Theoretical and Experimental Evaluation of the Temperature Distribution in a Dry Type Air Core Smoothing Reactor of HVDC Station

Abstract

:1. Introduction

2. Methods

2.1. Governing Equations

2.2. Basic Parameters

2.3. Hypothetical Conditions

- (1)

- This research focuses on the temperature rise in the encapsulation of the main body of the reactor. The calculation was aimed to examine the air flow and temperature distribution in the reactor.

- (2)

- The effect of the braces, spider arms, and spacers were ignored in modeling. The structure of the reactor main body exhibited circumferential symmetry, which indicates that the symmetry plane of the encapsulation, rain cover, acoustic enclosure, and silencer of the calculation model are heat insulation surfaces.

- (3)

- As the temperature differences and heat radiation ratio were small, the encapsulation transferred inner heat primarily through convection and conduction. The outer surfaces of the rain cover and acoustic enclosure were air-cooled through convection and radiation heat transfer and have a surface emissivity of 0.9 [11].

- (4)

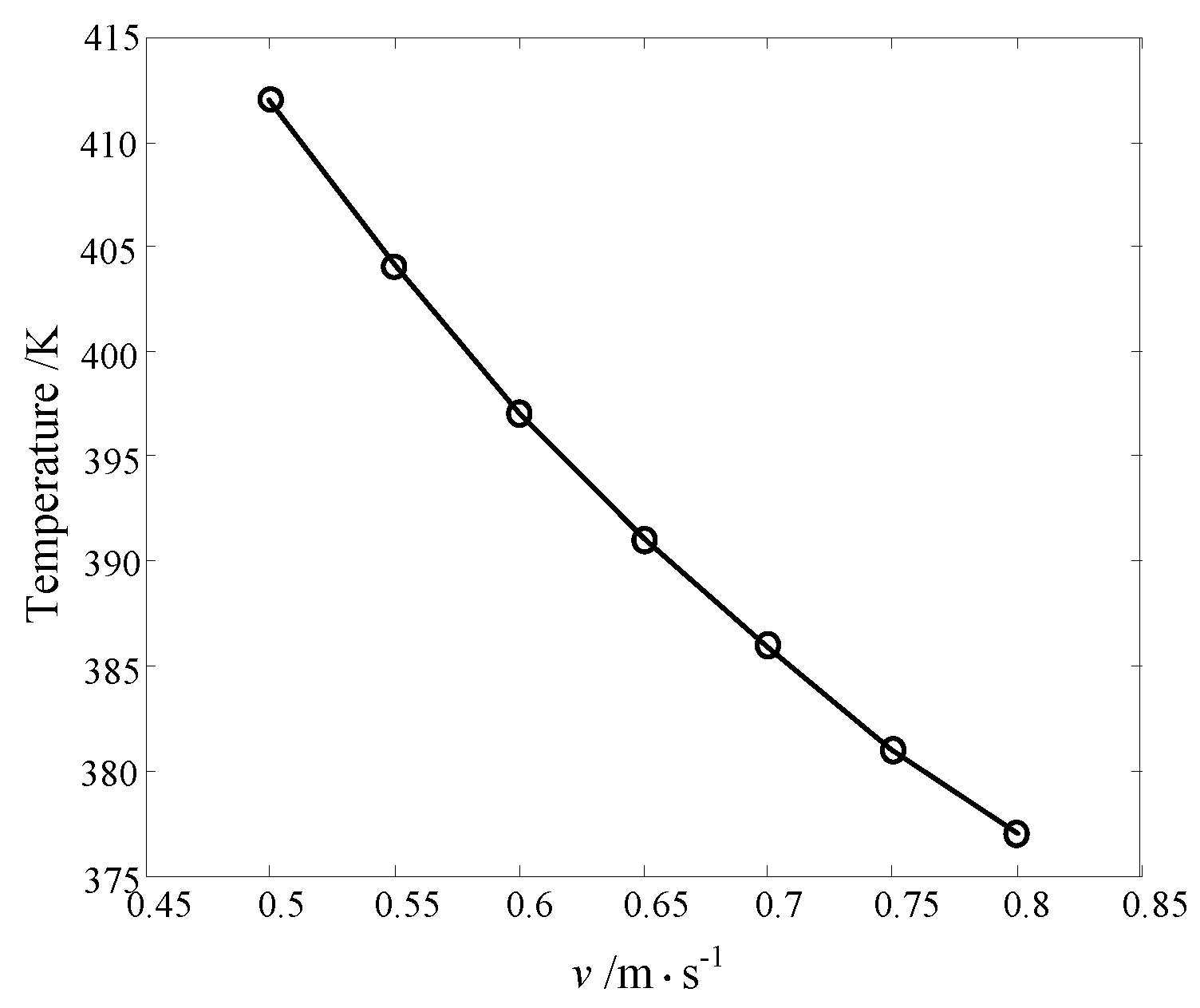

- The Reynolds number inside the silencer was represented as follows [20]:where the internal diameter of acoustic enclosure d equals 1.2 m, air flow velocity u equals 0.65 m/s, and the kinematic viscosity of air υ equals 16.96 × 10−6 m2/s. Thus, a turbulence model was employed to determine the solution for the coupled fluid and thermal field of the reactor.

