Overview of Real-Time Simulation as a Supporting Effort to Smart-Grid Attainment

Abstract

:1. Introduction

Similar Works

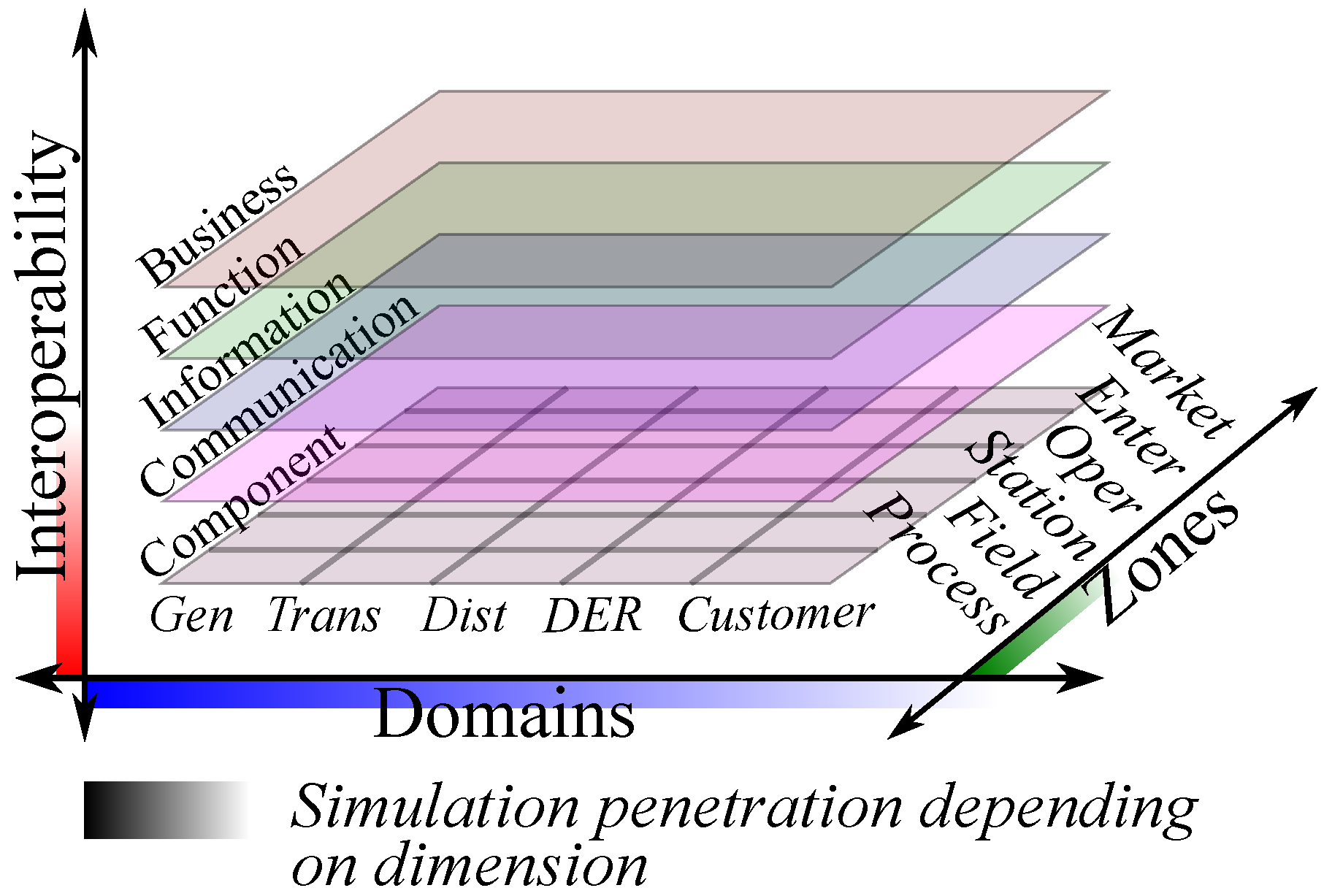

2. Current Status of Grid Modernization

3. Simulation Foundations

- Explicit single-step: These methods calculate ODE results for specific and fixed time steps and do not require information from past iterations; then, they can work with discontinuous input signals. Furthermore, the number of calculations per step can be easily estimated. Examples of these methods are ”Euler” and ”Runge-Kutta”.

- Implicit single-step: These methods are rarely used in real-time simulation since they solve a system of nonlinear equations at each step, increasing the computation effort. However, the number of iterations required to compute a valid result is bounded to a fixed value, making them sometimes suitable for RT processing.

- Multi-step methods: These methods require past information to calculate the next step (higher order approximation). Its main assumption is that the differential equation is smooth, producing inaccurate results when this assumption is not satisfied. However, the number of function evaluations per step is low. The Adams-Bashforth method is widely used in RT simulation.

