1. Introduction

As the sole power source in a traditional electric vehicle, a battery needs to satisfy the power and energy demands of a bus under different operating conditions. When the battery is repeatedly over-charged and over-discharged in the long-term operating, the battery degradation will be accelerated. Furthermore, when the battery is operated at low temperature, its capacity degradation is more significant. The hybrid energy storage system (HESS) is composed of a battery and super capacity (SC); the battery provides the required energy and the SC satisfies the instantaneous power requirements, can effectively inhibit the battery charge and discharge current changes, and optimizes the working conditions of the energy system [

1].

Currently, experts and scholars in the field of electric vehicle hybrid energy storage research are focused on the modeling and performance of the system components, system parameters matching, power distribution, etc. In terms of system component modeling and experimentation, Luo et al. [

2] derived and verified a driving cycle life prediction model for LiFePO

4 battery based on the experimental verification of the existing capacity decay model for LiFePO

4 under a constant current charge/discharge condition. Abeywardana et al. [

3] proposed a new type of inverter combined with boost circuits used in HESS, which eliminates the high current injected into the drive motor as compared to conventional controllers that eliminate the equivalent series resistance of the inverter. Henson et al. [

4] conducted a comparative study of the battery/SC with different depths of discharge (DODs) for minimizing the cost of the HESS. Xiong et al. [

5,

6] used different algorithms to estimate the relationship of the voltage to the state-of-charge (SOC) and capacity of lithium ion battery, and they also validated the accuracy of the method through hardware-in-the-loop experiments. In terms of system parameter matching and power distribution, Mid-Eum et al. [

7] used the convex optimization method to optimize the power loss and battery power fluctuations considering the real-time dynamic load to propose a method for calculating the SC reference voltage. Song et al. [

8,

9] proposed a new semi-active topology; the operation cost of the HESS, including the battery degradation cost and electricity cost, is minimized by using the dynamic programming (DP) approach. Further, they studied four topologies and proposed a rule-based power distribution strategy with four kinds of topologies based on the optimization results. Hu et al. [

10] conducted energy efficiency analysis and component selection of the plug-in hybrid power system using convex optimization.

In summary, there have been studies related to the parameter matching and system control of HESS facing battery degradation. However, to the best of our knowledge, there are no published papers that combine the climatic conditions in northern China and the corresponding urban driving cycle operating conditions to optimize the functioning of the HESS. In order to attain the full potential of the HESS to enhance the battery life of electric buses under local conditions, in this study, we considered the electric bus operating in Harbin, China as an example, and proposed a method to optimize charge/discharge current of battery through convex optimization considering the average monthly temperature change in one year.

This paper is organized as follows. In

Section 2, we analyze the configuration and working modes of the HESS. In

Section 3, we introduce the models of LiFePO

4 batteries, SCs, and vehicle.

Section 4 presents a convex optimization power distribution strategy based on the semi-empirical model of battery degradation. In

Section 5, the simulation results and operating years were analyzed and the results are compared with those of the rule-based strategy.

2. Analysis of Configuration and Working Modes of Hybrid Energy Storage System

As the main energy source of electric vehicles, energy-based batteries have the disadvantages of low power density and high capacity degradation [

11]. In order to satisfy the peak power demand, the power density of batteries should be sufficiently high; further, considering a battery that is the only power source of a traditional electric car, in principle, the only way to increase the power density of the batteries is to increase the number of batteries. Thus, it will result in high cost and high battery degradation. However, the SCs have characteristics of high power density and low capacity degradation. A combination of the battery and SC satisfies power and energy requirements, as well as the different performance requirements of the vehicles.

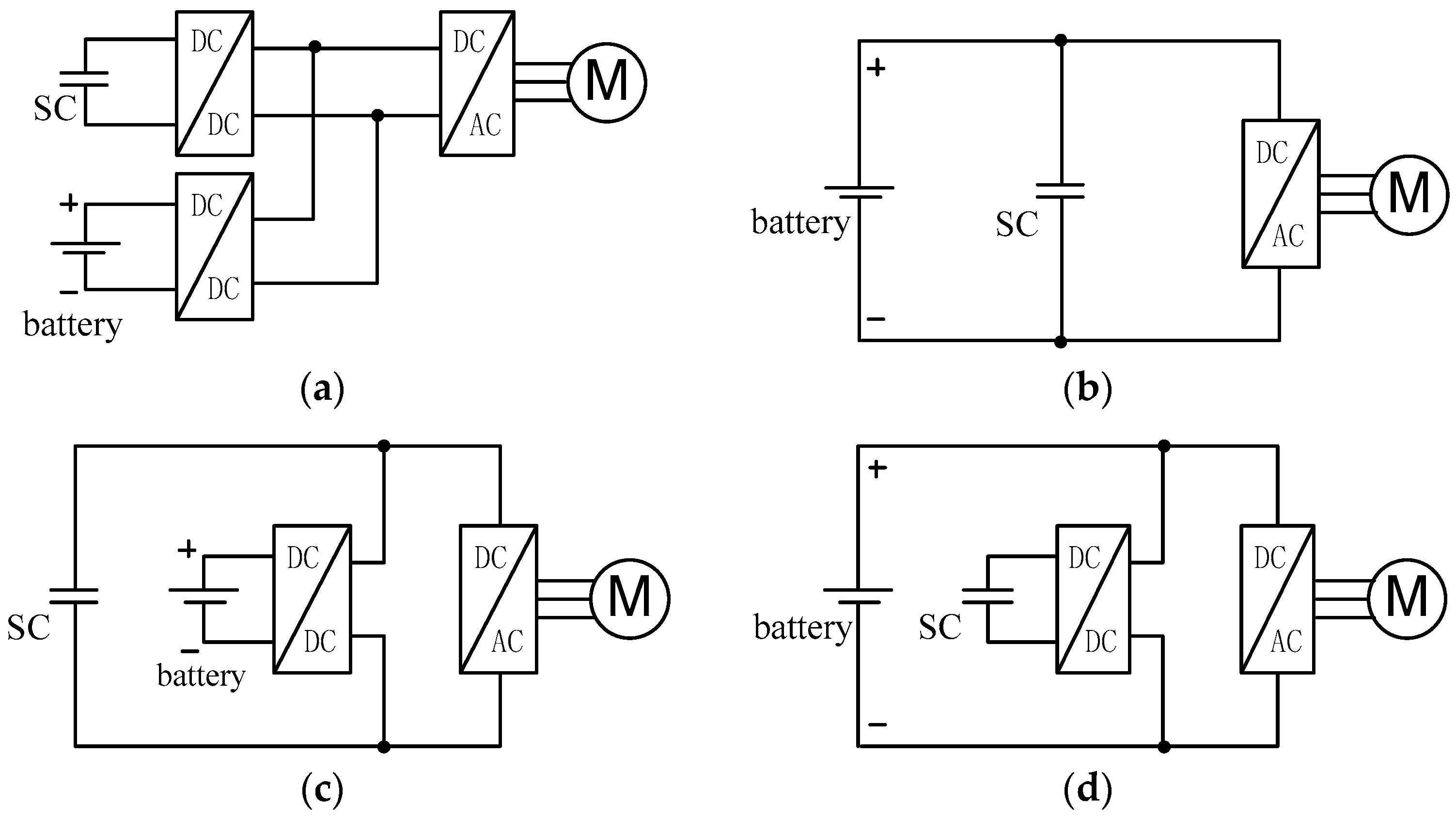

According to the different connections between the battery, SC, and DC/DC converter, the HESS can be classified into three major types, namely, fully active, passive, and semi-active, as shown in

Figure 1. In the fully active HESSs, both the battery and SC are connected to the DC bus via a DC/DC converter; two DC/DC converters can simultaneously control the output power of the battery and the SC. Further, it has good control margins. However, a fully active HESS has low system efficiency and a complicated system structure owing to the existence of the two converters; it also increases the system cost owing to the additional cost of the DC/DC converter. Therefore, the fully active topology can achieve a good control effect, but at the expense of system efficiency, complexity, and cost [

12]. In the passive topology, the battery and SC are directly connected to the DC bus and the system structure is simple. Owing to the absence of a converter, the system efficiency of the passive topology is the highest, whereas it is uncontrollable of the energy flowing [

13]. In the semi-active topology, either the battery or the SC is connected to the DC/DC converter through a unique converter to control the distribution of the output power of the two energy sources. Since the DC bus is connected to one of the battery and SC directly, a fast DC/DC converter is required to maintain DC voltage when the load is changed. However, compared to the fully active and passive topologies, the semi-active topology solved the problems of low efficiency, high cost, uncontrollability, etc. [

14].

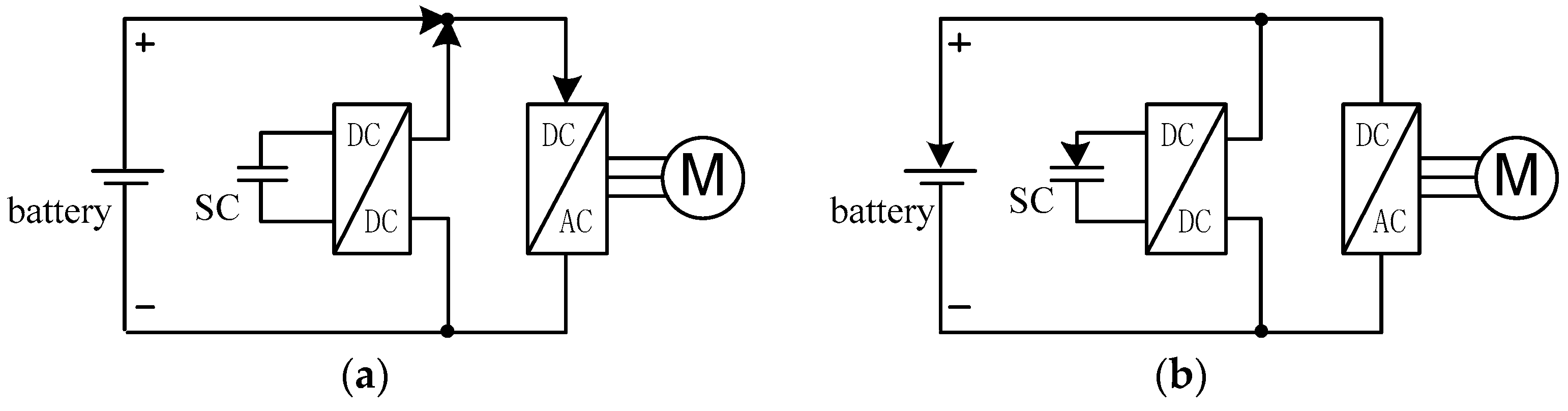

The topology adopted in this study is shown in

Figure 1d. Semi-active topology 2 employs a DC/DC converter to decouple the SC from the battery/DC bus. Furthermore, the DC bus voltage is equal to the battery voltage as they are directly connected. Compared to the other three topologies, the use of SC is more flexible [

15], and its working mode is shown in

Figure 2. In the driving mode, both the battery and SC provide power to the motor, and the SC satisfies the instantaneous high power requirements. In the braking mode, the energy charging for the SC first through the converter, then the braking energy charging for the battery when the SC is full. For the power conversion between SC and DC bus, a fast three-leg bidirectional DC/DC converter is used. It can be operated in the interleaved manner and has the merit of being commercially available [

16,

17]. The degradation of the SC is very small and its working life can accommodate millions of charge/discharge cycles. The power demand from the vehicle will be volatile during rapid acceleration and braking; hence, the SC plays the role of power and energy buffer when it is connected between the battery and driving motor through the DC/DC converter.

