4.2. Neural Network Model Evaluations

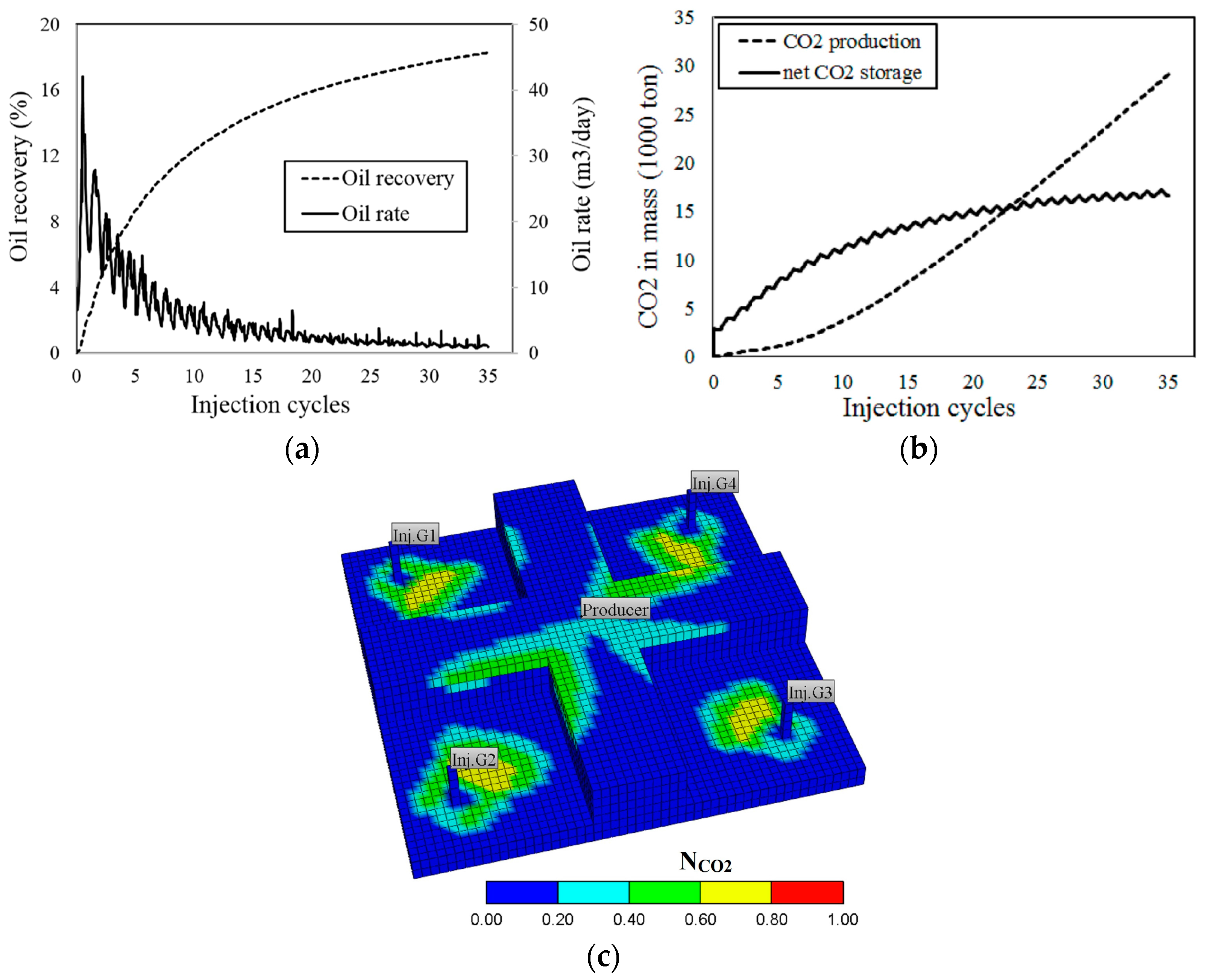

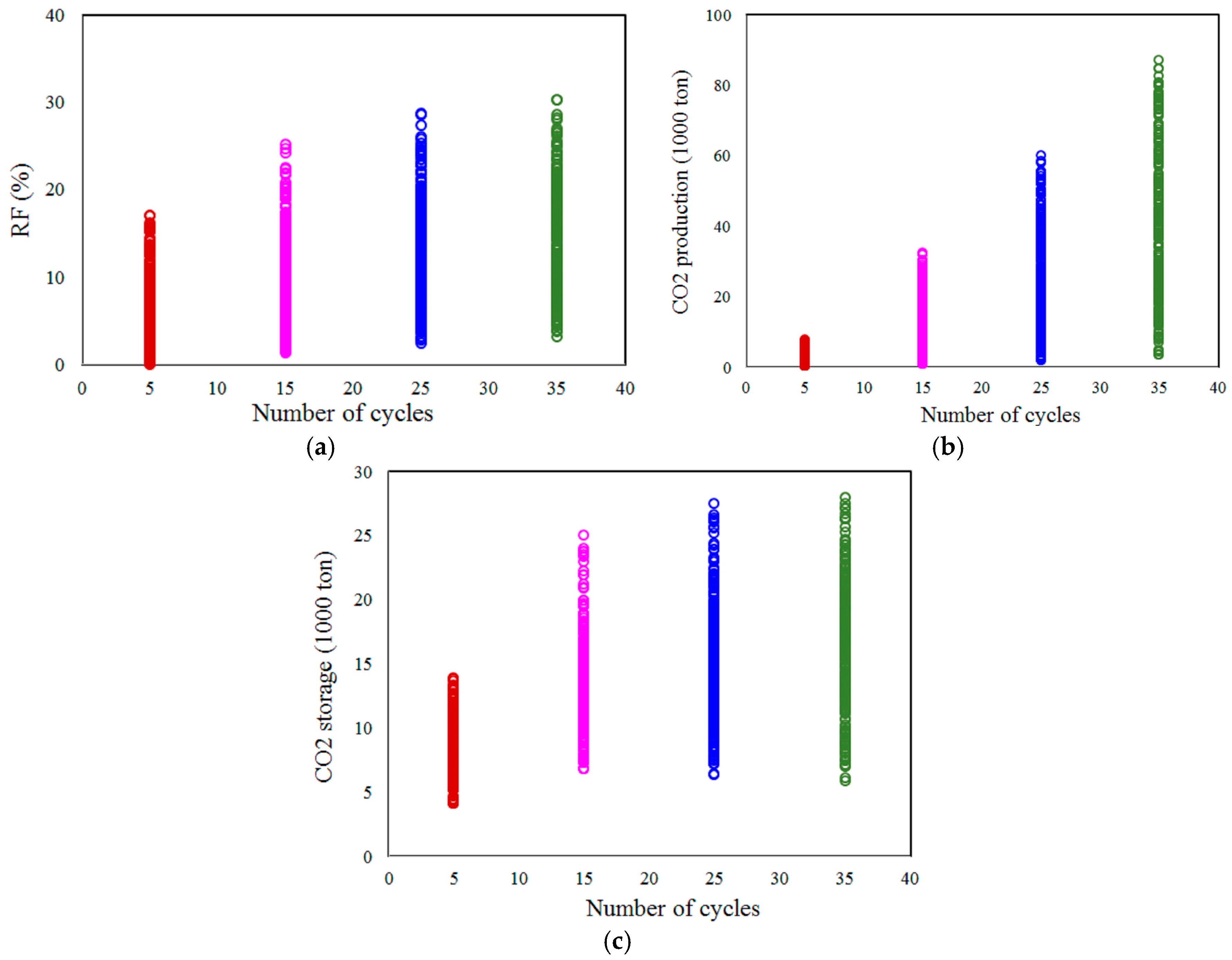

In total, 263 simulation samples are collected for generating four ANN models. The results present diversity in the critical objectives after each specific assigned injection cycle. As shown in

Figure 5, the ultimate oil recovery ranges from around 2% to less than 30% OIP; in some cases, the recovery factor (RF) can be up to 18% after 5 cycles. However, oil recoveries do not improve considerably from 25 to 35 cycles. The total amount of CO

2 stored underground is unpredictable after 15 cycles, as it might decline or increase at 25 and 35 injection cycles, while the gas produced rises continuously from the beginning of the process. Generally, the more complicated and diverse sample results correspond to higher levels of representation achieved from successful models used for estimation.