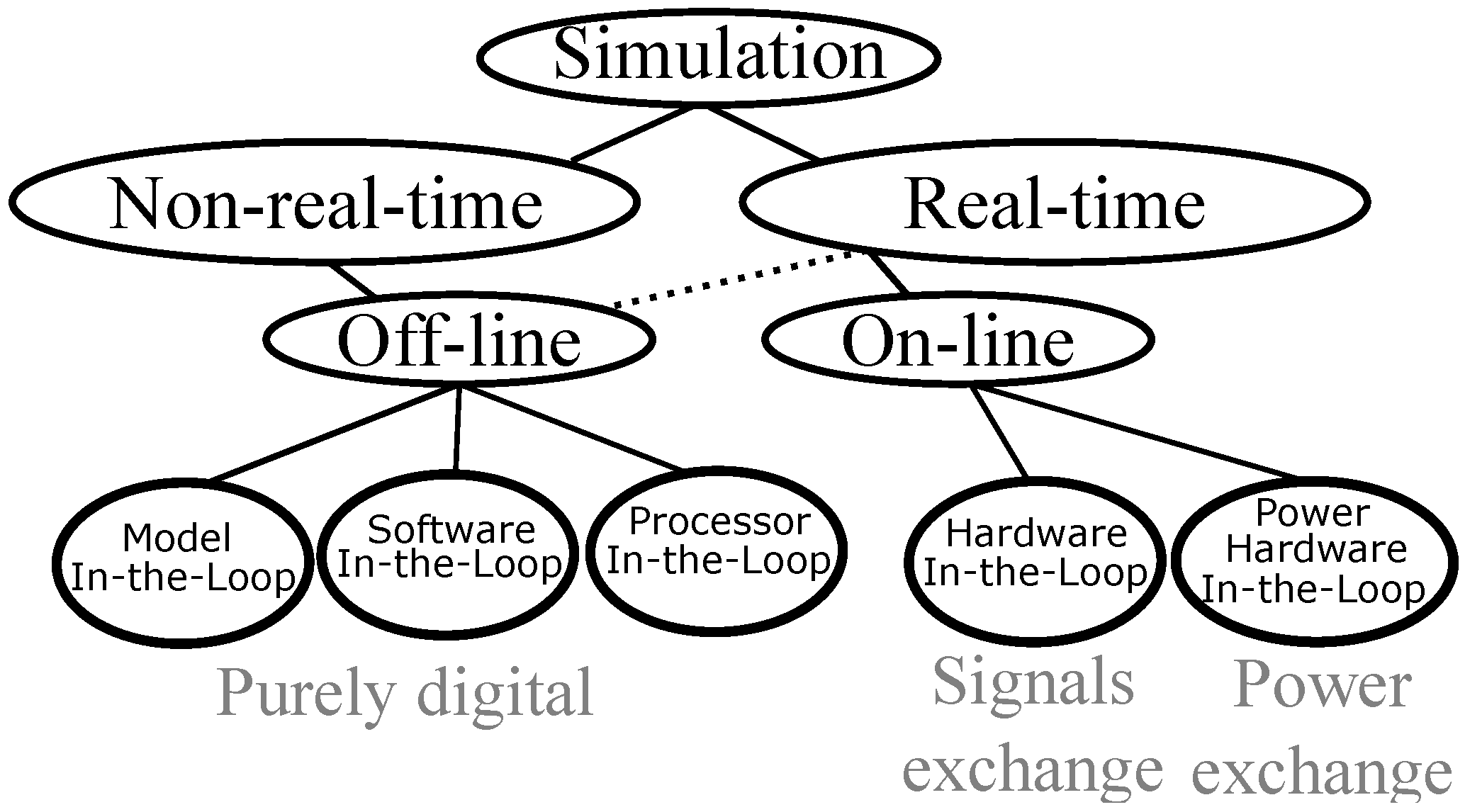

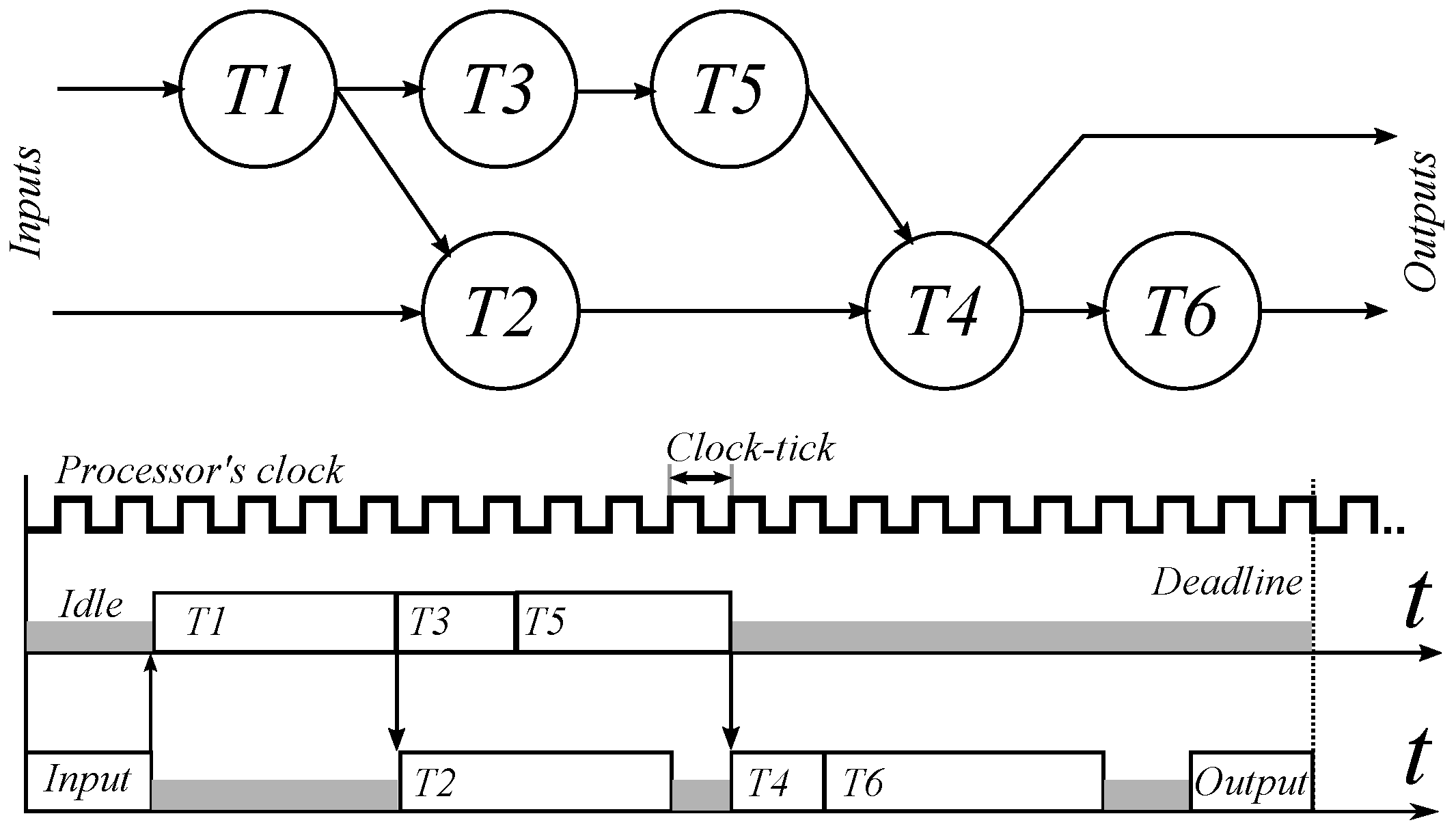

3.1. Real vs. Non-Real Time

3.2. On-Line vs. Off-Line

3.3. In-The-Loop

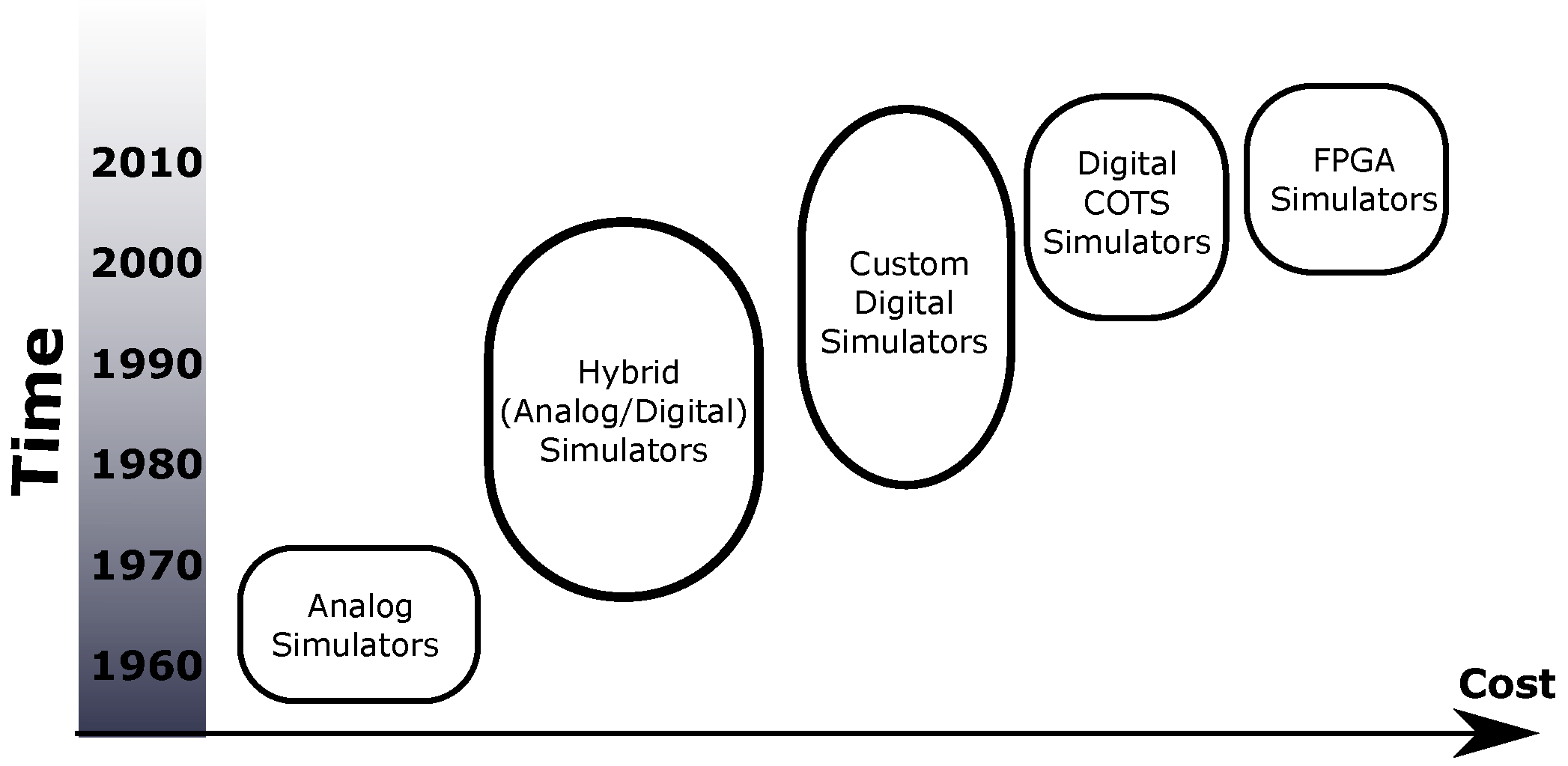

3.4. Evolution of RT Simulators

4. Simulation Examples

4.1. Digital Simulation

4.2. Hardware In-The-Loop

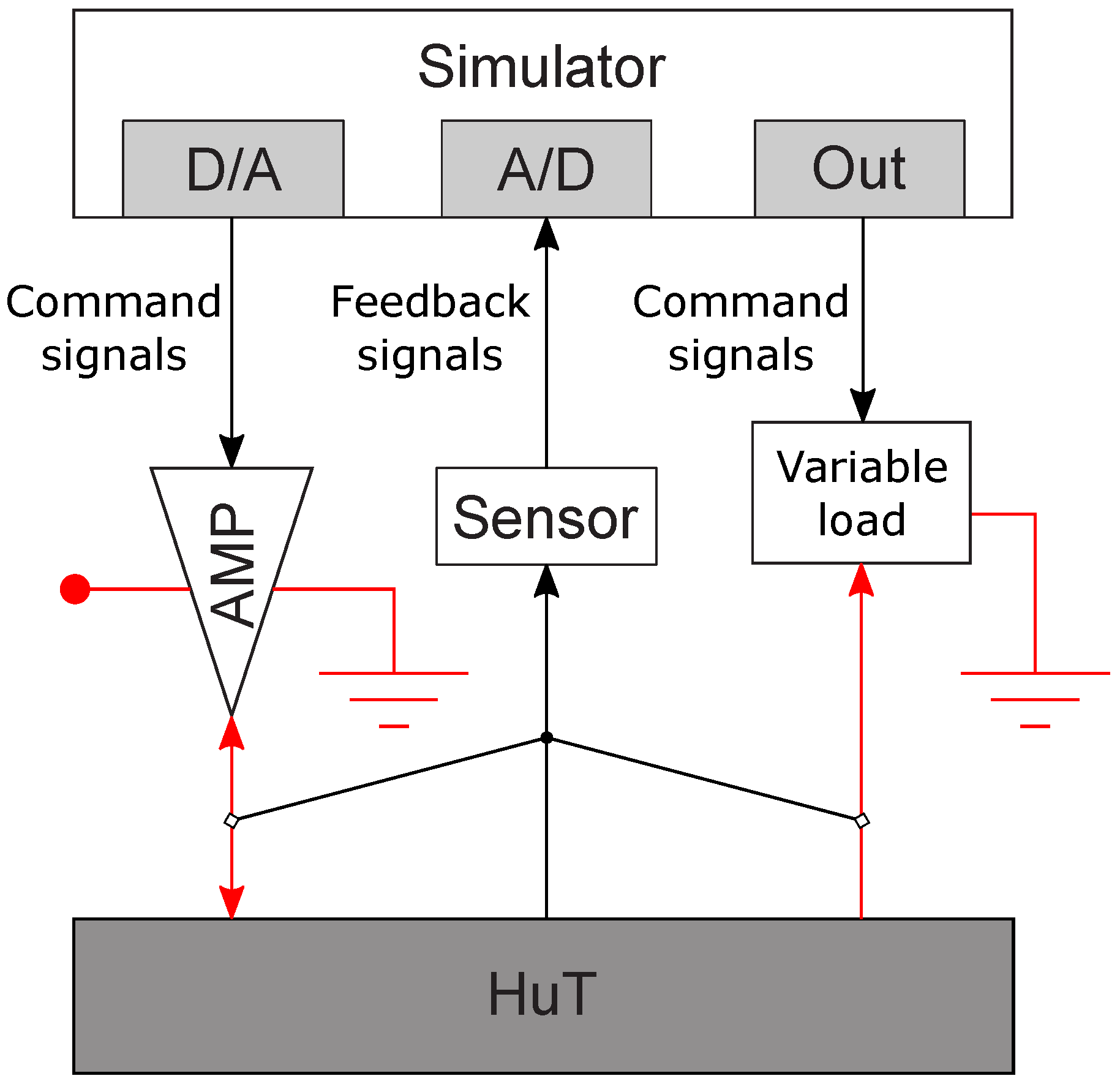

4.3. Power Hardware In-The-Loop

5. Real-Time Simulators for the Smart-Grid

5.1. Commercial Simulators

5.2. Lab-Made Simulators

- What kind of systems are to be simulated on the RT target? There are no generic simulators, so the hardware/software chosen or designed must fit research expectancies.

- What kind of interfacing is required? HIL and P-HIL simulations demand appropriate physical channels and, sometimes, adequate facilities. On the other hand, it is possible to complete a loop only using a communication channel.

- How is the loop to be closed? The system may be furnished to incorporate a controller board, electric machinery, a product prototype, etc., so specific high-end instrumentation will be needed, respectively.

- Is the system supposed to grow in complexity/capabilities? Modular simulators will fit better if different systems, tests and features are to be considered from experiment to experiment.