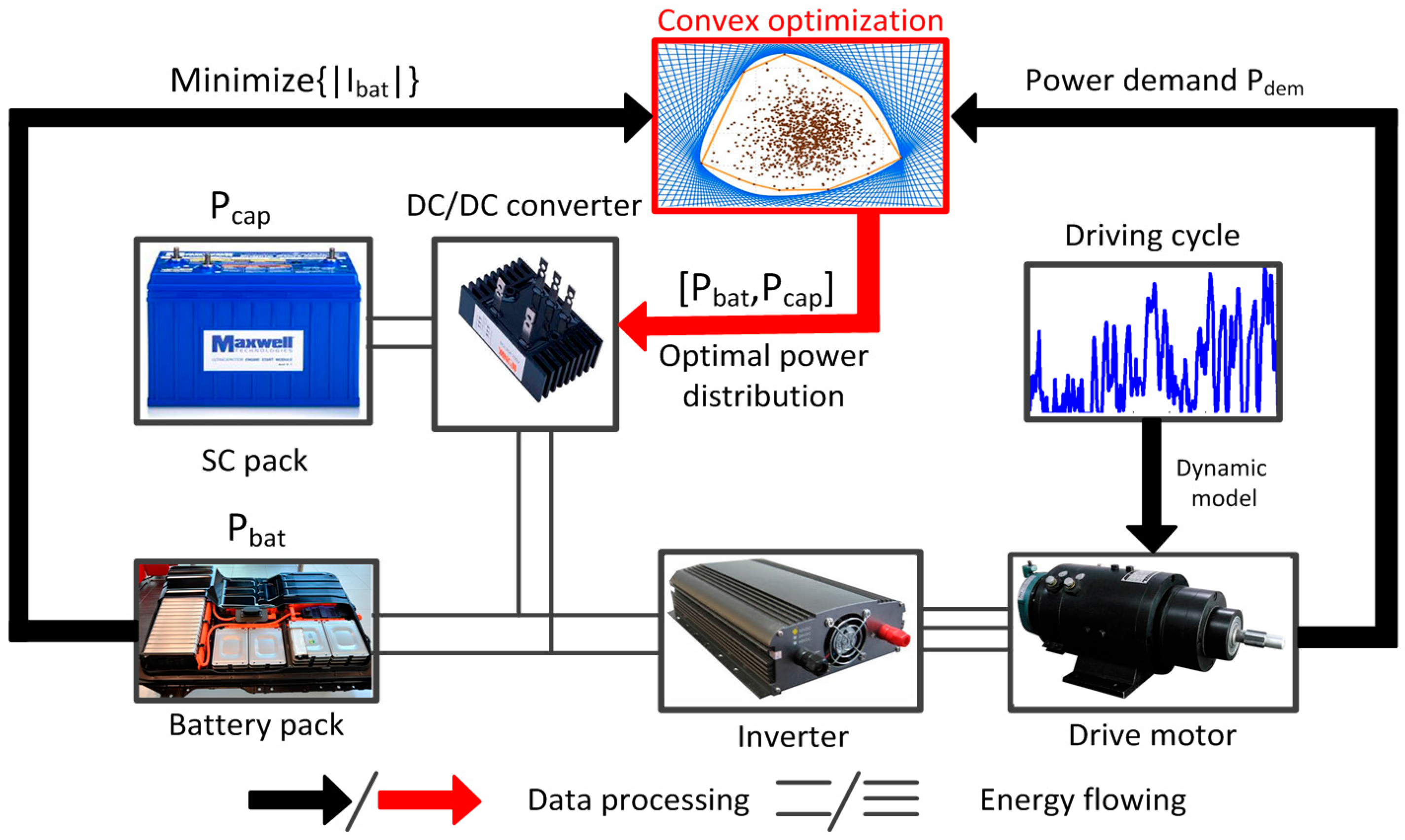

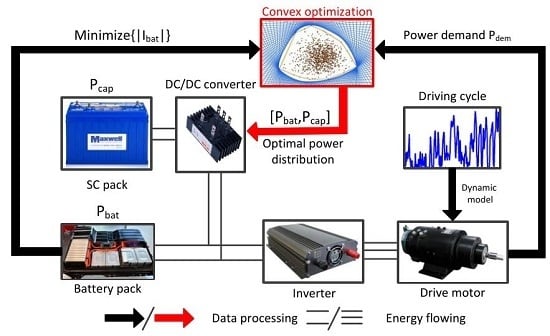

4. Convex Optimal Control Strategy Based on the Battery Degradation

Through the driving cycle, we can calculate the power demand of the bus at every step. In the driving mode, the required power Pdem should be the output power of the drive motor on its output shaft. The electrical power output on the DC bus is equal to the motor output power plus the motor power loss, which is obtained by the fitting. The electrical power output on the DC bus at this time is the total power to be satisfied by the batteries and the SCs (considering the efficiency of DC/DC converter).

Assuming that the SCs are in the same energy storage state at the beginning and end of the driving cycle, the degradation percentage Qloss_sum of the battery is calculated using the following equation.