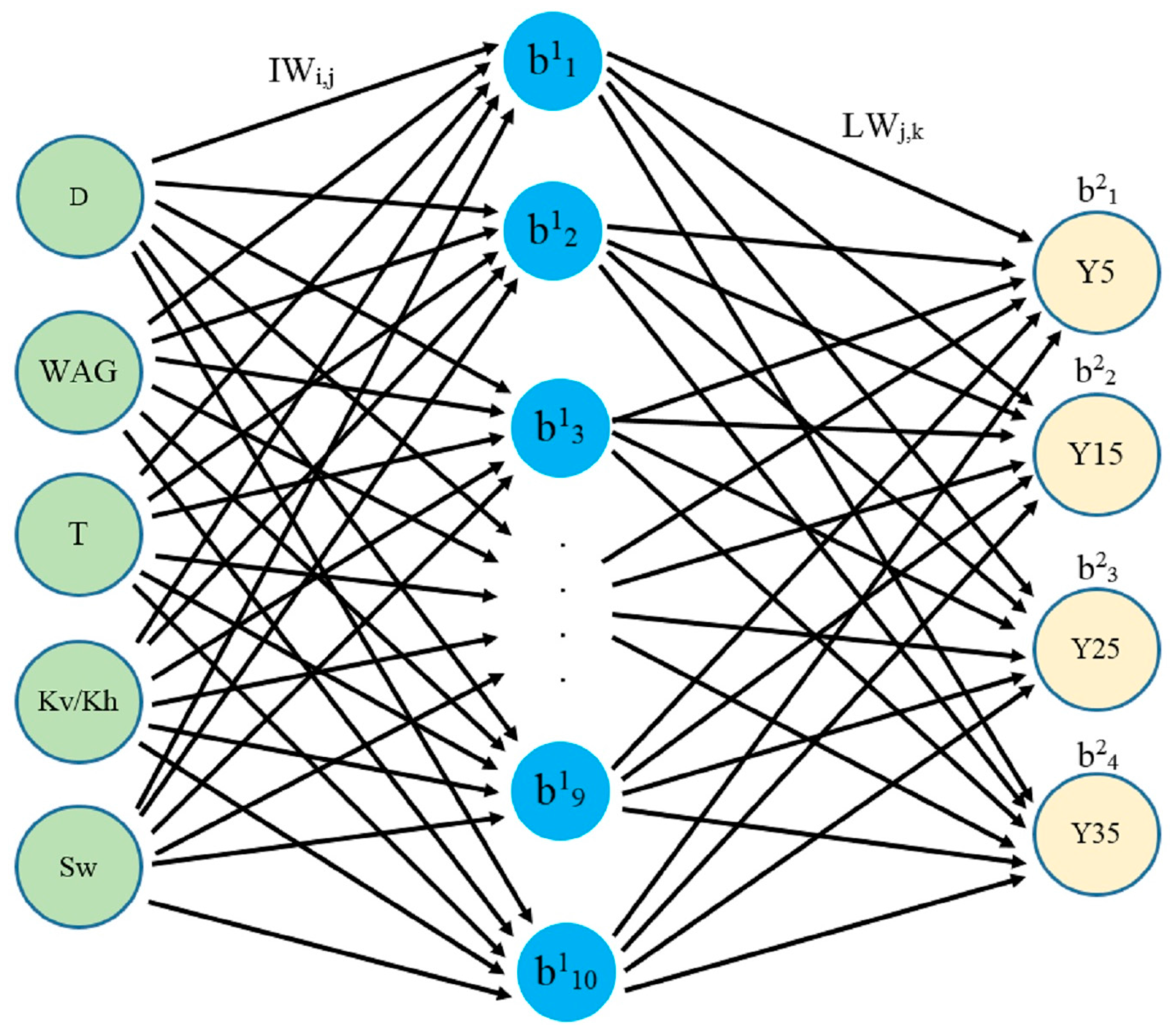

Using the MATLAB Network Toolbox, the ANN model for the previously described performances is trained following a 50%-20%-30% training scheme corresponding to the percentage ratio of data used for the training validation test in the 263 numerical samples. More specifically, the generated model from training is automatically applied to estimate 79 random blind data (30%) to ensure the avoidable over-training phenomenon. The same training scheme is applied to the three different targets, but the specific data points for the training processes, corresponding to dissimilar networks, are selected differently owing to non-concurrent training. Mathematically, neural networks are trained under a feed forward back propagation algorithm in which weights and biases are initially allocated in the structure. Neurons in the output layer are first calculated based on the initial structure; an adjustment is made for weights and biases thereafter based on errors between sampling and current computed targets. These forward and backward computations are performed during training until the lowest overall errors are obtained. The over-training phenomenon can occur in an unsuitable training scheme ratio. Therefore, a higher percentage of data points used for blind testing assures more confidence in the quality of the training and generated model.

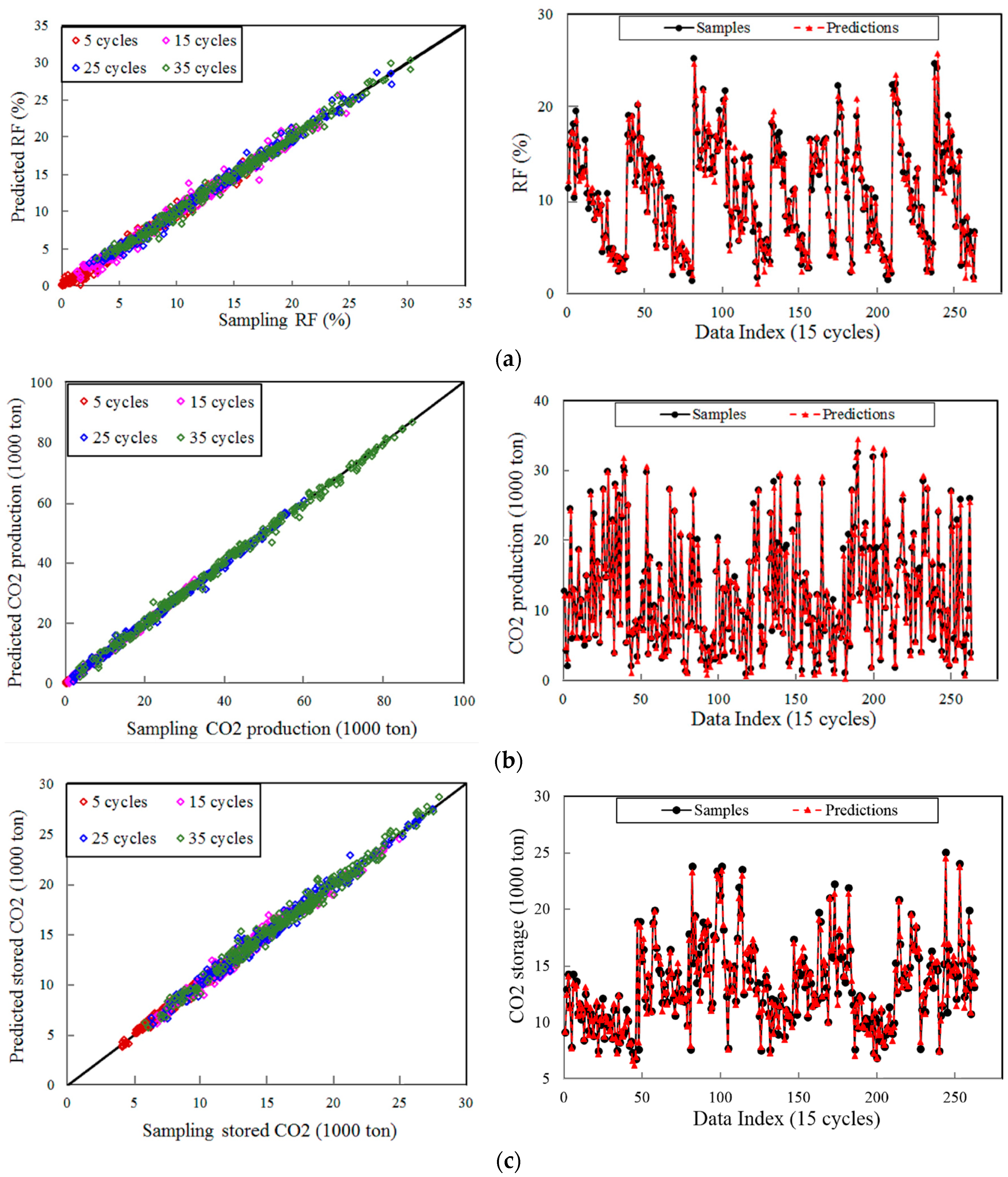

