Research on the Optimal Charging Strategy for Li-Ion Batteries Based on Multi-Objective Optimization

Abstract

:1. Introduction

2. Li-Ion Battery Modeling and VMCC Simulation

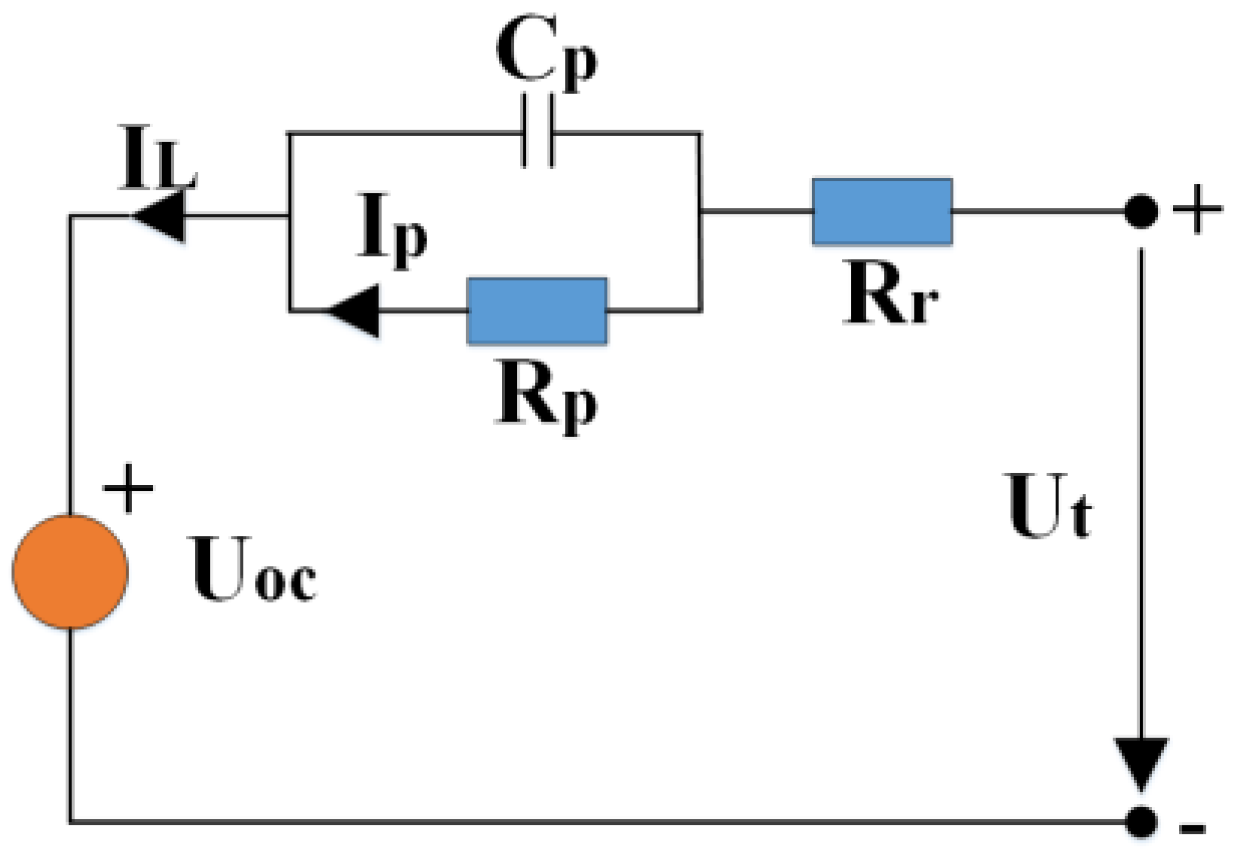

2.1. Battery Equivalent Circuit Model

2.2. Battery Parameter Estimation

2.3. Battery Thermal Model

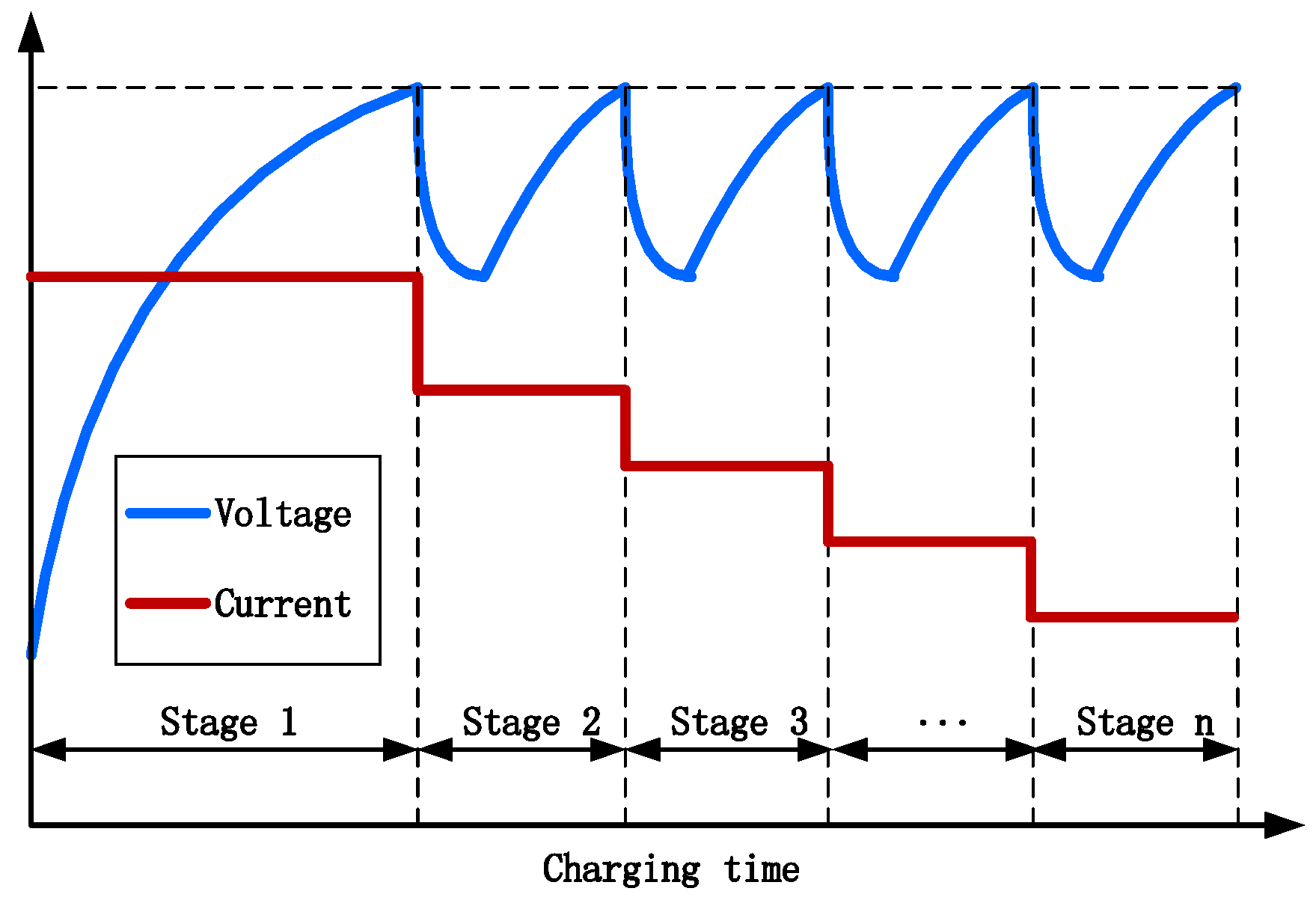

2.4. Simulation of the VMCC Charging Strategy

| Algorithm 1. Pseudo code of the VMCC charging strategy. |

VMCC (n, k,,,,, , ).

2: charging step update: k = k + 1 3: SOC update: SOC(k) = SOC(k − 1) + 4: if thend 5: break 6: end if 7: battery parameters update: , 8: 9: charging time update: 10: charged capacity update: 11: polarization voltage update: 12: battery terminal voltage update: 13: energy loss update: 14: temperature update: 15: if then 16: stage number update: n = n + 1 17: if n + 1 > then 18: break 19: else 20: charging current update: 21: end if 22: end if 23: Output , and |

