Analysis of Development Pattern of a Water-Flowing Fissure Zone in Shortwall Block Mining

Abstract

:1. Introduction

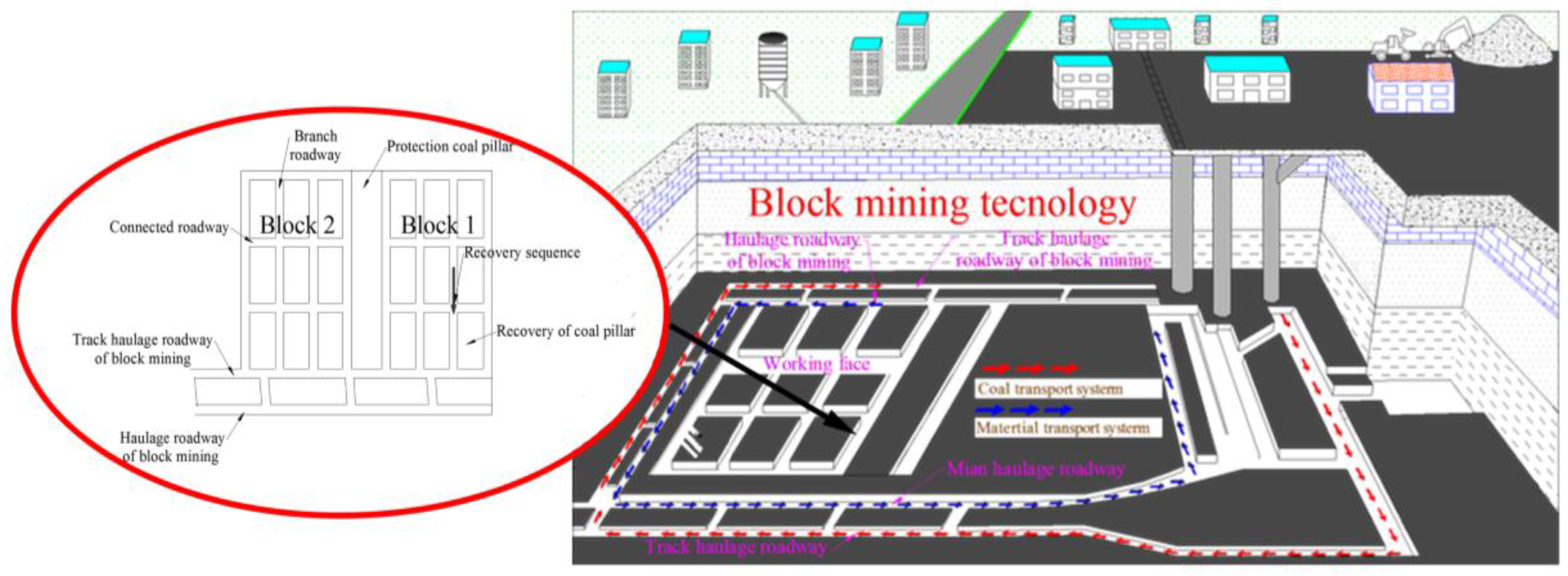

2. SBM Technology

2.1. Mining System

2.2. Main Equipment and the Related Parameter Settings in the Working Face

3. Development Mechanisms of WFZ in SBM

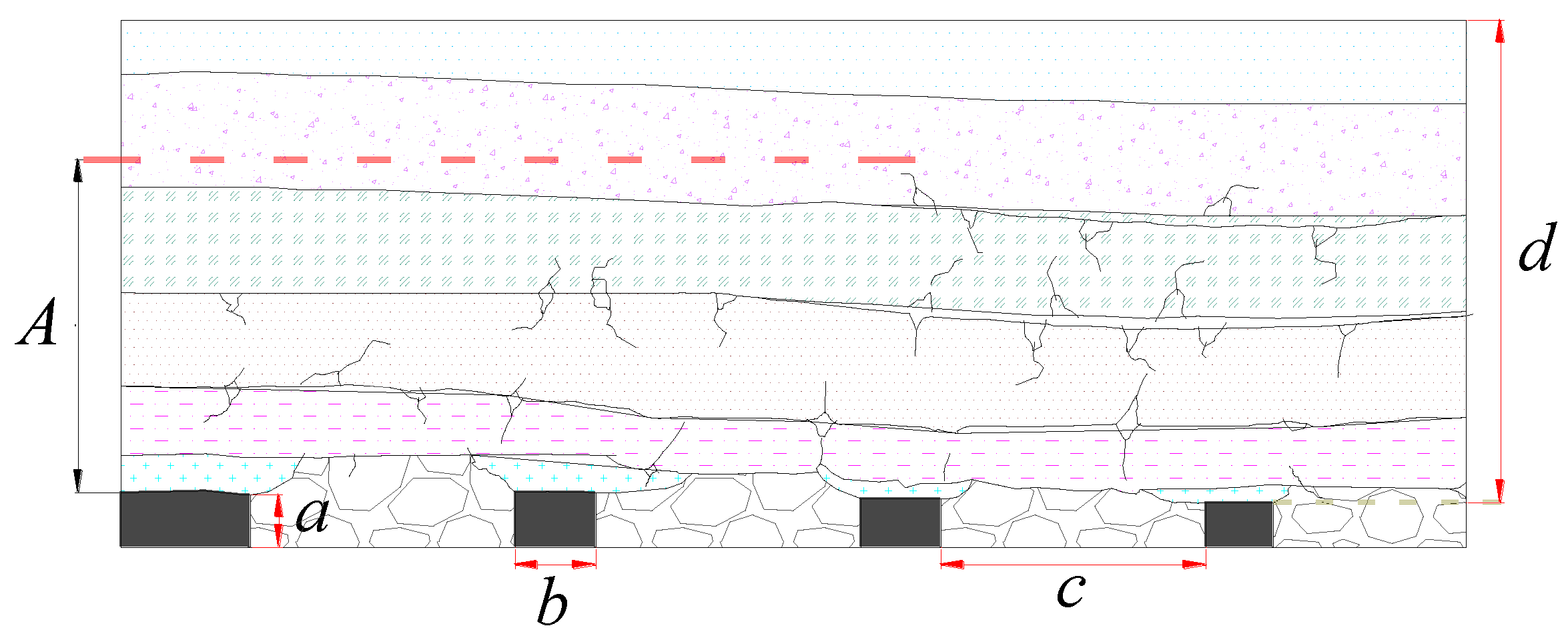

3.1. Characteristics of Overlying Strata Destruction in SBM

3.1.1 Traditional Longwall Caving Method

