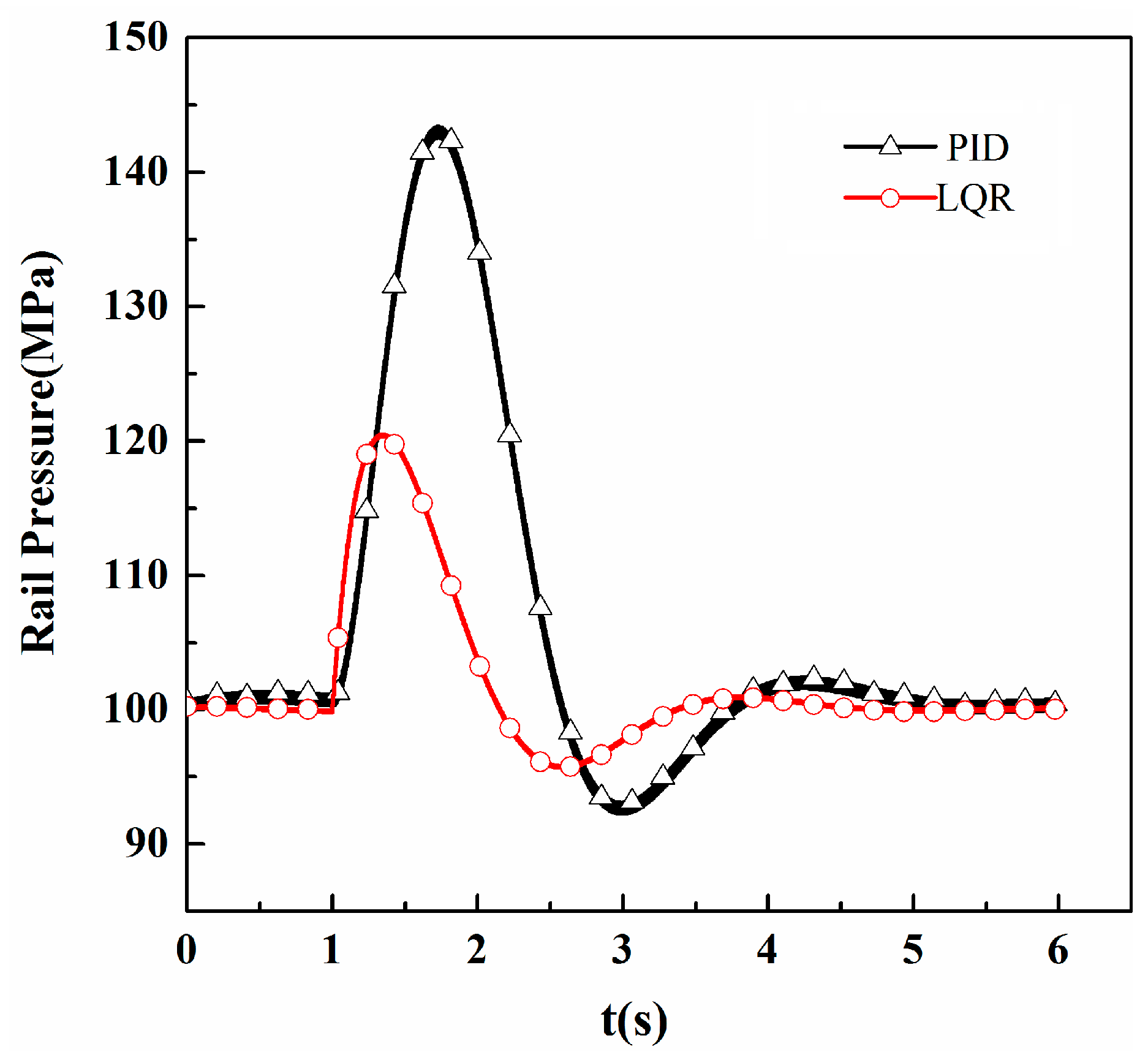

3.3.2. Results and Analysis

4. Conclusions

- (1)