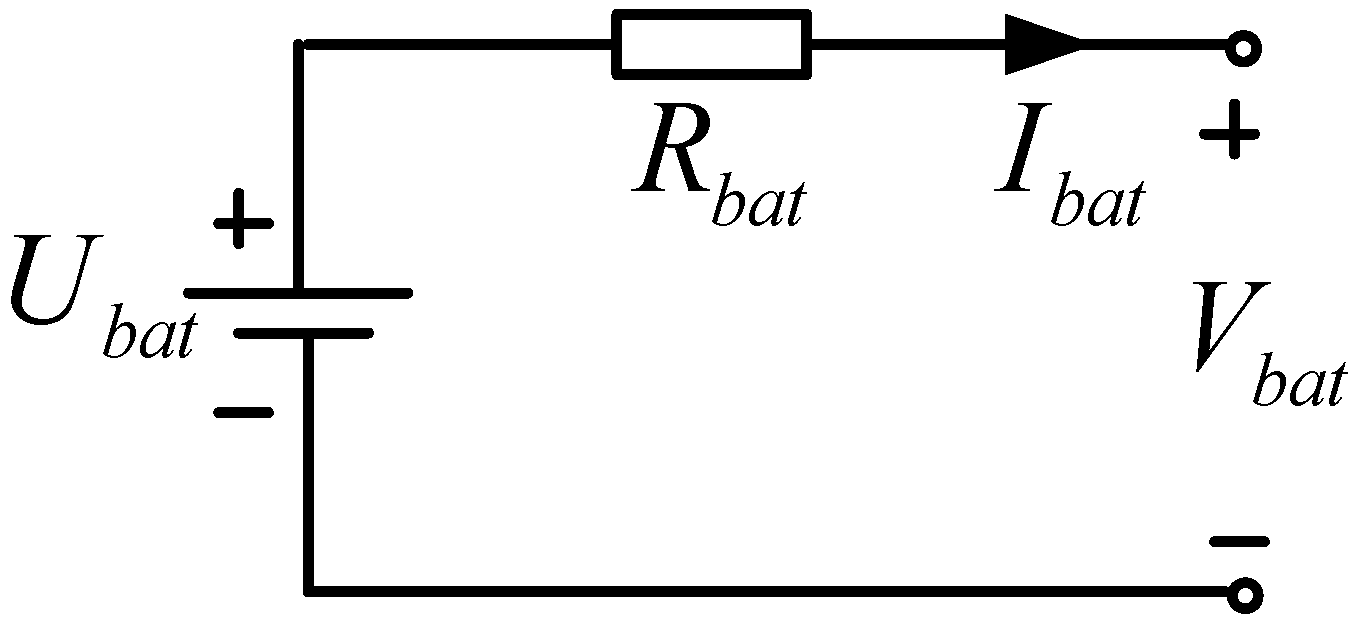

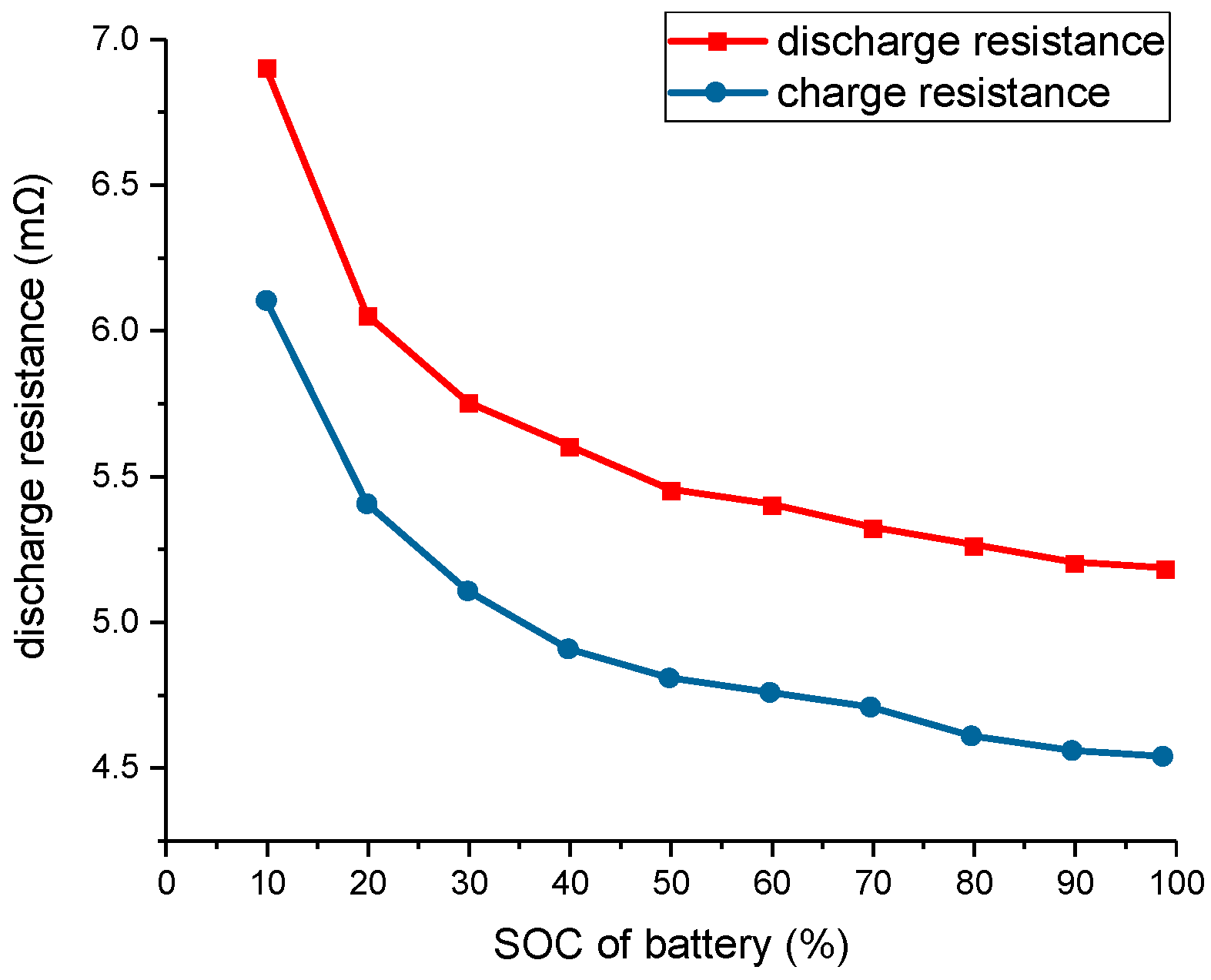

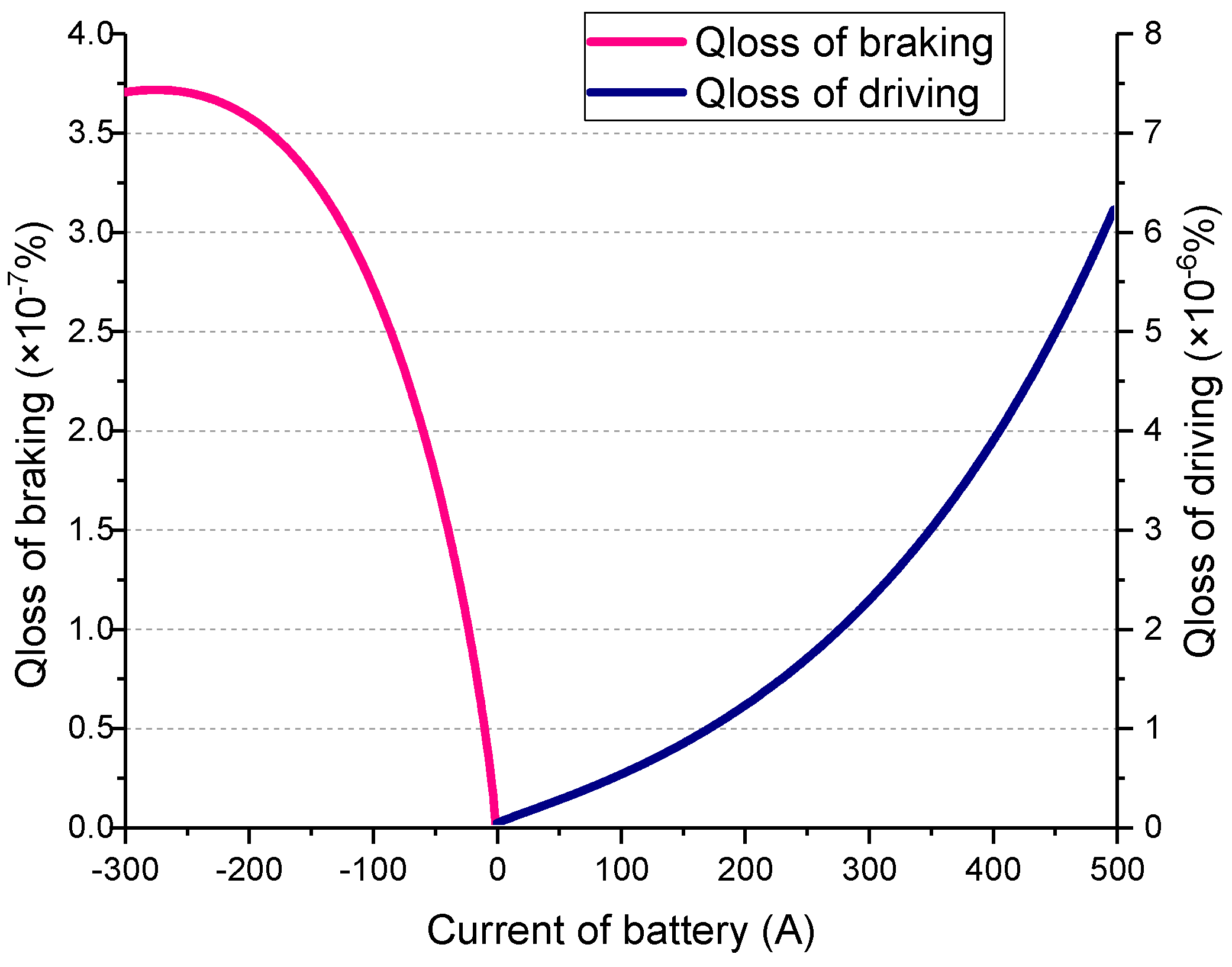

In order to reduce the computation time in the convex optimization, as shown in

Figure 7, the relationship between the battery current I

bat and the battery degradation percentage Q

loss is determined at room temperature 25 °C based on Equation (9). Irrespective of the braking or driving modes, Q

loss always increases as the charge or discharge current I

bat increases. Hence, the optimization of the entire driving cycle of battery degradation can be equivalent to optimizing the entire driving cycle of the battery current in the absolute value. There is the following relationship:

Therefore, as shown in Equation (18), the equivalent optimization target for the purpose of optimizing the battery degradation could be obtained. According to the constraints of the optimization target in the convex optimization [

26], Equation (18) satisfies the requirement that the convex optimization must be a convex function or an affine function for the objective function.

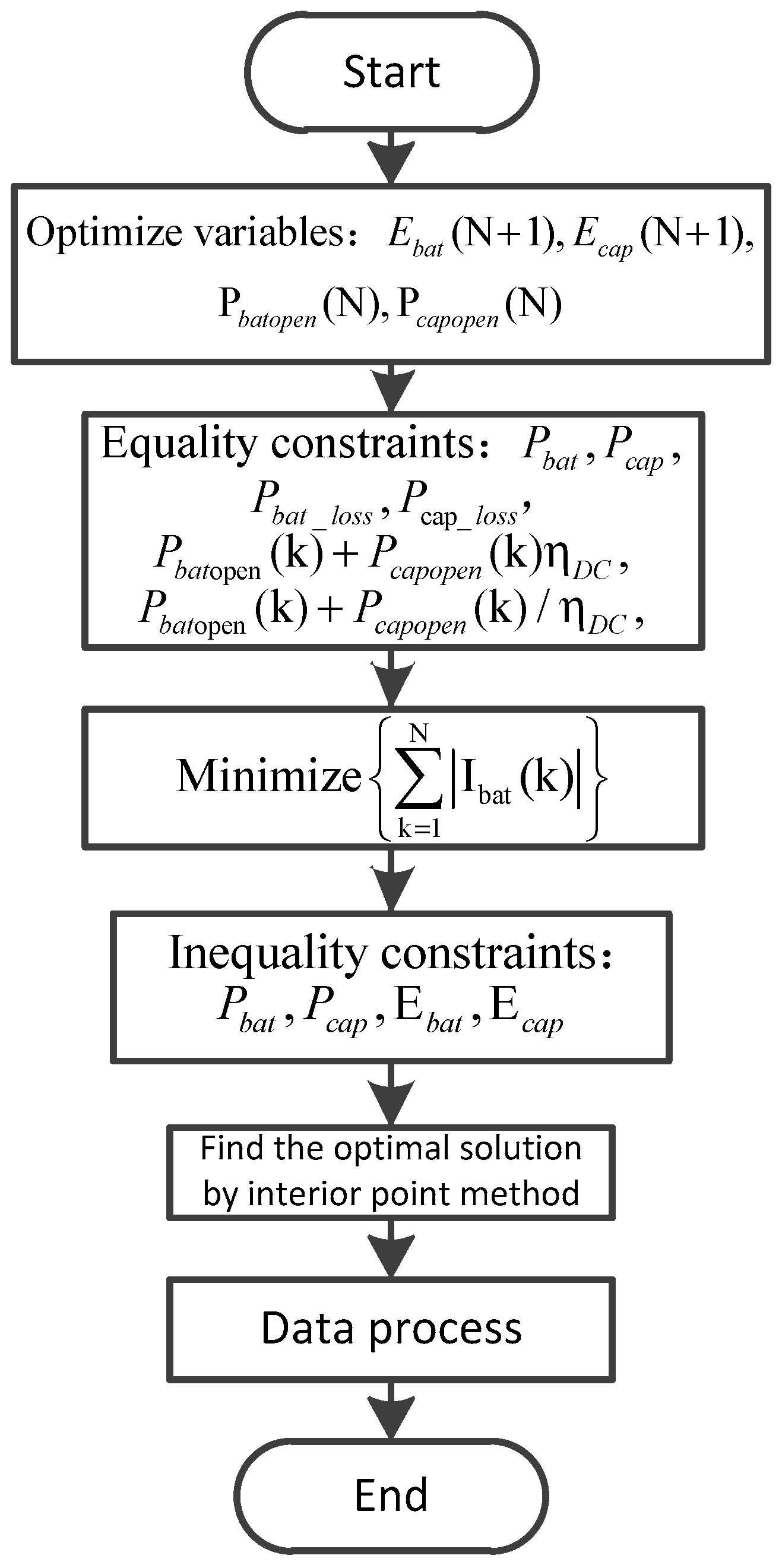

The implementation process of the convex optimization strategy used in this study is shown in

Figure 8. In order to satisfy the constraints on the number of battery cells and SC cells in Equations (14) and (15), the number of selected battery and SC cells is n

bat = 120 and n

cap = 240, respectively. The battery pack and SC pack in the HESS are all grouped by n series and one parallel connection, and the unbalance between the cells is ignored [

27]. As the energy source of the vehicle, the LiFePO

4 battery pack is not only for the drive motor to provide energy, but also for the super capacitor when SOC

cap is low. The SC pack is between the LiFePO

4 battery pack and the drive motor, acting as an energy and power buffer, and absorbing the braking energy from the drive motor during braking.

According to the output voltage changes of the battery and the SC cell, we can constrain the output energy range of the battery pack and capacitor group,

where V

bat_min, V

bat_max, V

cap_min, and V

cap_max are the maximum and minimum voltages corresponding to the battery and the SOC of the SC, given by Equation (20).

The range of the output power of the battery and SC pack can be limited according to the maximum charge/discharge current of the battery and SC cell.

