There is a large number of software packages for mooring analysis of floating structures, covering, e.g., quasi-static tools for design of ports and offshore oil and gas structures and likewise many tools for dynamic analysis. For the WECs, only dynamic tools are considered. A preliminary analysis provided the list of relevant software candidates defined in

Table 1. The versions of the software packages correspond to the version available at the time of the screening.

There are many other dynamic tools, e.g., the in-house code CASH by GVA, ZenMoor by Zentech Inc., WAMSIM by DHI Group and the MooDy code by Chalmers University of Technology [

31]. A widely-used software package is the Ariana-3Dynamics by Bureau Veritas, which uses a cable dynamic module, developed by Wood Group Kenny and which is based on the Flexcom software. From these additional codes, this paper will only consider MooDy further. The following sections will include a short description of each software package, followed by a full comparison of specifications.

Flexcom [

26], developed by MCS Kenny, is a structural analysis tool aimed at the offshore sector. The software is capable of including all environmental loads specified by the design standards and takes the hydrodynamic coefficients from external diffraction-radiation analysis software as input, including response amplitude operators (RAOs) and quadratic transfer functions (QTFs) for the calculation of respectively first and second order wave effects. The software models the mooring lines using a finite element solution based on a hybrid finite element beam model where the axial displacement and rotation are given by a linear basis function, a cubic basis function for the transverse displacement and a constant basis function for the axial force and torque moment. Time stepping is done by a second order implicit generalized-

method with the option of variable time steps based on the current period parameter.

MOSES [

27] is a software package for modeling, designing and planning for offshore floating structures, including the calculation of the hydrodynamic coefficients. The environmental loadings are well described, and mooring lines are solved for tension, bending and torsion. The beam equations are solved by linear finite elements. An implicit Newmark

-scheme, typically of second order, is used for time stepping.

ProteusDS [

28], developed by Dynamic System Analysis Ltd., is a software for full dynamic analysis of offshore structures in the time domain. The software uses a Morison approach for the calculation of wave loads or additionally user-specified hydrodynamic coefficients. The present version of ProteusDS does not calculate the second order wave effects, and the wave drift and LF motion are not computed. A part of the contribution to the wave drift is by now included, and the implementation of QTFs is expected in future releases. The software does contain advanced mechanism modeling capabilities suitable for predicting WEC performance, important for characterizing the PTO of WECs. The mooring lines are solved for both tension, bending and torsion, using a cubic spline finite element method, meaning that the solution inside an element is given by a fourth order polynomial with a lumped mass matrix in order to speed up calculations. A fourth order Runge–Kutta scheme with an adaptive time step is used for advancing in time. The numerical error introduced by the time integrator is maintained below a defined level by adjusting the time step.