- How long is the system expected to provide a valid output? The simulation project should consider the time regarding development, installation, facilities suitability, software/hardware learning-curve, testbed/model modifications and data acquisition and processing.

- How much does it cost? RT simulation is computationally demanding and requires specific/sophisticated supporting devices. Related characteristics are commonly expensive.

- Does the system includes support, examples and usage resources? The research team can take advantage of such resources to accelerate testing processes and to better fit the system to the team needs.

- Is the system standard? There are some systems, as those mentioned above, that are being used internationally and can be found as the enabler technology of research papers and academic materials. Such systems will ease the research process providing examples and a base for comparison.

5.3. Supporting Components for Power Systems’ RT Simulation

- Throughput: the amount of data that can be processed together;

- Bandwidth: the maximum bandwidth the processed signal can have before aliasing or data loss occur;

- Resolution: the number of bits used to describe a full-scale signal; a higher resolution implies that the device’s range is divided into more discrete steps, so the analog-digital conversion becomes more precise;

- Latency: the time it takes to the converter to perform the conversion; this is considered as a time delay;

- Linearity: the consistency between the signal and the digital value; how effectively a linear input resembles a linear output;

- Accuracy: the maximum absolute error toward the ideal conversion;

- Multiplexing: a single converter is sometimes connected to more than one input/output, which must be then multiplexed to be processed; this reduces conversion throughput and bandwidth as more channels are converted through the same converter.

6. Challenges of Real-Time Simulation of SGs

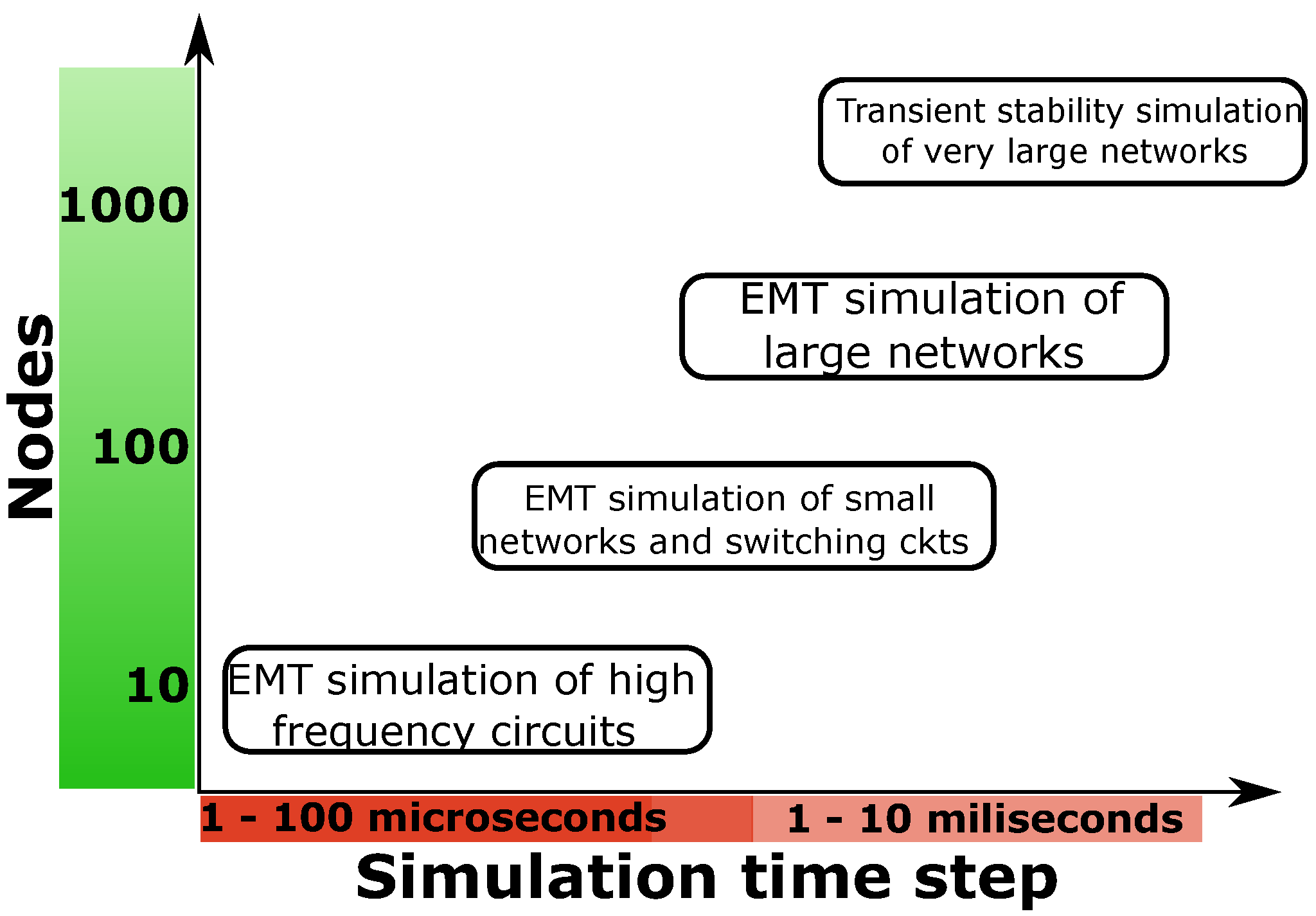

- Real-time simulation of large power systems: The ability of the simulator to replicate large power distributed systems with a considerable number of components, modules and buses. Electromagnetic Transients (EMT) of power grids require the computations of big matrices. Then, the challenge is to solve all of the grid equations in a simulation cycle. Dividing the grid model into groups and assigning each group to one of the multi-processors included in the simulator stands as the only possible solution [77].

