1. Introduction

With the rapid increase of the number of automobiles, worldwide energy consumption and greenhouse gas emissions have increased greatly. It is a challenge for the automotive industry to reduce energy consumption and carbon emissions. For this purpose, academia and industry have paid much attention to the energy consumption minimization of ground vehicles. For example, many solutions to alternative powertrains have been proposed, including hybrid electric vehicles (powered by an internal combustion engine and at least one electric motor) [

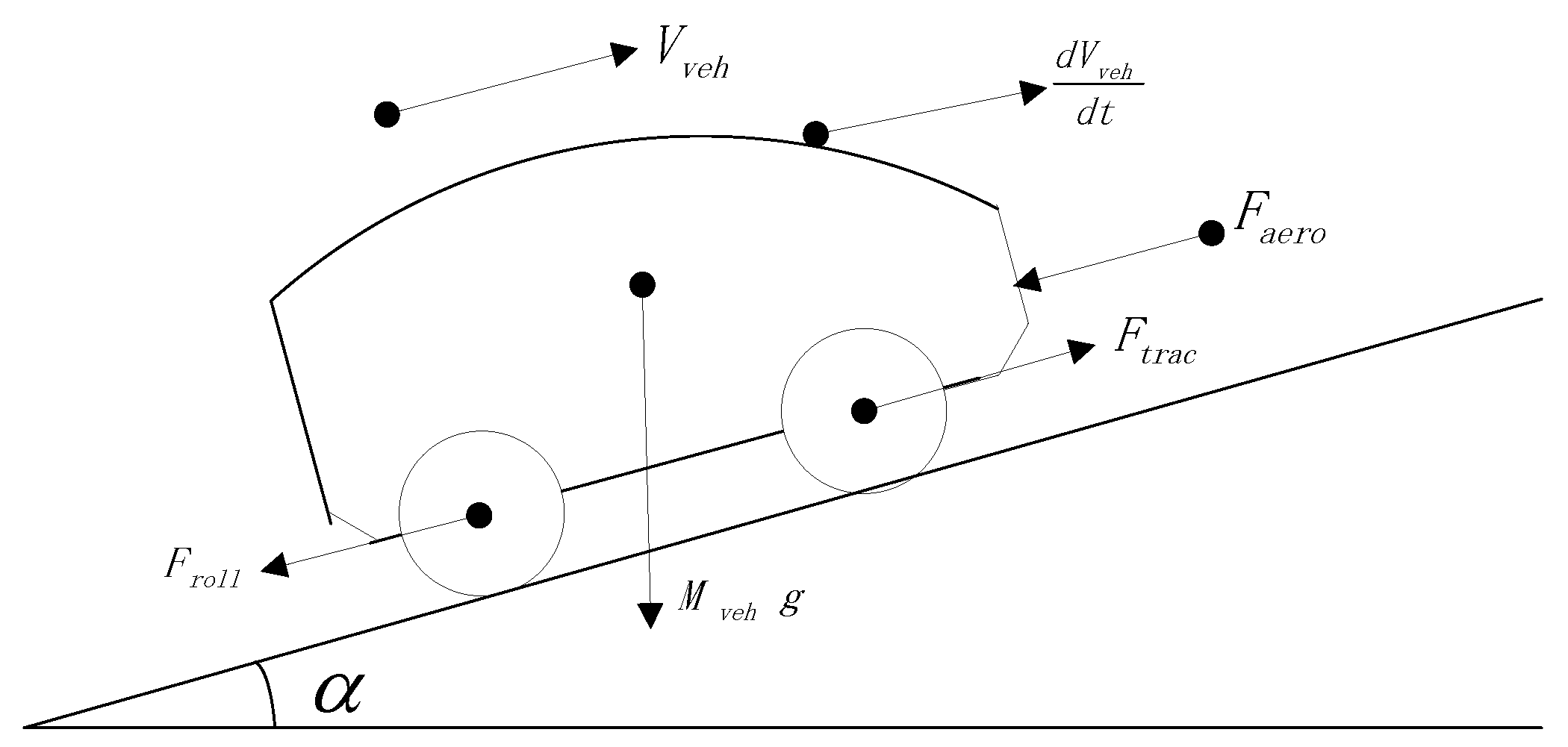

1,

2,

3,

4,

5], full electric vehicles [

6,

7,

8] and fuelcell vehicles [

9,

10]. Hybrid powertrains already became an affordable and popular approach to higher fuel efficiency and there are many successful products from Toyota, Honda, Volvo, BYD and so on. In addition to improving the energy efficiency of powertrains, the auxiliary systems, such as the power-assisted steering and brake and thermal management system, are also optimized for better energy efficiency [

11,

12,

13,

14,

15].

Another significant way for reducing fuel consumption is the optimal energy management control strategies [

16]. There are plentiful publications on this topic using different optimization approaches, e.g., dynamic programming [

3,

17,

18], convex optimization [

13], Pontryagin’s minimum principle [

19] and equivalent fuel consumption minimization strategy [

20]. These have been applied to achieve fuel optimal driving in conventional cars and trucks [

21], fuelcell cars [

8] and electric cars [

7]. Model predictive control recently becomes popular for energy management control of ground vehicles when future road condition is predictable [

22,

23].

Ecological cruise control, namely eco-driving, is an emerging technique for reducing fuel consumption through varying vehicle speed according to road grade angle [

24]. The road grade is the angle between the road surface and the horizontal. The road grade profile of a road is the distance-based continuous function of road grade angle along the road. The technology is applicable for both conventional vehicles powered completely by the international combustion engine and HEVs and EVs. For instance, eco-driving is used on a Peugeot EV and test results have shown a reduction of 14% in energy consumption [

25]. Thereby it has the potential to reduce the fuel consumption and will soon become a common feature in new commercial vehicles in the world.

All these methods above concentrate exclusively on the improvement or control of the vehicle, and consider the road conditions as external influencing factors. Recent studies suggest that improvements on the transport infrastructure are helpful for increasing traffic efficiency and reducing overall fuel consumption and unhealthy emissions of the transport system. Such improvements include intelligent transportation systems (ITS) [

26,

27] and the electric highway [

28]. A simple road condition that has large impact on fuel consumption is the road grade profile [

29,

30], which directly determines the maximal fuel reduction potential of HEVs and Eco-driving. The innovation of this paper is to consider the road grade profile as the design variable. We develop both analytical and numerical methods to find the optimal road grade profile between two given points so that the total energy consumption of all vehicles running on the optimal road is minimal. Compared to the conventional flat road, the optimal road can save up to 31.7% energy consumption. The benefit on energy saving of the optimal road is systematically studied through a large number of Monte Carlo simulations in this paper.

The road grade design method presented in this paper considers only the energy consumption of all vehicles using the road, but ignores the usual design objectives and constraints for road construction. The primary reason for the simplification is to derive the analytical solution. More comprehensive study including these design objectives and constraints can be included into the numerical solution in future work.

This paper is organized as follows. We formulate the road design problem as an optimization problem under uncertainty in

Section 2. The objective is the mean value of all vehicles’ energy consumptions.

Section 3 presents an analytical solution of the optimization problem by Pontryagin’s minimum principle (PMP).

Section 4 performs the numerical analysis of the optimal road grade design problem. The benefit of the optimal road is justified through a large number of Monte Carlo simulations under various traffic conditions.

Section 5 roughly estimates the cost of building or rebuilding the road and shows the economic benefit of rebuilding the road according to the optimal design.

Section 6 summarizes the main results and contributions of the paper and outlooks future work.

3. Analytical Solution

This section simplifies the optimal control problem in Equation (

15) and finds the analytical solution of the simplified problem by Pontryagin’s minimum principle (PMP) [

31]. The analytical solution provides insight into the problem and verifies the numerical solutions presented in

Section 4. Analytical solution may be found only if the state space model, the objective function, and the velocity profile are very simple. See [

32,

33,

34] for examples of finding analytical solutions to minimize vehicular energy consumption.

