Simulation Modeling Method and Experimental Investigation on the Uniflow Scavenging System of an Opposed-Piston Folded-Cranktrain Diesel Engine

Abstract

:1. Introduction

2. Uniflow Scavenging System of an OPFC Diesel Engine

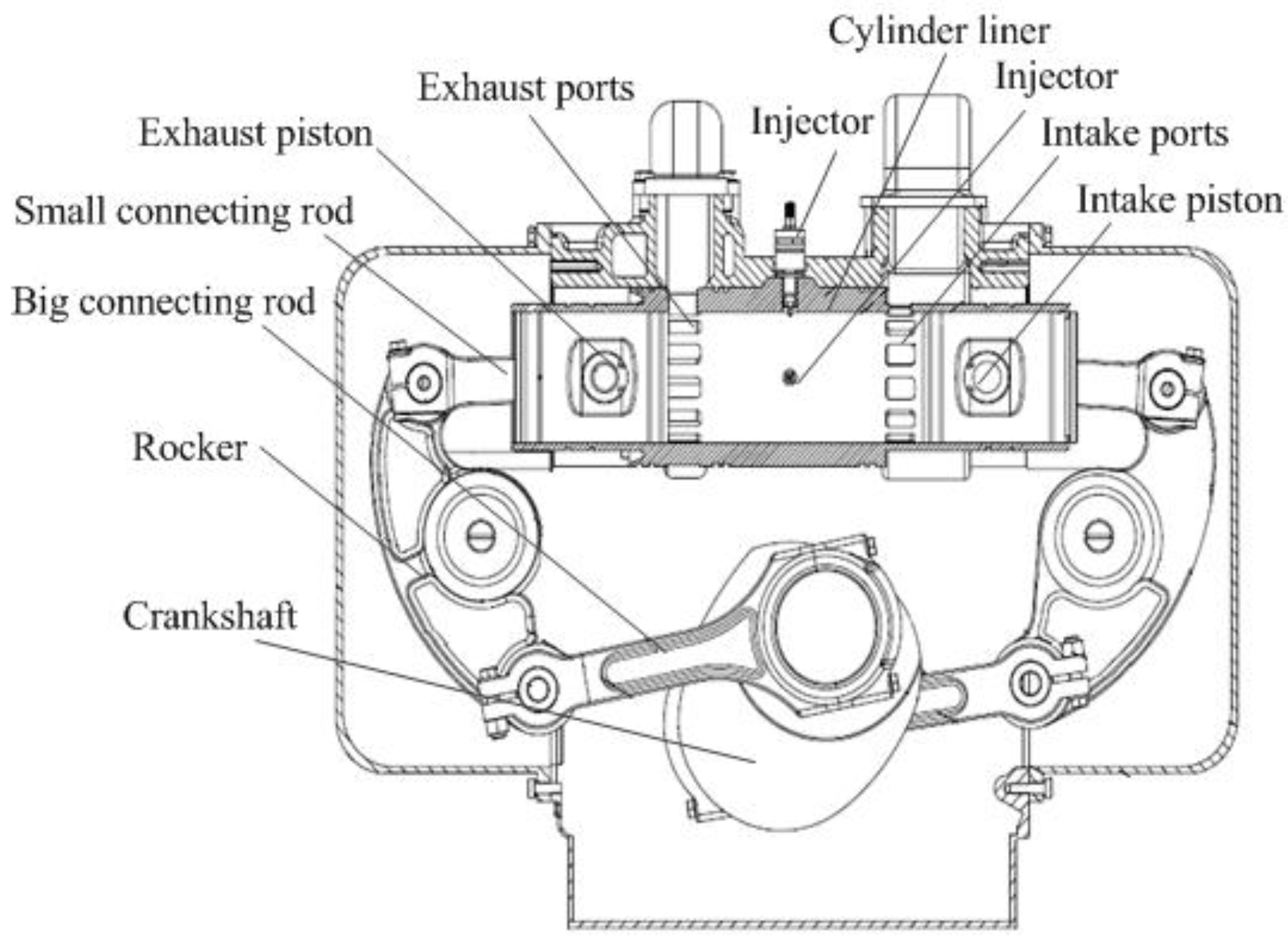

2.1. OPFC Diesel Engine Concept

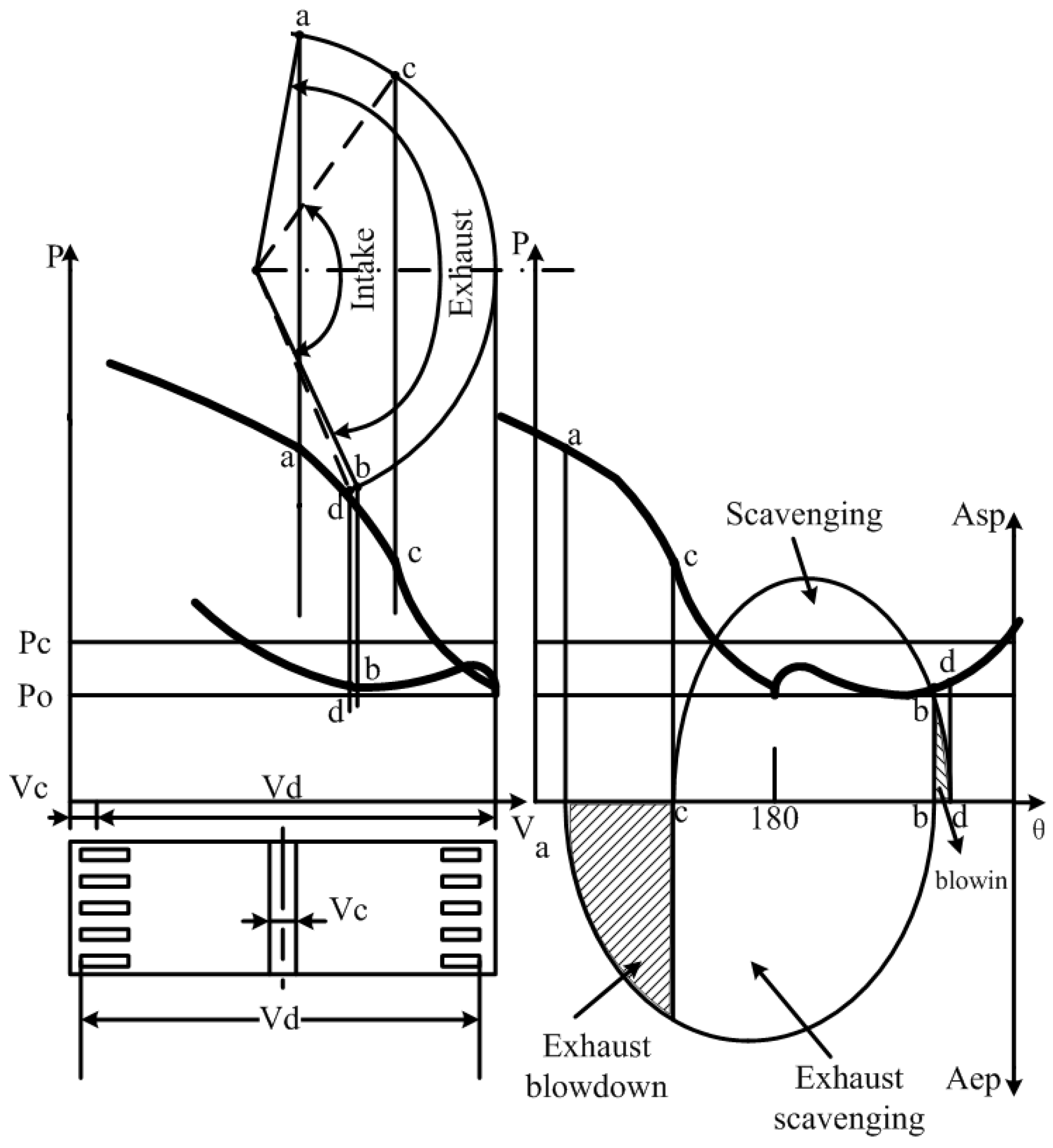

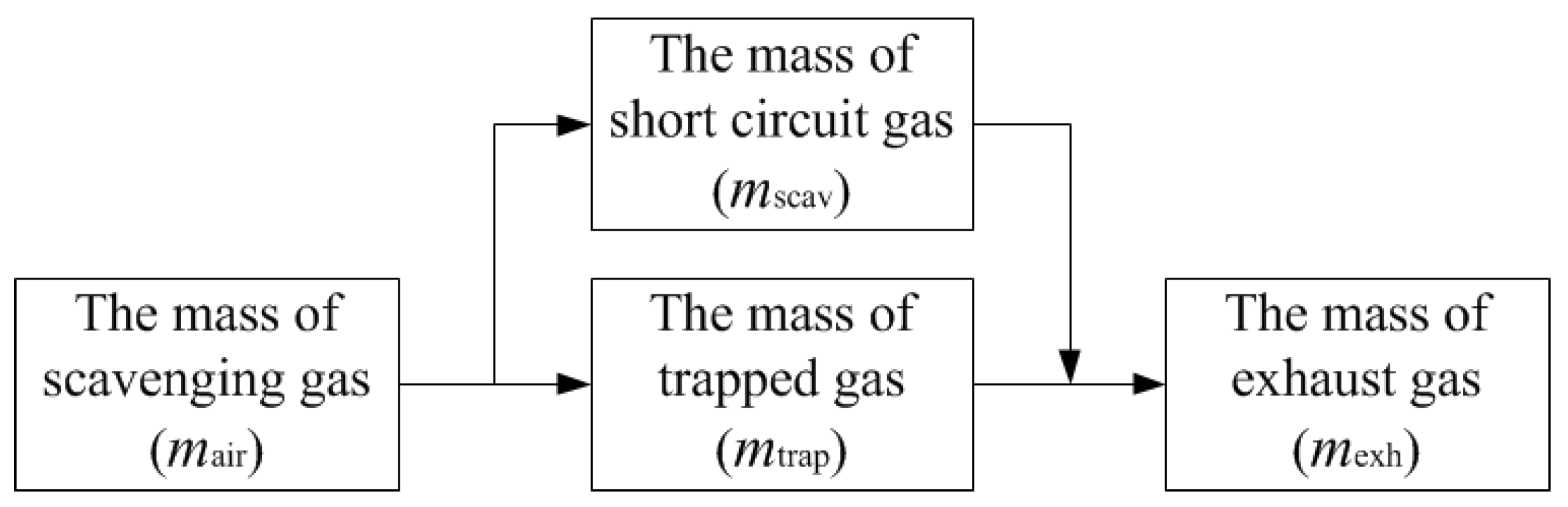

2.2. Scavenging Process Characterization

3. Uniflow Scavenging System Modeling

3.1. Working Process 1D Model

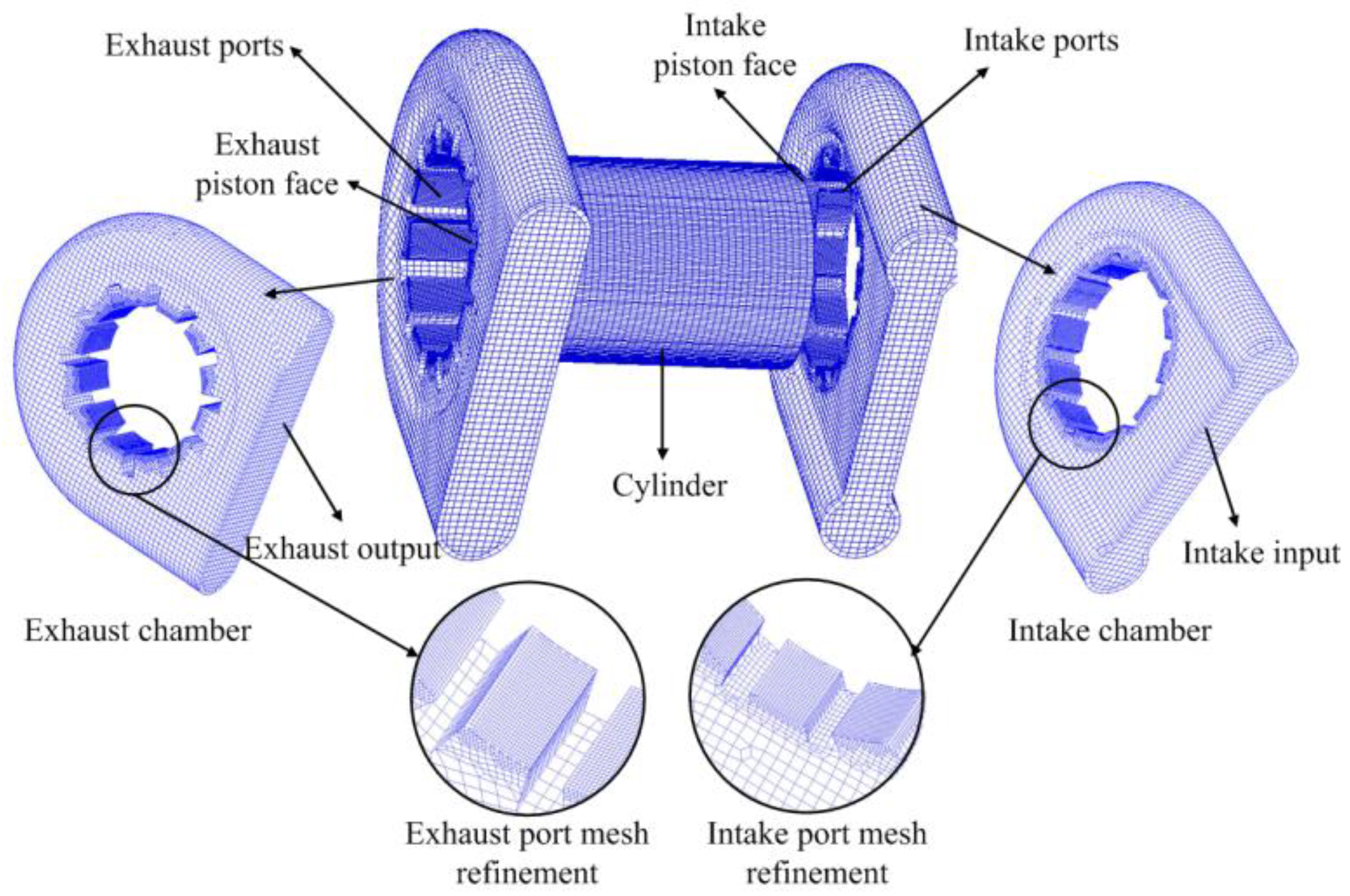

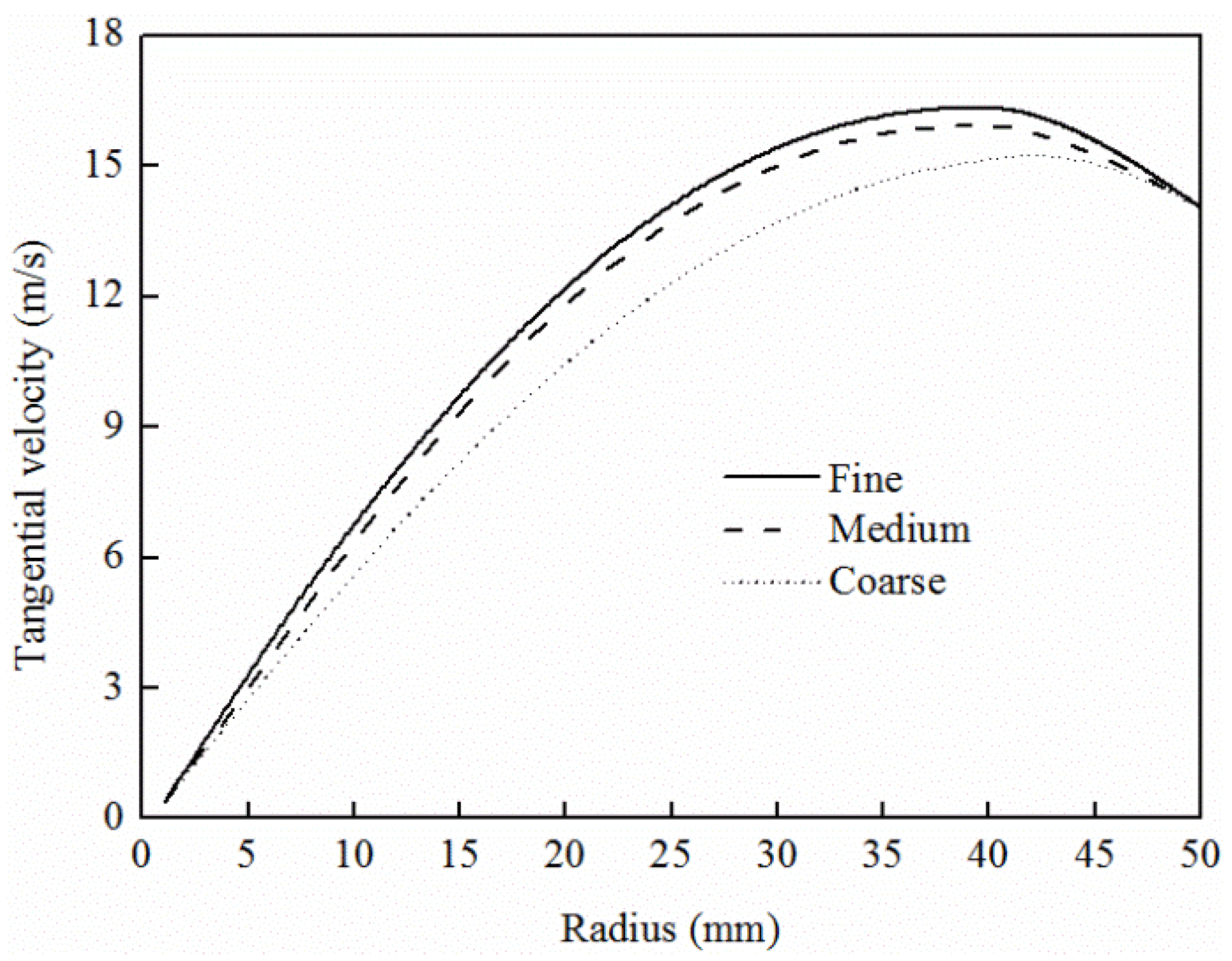