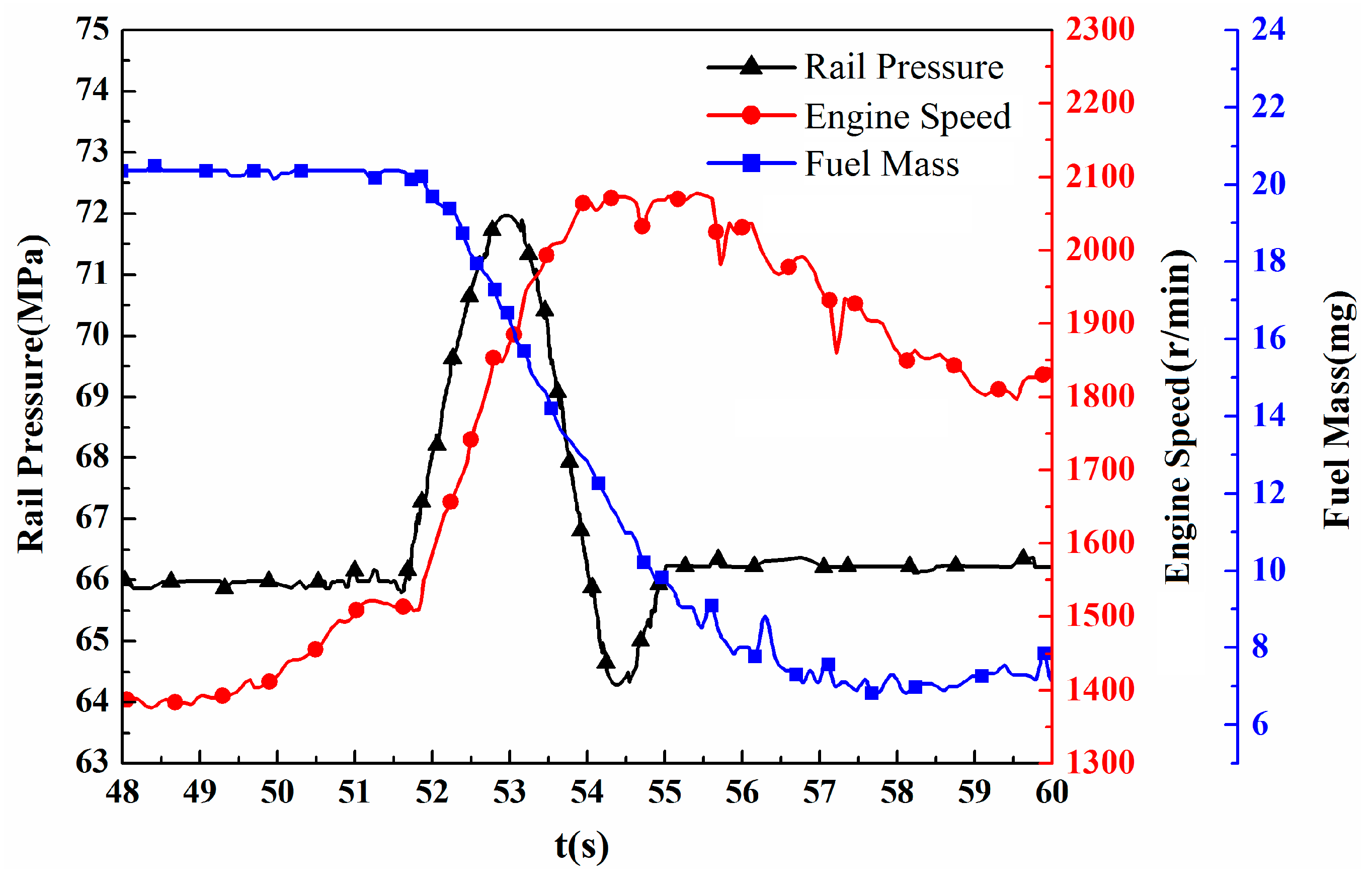

- After adopting a speed feedback control strategy, the control precision stays within the range of ±1 MPa. When that engine speed undergoes a 600 r/min variation, the fuel quantity decreases by 76.3% compared with the maximum fuel supply. The rail pressure fluctuation is less than 20 MPa and the time before the pressure returns to a stable value is less than 3.5 s. The control method restraining pressure overshoot problems is thus proved to be valid.

- (2)

- While using the LQR control system group on the basis of the LPV model design as well as the state feedback and servo compensation design, an ideal control effect results. The format of multi-state and coordinated control parameters could be applied to a multi-parameter control design of a multi-state complicated control system. Control parameters are designed off-line, thus reducing the calibration workload.

- (3)

- Aiming at the specific dynamic control problem of an OP2S diesel engine, the engine speed feedback, complex working conditions and nonlinear multi-parameter exponential equation family are added to the pressure control algorithm. The sensitivity of the dynamic fuel quantity variation characteristics of the OP2S diesel engine and the impact on the system dynamics from nonlinear parameters are preferably reduced. Finally, the algorithm is verified.

