1. Introduction

The high-speed development of industrial products and goods in the world has caused “technology” to be considered as a crucial competitive advantage for most large organizations. In general, there are two ways to acquire technology assets by a firm. These are: import (technology transfer) and production (technology commercialization by in-house research and development (R&D)) [

1]. Though in-house R&D is a good strategy for organizations with sufficient technological capabilities and finances, it is often time-consuming, expensive, and risky as it is impossible to take back the efforts in case of failure [

2]. In recent years, developing countries have considerably tended to promote their technological and innovative capabilities, labour efficacy, and economic growth rate through importing high-tech equipment owned and operated by developed countries. This increasing attempt to transfer modern production facilities and instruments from technology owners has offered a number of challenges to organizations. For instance, not all available technology transfer solutions are applicable in high-tech industries; cost or benefit implications of technology transfer solutions are not well captured in markets; technology developers/manufacturers might tend to export their technologies only to organizations with common economic and political interests; no systematic approach is present to assess and prioritize technology transfer solutions and related needs; etc.

The identification, evaluation, and prioritization process of technology transfer strategies for technology importers is very complex due to the presence of numerous decision makers, the qualitative nature of the evaluation process, and the existence of imprecision and uncertainty in the decision making process. For these types of decision-making problems, the technology importer must decide on the most appropriate technology transfer strategy for each piece of equipment or the entire equipment among a set of possible alternatives such as reverse engineering, foreign licensing, turn-key, etc. Moreover, many different goals or comparing criteria (e.g., the investment required to transfer a technology vs. cost of technology R&D, reliability of the technology, political relations between organizations, user-friendliness of the technology for the recipient) must be taken into account for the assessment of the alternatives’ performance. Therefore, technology transfer strategy selection is considered to be a complex decision-making problem.

To solve the technology transfer strategy selection problem, several methods have been introduced by researchers, e.g., benefit cost analysis (BCA) and strengths, weaknesses, opportunities, and threats (SWOT) analysis [

3]. In recent years, the multiple-criteria decision making (MCDM) approach has been quite extensively used to establish the metrics and prioritize the technology acquisition strategies for high-tech products and equipment. In this analysis approach, each alternative is evaluated with respect to all criteria and their associated sub-criteria using a suitable measure. Then, the evaluation ratings are aggregated to obtain a global evaluation for each alternative. Finally, the alternatives are prioritized [

4]. In order to find out the optimum solution, several techniques, e.g., analytic hierarchy process (AHP), analytic network process (ANP), technique for order of preference by similarity to ideal solution (TOPSIS), VIšekriterijumsko KOmpromisno Rangiranje (VIKOR), etc., can be applied (for more, see [

5,

6]). These techniques in practice may use either deterministic, stochastic, fuzzy, or combined models.

AHP is one of the most popular and widely employed MCDM analysis methodologies which was first developed by Professor Saaty in the 1970s [

7] to improve the decision-making process through prioritizing items pair-wise rather than prioritizing all items at once. AHP helps the decision makers to organize the critical aspects of a complex problem into a hierarchical structure through breaking down the problem into its constituent parts. The decision-making process using the AHP technique comprises three steps: (i) developing a hierarchical structure of the problem in terms of the overall goal, criteria, and alternatives; (ii) establishing priorities through pairwise comparisons; and (iii) performing a consistency check to ensure that the judgment is sufficiently consistent. TOPSIS is another practical and useful MCDM technique which was developed by Hwang and Yoon in 1981 [

8] with further developments by Yoon [

9] and Hwang et al. [

10]. This technique is based on the concept that the chosen alternative should have the shortest geometric distance from the positive ideal solution (PIS) and the farthest distance from the negative ideal solution (NIS). The relative closeness of each alternative to the PIS is defined as the distance to the NIS divided by the sum of the distance to the negative and the distance to the PIS. The alternatives are ranked in decreasing order by the closeness index. The TOPSIS procedure consists of the following steps: (i) construction of the normalized decision matrix; (ii) determination of the positive ideal and NIS; (iii) calculation of the separation measures using the

n dimensional Euclidean distance; (iv) calculation of the relative closeness to the ideal solution; and (v) ranking the preference order.

