Influences of Winding MMF Harmonics on Torque Characteristics in Surface-Mounted Permanent Magnet Vernier Machines

Abstract

:1. Introduction

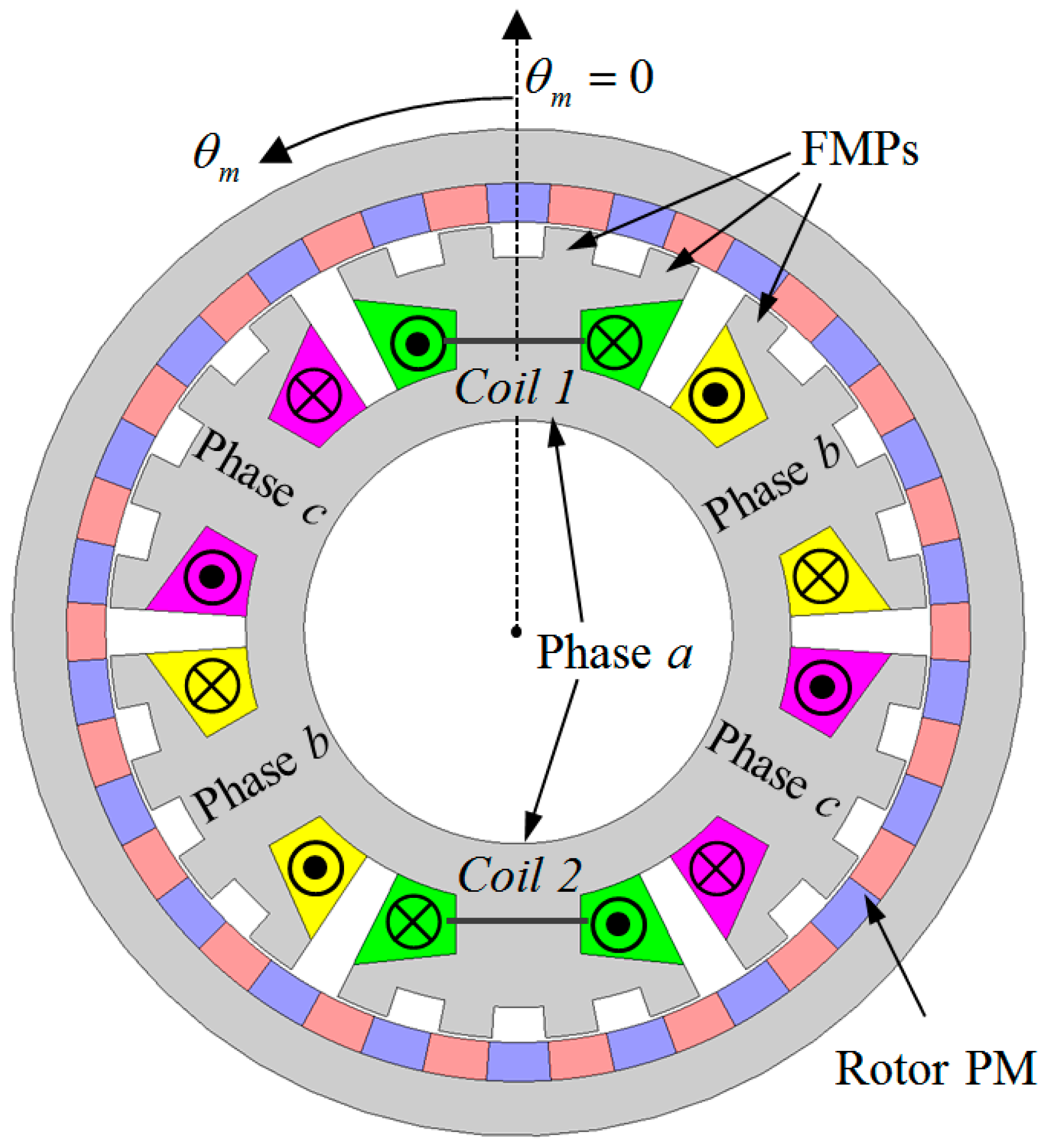

2. Operating Principle

2.1. Magnetic Gears

2.2. SPMV Machines

3. Design of the Armature Magnetic Field

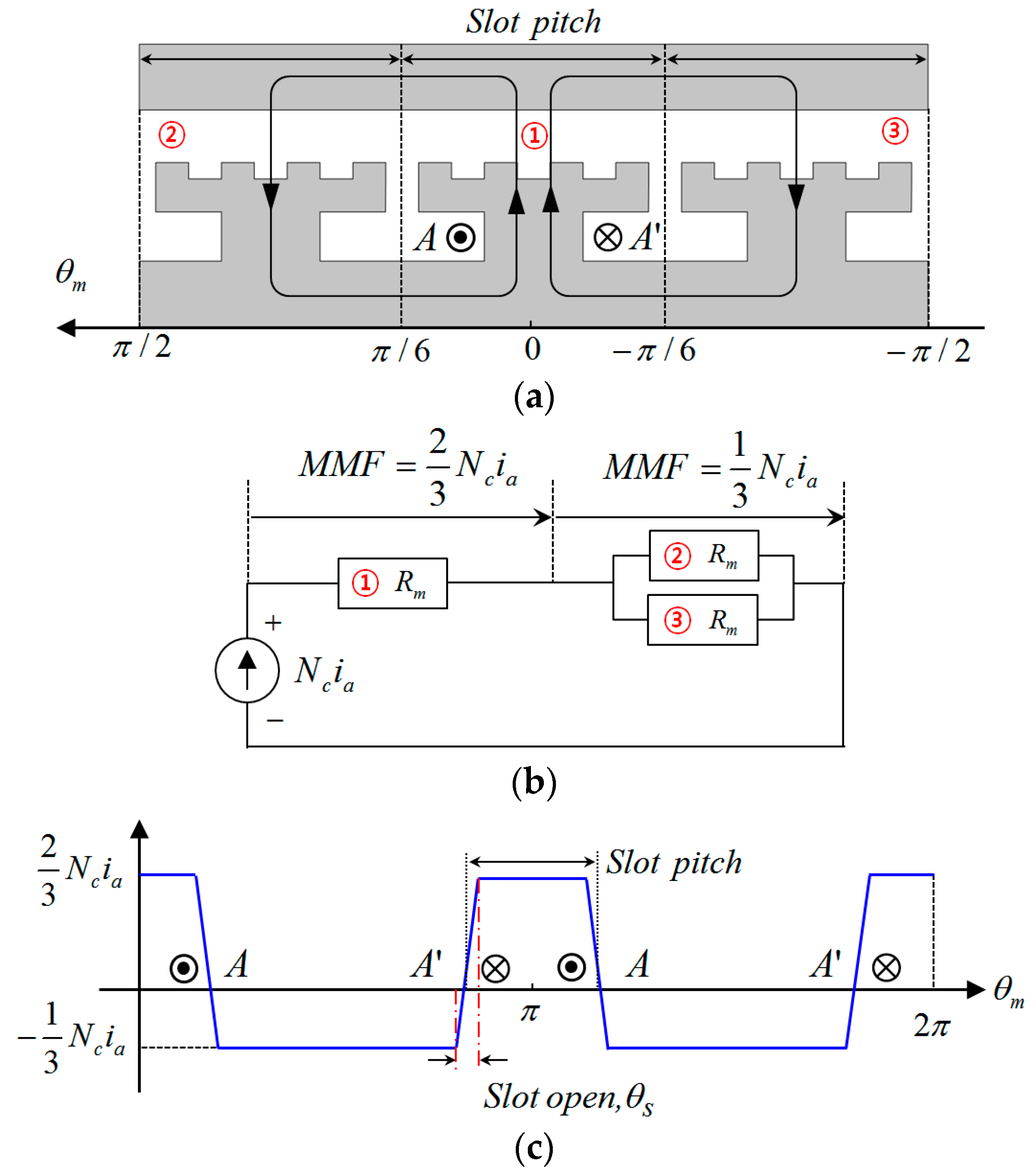

3.1. Winding MMF Distribution

- (1)

- The stator and rotor cores have infinite permeability.

- (2)

- All coils have the same number of turns.

- (3)

- The three-phase currents are symmetric and the sinusoidal waveforms are given by:

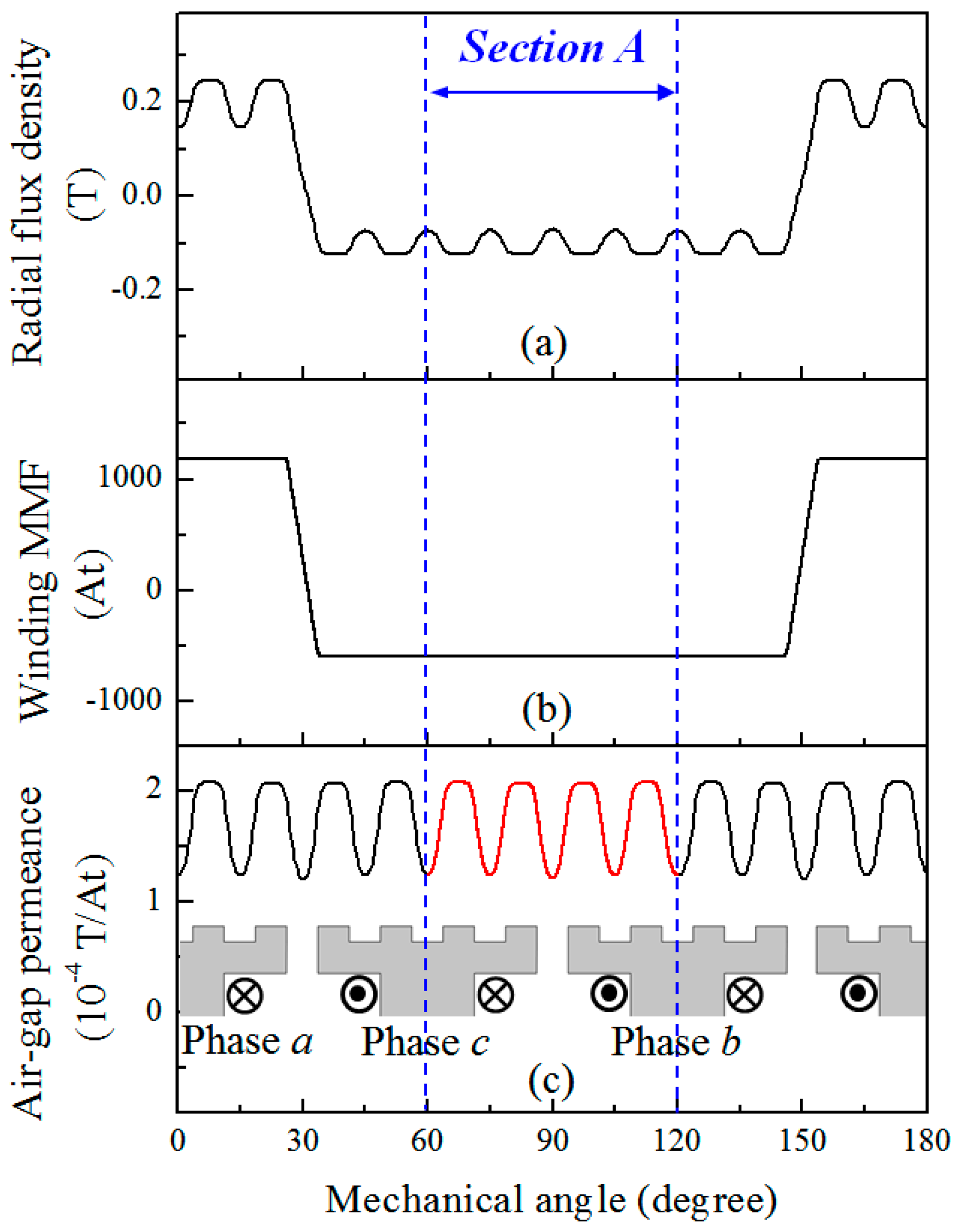

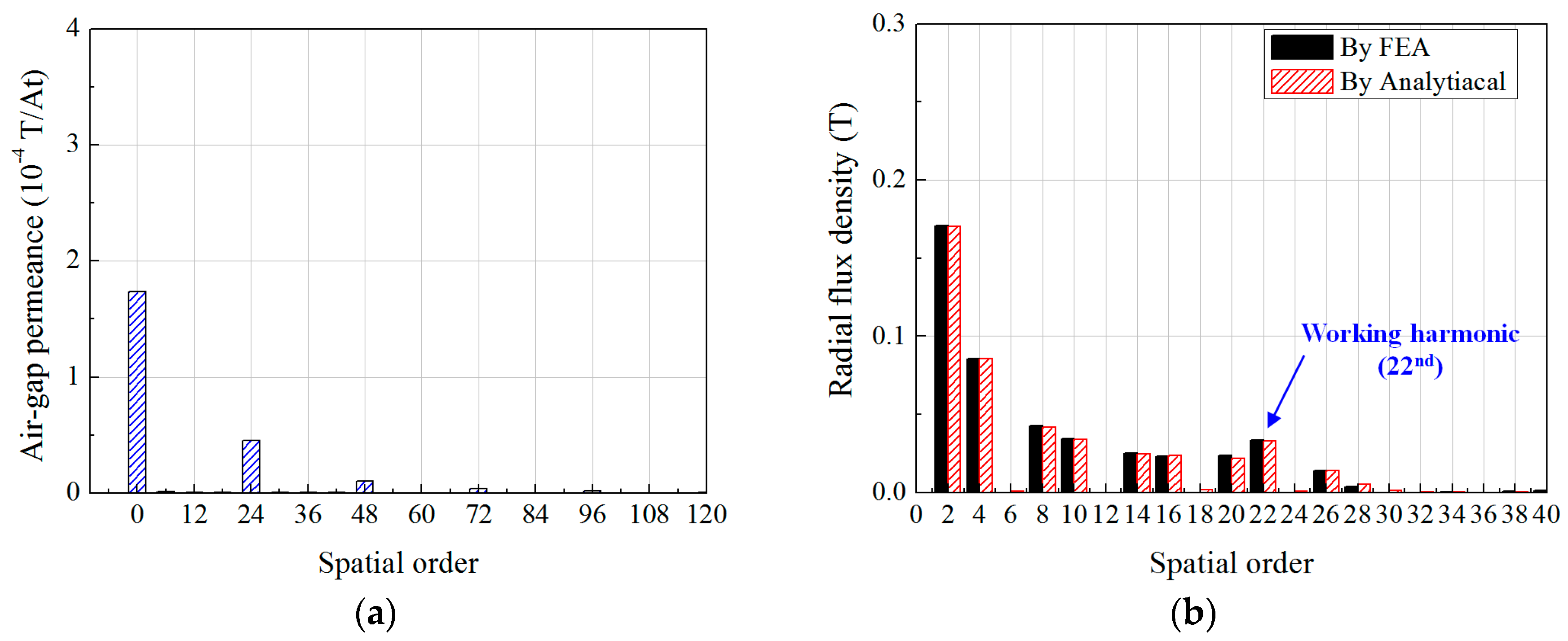

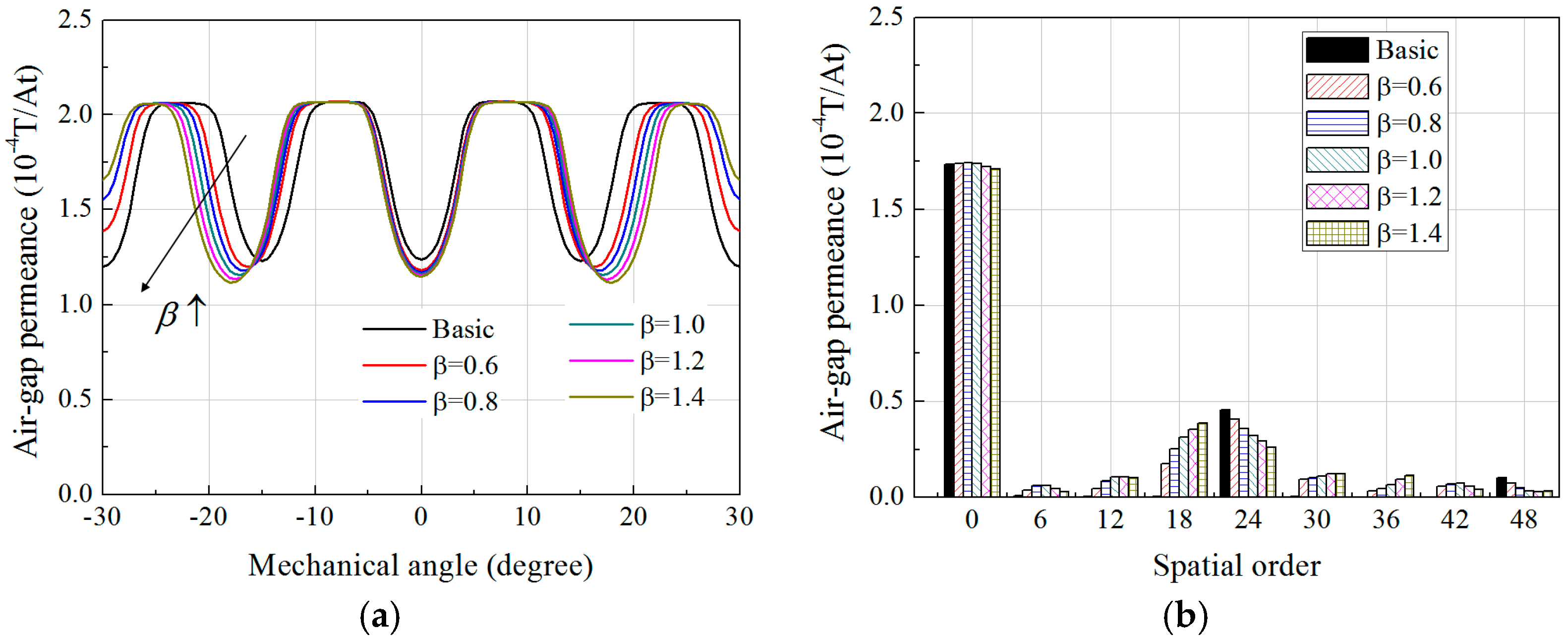

3.2. Air-Gap Permeance Function

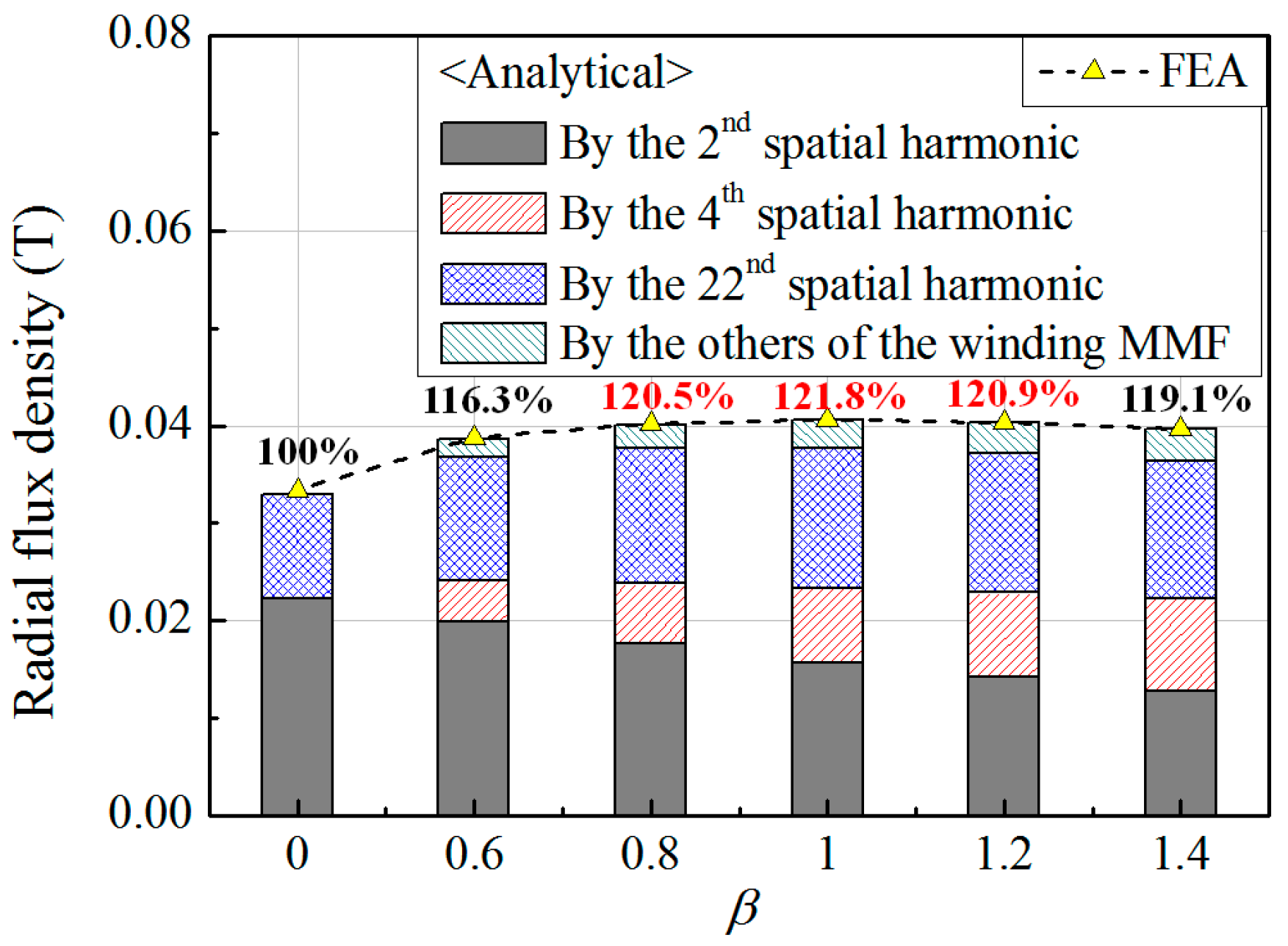

3.3. Effects of The Winding MMF Harmonics

3.4. Design Method for The FMP Shape

4. Performance Analysis

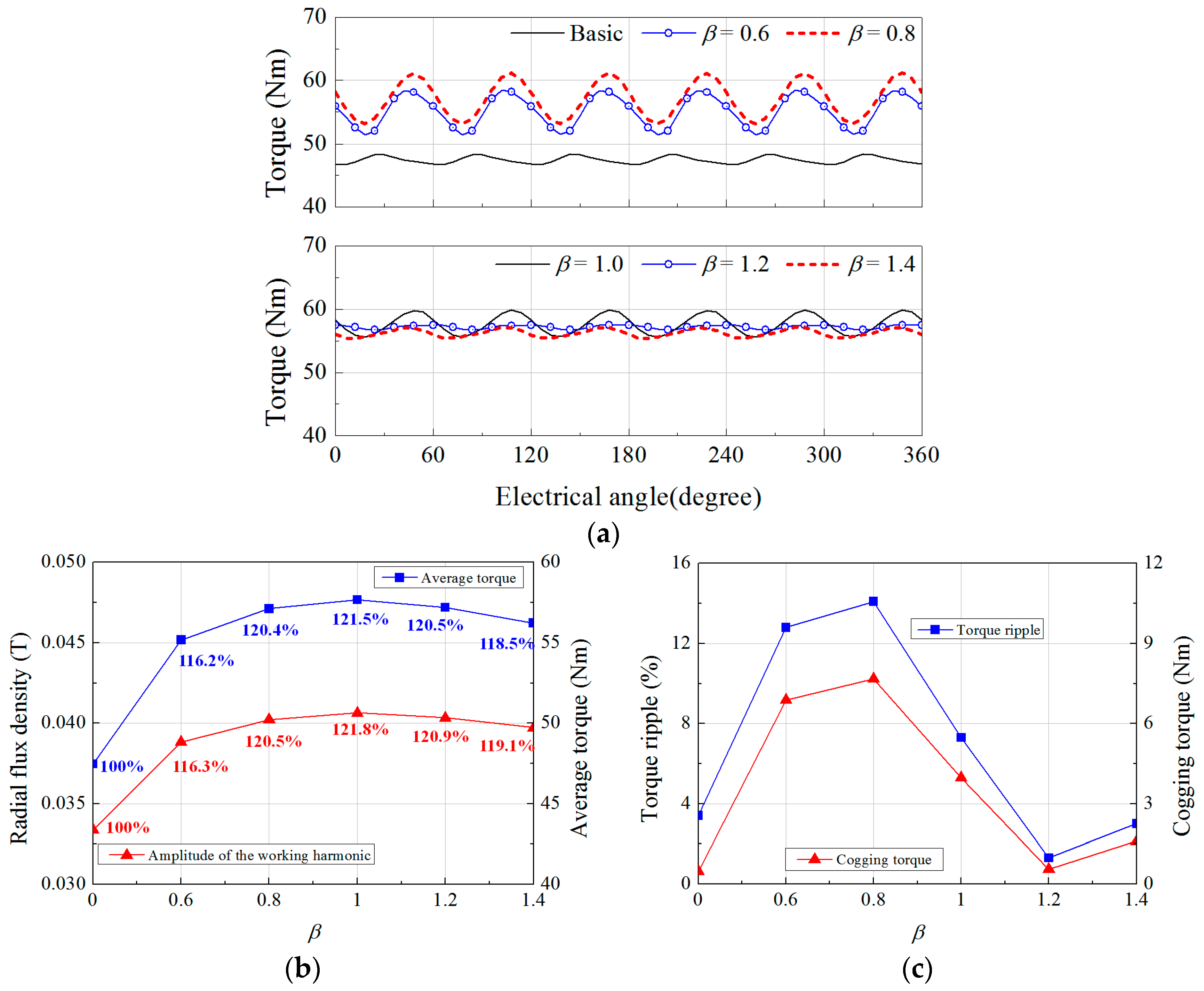

4.1. Torque Characteristics

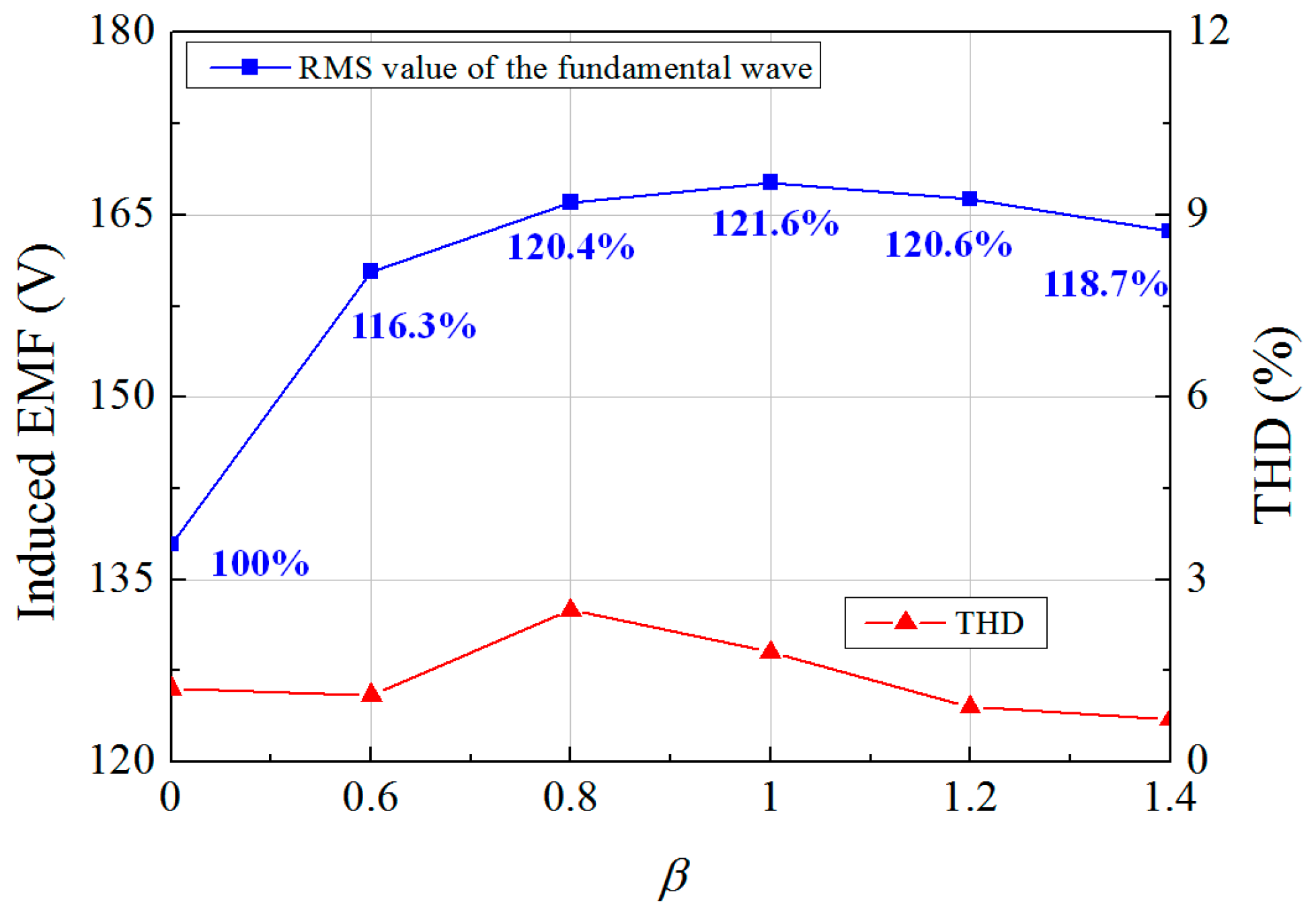

4.2. Induced EMF Characteristics under the No-Load Condition

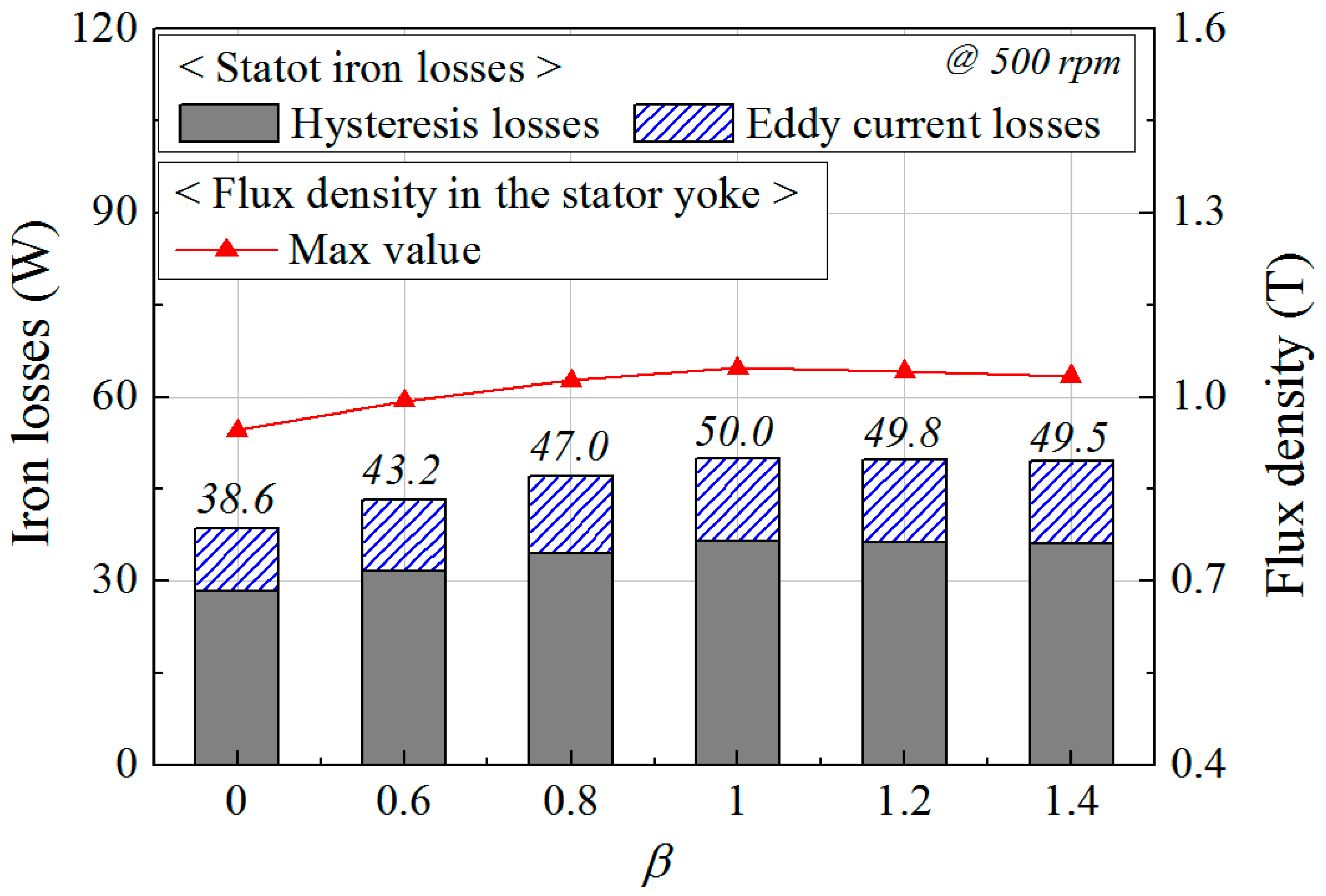

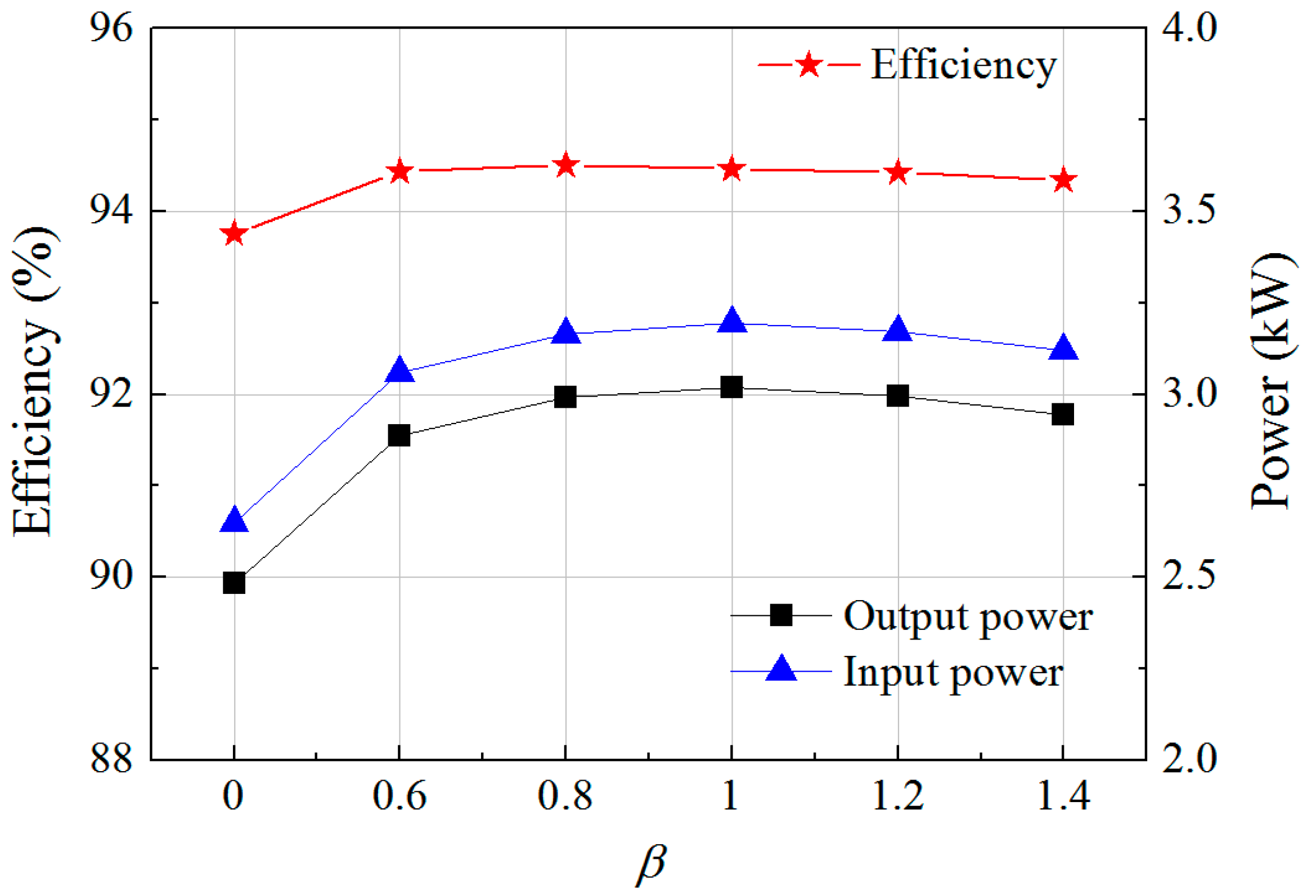

4.3. Efficiency