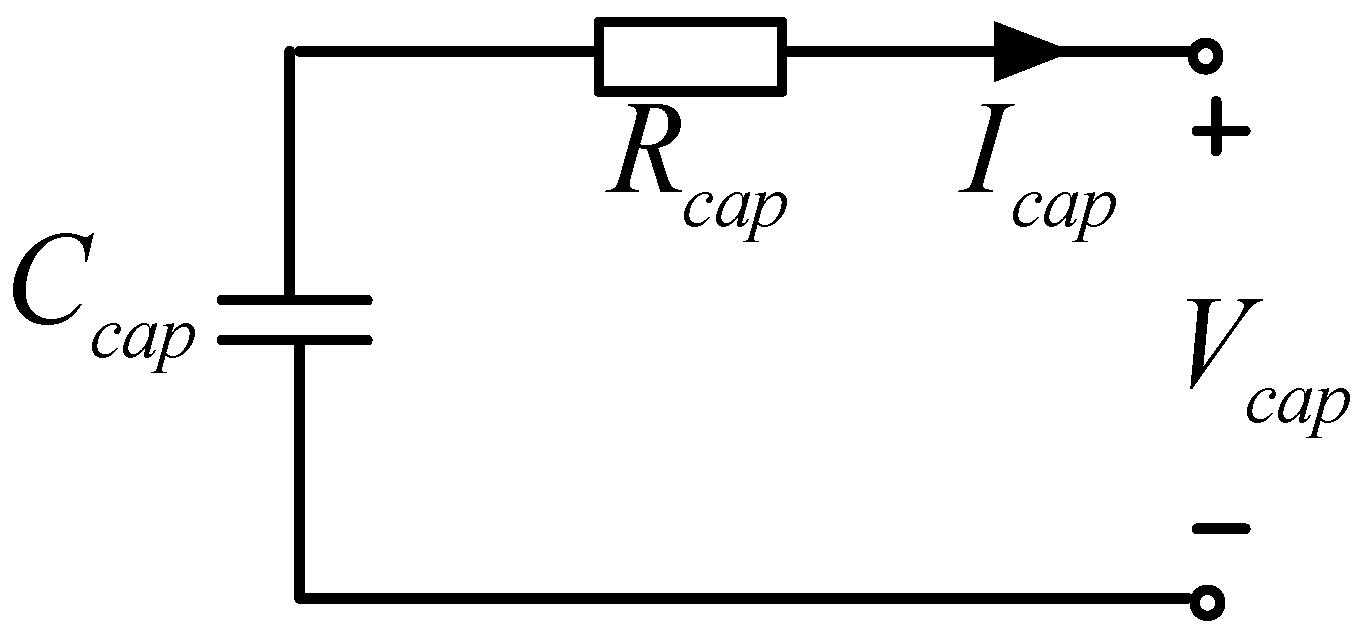

The power consumed on the battery pack and the SC pack internal resistance can be calculated from Equation (22).

where I

bat and I

cap are the currents flowing through the battery and the SC cell, respectively. Both I

bat and I

cap have the following constraints.

For the battery pack and the SC pack, it is necessary to satisfy the total power demand in different cases, by satisfying the following equation constraints.

where P

batopen and P

capopen are the output powers of the battery pack and SC pack, respectively. P

emloss is the motor power loss and can be interpolated by the motor power loss curve.

In this study, we use Equation (18) as an optimization target, and the battery pack energy E

b, SC pack energy E

cap, battery pack port output power P

batopen, and SC pack port output power P

capopen as the convex optimization variables. The battery pack power P

bat, SC pack power P

cap, battery pack power loss P

bat_loss, and SC pack power loss P

cap_loss are used as the equation constraints of the convex optimization. The overall optimization function is given in

Table 4.

According to the description of the convex optimization problem in Ref. [

26], the constraint conditions in

Table 4 are convex or affine functions; the entire convex optimization problem satisfies the convex optimization requirement, and the convex optimization implementation flow is shown in

Figure 9.

5. Simulation and Results Analysis

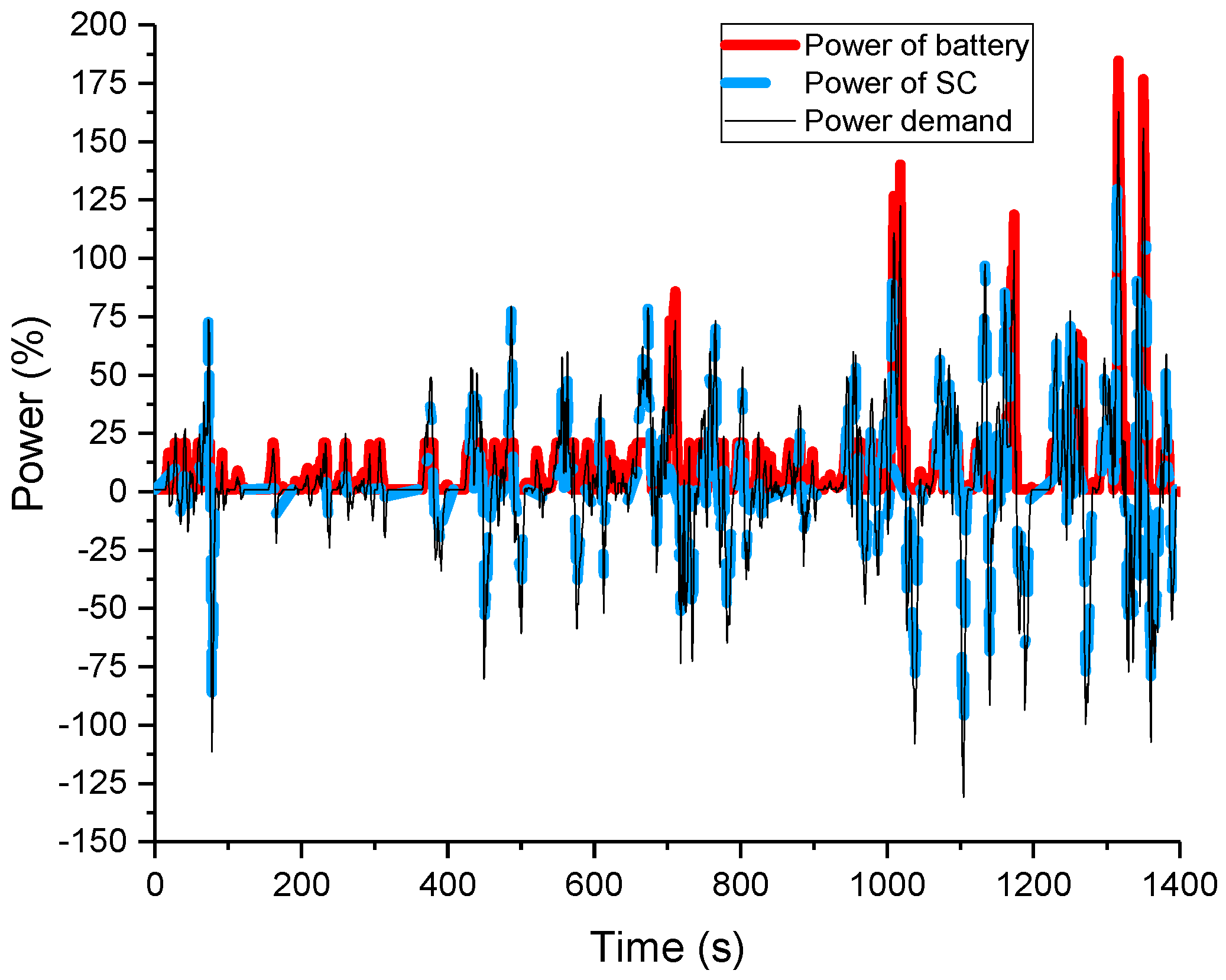

In order to verify the effectiveness of the HESS optimization proposed in this study, we compared its performance with that of the rule-based power distribution strategy under the Harbin city driving cycle [