We apply the following simplifications to the problem in Equation (

15).

Only one vehicle is considered in Equation (

15a). The expectation computation in the equation is then unnecessary.

The absolute value of the road grade angle in radiant is very small, i.e., and . Consequently, and for all .

Owing to the second simplification, the differential equation of the vehicle speed in Equation (

15b) is reduced to

whose solution is function

calculated by Equation (

3). The computing method of

ensures

for all

. The optimal control problem in Equation (

15) is then simplified to

s.t. for all

,

This section finds the analytical solution to the simplified control problem by PMP. For convenient presentation, we rewrite the expression of

as

where

To remove the nonlinear function max in Equation (

16a), we introduce the following assumptions on the sequence of accelerations.

Assumption . For all , if , then it must satisfy the inequality Assumption . For all , if , then it must satisfy the inequality Let be the maximal vehicle speed during the road.

Assumption . For all , if , then it must satisfy the inequality These assumptions are easily satisfiable for common driving scenarios. For instance, consider a small car with the following parameters: , , m, m/s, kg, kg/m, and km/h. Then Assumption 1 implies that if the vehicle is accelerated, the acceleration must be no less than m/s. This is a very small value for vehicle acceleration. Assumption 2 implies that if the vehicle is braked, the acceleration must be no more than m/s. The constraint is easily satisfiable by the vehicle’s brake. In Assumption 3, when the minimal road is , the traction force is N and obviously less than 0.

Assumption 1 ensures that the traction force is not negative during acceleration, and Assumption 2 ensures that the traction force is not positive during deceleration. Assumption 3 requires that the absolute value of the angle of the steepest downhill is so large that brake must be applied to keep constant speed. The statements are formalized as the following propositions.

Proposition 1. For all , if and Assumption 1 holds, then it must be true for all .

Proof. By the definition of

in Equation (

17), we have

If

, then

. If

and Assumption 1 holds, we apply the inequality of Assumption 1 to the previous equation.

Because , we have . Because , we have . Moreover, because and , we also have . Consequently, we obtain the final statement , . ☐

Proposition 2. For all , if and Assumption 2 holds, then it must be true for all .

Proof. The proof is very similar to the proof of Proposition 1. If

, then

. If

and Assumption 2 holds, we have the inequality

Since , , and , we obtain the final statement , . ☐

Proposition 3. For all , if and Assumption 3 holds, there must exist a unique angle such that , for all , and for all .

Proof. Since

,

for all

. Because

, Assumption 3 yields

Evidently

. The derivative of the traction force to angle is

Because

,

and

, we can show

Consequently,

is a monotonically increasing and differentiable function. There must exist a unique zero point

such that

Since both

and

are positive, it must be true

. The value of

can be obtained by solving the nonlinear equation; however, when

, the nonlinear equation is approximated as a linear equation

and its solution is

Finally, the monotonicity of ensures and . ☐

The Hamiltonian of the control problem in Equation (

16) is

where

is the costate function. Note that the Hamiltonian is independent of

. By PMP, the optimal costate function

satisfies the differential equation

Consequently, the optimal costate function is a constant

over the entire road and its value will be determined by solving a nonlinear equation at the end of this section. The optimal road grade angle at any position

is

This minimization problem is solved in three cases depending on the value of acceleration .

3.1. Positive Acceleration

If

, then Assumption 1 and Proposition 1 ensure that

is non-negative and the minimization problem in Equation (

20) becomes

where

,

,

, and

are defined in Equation (

17). The term

disappears at the second equation, because it is independent of

. A necessary condition of the minimum point is where the first derivative of

H being zero.

Since both and are positive in this case, we have . Three possible cases arise depending on the value of .

- (1)

If

, then

Equation (

21) has no solution in the range

and the Hamiltonian is monotonically increasing in the range. The minimum point is hence

.

- (2)

If

, then

Equation (

21) has no solution in the range

and the Hamiltonian is monotonically decreasing in the range. The minimum point is hence

.

- (3)

If

, then the solution to Equation (

21) is

Furthermore, the second derivative of

H at

is

Consequently, must be a local minimum point. We can further prove that at this case is the global minimum point in the range .

Proposition 4. If is positive and exists, then .

Proof. Since

, for any

, we have the inequality

and hence

Similarly, for any

,

and hence

The two inequalities imply that

is the global minimum point of

H, i.e.,

. ☐

Summarizing the three cases, we have the minimum point of

as

3.2. Negative Acceleration

If

, then Assumption 2 and Proposition 2 ensure that

is non-positive and the minimization problem in Equation (

20) becomes

Its solution depends on the value of

.

The symbol * in the last case represents an arbitrary value in .

3.3. Zero Acceleration

If

, Assumption 3 and Proposition 3 ensure that there is a unique angle

such that

and

and

. The Hamiltonian is then a continuous function of two cases.

Note that .

Let

be the minimum point of

and

the minimum point of

. The global minimum of the Hamiltonian is

and the global minimum point is

The values of and are dependent on . Three cases follow.

- (1)

If

,

is then monotonically increasing in

and

. The derivative of

to

is

Because

,

, and

, we have

Consequently,

. Since

H is a continuous function,

- (2)

If

,

and

. By the definition of

, we have

for all

. Consequently,

where * represents an arbitrary value.

- (3)

If

,

is then monotonically decreasing in

and

. The minimum point of

in

is identical to Equation (

23), except that

and

is replaced by

.

At the first case in Equation (

26),

. Then

. At the second case in Equation (

26),

. Then

. At the last case in Equation (

26),

. Then

. In summary, the global minimum point at this case is identical to

.

3.4. The Value of

Section 3.1,

Section 3.2 and

Section 3.3 show that the minimum road angle of the Hamiltonian in Equation (

20) is dependent on the value of

. The following properties related to the value of

can be proved.

Lemma 1. If and there are at least two accelerations and , , such that and , then the solution to Equation (20) is not unique. Proof. Since

and

, Equation (

24) states that

is arbitrary in

at

.

Since

, the vehicle speed at any position

is a the constant

. Since

,

The zero point

must exist and Equation (

25) states that

is arbitrary in

at

.

Since the optimal angles at two sections can be arbitrary, the total solution of () is not unique. ☐

Lemma 2. If , the solution to Equation (20) has the property for all . Proof. We show this lemma in three cases depending on the value of acceleration at position .

- (1)

: The minimum point to Equation (

20) is given by Equation (

23). In the first case of the equation, if

, then the value of

belongs to this case. Consequently,

must be

. If

, then the value of

may belong to the first or the third case. It cannot belong to the second case, because it is always true

. Therefore,

or

. By Equation (

22), if

, then

.

- (2)

: The minimum point to Equation (

20) is given by Equation (

24). If

, then

.

- (3)

: The minimum point to Equation (

20) is found in

Section 3.3. If

,

In summary, the optimum road angle is always negative for the entire road. ☐

Lemma 3. If and there is at least one accelerations , , such that , then the solution to Equation (20) has the property for all and for all . Proof. We show this lemma in three cases depending on the value of acceleration at position .

- (1)

: The minimum point to Equation (

20) is given by Equation (

23). If

, then

or

. By Equation (

22), if

, then

.

- (2)

: The minimum point to Equation (

20) is given by Equation (

24). If

, then

.

- (3)

: The minimum point to Equation (

20) when

is given by Equation (

26). Then

or

.

Since the negative acceleration exists, we must have for . In summary, the optimal road angle is always non-negative during the road and positive during the deceleration segment. ☐

Theorem 1. If there are at least two accelerations and , , such that and , the optimal control problem in Equation (16) with the altitude constraint in Equation (16d

) has a unique solution only if . Proof. If

, the solution is not unique by Lemma 1. If

, the optimal road angle function has the property

according to Lemma 2. Applying integration to Equation (

16b), we have the identity

Therefore,

and it violates the constraint in Equation (16d).