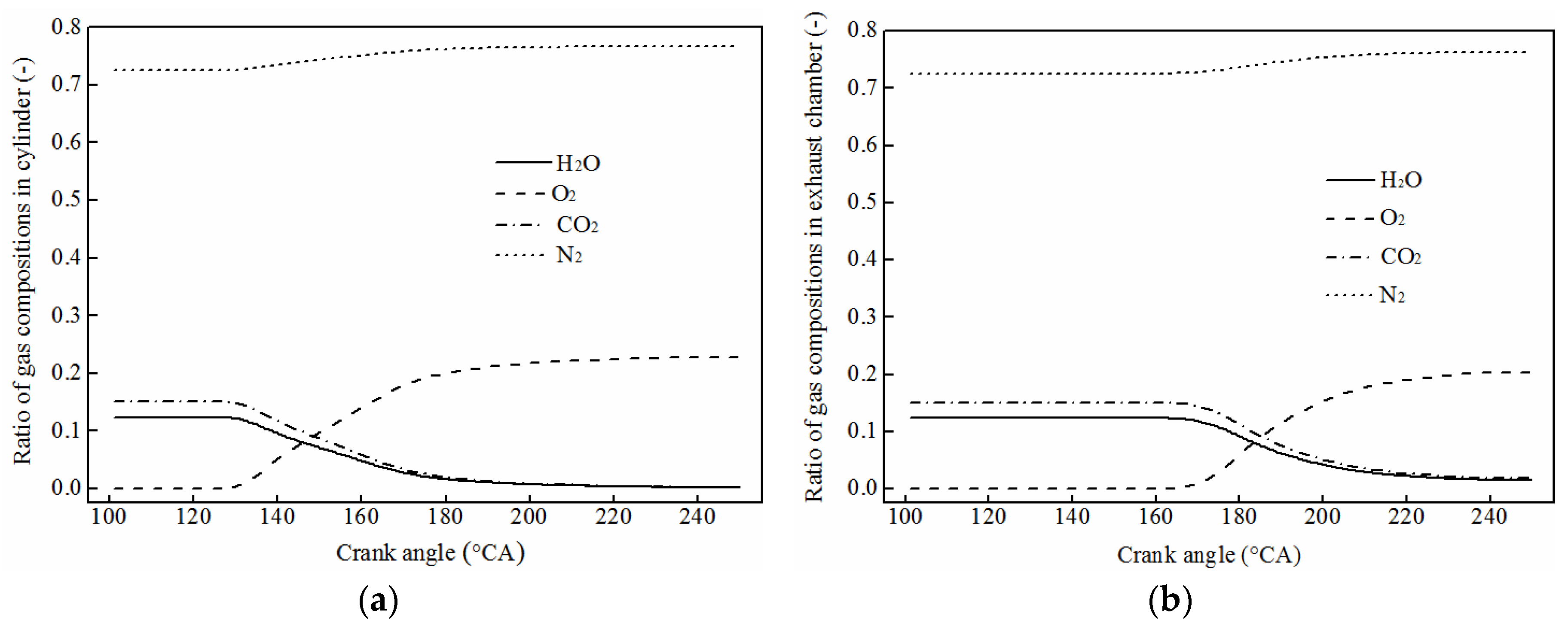

3.2. Scavenging Process 3D CFD Model

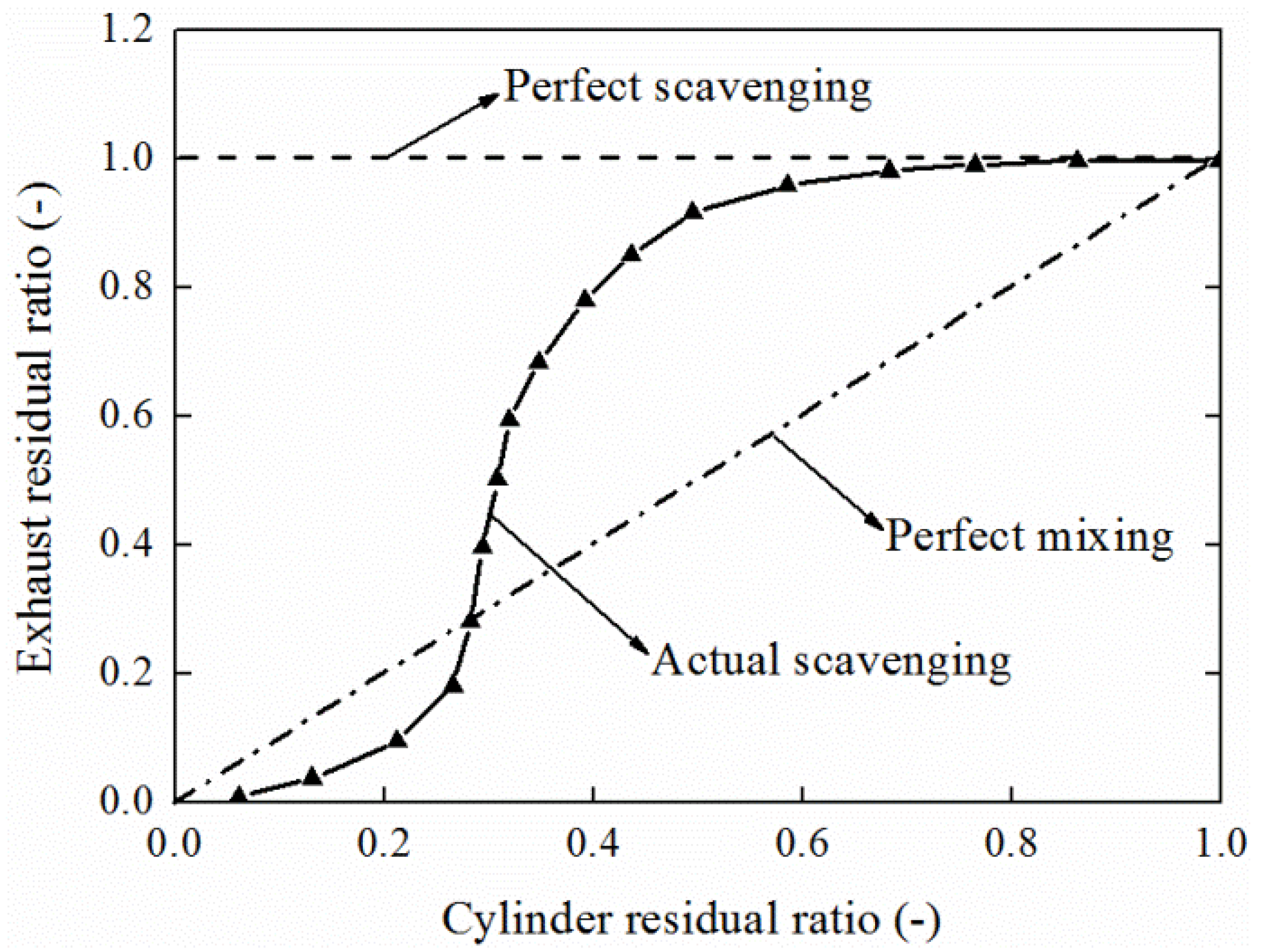

3.3. Scavenging Profile

4. Experimental Investigations

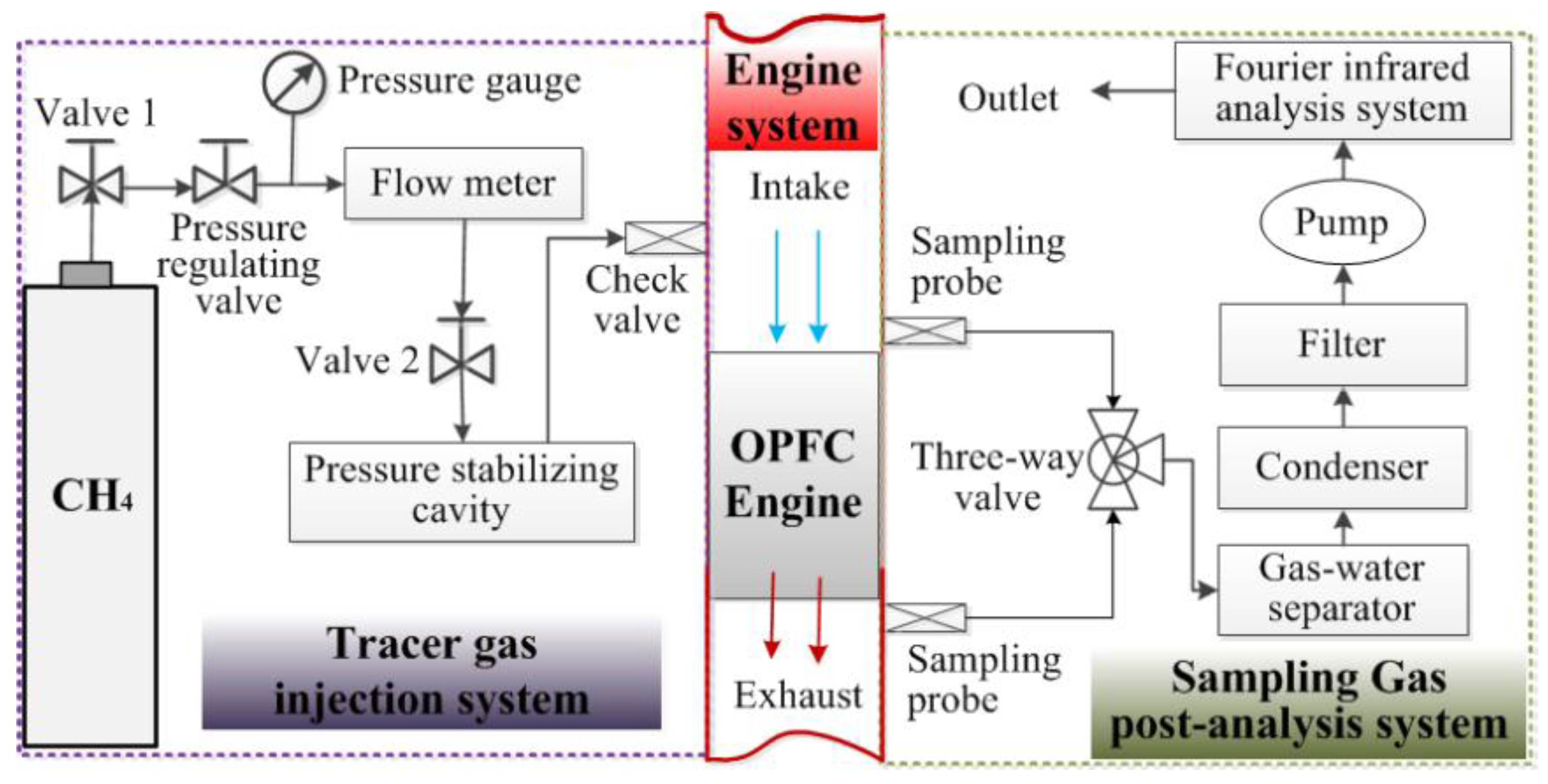

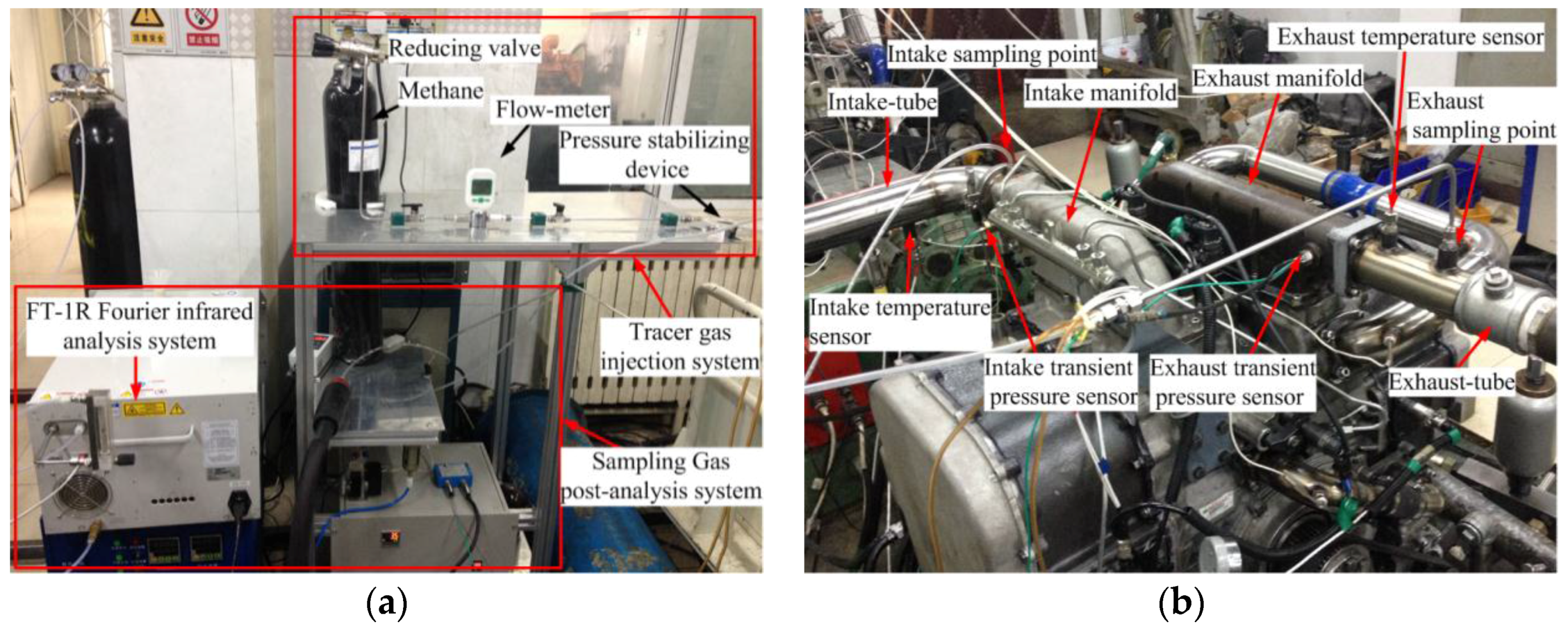

4.1. Tracer Gas Method

4.2. Scavenging Process Parameters

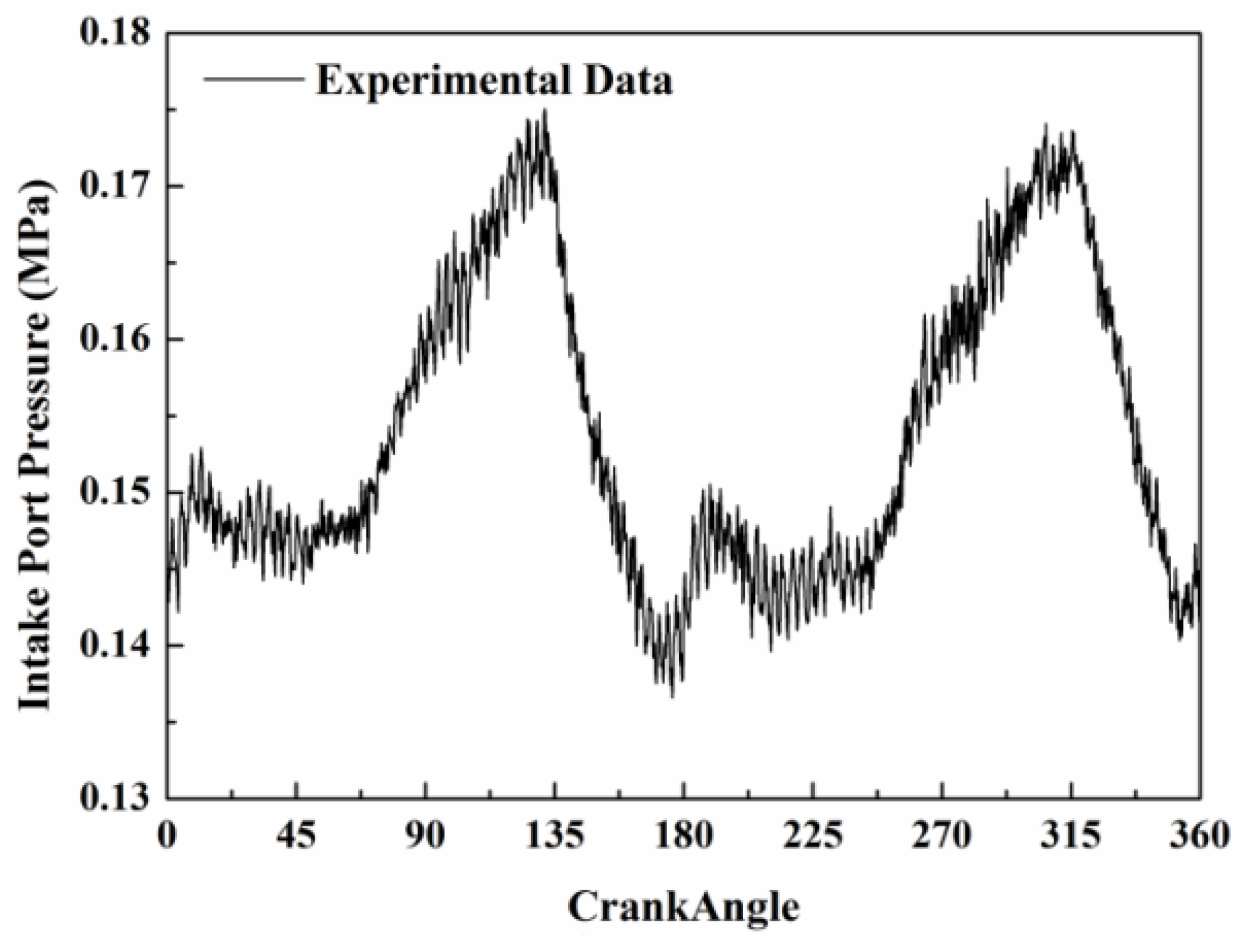

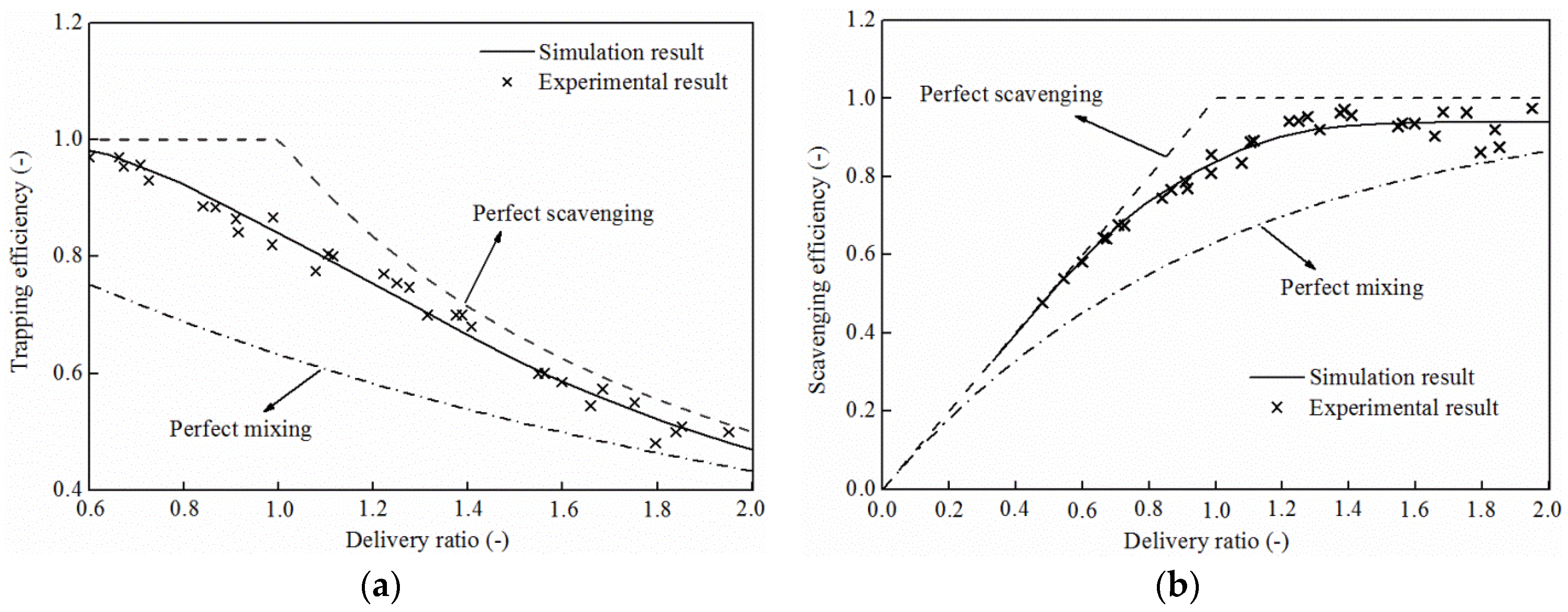

4.3. Validation of Scavenging Model

4.4. Experimental Results and Analysis

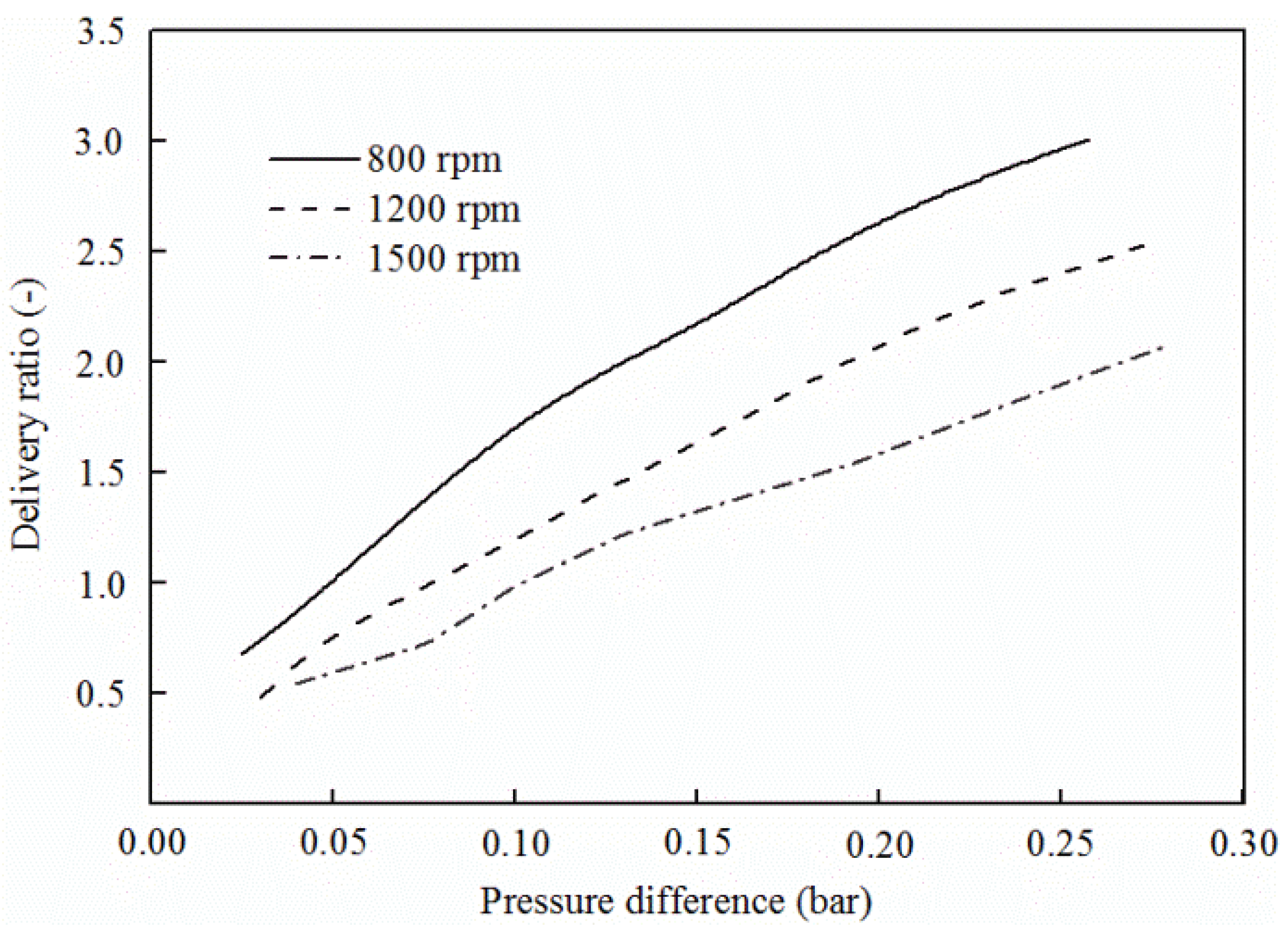

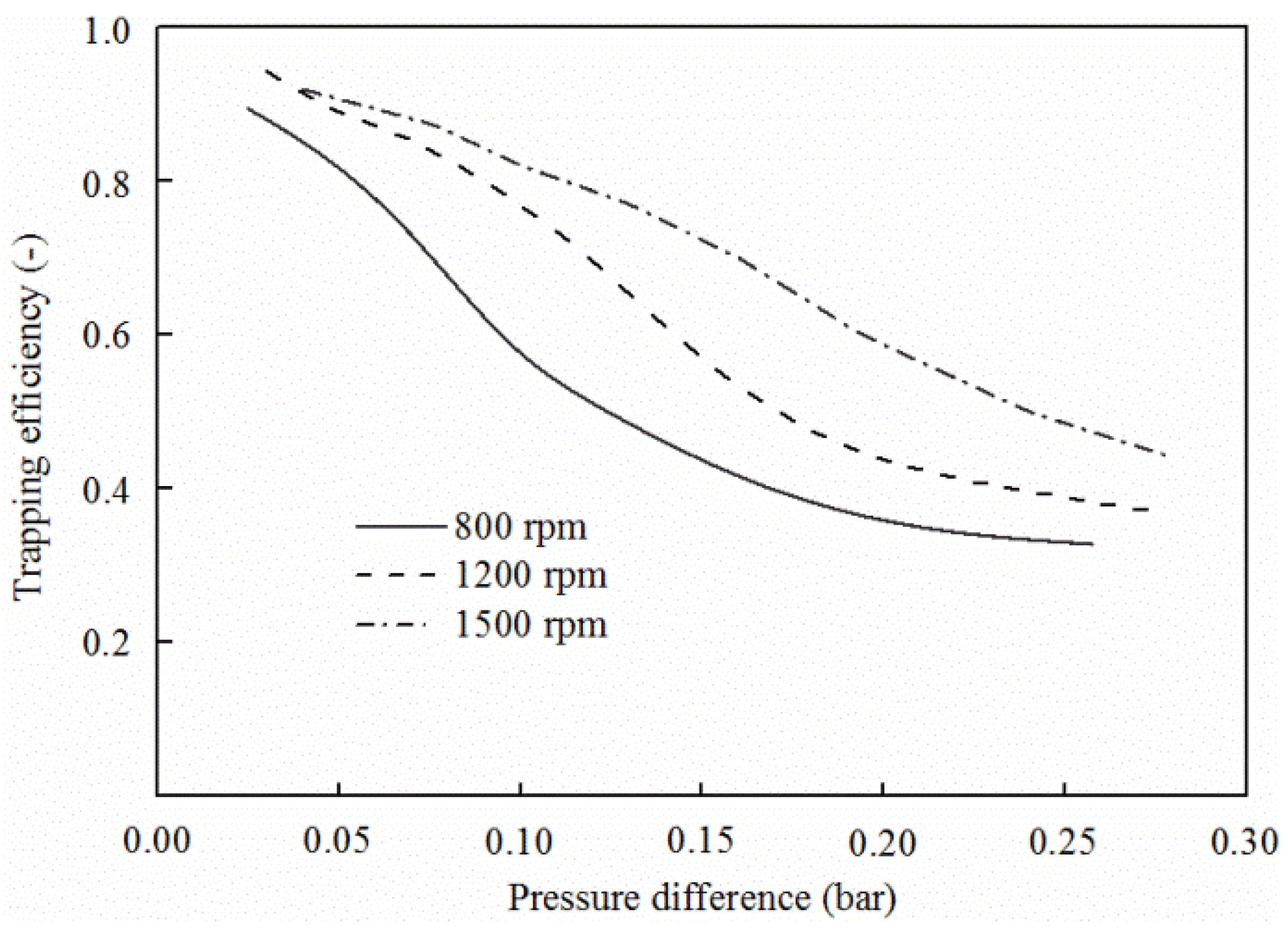

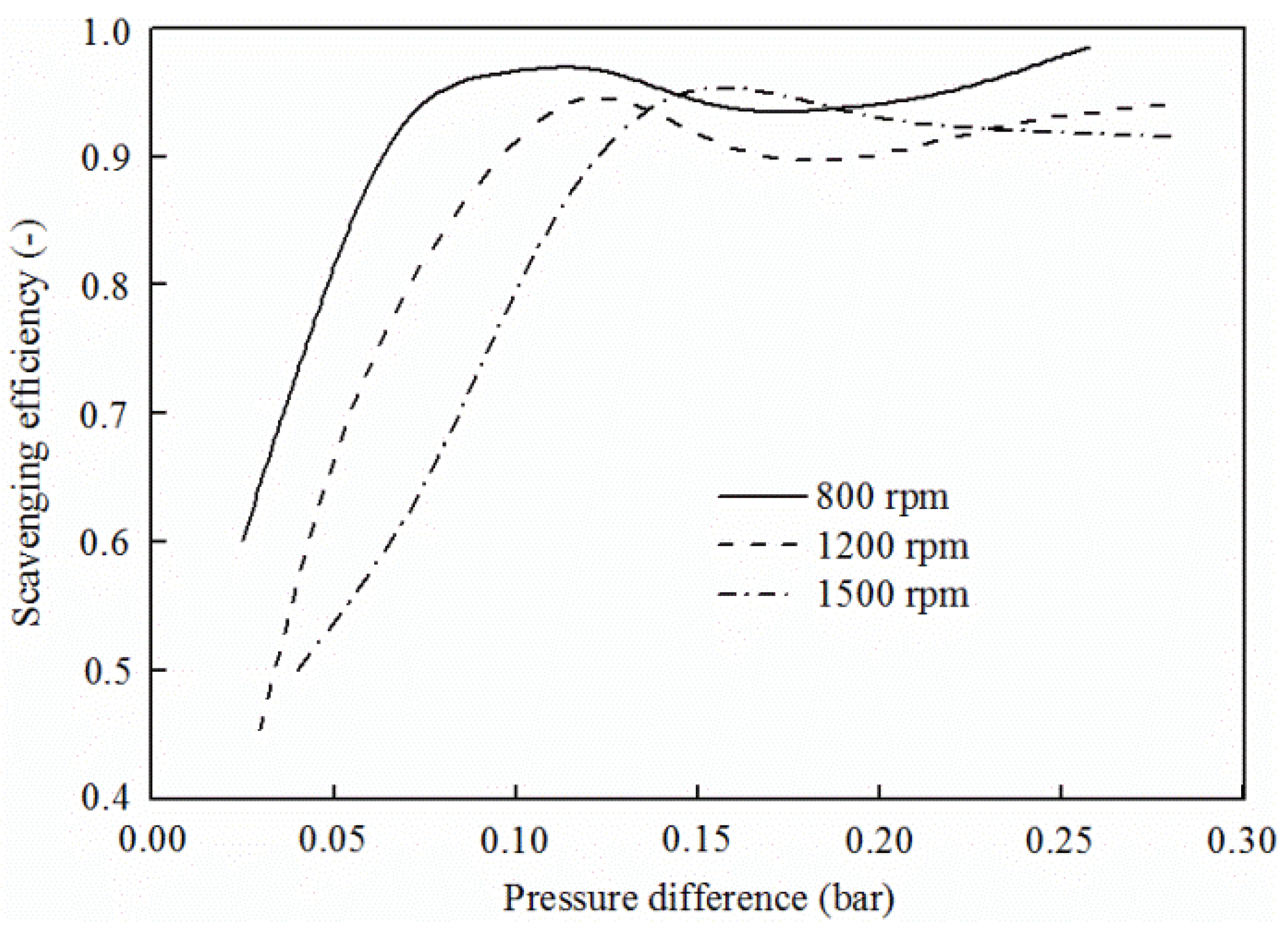