Table 1 presents the distribution of various MCDM models used for selecting the most appropriate technology transfer strategy for various applications, such as biotechnology, petrochemical, ship manufacturing, etc.

Chang and Chen [

11] proposed a fuzzy MCDM algorithm based on the AHP method for technology transfer strategy selection in the area of biotechnology management. The linguistic variables and fuzzy numbers were used to aggregate the decision makers’ subjective assessments about criteria weightings and appropriateness of alternatives. Tsao [

12] developed an interval arithmetic-based fuzzy MCDM approach to choose the most appropriate technology transfer strategy in biotechnology. The authors used fuzzy numbers to represent the ratings of various strategies versus different criteria and the importance weights of different criteria. Albayrak and Erensal [

13] presented a fuzzy AHP method to determine the most appropriate technology transfer option based on macro ergonomics criteria. Lee et al. [

14] used the ANP technique to select the most appropriate acquisition mode for a required technology on the basis of five criteria: capability, strategy, technology, market, and environment. The model obtained priorities of alternatives with consideration of interrelationships among criteria. Hamzei [

15] presented a “decision support system” based on statistical methods and MCDM models for determining an appropriate provider of technology. A case study of a jet unmanned air vehicle (UAV) was provided to illustrate the results. Chehrehpak et al. [

16] proposed a fuzzy AHP method to select the most suitable solution for technology transfer in the gas industry by collecting the opinions of a large number of experts. Mohaghar et al. [

17] used the AHP method to evaluate various technology transfer strategies in the petrochemical industry, including foreign direct investment (FDI), licensing, joint venture, turn-key, and reverse engineering. Radfar [

18] presented a fuzzy TOPSIS approach to identify and prioritize various foreign investment methods for technology transfer in the ship-making industry. Wang et al. [

19] proposed an optimal selection method of process patents for technology transfer, using fuzzy MCDM techniques and a 2-tuple fuzzy linguistic representation model. A case study of aero-engine turbine manufacturing was presented to demonstrate the applicability of the proposed method. Wibowo and Grandhi [

20] evaluated and selected the most suitable wastewater treatment technology using a fuzzy MCDM approach based on the TOPSIS technique.

In order to improve the strengths and eliminate the drawbacks of classical MCDM techniques, some hybrid decision models have been recently developed. Hybrid MCDM approaches represent a powerful group of decision-making techniques which can assist decision-makers in handling miscellaneous information, involving stakeholders’ preferences, interconnected or contradicting criteria, and uncertain environments [

21]. However, as

Table 1 shows, no earlier study has utilized hybrid MCDM techniques for solving technology transfer decision-making problems. Furthermore, as the above review has revealed, so far no application of the MCDM methods to wind turbine technology selection has been reported. In order to respond to these research gaps, in the current paper, a combined AHP and TOPSIS decision model is developed to select the most suitable technology transfer strategy for the design and manufacture of wind turbine systems and their associated structures. The proposed model consists of four sets of criteria, namely, economic, social, technical, and environmental, with a total of nine sub-criteria determined from the viewpoint of wind energy investors, wind turbine manufacturers, and wind farm operators. The weights of criteria and sub-criteria are computed using the eigenvalue method and then, the technology transfer alternatives are ranked based on their distance to the ideal or anti-ideal solutions. The model is finally applied to determine a suitable wind turbine technology transfer strategy in the renewable energy sector of Iran and the results are compared with those obtained by classical MCDM methods. The proposed approach can assist technology managers in selecting a profitable strategy for importing high-tech equipment and instruments, through which they can reduce the costs corresponding to the technology acquisition process.