3. Experimental Setup and Battery Parameter Estimation

3.1. Experimental Setup

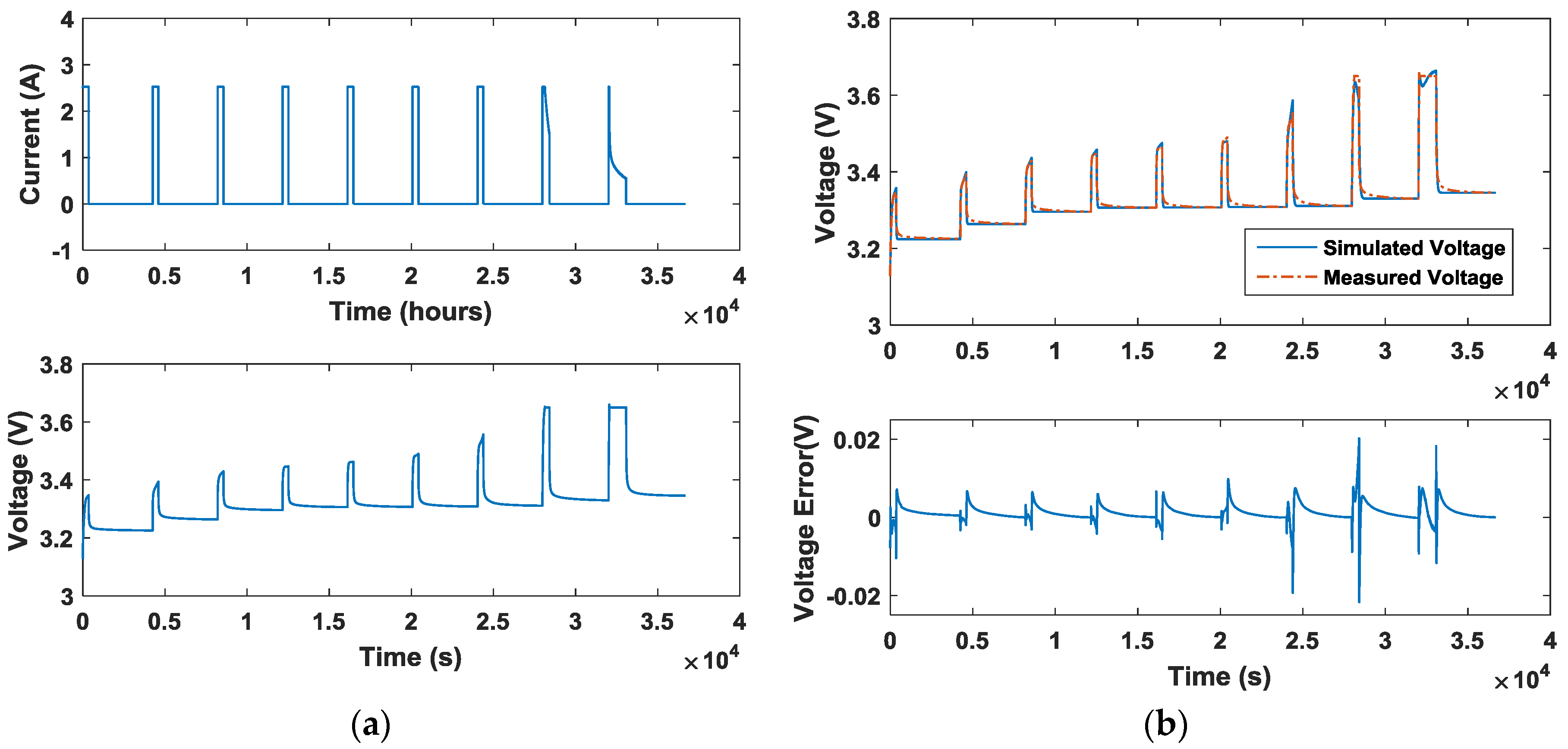

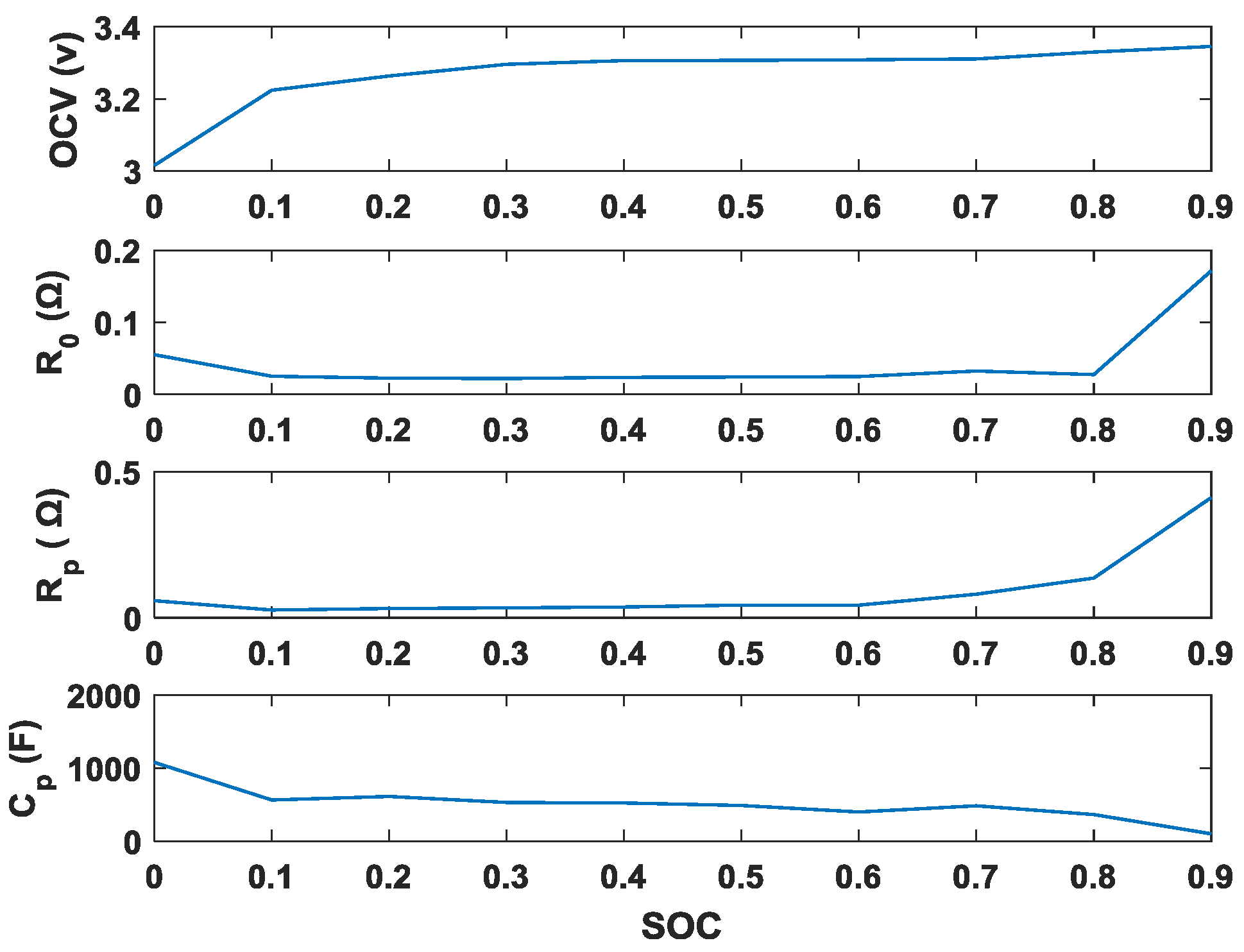

3.2. Battery Parameter Estimation

4. Multi-Object Optimization Problem Formulation

4.1. Problem Formulation

4.2. Constraint Conditions

5. MOPSO Based MCC Optimization

5.1. Multi-Object Optimization

- Step 1

- Particle initialization. An m-size population with random positions and zero velocities is generated. The position of the i-th particle is represented as and the velocity of the i-th particle is represented as , where n is the dimension of the search space.

- Step 2

- Evaluate the particles according to the simulation result of the MCC charging strategy.

- Step 3

- Store the nondominated particles in the repository (REP) and update the REP.

- Step 4

- Update the speed and velocity of each particle according to the following equations:where and denote the current and previous velocities in the n-th dimension, respectively. is the current position of the i-th particle in dimension n while is its previous position; is the inertia weight. is the cognitive learning factor, is the social learning factor. and are two random numbers in the range [0, 1]. is the local best value and is the global best value chosen from the repository.To determine , the explored objectives are meshed with hypercubes, and a fitness value is assigned to the hypercubes containing more than one particle with the following function:where, is the number of particles located in the i-th hypercube.Then is selected by applying a roulette-wheel selection.

