Modeling and Optimization of a CoolingTower-Assisted Heat Pump System

Abstract

:1. Introduction

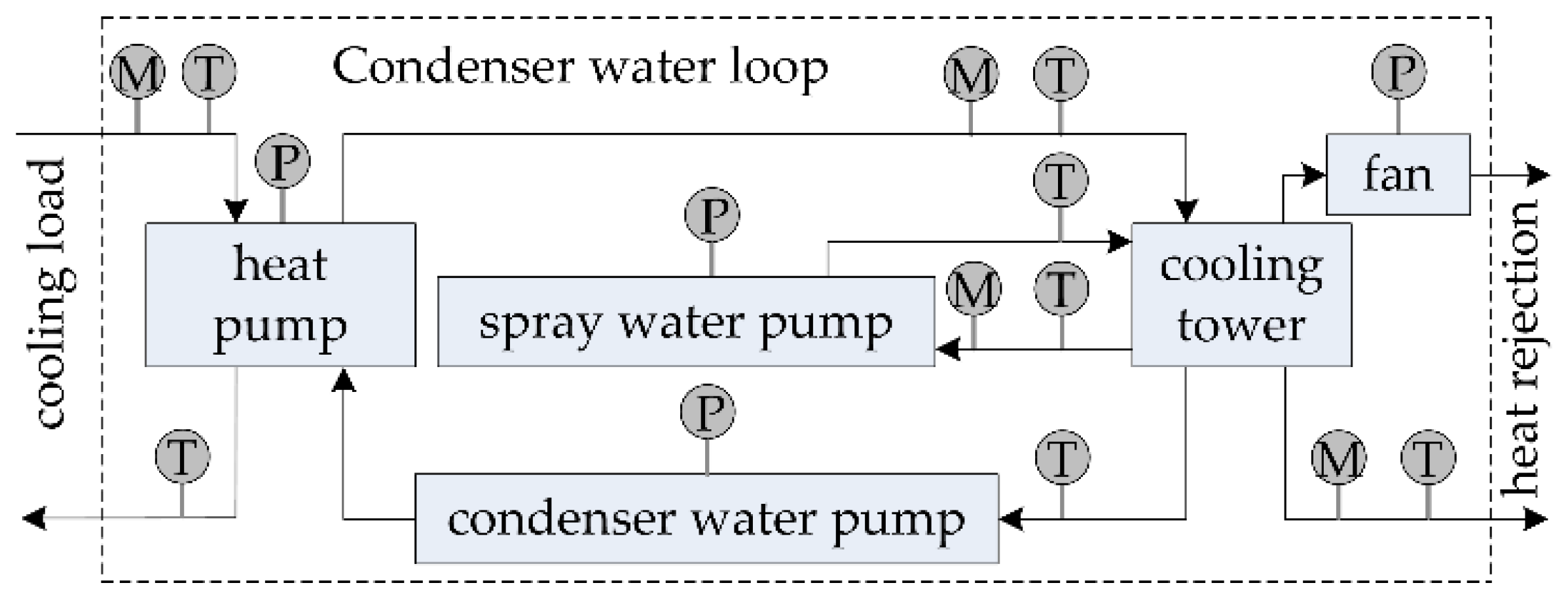

2. System Description

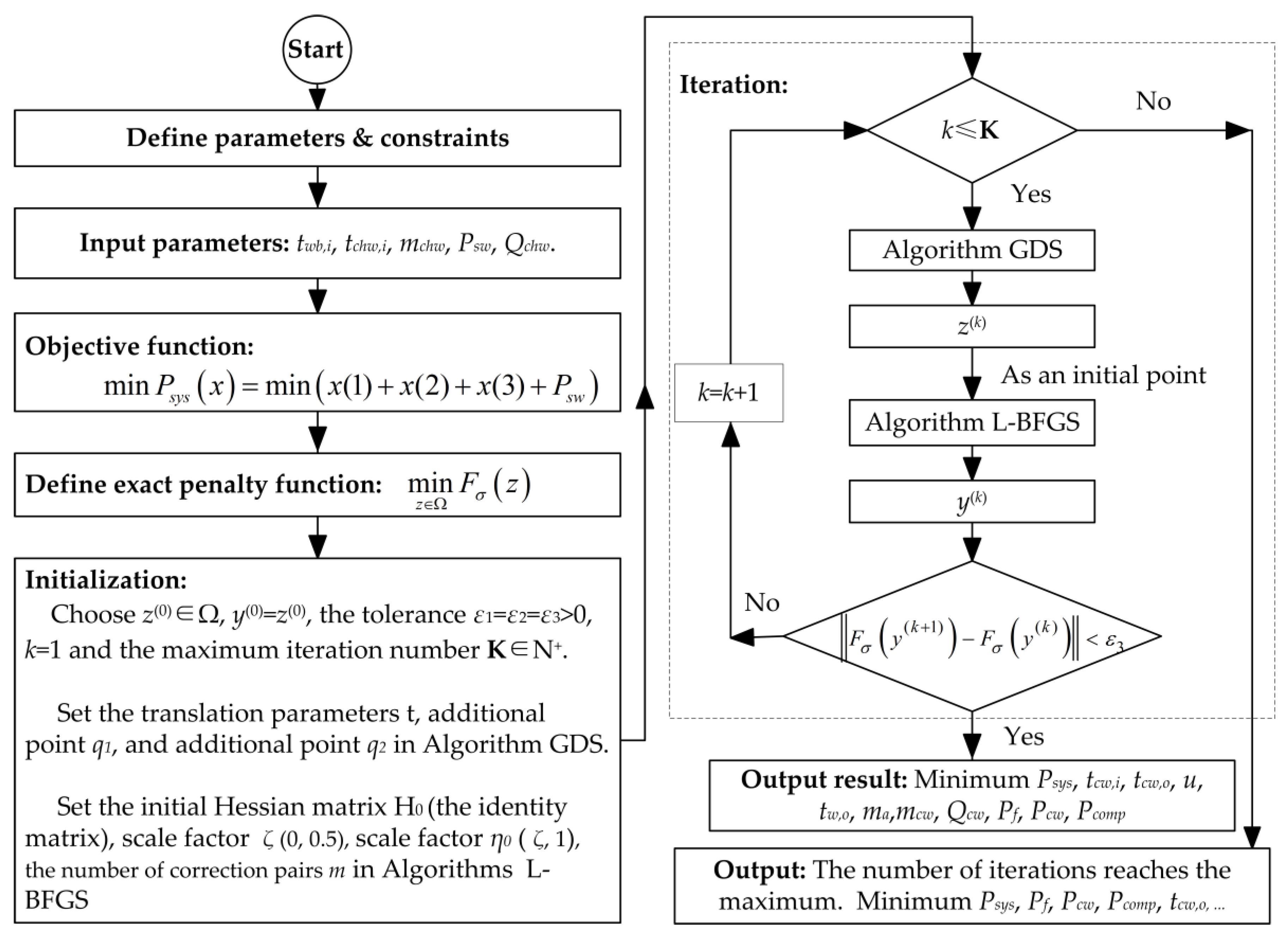

3. Formulation of the Optimization Problem

3.1. Mathematical Modeling

3.1.1. Heat Pump Model

3.1.2. Cooling Tower Model

3.1.3. Fan and Pump Models

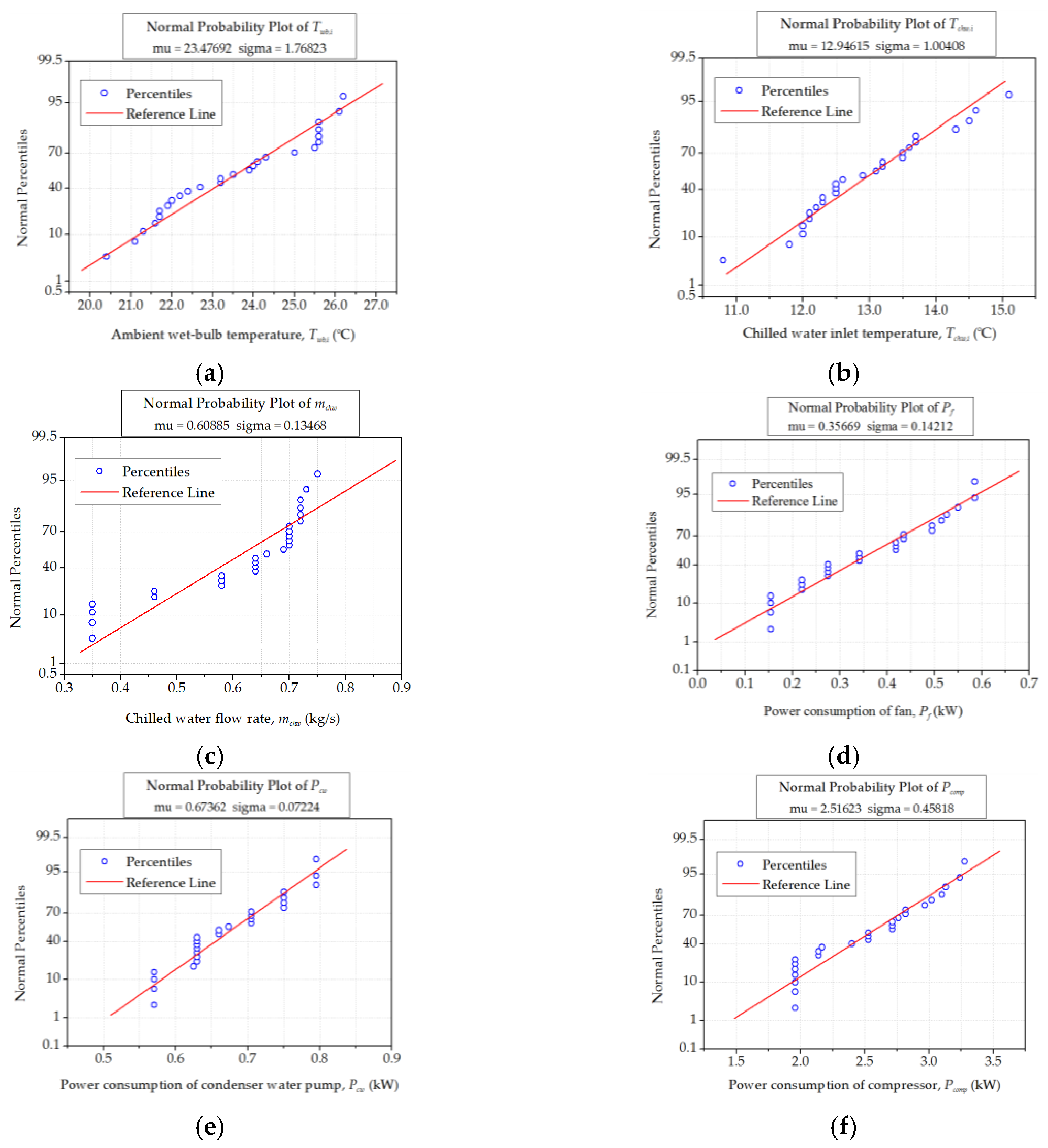

3.1.4. Uncertainty Analysis

3.2. Objective Function and Inequality Constraints

3.3. An Appropriate Optimization Algorithm and its Settings for the Problem at Hand

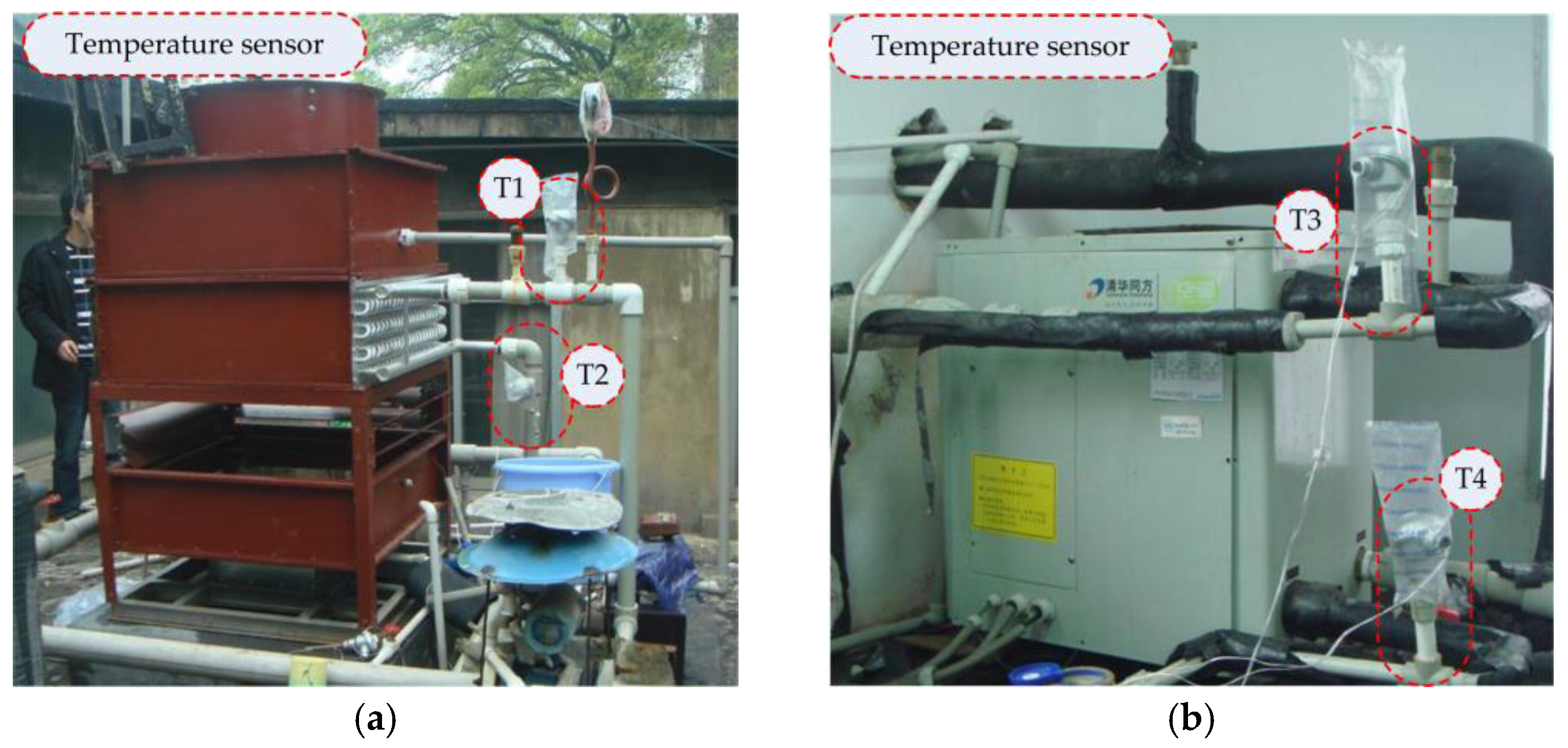

4. Experiments

5. Results and Discussion

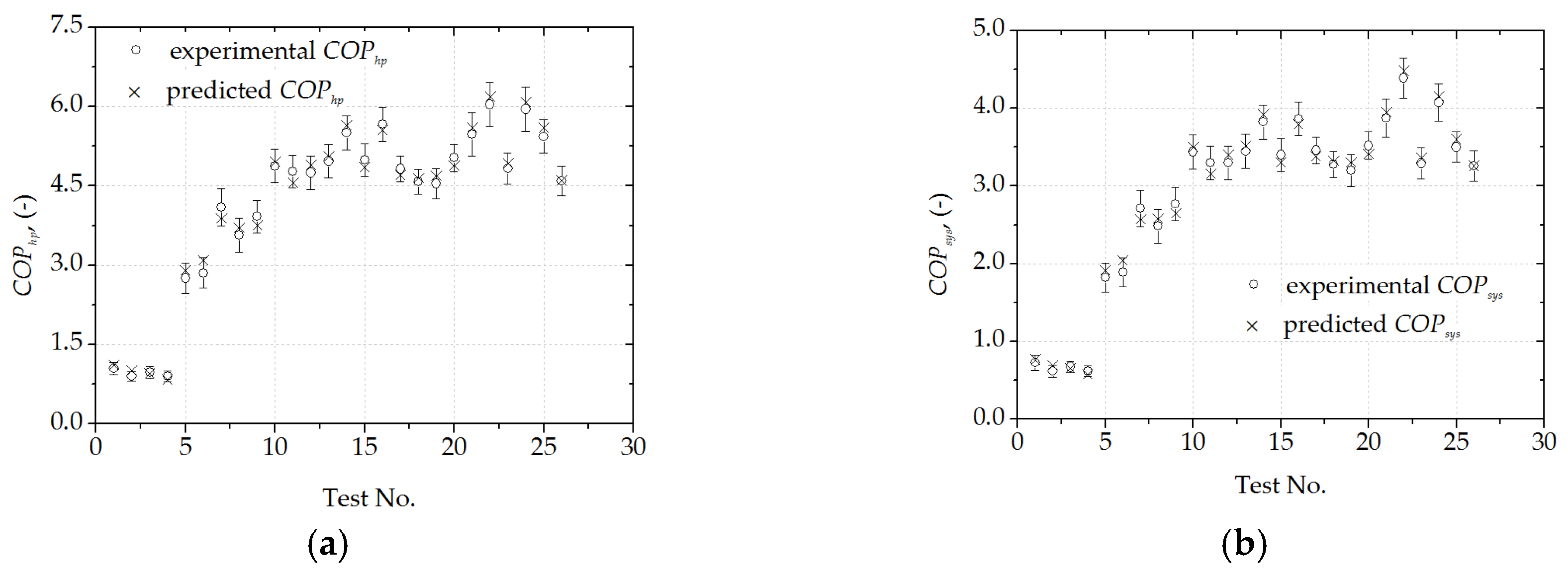