The rest of the paper is organized as follows. In

Section 2, an overview of the wind turbine technologies developed and deployed to date is presented.

Section 3 provides a step-by-step procedure of the proposed decision model to determine the most suitable technology transfer strategy for wind turbines.

Section 4 illustrates the applicability of the proposed approach, and finally

Section 5 concludes the paper.

3. Technology Transfer Strategy Selection Model

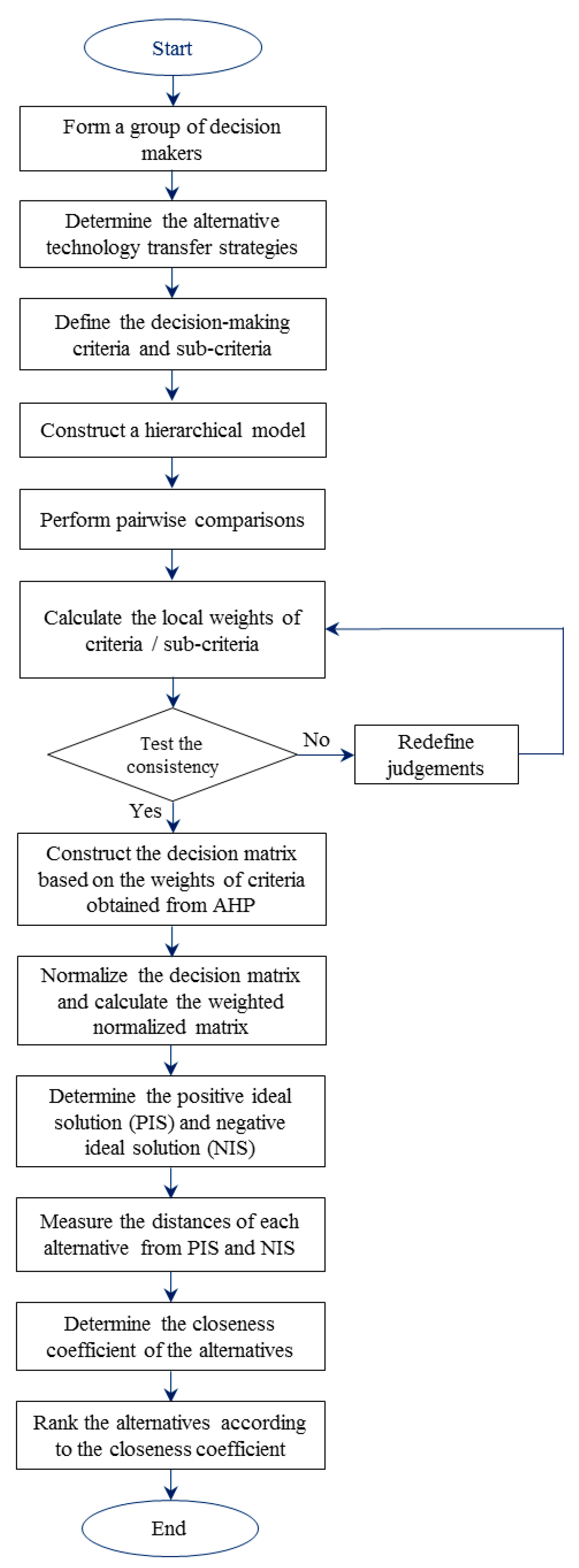

In this study, an integrated AHP-TOPSIS decision model is developed to evaluate and prioritize the technology transfer strategies that are applicable to the design and manufacture of wind energy systems and their associated structures. To achieve the desired goal (determining the most profitable technology transfer solution) the following step-by-step process is proposed (

Figure 1):

Step 1: Form a group of decision makers

A structured group of decision makers, including technology managers, investors, operators, and end-users is formed to analyse the data collected through literature reviews, expert elicitations, surveys, interviews, etc.