Figure 6 shows the training performances of the three crucial objectives based on the number of epochs and mean square errors during training. Principally, a successful training is only accomplished when the best standing points correspond to the lowest errors in the validation, and test curves are not very different in terms of the epoch number. Subsequently, all final training performances are definitely qualified as optimized points in both validation and test curves when they are sufficiently close to each other, with errors less than 0.001. The reasonably low errors in training presumably indicates the high accuracy of the ANN models for forecasting targets for any input values within their constraints. Indeed, the recomputed targets for the sample data show good agreement with the simulation results in

Figure 7, and the blind test data are also excellently matched during the injection processes.

The quality of estimations is evaluated quantitatively using two decisive factors, known as the coefficient of determination (

R2) and the root mean square error (RMSE) from the formulae:

where

zi,sam,

zi,ANN, and

represent data points from the samples, estimation by the network, and average values of the sampling data, respectively. Theoretically,

R2 values higher than 0.95 and RMSE values less than 4% for regressions are acceptable for prediction. Therefore, the ANN models are absolutely qualified, with most

R2 values higher than 0.98 and RMSE values less than 3.2% in all injection cycles (

Table 3). This potentially opens the possibility of extending the number of neurons in the output layer in future work to comprehensively estimate the flooding performance. Because the models have been successfully generated, they can be easily applied to any adequate spreadsheet based on the weights and biases in the network structure.