28]. The Harbin city driving cycle and the power demand is shown in

Figure 10. The convex optimization result is shown in

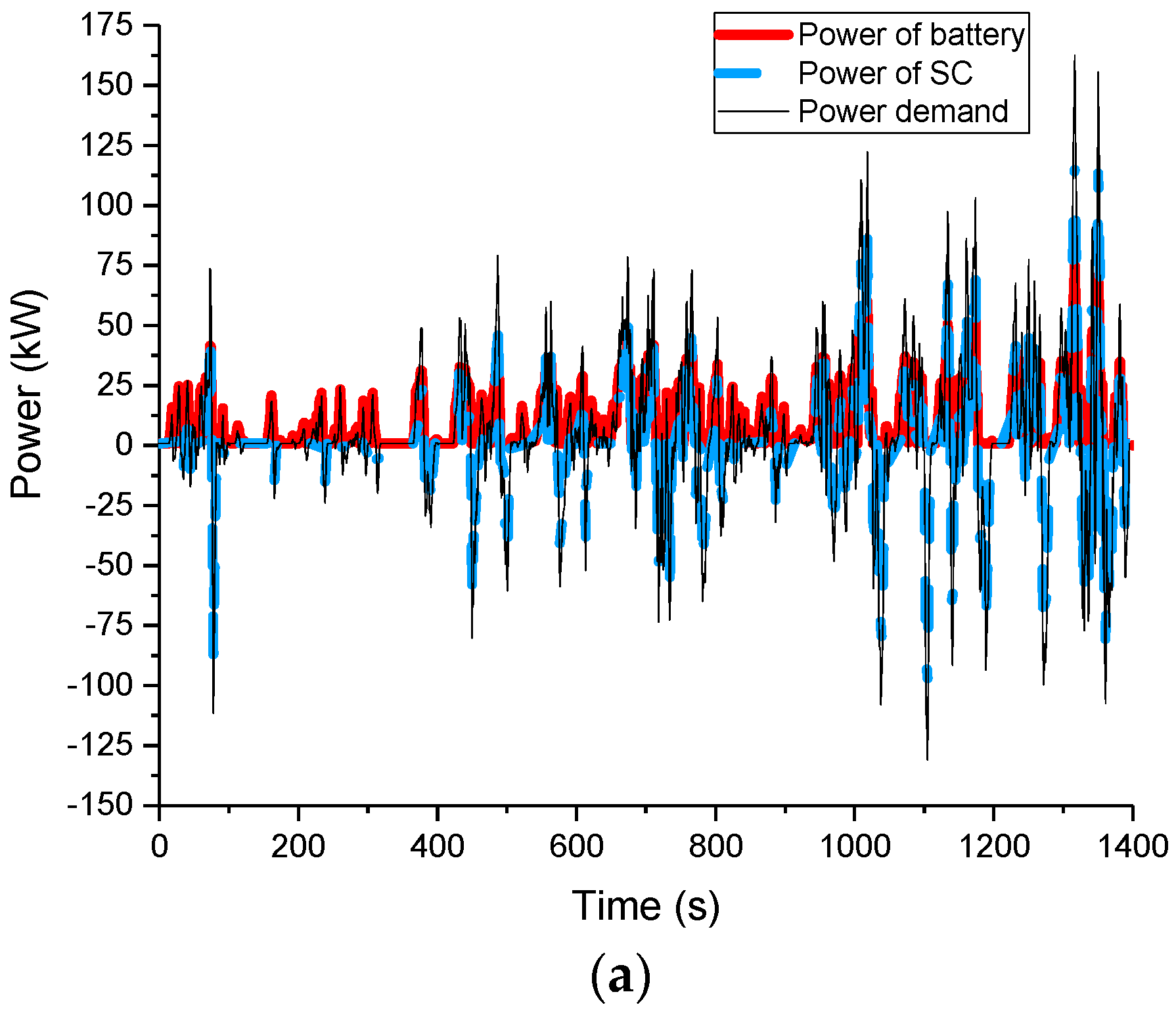

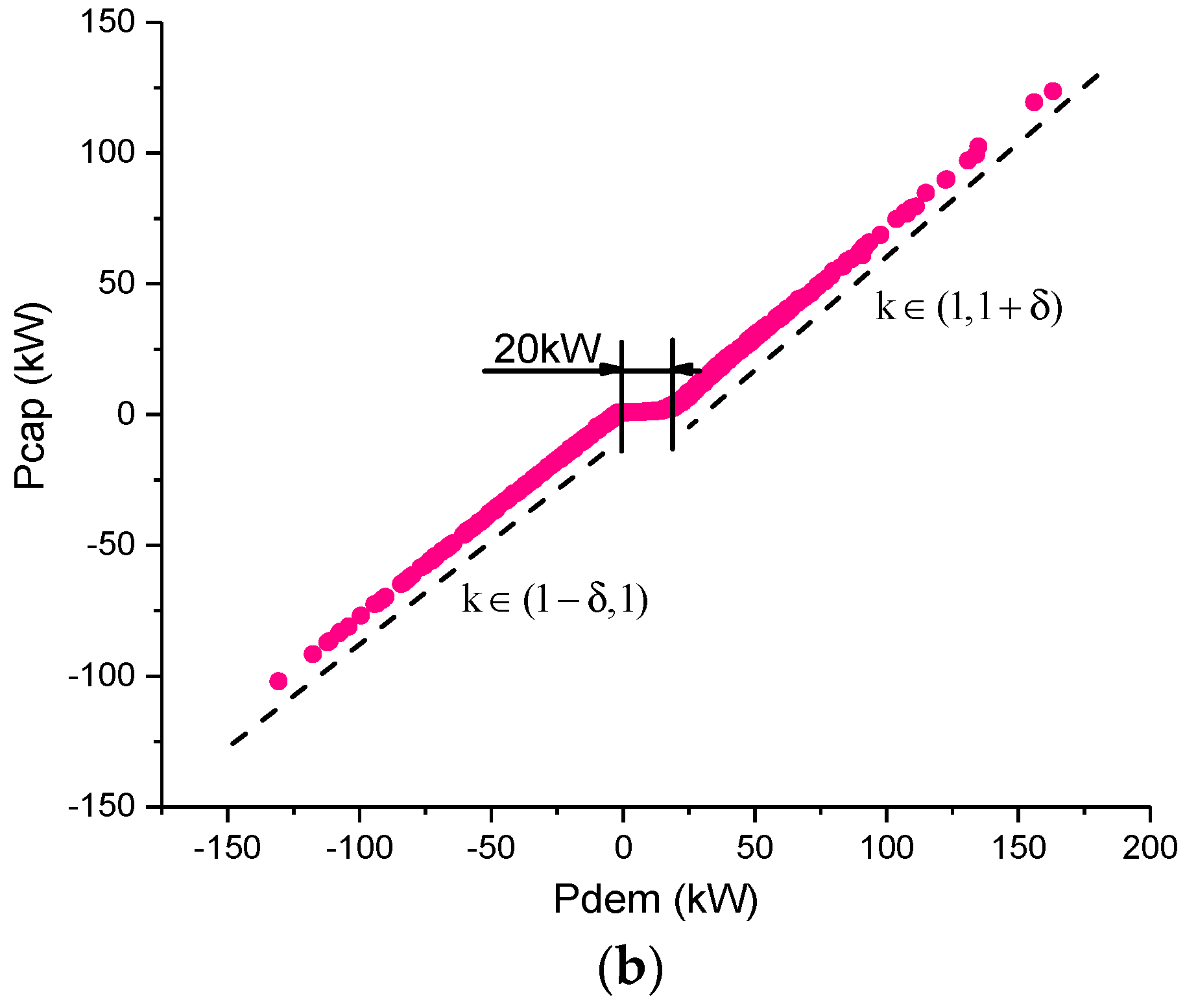

Figure 11. It can be observed that the battery only provides a small range of demand for power fluctuations, whereas the SC satisfies instantaneous high power requirements. When the required power is greater than a certain threshold, the SC and the battery pack together provide the power required. However, owing to the presence of DC/DC converter efficiency and powertrain efficiency, the sum of the power of the battery pack and the SC pack is much greater than the power demand. Furthermore, the same as the result of two efficiency effects, in the braking mode, the SC cannot recover all the braking energy. In addition, as shown in

Figure 11b, the battery only provides a small demand for power and the SC satisfies instantaneous high power requirements; this can be reflected in the relationship between power demand and SC power. When the power demand fluctuates in the range of 0 kW to 20 kW, the SC does not output power. This part of the power is borne by the battery and when the power demand fluctuates in the range of 20 kW to the highest power demand, the SC satisfies the power demand. Owing to the efficiency of DC/DC converter and the efficiency of the powertrain, the slope of the fitted line k is slightly greater than 1 when the demand power is greater than 20 kW. When the power demand fluctuates in the negative range, the SC absorbs the braking energy, and the slope of the fitting line k is less than 1 owing to the DC/DC converter efficiency and the efficiency of the powertrain. The entire convex optimization process consumes 1.33 × 10

7 J, i.e., approximately 3.70 kWh. Since the optimization target is absolute value of the battery current, while the terminal voltage drop of the battery pack is very small in one driving cycle. Therefore, the optimization goal also has a significant role in optimizing the battery energy consumption.