5.1. Experimental Data and Model Validation

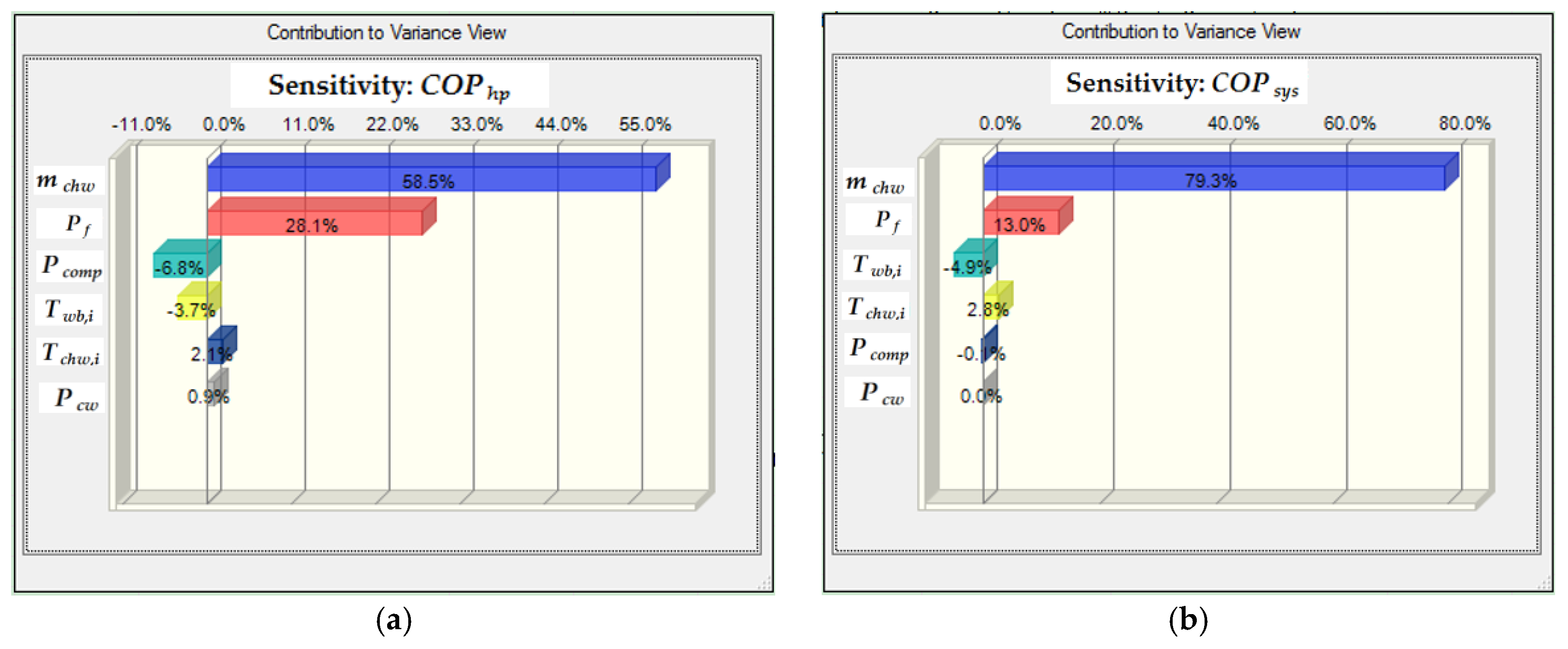

5.2. Sensitivity Analysis

5.3. Energy Analysis

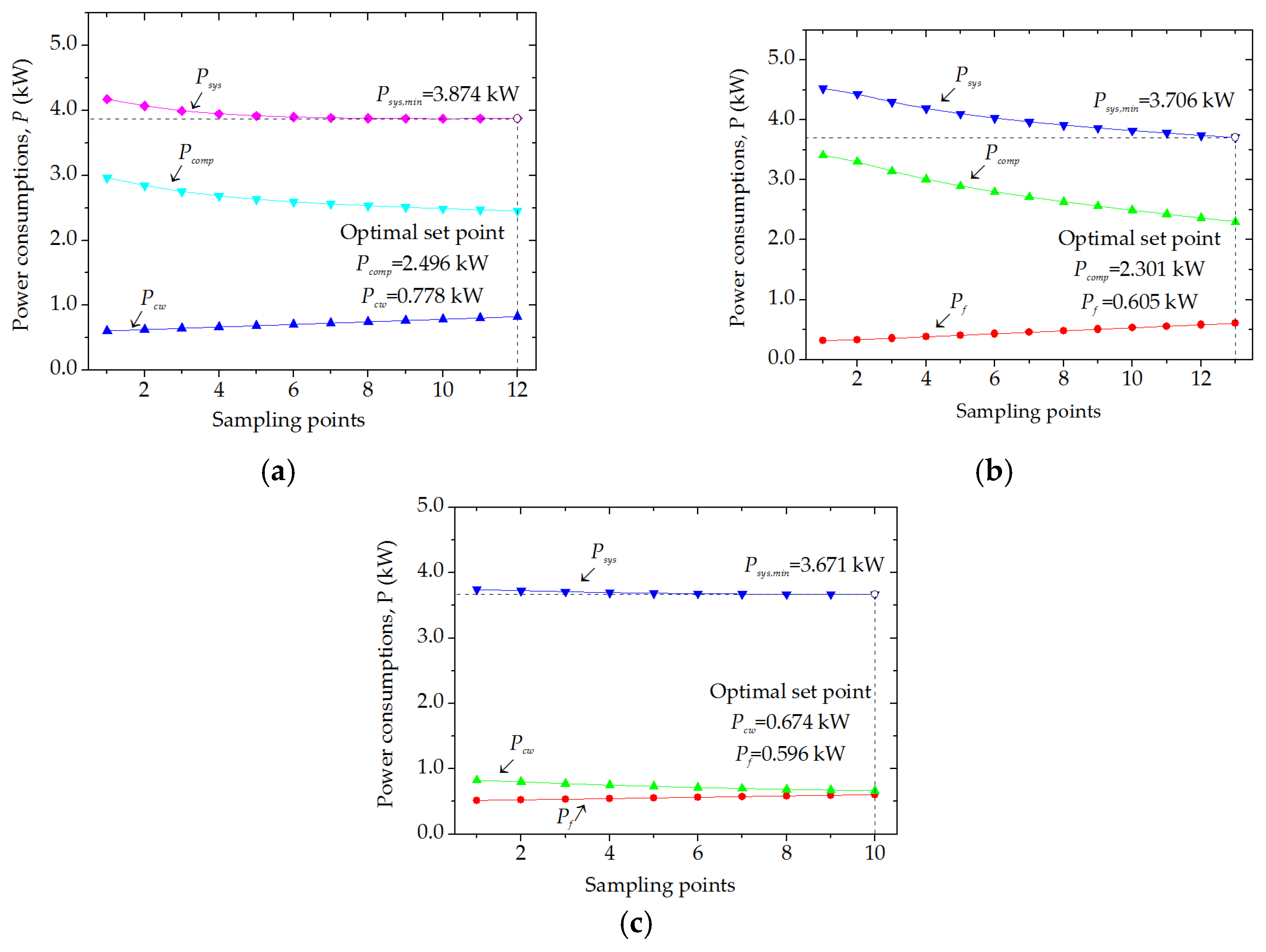

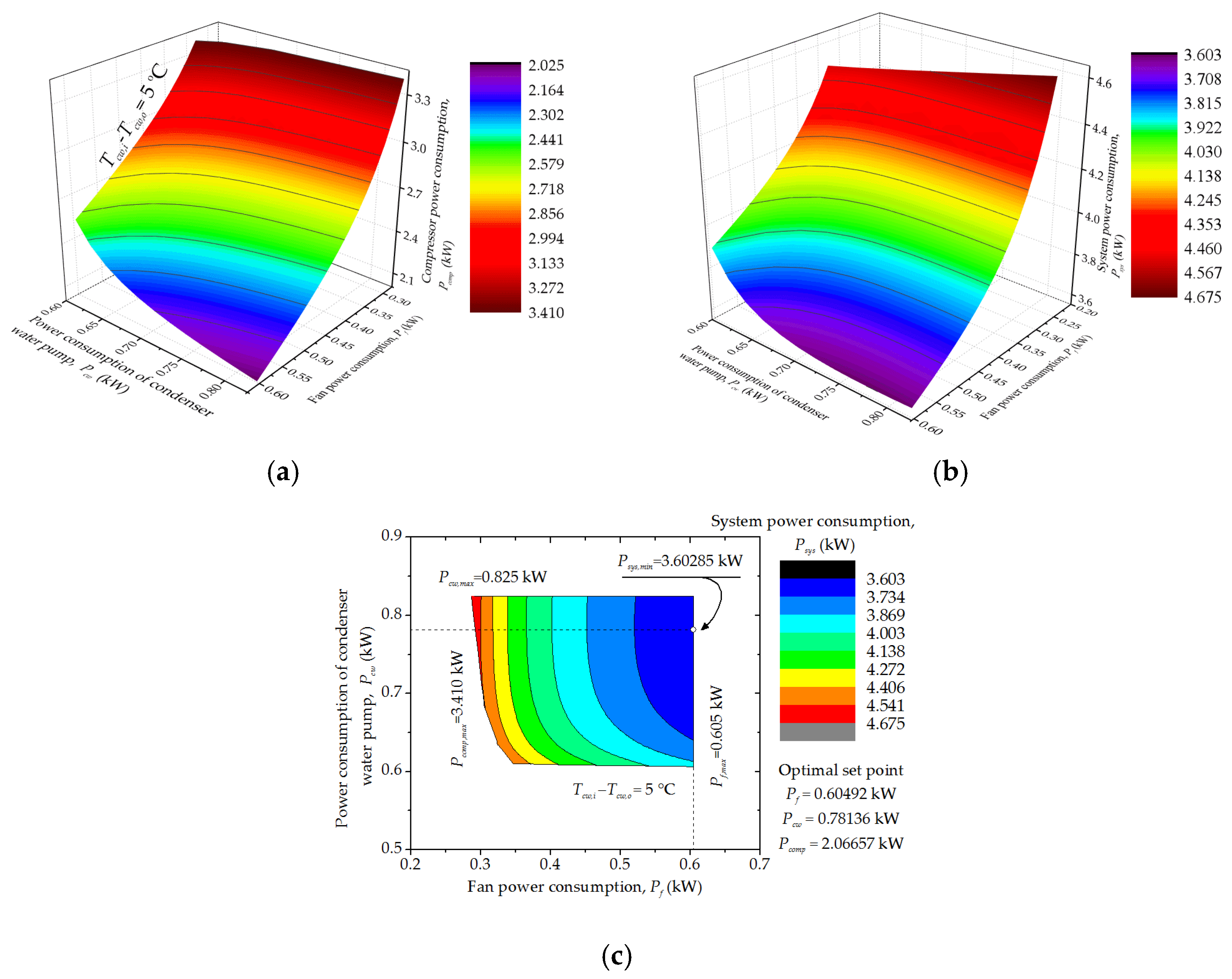

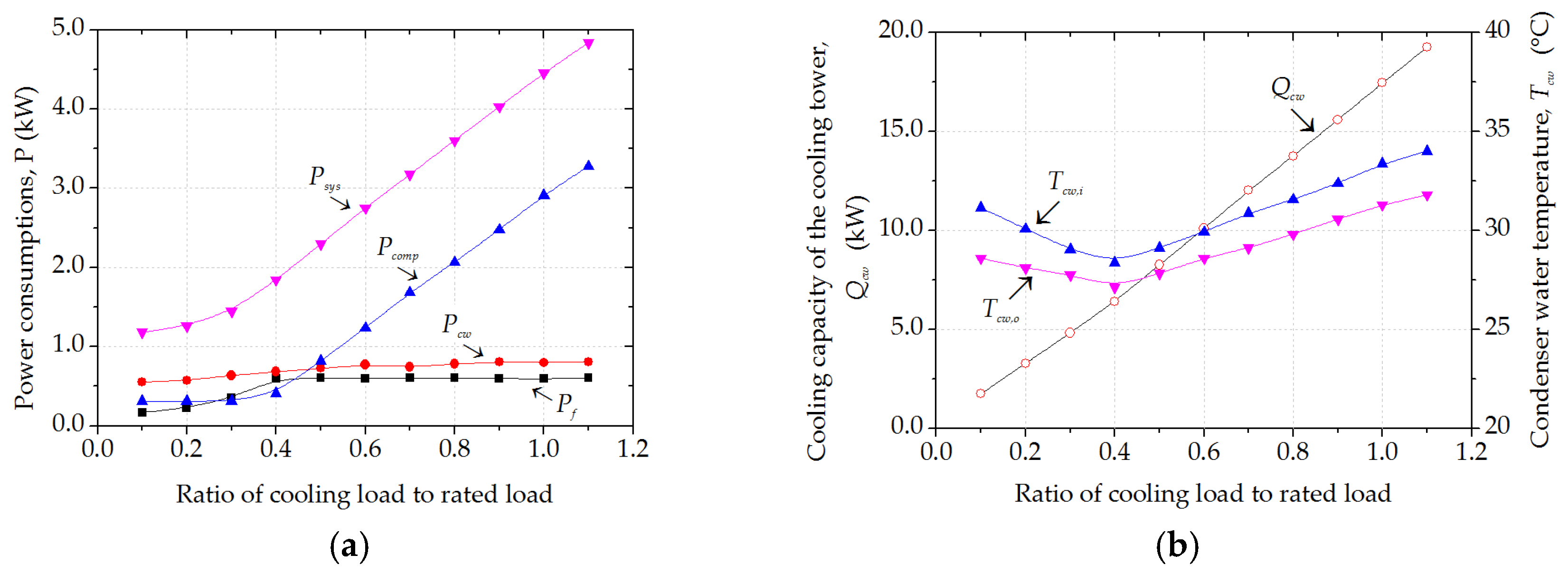

5.3.1. Effect of the Two Controlled Variables at a Required Cooling Load

5.3.2. Effect of Three Controlled Variables at a Desired Cooling Load

5.3.3. Effect of the Three Controlled Variables at Different Required Cooling Loads

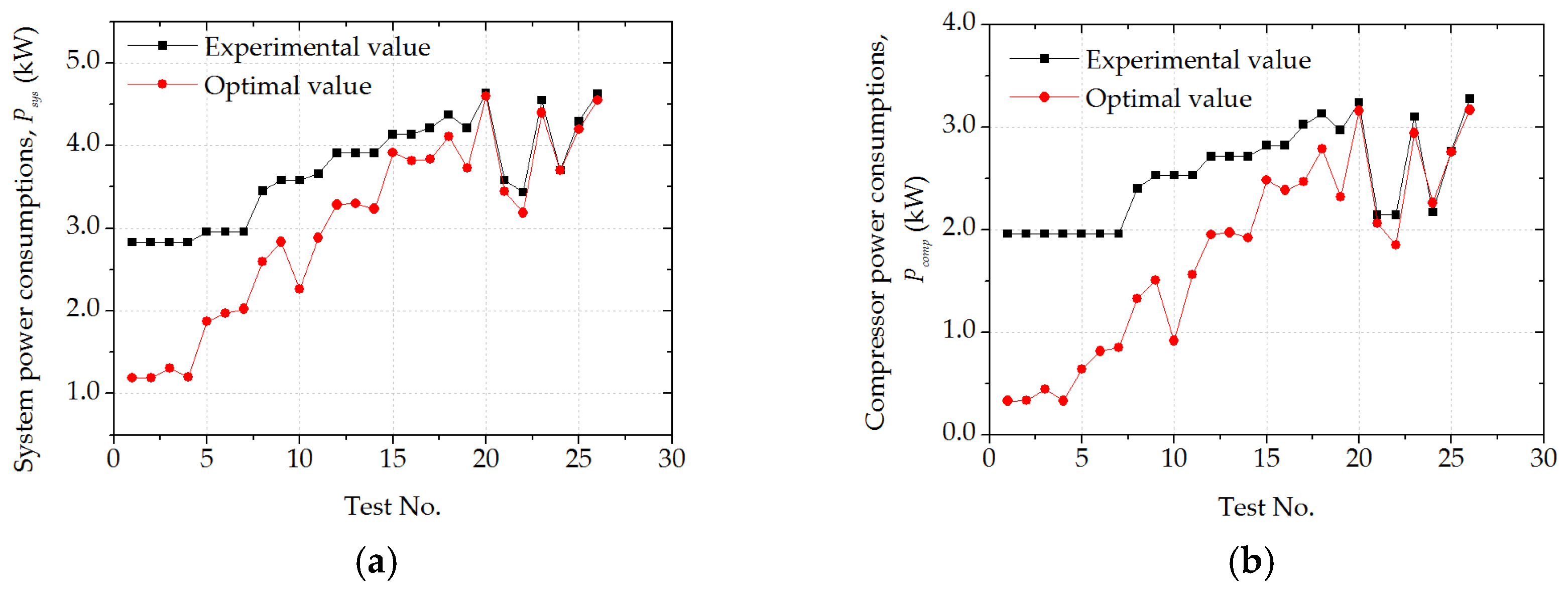

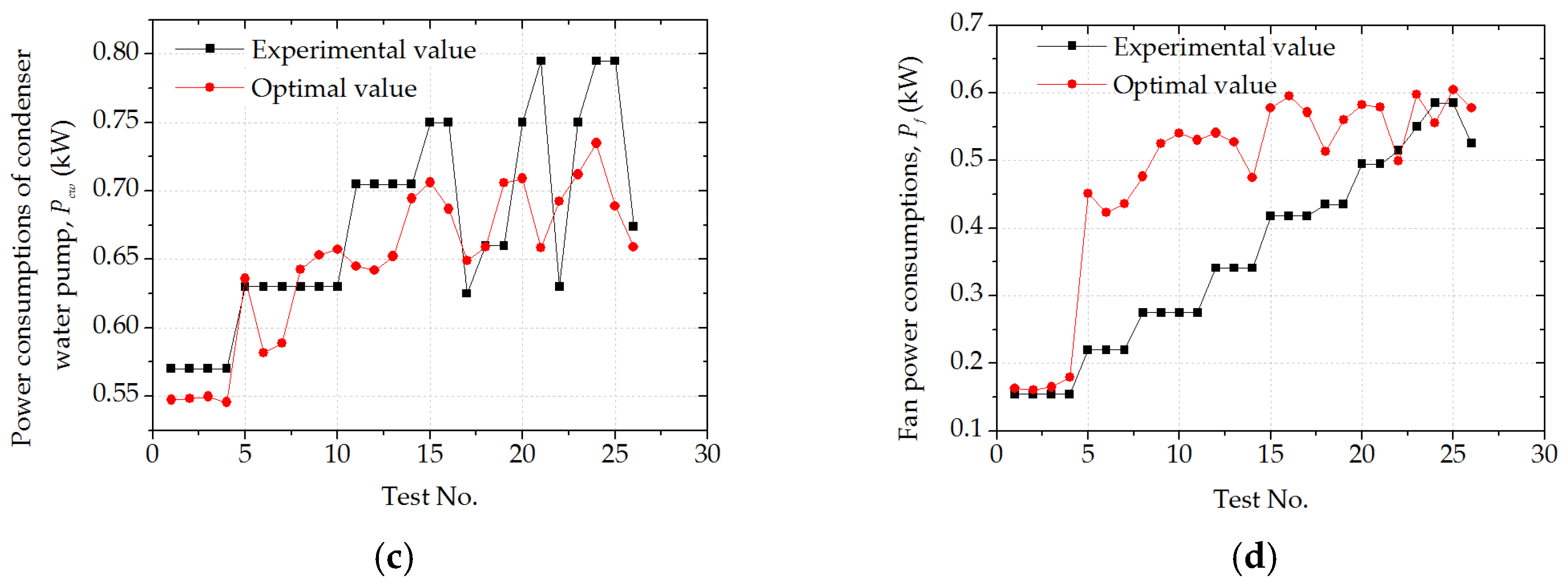

5.4. Analysis of Energy Saving Potential under Test Operating Conditions

6. Conclusions

- (1)