The values from the three networks are fully presented in

Table 4. Mathematically, the neural networks are proven to accurately compute subjective targets within the design variables. However, the technical relationships between variables also should be evaluated to validate the models and determine if there is sufficient sample data coverage.

4.3. Applicability of ANN Models

Conventionally, the oil recovery factor and capacity of carbon sequestration are primarily concerned with CO2 flooding from the technical perspective, while the ultimate profitability is the decisive factor for evaluating the success of the project economically. A large amount of oil production might appear preferable, but as oil prices are unexpectedly low, purchasing CO2 needs to be taken into consideration, particularly when the incentive tax credit is counted according to the total volume of carbon sequestration in the reservoirs. Therefore, competent ANN models should tackle both the technical and economic aspects of the problem.

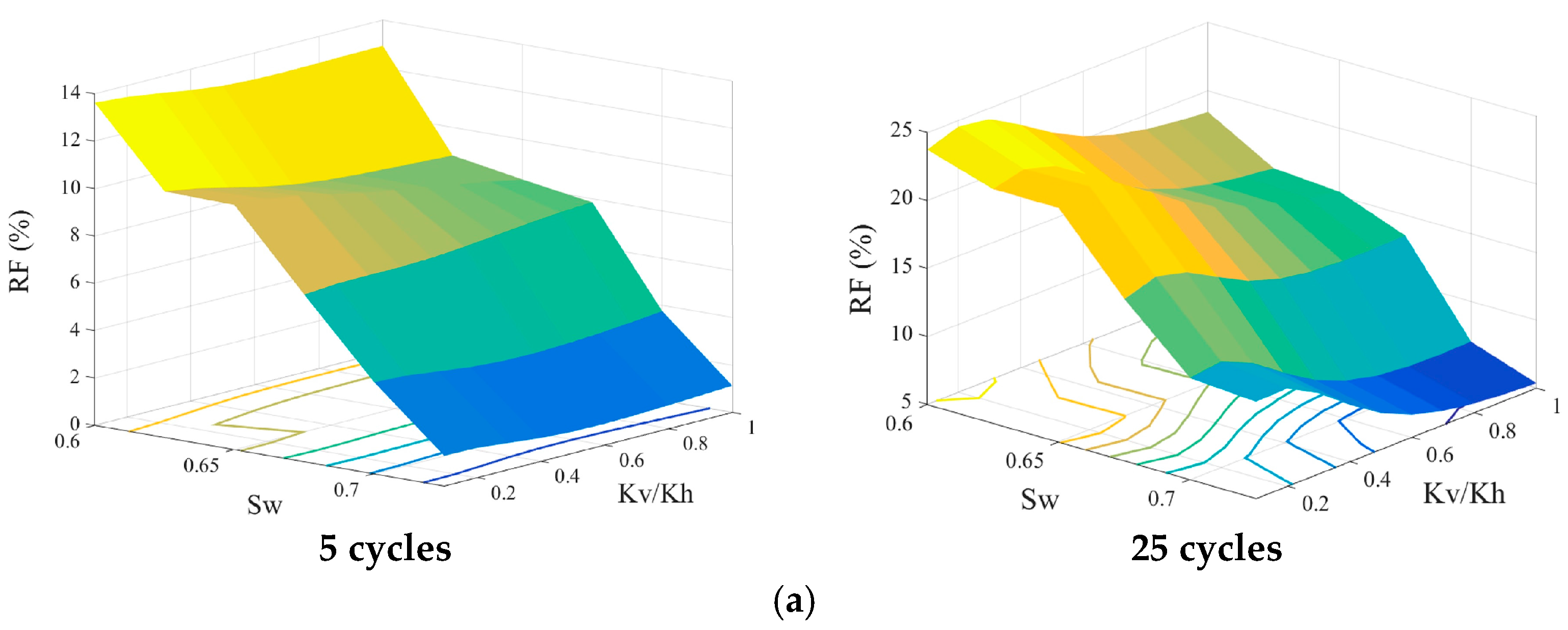

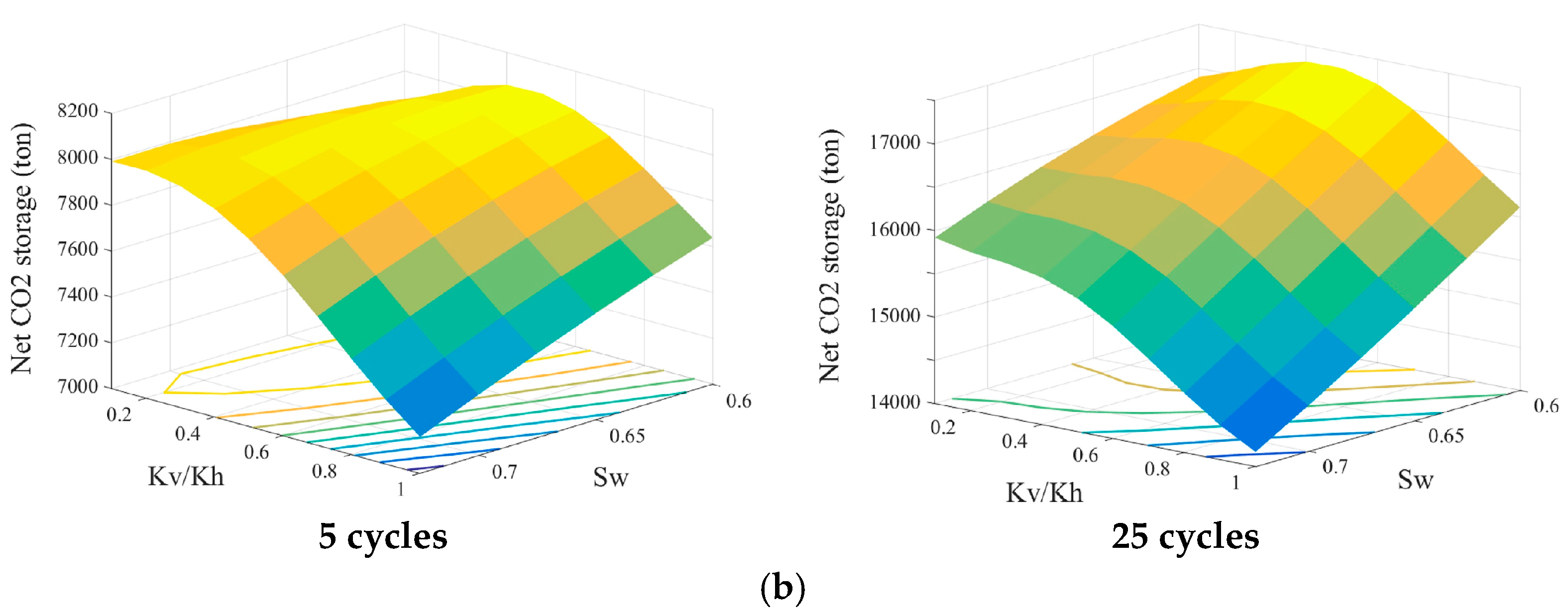

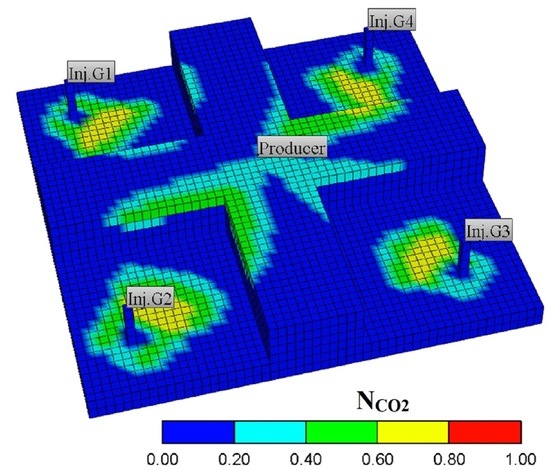

Favorable reservoir properties are investigated first through initial water saturation and a dimensional permeability ratio at the base case injection and well spacing design. As shown in

Figure 8, with a specific operation condition, the permeability ratio impacts the oil production differently according to the injection cycle progress. In detail, after five cycles, this factor seems to have no effect on RF, whereas RF has an inverse relationship with