- Accuracy of power electronics’ simulation: The accuracy in simulating switching power converters, especially considering the tendency of switching frequency increase. The accuracy of the simulator depends on the simulation step size, which should be small, but not too small, since RT processors have to solve all of the equations in limited time cycles. For example, EMT is simulated with a step-size between 20–100 s, and power electronics need to be simulated with a step size of 1 s or below (achieved by FPGAs).

7. RT Simulation Toward Innovation and Research on SG

- Define the experiment or case of study: The electrical or technical requirements of the system of study should be listed in order to verify if the RT simulator and its elements are capable of emulating the behavior and dynamics of the system. Voltage/current/power ranges, speed acquisition of A/D or D/A, size of the system (number of nodes/elements), etc., have to be considered.

- Verify stability: Classical methods, like Nyquist criteria, are commonly applied to analyze the stability of an P-HIL simulator. The characteristics of the power interface and the HuT like impedances play an important role on this analyses [57].

- Simulate the case of study via software: MATLAB/Simulink and Labview are two popular tools widely used to verify theoretical results, designs, controllers, etc., via simulation. Moreover, several RT platforms (coders) are capable of compiling MATLAB/Simulink and Labview files directly in the RT actual boards.

- Run the P-HIL simulation: Once all of the technical details have been considered, the stability of the system has been verified and its results are validated via off-line simulation, the P-HIL test can be executed.

Economic Benefits of Simulation

8. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Farhangi, H. The path of the smart grid. IEEE Power Energy Mag. 2010, 8, 18–28. [Google Scholar] [CrossRef]

- Verma, D.; Nema, S.; Shandilya, A.M. A different approach to design non-isolated DC-DC converters for maximum power point tracking in solar photovoltaic systems. J. Circuits Syst. Comput. 2016, 25, 1630004. [Google Scholar] [CrossRef]

- Zhou, B.; Li, W.; Chan, K.W.; Cao, Y.; Kuang, Y.; Liu, X.; Wang, X. Smart home energy management systems: Concept, configurations, and scheduling strategies. Renew. Sustain. Energy Rev. 2016, 61, 30–40. [Google Scholar] [CrossRef]

- Fang, X.; Misra, S.; Xue, G.; Yang, D. Smart grid—The new and improved power grid: A survey. IEEE Commun. Surv. Tutor. 2012, 14, 944–980. [Google Scholar] [CrossRef]

- Stephens, J.C.; Wilson, E.J.; Peterson, T.R. Smart Grid (R)Evolution: Electric Power Struggles; Cambridge University Press: New York, NY, USA, 2015. [Google Scholar]

- Podmore, R.; Robinson, M.R. The role of simulators for smart grid development. IEEE Trans. Smart Grid 2010, 1, 205–212. [Google Scholar] [CrossRef]

- Farhangi, H. A road map to integration: Perspectives on smart grid development. IEEE Power Energy Mag. 2014, 12, 52–66. [Google Scholar] [CrossRef]

- Hamzeh, M.; Emamian, S.; Karimi, H.; Mahseredjian, J. Robust control of an islanded microgrid under unbalanced and nonlinear load conditions. IEEE J. Emerg. Sel. Top. Power Electron. 2016, 4, 512–520. [Google Scholar] [CrossRef]

- Hamad, A.A.; Azzouz, M.A.; El-Saadany, E.F. Multiagent supervisory control for power management in DC microgrids. IEEE Trans. Smart Grid 2016, 7, 1057–1068. [Google Scholar] [CrossRef]

- Alliance, G. The Future of the Grid Evolving to Meet America’s Needs — Final Report: An Industry-Driven Vision of the 2030 Grid and Recommendations for a Path Forward. Available online: https://www.smartgrid.gov/files/Future_of_the_Grid_web_final_v2.pdf (accessed on 26 May 2017).

- Smart Grid 2013 Global Impact Report. Available online: https://www.smartgrid.gov/files/global_smart_grid_impact_report_2013.pdf (accessed on 26 May 2017).

- Dufour, C.; Belanger, J. On the use of real-time simulation technology in smart grid research and development. IEEE Trans. Ind. Appl. 2014, 50, 3963–3970. [Google Scholar] [CrossRef]

- Guo, F.; Herrera, L.; Murawski, R.; Inoa, E.; Wang, C.L.; Beauchamp, P.; Ekici, E.; Wang, J. Comprehensive real-time simulation of the smart grid. IEEE Trans. Ind. Appl. 2013, 49, 899–908. [Google Scholar] [CrossRef]

- Guillaud, X.; Faruque, M.O.; Teninge, A.; Hariri, A.H.; Vanfretti, L.; Paolone, M.; Dinavahi, V.; Mitra, P.; Lauss, G.; Dufour, C.; et al. Applications of real-time simulation technologies in power and energy systems. IEEE Power Energy Technol. Syst. J. 2015, 2, 103–115. [Google Scholar] [CrossRef]

- Sarhadi, P.; Yousefpour, S. State of the art: Hardware in the loop modeling and simulation with its applications in design, development and implementation of system and control software. Int. J. Dyn. Control 2015, 3, 470–479. [Google Scholar] [CrossRef]

- Dufour, C.; Cense, S.; Jalili-Marandi, V.; Bélanger, J. Review of state-of-the-art solver solutions for HIL simulation of power systems, power electronic and motor drives. In Proceedings of the 15th European Conference on Power Electronics and Applications (EPE), Lille, France, 2–6 September 2013; pp. 1–12. [Google Scholar]

- Mahseredjian, J.; Dinavahi, V.; Martinez, J.A. Simulation tools for electromagnetic transients in power systems: overview and challenges. IEEE Trans. Power Deliv. 2009, 24, 1657–1669. [Google Scholar] [CrossRef]

- Li, W.; Zhang, X.; Li, H. Co-simulation platforms for co-design of networked control systems: An overview. Control Eng. Pract. 2014, 23, 44–56. [Google Scholar] [CrossRef]

- Faruque, M.D.O.; Strasser, T.; Lauss, G.; Jalili-Marandi, V.; Forsyth, P.; Dufour, C.; Dinavahi, V.; Monti, A.; Kotsampopoulos, P.; Martinez, J.A.; et al. Real-time simulation technologies for power systems design, testing, and analysis. IEEE Power Energy Technol. Syst. J. 2015, 2, 63–73. [Google Scholar] [CrossRef]

- Smart Grid Reference Architecture. Available online: https://ec.europa.eu/energy/sites/ener/files/documents/xpert_group1_reference_architecture.pdf (accessed on 26 May 2017).