- Step 5

- Convergence determination. Compare the average fitness value of the current particle swarm with the previous particle swarm; if the difference is less than the threshold value α, the search procedure is terminated.

- Step 6

- Repeat the steps from Step 2 to Step 5 until the best point is found or a fixed number of iterations has been reached.

5.2. Parameter Setting

5.3. Multi-Objective Decision Making

6. Results and Discussion

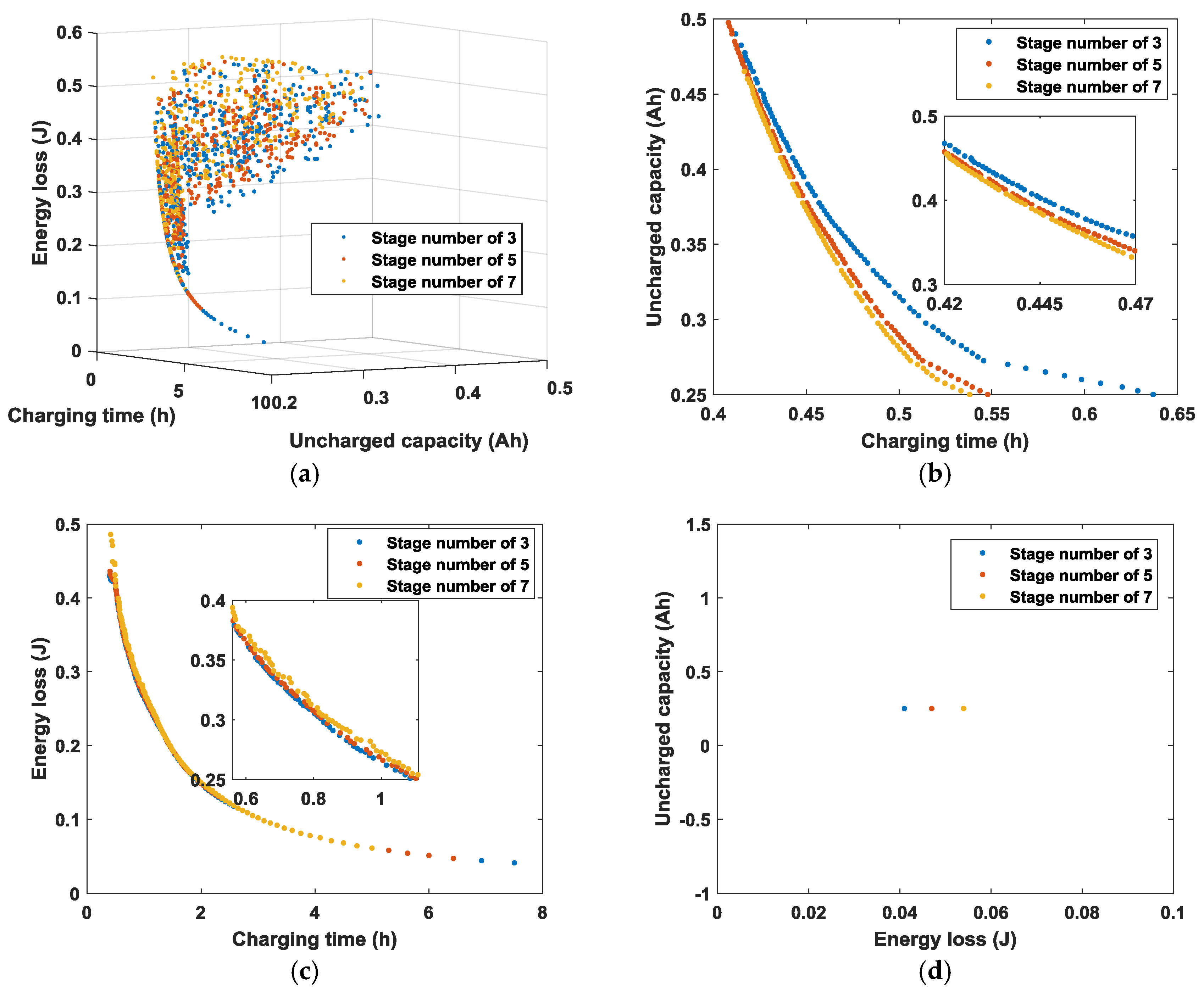

6.1. Impact of Stage Numbers

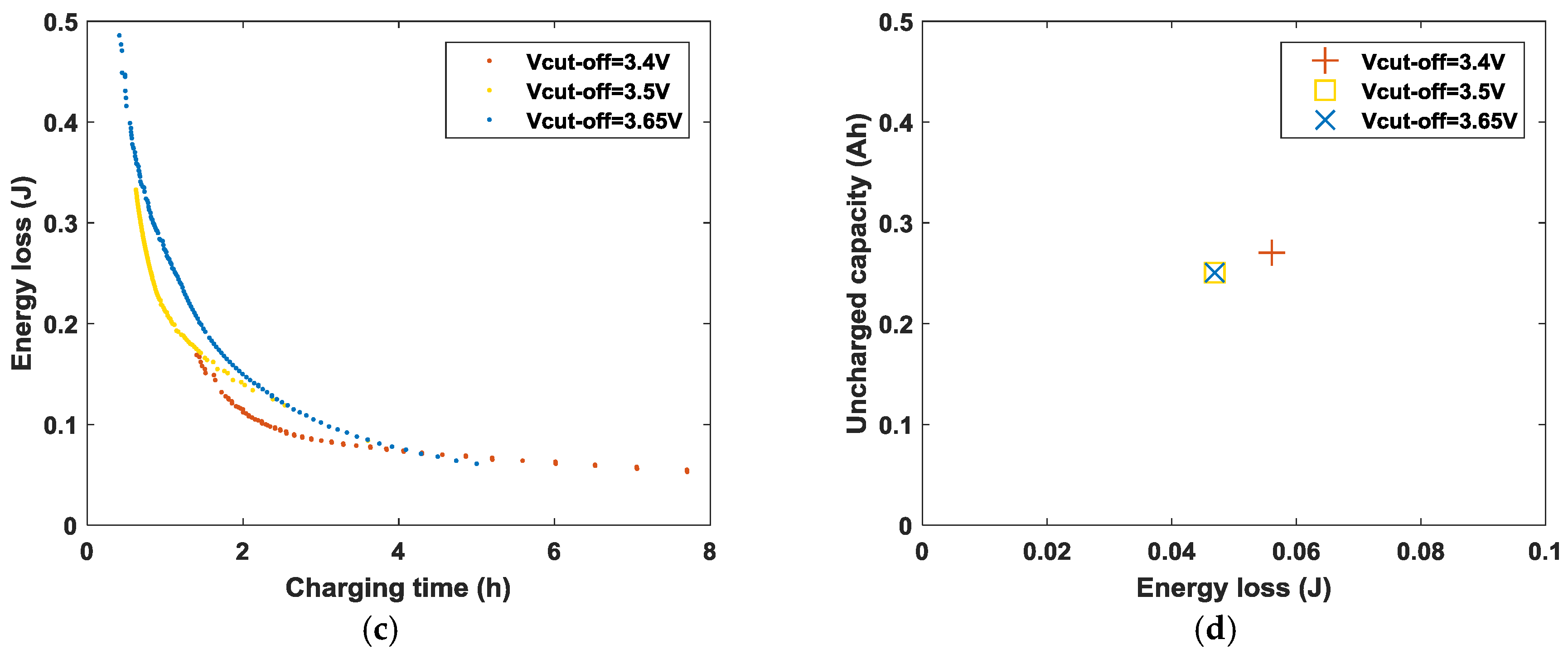

6.2. Impact of Cut-Off Voltage

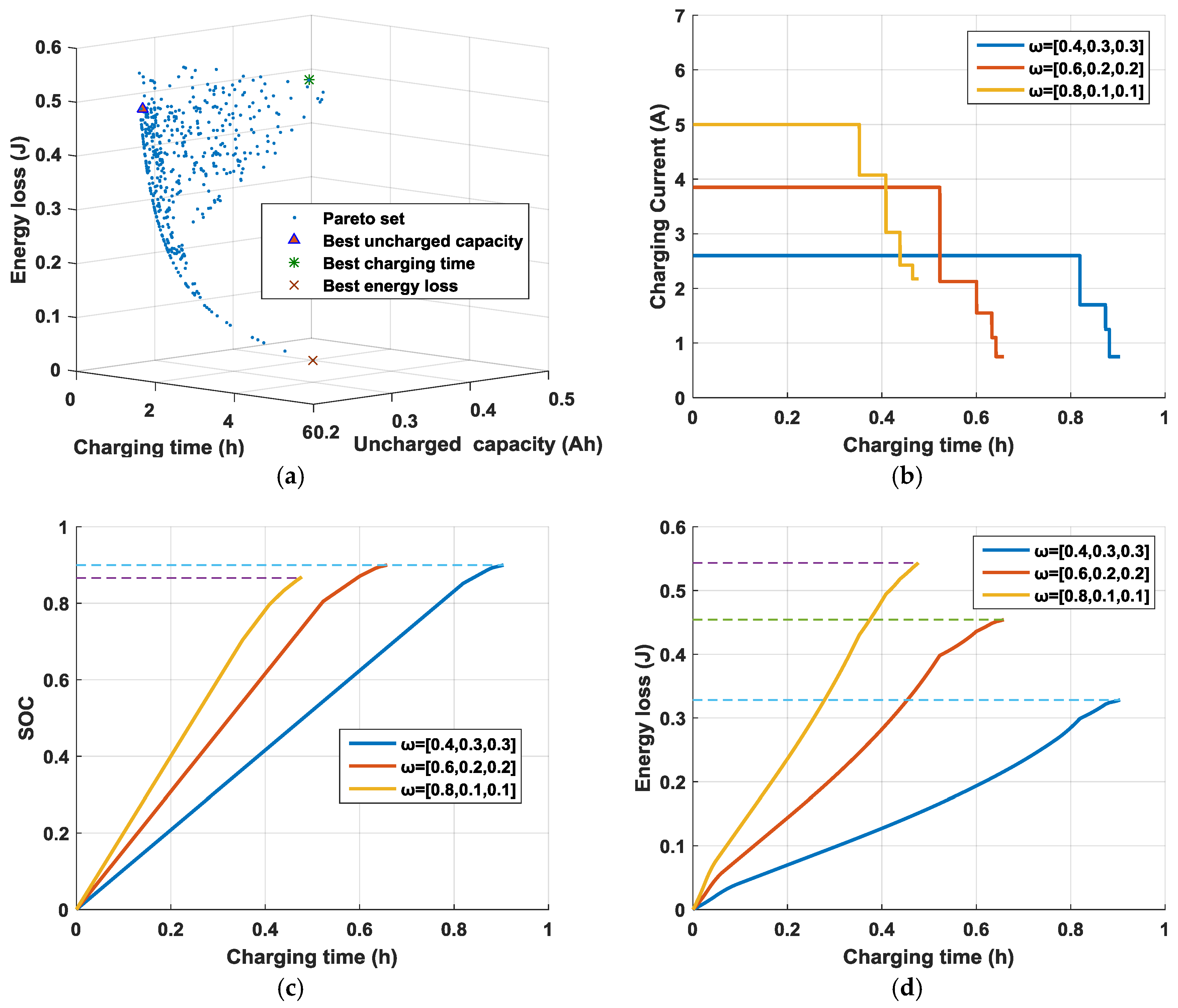

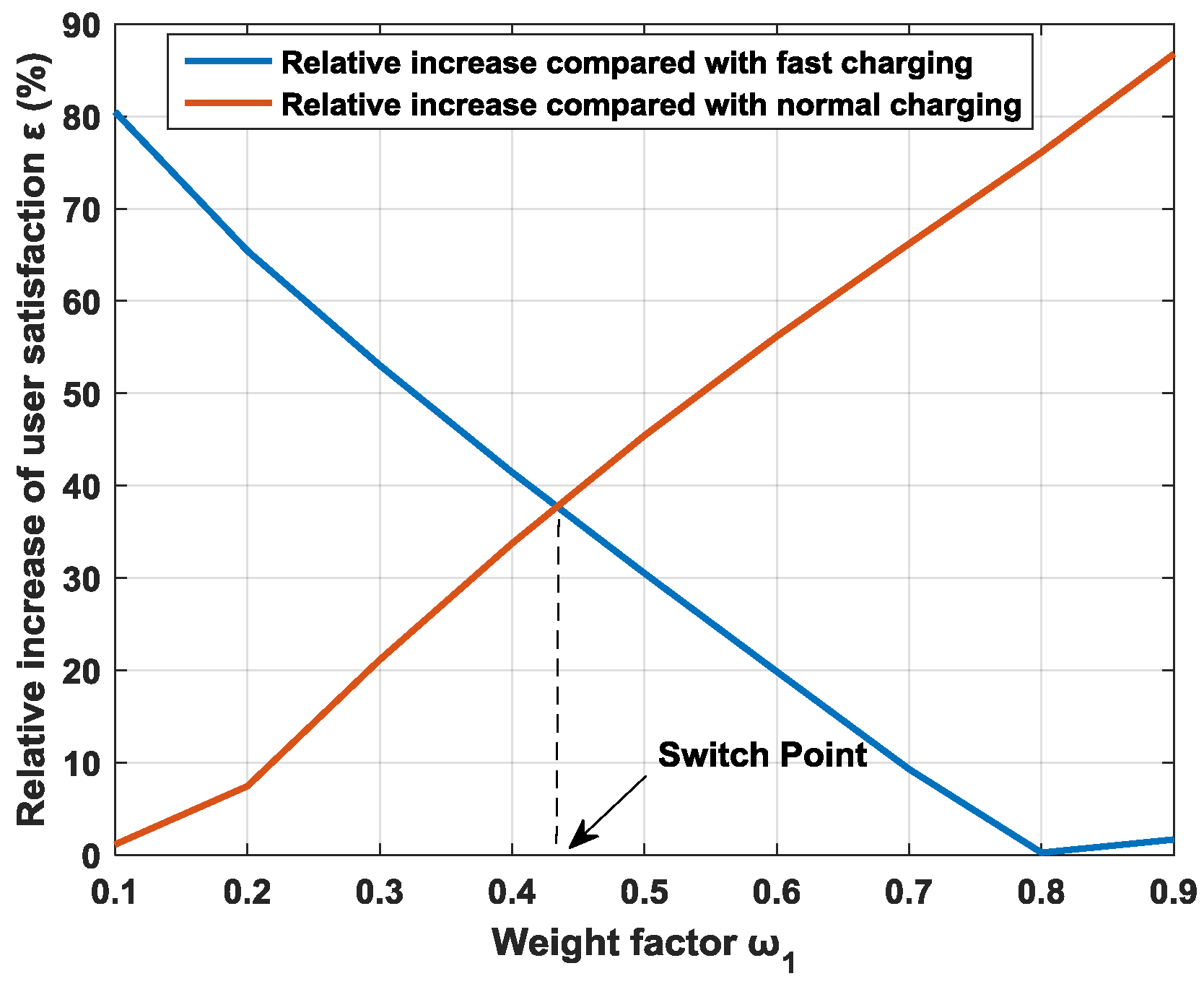

6.3. Impact of Weight Factors

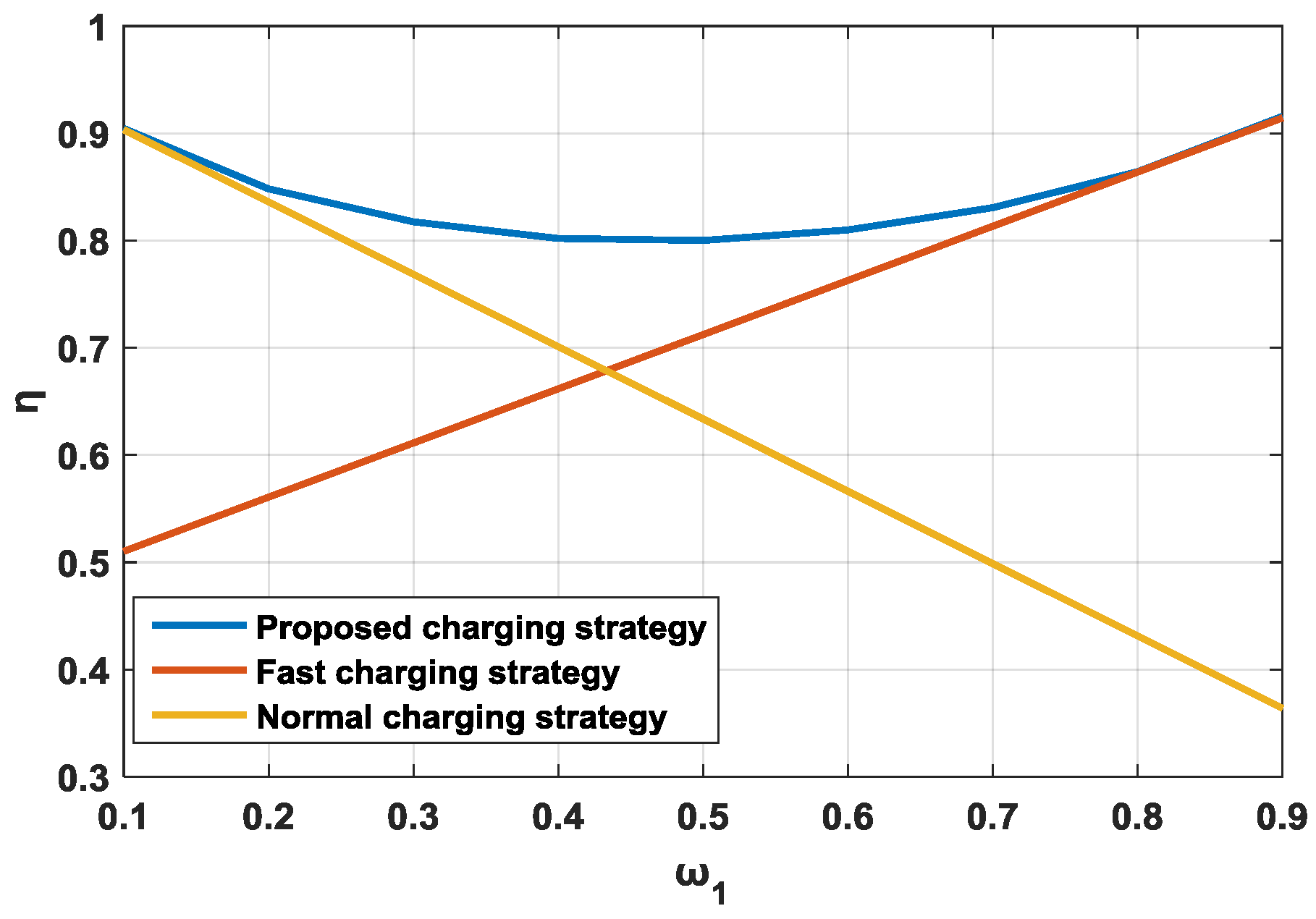