3.1.2. SBM Method

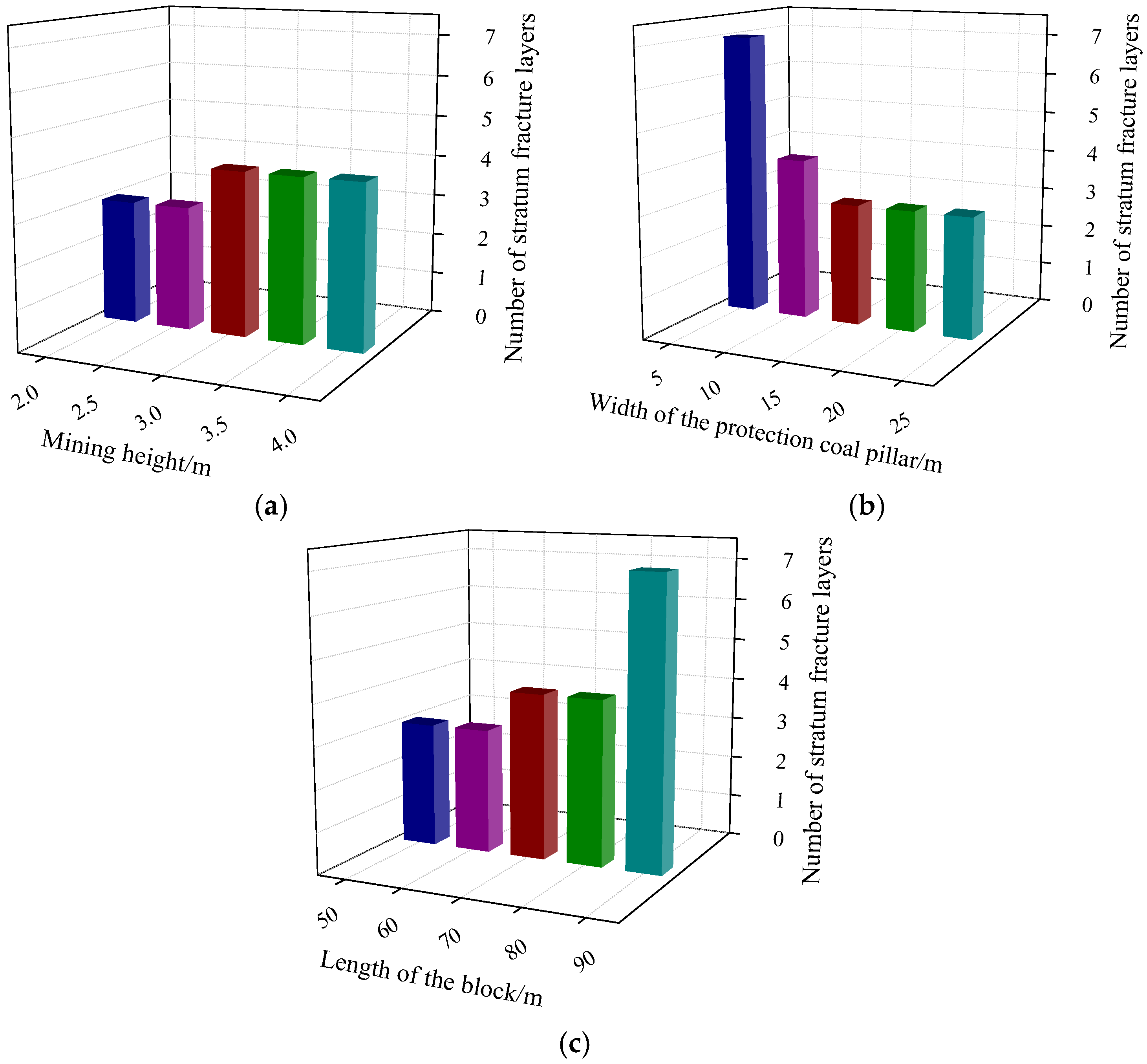

3.2. Main Controlling Factors of HWFZ in SBM

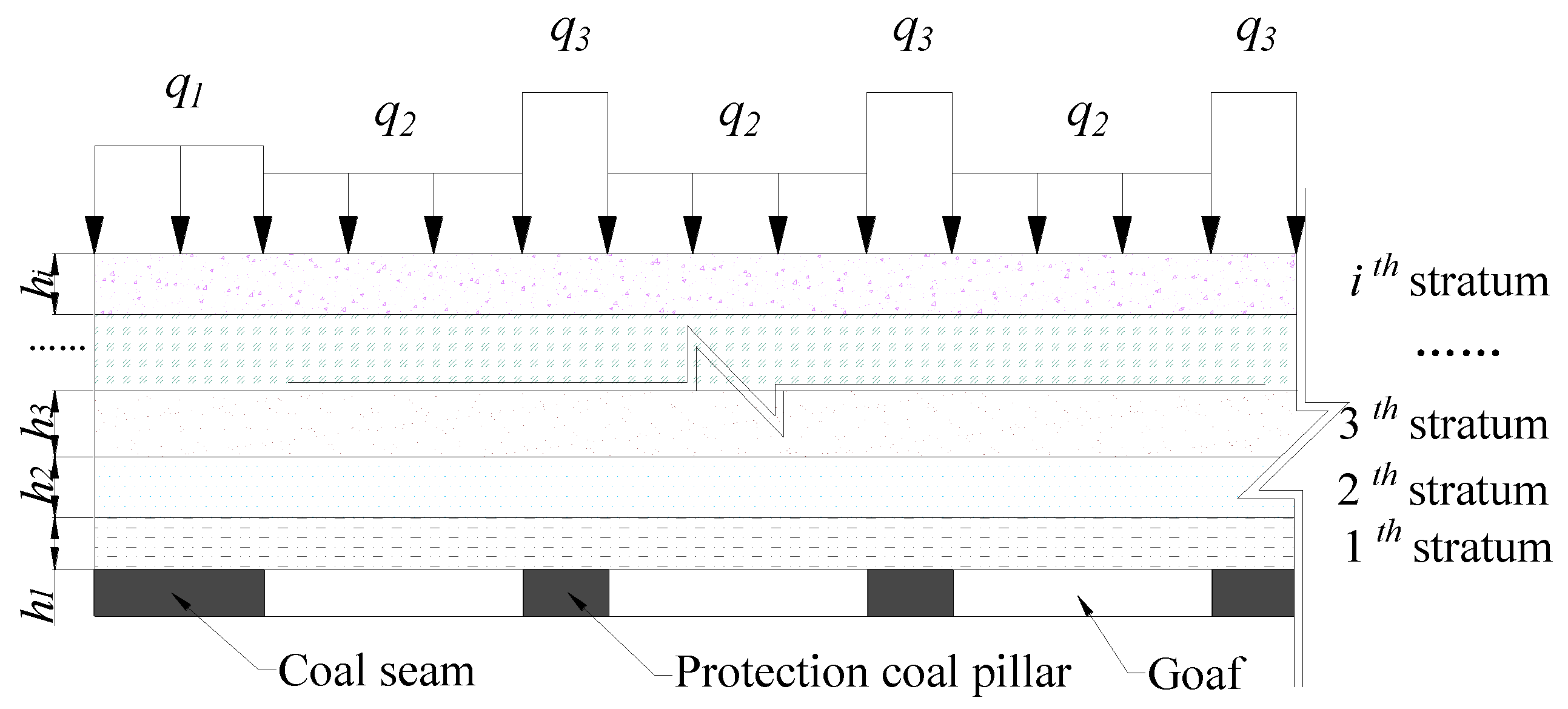

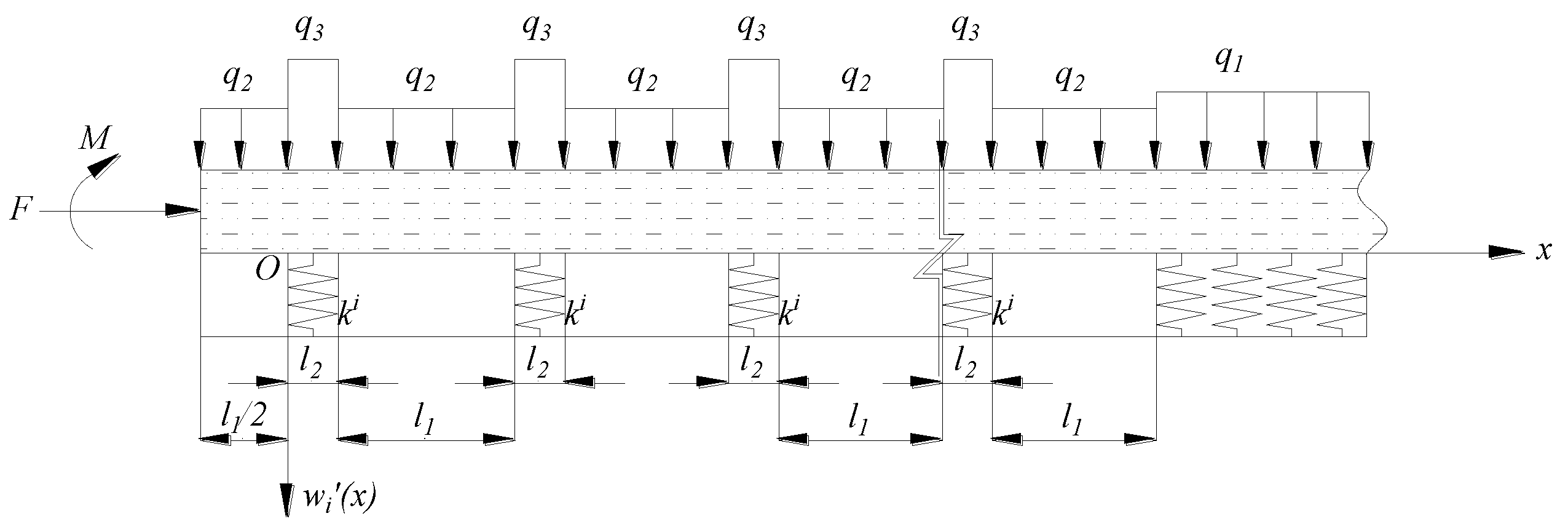

3.3. Establishment of the Mechanical Model and Analysis of Bending Deformation

3.3.1. The Calculation Method—Even Number of Blocks

3.3.2. The Calculation Method—Odd Number of Blocks

3.4. Calculation of HWFZ

4. A Case Study