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Li, J.; Chau, K.T.; Jiang, J.Z.; Liu, C.; Li, W. A new efficient permanent-magnet vernier machine for wind power generation. IEEE Trans. Magn. 2010, 46, 1475–1478. [Google Scholar] [CrossRef]

- Yang, H.; Lin, H.; Zhu, Z.-Q.; Fang, S.; Huang, Y. Dual-consequent-pole vernier memory machine. Energies 2016, 9, 134. [Google Scholar] [CrossRef]

- Liu, G.; Yang, J.; Zhao, W.; Ji, J.; Chen, Q.; Gong, W. Design and analysis of a new fault-tolerant permanent-magnet vernier machine for electric vehicles. IEEE Trans. Magn. 2012, 48, 4176–4179. [Google Scholar] [CrossRef]

- Zhao, F.; Kim, M.S.; Kwon, B.I.; Baek, J.H. A small axial-flux vernier machine with ring-type magnets for the auto-focusing lens drive system. IEEE Trans. Magn. 2016, 52, 1–4. [Google Scholar] [CrossRef]

- Du, Y.; Cheng, M.; Chau, K.T.; Liu, X.; Xiao, F.; Zhao, W. Linear primary permanent magnet vernier machine for wave energy conversion. IET Electr. Power Appl. 2015, 9, 203–212. [Google Scholar] [CrossRef]

- Ho, S.L.; Niu, S.; Fu, W.N. Design and comparison of vernier permanent magnet machines. IEEE Trans. Magn. 2011, 47, 3280–3283. [Google Scholar] [CrossRef]