2.4. Boundary Conditions

- (1)

- The environment temperature during the testing process was 33.4 °C (306.55 K).

- (2)

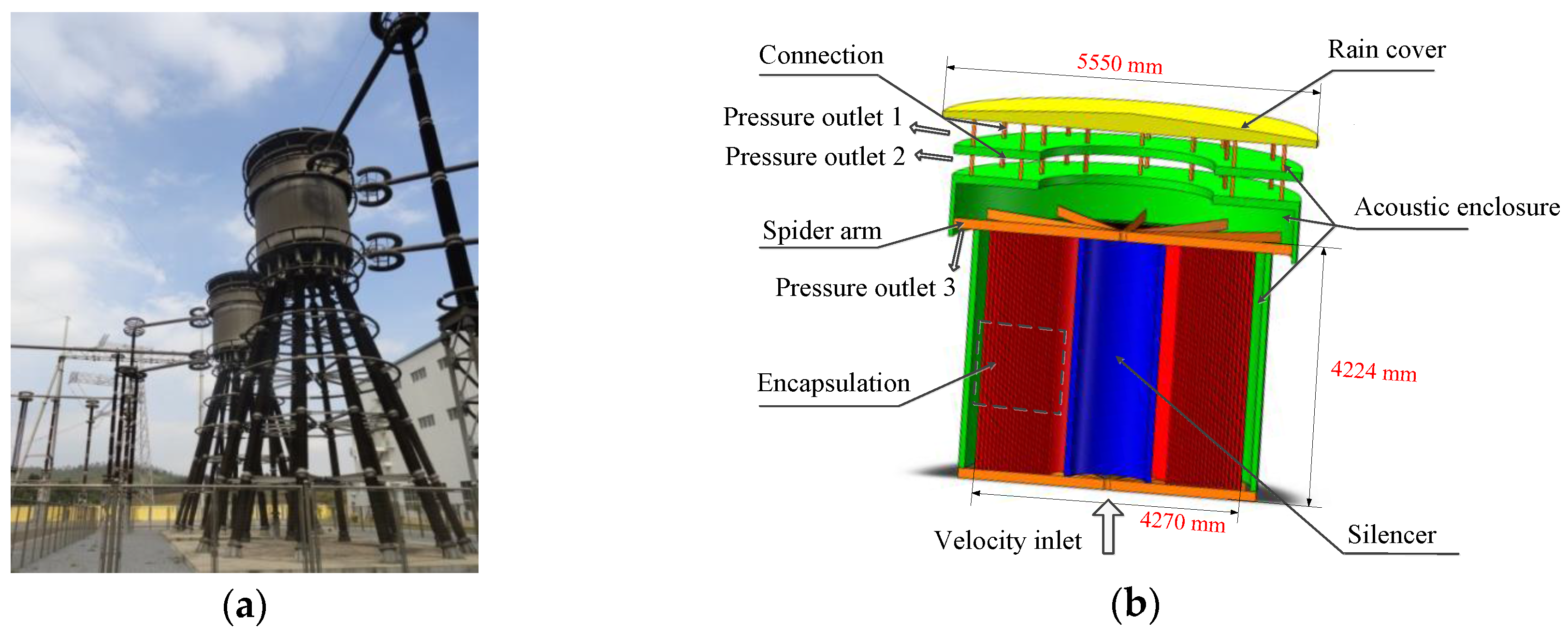

- The air in the reactor was considered to be an incompressible fluid in natural convection. The pressure inlet boundary was the lower-end surface of the encapsulation and the acoustic enclosure. The three interfaces between the rain cover, acoustic enclosure and ambient air are set to be the pressure outlet boundary (Figure 1). The relative pressure of the pressure outlet boundary was 0 Pa and the inlet flow velocity was 0.65 m/s.

- (3)

- The natural convection equations of vertical flat and vertical cylindrical convection in heat transfer theory were used to calculate the convective heat transfer between the air and the outer surfaces of the rain cover and the acoustic enclosure [20]:where Gr is the Grashof number; Nu is the Nusselt number; Pr is the Prandlt number; constant C and index n are determined by Gr value; g is the gravitational acceleration, m/s2; αV is the expansion coefficient, 1/K; υ is the kinematic viscosity of air, m2/s; ∆T refers to the temperature difference between the air and the wall, K; L is the characteristic length (i.e., height) of the acoustic enclosure, m; and h is the convective heat transfer coefficient, W/(m2·K).