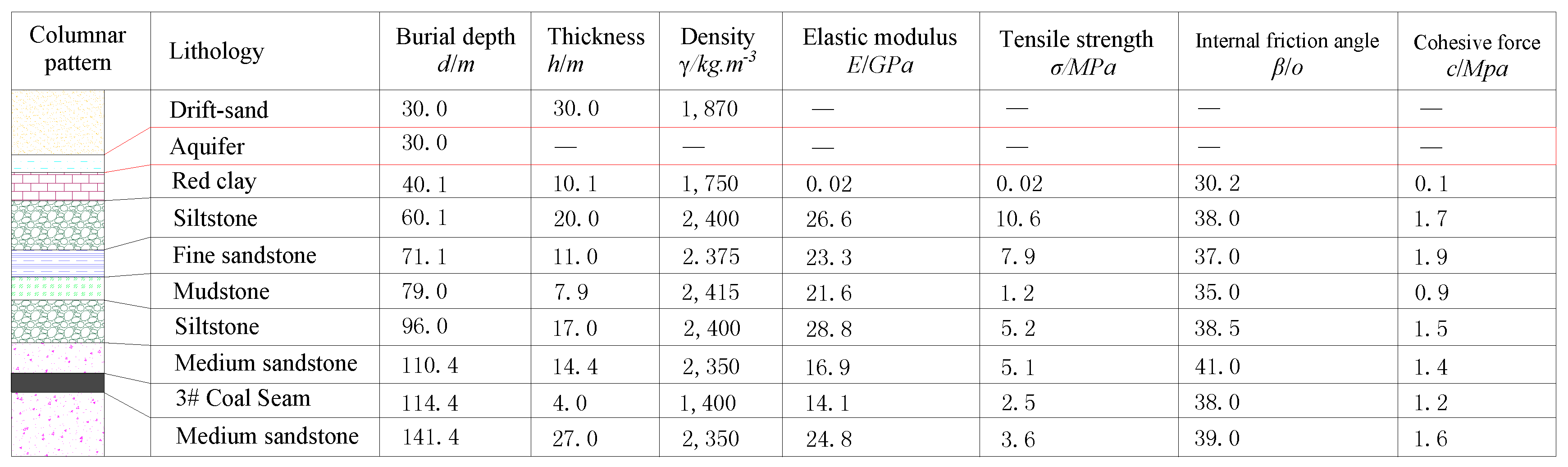

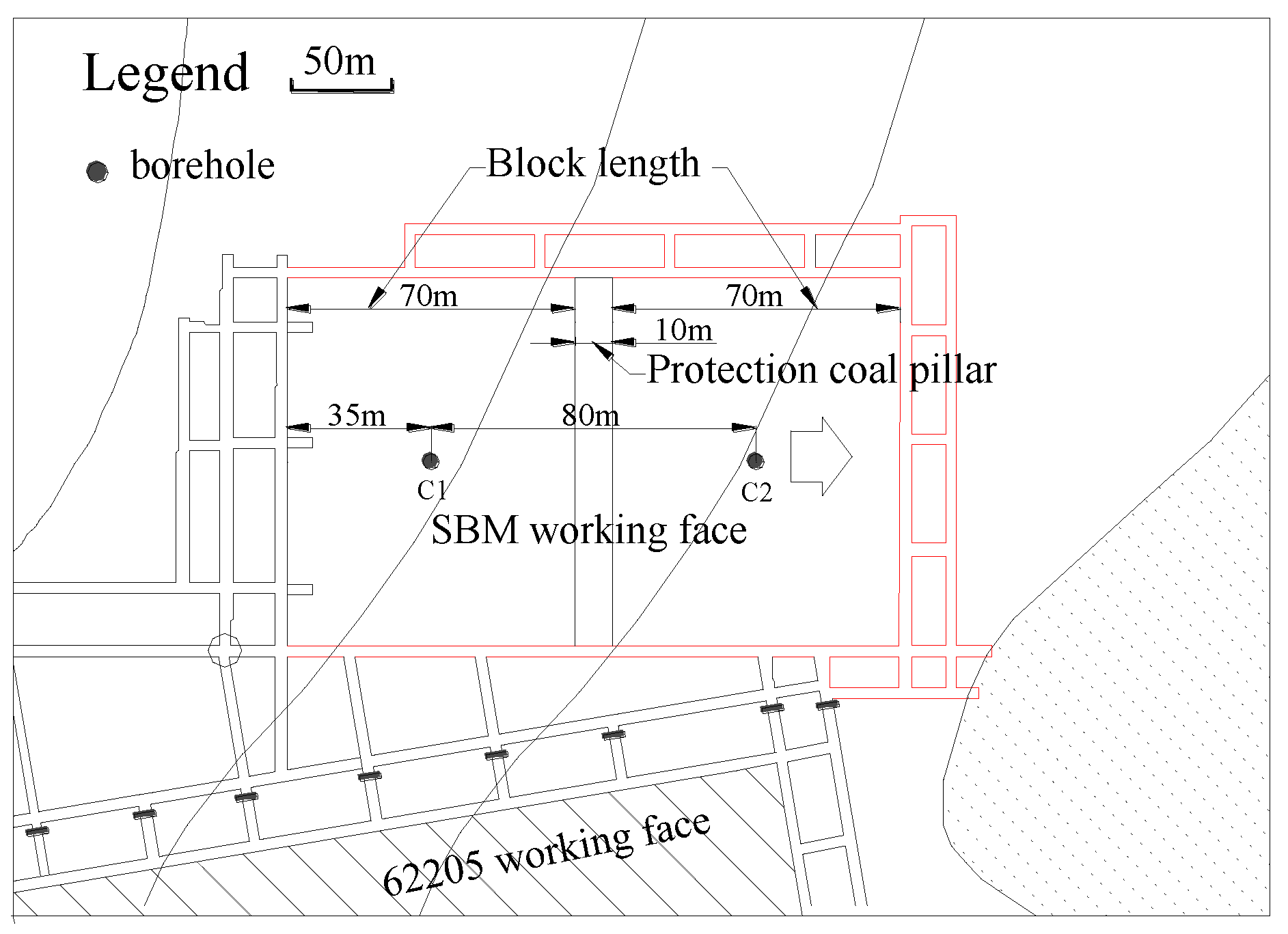

4.1. Background of the Project

4.2. Development of HWFZ

5. Practical Application

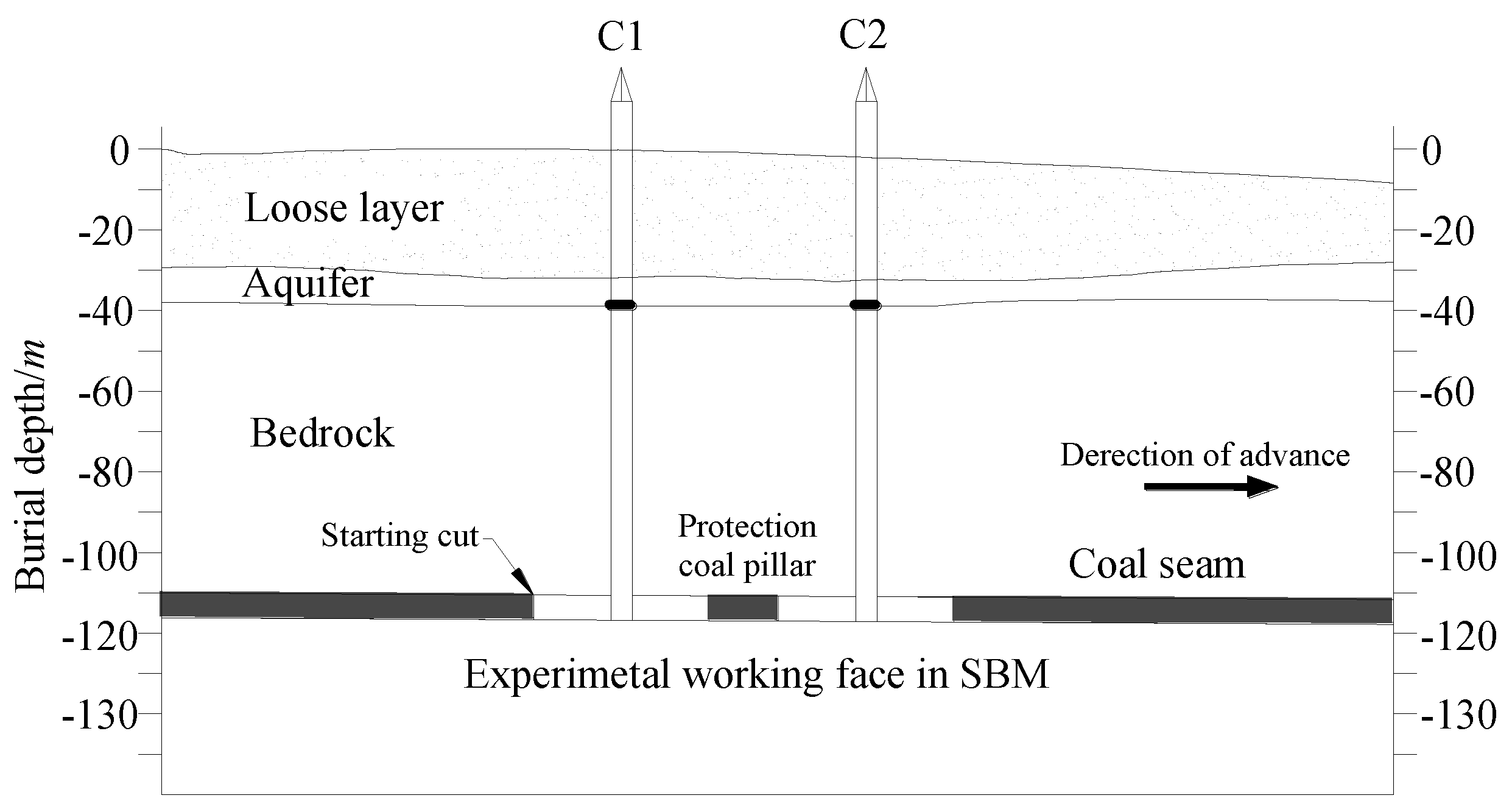

5.1. Monitoring Method of HWFZ

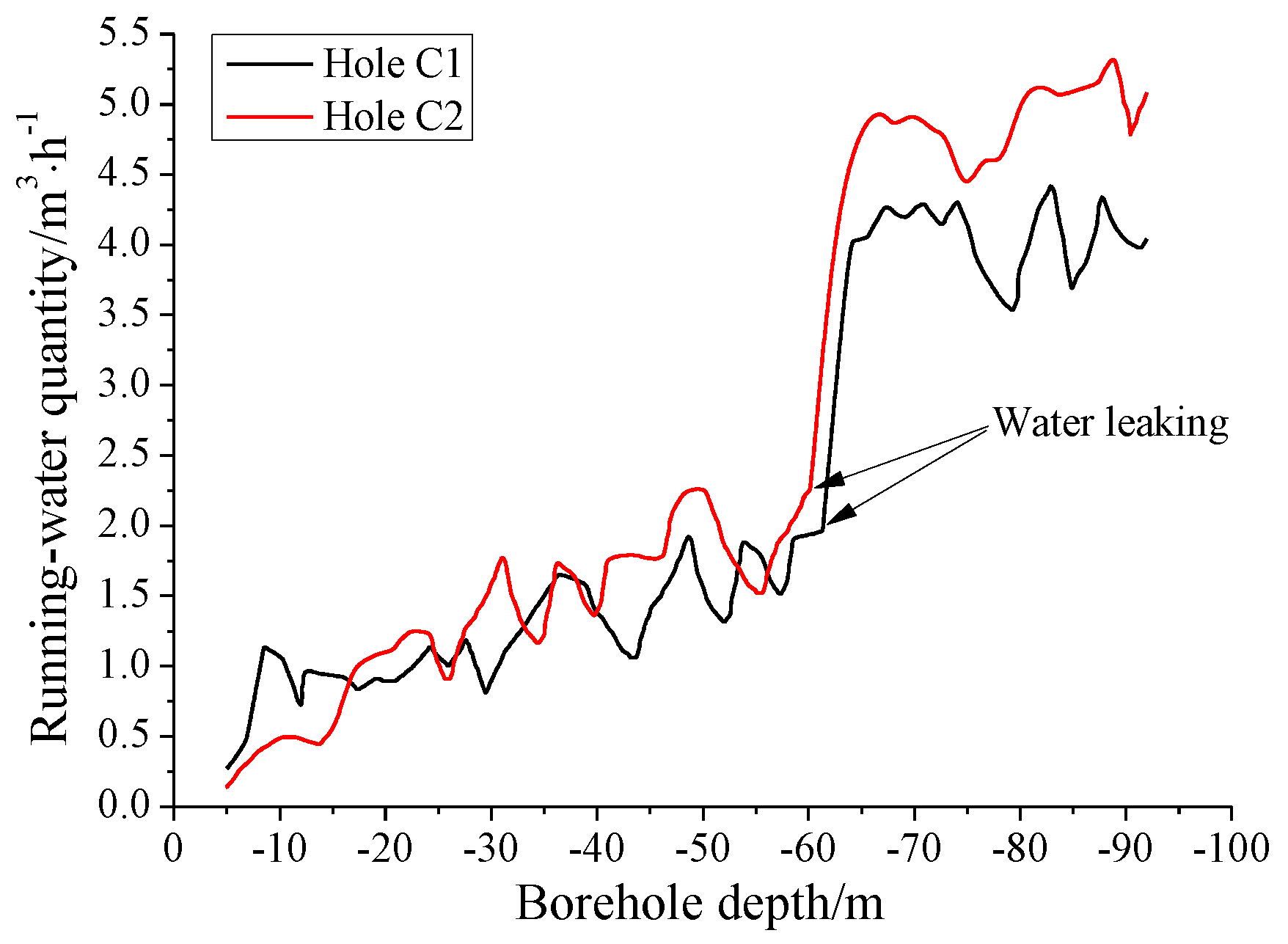

5.2. Analysis of the Monitored Data

5.3. Comparison between Measured and Predicted Results of HWFZ

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ye, G.X.; Jiang, F.X.; Liu, P.L.; Feng, Z.Q.; Wang, D.Z. Design