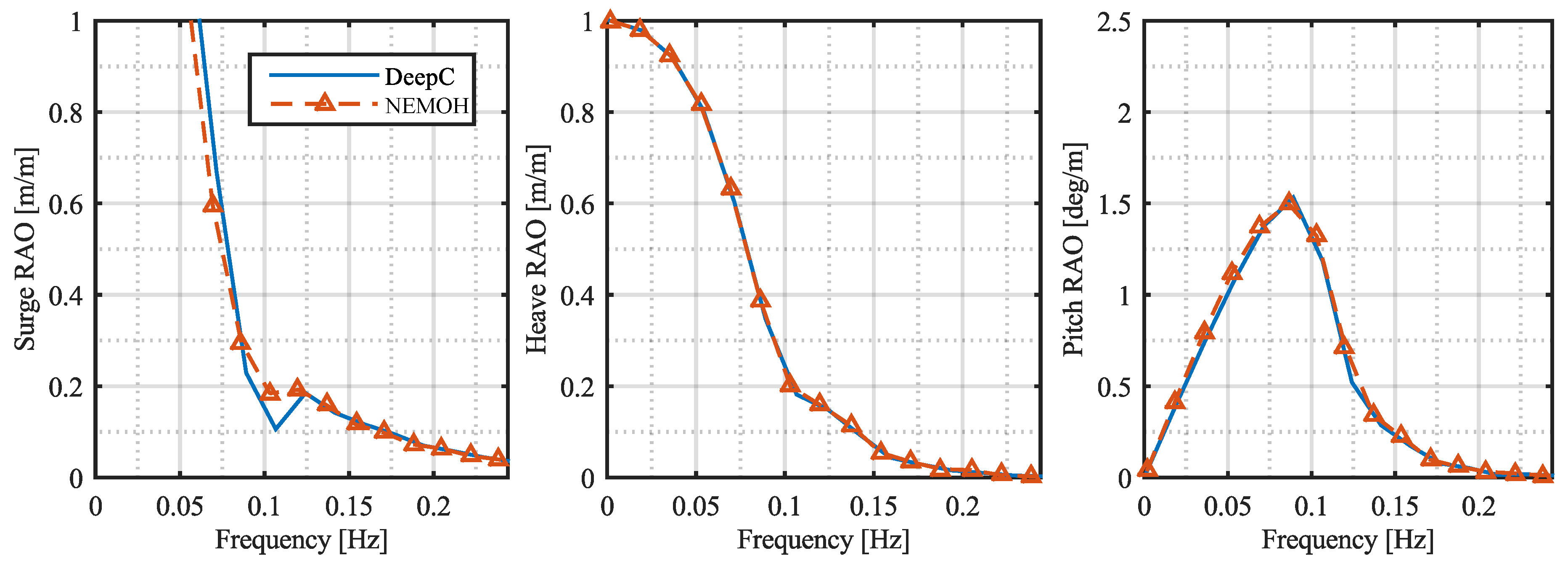

DeepC [

30] is a software package distributed by DNV-GL consisting of two pieces of software Riflex and Simo and combined with the HydroD package for hydrodynamic analysis. In combination, the DeepC software is capable of analyzing the environmental impact on floating structures and mooring lines accounting for first and second order wave effects, current and wind. The lines are solved for tension, bending and torsion and come with a linear bar element and with hybrid bar elements using a combination of linear basis functions and cubic basis functions. The mass matrix can be lumped for computations that are more efficient. The time integration uses an implicit Newmark

-scheme, typically second order, and solved with a Newton–Raphson method.

4.1. Comparison of Software Packages

Largely, the software packages provide the same specifications, and since most codes are validated, it is expected that the obtained results will be in the same range. Still, some of the software packages excel when comparing all specifications. For comparison, the requirements from the design standards are considered. According to these, moorings need to be analyzed in the time domain using a fully-coupled analysis, and in addition, the software needs to be able to model the wind and current loads as profiled in the vertical direction. Modeling of the time-varying nature of the wind is a requirement, while it is only necessary to model a steady current velocity.

Table 2 compares the software according to these requirements.

As seen from

Table 2, all software fulfils the requirements, though SeaFEM is only capable of modeling a uniform current and wind.

