Efficiency of Recycling Double-Pass V-Corrugated Solar Air Collectors

Abstract

:1. Introduction

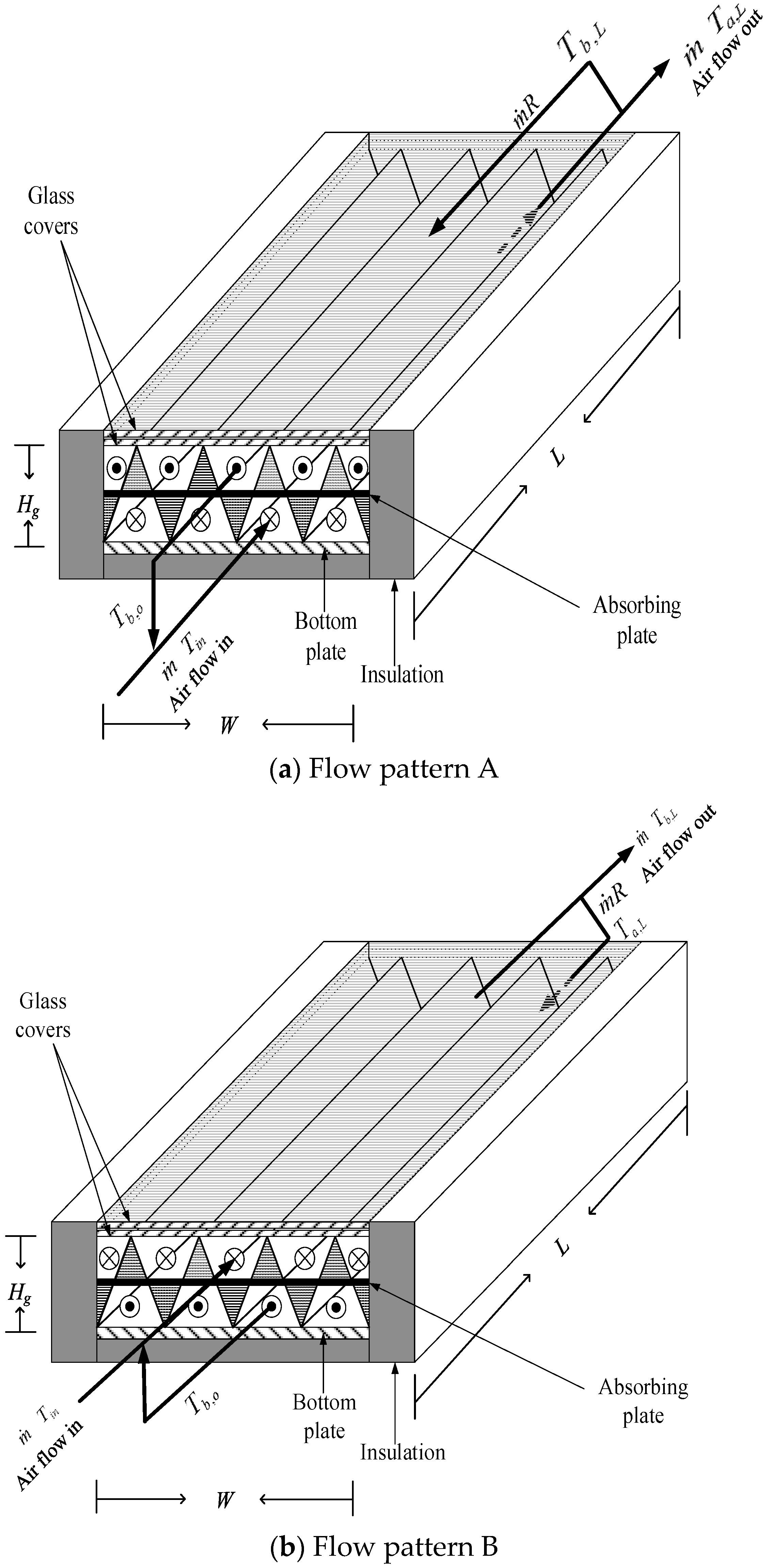

2. Theoretical Analysis

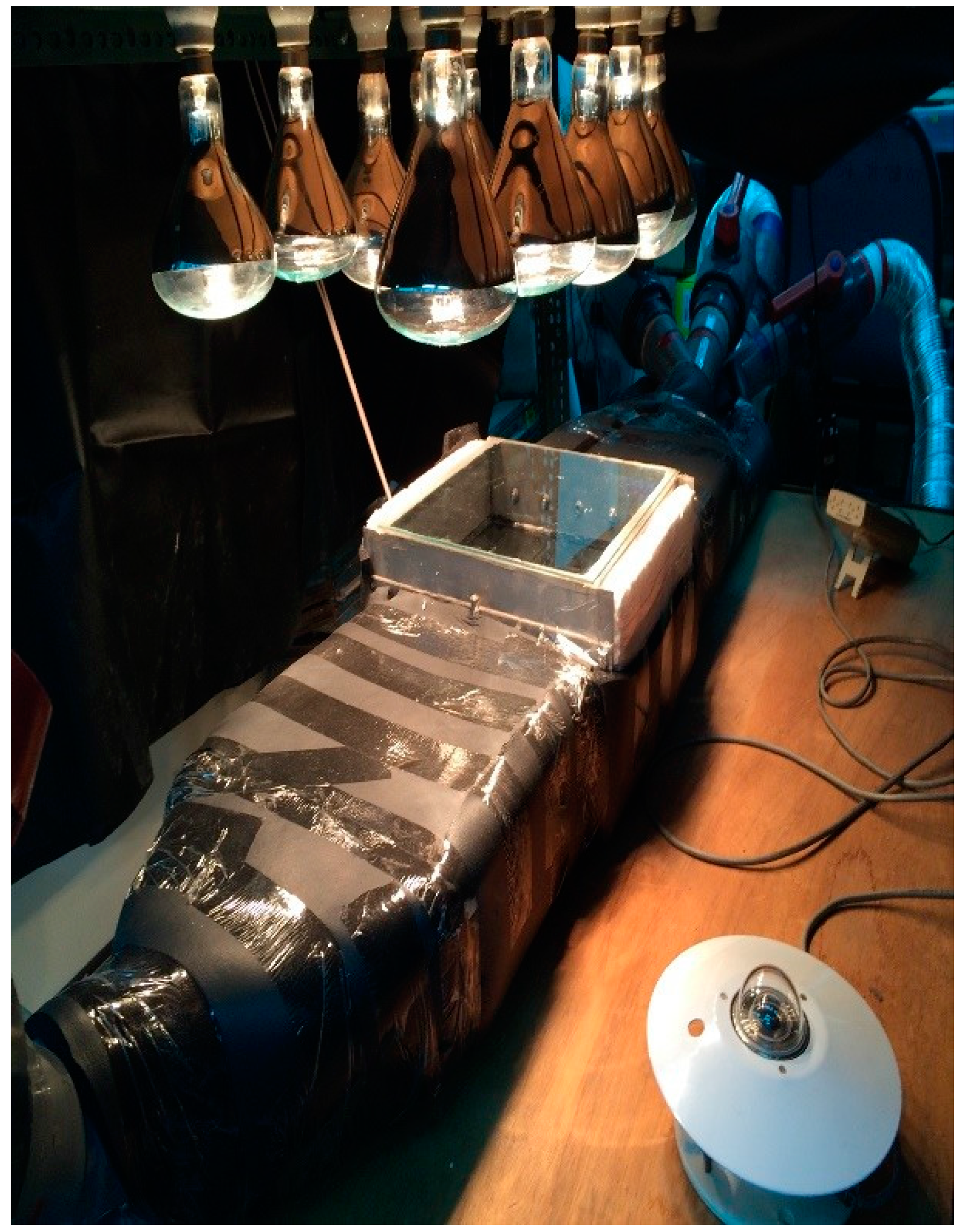

3. Experimental Setup

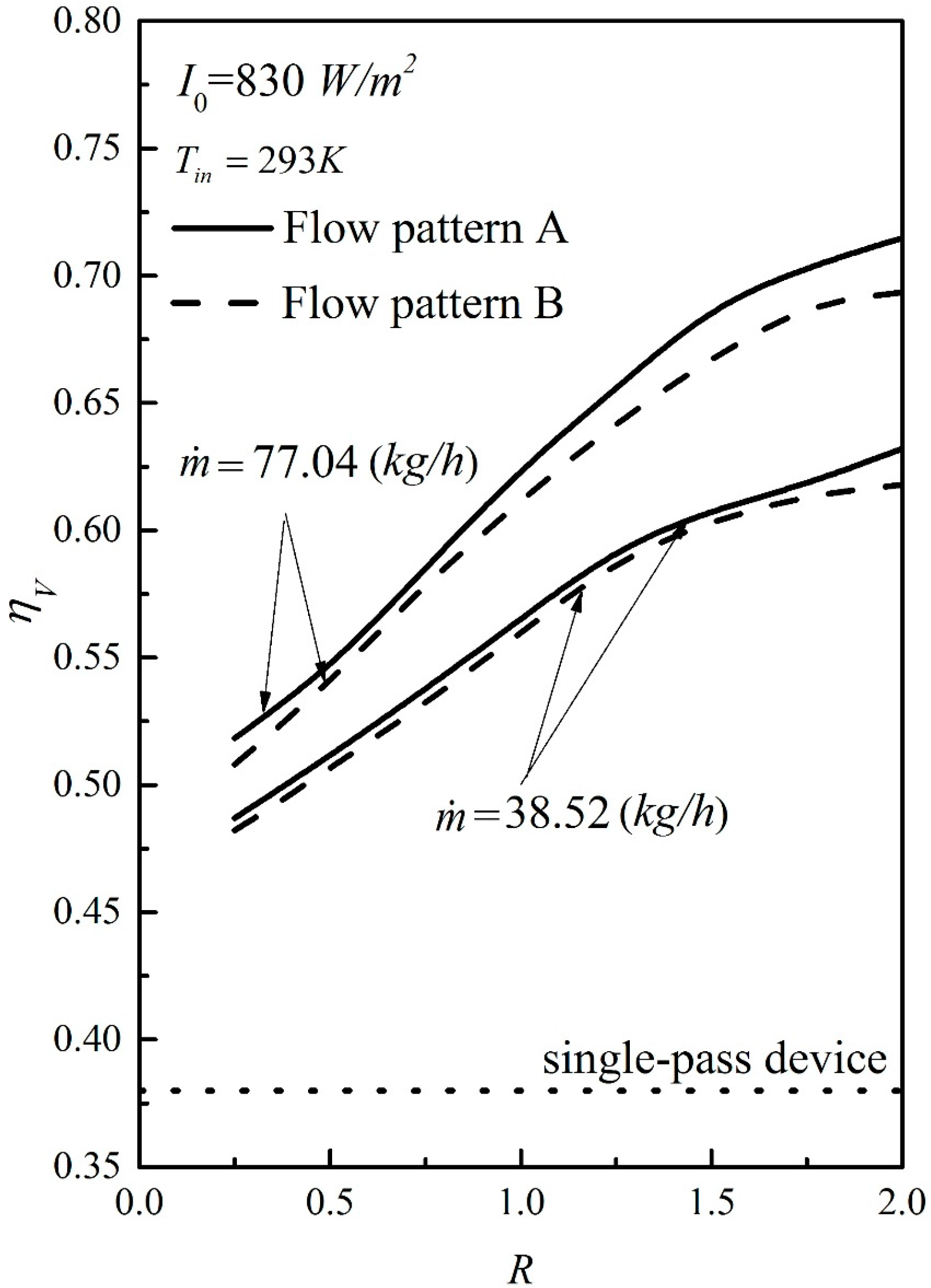

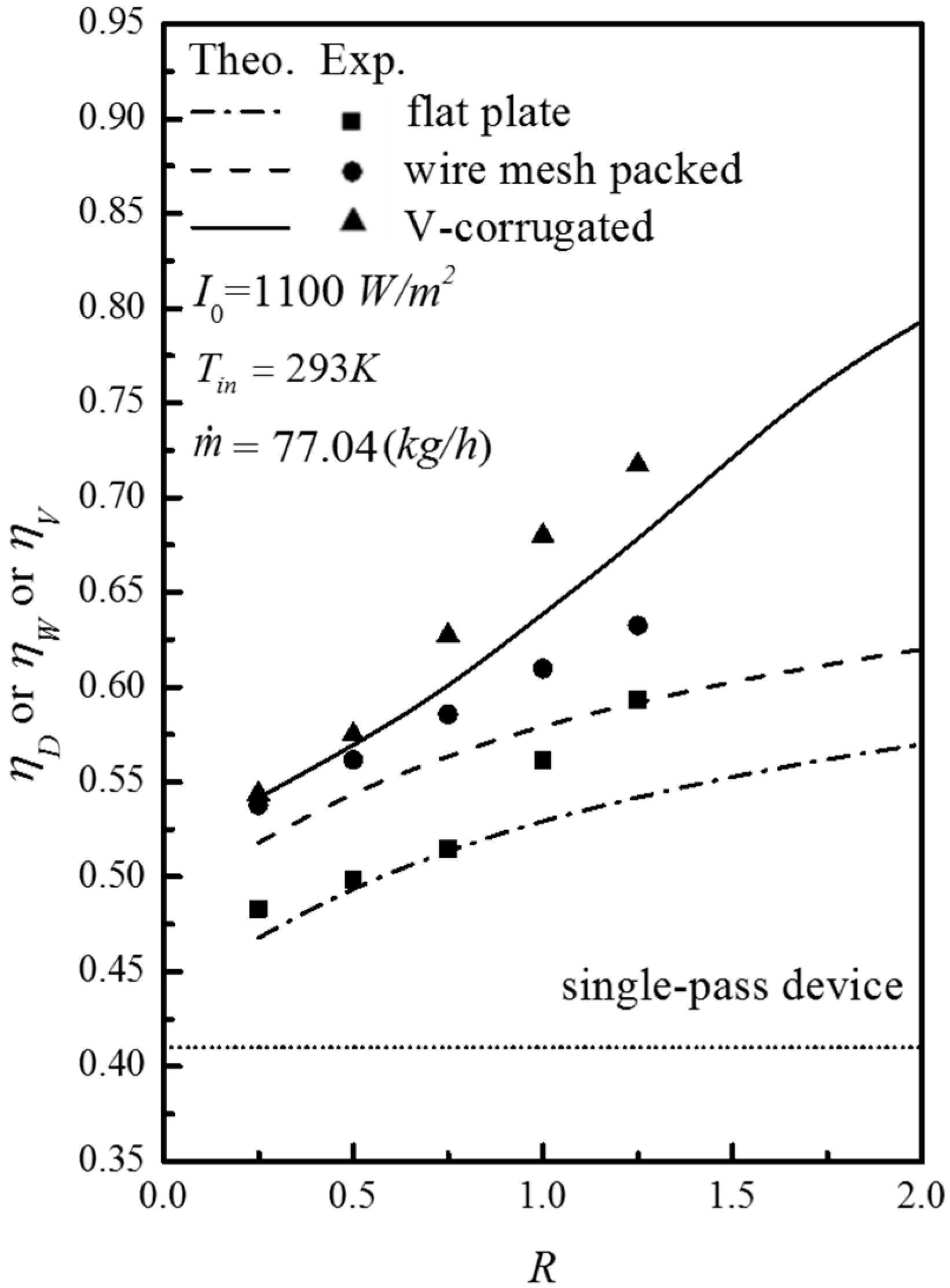

4. Collector Efficiency Improvement

5. Results and Discussion

6. Conclusions

Acknowledgment

Author Contributions

Conflicts of Interest

Nomenclature

| Surface area of the collector = LW (m2) | |

| Bi | Coefficients defined in Equations (A1)–(A6) |

| Ci | Coefficients defined in Equations (A16) and (A17) |

| Specific heat of air at constant pressure (J/(kg K)) | |

| Equivalent diameter of downward-type single-pass device (m) | |

| Equivalent diameter of lower subchannel of double-pass device (m) | |

| Equivalent diameter of upper subchannel of double-pass device (m) | |

| Deviation of the experimental measurements from theoretical predictions, defined in Equation (11) | |

| Fi | Coefficients defined in Equations (A18)–(A20) |

| Fanning friction factor | |

| Coefficients defined in Equations (A7)–(A13) | |

| Hg | Height of channels (m) |

| ha | Convection coefficient between the absorber plate and subchannel a (W/(m2 K)) |

| hb | Convection coefficient between the absorber plate and subchannel b (W/(m2 K)) |

| Radiation heat transfer coefficient between cover 1 and absorber plate (W/m2 K) | |

| Radiation heat transfer coefficient between absorber plate and bottom plate (W/m2 K) | |

| hw | Convective heat transfer coefficient for air flowing over the outside surface of glass cover (W/(m2 K)) |