and optimization of efficient mining technology in boundary coal recovery. J. Univ. Sci. Technol. B. 2007, 29, 655–659. [Google Scholar]

- Zhang, N.H. Study on the Theory and Practice about Mechanized Mining Technology of Bound Coal at Irregular Block Section. Ph.D. Thesis, China University of Mining & Technology, Xuzhou, China, 2011. [Google Scholar]

- Zhou, M.P. Research on Continuous Mining Methods and Rock Control Technology. Ph.D. Thesis, China University of Mining & Technology, Xuzhou, China, 2014. [Google Scholar]

- Cao, S.G.; Cao, Y.; Jiang, H.J. Research on catastrophe instability mechanism of section coal pillars in block mining. J. Min. Saf. Eng. 2014, 31, 908–913. [Google Scholar]

- Zhang, W.; Zhang, D.S.; Wu, L.X.; Wang, H.Z. On-site radon detection of mining-induced fractures from overlying strata to the surface: A case study of the Baoshan coal mine in China. Energies 2014, 7, 8483–8507. [Google Scholar] [CrossRef]

- Zhang, D.S.; Fan, G.W.; Liu, Y.D.; Ma, L.Q. Field trials of aquifer protection in longwall mining of shallow coal seams in China. Int. J. Rock Mech. Min. Sci. 2010, 47, 908–914. [Google Scholar] [CrossRef]

- Zhang, D.S.; Fan, G.W.; Ma, L.Q.; Wang, X.F. Aquifer protection during longwall mining of shallow coal seams: A case study in the Shendong coalfield of China. Int. J. Coal Geol. 2011, 86, 190–196. [Google Scholar] [CrossRef]

- Zhang, J.C.; Shen, B.H. Coal mining under aquifers in China: A case study. Int. J. Rock Mech. Min. Sci. 2004, 41, 629–639. [Google Scholar] [CrossRef]

- Miao, X.X.; Chen, R.H.; Bai, H.B. Fundamental concepts and mechanical analysis of water-resisting key strata in water-preserved mining. J. China Coal Soc. 2007, 32, 562–564. [Google Scholar]