- (4)

- Although the control strategy in this study is designed for the rail pressure overshoot problem of OP2S diesel engines, the method could also be appropriate for other types of common rail systems thanks to its universality.

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| Abbreviation | |

| BDC | Bottom Dead Center |

| ECU | Electronic Control Unit |

| LPV | Linear Parameter Varying |

| LQR | Linear Quadratic Regulator |

| OP2S | Opposed-Piston Two-Stroke |

| PCV | Pressure Control Valves |

| PWM | Pulse Width Modulation |

| PID | Proportion Integration Differentiation |

| Symbols | |

| Crank angle, deg | |

| Fuel density, | |

| Correction coefficient | |

| Correction coefficient | |

| Discharge coefficient | |

| Injection pulse width | |

| Moment of inertia in engine, | |

| Injector number | |

| Fuel bulk modulus of elasticity, MPa | |

| Model constants | |

| Rail pressure state feedback parameter | |

| Speed state feedback parameter | |

| Servo compensation state feedback parameter | |

| Crankshaft speed, r/min | |

| Time varying fuel pressure, MPa | |

| Constant fuel pressure,0.5MPa | |

| Fuel flow, | |

| Plunger instantaneous axial displacement, m | |

| Load torque, | |

| Control signals | |

| Instantaneous fuel volume, | |

| Constant volume, | |

| Subscripts | |

| Initial value | |

| cylinder | |

| injector | |

| flow direction | |

| flow direction | |

| pump | |

| rail | |

| solenoid valve of pump | |

| desired rail pressure | |

References

- Pirault, J.P.; Flint, M. Opposed Piston Engines: Evolution, Use, and Future Applications; SAE International: Warrendale, PA, USA, 2009. [Google Scholar]

- Ma, F.; Zhao, C.; Zhang, F.; Zhao, Z.; Bingham, C. Effects of Scavenging System Configuration on In-Cylinder Air Flow Organization of an Opposed-Piston Two-Stroke Engine. Energies 2015, 2015, 5866–5884. [Google Scholar] [CrossRef]

- Peter, H. Opposed Piston Opposed Cylinder (OPOC) Engine for Military Ground Vehicles; SAE Technical Paper 2005-01-1548; SAE International: Warrendale, PA, USA, 2005. [Google Scholar]

- Naik, S.; Johnson, D.; Koszewnik, J.; Fromm, L.; Redon, F.; Regner, G.; Fuqua, K. Practical Applications of Opposed-Piston Engine Technology to Reduce Fuel Consumption and Emissions; SAE Technical Paper 2013-01-2754; SAE International: Warrendale, PA, USA, 2013. [Google Scholar]

- Regner, G.; Johnson, D.; Koszewnik, J.; Lynn, F. Modernizing the Opposed Piston, Two Stroke Engine for Clean, Efficient Transportation; SAE Technical Paper 2013-26-0114; SAE International: Warrendale, PA, USA, 2013. [Google Scholar]

- Gharakhani, A.; Ghoniem, A.F. 3D vortex simulation of flow in an opposed-piston engine. Esaim Proc. 1999, 7, 161–172. [Google Scholar] [CrossRef]

- Regner, G.; Herold, R.E.; Wahl, M.H.; Dion, E.; Redon, F.; Johnson, D.; McIntyre, S. The Achates Power Opposed-Piston Two-Stroke Engine: Performance and Emissions Results in a Medium-Duty Application; SAE Technical Paper 2011-01-2221; SAE International: Warrendale, PA, USA, 2011. [Google Scholar]

- Stumpp, G.; Ricco, M. Common Rail-An Attractive Fuel Injection System for Passenger Car DI Diesel Engines. In Proceedings of the International Congress and Exposition of the Society of Automotive Engineers (SAE), Detroit, MI, USA, 26–29 February 1996. [Google Scholar]

- Boehner, W.; Hummel, K. Common Rail Injection System for Commercial Diesel Vehicles; SAE International: Warrendale, PA, USA, 1997. [Google Scholar]

- Catania, A.E.; Ferrari, A.; Manno, M.; Spessa, E. Experimental Investigation of Dynamic Effects on Multiple-Injection Common Rail System Performance. J. Eng. Gas Turbines Power 2008, 130, 460–466. [Google Scholar] [CrossRef]

- Henein, N.A.; Lai, M.C.; Singh, I.P.; Zhong, L.; Han, J. Characteristics of a Common Rail Diesel Injection System under Pilot and Postinjection Modes; SAE Technical Paper 2002-01-0218; SAE International: Warrendale, PA, USA, 2002. [Google Scholar]