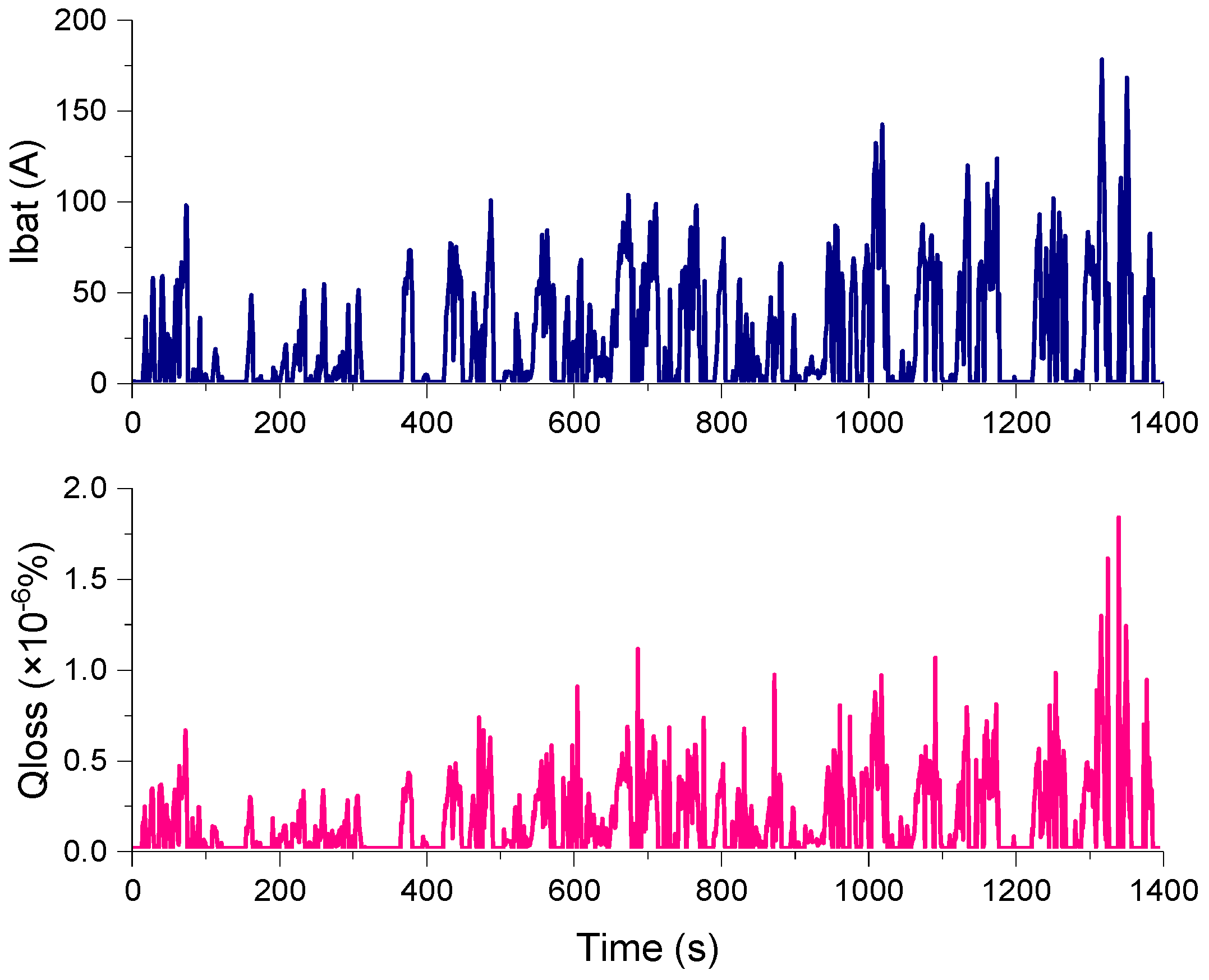

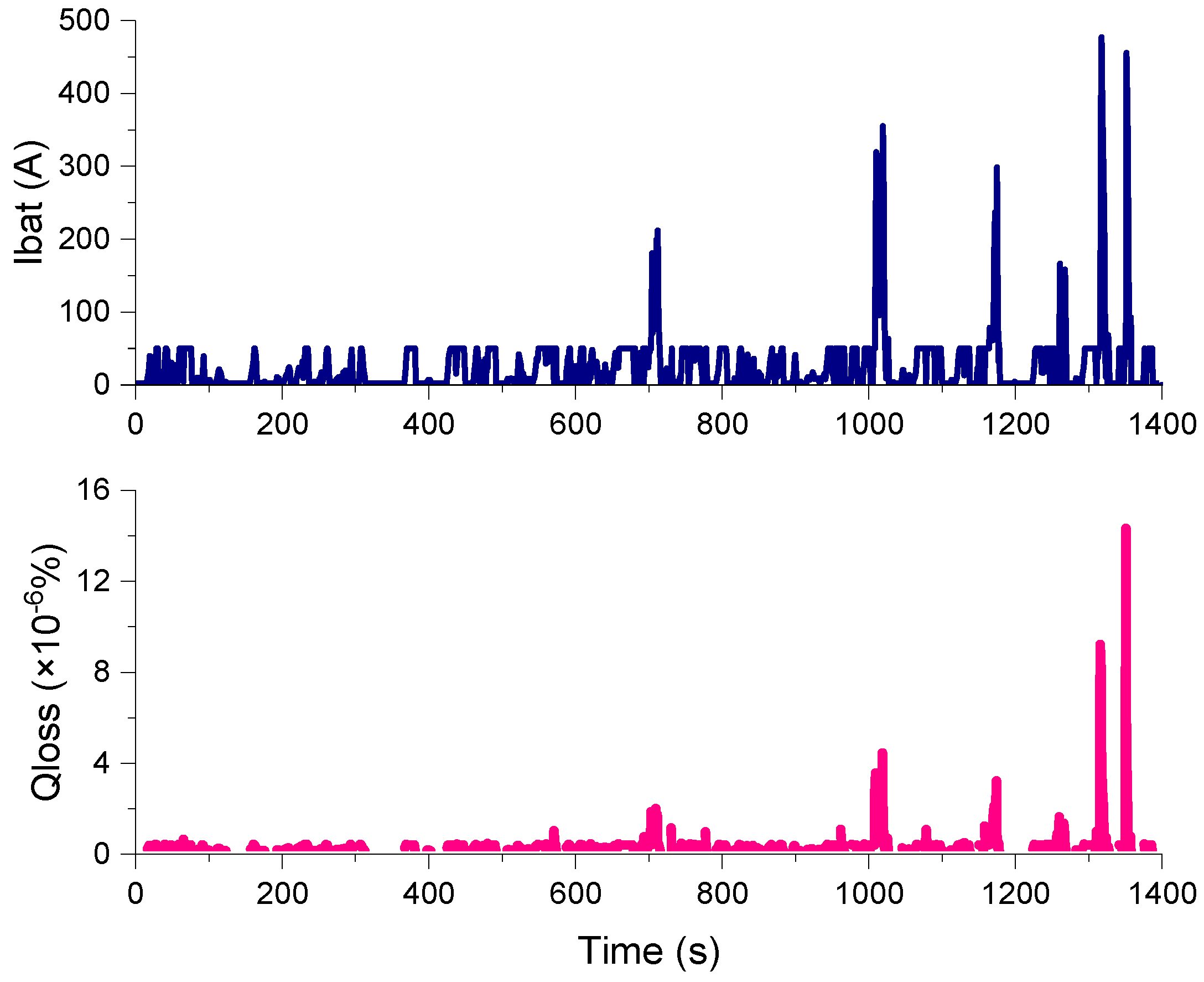

Figure 12 shows the battery current and battery degradation percent at a room temperature of 25 °C based on convex optimization. In the latter part of the driving cycle, the acceleration/deceleration of the vehicle is violent; hence, the battery current undergoes greater fluctuations. However, the maximum value of the battery current does not exceed 200 A. The battery runs within 1C discharge magnification rate altogether. In addition, according to the relationship between the battery charge/discharge current I

bat and the battery degradation percentage Q

loss in

Figure 7, it can be observed that the battery current has approximately an exponential relationship with the battery degradation percentage Q

loss when the battery current is greater than zero. Therefore, Q

loss obtained in

Figure 12 is more intense than the battery current fluctuation. At room temperature of 25 °C, the battery degradation percent in one driving cycle is 2.16 × 10

−4%.

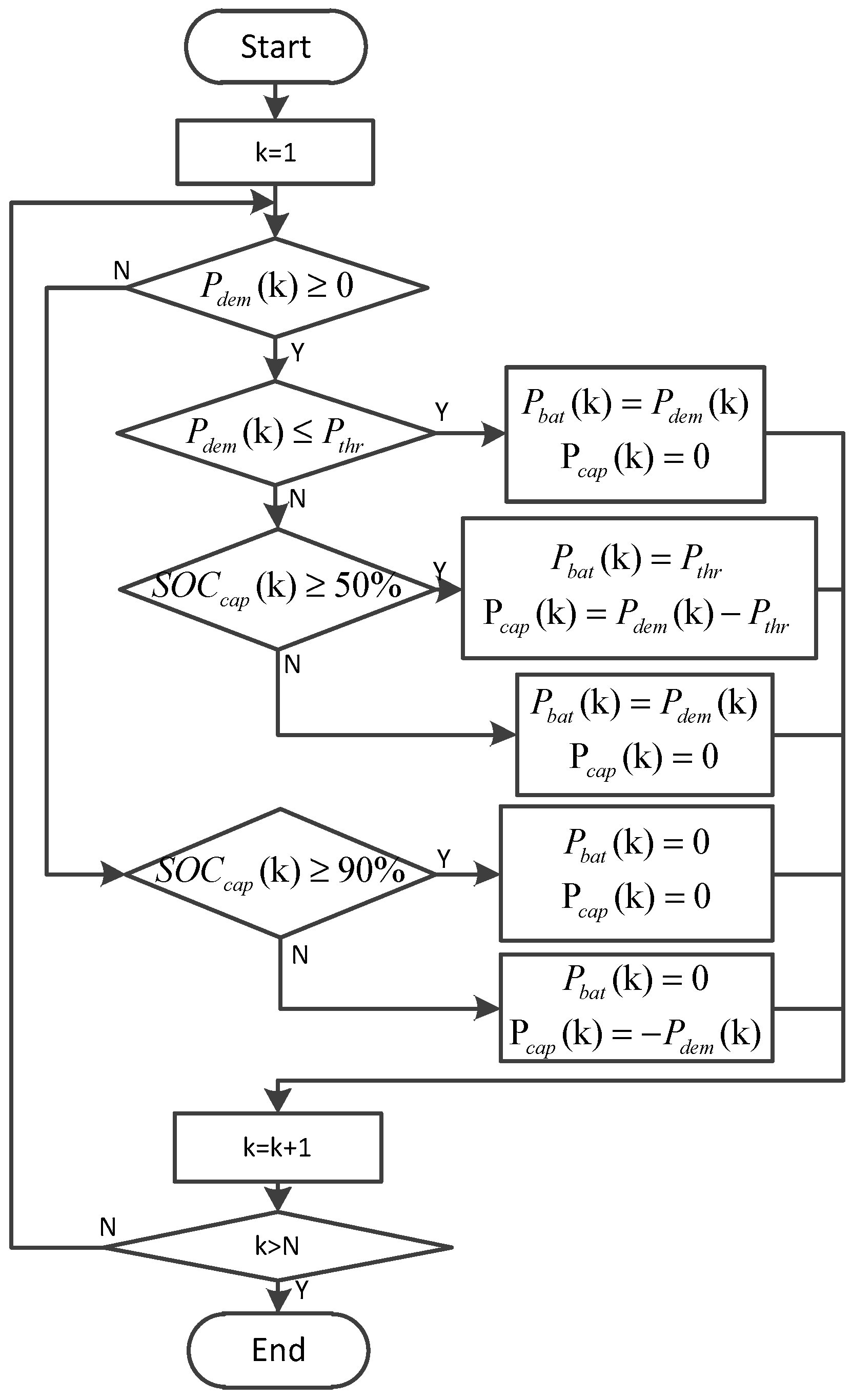

In order to verify the effectiveness of the proposed optimization method in this paper for the electric bus equipped with semi-active HESS, it is compared with the rule-based strategy in Harbin driving cycle. The rule-based strategy is shown in

Figure 13 [

9,

29]. When the power demand P

dem ≥ 0, the battery only provides the threshold power P

thr, and when P

dem > P

thr, the battery will provide the part of power demand exceed according to the SOC

cap. When the power demand P

dem < 0, it is also need to charge for SC according to the charge of state of the SC, when the SC pack is fully charged and then to the battery pack for energy braking. According to the characteristics of the SC power and the power demand relationship obtained from the convex optimization, the threshold power P

thr in the rule-based strategy is set to 20 kW, and the same power system model and initial parameters are used to calculate the power distribution based on the rules strategy, as shown in

Figure 14.

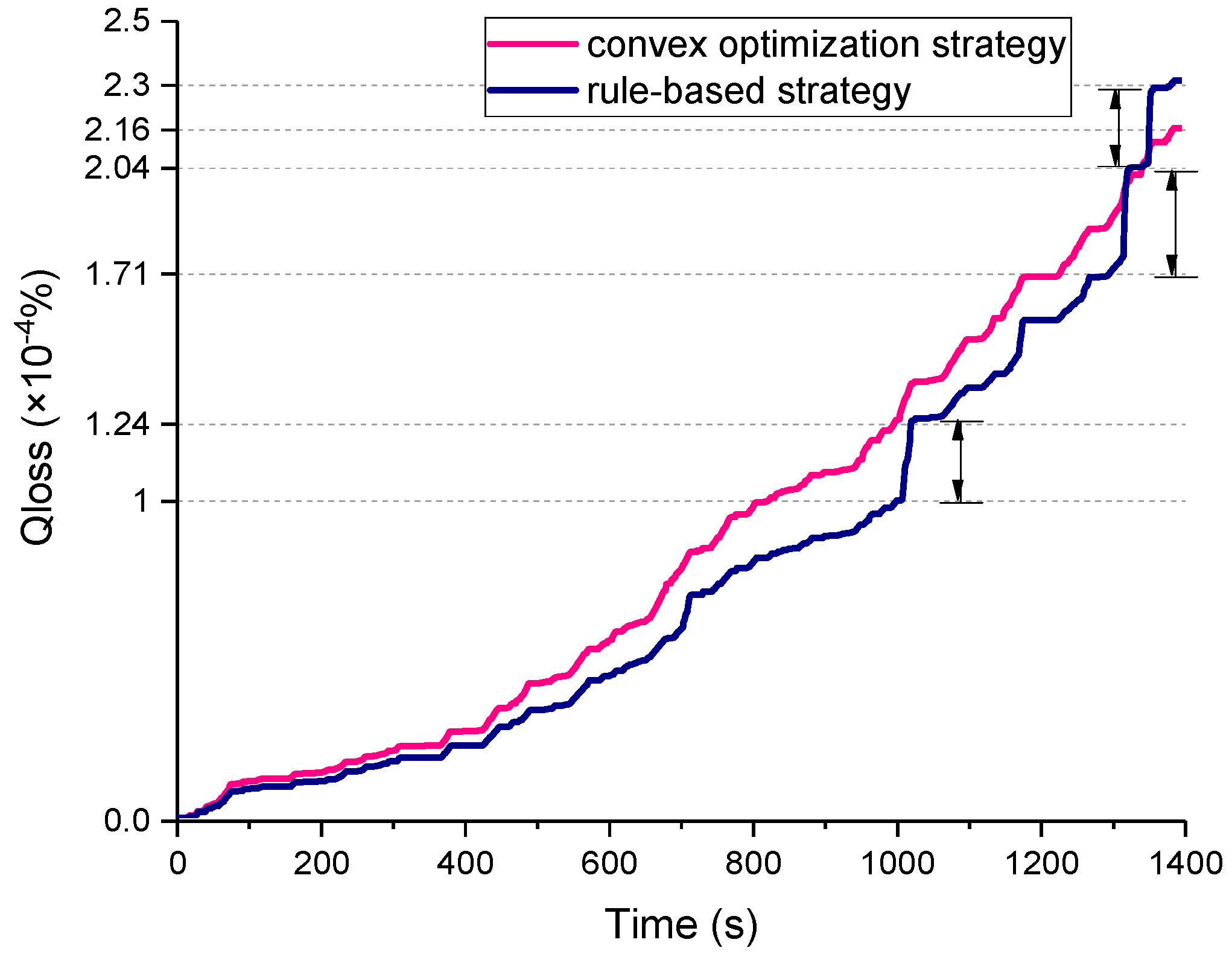

Figure 15 shows the battery current and battery degradation percent at 25 °C based on the rule strategy. In the latter part of the driving cycle, it can be seen that the SC obtained the energy from braking cannot satisfy the power demand; this part of the power demand difference can only be borne by the battery. Therefore, the battery experiences a large output power fluctuation. The battery current and battery decay percentages have several significant peaks in the later stages based on the rule strategy. However, in contrast, the SC satisfies the instantaneous high power ripple and the battery outputs a smaller power fluctuation in the convex optimization. According to the energy management strategy evaluation method in Ref. [

30], the standard deviation of the battery current in two strategies has been calculated, as shown in Equation (25), where the I

b_avg is the average of battery current, s is the standard deviation of battery current.