4.4.1. Effect of Pressure Difference on Scavenging Process

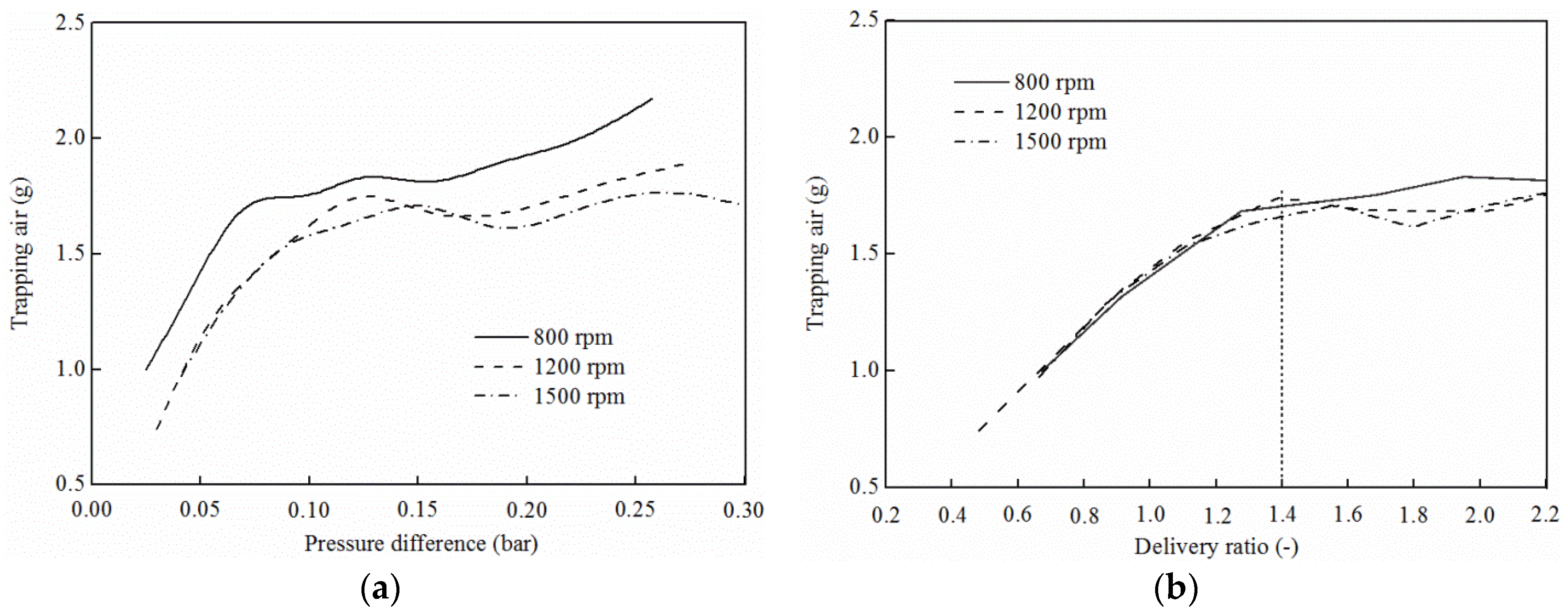

4.4.2. Effect of Pressure Difference on Trapping Air

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| 1D | mono-dimensional | IPC | intake ports closing |

| 3D | three-dimensional | ODC | outer dead center |

| CA | crank angle | OP2S | opposed-piston two-stroke |

| CFD | computational fluid dynamics | OPFC | opposed-piston folded-cranktrain |

| EPO | exhaust port opening | TDC | top dead center |

| IDC | inner dead center | TGM | tracer gas method |

References