- The predicted coefficient of performances (COPs) of the heat pump unit and the system are in good agreement with the experimental data, which means the modeling method is reliable and accurate for performance prediction of the CTAHP system.

- (2)

- Sensitivity analysis results demonstrate that chilled water flow rate has a significant positive effect on the values of COPhp and COPsys, followed by fan input power. Compressor input power has a significant negative effect on the COPhp, while it has little effect on the COPsys.

- (3)

- The average systemic power consumption with optimization is nearly 20.8% less than that without optimization under certain testing conditions.

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| m | mass flow rate, kg/s |

| T | temperature, °C |

| cw | specific heat of cooling water at constant pressure, 4.1868 kJ/(kg·°C) |

| cpsat | the fictitious specific heat of saturated air at constant pressure, kJ/(kg·°C) |

| H | Hessian matrix |

| P | power consumption, kW |

| Q | heat rejection rate, kW |

| x | x = (x(1), x(2), …, x(10))∈R10 |

| hi | continuously differentiable functions, Equation (i), i = 1, 2, …, 8 |

| gj | continuously differentiable functions, Equation (j), j = 16, 17 |

| L,U | L = [L1, L2, …, L10] and U = [U1, U2, …, U10] are, respectively, the lower and upper bounds of the ten unknown variables. |

| Greek Symbols | |

| μcw | dynamic viscosity coefficient of water at the temperatures Tcw,i, kg/(m·s) |