2.5. Grid Model

3. Calculation Results

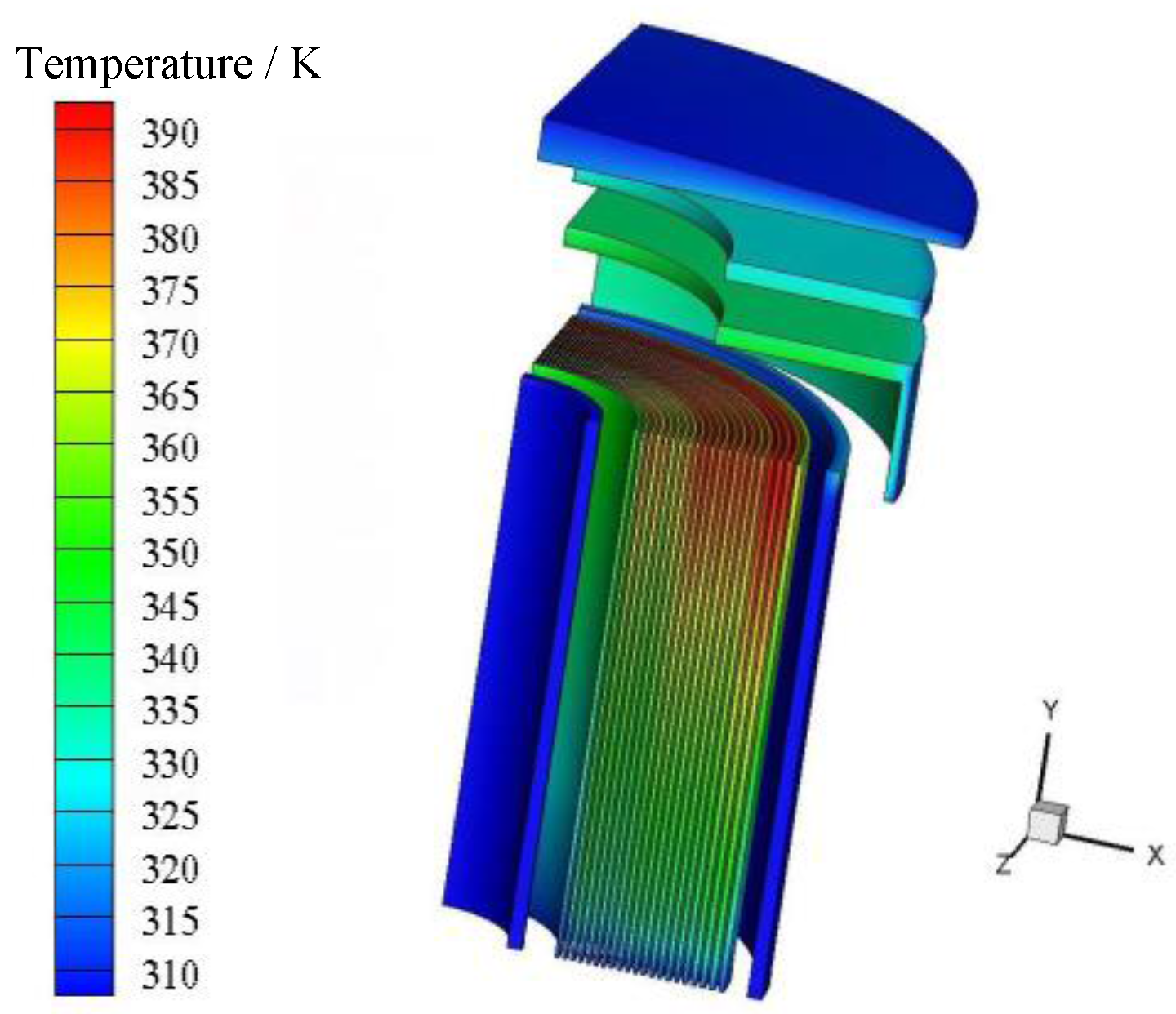

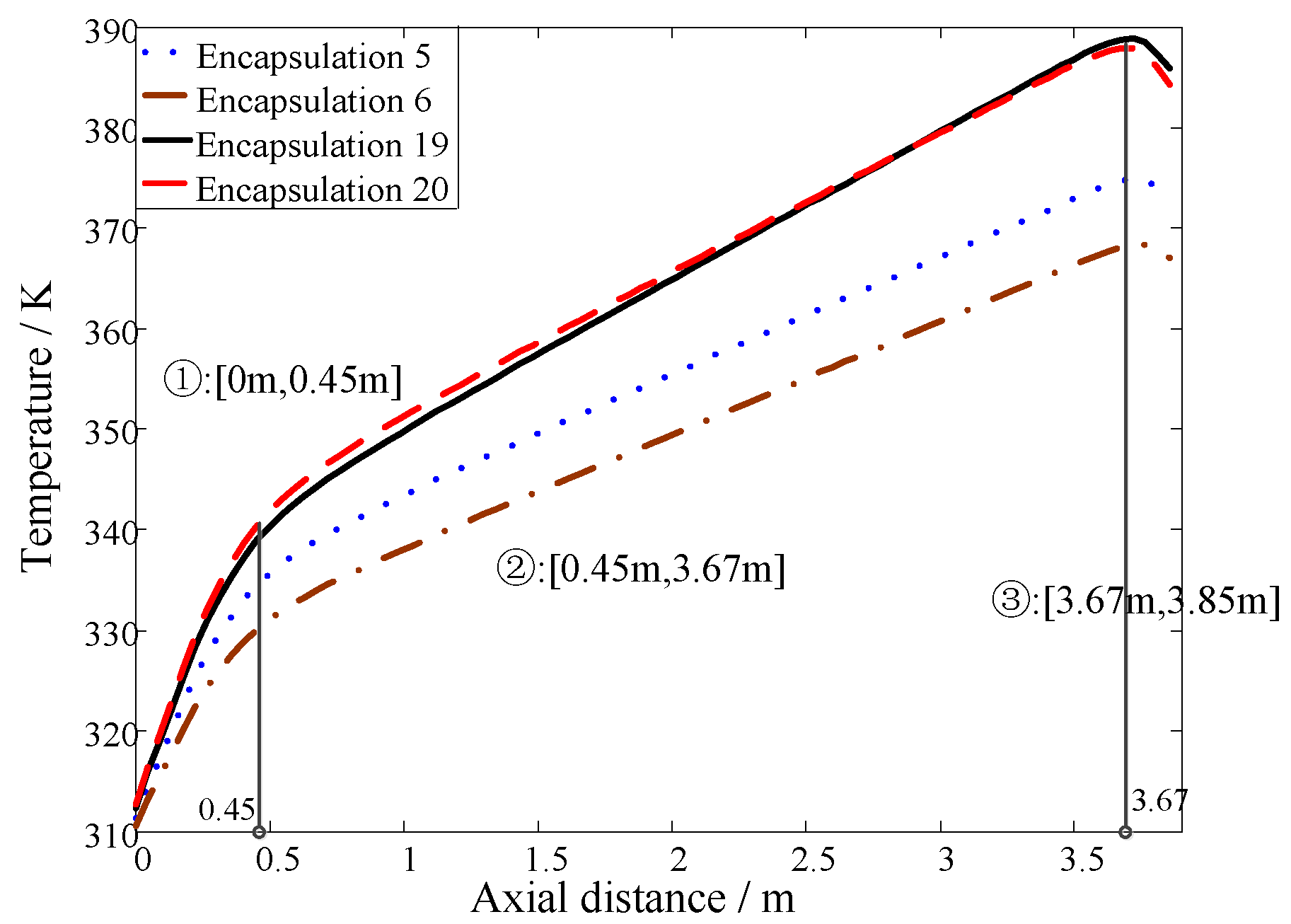

3.1. Analysis of the Temperature Field

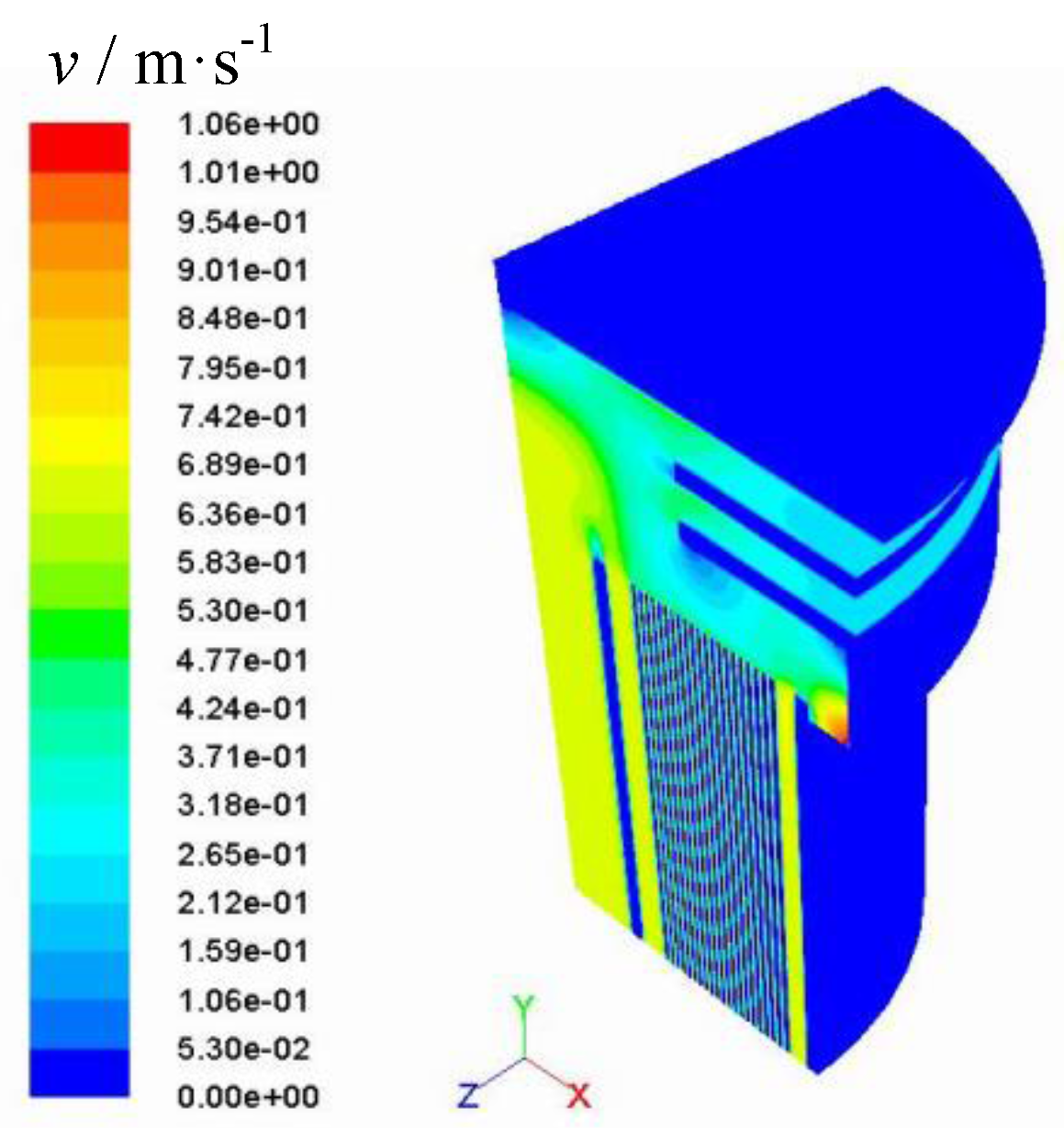

3.2. Analysis of the Fluid Field

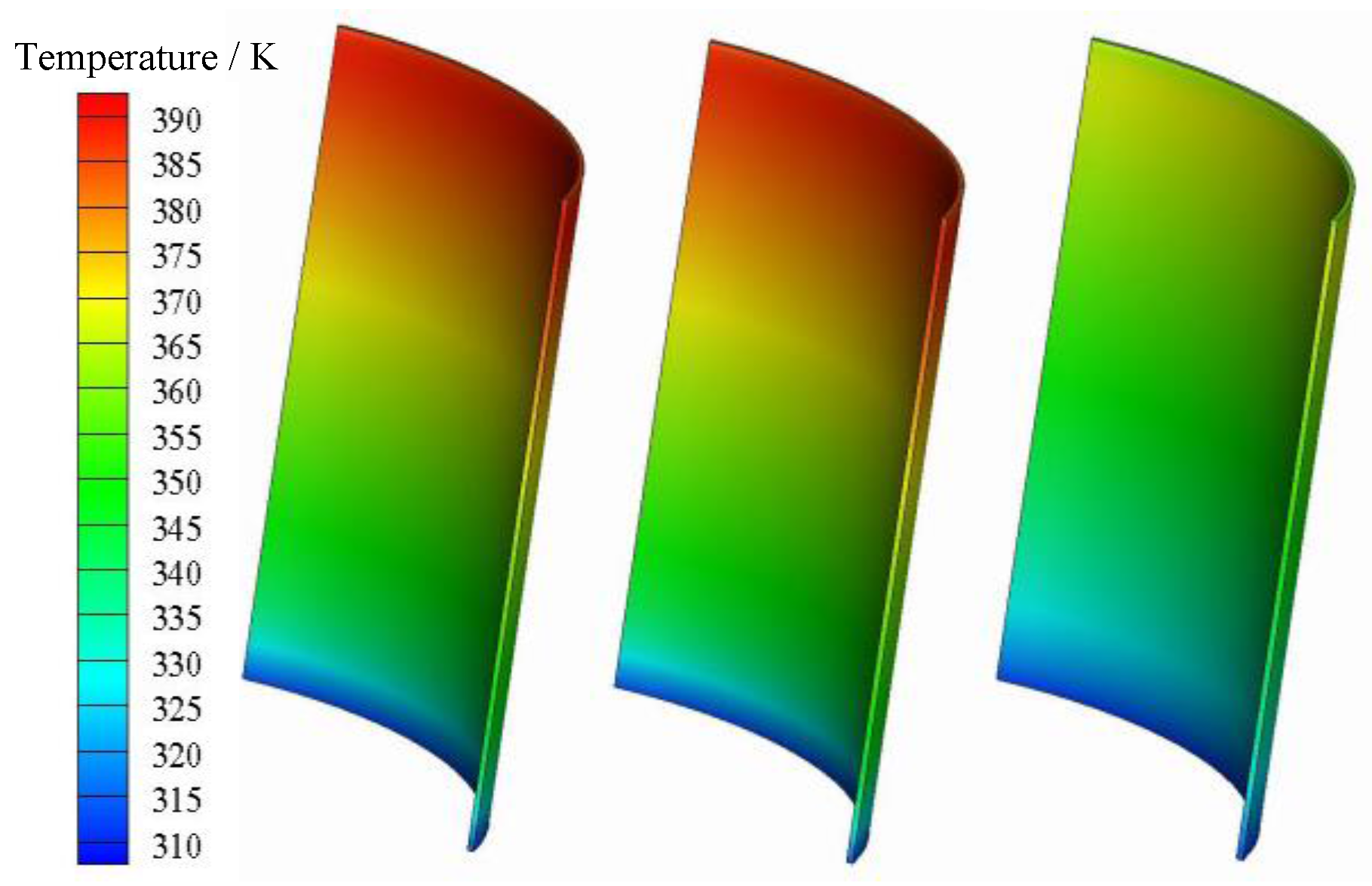

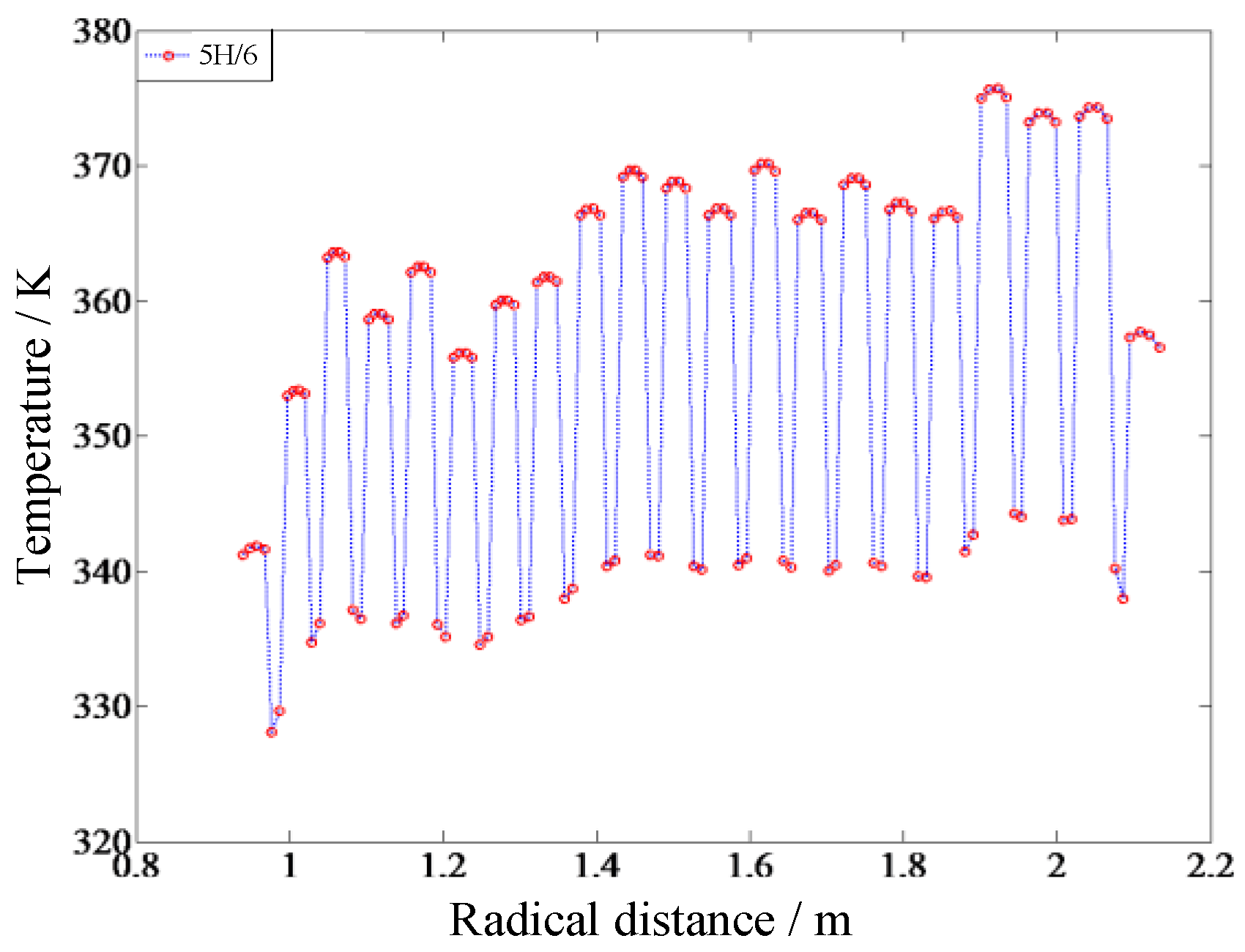

3.3. Distribution of the Encapsulation Temperatures

4. Temperature Rise Test and Result Analysis

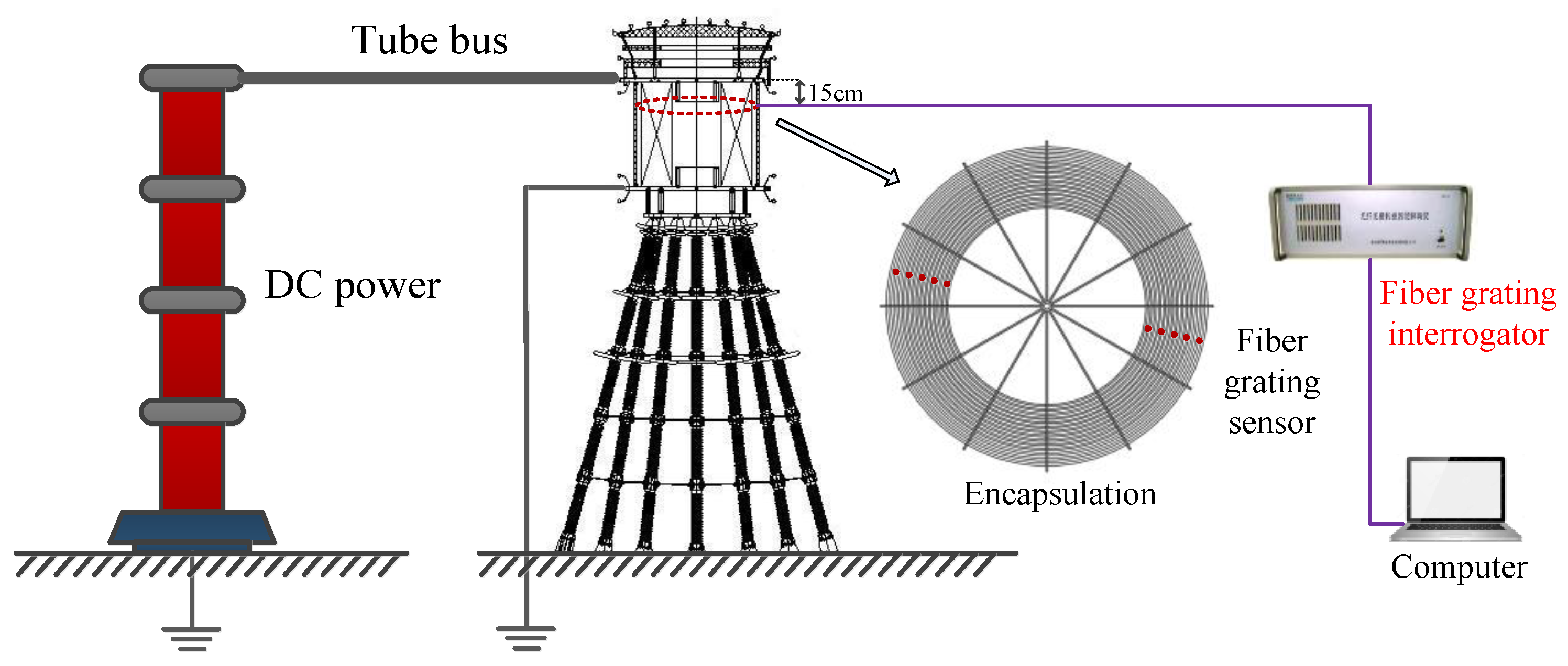

4.1. Testing Approaches

4.2. Test Results and Verification of the Calculation

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| ρ | Density of the fluid, kg/m3 |

| x, y, z | Cartesian coordinates, m |

| u, v, w | Vectors of airflow velocity in Cartesian coordinates, m/s |