- Technology Roadmap—Smart Grids. Available online: https://www.smartgrid.gov/files/Technology_Roadmap_Smart_Grids_201112.pdf (accessed on 26 May 2017).

- 2010 Smart Grid System Report. Available online: https://energy.gov/sites/prod/files/2010%20Smart20Grid%20System%20Report.pdf (accessed on 26 May 2017).

- Good, N.; Ellis, K.A.; Mancarella, P. Review and classification of barriers and enablers of demand response in the smart grid. Renew. Sustain. Energy Rev. 2017, 72, 57–72. [Google Scholar] [CrossRef]

- Consulting, Z.R. Smart Meter Uprising: An Industry Brief Spotlighting the Burgeoning U.S. Smart Meter Market from 2009–2011. Available online: https://etsinsights.com/reports/smart-meter-uprisinganindustry-brief-spotlighting-the-burgeoning-u-s-smart-meter-market-from-2009-to-2011-part-1-of-3/ (accessed on 26 May 2017).

- Consulting, Z.R. China: Rise of the Smart Grid. Available online: https://www.smartgrid.gov/files/China_Rise_Smart_Grid_201103.pdf (accessed on 26 May 2017).

- Consulting, Z.R. South Korea—Smart Grid Revolution. Available online: https://etsinsights.com/reports/south-korea-smart-grid-revolution/ (accessed on 26 May 2017).

- Kiviat, P.J. Digital Computer Simulation: Modeling Concepts. Available online: http://oai.dtic.mil/oai/oai?verb=getRecord&metadataPrefix=html&identifier=AD0658429 (accessed on 26 May 2017).

- Cellier, F.E.; Kofman, E. Continuous System Simulation; Springer: Berlin, Germany, 2006. [Google Scholar]

- Zhao, J.; Wang, H.; Zhang, H. An accurate method for real-time aircraft dynamics simulation based on predictor-corrector scheme. Math. Probl. Eng. 2015, 2015, 193179. [Google Scholar] [CrossRef]

- Buttazzo, G.C. Hard Real-Time Computing Systems: Predictable Scheduling Algorithms and Applications, 3rd ed.; Buttazzo, G.C., Ed.; Springer: Berlin, Germany, 2011. [Google Scholar]

- Cornell, A. Real-time Systems: Modeling, Design, and Applications; World Scientific Publishing Company: Singapore, 2007. [Google Scholar]

- Dufour, C.; Belanger, J.; Lapointe, V. FPGA-based ultra-low latency HIL fault testing of a permanent magnet motor drive using RT-LAB-XSG. Simul. Trans. Soc. Model. Simul. Int. 2008, 84, 161–171. [Google Scholar]

- Patnaik, S.S.; Panda, A.K. Real-time performance analysis and comparison of various control schemes for particle swarm optimization-based shunt active power filters. Int. J. Electr. Power Energy Syst. 2013, 52, 185–197. [Google Scholar] [CrossRef]

- Ionutiu, R.; Scheiben, E.; Ke, X.; Stump, D.; Mastellone, S.; Oikonomou, N.; Cottet, D. Need for Speed: Real-Time Simulation for Power Electronics in Railway Applications and Beyond; TABB Technology: Zurich, Switzerland, 2014. [Google Scholar]

- Valverde, H.H. Flight Simulators. A Review of the Research and Development. Available online: http://oai.dtic.mil/oai/oai?verb=getRecord&metadataPrefix=html&identifier=AD0855582 (accessed on 26 May 2017).

- Bélanger, J.; Venne, P.; Paquin, J.N. The What, Where and Why of Real-Time Simulation. Available online: http://oai.dtic.mil/oai/oai?verb=getRecord&metadataPrefix=html&identifier=AD0855582 (accessed on 26 May 2017).

- Panigrahi, R.; Panda, P.C.; Subudhi, B. A robust extended complex kalman filter and sliding-mode control based shunt active power filter. Electr. Power Compon. Syst. 2014, 42, 520–532. [Google Scholar] [CrossRef]

- Farrokhabadi, M.; Vanfretti, L. An efficient automated topology processor for state estimation of power transmission networks. Electr. Power Syst. Res. 2014, 106, 188–202. [Google Scholar] [CrossRef]

- Parma, G.G.; Dinavahi, V. Real-time digital hardware simulation of power electronics and drives. IEEE Trans. Power Deliv. 2007, 22, 1235–1246. [Google Scholar] [CrossRef]

- Huber, M.; Bons, C.; Müller, D. Exergetic evaluation of solar controller using software-in-the-loop method. Energy Proced. 2014, 48, 850–857. [Google Scholar] [CrossRef]

- Bastian, J.; Clauß, C.; Wolf, S.; Schneider, P. Master for Co-Simulation Using FMI; Linköping University Electronic Press: Linköping, Sweden, 2011; pp. 115–120. [Google Scholar]

- Zhang, B.; Deng, W.; Ruan, L.; Wang, T.; Quan, J.; Cao, Q.; Teng, Y.; Wang, W.; Yuan, Y.; Li, L. Field-circuit cosimulation of 500-kV transformers in AC/DC hybrid power grid. IEEE Trans. Appl. Supercond. 2016, 26, 1–5. [Google Scholar] [CrossRef]

- Palmintier, B.; Lundstrom, B.; Chakraborty, S.; Williams, T.; Schneider, K.; Chassin, D. A power hardware-in-the-loop platform with remote distribution circuit cosimulation. IEEE Trans. Ind. Electron. 2015, 62, 2236–2245. [Google Scholar] [CrossRef]