| μo | dynamic viscosity coefficient of water at 0 °C, 1.792 × 10−3 kg/(m·s) |

| α, β | positive constants, 1 ≤ β ≤ α |

| σ | penalty parameter, σ > 0 |

| βint | a constant which is influenced by the coil’s geometry and constant water-properties |

| βext | a constant which depends on the thermal properties of air and on the coil’s geometry |

| η | heat generated efficiency by the compressor |

| ζ, ηo | scale factor, 0 < ζ < 0.5, ζ < ηo < 1 |

| Subscripts | |

| a | air |

| f | cooling tower fan |

| sw | spray water |

| cw | condenser water |

| chw | chilled water |

| comp | compressor |

| i | inlet |

| o | outlet |

| wb | ambient wet-bulb |

References

- American Society of Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE). ASHRAE Handbook—2011 HVAC Applications; ASHRAE: Atlanta, GA, USA, 2011. [Google Scholar]

- Thangavelu, S.R.; Myat, A.; Khambadkone, A. Energy optimization methodology of multi-chiller plant in commercial buildings. Energy 2017, 123, 64–76. [Google Scholar] [CrossRef]

- Sayyaadi, H.; Nejatolahi, M. Multi-objective optimization of a cooling tower assisted vapor compression refrigeration system. Int. J. Refrig. 2011, 34, 243–256. [Google Scholar] [CrossRef]

- Shan, K.; Wang, S.; Gao, D.C.; Xiao, F. Development and validation of an effective and robust chiller sequence control strategy using data-driven models. Autom. Constr. 2016, 65, 78–85. [Google Scholar] [CrossRef]