- Pirault, J.P.; Flint, M. Opposed Piston Engines: Evolution, Use, and Future Applications; SAE International: Warrendale, PA, USA, 2010. [Google Scholar]

- Naik, S.; Johnson, D.; Koszewnik, J. Practical Applications of Opposed-Piston Engine Technology to Reduce Fuel Consumption and Emissions; SAE Technical Paper 2013-01-2754; SAE International: Warrendale, PA, USA, 2013. [Google Scholar]

- Hofbauer, P. Opposed Piston Opposed Cylinder (OPOC) Engine for Military Ground Vehicles; SAE Technical Paper 2005-01-1548; SAE International: Warrendale, PA, USA, 2005. [Google Scholar]

- Hirsch, N.R.; Schwarz, E.E.; McGough, M.G. Advanced Opposed-Piston Two-Stroke Diesel Demonstrator; SAE Technical Paper 2006-01-0926; SAE International: Warrendale, PA, USA, 2006. [Google Scholar]

- Herold, R.E.; Wahl, M.H.; Regner, G. Thermodynamic Benefits of Opposed-Piston Two-Stroke Engines; SAE Technical Paper 2011-01-2216; SAE International: Warrendale, PA, USA, 2011. [Google Scholar]

- Regner, G.; Herold, R.E.; Wahl, M.H. The Achates Power Opposed-Piston Two-Stroke Engine: Performance and Emissions Results in a Medium-Duty Application; SAE Technical Paper 2011-01-2221; SAE International: Warrendale, PA, USA, 2011. [Google Scholar]