| Incident solar radiation (W/m2) | |

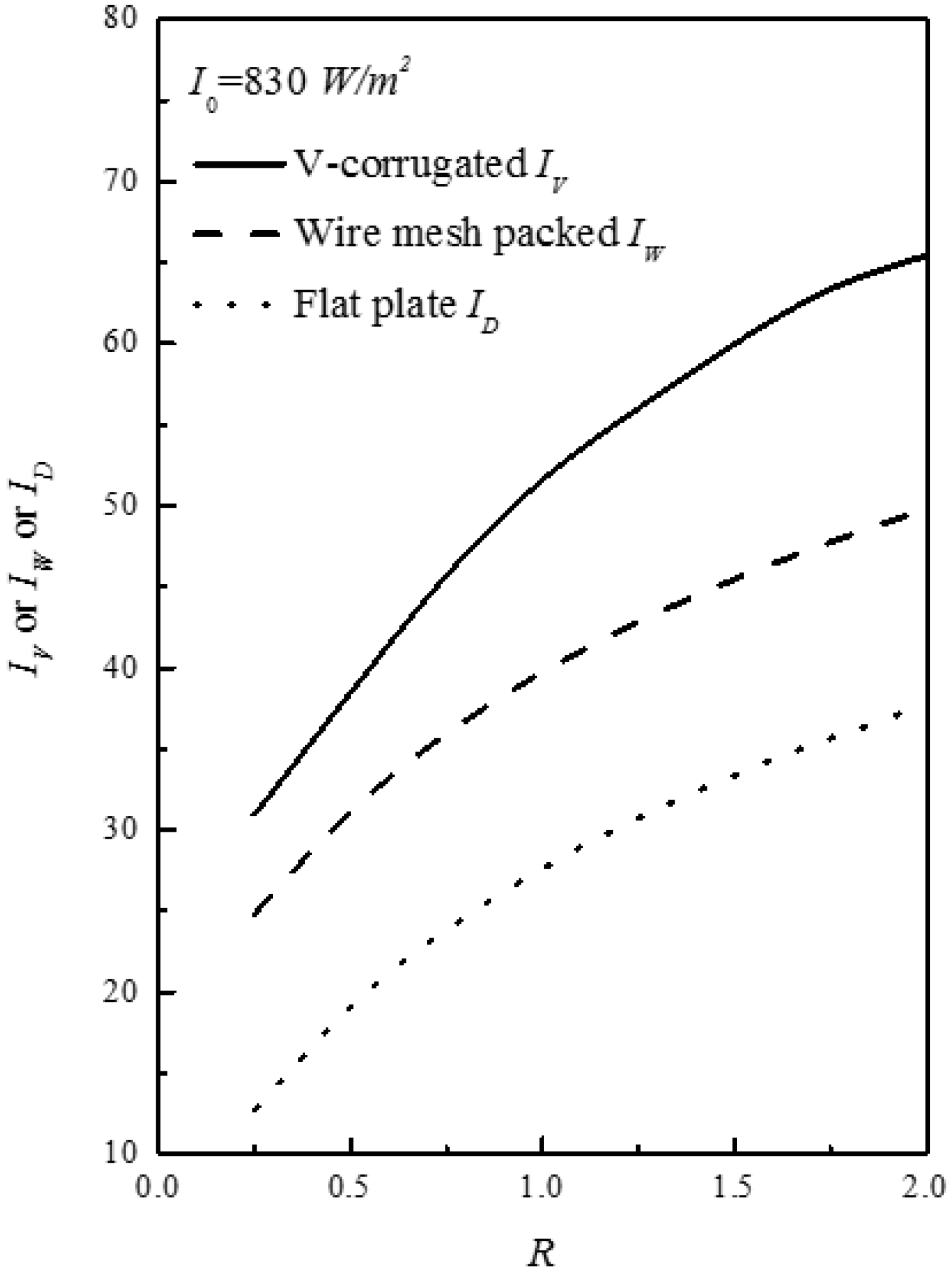

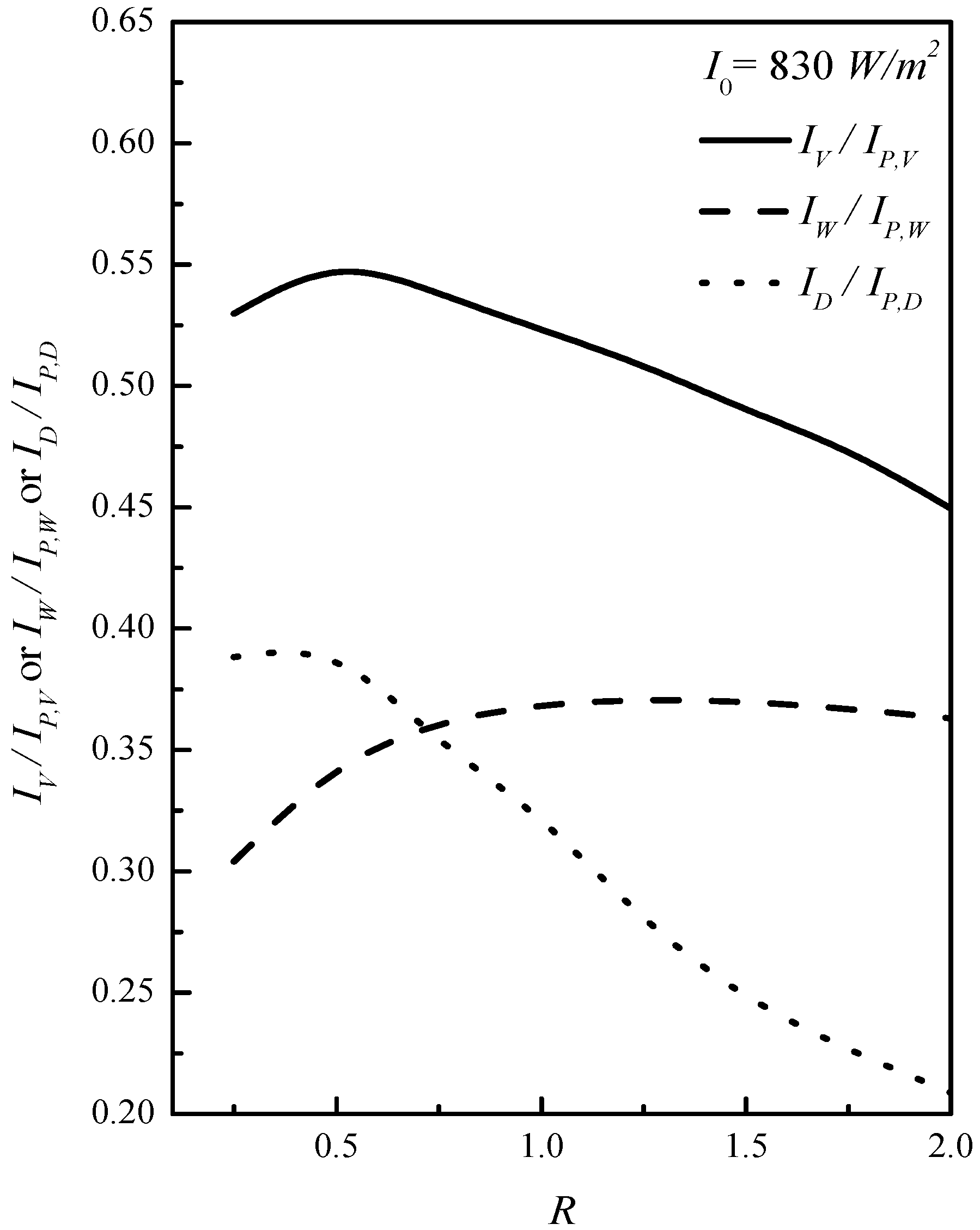

| Percentage of collector efficiency improvement, defined in Equation (12) | |

| Power consumption increment, defined in Equations (20)–(22) | |

| Percentage of collector efficiency improvement, defined in Equation (13) | |

| Percentage of collector efficiency improvement, defined in Equation (14) | |

| ks | Thermal conductivity of insulator (W/(m K)) |

| Channel length (m) | |

| ls | Thickness of insulator (m) |

| Lower subchannel friction loss of double-pass device (J/kg) | |

| Upper subchannel friction loss of double-pass device (J/kg) | |

| Friction loss of downward-type single-pass device (J/kg) | |

| Total air mass flow rate (kg/h) | |

| N | Number of glass cover |

| Number of experimental measurements | |

| Nu | Nusselt number |

| PD | Power consumption of the flat plate double-pass device (W) |

| PS | Power consumption of downward-type single-pass device (W) |

| PV | Power consumption of the V corrugated double-pass device (W) |

| PW | Power consumption of the wire mesh packed double-pass device (W) |

| Useful energy gained by air (W) | |

| R | Recycle ratio, reverse air mass flow rate divided by input air mass flow rate |

| The experimental uncertainty of an individual measurement | |

| The mean value of | |

| Re | Reynolds number |

| Inlet air temperature (K) | |

| The mixing temperature of the subchannel a at x = 0 (K) | |

| The temperature of the subchannel a at x = L (K) | |

| The temperature of the subchannel b at x = 0 (K) | |

| The temperature of the subchannel b at x = L (K) | |

| Axial fluid temperature distribution in subchannel a (K) | |

| Axial fluid temperature distribution in subchannel b (K) | |

| Temperature of glass cover 1 (K) | |

| Temperature of absorbing plate (K) | |

| Mean temperature of absorbing plate (K) | |

| Ambient temperature (K) | |

| Loss coefficient from the bottom of solar air heater to the ambient environment (W/(m2 K)) | |