The standard deviation of the battery current based on the convex optimization strategy and rule-based strategy is 31.03 and 43.99, respectively, the battery current fluctuation based on the convex optimization strategy is smaller than rule-based strategy.

Figure 16 shows the battery capacity degradation curve based on convex optimization and rule-based strategy. At approximately t = 1050 s, t = 1320 s, and t = 1360 s, the battery degradation percent based on the rule strategy has three significant rising intervals, which correspond to three battery current pulses based on the rules strategy; further, it can be reflected from the battery current and battery degradation percentage result of the rule-based strategy shown in

Figure 15. In contrast, the battery power fluctuation is smoother when based on the convex optimization strategy, thus protecting the battery better. The rule-based strategy consumes 1.35 × 10

7 J in one driving cycle, i.e., approximately 3.75 kWh, and the percentage of battery degradation is 2.31 × 10

−4%.

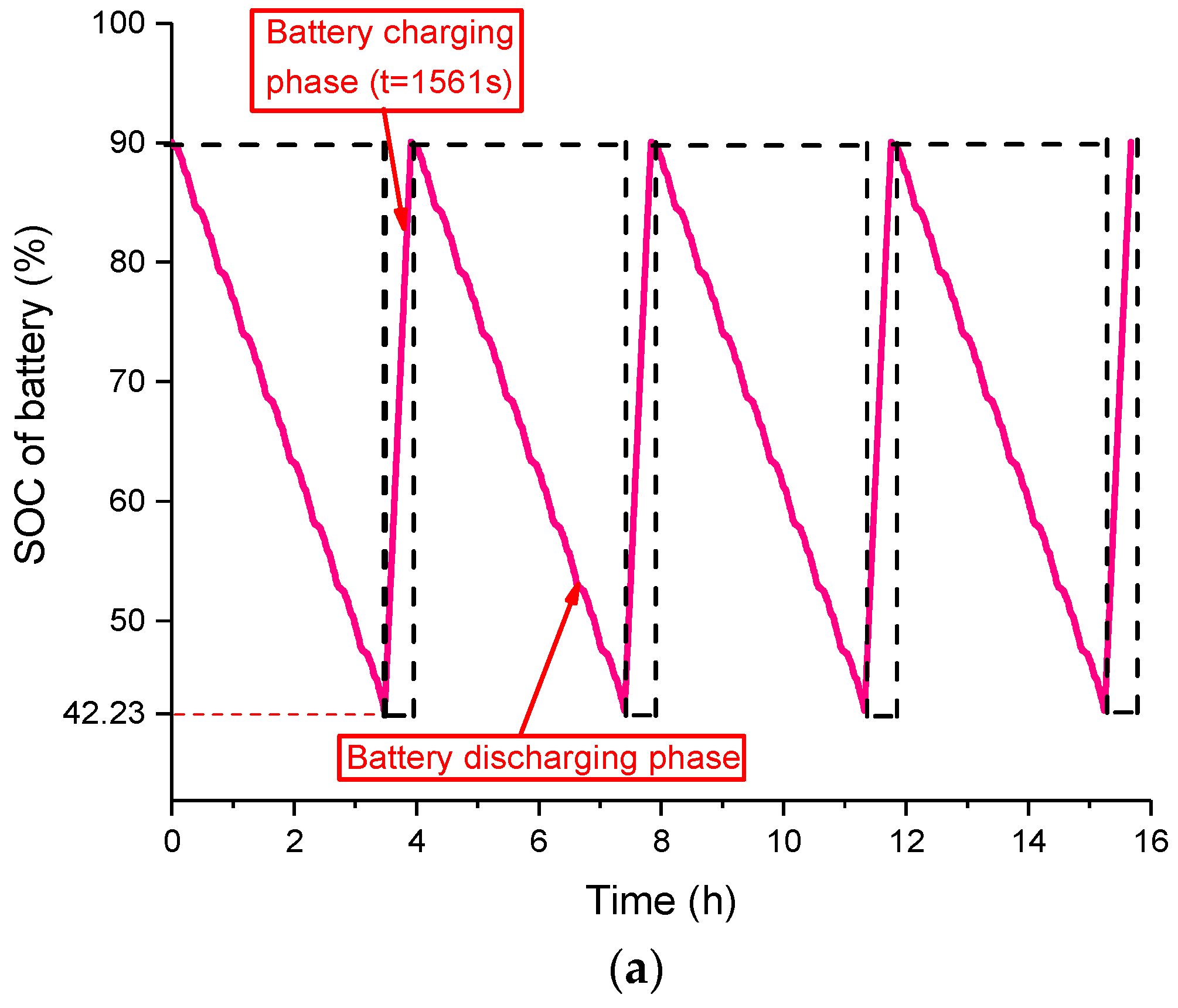

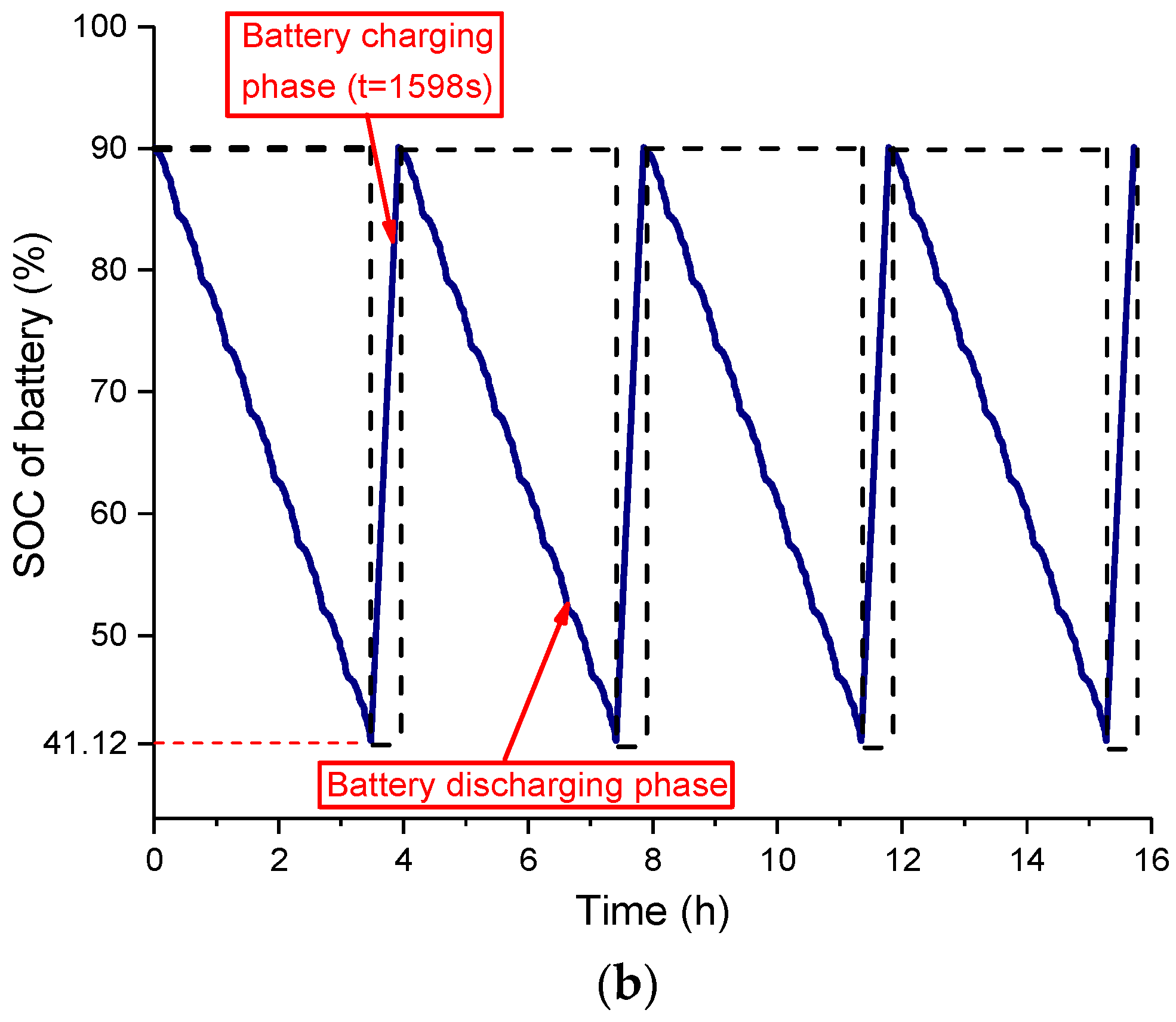

In order to further reflect the real situation of a bus running on Harbin city roads in a day, and quantitatively analyze the potential of convex optimization relative to the rule-based strategy to improve battery life, we use nine Harbin city driving cycles (total 50.4 km) to simulate a cycle line: a bus from the bus terminal, followed by a cycle line, and subsequently back to the bus terminal. When the bus arrives at the terminal again, the CC-CV is used to recharge the battery. When the battery pack is recharged, the SOC

bat returns to 0.9.

Table 5 shows the indicators of the battery pack when the bus drives in one cycle line based on the two strategies.

For the LiFePO

4 battery pack with 120 cells in series and one in parallel, the SOC of the battery varies from SOC

bat = 0.9 to SOC

bat = 0.4223 through one cycle line under convex optimization, and the SOC of the battery varies from SOC

bat = 0.9 to SOC

bat = 0.4112 through one cycle line under rule-based strategy. In the process of the recharge phase, the recharge magnification is set to 1C. The entire recharge state continues for 1561 s in convex optimization and 1598 s in rule-based strategy. After the recharge, the battery SOC of the convex optimization strategy and the rule-based strategy are returned from SOC

bat = 0.4223 and SOC

bat = 0.4112 to SOC

bat = 0.9, respectively. According to the actual operation, the electric bus run four line cycles (approximately 200 km) in one day, and the electric bus needs to recharge the battery four times. Assuming that the battery is fully charged (SOC

bat = 0.9) in the first trip every day, the battery SOC change curve based on the convex optimization strategy and rule-based strategy can be obtained as shown in

Figure 17.