- Redon, F.; Kalebjian, C.; Kessler, J. Meeting Stringent 2025 Emissions and Fuel Efficiency Regulations with an Opposed-Piston, Light-Duty Diesel Engine; SAE Technical Paper 2014-01-1187; SAE International: Warrendale, PA, USA, 2014. [Google Scholar]

- Regner, G.; Johnson, D.; Koszewnik, J. Modernizing the Opposed Piston, Two-Stroke Engine for Clean, Efficient Transportation; SAE Technical Paper 2013-26-0114; SAE International: Warrendale, PA, USA, 2013. [Google Scholar]

- Hopkinson, B. The charging of two-cycle internal-combustion engines. J. Am. Soc. Naval Eng. 2010, 26, 974–985. [Google Scholar] [CrossRef]

- Merker, G.; Gerstle, M. Evaluation on Two Stroke Engines Scavenging Models; SAE Paper 970358; SAE International: Warrendale, PA, USA, 1997. [Google Scholar]

- Benson, R.S.; Brandham, P.T. A method for obtaining a quantitative assessment of the influence of charging efficiency on two-stroke engine performance. Int. J. Mech. Sci. 1969, 11, 303–312. [Google Scholar] [CrossRef]

- Dang, D.; Wallace, F.J. Some single zone scavenging models for two-stroke engines. Int. J. Mech. Sci. 1992, 34, 595–604. [Google Scholar] [CrossRef]