- Mu, B.; Li, Y.; Seem, J.E.; Hu, B. A multivariable newton-based extremum seeking control for condenser water loop optimization of chilled-water plant. J. Dyn. Syst. 2015, 137, 111011. [Google Scholar] [CrossRef]

- Liu, C.W.; Chuah, Y.K. A study on an optimal approach temperature control strategy of condensing water temperature for energy saving. Int. J. Refrig. 2011, 34, 816–823. [Google Scholar] [CrossRef]

- Wei, X.; Xu, G.; Kusiak, A. Modeling and optimization of a chiller plant. Energy 2014, 73, 898–907. [Google Scholar] [CrossRef]

- Sayyadi, H.; Nejatolahi, M. Thermodynamic and thermoeconomic optimization of a cooling tower-assisted ground source heat pump. Geothermics 2011, 40, 221–232. [Google Scholar] [CrossRef]

- Chargui, R.; Sammouda, H.; Farhat, A. Numerical simulation of a cooling tower coupled with heat pump system associated with single house using TRNSYS. Energy Convers. Manag. 2013, 75, 105–117. [Google Scholar] [CrossRef]

- Yuan, S.; Grabon, M. Optimizing energy consumption of a water-loop variable-speed heat pump system. Appl. Therm. Eng. 2011, 31, 894–901. [Google Scholar] [CrossRef]

- Ma, Z.; Wang, S. Supervisory and optimal control of central chiller plants using simplified adaptive models and genetic algorithm. Appl. Energy 2011, 88, 198–211. [Google Scholar] [CrossRef]

- Cheng, J.; Li, N.; Wang, K. Study of heat-source-tower heat pump system efficiency. Procedia Eng. 2015, 121, 915–921. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, S.; Wu, C.; Liang, J.; Wang, X.; Teo, K.L. A hybrid approach to constrained global optimization. Appl. Soft Comput. 2016, 47, 281–294. [Google Scholar] [CrossRef]

- Liu, D.C.; Nocedal, J. On the limited memory BFGS method for large scale optimization. Math. Program. 1989, 45, 503–528. [Google Scholar] [CrossRef]

- Braun, J.E.; Comstock, M.C. Development of Analysis Tools for the Evaluation of Fault Detection and Diagnostics for Chillers; Deliverable for Ashrae Research Project: Atlanta, GA, USA, 1999. [Google Scholar]

- Cheung, H.; Braun, J.E. Empirical modeling of the impacts of faults on water-cooled chiller power consumption for use in building simulation programs. Appl. Therm. Eng. 2016, 99, 756–764. [Google Scholar] [CrossRef]

- American Society of Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE). ASHRAE Handbook—1999 HVAC Applications Handbook; ASHRAE: Atlanta, GA, USA, 1999; Volume 40, pp. 1–36. [Google Scholar]

- Lu, L.; Cai, W.; Soh, Y.C.; Xie, L.; Li, S. HVAC system optimization—Condenser water loop. Energy Convers. Manag. 2004, 45, 613–630. [Google Scholar] [CrossRef]

- Wei, X.; Li, N.; Peng, J.; Cheng, J.; Hu, J.; Wang, M.; Sciubba, E. Performance analyses of counter-flow closed wet cooling towers based on a simplified calculation method. Energies 2017, 10, 282. [Google Scholar] [CrossRef]

- Stabat, P.; Marchio, D. Simplified model for indirect-contact evaporative cooling-tower behaviour. Appl. Energy 2004, 78, 433–451. [Google Scholar] [CrossRef]

- Kreider, J.F.; Curtiss, P.; Rabl, A. Heating and Cooling of Buildings: Design for Efficiency, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2010. [Google Scholar]

- Kline, S.J.; Mcclintock, F.A. Describing uncertainties in single sample experiments. Mech. Eng. 1953, 78, 3–8. [Google Scholar]

- Afram, A.; Janabi-Sharifi, F. Review of modeling methods for HVAC systems. Appl. Therm. Eng. 2014, 67, 507–519. [Google Scholar] [CrossRef]

- General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China. GB/T 19409–2013 Water-Source (Ground-Source) Heat Pump; Standards Press of China: Beijing, China, 2013.

- Lin, Q.; Loxton, R.; Teo, K.L.; Wu, Y.H.; Yu, C. A new exact penalty method for semi-infinite programming problems. J. Comput. Appl. Math. 2014, 261, 271–286. [Google Scholar] [CrossRef]

- Xiao, Y.; Wei, Z.; Wang, Z. A limited memory BFGS-type method for large-scale unconstrained optimization. Comput. Math. Appl. 2008, 56, 1001–1009. [Google Scholar] [CrossRef]

- Wei, X.; Li, N.; Peng, J.; Cheng, J.; Su, L. Analysis of the effect of the CaCl2 mass fraction on the efficiency of a heat pump integrated heat-source tower using an artificial neural network model. Sustainability 2016, 8, 410. [Google Scholar] [CrossRef]

- Yoo, S.Y.; Kim, J.H.; Han, K.H. Thermal performance analysis of heat exchanger for closed wet cooling tower using heat and mass transfer analogy. J. Mech. Sci. Technol. 2010, 24, 893–898. [Google Scholar] [CrossRef]

| Variables | Uniform Symbols | Variables | Uniform Symbols |

|---|---|---|---|

| Pf, kW | x(1) | µ, kg/(m·s) | x(6) |

| Pcw, kW | x(2) | Qcw, kW | x(7) |

| Pcomp, kW | x(3) | Tcw,i, °C | x(8) |

| ma, kg/s | x(4) | Tcw,o, °C | x(9) |

| mcw, kg/s | x(5) | Tw,o, °C | x(10) |

| Test No. | Input Parameters | Output Parameters | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Twb,i | Pf | Pcw | Pcomp | mchw | Tchw,i | ma | mcw | Tcw,i | Tcw,o | Tchw,o | |

| (°C) | (kW) | (kW) | (°C) | (kg/s) | (°C) | (kg/s) | (kg/s) | (°C) | (°C) | (°C) | |

| 1 | 21.3 | 0.154 | 0.570 | 1.957 | 0.35 | 12.3 | 0.18 | 0.35 | 38.6 | 36.1 | 10.9 |

| 2 | 22.4 | 0.154 | 0.570 | 1.957 | 0.35 | 12.3 | 0.18 | 0.35 | 38.7 | 36.4 | 11.1 |

| 3 | 23.2 | 0.154 | 0.570 | 1.957 | 0.35 | 12.5 | 0.18 | 0.35 | 39.0 | 36.7 | 11.2 |

| 4 | 24.0 | 0.154 | 0.570 | 1.957 | 0.35 | 12.1 | 0.18 | 0.35 | 38.7 | 36.6 | 10.9 |

| 5 | 25.6 | 0.220 | 0.630 | 1.957 | 0.46 | 11.8 | 0.83 | 0.86 | 35.6 | 33.6 | 9.0 |