6.4. Experimental Comparison with the Traditional Charging Strategies

7. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Wang, D.; Guan, X.H.; Wu, J.; Li, P.; Zan, P.; Xu, H. Integrated energy exchange scheduling for multimicrogrid system with electric vehicles. IEEE Trans. Smart Grid 2016, 7, 1762–1774. [Google Scholar] [CrossRef]

- Gan, L.; Ufuk, T.; Steven, H.L. Optimal decentralized protocol for electric vehicle charging. IEEE Trans. Power Syst. 2011, 28, 940–951. [Google Scholar] [CrossRef]

- Pellegrino, G. Performance comparison between surface-mounted and interior PM motor drives for electric vehicle application. IEEE Trans. Ind. Electron. 2013, 59, 803–811. [Google Scholar] [CrossRef]

- Ansean, D.; Gonzalez, M.; Garcia, M.V. Evaluation of LiFePO4 batteries for electric vehicle applications. IEEE Trans. Ind. Appl. 2015, 2, 1855–1863. [Google Scholar] [CrossRef]

- Rahimi-Eichi, H.; Ojha, U.; Baronti, F.; Chow, M. Battery management system: An overview of its application in the smart grid and electric vehicles. IEEE Ind. Electron. Mag. 2013, 7, 4–16. [Google Scholar] [CrossRef]

- Lin, H.T.; Liang, T.J.; Chen, S.M. Estimation of battery state of health using probabilistic neural network. IEEE Trans. Ind. Inform. 2013, 9, 679–685. [Google Scholar] [CrossRef]

- Valle, B.D.; Wentz, C.T.; Sarpeshkar, R. An area and power-efficient analog Li-ion battery charger circuit. IEEE Trans. Biomed. Circuits. Syst. 2011, 5, 131–137. [Google Scholar] [CrossRef] [PubMed]

- Rahimi-Eichi, E.H.; Ojha, U.; Baronti, F.; Chow, M. Evaluation of acceptable charging current of power li-ion batteries based on polarization characteristics. IEEE Ind. Electron. 2014, 61, 6844–6851. [Google Scholar] [CrossRef]

- Hoffart, F. Proper care extends li-ion battery life. Power Electron. Technol. Mag. 2008, 34, 24–28. [Google Scholar]

- Hua, C.C.; Lin, M.Y. A study of charging control of lead-acid battery for electric vehicles. In Proceedings of the 2000 IEEE International Symposium on Industrial Electronics, Cholula, Puebla, Mexico, 4–8 December 2000; pp. 135–140. [Google Scholar]

- Abousleiman, R. Charge Capacity versus Charge Time in CC-CV and Pulse Charging of Li-Ion Batteries. Available online: http://papers.sae.org/2013-01-1546/ (accessed on 12 May 2017).