- Sher, E.; Harari, R. A simple and realistic model for the scavenging process in a crankcase-scavenged two-stroke cycle engine. Proc. Inst. Mech. Eng. Part A J. Power Energy 1991, 205, 129–137. [Google Scholar] [CrossRef]

- Streit, E.E.; Borman, G.L. Mathematical Simulation of a Large Turbocharged Two-Stroke Diesel Engine; SAE International: Warrendale, PA, USA, 1971. [Google Scholar]

- Wallace, F.; Cave, P. Experimental and Analytical Scavenging Studies on a Two-Cycle Opposed Piston Diesel Engine; SAE Technical Paper 710175; SAE International: Warrendale, PA, USA, 1971. [Google Scholar]

- Bozza, F.; Gimelli, A. A Comprehensive 1D Model for the Simulation of a Small-Size Two-Stroke SI Engine; SAE Paper 2004-01-0999; SAE International: Warrendale, PA, USA, 2004. [Google Scholar]

- Ferrara, G.; Balduzzi, F.; Vichi, G. An Innovative Solution for Two-Stroke Engines to Reduce the Short-Circuit Effects; SAE Technical Paper 2012-01-0180; SAE International: Warrendale, PA, USA, 2012. [Google Scholar]

- Laget, O.; Ternel, C.; Thiriot, J.; Charmasson, S.; Tribotte, P.; Vidal, F. Preliminary design of a two-stroke uniflow diesel engine for passenger car. SAE Int. J. Engines 2013, 6, 596–613. [Google Scholar] [CrossRef]

- Tribotte, P.; Ravet, F.; Dugue, V.; Obernesser, P.; Quechon, N.; Benajes, J.; Novella, R.; De Lima, D. Two strokes diesel engine-promising solution to reduce CO2 emissions. Proced. Soc. Behav. Sci. 2012, 48, 2295–2314. [Google Scholar] [CrossRef]

- Pohorelsky, L.; Brynych, P.; Macek, J.; Vallaude, P.-Y.; Ricaud, J.-C.; Obernesser, P.; Tribottre, P. Air System Conception for a Downsized Two-Stroke Diesel Engine; SAE Technical Paper 2012-01-0831; SAE International: Warrendale, PA, USA, 2012. [Google Scholar]

- He, C.; Xu, S. Transient Gas Exchange Simulation and Uniflow Scavenging Analysis for a Unique Opposed Piston Diesel Engine; SAE Technical Paper 2016-01-1087; SAE International: Warrendale, PA, USA, 2016. [Google Scholar]

- Wang, X.; Ma, J.; Zhao, H. Evaluations of Scavenge Port Designs for a Boosted Uniflow Scavenged Direct Injection Gasoline (BUSDIG) Engine by 3D CFD Simulations; SAE Technical Paper 2016-01-1049; SAE International: Warrendale, PA, USA, 2011. [Google Scholar]

- Ma, J.; Zhao, H. The Modeling and Design of a Boosted Uniflow Scavenged Direct Injection Gasoline (BUSDIG) Engine; SAE Technical Paper 2015-01-1970; SAE International: Warrendale, PA, USA, 2015. [Google Scholar]

- Nuti, M.; Martorano, L. Short-Circuit Ratio Evaluation in the Scavenging of Two-Stroke S. I. Engines; SAE 850177; SAE International: Warrendale, PA, USA, 1985. [Google Scholar]

- Olsen, D.B.; Holden, J.C.; Hutcherson, G.C.; Willson, B.D. Formaldehyde characterization utilizing in-cylinder sampling in a large bore natural gas engine. ASME J. Eng. Gas Turbines Power 2001, 123, 669–676. [Google Scholar] [CrossRef]

- Matthew, G.M.; Robert, F. Experimental Investigation of the Scavenging Performance of a Two-Stroke Opposed-Piston Diesel Tank Engine; SAE Paper, 2004-01-1591; SAE International: Warrendale, PA, USA, 2004. [Google Scholar]

- Olsen, D.B.; Hutcherson, G.C.; Willson, B.D.; Mitchell, G.E. Development of the tracer gas method for large bore natural gas engines—Part I method validation. J. Eng. Gas Turbines Power 2002, 124, 678–685. [Google Scholar] [CrossRef]

- Wu, Y.; Wang, Y.; Zhen, X.; Guan, S.; Wang, J. Three-dimensional CFD (computational fluid dynamics) analysis of scavenging process in a two-stroke free-piston engine. Energy 2014, 68, 167–173. [Google Scholar] [CrossRef]

- Ma, F.K.; Zhao, C.L.; Zhang, S.L. Scheme Design and Performance Simulation of Opposed-Piston Two-Stroke Gasoline Direct Injection Engine; SAE Technical Paper 2015-01-1276; SAE International: Warrendale, PA, USA, 2015. [Google Scholar]

- Ma, F.K.; Zhao, C.L.; Zhang, F.J. An experimental investigation on combustion and heat release characteristics of an opposed-piston folded-cranktrain diesel engine. Energies 2015, 8, 6365–6381. [Google Scholar] [CrossRef]

- Taylor, C.F. The Internal-Combustion Engine in Theory and Practice: Thermodynamics, Fluid Flow, Performance, 2nd ed.; MIT Press: Cambridge, UK, 1985. [Google Scholar]

- GT-Powerv.7.1. Engine Performance Application Manual; Gamma Technologies: Detroit, MI, USA, 2010.

- AVL-Fire vs. CFD User Guide; AVL Technologies: Graz, Austria, 2012.

- Basara, B.; Krajnovic, S.; Girimaji, S.; Pavlovic, Z. Near-wall formulation of the partially averaged navier stokes turbulence model. AIAA J. 2011, 49, 2627–2636. [Google Scholar] [CrossRef]

- Sigurdsson, E.; Ingvorsen, K.M.; Jensen, M.V. Numerical analysis of the scavenge flow and convective heat transfer in large two-stroke marine diesel engines. Appl. Energy 2014, 123, 37–46. [Google Scholar] [CrossRef]

- McGough, M.G.; Fanick, E.R. Experimental Investigation of the Scavenging Performance of a Two-Stroke Opposed-Piston Diesel Tank Engine; SAE International: Warrendale, PA, USA, 2004. [Google Scholar]

| Parameters (unit) | Value |

|---|---|

| Number of cylinders (-) | 2 |

| Bore (mm) | 100 |

| Stroke (intake/exhaust) (mm) | 110/110 |

| Nominal compression ratio (-) | 22 |

| Trapping compression ratio (-) | 15.8 |

| Displacement (L) | 3.4 |

| Intake port height (mm) | 24 |

| Exhaust port height (mm) | 28 |

| Intake port circumference ratio (-) | 0.75 |

| Exhaust port circumference ratio (-) | 0.6 |

| Intake port radial angle (°) | 15 |

| Exhaust port radial angle (°) | 0 |

| Opposed-piston motion phase difference (°CA) | 17 |

| Maximum engine power (kW) | 80 @ 2400 rpm |

| Maximum engine moment (N·m) | 420 @ 1600 rpm |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, F.; Zhao, Z.; Zhang, Y.; Wang, J.; Feng, Y.; Su, T.; Zhang, Y.; Liu, Y. Simulation Modeling Method and Experimental Investigation on the Uniflow Scavenging System of an Opposed-Piston Folded-Cranktrain Diesel Engine. Energies 2017, 10, 727. https://doi.org/10.3390/en10050727

Ma F, Zhao Z, Zhang Y, Wang J, Feng Y, Su T, Zhang Y, Liu Y. Simulation Modeling Method and Experimental Investigation on the Uniflow Scavenging System of an Opposed-Piston Folded-Cranktrain Diesel Engine. Energies. 2017; 10(5):727. https://doi.org/10.3390/en10050727

Chicago/Turabian StyleMa, Fukang, Zhenfeng Zhao, Yangang Zhang, Jun Wang, Yaonan Feng, Tiexiong Su, Yi Zhang, and Yuhang Liu. 2017. "Simulation Modeling Method and Experimental Investigation on the Uniflow Scavenging System of an Opposed-Piston Folded-Cranktrain Diesel Engine" Energies 10, no. 5: 727. https://doi.org/10.3390/en10050727