| Loss coefficient from the surfaces of edges and the bottom of the solar collector to the ambient environment (W/m2 K) | |

| Loss coefficient from the inner cover to the ambient environment (W/m2 K) | |

| Loss coefficient from the top of solar air heater to the ambient environment (W/m2 K) | |

| W | Width of both upper and lower subchannels (m) |

| Mean air velocity in the downward-type single-pass device (m/s) | |

| Mean air velocity in subchannel a of double-pass device (m/s) | |

| Mean air velocity in subchannel b of double-pass device (m/s) | |

| Yi | Coefficients defined in Equations (A14) and (A15) |

| Axial coordinate (m) | |

| Greek Letters | |

| Absorptivity of the absorbing plate | |

| Collector efficiency of the flat-plate double-pass device | |

| Collector efficiency of the downward type single-pass device | |

| Collector efficiency of the double-pass V-corrugated solar air ter | |

| Collector efficiency of the double-pass wire mesh packed solar air heater | |

| Experimental data of collector efficiency | |

| The mean value of the experimental data | |

| Theoretical prediction of collector efficiency | |

| Air viscosity (kg/ms) | |

| Transmittance of glass cover | |

| Emissivity of glass cover | |

| Emissivity of absorbing plate | |

| Air density (kg/m3) | |

| Dimensionless channel length | |

Appendix A

References

- El-Sebaii, A.A.; Shalaby, S.M. Experimental investigation of an indirect-mode forced convection solar dryer for drying thymus and mint. Energy Convers. Manag. 2013, 74, 109–116. [Google Scholar] [CrossRef]

- Sevik, S. Design, experimental investigation and analysis of a solar drying system. Energy Convers. Manag. 2013, 8, 27–34. [Google Scholar]

- Razika, I.; Nabila, I.; Madani, B.; Zohra, H.F. The effects of volumetric flow rate and inclination angle on the performance of a solar thermal collector. Energy Convers. Manag. 2014, 78, 931–937. [Google Scholar] [CrossRef]

- Al-Kayiem, H.H.; Yassen, T.A. On the natural convection heat transfer in a rectangular passage solar air heater. Sol. Energy 2015, 12, 10–18. [Google Scholar] [CrossRef]

- El-Sebaii, A.A.; Al-Snani, H. Effect of selective coating on thermal performance of flat plate solar air heaters. Energy 2010, 35, 1820–1828. [Google Scholar] [CrossRef]

- Vaziri, R.; Ilkan, M.; Egelioglu, F. Experimental performance of performance of perforated glazed solar air heaters and unglazed transpired solar air heater. Sol. Energy 2015, 119, 251–260. [Google Scholar] [CrossRef]

- Sharma, K.S.; kalamkar, V.R. Experimental and numerical investigation of forced convection heat transfer in solar air heater with thin ribs. Sol. Energy 2017, 147, 227–291. [Google Scholar] [CrossRef]

- Fudholi, A.; Sopian, K.; Othman, M.Y.; Ruslan, M.H.; Bakhtyar, B. Energy analysis and improvement potential of finned double-pass solar collector. Energy Convers. Manag. 2013, 75, 234–240. [Google Scholar] [CrossRef]

- Tamna, S.; Skullong, S.; Thianpong, C.; Promvonge, P. Heat transfer behaviors in a solar air heater channel with multiple V-baffle vortex generators. Sol. Energy 2014, 110, 720–735. [Google Scholar] [CrossRef]

- Skullong, S.; Promvonge, P.; Thianpong, C.; Pimsarn, M. Thermal performance in solar air heater channel with combined wavy-groove and perforated-delta wing vortex generators. Sol. Appl. Therm. Eng. 2016, 100, 611–620. [Google Scholar] [CrossRef]

- Maithani, R.; Saini, J.S. Heat transfer and friction factor correlations for a solar air heater duct roughened artificially with V-ribs with symmetrical gaps. Exp. Therm. Fluid Sci. 2016, 70, 220–227. [Google Scholar] [CrossRef]

- El-Sebaii, A.A.; Aboul-Enein, S.; Ramadan, M.R.I.; Shalaby, S.M.; Moharram, B.M. Investigation of thermal performance of double-pass flat and v-corrugated plate solar air heaters. Energy 2011, 36, 1076–1086. [Google Scholar] [CrossRef]

- Garg, H.P.; Sharma, V.K.; Bhargava, A.K. Theory of multiple-pass solar air heaters. Energy 1985, 10, 589–599. [Google Scholar] [CrossRef]