- Bianchi, G.M.; Falfari, S.; Pelloni, P.; Filicori, F.; Milani, M.A. Numerical and Experimental Study towards Possible Improvements of Common Rail Injectors; SAE Technical Paper 2002-01-0500; SAE International: Warrendale, PA, USA, 2002. [Google Scholar]

- Yang, F.Y.; Zhang, J.Y.; Wang, X.G.; Zhou, M.; Ouyang, M.G. Judgement and Application of Ignition Moment during Engine Startup Period Based on Crankshaft Transient Acceleration Analysis. Autom. Eng. 2003, 25, 111–115. [Google Scholar]

- Song, G.M.; Yang, F.Y.; Ouyang, M.G.; Hu, L.F.; Hang, Y. Equilibrium Algorithm Research for Each Individual Cylinders of Common Rail Based on Self-Adaptive Fuzzy Control. Trans. Csice 2005, 23, 451–456. [Google Scholar]

- Song, J.; Tian, L.Y.; Li, X.L.; Qiao, X.Q.; Huang, Z. Design of ECU for Common Rail System of Diesel Engine and Study of Injection Characteristics. Trans. Csice 2006, 24, 28–34. [Google Scholar]

- Xu, J.; Shen, L.Z.; Wang, G.; Bi, Y. Study on Compound Control Strategy of Rail Pressure for High Pressure Common Rail Diesel Engine. Chin. Intern. Combust. Engine Eng. 2012, 33, 54–59. [Google Scholar]

- Zhou, W.H.; Zhu, C.D.; Yu, S.U. Key technology of electronic controlled system of common-rail diesel engine. J. Zhejiang Univ. 2011, 45, 118–121. [Google Scholar]

- Li, S.; Chen, H.; Ma, M. Model predictive control based on linear programming for engine idle speed control. In Proceedings of the IEEE Conference on Mechatronics and Automation (ICMA), Changchun, China, 9–12 August 2009. [Google Scholar]

- Li, S.; Chen, H.; Yu, S. Nonlinear model predictive control for idle speed control of SI engine. In Proceedings of the IEEE Conference on Decision and Control Jointly with the, Chinese Control Conference, Shanghai, China, 16–18 December 2009. [Google Scholar]

- Fialho, I.; Balas, G.J. Road adaptive active suspension design using linear parameter-varying gain-scheduling. IEEE Trans. Control Syst. Technol. 2002, 10, 43–54. [Google Scholar] [CrossRef]

- Kjergaard, L.; Nielsen, S.; Vesterholm, T.; Hendricks, E. Advanced Nonlinear Engine Idle Speed Control Systems. In Proceedings of the International congress and exposition of the Society of Automotive Engineers (SAE), Detroit, MI, USA, 26–29 March 1994. [Google Scholar]

- Yu, S.T.; Zhou, X.L.; Yang, X.F.; Gong, Y.M.; Yang, L.; Zhou, B. Research on torque based control simulation model for electronic unit pump diesel engine. Chin. Intern. Combust. Engine Eng. 2006, 27, 29–32. [Google Scholar]

- Lino, P.; Maione, B.; Rizzo, A. Nonlinear modeling and control of a common rail injection system for diesel engines. Appl. Math. Model. 2007, 31, 1770–1784. [Google Scholar] [CrossRef]

- Lino, P.; Maione, B.; Amorese, C. Modelling and predictive control of a new injection system for compressed natural gas engines. Control Eng. Pract. 2006, 16, 1216–1230. [Google Scholar] [CrossRef]

- Catania, A.E.; Ferrari, A.; Manno, M. Development and Application of a Complete Common-Rail Injection System Mathematical Model for Hydrodynamics Analysis and Diagnostics. In Proceedings of the ASME ICE Spring Technical Conference, Chicago, IL, USA, 5–7 April 2005. [Google Scholar]

- Di Gaeta, A.; Palladino, G.F.A.; Giglio, V. A control oriented model of a Common-Rail System for Gasoline Direct Injection Engine. In Proceedings of the IEEE Conference on Decision and Control jointly with the Chinese Control Conference, Shanghai, China, 16–18 December 2009. [Google Scholar]

- Di Gaeta, A.; Fiengo, G.; Palladino, A.; Giglio, V. Design and Experimental Validation of a Model-Based Injection Pressure Controller in a Common Rail System for GDI Engine. In Proceedings of the American Control Conference, San Francisco, CA, USA, 29 June–1 July 2011. [Google Scholar]