- Wu, L.; Qu, R.; Li, D.; Gao, Y. Influence of pole ratio and winding pole numbers on performance and optimal design parameters of surface permanent-magnet vernier machines. IEEE Trans. Ind. Appl. 2015, 51, 3707–3715. [Google Scholar] [CrossRef]

- Li, D.; Qu, R.; Xu, W.; Li, J.; Lipo, T.A. Design procedure of dual-stator spoke-array vernier permanent-magnet machines. IEEE Tran. Ind. Appl. 2015, 51, 2972–2983. [Google Scholar] [CrossRef]

- Jang, D.K.; Chang, J.H. Design of a vernier machine with pm on both sides of rotor and stator. IEEE Trans. Magn. 2014, 50, 877–880. [Google Scholar] [CrossRef]

- Li, X.; Chau, K.T.; Cheng, M. Analysis, design and experimental verification of a field-modulated permanent-magnet machine for direct-drive wind turbines. IET Electr. Power Appl. 2015, 9, 150–159. [Google Scholar] [CrossRef]

- Vukotić, M.; Miljavec, D. Design of a permanent-magnet flux-modulated machine with a high torque density and high power factor. IET Electr. Power Appl. 2016, 10, 36–44. [Google Scholar] [CrossRef]

- Zhu, Z.Q.; Howe, D. Instantaneous magnetic field distribution in brushless permanent magnet DC motors. Iii. Effect of stator slotting. IEEE Trans. Magn. 1993, 29, 143–151. [Google Scholar] [CrossRef]

- Zhu, Z.Q.; Howe, D. Influence of design parameters on cogging torque in permanent magnet machines. IEEE Trans. Energy Convers. 2000, 15, 407–412. [Google Scholar] [CrossRef]

- Fornasiero, E.; Bianchi, N.; Bolognani, S. Slot harmonic impact on rotor losses in fractional-slot permanent-magnet machines. IEEE Trans. Ind. Electron. 2012, 59, 2557–2564. [Google Scholar] [CrossRef]

- Toba, A.; Lipo, T.A. Generic torque-maximizing design methodology of surface permanent-magnet vernier machine. IEEE Trans. Ind. Appl. 2000, 36, 1539–1546. [Google Scholar]