If , Lemma 3 ensures that and . This yields the inequality and it violates the constraint in Equation (16d).

In summary, the necessary condition for the existence of a unique optimal road angle function to Equation (

16) is

. ☐

With the new knowledge of Theorem 1, we summarize the optimal road angle function in one equation depending on acceleration

. At any

,

In the equation, if is very large, the argument in the arcsin function may be larger than 1. Then takes the second value in the max function.

Equations (

16b) and (16d) yield a nonlinear equation of

.

The tricky part of establishing this equation is that

at the segments where

are dependent on

, which is yet unknown. Conjecture on the value of

and iterations are necessary to find

. We start with conjectures on

for the segments

where

and construct the equation as in Equation (

28). After solving the equation, we verify if the conjectures are correct. If so, we have found a candidate of the optimal costate

. Moreover, since PMP and Theorem 1 provide only necessary conditions on the optimal costate, there may be multiple candidates satisfying Equation (

28) and all relevant constraints derived from Equation (

27). In this case, we must compute the energy consumptions by Equation (

16a) for all these candidates and identify the one with the minimal energy consumption.

There are more complicated cases where the optimal angle value switches from one extreme to the other. For example, if in the segment , then we know is monotonically increasing in the segment . If there exists a position such that for and for , then a corresponding equation can be constructed and solved. Among the n acceleration values of the sequence , , if there are accelerations that are positive, we repeat the equation solving process at least times.

3.5. An Illustrative Example

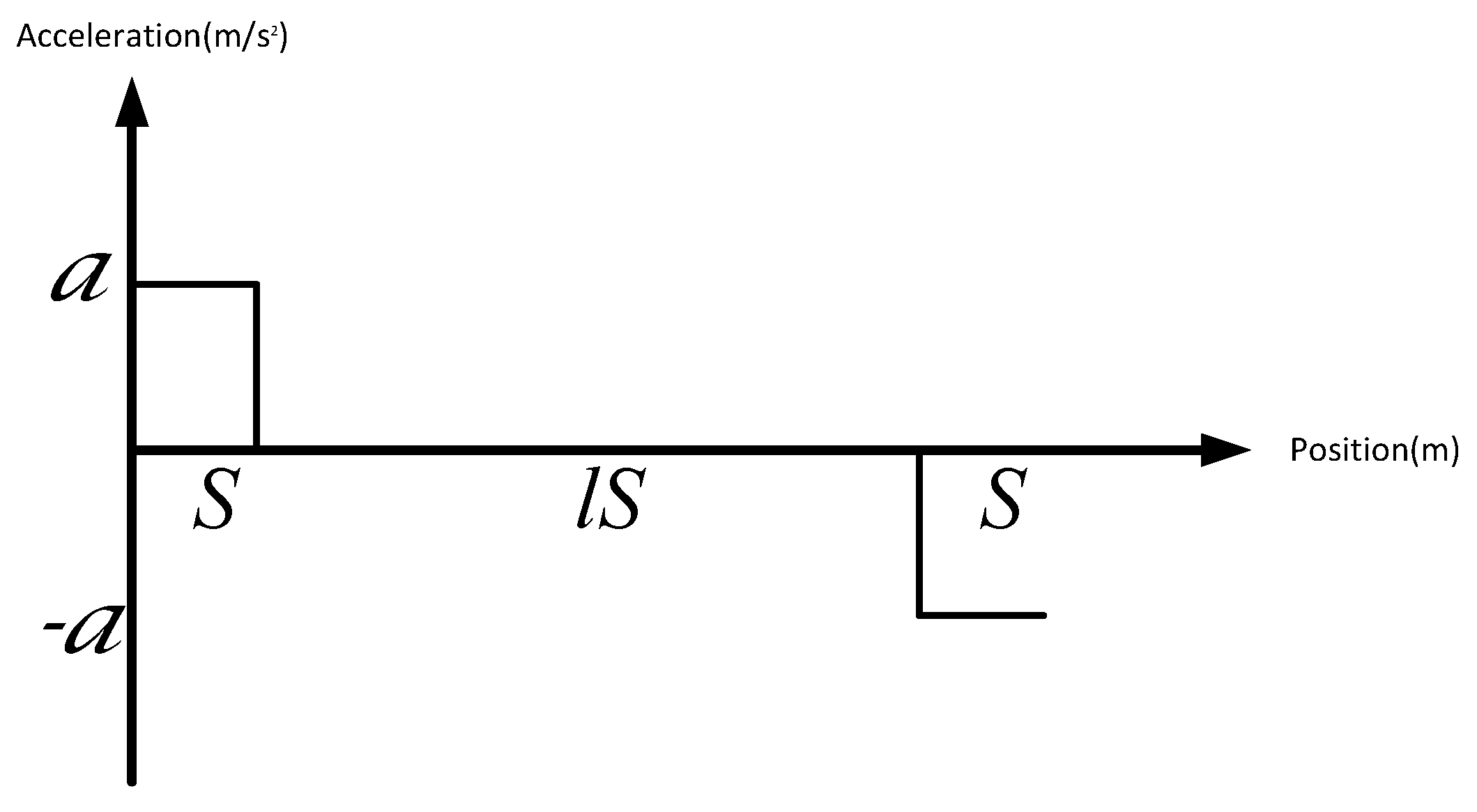

Figure 2 shows the acceleration sequence

corresponding to the position sequence

, where

,

, and

. Evidently, the road is divided into

segments for this example. Let

. The speed sequence by Equation (

2) is

.

Let

. By Equation (

3),

when

. By Equation (

27), the optimal angles in segment

are negative and the optimal angle in segment

is

. Therefore the optimal angle during the first segment

cannot be always

. We further assume that the optimal road angle in the first segment is always larger than

, i.e.,

Since

, we have the approximation

and

The vehicle speed is constant

in segment

. The optimal road angle in the segment cannot be determined yet.

Since

, we have the approximation

and

The optimal road angle in the last segment

is constant

. The change of the road altitude during this segment is

For convenient presentation, define

and

. The final equation by Equation (

28) is

or

The solutions to Equations (

29a) and (

29b) are

and

respectively. The two solutions must both satisfy the inequalities

where

. Since the second inequality must hold for all

and

, it is reduced to

The two solutions also individually satisfy the following two inequalities.

To complete the example, we use the vehicle parameters given behind Assumption 3. Let m/s and the maximal speed be km/h m/s. Then m. Solving the problem with different values of l, we find the following results.

When

,

is the only valid costate value and hence the optimal one. The optimal road angle function is

When

,

is the only valid costate value and hence the optimal one. The optimal road angle function is