Kv/Kh after 25 injection cycles with a deviation of approximately 5% in RF between the lower and upper permeability ratio thresholds. This confirms that a high difference between vertical and horizontal permeability has an advantage in extracting reservoir oil; reservoirs that have low vertically permeable flow capacity are preferable. Physically, this result can be explained by the gravitational effect, associated with a heterogeneous system, which inevitably occurs while injecting CO

2 into the reservoir even though water is also used for cycling.

Regarding carbon sequestration, a system having

Kv/Kh less than 0.5 proves to be the most advantageous for initial fluid conditions and storing CO

2 throughout the flooding process. Principally, the gas can be trapped under various mechanisms in the geological formation, such as mineral trapping, solubility trapping, or residual trapping. In particular, the amount of oil displaced is proportional to the CO

2 storage volume in the reservoir. This explains the increase in trapped gas following the decrease in water saturation after either 5 or 25 cycles, as shown in

Figure 8. Clearly, the dependence of oil production and net CO

2 storage on both reservoir factors implies an identical assessment for potential CO

2-EOR using reservoir characteristics.

In terms of surface control, the relevant injection designs should also be determined to address dependent performances according to different flooding schemes [

32,

33,

34]. Fundamentally, an appropriate WAG injection design helps extend the contact time between gas and in situ hydrocarbon, mitigating viscous fingering and maximizing thoroughly swept areas. Depending on reservoir properties and initial fluid conditions, optimal designs for injecting gas and water might differ, however the basic technical relationships will presumably be identical for all system properties.