Step 2: Determine the alternative technology transfer strategies

Several strategies can be taken into account for the transfer of an advanced technology to an organization. In this study, four alternative technology transfer strategies are considered for wind turbines: reverse engineering, technology skills training, turn-key contracts, and technology licensing.

Step 3: Define the decision-making criteria and sub-criteria

In order to evaluate and prioritize the technology transfer strategies for wind turbines, the decision-making group must specify a set of criteria. Different decision-makers may have different objectives. In this paper, we first determined a list of criteria based on the review of the literature. Then, semi-structured interviews were conducted with the decision making group in order to get a better understanding of their objectives. Finally, four main criteria with nine sub-criteria were identified for consideration. All these criteria along with their relevant sub-criteria are further described in the following paragraphs.

C1. Economic criterion

In order to determine the most appropriate alternative for technology transfer, it must be investigated how costly each strategy will be and how much added-value each of them can generate and how soon. Thus, the relevant factors describing the economic criterion are:

C1.1. Cost of technology transfer

The investment required to import a particular technology is of particular importance in technology transfer strategy selection decision-making. The economic justification of each alternative must be examined according to a schedule established in cooperation with the technology transfer experts.

C1.2. Time to transfer a technology

It is important to determine the length of time that each technology solution takes to be imported from a technology owner. This length of time can affect the annual economic performance of the technology transfer options and thereby their rates of investment return.

C1.3. Resilience against economic sanctions

Economic sanctions are commercial and financial penalties applied by one or more countries against a targeted country, group, or individual. The sanctions may significantly impact the strategy of technology transfer from the owner to the user.

C1.4. Available market

Available market is a term that is typically used to reference the revenue opportunity available for a technology, product, or service. It is defined as the number of users who are willing and capable of buying the particular technology after transfer.

C2. Social criterion

In order to select the most suitable technology transfer strategy, the impact of each strategy on the social welfare of the destination country must be evaluated.

C2.1. Social acceptance

The degree of acceptability of each technology transfer strategy in the destination country must be evaluated.

C2.2. Entrepreneurship

The entrepreneurship sub-criterion represents the potential of each technology transfer alternative in job creation.

C3. Technical criterion

The level of readiness of the importer’s organization with respect to each technological option needs to examined and evaluated.

C3.1. Knowledge improvement

Knowledge improvement is measured by the degree to which the knowledge, skills, and abilities in the technology importer organization can be expanded by new technologies.

C3.2. Coordination with domestic technology

While selecting technology transfer strategies, the degree of adaptation of each option with domestic technology and the local conditions needs to be considered.

C4. Environmental criterion

The impact of different technology transfer options on the environment should be examined [

28].

C4.1. Environmental friendliness

A high degree of environmental friendliness (e.g., minimum pollution impacts during production/use, potential to be recycled, safe disposal at the end of technology life) is required while selecting a technology transfer solution.