- Isermann, R.; Schaffnit, J.; Sinsel, S. Hardware-in-the-loop simulation for the design and testing of engine-control systems. Control Eng. Pract. 1999, 7, 643–653. [Google Scholar] [CrossRef]

- Panwar, M.; Lundstrom, B.; Langston, J.; Suryanarayanan, S.; Chakraborty, S. An overview of real time hardware-in-the-loop capabilities in digital simulation for electric microgrids. In Proceedings of the North American Power Symposium (NAPS), Manhattan, KS, USA, 22–24 September 2013; pp. 1–6. [Google Scholar]

- Lemaire, M.; Sicard, P.; Belanger, J. Prototyping and testing power electronics systems using controller hardware-in-the-loop (hil) and power hardware-in-the-loop (phil) simulations. In Proceedings of the 2015 IEEE Vehicle Power and Propulsion Conference (VPPC), Montreal, QC, Canada, 19–22 October 2015; pp. 1–6. [Google Scholar]

- Kennel, R.M.; Boller, T.; Holtz, J. Hardware-in-the-loop systems with power electronics: A Powerful simulation tool. In Power Electronics for Renewable Energy Systems, Transportation and Industrial Applications; Abu-Rub, H., Al-Haddad, K., Eds.; John Wiley & Sons: New York, NY, USA, 2014; pp. 573–590. [Google Scholar]

- Huerta, F.; Gruber, J.K.; Prodanovic, M.; Matatagui, P. Power-hardware-in-the-loop test beds: Evaluation tools for grid integration of distributed energy resources. IEEE Ind. Appl. Mag. 2016, 22, 18–26. [Google Scholar] [CrossRef]

- Edrington, C.S.; Steurer, M.; Langston, J.; El-Mezyani, T.; Schoder, K. Role of power hardware in the loop in modeling and simulation for experimentation in power and energy systems. Proc. IEEE 2015, 103, 2401–2409. [Google Scholar] [CrossRef]

- Zhou, Y.; Lin, J.; Song, Y.; Cai, Y.; Liu, H. A power hardware-in-loop based testing bed for auxiliary active power control of wind power plants. Electr. Power Syst. Res. 2015, 124, 10–17. [Google Scholar] [CrossRef]

- König, O.; Hametner, C.; Prochart, G.; Jakubek, S. Battery emulation for power-HIL using local model networks and robust impedance control. IEEE Trans. Ind. Electron. 2014, 61, 943–955. [Google Scholar] [CrossRef]

- Helmedag, A.; Isermann, T.; Monti, A. Fault ride through certification of wind turbines based on a hardware in the loop setup. IEEE Trans. Instrum. Meas. 2014, 63, 2312–2321. [Google Scholar] [CrossRef]

- Steurer, M.; Edrington, C.S.; Sloderbeck, M.; Ren, W.; Langston, J. A megawatt-scale power hardware-in-the-loop simulation setup for motor drives. IEEE Trans. Ind. Electron. 2010, 57, 1254–1260. [Google Scholar] [CrossRef]

- Ren, W.; Steurer, M.; Baldwin, T.L. Improve the stability and the accuracy of power hardware-in-the-loop simulation by selecting appropriate interface algorithms. IEEE Trans. Ind. Appl. 2008, 44, 1286–1294. [Google Scholar] [CrossRef]

- Lauss, G.F.; Faruque, M.O.; Schoder, K.; Dufour, C.; Viehweider, A.; Langston, J. Characteristics and design of power hardware-in-the-loop simulations for electrical power systems. IEEE Trans. Ind. Electron. 2016, 63, 406–417. [Google Scholar] [CrossRef]

- Viehweider, A.; Lauss, G.; Felix, L. Stabilization of power hardware-in-the-loop simulations of electric energy systems. Simul. Model. Pract. Theory 2011, 19, 1699–1708. [Google Scholar] [CrossRef]

- Dargahi, M.; Ghosh, A.; Ledwich, G. Stability synthesis of power hardware-in-the-loop (PHIL) simulation. In Proceedings of the 2014 IEEE PES General Meeting, Conference & Exposition, National Harbor, MD, USA, 27–31 July 2014; IEEE: New York, NY, USA, 2014. [Google Scholar]

- PB5 Processor Card. Available online: https://www.rtds.com/wpcontent/uploads/2015/01/PB5-150109.pdf (accessed on 2 December 2016).

- Microgrid Testbed. Available online: https://www.typhoon-hil.com/doc/brochures/Typhoon-HIL-and-SPS-Microgrid-Testbed.pdf (accessed on 21 March 2017).

- What Is PXI?—National Instruments. Available online: http://www.ni.com/pxi/whatis/zhs/ (accessed on 2 December 2016).

- Buccella, C.; Cecati, C.; Latafat, H. Digital control of power converters—A survey. IEEE Trans. Ind. Inf. 2012, 8, 437–447. [Google Scholar] [CrossRef]

- Lu, B.; Wu, X.; Monti, A. Implementation of a low-cost real-time virtue test bed for hardware-in-the-loop testing. In Proceedings of the 31st Annual Conference of IEEE Industrial Electronics Society, Raleigh, NC, USA, 6–10 November 2005. [Google Scholar]

- Adler, F.; Benigni, A.; Stagge, H.; Monti, A.; Doncker, R.W.D. A new versatile hardware platform for digital real-time simulation: Verification and evaluation. In Proceedings of the IEEE 13th Workshop on Control and Modeling for Power Electronics (COMPEL), Kyoto, Japan, 10–13 June 2012; pp. 1–8. [Google Scholar]

- De Souza, I.D.T.; Silva, S.N.; Teles, R.M.; Fernandes, M.A.C. Platform for real-time simulation of dynamic systems and hardware-in-the-loop for control algorithms. Sensors 2014, 14, 19176–19199. [Google Scholar] [CrossRef] [PubMed]

- Barnert, T.; Piesik, E.; Śliwiński, M. Real-time simulator of agricultural biogas plant. Comput. Electron. Agric. 2014, 108, 1–11. [Google Scholar] [CrossRef]

- Menghal, P.M.; Laxmi, A.J. Real time simulation: Recent progress & challenges. In Proceedings of the International Conference on Power, Signals, Controls and Computation, Thrissur, India, 3–6 January 2012; pp. 1–6. [Google Scholar]

- Pickering, J. Analogue to digital and digital to analogue converters (ADCs and DACs): A review update. In Proceedings of the CAS-CERN Accelerator School: Power Converters, Baden, Switzerland, 7–14 May 2014; pp. 363–377. [Google Scholar]

- Bastos, M.C. High precision current measurement for power converters. In Proceedings of the CAS-CERN Accelerator School: Power Converters, Baden, Switzerland, 7–14 May 2014; pp. 353–362. [Google Scholar]

- Lehfuss, F.; Lauss, G.; Kotsampopoulos, P.; Hatziargyriou, N.; Crolla, P.; Roscoe, A. Comparison of multiple power amplification types for power Hardware-in-the-Loop applications. In Proceedings of the 2012 Complexity in Engineering (COMPENG), Aachen, Germany, 11–13 June 2012. [Google Scholar]

- Power Hardware in the Loop Simulation. Available online: http://www.opal-rt.com/power-hardware-inthe-loop/ (accessed on 26 May 2017).