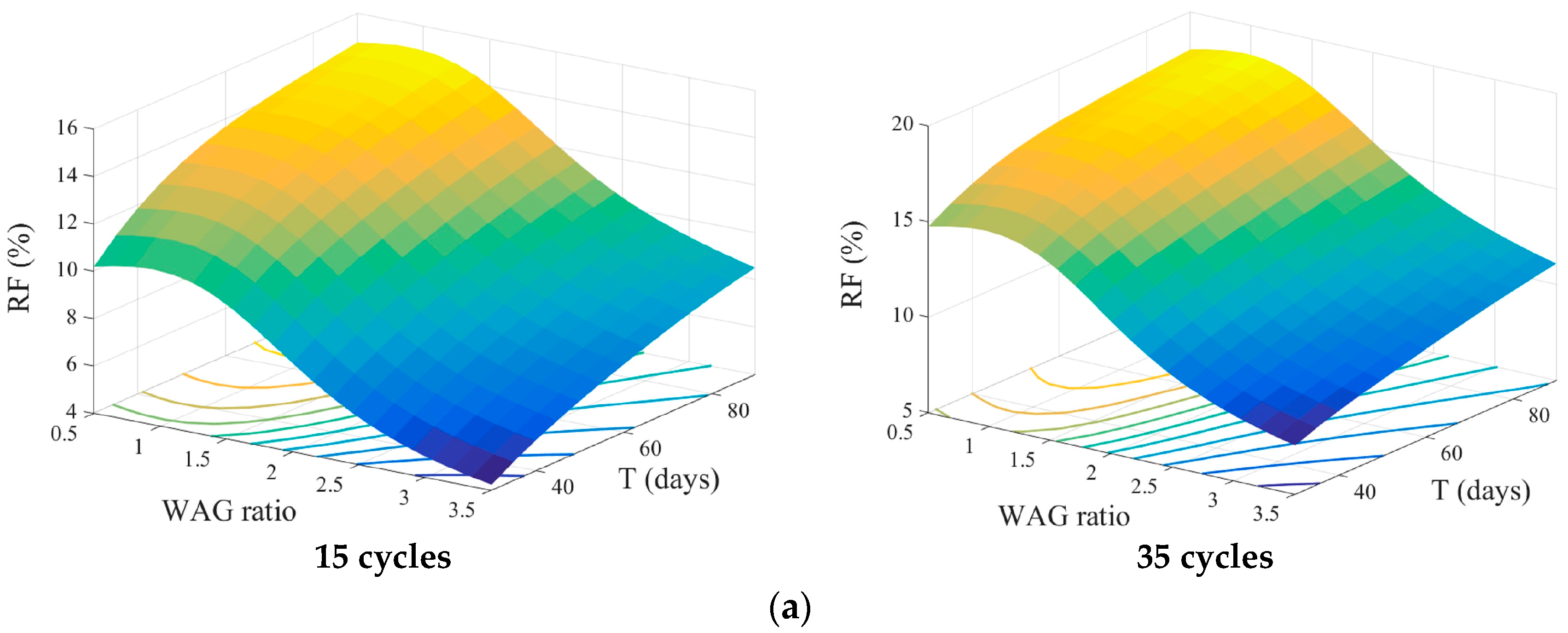

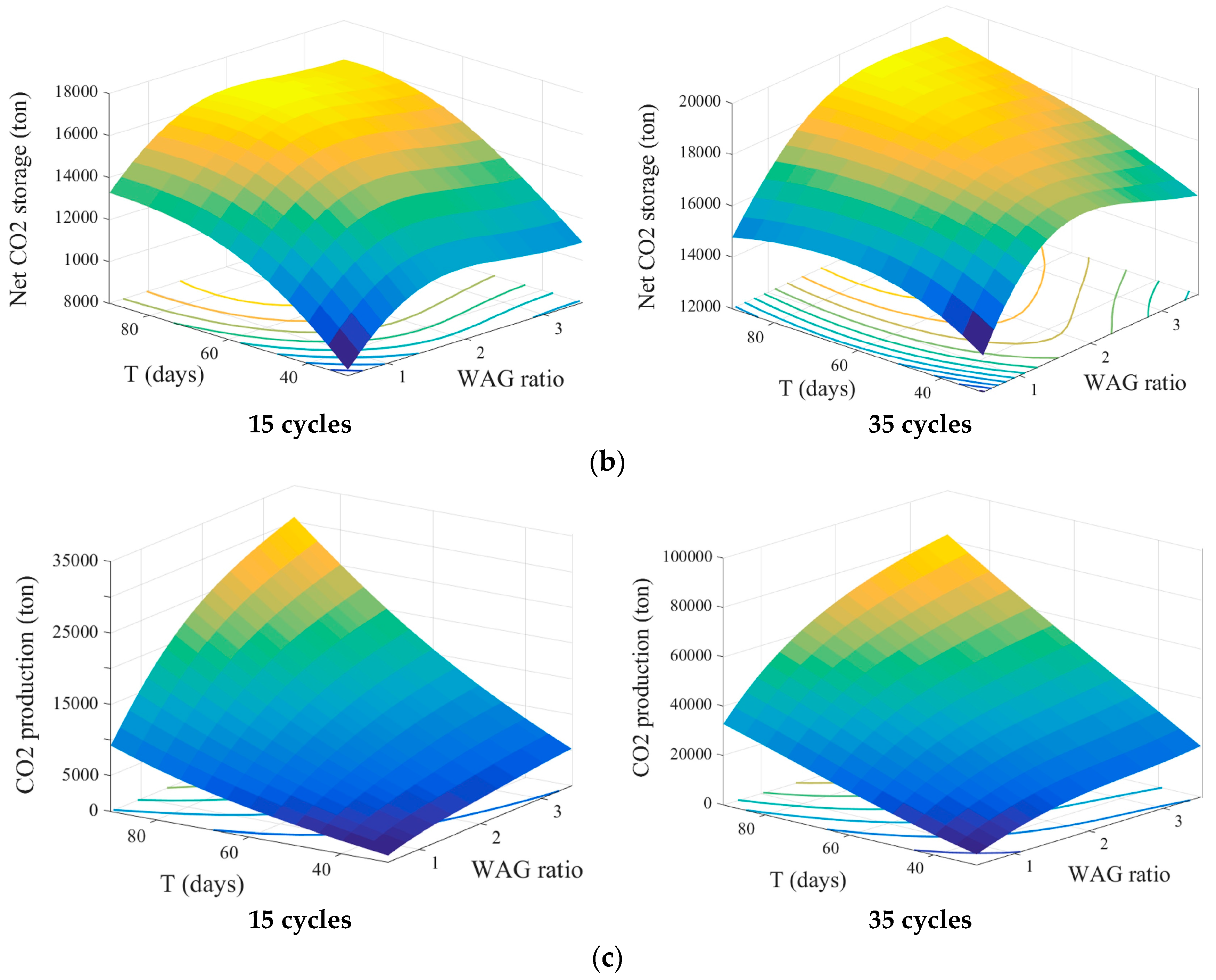

Figure 9 illustrates the changes in the three subjective targets following various WAG ratio and duration time

T designs, at reservoir conditions

Kv/Kh = 0.5 and initial

Sw = 0.67. Obviously, an increase in T enhances all targets at dissimilar magnitudes during the injection process, while rising RF and net CO

2 storage stop at an optimal WAG ratio region before decreasing according to increases in this parameter. Specifically, WAG ratios around 1 maximize the recovery factor after either 15 or 35 cycles, whereas a ratio of 2:1 for the injection time for CO

2 to water is most favorable for gas storage in the formation (

Figure 9).

The continuous increase in gas injection might initially extract a significant amount of trapped oil, but it causes an early breakthrough as a result of high mobility. In contrast, unsuitably low WAG ratios do not guarantee sufficient contact between solvent and hydrocarbon due to a rapid overlap by the injected water. As presented, the high RF is only achieved at a low WAG ratio (less than 1.5). Higher ratios up to 3.5 are undesirable as the RF drops by approximately 5% at the upper WAG ratio. This is also clearly indicated by the large gas production profile after 35 cycles and large incremental change from approximately 50,000 tons to more than 80,000 tons corresponding to a WAG ratio increase from 1 to 3.5 (

Figure 9). Similarly, inappropriately high WAG ratios undoubtedly lower the amount of CO

2 sequestration, demonstrating the CO

2 storage limit in the reservoir corresponding to a specific operating condition, particularly when oil is inefficiently displaced by the injected fluids. From the figure, it is clear that the WAG ratio is more important than time T for injection design [

35], even though T has a broad range (30 to 90 days).

