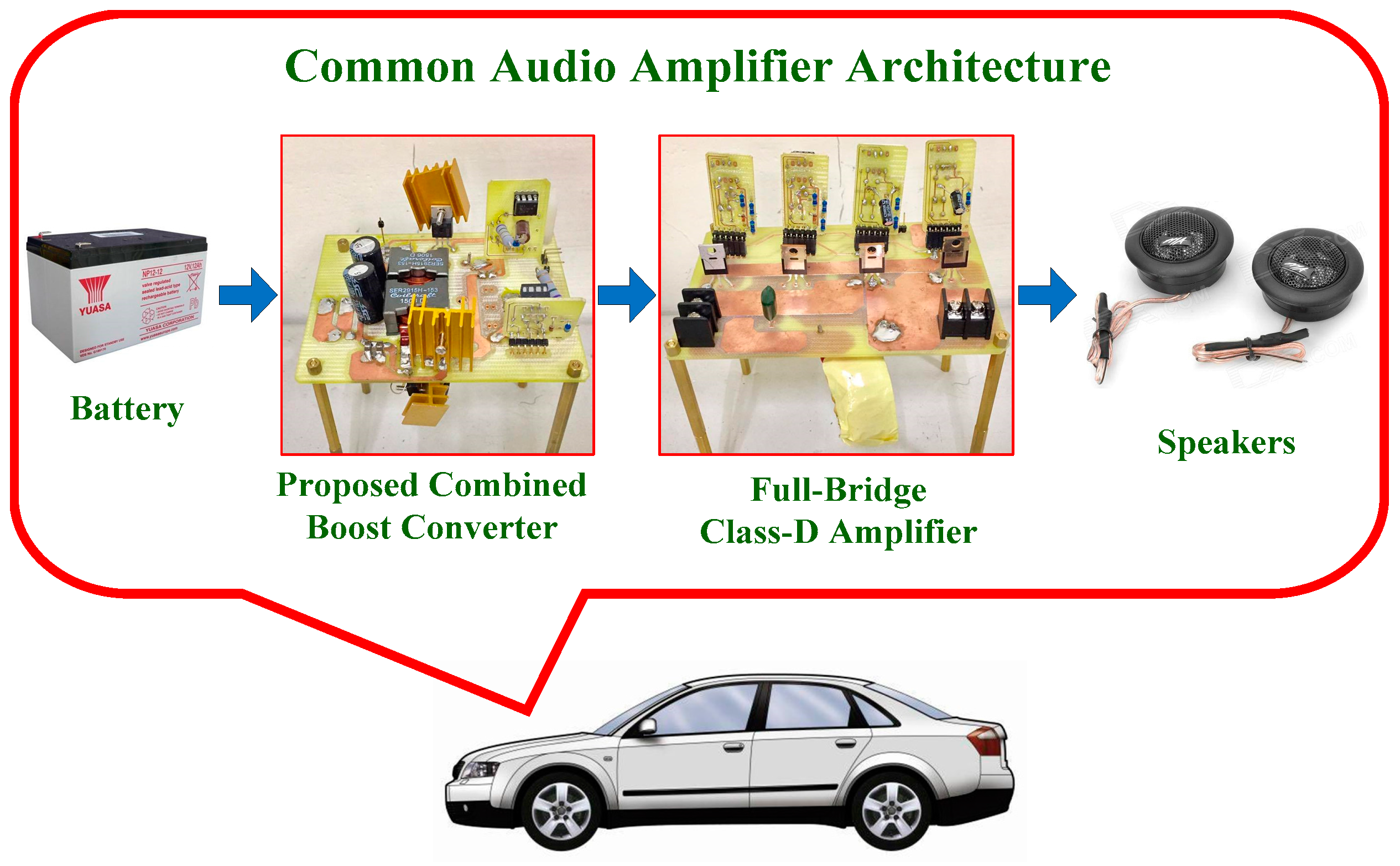

A New Combined Boost Converter with Improved Voltage Gain as a Battery-Powered Front-End Interface for Automotive Audio Amplifiers