- Wei, X.; del Re, L. Gain Scheduled H Control for Air Path Systems of Diesel Engines Using LPV Techniques. IEEE Trans. Control Syst. Technol. 2007, 15, 406. [Google Scholar] [CrossRef]

- Salcedo, J.; Martínez, M. LPV identification of a turbocharged diesel engine. Appl. Numer. Math. 2008, 58, 1553–1571. [Google Scholar] [CrossRef]

- White, A.P.; Zhu, G.; Choi, J. Gain-scheduling control of port-fuel-injection processes. Control Eng. Pract. 2011, 19, 380–394. [Google Scholar] [CrossRef]

- Bullock, D.; Johnson, B.; Wells, R.B.; Kyte, M.; Li, Z. Hardware-in-the-loop simulation. Transp. Res. Part C Emerg. Technol. 2004, 12, 73–89. [Google Scholar] [CrossRef]

- Heemels, W.P.M.H.; Daafouz, J.; Millerioux, G. Observer-based control of discrete-time LPV systems with uncertain parameters. IEEE Trans. Autom. Control 2010, 55, 2130–2135. [Google Scholar] [CrossRef]

- White, A.; Zhu, G.; Choi, J. Optimal LPV control with hard constraints. Int. J. Control Autom. Syst. 2016, 14, 148–162. [Google Scholar] [CrossRef]

- GT-Power User’s Manual Version 6.2[M]; Gamma Technologies: Westmont, IL, USA, 2006.

- Ciesla, C.; Keribar, R.; Morel, T. Engine/Powertrain/Vehicle Modeling Tool Applicable to All Stages of the Design Process; SAE Technical Paper 2000-01-0934; SAE International: Warrendale, PA, USA, 2000. [Google Scholar]

- Morel, T.; Keribar, R.; Leonard, A. Virtual Engine/Powertrain/Vehicle Simulation Tool Solves Complex Interacting System Issues; SAE Technical Paper 2003-01-0372; SAE International: Warrendale, PA, USA, 2003. [Google Scholar]

| Parameter Item (Units) | Value |

|---|---|

| Number of cylinders (-) | 2 |

| Cylinder diameter (mm) | 100 |

| Stroke (mm) | 110 |

| Displacement (L) | 3.4 |

| Phase difference of the opposed-piston (°CA) | 17 |

| Maximum power (kW) | 80 (2400 rpm) |

| Maximum torque (Nm) | 420 (1600 rpm) |

| Nominal compression ratio (-) | 22 |

| Angle of intake valve open (°CA) | 116 |

| Angle of intake valve close (°CA) | 110 |

| Angle of exhaust valve open (°CA) | 100 |

| Angle of exhaust valve close (°CA) | 113 |

| Engine Speed (r/min) | Indicated Torque (N·m) | Effective Power (KW) | Mechanical Losses (KW) | Torque Losses (N·m) |

|---|---|---|---|---|

| 900 | 11.111 | 0 | 11.111 | 117.909 |

| 1200 | 20.962 | 4.712 | 16.250 | 166.823 |

| 1400 | 32.103 | 10.995 | 21.108 | 218.992 |

| 1600 | 46.007 | 18.848 | 27.159 | 274.606 |

| ET/ms | 1.0 | 1.5 | 2.0 | |

|---|---|---|---|---|

| Rail Pressure/MPa | ||||

| 40 | 1.95 ms | 2.97 ms | 3.95 ms | |

| 80 | 2.14 ms | 3.24 ms | 4.38 ms | |

| 120 | 2.28 ms | 3.39 ms | 4.44 ms | |

| 140 | 2.35 ms | 3.43 ms | 4.61 ms | |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, Y.; Zhao, C.; Zuo, Z.; Zhang, F.; Zhang, S. Research on the Common Rail Pressure Overshoot of Opposed-Piston Two-Stroke Diesel Engines. Energies 2017, 10, 571. https://doi.org/10.3390/en10040571

Lu Y, Zhao C, Zuo Z, Zhang F, Zhang S. Research on the Common Rail Pressure Overshoot of Opposed-Piston Two-Stroke Diesel Engines. Energies. 2017; 10(4):571. https://doi.org/10.3390/en10040571

Chicago/Turabian StyleLu, Yi, Changlu Zhao, Zhe Zuo, Fujun Zhang, and Shuanlu Zhang. 2017. "Research on the Common Rail Pressure Overshoot of Opposed-Piston Two-Stroke Diesel Engines" Energies 10, no. 4: 571. https://doi.org/10.3390/en10040571