| υ | Fluid kinematic viscosity, m2/s |

| p | Fluid pressure, Pa |

| λ | Thermal conductivity, W/(m·K) |

| Cp | Specific heat, J/(kg·K) |

| ST | Fluid source term |

| Ts | Solid temperature, K |

| Tf | Fluid temperature, K |

| λx, λy, λz | Thermal conductivity in x, y, and z direction, W/(m·K) |

| QV | Heat generation rate of unit volume, W/m3 |

| h | Heat transfer coefficient of the solid surface, W/(m2·K) |

| Aj | Adiabatic surface |

| As | Heat dissipating surface |

| Gr | Grashof number |

| Nu | N usselt number |

| Pr | Prandlt number |

| g | Gravitational acceleration, m/s2 |

| αV | Expansion coefficient, 1/K; |

| υ | Kinematic viscosity of air, m2/s |

| ∆T | Temperature difference between the air and the wall, K |

| L | Characteristic length (i.e., height) of the acoustic enclosure, m |

References

- Dry-Type Air-Core Smoothing Reactors for HVDC Applications; GB/T 25092-2010; General Administration of Quality Supervision, Inspection and Quarantine of the People′s Republic of China, Standards Publishing House: Beijing, China, 2010. (In Chinese)

- Yu, Q.; Sebo, S.A. Accurate evaluation of the magnetic field strength of large substation air-core reactor coils. IEEE Trans. Power Deliv. 1998, 13, 1114–1119. [Google Scholar]

- Bottauscio, O.; Chiampi, M.; Manzin, A. Transient analysis of thin layers for the magnetic field shielding. IEEE Trans. Magn. 2006, 42, 871–874. [Google Scholar] [CrossRef]