- Gao, Y.; Zhang, C. An optimal charging strategy of lithium-ion batteries based on polarization and temperature rise. In Proceedings of the IEEE Conference and Expo Transportation Electrification Asia-Pacific (ITEC Asia Pacific ’14), Beijing, China, 31 August–3 September 2014. [Google Scholar]

- Jiang, J.; Zhang, C.J. An optimal charging method for Li-ion batteries using a fuzzy-control approach based on polarization properties. IEEE Trans. Veh. Technol. 2013, 62, 3000–3009. [Google Scholar] [CrossRef]

- Chen, L.R. Design of duty-varied voltage pulse charger for improving Li-ion battery-charging response. IEEE Trans. Ind. Electron. 2009, 56, 480–487. [Google Scholar] [CrossRef]

- Ikeya, T. Multi-step constant-current charging method for electric vehicle, valve-regulated, lead/acid batteries during night time for load leveling. J. Power Sources 1998, 75, 101–107. [Google Scholar] [CrossRef]

- Ikeya, T. Multi-step constant-current charging method for an electric vehicle nickel/metal hydride battery with high energy efficiency and long cycle life. J. Power Sources 2002, 105, 6–12. [Google Scholar] [CrossRef]

- Liu, Y.H.; Luo, Y.F. Search for an optimal rapid-charging pattern for Li-ion batteries using the Taguchi approach. IEEE Trans. Ind. Electron. 2010, 57, 3963–3971. [Google Scholar] [CrossRef]

- Vo, T.T.; Chen, X; Shen, W. New charging strategy for lithium-ion batteries based on the integration of Taguchi method and state of charge estimation. J. Power Sources 2015, 273, 413–422. [Google Scholar] [CrossRef]

- Zhang, C.P.; Wen, J.P.; Zhang, W.G. A PSO-Based fuzzy-controlled searching for the optimal charge pattern of li-ion batteries. IEEE Trans. Ind. Electron. 2015, 62, 2983–2993. [Google Scholar] [CrossRef]

- Liu, Y.H.; Teng, J.H.; Lin, Y.C. Search for an optimal rapid charging pattern for lithium-ion batteries using Ant Colony System algorithm. IEEE Trans. Ind. Electron. 2005, 52, 1328–1336. [Google Scholar] [CrossRef]

- Dung, L.R.; Yen, J.H. ILP-based algorithm for Lithium-ion battery charging profile. Proceeding of the 2010 IEEE International Symposium on Industrial Electronics (ISIE), Bari, Italy, 4–7 July 2010; pp. 2286–2291. [Google Scholar]

- Hu, X.; Li, S.; Peng, H. Charging time and loss optimization for LiNMC and LiFePO4 batteries based on equivalent circuit models. J. Power Sources 2013, 239, 449–457. [Google Scholar] [CrossRef]

- Abdollahi, A.; Han, X.; Avvari, G.V. Optimal battery charging, part I: Minimizing time-to-charge, energy loss, and temperature rise for OCV-resistance battery model. J. Power Sources 2016, 303, 388–398. [Google Scholar] [CrossRef]

- Ceraolo, M.; Lutzemberger, G.; Huria, T. Experimentally Determined Models for High-Power Lithium Batteries. Available online: http://papers.sae.org/2011-01-1365/ (accessed on 12 May 2017).

- Roscher, M.A.; Assfalg, J.; Bohlen, O.S. Detection of utilizable capacity deterioration in battery systems. IEEE Trans. Veh. Technol. 2011, 60, 98–103. [Google Scholar] [CrossRef]

- Hu, X.; Li, S.; Peng, H. A comparative study of equivalent circuit models for Li-ion batteries. J. Power Sources. 2012, 198, 359–367. [Google Scholar] [CrossRef]

- Moura, S.J.; Fathy, H.K.; Callaway, D.S. A stochastic optimal control approach for power management in plug-in hybrid electric vehicles. IEEE Trans. Contr. Syst. Technol. 2008, 19, 545–555. [Google Scholar] [CrossRef]

- Kum, D.; Peng, H.; Bucknor, N.K. Optimal energy and catalyst temperature management of plug-in hybrid electric vehicles for minimum fuel consumption and tail-pipe emissions. IEEE Trans. Contr. Syst. Technol. 2013, 21, 14–26. [Google Scholar] [CrossRef]

- Coello, C.A.; Pulido, G.T.; Lechuga, M.S. Handling multiple objectives with particle swarm optimization. IEEE Trans. Evol. Comput. 2004, 8, 256–279. [Google Scholar] [CrossRef]

- Chamaani, S.; Mirtaheri, S.A.; Abrishamian, M.S. Time-domain design of UWB Vivaldi antenna array using multi-objective particle swarm optimization. IEEE Antennas Wirel. Propag. Lett. 2010, 9, 666–669. [Google Scholar] [CrossRef]

- Shen, Y.; He, Z.; Liu, D. Optimization of fuel consumption and emissions for auxiliary power unit based on multi-objective optimization model. Energies 2016, 9, 90. [Google Scholar] [CrossRef]

- Liu, D.; Wang, Y.; Shen, Y. Electric vehicle charging and discharging coordination on distribution network using multi-objective particle swarm optimization and fuzzy decision making. Energies 2016, 9, 186. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Min, H.; Sun, W.; Li, X.; Guo, D.; Yu, Y.; Zhu, T.; Zhao, Z. Research on the Optimal Charging Strategy for Li-Ion Batteries Based on Multi-Objective Optimization. Energies 2017, 10, 709. https://doi.org/10.3390/en10050709

Min H, Sun W, Li X, Guo D, Yu Y, Zhu T, Zhao Z. Research on the Optimal Charging Strategy for Li-Ion Batteries Based on Multi-Objective Optimization. Energies. 2017; 10(5):709. https://doi.org/10.3390/en10050709

Chicago/Turabian StyleMin, Haitao, Weiyi Sun, Xinyong Li, Dongni Guo, Yuanbin Yu, Tao Zhu, and Zhongmin Zhao. 2017. "Research on the Optimal Charging Strategy for Li-Ion Batteries Based on Multi-Objective Optimization" Energies 10, no. 5: 709. https://doi.org/10.3390/en10050709