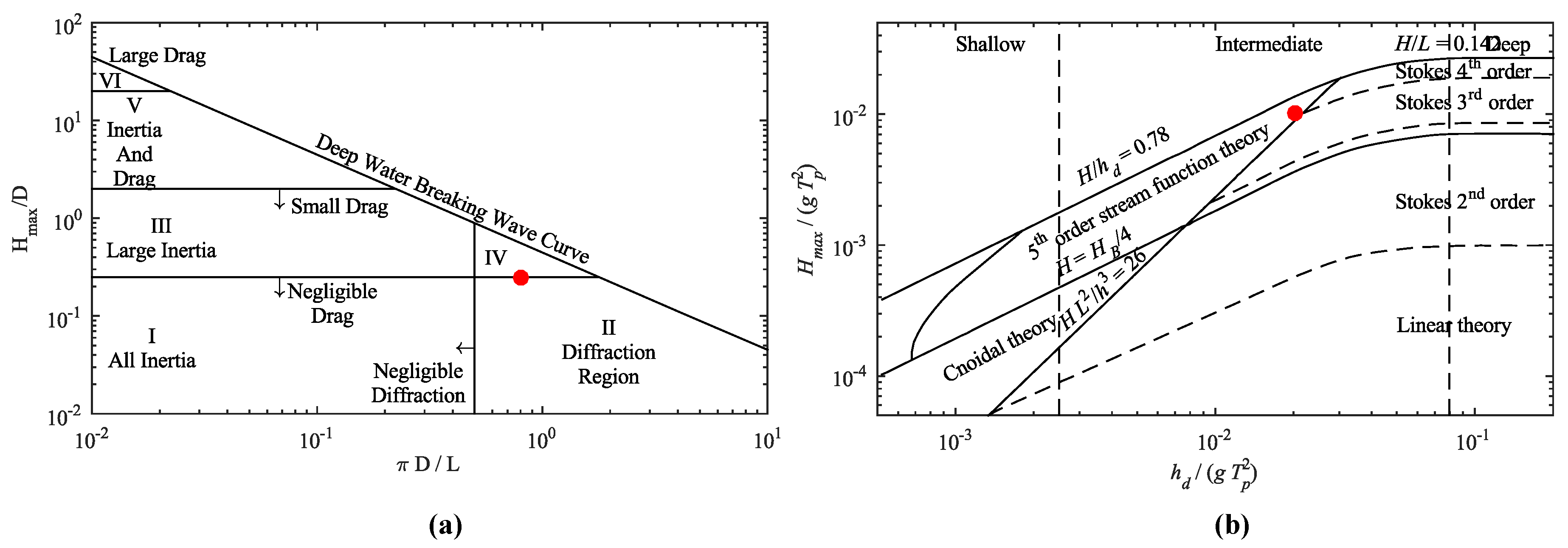

When considering shallow water depths, in which many WECs are planned for deployment, the need for high order wave theory is present. All software needs to be able to implement diffraction/radiation loads in the case of large structures either by performing the analysis itself or using input variables.

Table 3 specifies the capabilities for each software package concerning the wave influence.

Some variation of the implemented wave theories is present, but in general, high order Stokes theory is available. All software packages are capable of simulating irregular sea states, and diffraction/radiation or Morison load can either be computed by the software packages or input by the user. Most software includes second order wave effects, except from ProteusDS, which at present only includes some contribution to the wave drift. SeaFEM has implemented a second order solver, but this cannot be enabled together with current loads in the available version.

In mooring analysis, the dynamic cable solver is obviously one of the main features.

Table 4 defines the specification of each software package, now also considering the MooDy code. The comparison considers the included contribution to the calculated mooring loads, together with the order of the schemes used for advancing in time and space. The use of a lumped mass matrix in the software is stated, but the table does not differ between the two meanings of the approach as described previously. Finally, the table lists the capability to model non-linear axial mooring line stiffness, which is an important feature when modeling, e.g., synthetic ropes.

The capabilities are identical in most software packages, while codes such as MooDy and ProteusDS are highlighted due to the high spatial and temporal order. However, it is still expected that similar results will be achieved in all software, despite the order of the code.

Table 2,

Table 3 and

Table 4 are suitable for choosing an optimal tool for dynamic mooring design and ensuring that the design standards can be satisfied. Many of the software packages have apparent similar specifications, but OrcaFlex, DeepC, ProteusDS and SeaFEM are considered strong candidates. As seen in

Table 4, the dynamic cable solver in ProteusDS is most advanced, but at present, the main drawback of this software is the lack of capability to calculate the second order wave effect. Considering WECs in shallow water with compliant mooring, the drift effect is of paramount importance.

The SeaFEM software mainly advances because of its hydrodynamic solver, based on an FE formulation of the entire fluid domain. The software is, therefore, not dependent on frequency domain results (RAOs and QTFs) for calculation of motions and will provide the best description of non-linear irregular waves. Similar, the code has the potential to provide a better description of the current effect as it is calculated from the pressure on the body and not from a drag coefficient. However, for large structures with a high Reynolds number and turbulent flow, SeaFEM does not model this properly since the solver assumes steady streamlines. At present, the solver is also not capable of solving second order effects in combination with current, and computing just the second order wave effects puts such high demands on the mooring solver that the solutions often diverge. Another important factor to consider if using SeaFEM is the much higher computational time, compared to the other software packages. It should be noted that this is caused by the fact that SeaFEM solves the entire domain in each time step and, therefore, gives a better description paid by the longer simulation time.