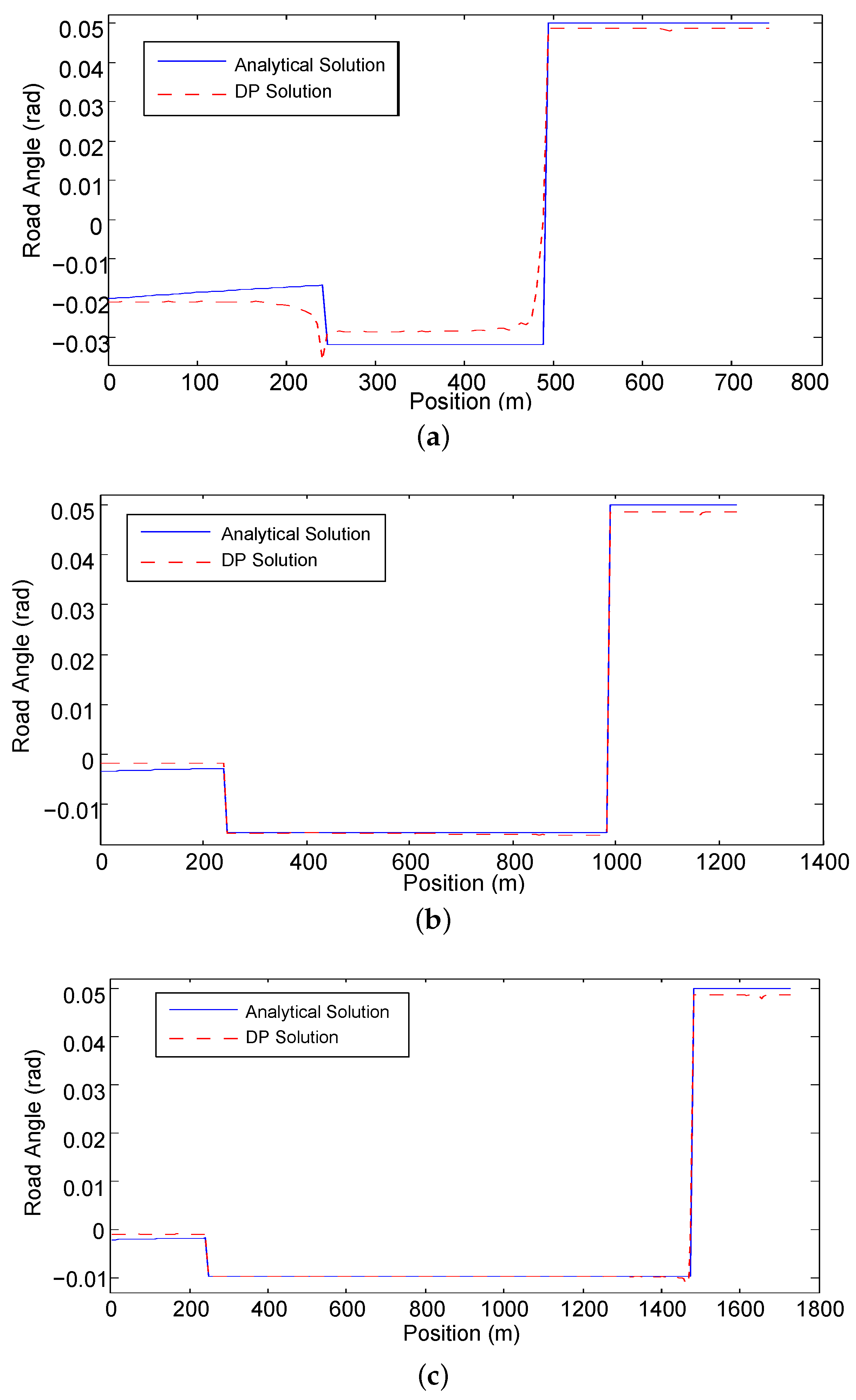

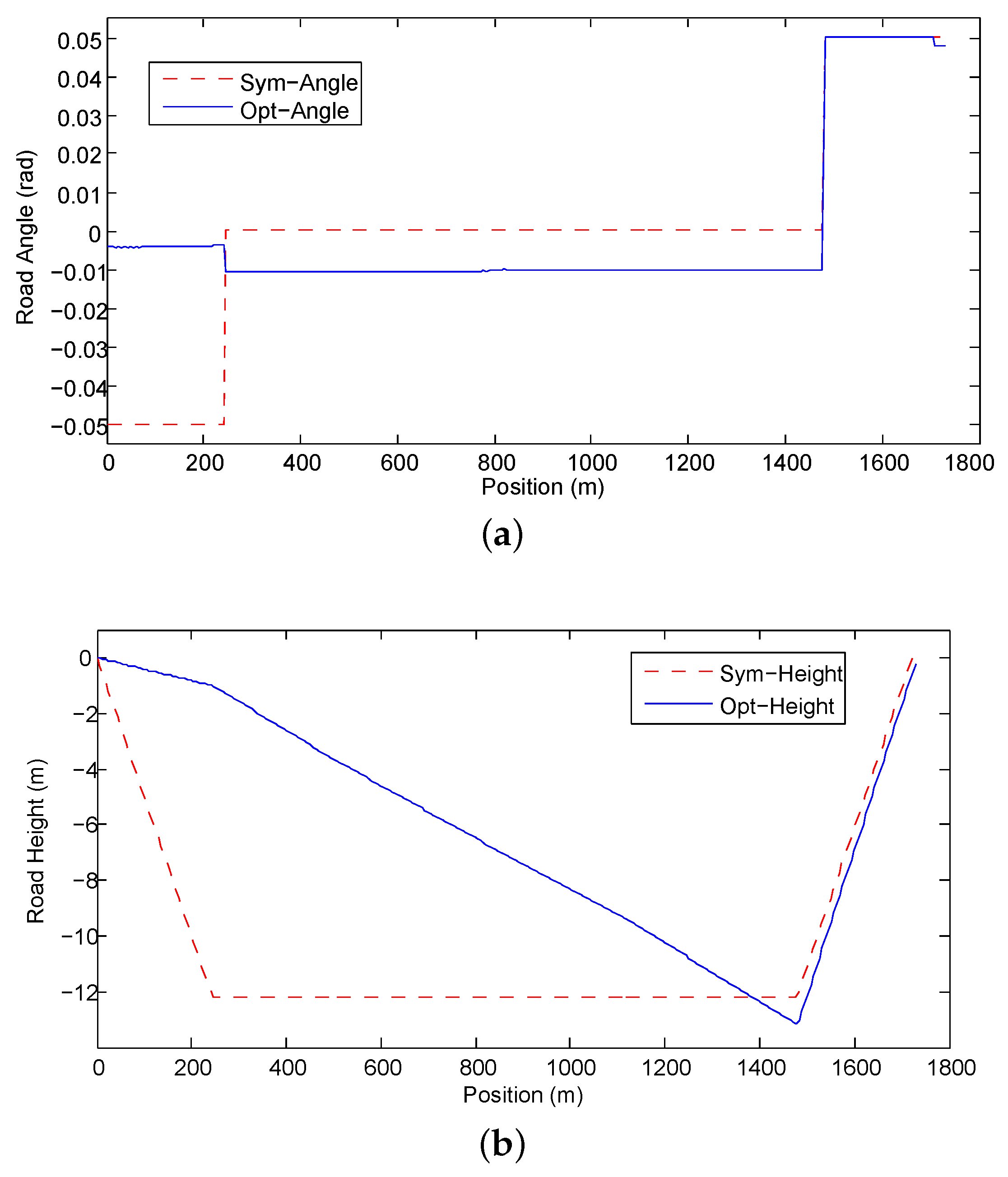

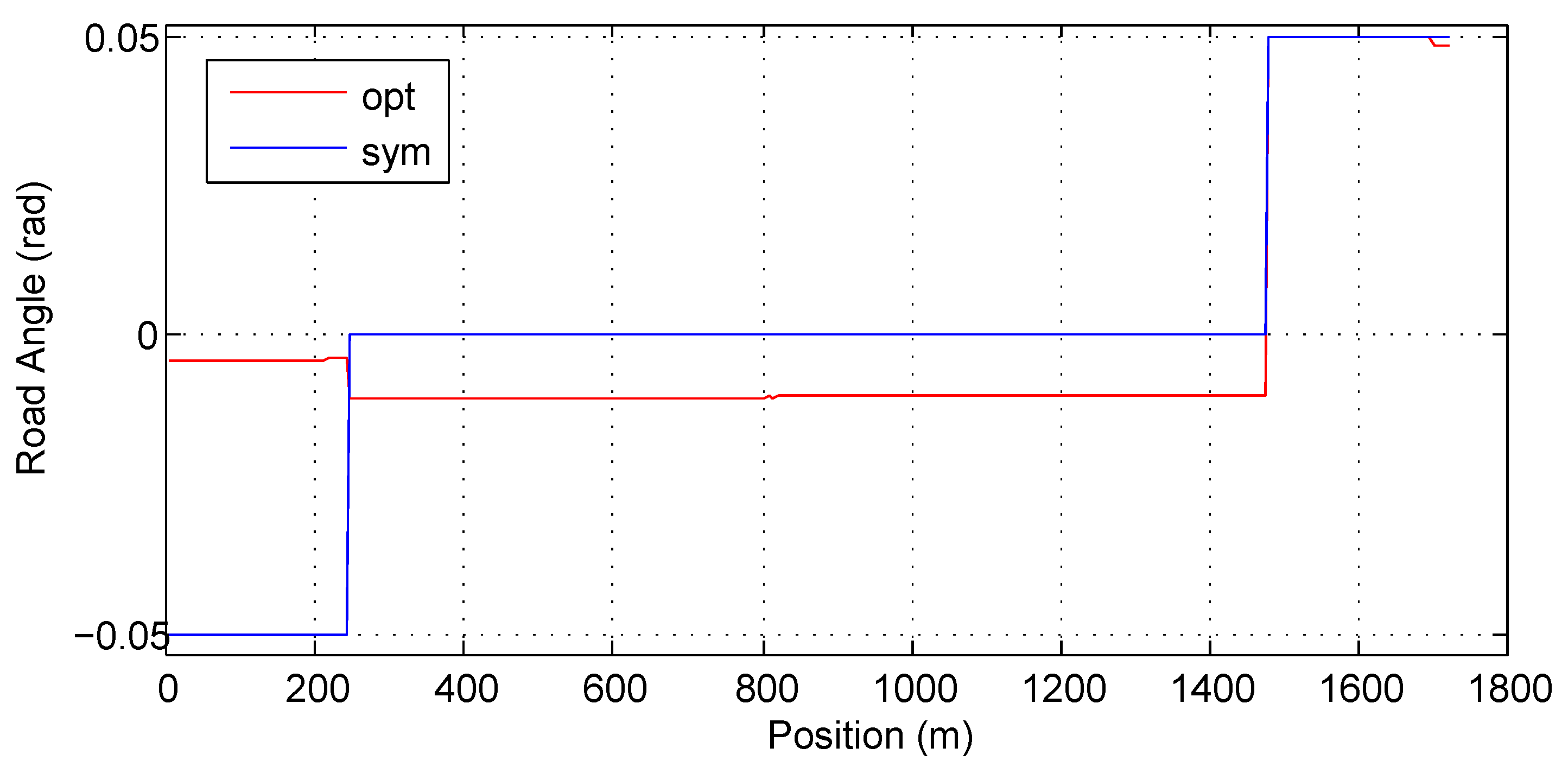

Figure 3 and

Figure 4 show the optimal road grade and the optimal road height with different values of

l, respectively. When

, the road angle is about

rad during the acceleration segment. During the constant speed segment, the road angle is about

rad and during the deceleration segment, the road grade reaches its maximal limit. When

, the road angle is approximately within the range

in the acceleration and constant-speed segments. During the deceleration segment, the road angle always reaches the its maximal limit. The larger is the value of

l, the larger is the road angle in the acceleration and constant-speed segments. Contrary to intuition, the optimal road has steeper downhill during the constant speed segment than during the acceleration segment.

Figure 4 shows that regardless of the length of the road, the lowest road height is identical, because it is determined by the length of

S and the maximal road angle

.

Recall that the optimization problem in Equation (

16) ignores the speed dynamics in Equation (

15b).