- Miao, X.X.; Wang, A.; Sun, Y.J.; Wang, L.G.; Pu, H. Research on basic theory of mining with water resources protection and its application to arid and semi-arid mining areas. Chin. J. Rock Mech. Eng. 2009, 28, 217–227. [Google Scholar]

- Fan, G.W.; Zhang, D.S. Mechanisms of aquifer protection in underground coal mining. Mine Water Environ. 2015, 34, 95–104. [Google Scholar] [CrossRef]

- Fan, L.M.; Zhang, X.T.; Xiang, M.X.; Zhang, H.Q.; Shen, T.; Lin, P.X. Characteristics of ground fissure development in high intensity mining area of shallow seam in Yushenfu coal fiel. J. China Coal Soc. 2015, 40, 1442–1447. [Google Scholar]

- Fan, L.M.; Ma, X.D.; Ji, R.J. Progress in engineering practice of water-preserved coal mining in western eco-environment frangible area. J. China Coal Soc. 2015, 40, 1711–1717. [Google Scholar]

- Zhou, M.P.; Cao, S.G.; Jiang, X.J. The law of rock pressure in the stope with blocking mining by the continuous miner. J. Min. Saf. Eng. 2014, 31, 413–417. [Google Scholar]

- Huang, Q.X. Ground pressure behavior and definition of shallow coal seams. Chin. J. Rock Mech. Eng. 2009, 28, 217–227. [Google Scholar]

- Qian, M.G.; Shi, P.W.; Xu, J.L. Mining Pressure and Strata Control, 2nd ed.; China University of Mining & Technology Press: Xuzhou, China, 2010; pp. 115–116. [Google Scholar]

- Hoek, E.; Brown, E.T. Underground Excavations in Rocks, 1st ed.; Institution of Mining and Metallurgy: London, UK, 1980; pp. 382–395. [Google Scholar]

- Tan, T. The mechanical problems for the long-term stability of underground galleries. J. Rock Mech. Eng. 1982, 1, 7–26. [Google Scholar]

- Li, J.P. Mining Rock Mechanics, 1st ed.; Metallurgical Industry Press: Beijing, China, 2011; pp. 50–55. [Google Scholar]

- Zhang, J.X.; Li, J.; An, T.L.; Huang, Y.L. Deformation characteristic of key stratum overburden by raw waste backfilling with fully-mechanized coal mining technology. J. China Coal Soc. 2011, 36, 357–362. [Google Scholar]

- Yang, X.X. The feature of foundation pressure on winkler foundation beam with one fixed end and its application. Eng. Mech. 2006, 23, 76–79. [Google Scholar]

- Huang, Y.L.; Li, J.M.; Song, T.Q.; Kong, G.Q.; Li, M. Analysis on filling ratio and shield supporting pressure for overburden movement control in coal mining with compacted backfilling. Energies 2017, 10, 31. [Google Scholar] [CrossRef]

- Deng, X.J.; Zhang, J.X.; Huang, P.; Zhang, Q.; Hao, X.F. Roof movement characteristics in extra thick coal seam mining with the upward slicing filling technology. China Coal Soc. 2015, 40, 994–1000. [Google Scholar]

- Qian, M.G.; Miao, X.X.; Xu, J.L. Key Strata Theory of Strata Control, 1st ed.; China University of Mining & Technology Press: Xuzhou, China, 2003; pp. 16–20. [Google Scholar]

| Scheme | Mining Height/m | Width of Protection Coal Pillar/m | Block Length/m |

|---|---|---|---|

| 1 | 2/2.5/3.0/3.5/4.0 | 10 | 70 |

| 2 | 4 | 5/10/15/20/25 | 70 |

| 3 | 4 | 10 | 50/60/70/80/90 |

| HWFZ | Measured Results | Predicted Results According to The Regulation | Predicted Results Based on the Mechanical Model | |

| C1 | C2 | |||

| 47.98 m | 50.06 m | 75 m | 50.3 m | |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Cao, S.; Lan, L.; Gao, R.; Yan, H. Analysis of Development Pattern of a Water-Flowing Fissure Zone in Shortwall Block Mining. Energies 2017, 10, 734. https://doi.org/10.3390/en10050734

Zhang Y, Cao S, Lan L, Gao R, Yan H. Analysis of Development Pattern of a Water-Flowing Fissure Zone in Shortwall Block Mining. Energies. 2017; 10(5):734. https://doi.org/10.3390/en10050734

Chicago/Turabian StyleZhang, Yun, Shenggen Cao, Lixin Lan, Rui Gao, and Hao Yan. 2017. "Analysis of Development Pattern of a Water-Flowing Fissure Zone in Shortwall Block Mining" Energies 10, no. 5: 734. https://doi.org/10.3390/en10050734