Step 4: Construct a hierarchical model

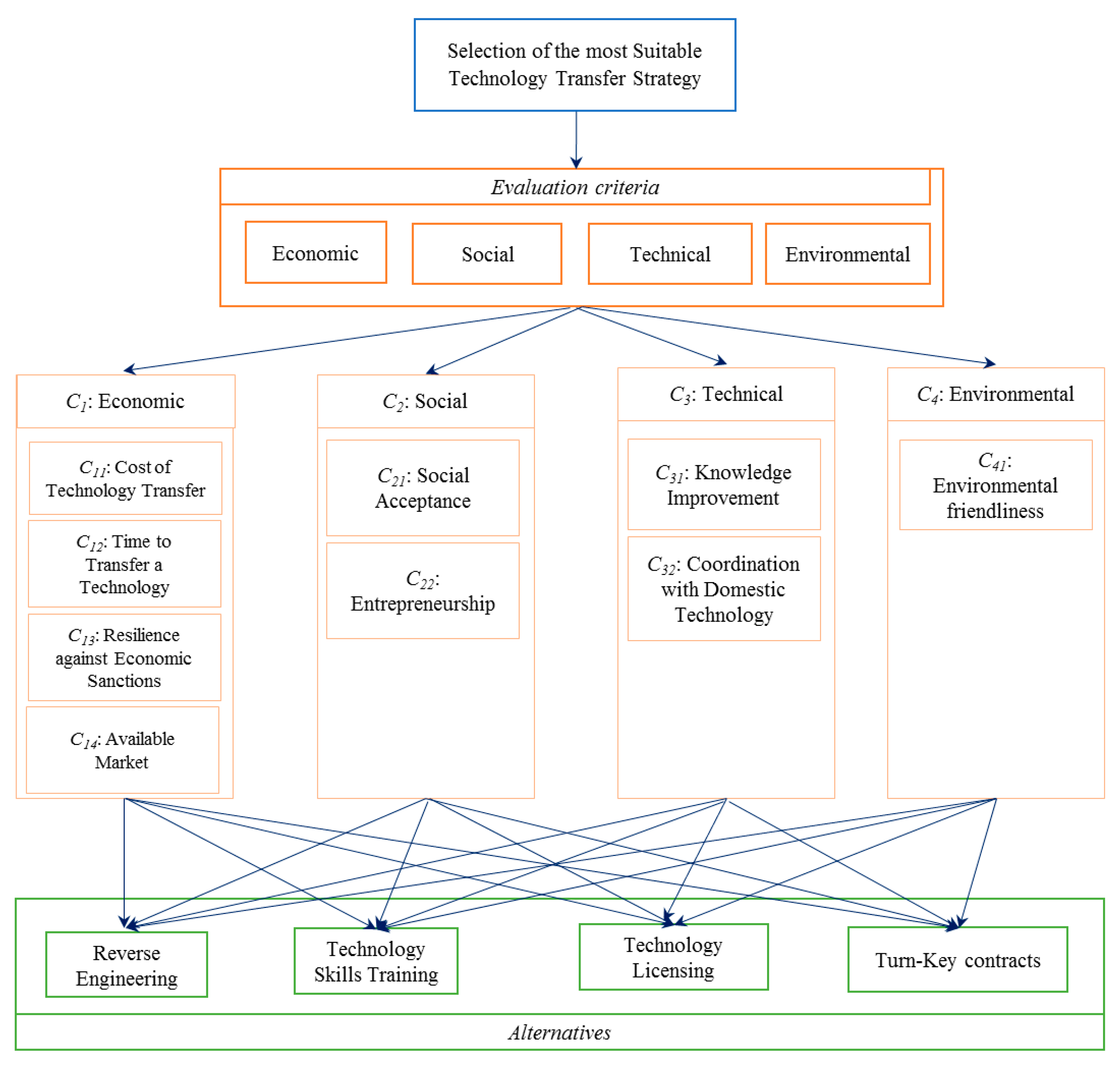

Using criteria, sub-criteria, and alternatives, a hierarchical model is constructed.

Figure 2 illustrates a hierarchical model for the decision problem of selecting a suitable wind turbine technology transfer strategy. As can be seen, the proposed structure includes an ultimate goal, four criteria, nine sub-criteria, and four alternatives.

Step 5: Perform pairwise comparisons

After defining alternatives, criteria, and sub-criteria, and constructing the hierarchical model, the decision-making group will need to estimate the relative preference/importance of criteria/sub-criteria with respect to the ultimate goal. The simplest and most common method for weighing the criteria/sub-criteria is the

pairwise comparison. Pairwise comparisons are done by comparing elements with respect to their parent element and the results are represented in a form of matrix, called a pairwise comparison matrix. A pairwise comparison matrix is a square matrix of size

n × n, represented by

A = [

aij], where

n is the number of decision elements (criteria or alternatives) and

aij denotes the comparative importance of the criterion

i with respect to the criterion

j, i.e.,

In the pairwise comparison matrix, a reciprocal value is assigned to the inverse comparison, that is,

aji = 1/

aij, and the diagonal values are preserved as one. Thus, the pairwise comparison matrix can be represented in the following form:

The criteria (sub-criteria)’s relative importance values are expressed with a scale from 1 to 9 as shown in

Table 2. This scale indicates how many times more important or dominant one element is over another element with respect to the criterion or property to which they are compared [

29]. A score of 1 represents equal importance between the two criteria (sub-criteria) and a score of 9 indicates the extreme importance of one element compared to the other one. To complete the pairwise comparison matrix, the decision maker is asked questions such as: “on a scale from 1 to 9, how much more important is the element

i compared to element

j?”

Step 6: Calculate the local weights of criteria/sub-criteria and test the consistency

After performing pairwise comparisons between the elements, the eigenvalue method is used to estimate the relative weights of the decision elements. In this method, we can estimate the relative weights of the criteria (sub-criteria) (

w) by the following equation:

where λ

max represents the largest eigenvalue of the pairwise comparison matrix

A. The consistency property of each pairwise comparison matrix needs to be examined. The consistency index (

CI) and consistency ratio (

CR) are used to measure the consistency of the pairwise comparison matrix. The

CI and

CR values are defined as follows:

where

RI represents the average value of

CI for numerous random entries of same order reciprocal matrices. The values of

RI for

n = 3 to

n = 11 are computed and given in

Table 3. If the value of

CR is smaller or equal to 10%, the inconsistency is acceptable; otherwise, the decision makers are asked to revise their judgments in order to improve the consistency level [

31].

Step 7: Construct the decision matrix based on the weights of criteria obtained from AHP

After the weights of the criteria and sub-criteria are obtained by the AHP method, the decision matrix is constructed to represent the performance ratings of alternatives with respect to the criteria. As shown in

Table 4, the decision matrix has a size of

m ×

n, where

m and

n represent the number of alternatives and criteria (sub-criteria), respectively.

Step 8: Normalize the decision matrix and calculate the weighted normalized matrix

Given that the decision matrix consists of attributes with different units, the values within the matrix must be normalized so that all attributes can be measured in dimensionless units. We use the following formula to normalize each value

bij in a decision matrix

B = (

bij)

m×n into a corresponding element

rij in the normalized decision matrix [

32]:

After normalizing the decision matrix, the resulting matrix is multiplied by the local weights matrix obtained for criteria/sub-criteria using the eigenvalue method, which is itself a diagonal matrix whose elements on the main diagonal are equal to the weights of the criteria/sub-criteria. Thus, the weighted normalized decision matrix (

v) is given by:

Step 9: Determine the positive ideal solution (PIS) and negative ideal solution (NIS)

After obtaining the weighted normalized decision matrix, the PIS and the NIS are determined. The PIS is composed of all the best criteria values attainable, whereas the NIS is composed of all the worst criteria values attainable. The maximum value of the benefit attributes and the minimum value of the cost attributes constitute the PIS (

A+), while the minimum value of the benefits attributes and the maximum value of the cost attributes constitute the NIS (

A−). The PIS (

A+) and NIS (

A−) for the benefit attributes are defined, respectively, as follows:

Step 10: Measure the distances of each alternative from PIS and NIS

To prioritize the technology transfer strategies using the TOPSIS method, their distances from the PIS and NIS must be measured. The following formulas are used to calculate these distances:

Step 11: Determine the closeness coefficient of the alternatives

The closeness coefficient (

CL) of the

ith alternative strategy

Ai with respect to the PIS is defined as:

Step 12: Rank the alternatives according to the closeness coefficient

A set of alternatives can be ranked by preference according to the descending order of the closeness coefficient; in other words, a larger closeness coefficient means a better alternative. The strategy with the largest closeness coefficient will be chosen as the superior technology transfer solution.