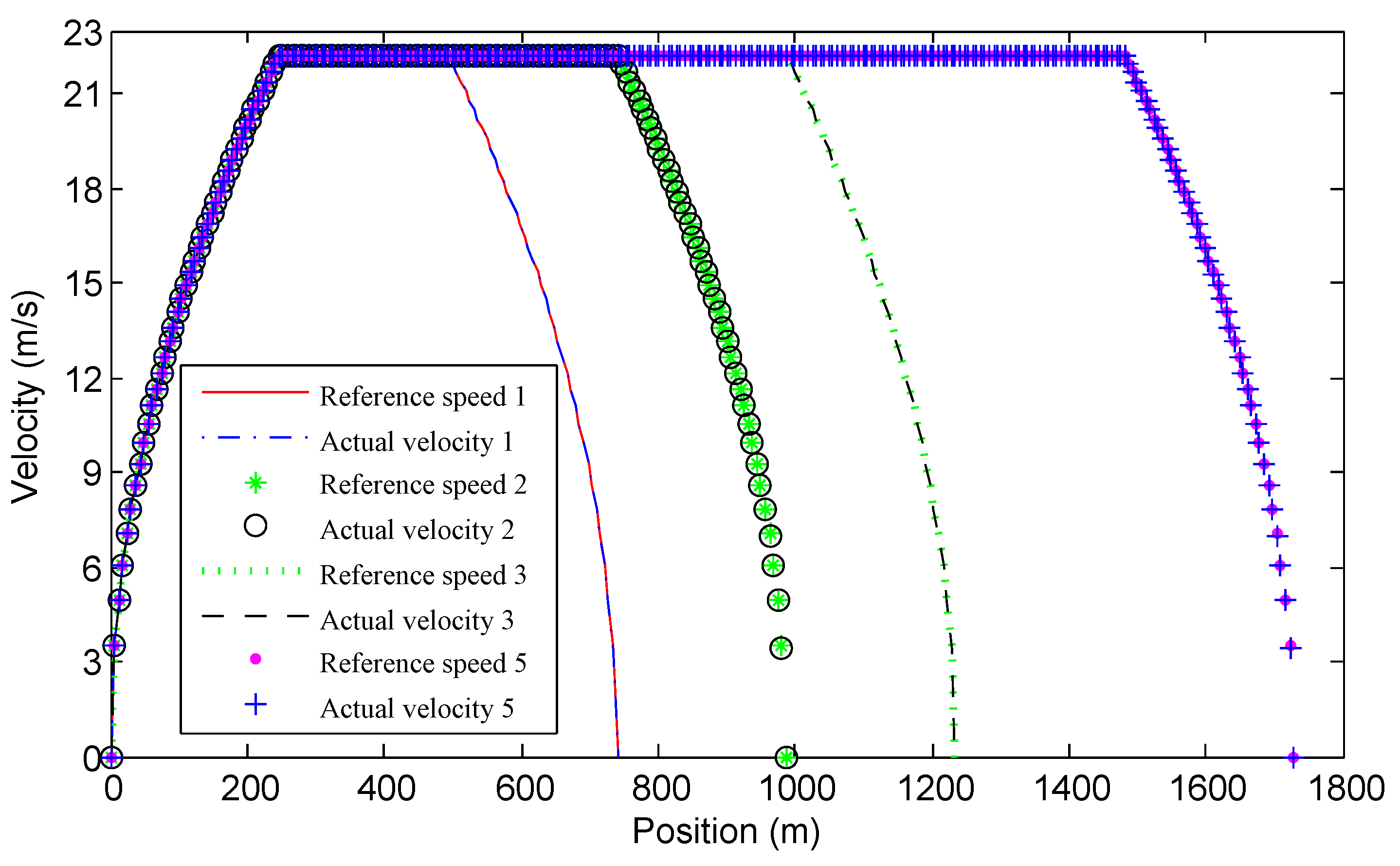

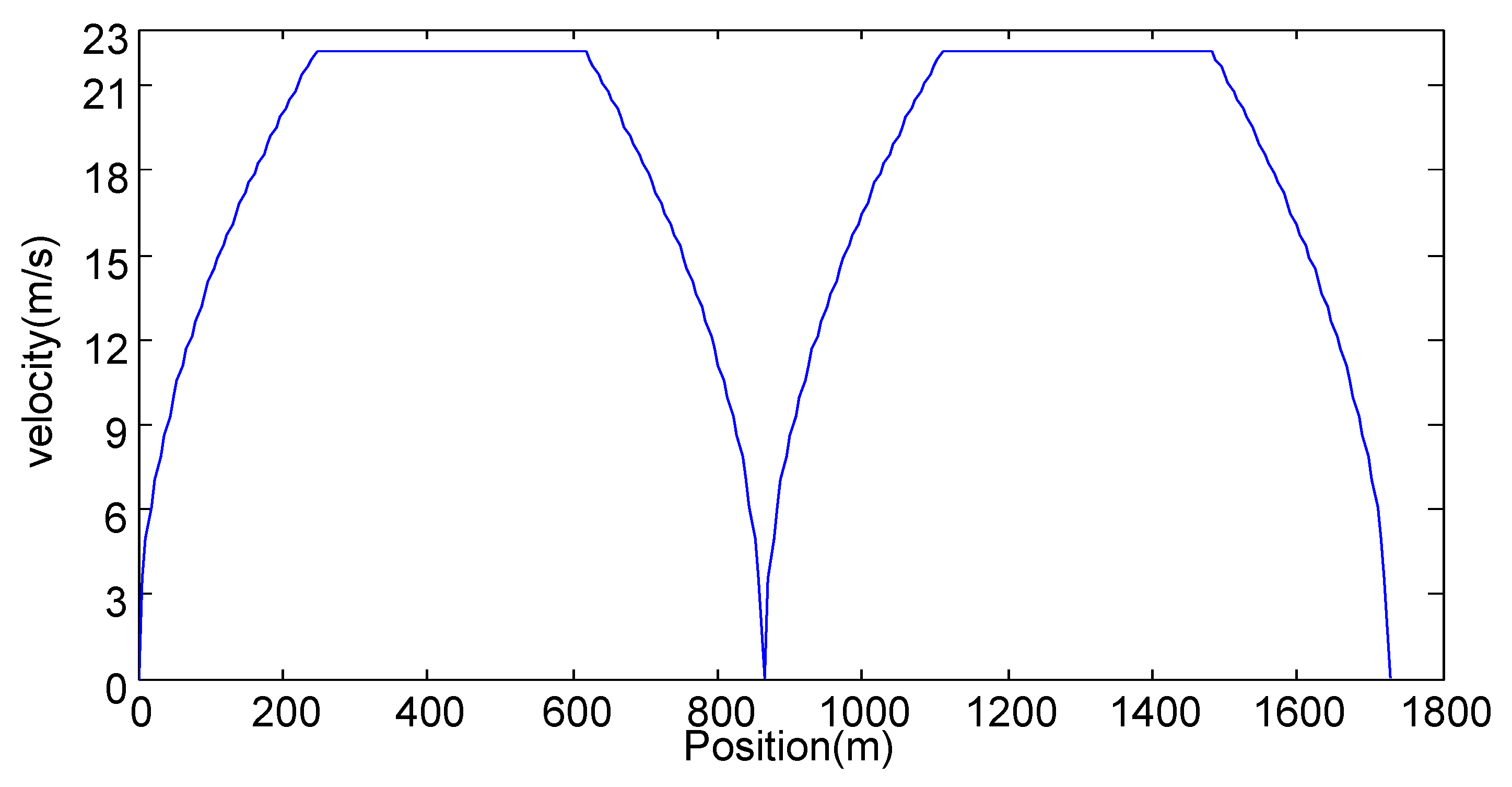

Figure 5 justifies the validity of the simplification. In the figure, the numbers

correspond to different values of

l , reference speed means the velocity of the vehicle running on the flat road and actual speed means the velocity of the vehicle running on the optimal road. For example, the annotation "Reference speed 1" represents the velocity of the vehicle running on the flat road when

.

Figure 5 shows the relationship between actual speed and reference speed. Evidently, the actual speed is very close to the reference speed.

Table 1 provides RMSE and normalized RMSE between the reference and actual speeds.

Finally, we validate the correctness of the optimal road angle function by comparing energy consumption with two reference road profiles. The first one is the flat road. The second one is the road that has the minimal/maximal angle during the acceleration/deceleration segments and zero angle during the constant-speed segment. We call it the symmetric road. Its corresponding road angle

is provided in Equation (

32). The results are listed in

Table 2. Evidently the road profile obtained by PMP results in the least energy consumption.

5. Preliminary Cost Analysis

The analysis suggests large reduction of the total energy consumption of all vehicles running on the optimally designed road, but a major concern to road optimization is cost. Road construction is expensive and has many concerns in addition to cost and energy consumption. If we build a new road, the dominating costs are for evacuating assets along the road, hiring the construction company, digging earth and rock, transporting waste and construction materials, paving the road, etc. These costs are independent of the road grade profile and hence our method can be applied with little influence on the cost of building the road. The benefit of the new road design method is obvious in this case. In our future work, we shall include more practical constraints, e.g., the maximal/minimal altitude, the longest distance for downhill/uphill, into the optimization process.

The questionable case is then to rebuild an existing road to obtain the optimal angle profile. We have no expertise in cost estimation of road construction and can only give a very preliminary estimate on it. Take the road in

Section 4.3 and

Section 4.4 for an example. Its direct distance is around 1.7 km and we estimate its cost by the methods presented in [

37]. Relevant data for making the gross estimate are taken from a practical example in China [

38]. The example project spends about

$10.5 million to build a 8.5 km-long road. Consequently it takes nearly

$1.23 million to build 1 km-long road. Thus, the budget of building the 1.7 km-long optimal road is approximately

$2.1 million, which is about the same expenses as that for building a flat road, since the grade of the optimal road is very small. For estimating the cost of rebuilding road, the relevant data come from another example of reconstructing a 25.124 km-long road [

39]. The additional cost to rebuild the road is very small. In this reconstruction example, it takes about

$5.4 million to rebuild the road and hence the average cost is approximately

$0.215 million per km. Then the budget to rebuild the 1.7 km-long optimal road is about

$0.365 million.