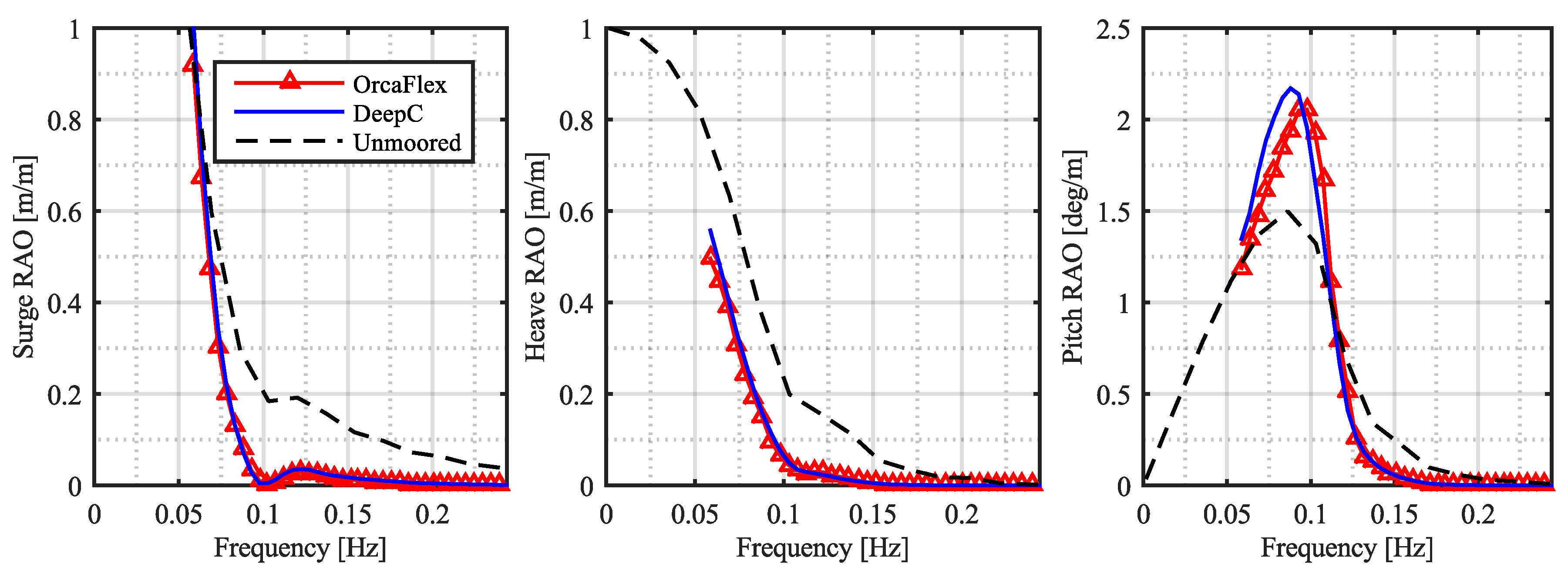

Considering

Table 2,

Table 3 and

Table 4, DeepC and OrcaFlex appear to have similar specifications. The DeepC solver might be more advanced than OrcaFlex as it can solve the mass continuously over the mooring line, while OrcaFlex uses the lumped mass approach and models the lines as point masses and springs. However, studies have indicated that an acceptable level of accuracy can also be achieved with this method. Both DeepC and OrcaFlex have been validated in several studies, and OrcaFlex is widely used for commercial purpose in different offshore sectors, while DeepC is developed and distributed by the certification company DNV-GL. A drawback of the DeepC package is the need for calculating static position in additional software, and for long simulations like, e.g., three hours, the software introduces a limitation of the number of calculations, which results in higher time steps and therefore possibly unstable solutions.