- Conway, J.T. Inductance calculations for circular coils of rectangular cross section and parallel axes using Bessel and Struve functions. IEEE Trans. Magn. 2010, 46, 75–81. [Google Scholar] [CrossRef]

- Giaccone, L.; Ragusa, C.; Khan, O.; Manca, M. Fast magnetic field mode ling for shielding systems. IEEE Trans. Magn. 2013, 49, 4128–4131. [Google Scholar] [CrossRef]

- Burke, P.E.; Fawzi, T.H. Effect of eddy losses on design and modeling of air-cored reactors. IEEE Trans. Magn. 1991, 27, 5001–5003. [Google Scholar] [CrossRef]

- Xia, T.-W.; Cao, Y.D.; Jin, W.; Gao, Y.Z. The analysis of temperature field in dry air core reactor. High Volt. Eng. 1999, 25, 86–88. (In Chinese) [Google Scholar]

- Wei, X.-L. Study of Designing Theory for Large Air-Core Power Reactors; Harbin Institute of Technology: Harbin, China, 2002. (In Chinese) [Google Scholar]

- Nogawa, S.; Kuwata, M.; Miyagi, D.; Hayashi, T.; Tounai, H.; Nakau, T.; Takahashi, N. Study of eddy-current loss reduction by slit in reactor core. IEEE Trans. Magn. 2005, 41, 2024–2027. [Google Scholar] [CrossRef]

- Kurita, N.; Onda, K.; Nakanoue, K.; Inagaki, K. Loss estimation method for three-phase AC reactors of two types of structures using amorphous wound cores in 400-kVA UPS. IEEE Trans. Power Electron. 2014, 29, 3657–3668. [Google Scholar] [CrossRef]

- Liu, Z.-G.; Geng, Y.-S.; Wang, J.-H.; Chen, D.-G.; Wu, A.-B. Design and analysis of new type air-core reactor based on coupled fluid-thermal field calculation. Trans. China Electrotech. Soc. 2003, 18, 59–63. (In Chinese) [Google Scholar]