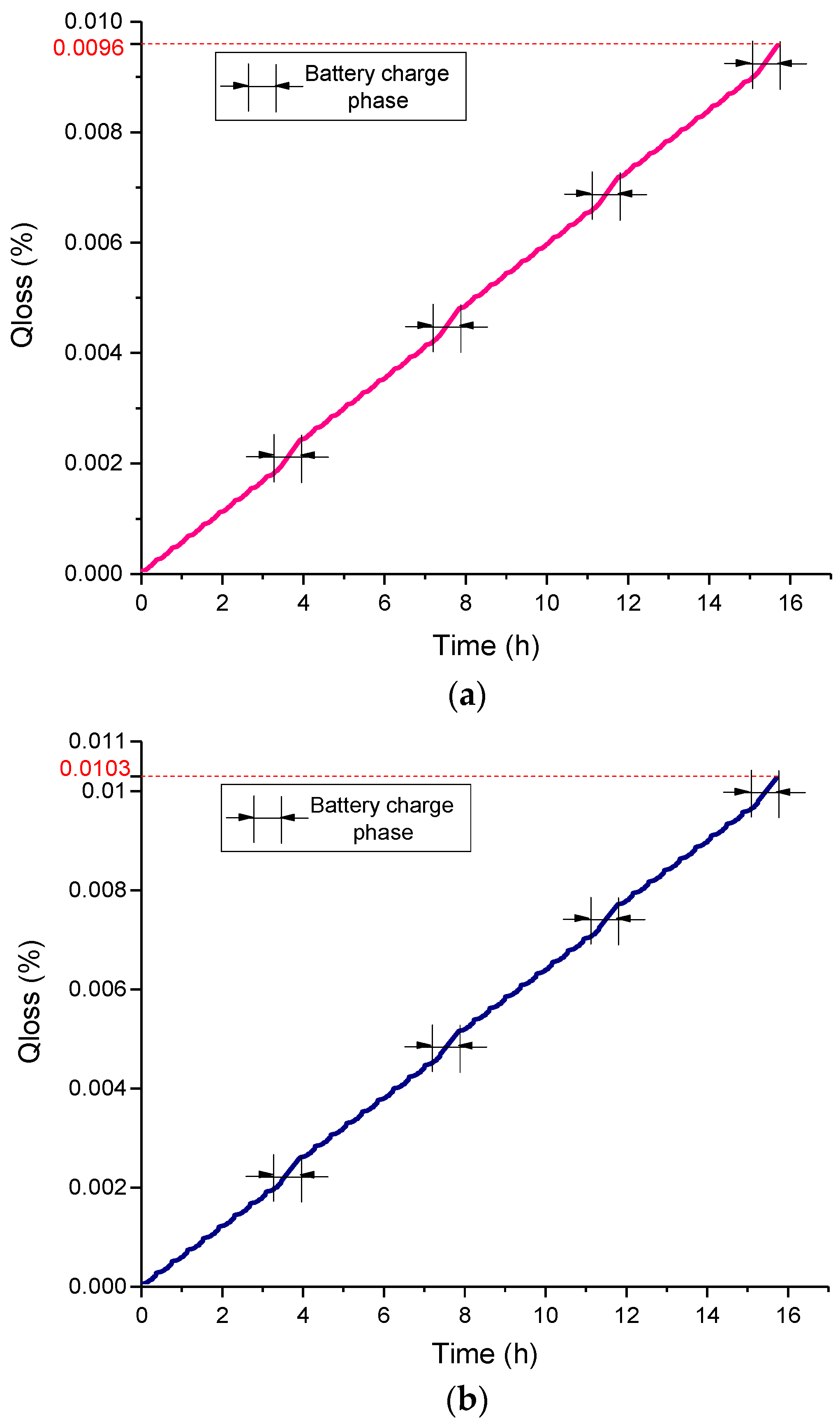

The battery capacity degradation will occur during the entire charge/discharge process. Therefore, we can obtain the battery degradation percentage curve of the battery pack using the semi-empirical model in one day according to the battery charge/discharge situation. At room temperature of 25 °C, Q

loss base on the convex optimization strategy and the rules strategy are shown in

Figure 18. After a day of operation (four cycle lines and four charging phases), Q

loss based on convex optimization is 9.6 × 10

−3%, and the battery pack can be used for approximately 2.08 × 10

3 days when the battery degradation is attenuated to 80% of its initial capacity, whereas Q

loss based on rules strategy is 10.3 × 10

−3%, and the battery pack can be used for approximately 1.94 × 10

3 days when the battery is attenuated to 80% of its initial capacity.

Notably, there are two main causes of the greater battery degradation under rule-based strategy: (1) The battery current I

bat based on the convex optimization is more stable; hence, this results in a smaller Q

loss than the rule-based strategy, and this is reflected in the comparison of battery degradation under the two strategies shown in

Figure 16; (2) Since the rule-based strategy consumes more energy in one day, the battery discharges deeper during operation (SOC

bat [0.4223, 0.9] during one cycle line based on convex optimization and SOC

bat [0.4112, 0.9] during one cycle line based on rules). Similarly, in order to return the battery back to the initial SOC, the rule-based strategy must be charging deeper than the convex optimized strategy (charging time t = 1561 s based on the convex optimization and t = 1598 s based on the rules). Consequently, the rule-based strategy increases the SOC operating range of the battery used in the same road cycle as compared to the strategy based on the convex optimization, which also increases the percentage of battery capacity degradation.

The battery usage time based on the two strategies is approximately 15 h in one day, but the usage time of the rule-based strategy is slightly longer because the charging time is longer. In

Figure 18, Q

loss slope of the battery charging phase is larger than Q

loss at the time of traveling on the road; hence, the battery degradation caused by charging the battery at a charging magnification of 1C is greater than that caused by running on the road.

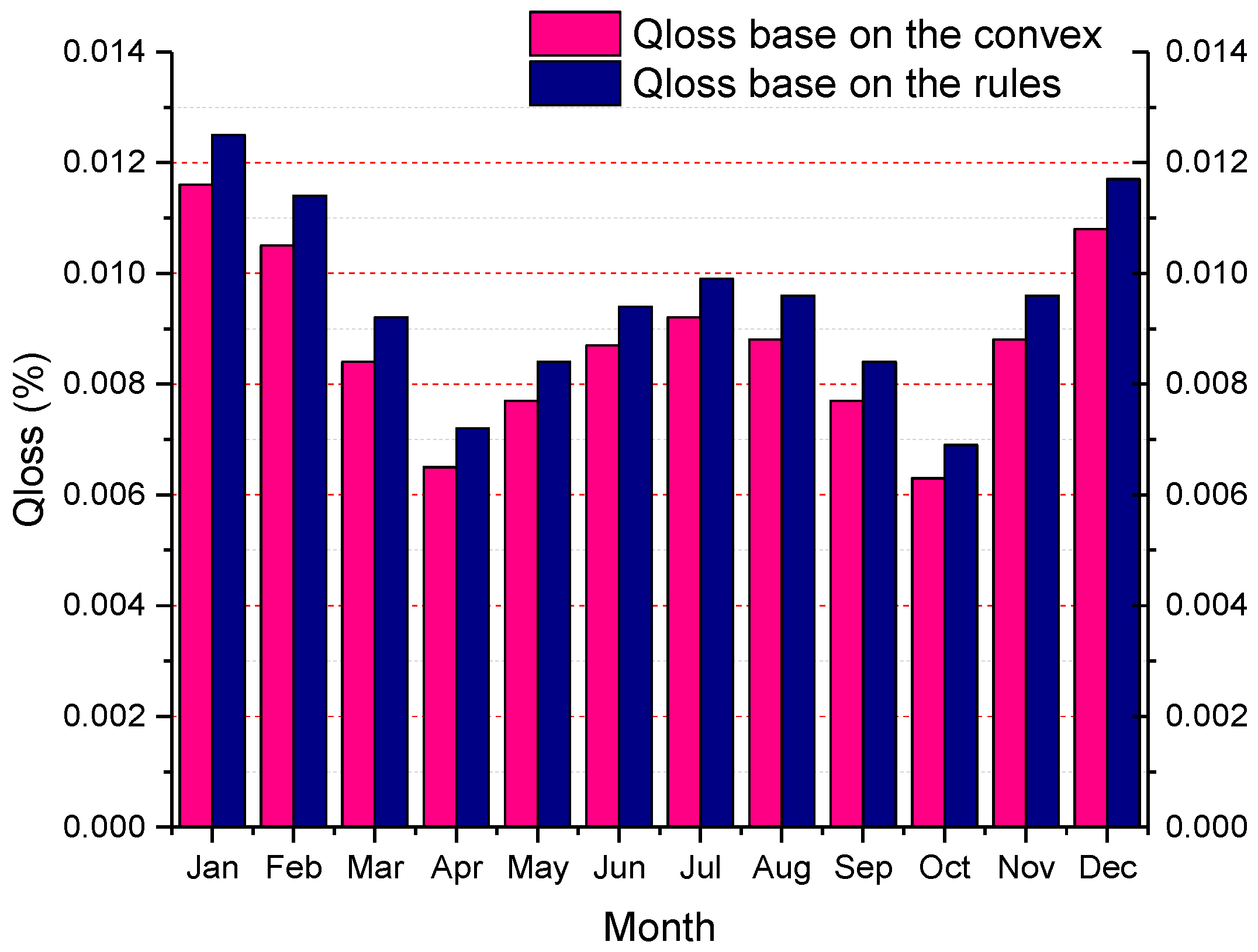

In order to obtain further analysis of Q

loss for one year in Harbin, we assume that the Harbin city bus will run for cycle lines in one day, and the bus operates for 30 days in a month. Therefore, the bus will operate for 360 days in a year. According to the average temperature of different months in Harbin, the daily value of Q

loss for every month can be calculated. It is assumed that the vehicle in each month is running at the monthly average temperature value and ignores the self-heating effect of the battery [

31]. The semi-empirical model is also used to calculate the battery degradation. The average monthly temperature in Harbin is given in

Table 6 [

32], i.e., the temperature range of T

[−18.3 °C, 23.0 °C].

According to the different average temperatures in different months, we can calculate the electric bus battery degradation percentage in one day for different months, as shown in

Figure 19.

As evident in

Figure 19, Q

loss in different months based on the rules strategy is larger than that based on the convex optimization strategy. It can also be observed that, when the temperature is within ±10 °C during spring and autumn, Q

loss is minimal, whereas Q

loss is large in summer and winter with higher or lower temperatures. Especially in the winter months of December, January, and February, the two strategies under daily operation of the battery degradation reached ≥ 0.01%. This directly reflects the problem of large degradation of LiFePO

4 battery at low temperatures. The total battery degradation percentage of the year is shown in

Table 7.

In

Table 7, Q

loss in one year based on the convex optimization strategy is 3.15%, and Q

loss based on the rules strategy is 3.43%. A quantitative analysis of battery life extension is addressed in this paper, assuming that the battery cannot be used when its capacity reduces to 80% of the initial value. Subsequently, the year of usage of the battery can be calculated using Equation (26).

where Y

ope is the year of usage of battery and Q

loss_month is the percentage of Q

loss per month. It can be calculated that the bus equipped with HESS can operate for 6.35 years based on the convex optimization strategy. However, the bus equipped with HESS can operate for 5.84 years based on the rules strategy. The superiority of the convex optimization strategy is reflected, further illustrating the effectiveness of the use of convex optimization.