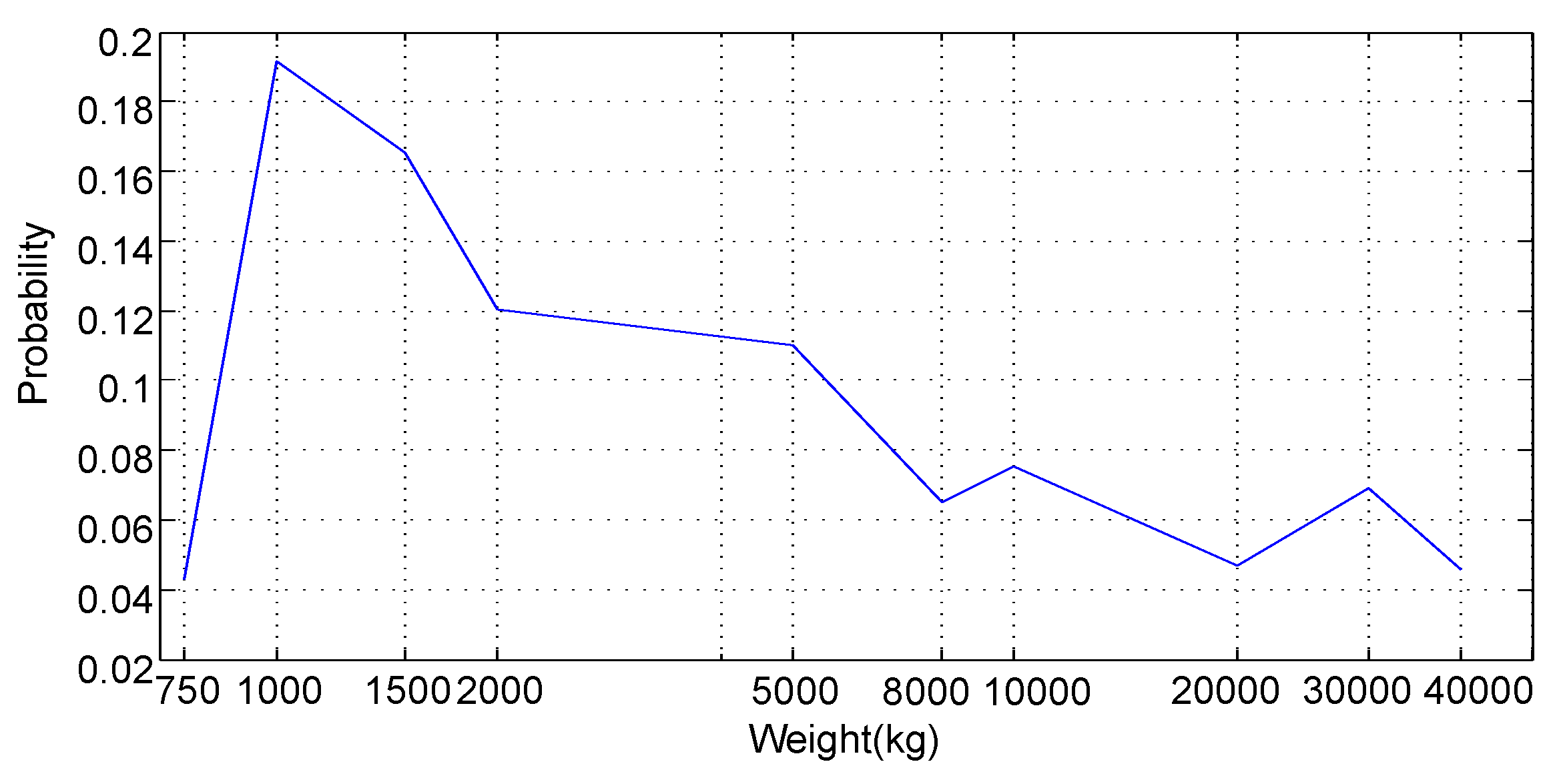

Suppose that averagely 5000 vehicles use the road every day and the road can be in service for 30 years. If the weights of the vehicles satisfy the distribution in

Table 5,

Table 6 shows about 31.7% reduction of the total energy consumption over 30 years. Assume that the average fuel consumption is 6.5 L gasoline per 100 km. Thus, one vehicle averagely saves 0.0350 L gasoline per day on the 1.7 km optimal road. The total saving for 5000 vehicles per day for 30 years is roughly 1.918 million liter gasoline. The current gasoline price in China is about

$0.93 per liter and assume the same price for the next 30 years. The total saving in money is about

$1.8 million for 30 years. Since the fuel price will certainly increase in the future, more saving can be achieved. The saving outweighs the cost of rebuilding the road. Moreover, the reduction on energy consumption also reduces harmful vehicle emissions and contributes to cleaner environment.