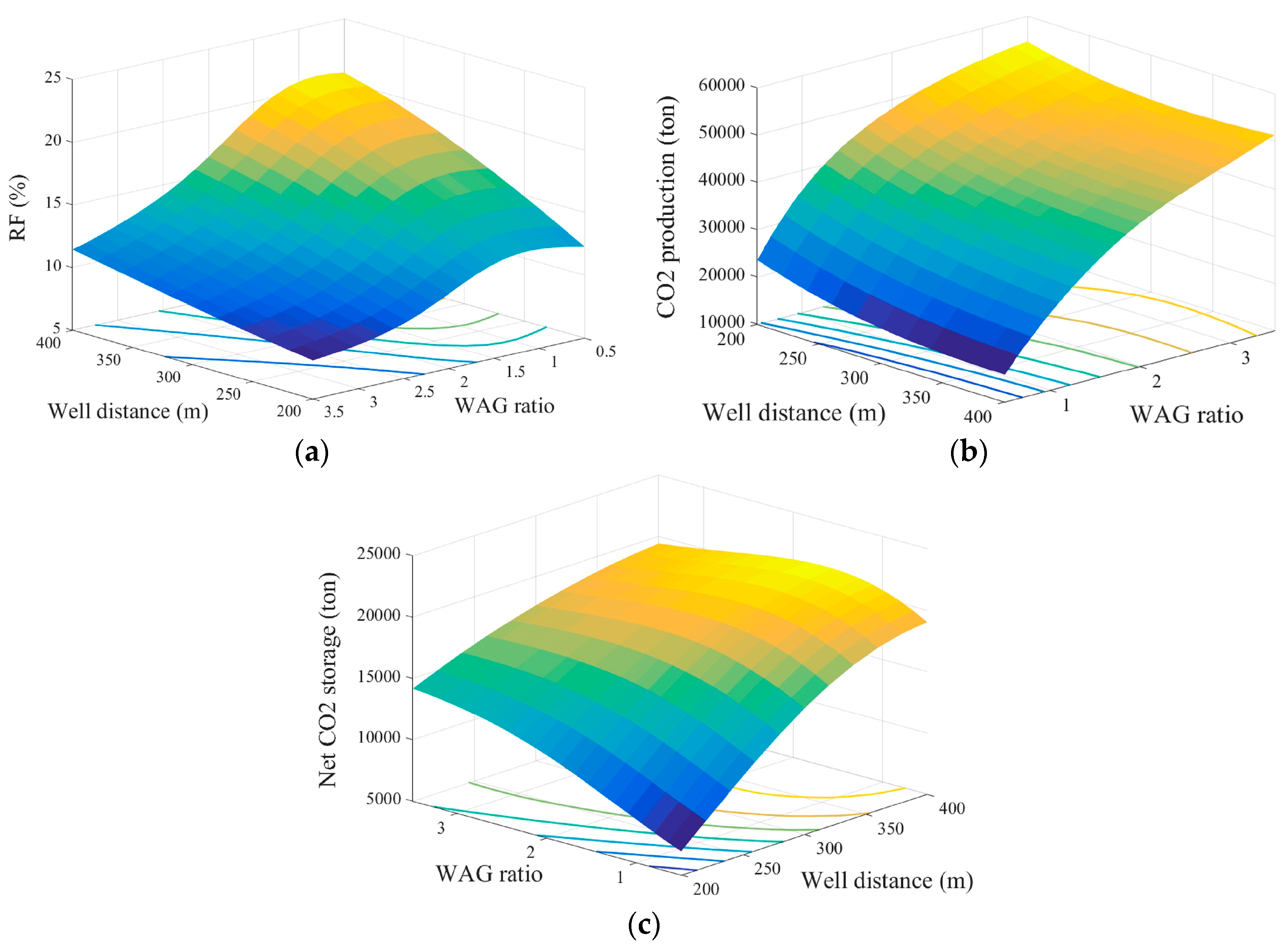

The effects of well spacing on essential performances should also be examined using the network models. Generally, the longer distance between an injector and producer results in a later time of gas breakthrough observed at the producing well and higher oil volume recovered during the flooding process. However, when the injected fluid ratio (CO

2 to water) is sufficiently high, this spatial factor does not have a significant impact on the WAG project success, for both the RF and other critical targets. As clearly shown in

Figure 10, with a WAG ratio at 0.5, the ultimate oil recovery can be improved from nearly 12% to 21% corresponding to an increase of 200 m in well distance. The increment is just 10% if the WAG ratio is designed at 3.5. The deviations in the increment for net CO

2 storage between these two WAG ratios are also significant, with increases of approximately 5 kt and 13 kt at the upper and lower constraints of the injecting ratio, respectively. Regarding CO

2 production, this target is inversely related to well spacing, but is impacted more by the WAG ratio compared to the spatial factor (

Figure 10).

The aforementioned technical verifications have validated the ANN models, not only for forecasting mathematically, but also for providing viable evaluations for targets’ behavior with changes in input parameters. Consequently, the models are flexible for other analyses, such as quantitative optimization or economic feasibility studies. To clearly acknowledge these concerns, a specific fiscal condition is assumed in this work, taking into account the important factors for economic analysis. The detailed expenditure components corresponding to the five-spot well pattern are listed in

Table 5, as referenced from the literature [

15,

36]. Among these, the predicted oil prices from 35

$/bbl to 65

$/bbl are investigated; uncertainty in the crude oil market remarkably influences any oil production project. The encouragement for storing CO

2 underground is reflected through an additional incentive term. Furthermore, assuming that all CO

2 produced is re-injected in addition to the purchased amount, the cost is ~30% less than if all gas is purchased for injection.