| 6 | 26.1 | 0.220 | 0.630 | 1.957 | 0.46 | 13.1 | 0.83 | 0.86 | 36.6 | 34.5 | 10.2 |

| 7 | 21.7 | 0.220 | 0.630 | 1.957 | 0.58 | 12.0 | 0.83 | 0.86 | 34.4 | 31.9 | 8.7 |

| 8 | 25.6 | 0.275 | 0.630 | 2.400 | 0.64 | 13.2 | 1.27 | 0.86 | 36.7 | 33.7 | 10.0 |

| 9 | 26.2 | 0.275 | 0.630 | 2.528 | 0.64 | 14.3 | 1.27 | 0.86 | 38.0 | 34.9 | 10.6 |

| 10 | 21.1 | 0.275 | 0.630 | 2.528 | 0.64 | 14.6 | 1.27 | 0.86 | 36.1 | 32.1 | 10.0 |

| 11 | 22.7 | 0.275 | 0.705 | 2.528 | 0.64 | 13.5 | 1.27 | 1.38 | 35.8 | 33.5 | 9.0 |

| 12 | 24.3 | 0.341 | 0.705 | 2.715 | 0.70 | 14.5 | 1.71 | 1.38 | 36.4 | 33.7 | 10.1 |

| 13 | 22.0 | 0.341 | 0.705 | 2.715 | 0.70 | 12.9 | 1.71 | 1.38 | 34.5 | 31.8 | 8.3 |

| 14 | 20.4 | 0.341 | 0.705 | 2.715 | 0.70 | 13.7 | 1.71 | 1.38 | 34.1 | 31.1 | 8.6 |

| 15 | 23.9 | 0.418 | 0.750 | 2.820 | 0.70 | 12.1 | 2.15 | 1.67 | 34.2 | 32.0 | 7.3 |

| 16 | 21.6 | 0.418 | 0.750 | 2.820 | 0.72 | 12.6 | 2.15 | 1.67 | 33.2 | 30.7 | 7.3 |

| 17 | 23.5 | 0.418 | 0.625 | 3.022 | 0.58 | 13.2 | 2.15 | 0.82 | 35.9 | 31.1 | 7.2 |

| 18 | 22.2 | 0.435 | 0.660 | 3.130 | 0.58 | 10.8 | 2.25 | 1.08 | 33.8 | 30.1 | 4.9 |

| 19 | 24.1 | 0.435 | 0.660 | 2.968 | 0.70 | 12.5 | 2.25 | 1.08 | 35.2 | 31.6 | 7.9 |

| 20 | 25.6 | 0.495 | 0.750 | 3.240 | 0.66 | 13.5 | 2.59 | 1.67 | 36.1 | 33.5 | 7.6 |

| 21 | 21.9 | 0.515 | 0.795 | 2.142 | 0.72 | 12.2 | 2.59 | 1.98 | 30.7 | 28.8 | 7.6 |

| 22 | 21.7 | 0.550 | 0.630 | 2.142 | 0.72 | 15.1 | 2.71 | 0.86 | 32.7 | 28.0 | 10.1 |

| 23 | 25.0 | 0.585 | 0.750 | 3.100 | 0.73 | 12.0 | 2.94 | 1.67 | 34.3 | 31.8 | 7.1 |

| 24 | 23.2 | 0.585 | 0.795 | 2.169 | 0.72 | 13.7 | 3.19 | 1.98 | 31.5 | 29.4 | 8.7 |

| 25 | 25.6 | 0.585 | 0.795 | 2.764 | 0.69 | 13.6 | 3.19 | 1.98 | 34.1 | 32.0 | 8.4 |

| 26 | 25.5 | 0.526 | 0.674 | 3.277 | 0.75 | 12.5 | 2.78 | 1.18 | 35.8 | 32.3 | 7.7 |

| Equations | Coefficients |

|---|---|

| (2) | a0 = −4.6929; a1 = 0.2698; a2 = −0.0011; a3 = 0.1782; a4 = −9.4509 × 10−5; a5 = −1.102 × 10−3 |

| (5) | βext = 0.310; βint = 0.574 |

| (7) | b0 = 0.2336; b1 = −0.0961; b2 = 0.1262; b3 = −0.0193 |

| (8) | c0 = 0.5417; c1 = 0.0673; c2 = 0.0482; c3 = −0.0083 |

| Parameters | Twb,i (°C) | mchw (kg/s) | Tchw,i (°C) | Pf (kW) | Pcw (kW) | Pcomp (kW) | |

|---|---|---|---|---|---|---|---|

| Assumption | Distribution | Normal | Normal | Normal | Normal | Normal | Normal |

| Arithmetic mean | 23.48 | 0.61 | 12.95 | 0.36 | 0.67 | 2.52 | |

| Standard deviation | 1.77 | 0.13 | 1.00 | 0.14 | 0.07 | 0.46 | |

| Decision | Min.: 0; Max.: 8 | ||||||

| Forecast | COPhp = 0.0595 + 5.3095×Pf + 1.3963×Pcw − 0.7907×Pcomp − 0.1785×Twb,i + 8.0858×mchw + 0.2053×Tchw,i, R2 = 0.9431 | ||||||

| COPsys = −0.5018 + 2.2054×Pf + 0.3148×Pcw − 0.0199×Pcomp − 0.1150×Twb,i + 5.5347×mchw + 0.1373×Tchw,i, R2 = 0.9339 | |||||||

| Parameters | Rated Values | Constant Values for the Case Study | Specified Range |

|---|---|---|---|

| Twb,i (°C) | 25.0 | 25.0 | — |

| mchw (kg/s) | 0.73 | 0.73 | — |

| Tchw,i (°C) | 12.0 | 12.0 | — |

| Psw (kW) | 0.150/0.175/0.200 | 0.150 | — |

| Qchw (kW) | 15.30 | 12.24 | 1.53–16.83 |

| Pf (kW) | 0.550 | 0.450 | 0.055–0.605 |

| Pcw (kW) | 0.750 | 0.650 | 0.075–0.825 |

| Pcomp (kW) | 3.100 | 2.000 | 0.310–3.410 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, X.; Li, N.; Peng, J.; Cheng, J.; Hu, J.; Wang, M. Modeling and Optimization of a CoolingTower-Assisted Heat Pump System. Energies 2017, 10, 733. https://doi.org/10.3390/en10050733

Wei X, Li N, Peng J, Cheng J, Hu J, Wang M. Modeling and Optimization of a CoolingTower-Assisted Heat Pump System. Energies. 2017; 10(5):733. https://doi.org/10.3390/en10050733

Chicago/Turabian StyleWei, Xiaoqing, Nianping Li, Jinqing Peng, Jianlin Cheng, Jinhua Hu, and Meng Wang. 2017. "Modeling and Optimization of a CoolingTower-Assisted Heat Pump System" Energies 10, no. 5: 733. https://doi.org/10.3390/en10050733