- Wijeysundera, N.E.; Ah, L.L.; Tjioe, L.E. Thermal performance study of two-pass solar air heaters. Sol. Energy 1982, 28, 363–370. [Google Scholar] [CrossRef]

- Singh, S.; Dhiman, P. Thermal and thermohydraulic performance evaluation of a novel type double pass packed bed solar air heater under external recycle using an analytical and RSM (response surface methodology) combined approach. Energy 2014, 72, 344–359. [Google Scholar] [CrossRef]

- Ho, C.D.; Lin, C.S.; Chuang, Y.C.; Chao, C.C. Performance improvement of wire mesh packed double-pass solar air heaters with external recycle. Renew. Energy 2013, 57, 479–489. [Google Scholar] [CrossRef]

- Gupta, M.K.; Kaushik, S.C. Performance evaluation of solar air heater for various artificial roughness geometries based on energy, effective and energy efficiencies. Renew. Energy 2009, 34, 465–476. [Google Scholar] [CrossRef]

- Moffat, R.J. Describing the uncertainties in experimental results. Exp. Therm. Fluid Sci. 1988, 1, 3–17. [Google Scholar] [CrossRef]

- Verma, R.; Chandra, R.; Garg, H.P. Optimization of solar air heaters of different designs. Renew. Energy 1992, 2, 521–531. [Google Scholar] [CrossRef]

| Mass Flow Rate | Recycle Ratio | I0 = 830 (W/m2) | I0 = 1100 (W/m2) | ||

|---|---|---|---|---|---|

| m (kg/h) | R | ||||

| 38.52 | 0.25 | 0.487 | 57.60 | 0.510 | 69.51 |

| 0.5 | 0.511 | 65.52 | 0.535 | 77.85 | |

| 0.75 | 0.538 | 73.99 | 0.563 | 86.88 | |

| 1 | 0.565 | 82.89 | 0.592 | 96.58 | |

| 1.25 | 0.593 | 91.86 | 0.623 | 106.87 | |

| 1.5 | 0.608 | 96.79 | 0.655 | 117.45 | |

| 1.75 | 0.618 | 99.97 | 0.685 | 127.48 | |

| 2 | 0.632 | 104.58 | 0.704 | 134.01 | |

| 57.96 | 0.25 | 0.503 | 35.98 | 0.530 | 45.62 |

| 0.5 | 0.526 | 42.07 | 0.553 | 52.01 | |

| 0.75 | 0.565 | 52.76 | 0.578 | 58.86 | |

| 1 | 0.597 | 61.34 | 0.622 | 70.99 | |

| 1.25 | 0.630 | 70.32 | 0.658 | 80.84 | |

| 1.5 | 0.663 | 79.15 | 0.697 | 91.55 | |

| 1.75 | 0.676 | 82.65 | 0.744 | 104.32 | |

| 2 | 0.688 | 85.97 | 0.766 | 110.40 | |

| 77.04 | 0.25 | 0.508 | 21.94 | 0.508 | 29.34 |

| 0.5 | 0.536 | 28.46 | 0.536 | 36.06 | |

| 0.75 | 0.580 | 39.11 | 0.580 | 43.41 | |

| 1 | 0.614 | 47.29 | 0.614 | 55.44 | |

| 1.25 | 0.651 | 56.04 | 0.651 | 64.83 | |

| 1.5 | 0.688 | 65.03 | 0.688 | 75.58 | |

| 1.75 | 0.703 | 68.68 | 0.703 | 85.69 | |

| 2 | 0.715 | 71.41 | 0.715 | 92.99 | |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ho, C.-D.; Hsiao, C.-F.; Chang, H.; Tien, Y.-E.; Hong, Z.-S. Efficiency of Recycling Double-Pass V-Corrugated Solar Air Collectors. Energies 2017, 10, 875. https://doi.org/10.3390/en10070875

Ho C-D, Hsiao C-F, Chang H, Tien Y-E, Hong Z-S. Efficiency of Recycling Double-Pass V-Corrugated Solar Air Collectors. Energies. 2017; 10(7):875. https://doi.org/10.3390/en10070875

Chicago/Turabian StyleHo, Chii-Dong, Ching-Fang Hsiao, Hsuan Chang, Yi-En Tien, and Zih-Syuan Hong. 2017. "Efficiency of Recycling Double-Pass V-Corrugated Solar Air Collectors" Energies 10, no. 7: 875. https://doi.org/10.3390/en10070875