In total, six reservoir cases with interchanging Sw (0.6 and 0.7) and Kv/Kh (0.1, 0.5 and 1) are optimized for NPV by selecting the most favorable injection design and well distance. The procedure is a simple iterative scheme in which the variables are divided into intervals within their constraints. In detail, the well distance has an increment of 20 m from 200 m, and the WAG ratio and T are examined in 0.15 and 5 day intervals, respectively. Subsequently, the maximal NPV is chosen for each reservoir case at 25 injection cycles, and the optimal variables are obtained concurrently. Presumably, the optimized results will be different according to reservoir categories, and the maximized profit and recovery factor might not be achieved with the same parameter values.

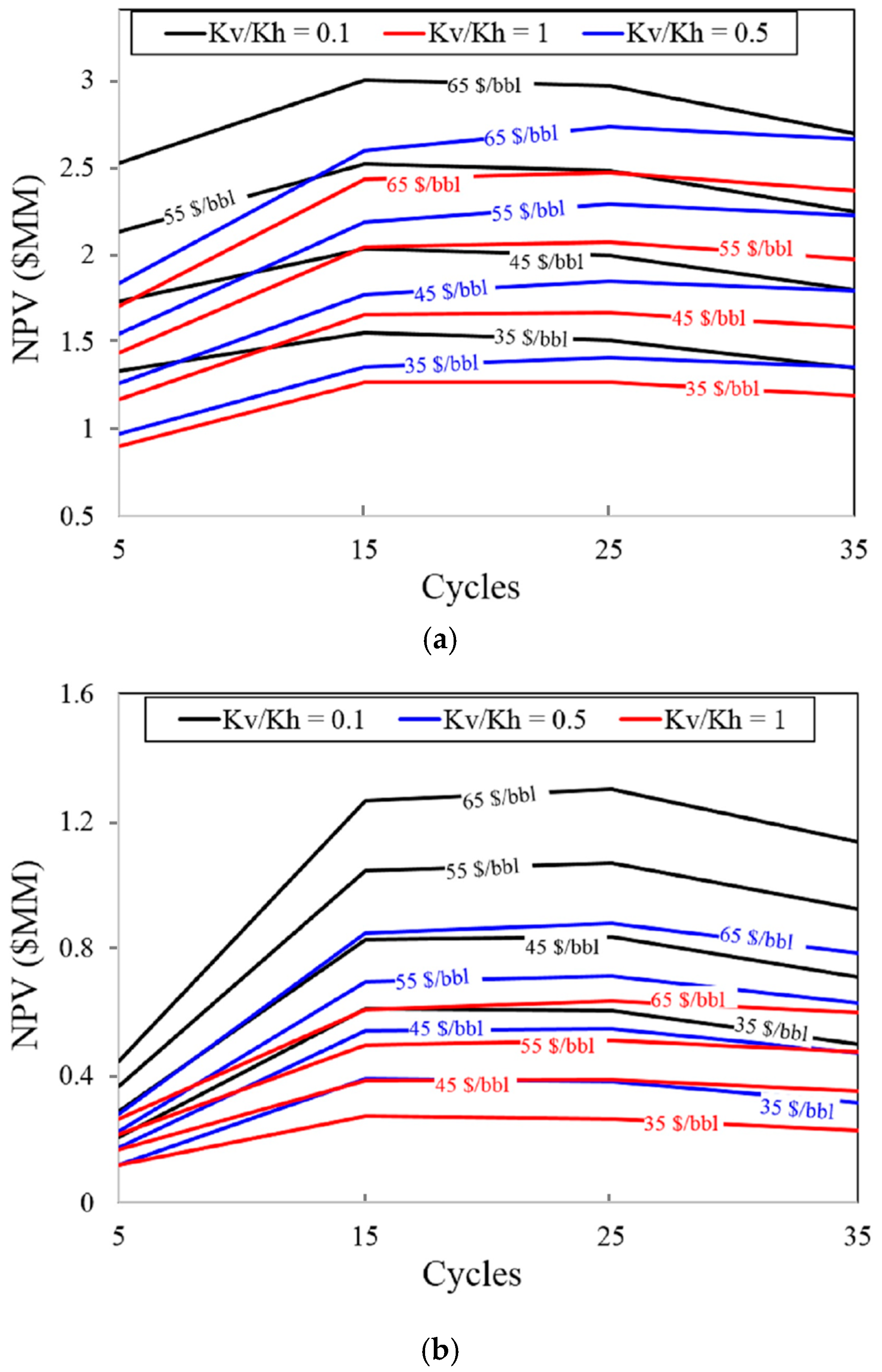

Indeed, as presented in

Table 6, the most dominant well distance and duration time obtained are dissimilar among the six cases, while the most favorable injected fluid ratio is proposed as 0.5 for most cases. It is clear that although the upper threshold of T is suggested for maximum recovery of the crude oil and CO

2 storage underground, a parameter value from 30 to 60 days produces the most economic benefit for the project. In addition, despite the fact that the WAG ratio essentially determines the technical success of the flooding process, a lower value is more preferable for project feasibility and profitability. Clearly, positive NPV values show the profitability of this CO

2-EOR project after 25 cycles at a specific oil price (45

$/bbl). However, the project needs to be verified in the context of various market forces to aid in scheduling and evaluating the process.

The comprehensive profits for the six cases are illustrated in

Figure 11. As described, oil price changes significantly affect the NPV, particularly when reservoir conditions are favorable for deploying the project. However, all cases indicate a positive profit even at the lowest oil price (35

$/bbl), indicating that the project is feasible over a wide range of market conditions. Furthermore, the figure also indicates an unstable trend of progressing NPV following injection cycles among cases and oil prices. In detail, the profits all peak prior to 35 cycles, and in some cases have the highest NPV at 15 cycles. Subsequently, the project maintains a maximum NPV until 25 cycles, but the economic performance does not improve further. These trends depend not only on the reservoir case, but also on the variation in oil price, indicating the important contribution of market factors to the project. The results definitely confirm the excellent applicability of network models for analyzing the economic feasibility of a project. The implications and conclusions will be undoubtedly different given other fiscal conditions, but these ANN models will remain helpful for evaluating project economic benefits.

Clearly, the models in this work can be reused in other similarly constrained flooding projects; in particular, this methodology can be utilized in CO2-EOR projects and even other research areas. While this study investigated a five-spot pattern, the method should be scalable to larger reservoirs and different patterns.