6. Conclusions and Future Work

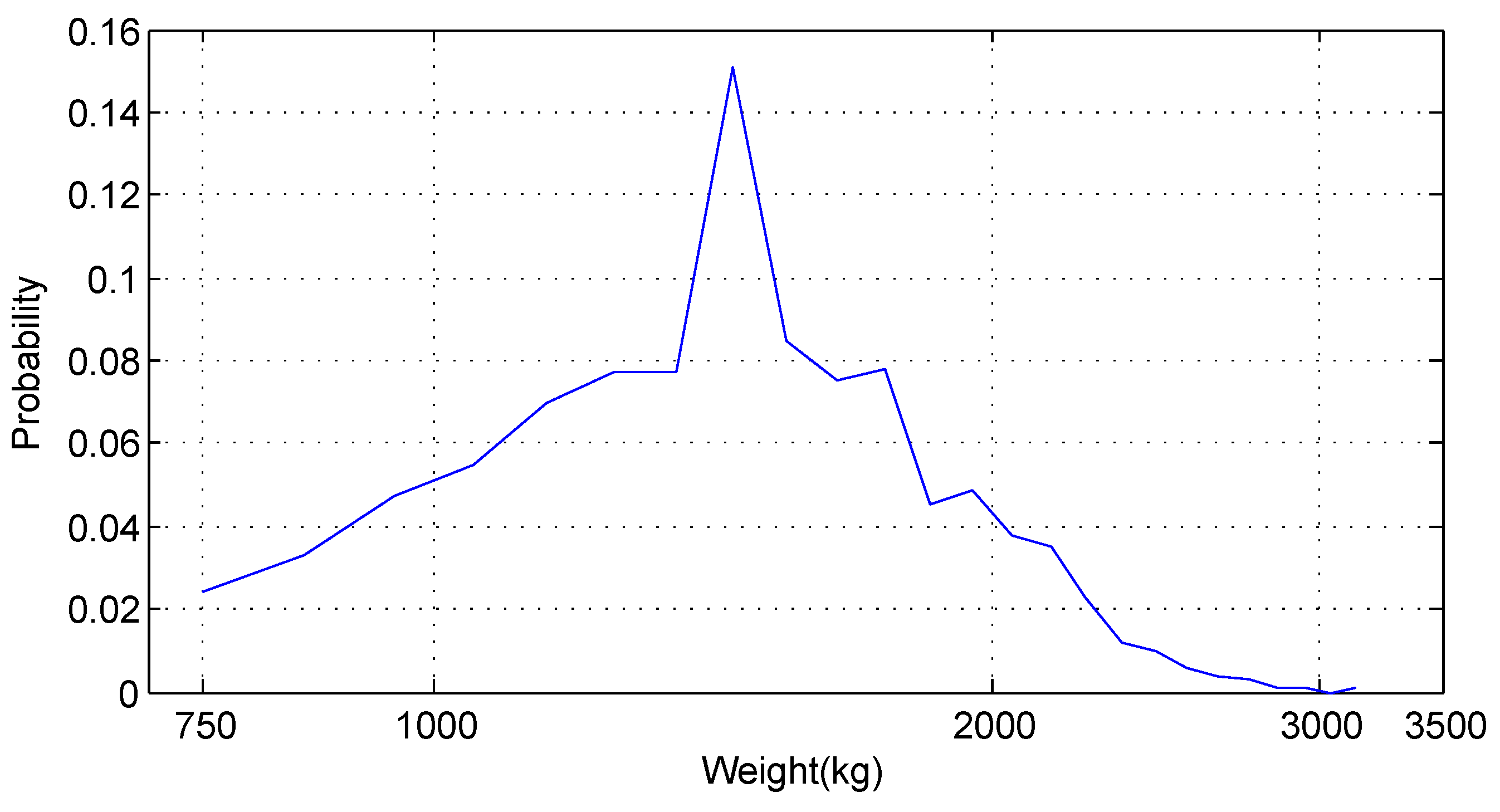

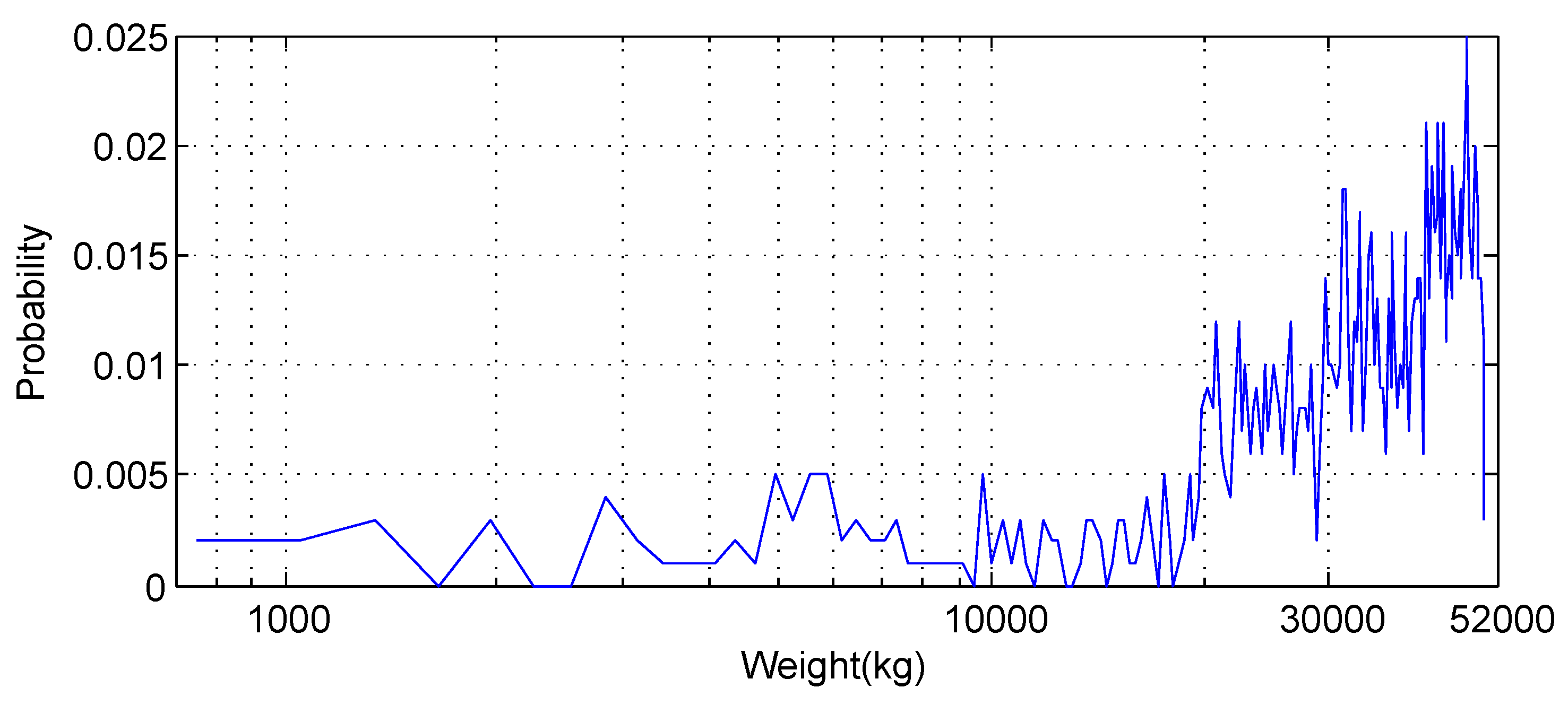

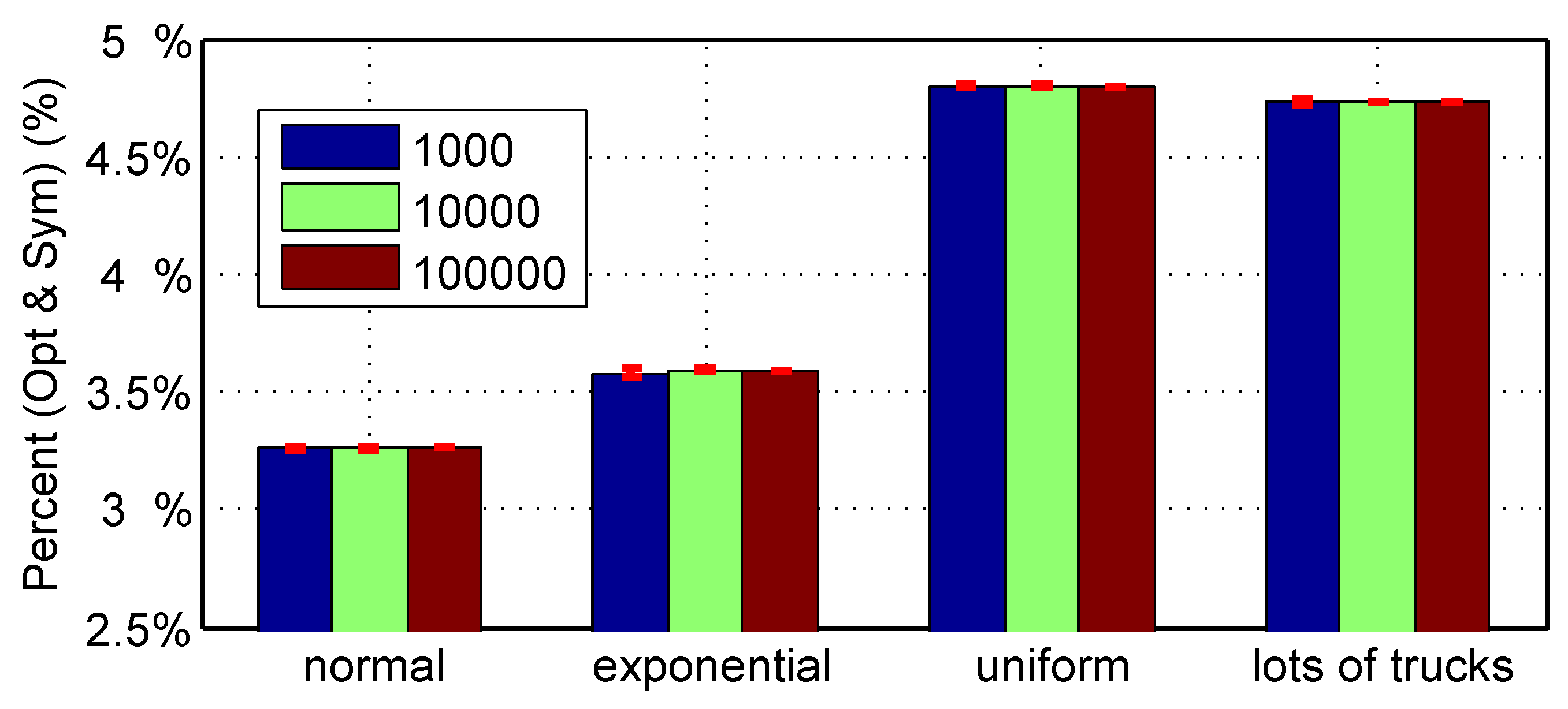

This article presents both analytical and numerical solutions to the optimization problem of finding the optimal road grade that minimizes the overall energy consumption of all vehicles running on the road. We assume that all vehicles on the road follow a given acceleration profile between the two given points. In order to find the analytical solution, the optimal control problem is simplified and the Pontryagin’s minimum principle is used to derive the optimal road grade trajectories. Dynamic programming (DP) is utilized to solve the problem numerically. The paper finds that the numerical solution is almost identical to the analytical solution. Then we use DP to find the optimal road angle profile between two points for a larger number of different vehicles. After that we verify the correctness and advantage of the DP solution via Monte Carlo simulations on a large number of vehicles with various weights. Three cases are considered in the Monte Carlo simulations. First, a large number of vehicles with random weights whose probability distribution function is consistent with the assumption. Second, the distribution of vehicle weights is inconsistent with the assumption. Third, all vehicles must make an extra stop during the travel. The simulations reveal that the optimal road saves energy for all cases, except one. Explanation of the exception is given in the paper.

Compared to the flat road, the optimal road reduces the energy consumption of all vehicles by around 31.7%. Thereby the optimal road has advantage in reducing fuel consumption of ground vehicles and has large application potential.

In the future, we will continue to improve fuel economy by the optimal design of the road infrastructural. Firstly, more comprehensive design objectives and constraints coming from road construction techniques will be included in the DP formalism. Secondly, as stated in

Section 4.4.3, if the actual speed profile is inconsistent with the assumed speed profile, the energy consumption on the optimal road may not be the least if the traveling distance is short. We will thus investigate robust road optimization method for reducing the total energy consumption of vehicles with more complex and stochastic velocity trajectories. Thirdly, the optimal road grade profile is dependent on the driving direction. If we design an optimal road between two destinations for both driving directions, the road profiles for both ways are distinct. The implication of the asymmetric design will be further analyzed.