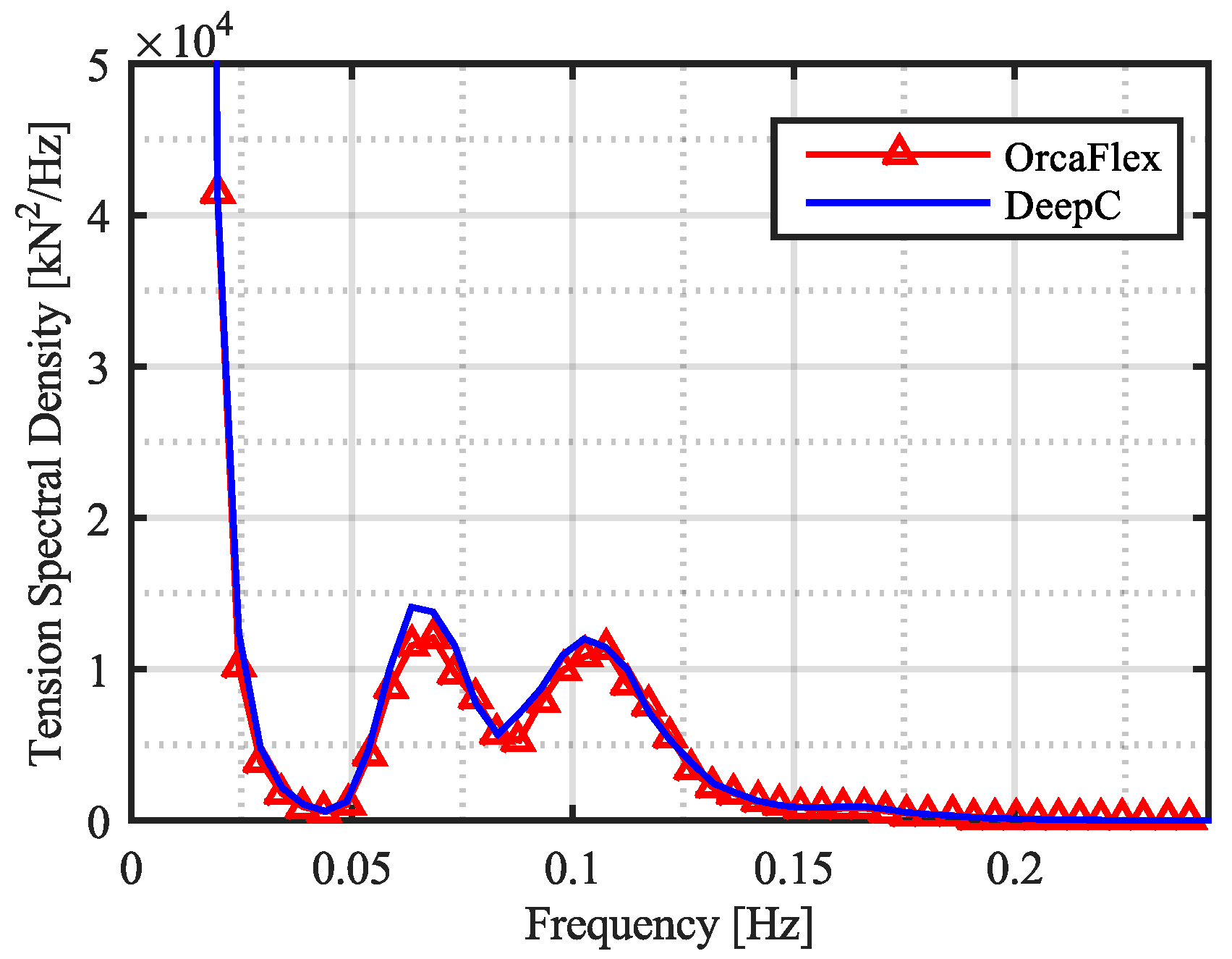

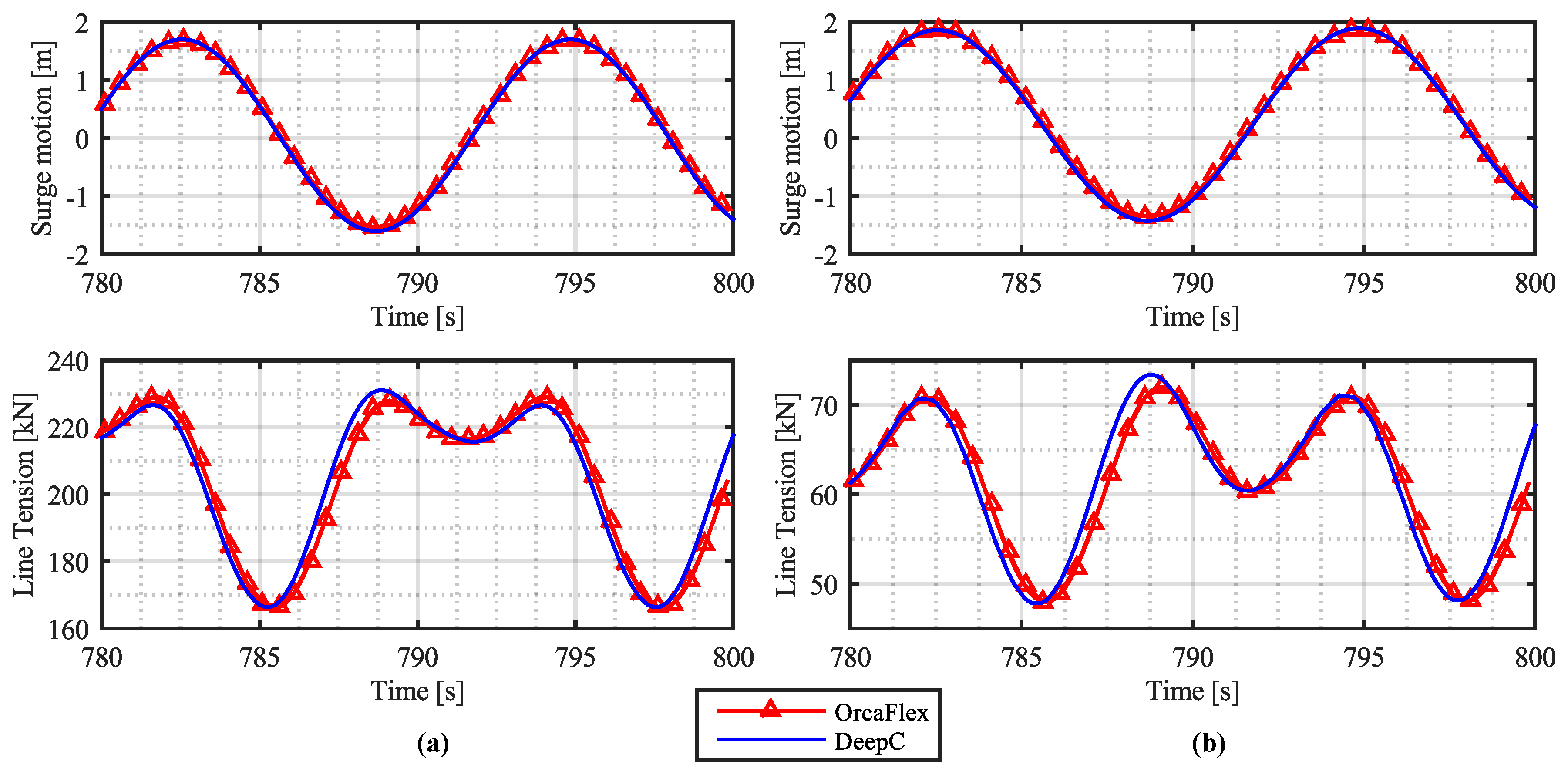

This paper will compare the performances of the OrcaFlex and DeepC packages, as these seem to fulfil the requirements in the design standards. No validation of the software packages will be conducted in this paper, as they are both commercial software packages, which have been validated for other applications as stated by [

32,

33]. The purpose of the following section is to investigate the potential difference between the results from each software package and allow for selection of the final tool. In a later publication, the selected software package will be validated for the present application.