- Jha, K.; Mishra, S.; Joshi, A. Boost-amplifier-based power-hardware-in-the-loop simulator. IEEE Trans. Ind. Electron. 2015, 62, 7479–7488. [Google Scholar] [CrossRef]

- California Instruments MX Series: Specifications. Available online: http://www.programmablepower.com/ac-power-source/MX/Specifications.htm (accessed on 21 March 2017).

- COMPISO Digital Amplifier CDA Technical Data. Available online: http://www.egston.com/files/pe/2015_0707_01F_TechnicalData_CDA.PDF (accessed on 21 March 2017).

- PA-AB 4Q POWER AMPLIFIER. Available online: http://puissanceplus.b4.catalyz.fr/uploads/assets/FT-PA_V10.pdf (accessed on 21 March 2017).

- PM15A60F60. Available online: https://triphase.com/products/power-modules/PM15/A60F60/ (accessed on 21 March 2017).

- Yamane, A.; Abourida, S.; Yahia, B.; Francois, T. Real-time simulation of distributed energy systems and microgrids. IFAC 2016, 49, 183–187. [Google Scholar] [CrossRef]

- Yamane, A.; Abourida, S. Real-time simulation of distributed energy systems and microgrids. In Proceedings of the 2015 International Conference on Sustainable Mobility Applications, Renewables and Technology (SMART), Kuwait City, Kuwait, 23–25 November 2015; pp. 1–6. [Google Scholar]

- Washom, B.; Dilliot, J.; Weil, D.; Kleissl, J.; Balac, N.; Torre, W.; Richter, C. Ivory tower of power: Microgrid implementation at the University of California, San Diego. IEEE Power Energy Mag. 2013, 11, 28–32. [Google Scholar] [CrossRef]

- Loper, M.L. Modeling and Simulation in the Systems Engineering Life Cycle; Springer: Berlin, Germany, 2015. [Google Scholar]

- Hajifathalian, K.; Howell, G.; Wambeke, B.W.; Hsiang, S.M.; Liu, M. “Oops” simulation: Cost–benefits trade-off analysis of reliable planning for construction activities. J. Constr. Eng. Manag. 2016, 142, 04016030. [Google Scholar] [CrossRef]

- National Instruments. HIL Testing reduces compactrio control system development cost. Newsl. Instrum. 2010, 22, 29. [Google Scholar]

- Pochacker, M.; Sobe, A.; Elmenreich, W. Simulating the smart grid. In Proceedings of the 2013 IEEE Grenoble PowerTech (POWERTECH), Grenoble, France, 16–20 June 2013. [Google Scholar]

| Simulator | Hardware Engines | OS | Software Compatibility | Communication, Interfacing | Applications |

|---|---|---|---|---|---|

| Opal-RT | Intel processors and FPGAs | Windows and Linux | MATLAB, Simulink, Labview | Gigabit Ethernet, PCIe with DSP-based A/C and D/A, CAN | Power electronics, control systems, HIL, power systems like smart grid |

| RTDS | NPX processor | Windows and Linux | MATLAB and Simulink | Optical fiber, Gigabit Ethernet, TCP/IP | Power electronics, control systems, HIL, power systems like smart grid |

| Typhoon | Processor and FPGA | Windows | MATLAB | Ethernet RJ45, CAN | Power electronics, control systems, HIL |

| NI Hardware | Intel processors and FPGA | Windows and Linux | Labview | Optical fiber, Gigabit Ethernet, PCI, CAN | Power electronics, control systems, HIL, power systems like smart grid |

| dSPACE | Intel processor and FPGA | Windows | MATLAB and Simulink | Gigabit Ethernet, PCIe, CAN | Power electronics, real-time control, rapid prototyping, power systems like smart grid |

| Amplifier Operation | Definition | Complexity | Types | Dynamic Response | Cost | Application |

|---|---|---|---|---|---|---|

| Linear | Output is proportional to input | Low | Voltage or current | High bandwidth and fast response time (<6 s) | High | Low flexibility (voltage or current). Difficult to build in the MW range due to high power losses. |

| Non-Linear | Output is not proportional to the input | High | Switching mode | Reduced bandwidth and slow response time (>50 s) (due to additional control circuitry) | Low | High flexibility (voltage and/or current). Commonly used in the MW range. |

| Power Amplifier | Operating Modes | DC and AC Ratings | Measurements |

|---|---|---|---|

| Ametek (Pi version) | AC, DC and AC + DC |

| AC measurements: voltage and current rms, DC voltage and current, real power, apparent power, power factor |

| Egston (CDAR200) | AC, DC |

| Current and voltage, Opal-RT integration |

| Puissance plus (PA-24K) | AC, DC and AC + DC |

| Current, voltage, power analyzer |

| Triphase (PM15A60F60) | AC, DC |

| Voltage, Currents, MATLAB/Simulink integration |

| Typhoon Power Emulator | AC, DC, AC + DC |

| Voltage, currents (using Typhoon HIL) |

| Spitzenberger Spies | AC, DC |

| Voltage, currents |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ibarra, L.; Rosales, A.; Ponce, P.; Molina, A.; Ayyanar, R. Overview of Real-Time Simulation as a Supporting Effort to Smart-Grid Attainment. Energies 2017, 10, 817. https://doi.org/10.3390/en10060817

Ibarra L, Rosales A, Ponce P, Molina A, Ayyanar R. Overview of Real-Time Simulation as a Supporting Effort to Smart-Grid Attainment. Energies. 2017; 10(6):817. https://doi.org/10.3390/en10060817

Chicago/Turabian StyleIbarra, Luis, Antonio Rosales, Pedro Ponce, Arturo Molina, and Raja Ayyanar. 2017. "Overview of Real-Time Simulation as a Supporting Effort to Smart-Grid Attainment" Energies 10, no. 6: 817. https://doi.org/10.3390/en10060817