- Wang, Q.-W.; Chen, Q.-Y.; Zeng, M. A CFD-Taguchi combined method for numerical investigation of natural convection cooling performance of air-core reactor with noise reducing cover. Numer. Heat Transf. Part A 2009, 55, 1116–1130. [Google Scholar] [CrossRef]

- Dai, Z.-B. Loss Calculation and Temperature Field Research of Air Core Reactor; Shenyang University of Technology: Shenyang, China, 2012. (In Chinese) [Google Scholar]

- Kim, J.K.; Hahn, S.C.; Park, K.Y.; Oh, Y.H. Temperature rise prediction of EHV GIS bus bar by coupled magneto thermal finite element method. IEEE Trans. Magn. 2005, 41, 1636–1639. [Google Scholar]

- Ortiz, C.; Skorek, A.; Lavoie, M.; Benard, P. Parallel CFD analysis of conjugate heat transfer in a dry-type transformer. IEEE Trans Ind. Appl. 2009, 45, 1530–1534. [Google Scholar] [CrossRef]

- Smolka, J.; Nowak, A.J. Shape optimization of coils and cooling ducts in dry-type transformers using computational fluid dynamics and genetic algorithm. IEEE Trans. Magn. 2011, 47, 1726–1731. [Google Scholar] [CrossRef]

- Li, W.-L.; Zhang, Y.; Chen, Y.-H. Calculation and analysis of heat transfer coefficients and temperature fields of air-cooled large hydro-generator rotor excitation windings. IEEE Trans. Energy Convers. 2011, 26, 946–952. [Google Scholar]

- Ahn, H.M.; Kim, J.K.; Oh, H.Y.; Song, K.D.; Hahn, S.C. Multi-physics analysis for temperature rise prediction of power transformer. J. Electr. Eng. Technol. 2014, 9, 114–120. [Google Scholar] [CrossRef]

- Deng, Q.; Li, Z.-B.; Yin, X.-G.; Yuan, Z. Steady thermal field simulation of forced air-cooled colunm-type air-core reactor. High Volt. Eng. 2013, 39, 839–844. [Google Scholar]

- Tao, W.-Q. Numerical Heat Transfer, 2nd ed.; Xi’an Jiaotong University Press: Xi’an, China, 2001. (In Chinese) [Google Scholar]

- Ding, S.; Ge, Y.; Sun, Z.; Liu, H.; Guo, B. Calculation and analysis of fluid field and temperature field for high-altitude type doubly-fed wind generators. Proc. CSEE 2012, 32, 74–79. (In Chinese) [Google Scholar]

- International Electrotechnical Commission (IEC). International Standard Power Transformers–Part 6: Reactors; 60076–6; IEC: Geneva, Switzerland, 2007. [Google Scholar]

- Rand, W. Introduction to Robust Estimation and Hypothesis Testing; Academic Press: Cambridge, MA, USA, 2011. [Google Scholar]

| Materials | Air | Encapsulation | Epoxy-Glass |

|---|---|---|---|

| Thermal conductivity/(W∙m−1∙K−1) | 0.0242 | 2 | 0.4 |

| Density/(kg·m−3) | incompressible gas (density varies with temperature) | 2719 | 2000 |

| Dynamic coefficient of viscosity/(kg∙m−1∙s) | 1.7894 × 10−5 | - | - |

| Specific heat/(J kg−1·K−1) | 1006.43 | 871 | 535 |

| Encapsulation Number | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| Heat Density (W/m3) | 8505.70 | 11,203.07 | 13,556.48 | 10,600.52 | 12,238.34 | 10,367.21 | 11,991.10 |

| Encapsulation Number | 8 | 9 | 10 | 11 | 12 | 13 | 14 |

| Heat Density (W/m3) | 11,135.47 | 12,622.39 | 12,850.74 | 12,626.13 | 11,083.75 | 12,345.76 | 10,682.18 |

| Encapsulation Number | 15 | 16 | 17 | 18 | 19 | 20 | 21 |

| Heat Density (W/m3) | 11,746.26 | 11,235.45 | 10,071.47 | 11,282.76 | 10,190.63 | 10,118.61 | 8511.31 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Chen, X.; Pan, Z.; Lu, H.; Wen, X.; Jiang, Z.; Chen, B.; Chen, T. Theoretical and Experimental Evaluation of the Temperature Distribution in a Dry Type Air Core Smoothing Reactor of HVDC Station. Energies 2017, 10, 623. https://doi.org/10.3390/en10050623

Wang Y, Chen X, Pan Z, Lu H, Wen X, Jiang Z, Chen B, Chen T. Theoretical and Experimental Evaluation of the Temperature Distribution in a Dry Type Air Core Smoothing Reactor of HVDC Station. Energies. 2017; 10(5):623. https://doi.org/10.3390/en10050623

Chicago/Turabian StyleWang, Yu, Xiaoyue Chen, Zhuohong Pan, Hailiang Lu, Xishan Wen, Zhipeng Jiang, Bin Chen, and Tuteng Chen. 2017. "Theoretical and Experimental Evaluation of the Temperature Distribution in a Dry Type Air Core Smoothing Reactor of HVDC Station" Energies 10, no. 5: 623. https://doi.org/10.3390/en10050623