- Kim, B.; Lipo, T.A. Operation and design principles of a PM vernier motor. IEEE Trans. Ind. Appl. 2014, 50, 3656–3663. [Google Scholar] [CrossRef]

- Yang, J.; Liu, G.; Zhao, W.; Chen, Q.; Jiang, Y.; Sun, L.; Zhu, X. Quantitative comparison for fractional-slot concentrated-winding configurations of permanent-magnet vernier machines. IEEE Trans. Magn. 2013, 49, 3826–3829. [Google Scholar] [CrossRef]

- Atallah, K.; Calvwelwy, S.D.; Howe, D. Design, analysis and realization of a high-performance mangetic gear. IET Electr. Power Appl. 2004, 151, 135–143. [Google Scholar] [CrossRef]

- Clayton, A.E. A mathematical development of the theory of the magnetomotive force of windings. J. Inst. Electr. Eng. 1923, 61, 749–787. [Google Scholar] [CrossRef]

- Bertotti, G. General properties of power losses in soft ferromagnetic materials. IEEE Trans. Magn. 1988, 24, 621–630. [Google Scholar] [CrossRef]

| Spatial Harmonic Order of the Winding MMF, mpir | Spatial Harmonic Order of the Permeance, v | By Term of Equation (2) | The Modulated Harmonic | |

|---|---|---|---|---|

| Spatial Order | Speed | |||

| 4 | 26 | 3rd | 22 | −4/22 × ωir |

| 12 | 10 | 2nd | +12/22 × ωir | |

| 20 | 2 | 2nd | +20/22 × ωir | |

| 28 | 6 | 3rd | −28/22 × ωir | |

| Spatial Harmonic Order of the Winding MMF, mps | Spatial Harmonic Order of the Permeance, k | By Term of Equation (8) | The Modulated Harmonic | |

|---|---|---|---|---|

| Spatial Order | Speed | |||

| 2 | 24 | 5th | 22nd | −ωe/22 |

| 4 | 18 | 4th | ||

| 8 | 30 | 5th | ||

| 10 | 12 | 4th | ||

| 14 | 36 | 5th | ||

| 16 | 6 | 4th | ||

| 20 | 42 | 5th | ||

| 22 | 0 | 2nd | ||

| Winding MMF Harmonics | Air-Gap Permeance Harmonics | Working Harmonic (22nd ) | |||

|---|---|---|---|---|---|

| Spatial Order | Fourier Coefficient (At) | Spatial Order | Fourier Coefficient (T/At) | Fourier Coefficient (T) | Percent (%) |

| 2 | 979.61 | 24 | −4.5 × 10−5 | −0.02225 | 66.7 |

| 4 | 485.62 | 18 | 0 | 0 | 0 |

| 8 | −234.54 | 30 | 0 | 0 | 0 |

| 10 | −182.75 | 12 | 0 | 0 | 0 |

| 14 | 121.51 | 36 | 0 | 0 | 0 |

| 16 | 101.56 | 6 | 0 | 0 | 0 |

| 20 | −72.49 | 42 | 0 | 0 | 0 |

| 22 | −61.50 | 0 | 1.7 × 10−4 | −0.01067 | 32.0 |

| Sum | −0.03280 | 98.7 | |||

| The FEA result | −0.03336 | 100 | |||

| β | Design Variables (Degree) | ||||

|---|---|---|---|---|---|

| θ1 | θ2 | θ3 | θ4 | θs | |

| 0 (Basic model) | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 |

| 0.6 | 8.27 | 8.21 | 7.93 | 6.9 | 5.64 |

| 0.8 | 8.44 | 8.4 | 8.23 | 7.02 | 4.26 |

| 1.0 | 8.57 | 8.57 | 8.57 | 6.82 | 3.5 |

| 1.2 | 8.69 | 8.72 | 8.92 | 6.27 | 3.5 |

| 1.4 | 8.78 | 8.84 | 9.24 | 5.78 | 3.5 |

| Winding MMF Harmonics | Air-Gap Permeance Harmonics | Working Harmonic (22nd ) | |||

|---|---|---|---|---|---|

| Spatial Order | Fourier Coefficient (At) | Spatial Order | Fourier Coefficient (T/At) | Fourier Coefficient (T) | Percent (%) |

| 2 | 981.81 | 24 | −3.2 × 10−5 | −0.01570 | 38.6 |

| 4 | 489.99 | 18 | −3.1 × 10−5 | −0.00768 | 18.9 |

| 8 | −243.17 | 30 | 1.1 × 10−5 | −0.00132 | 3.3 |

| 10 | −193.44 | 12 | 1.1 × 10−5 | −0.00101 | 2.5 |

| 14 | 136.11 | 36 | −6.5 × 10−6 | −0.00044 | 1.1 |

| 16 | 117.97 | 6 | −6.4 × 10−6 | −0.00038 | 0.9 |

| 20 | −92.24 | 42 | −7.1 × 10−6 | 0.00033 | −0.8 |

| 22 | −82.74 | 0 | 1.7 × 10−4 | −0.01437 | 35.4 |

| Sum | −0.04057 | 99.9 | |||

| The FEA result | −0.04063 | 100 | |||

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jang, D.; Chang, J. Influences of Winding MMF Harmonics on Torque Characteristics in Surface-Mounted Permanent Magnet Vernier Machines. Energies 2017, 10, 580. https://doi.org/10.3390/en10040580

Jang D, Chang J. Influences of Winding MMF Harmonics on Torque Characteristics in Surface-Mounted Permanent Magnet Vernier Machines. Energies. 2017; 10(4):580. https://doi.org/10.3390/en10040580

Chicago/Turabian StyleJang, Daekyu, and Junghwan Chang. 2017. "Influences of Winding MMF Harmonics on Torque Characteristics in Surface-Mounted Permanent Magnet Vernier Machines" Energies 10, no. 4: 580. https://doi.org/10.3390/en10040580