Abstract

:1. Introduction

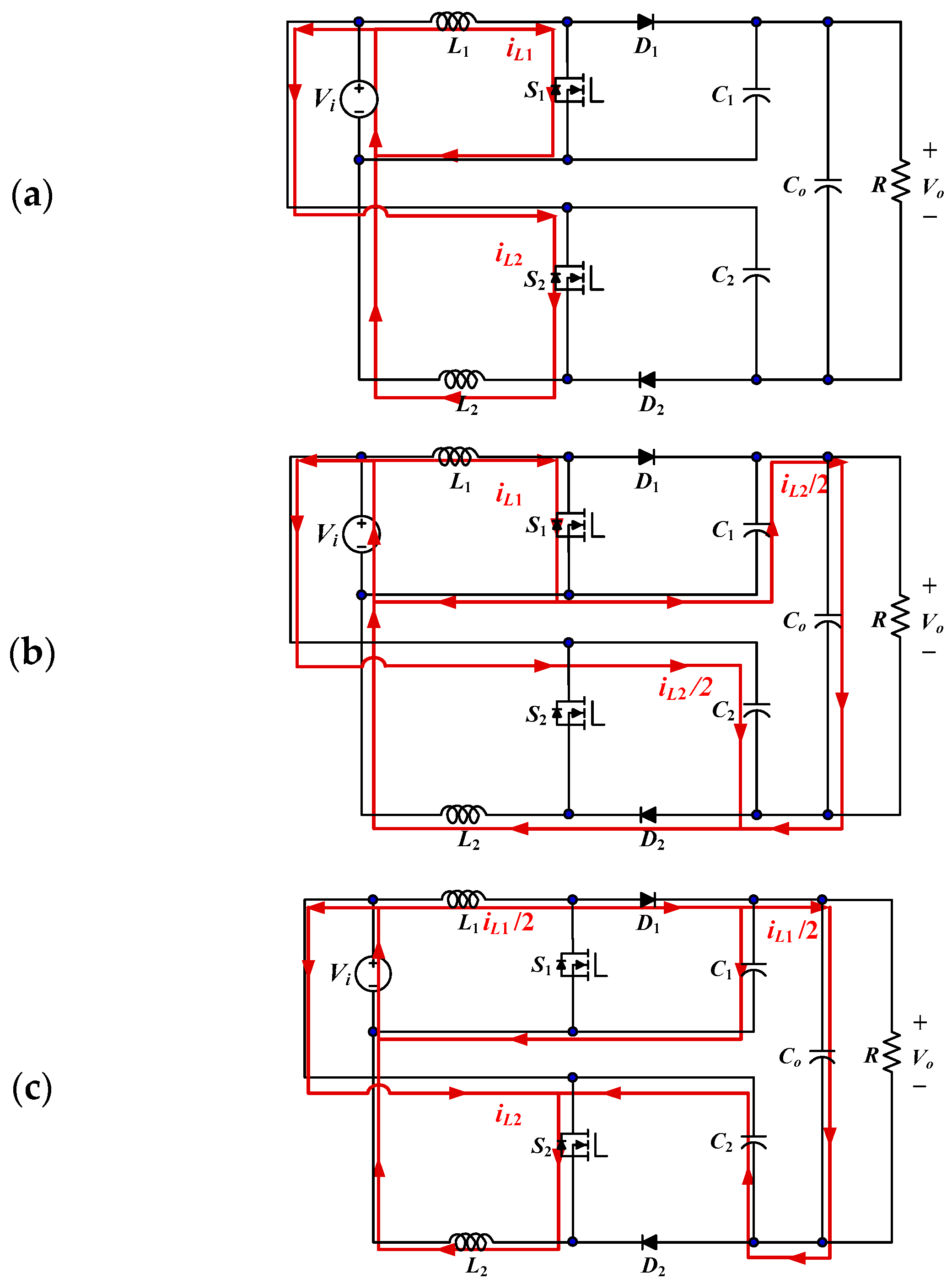

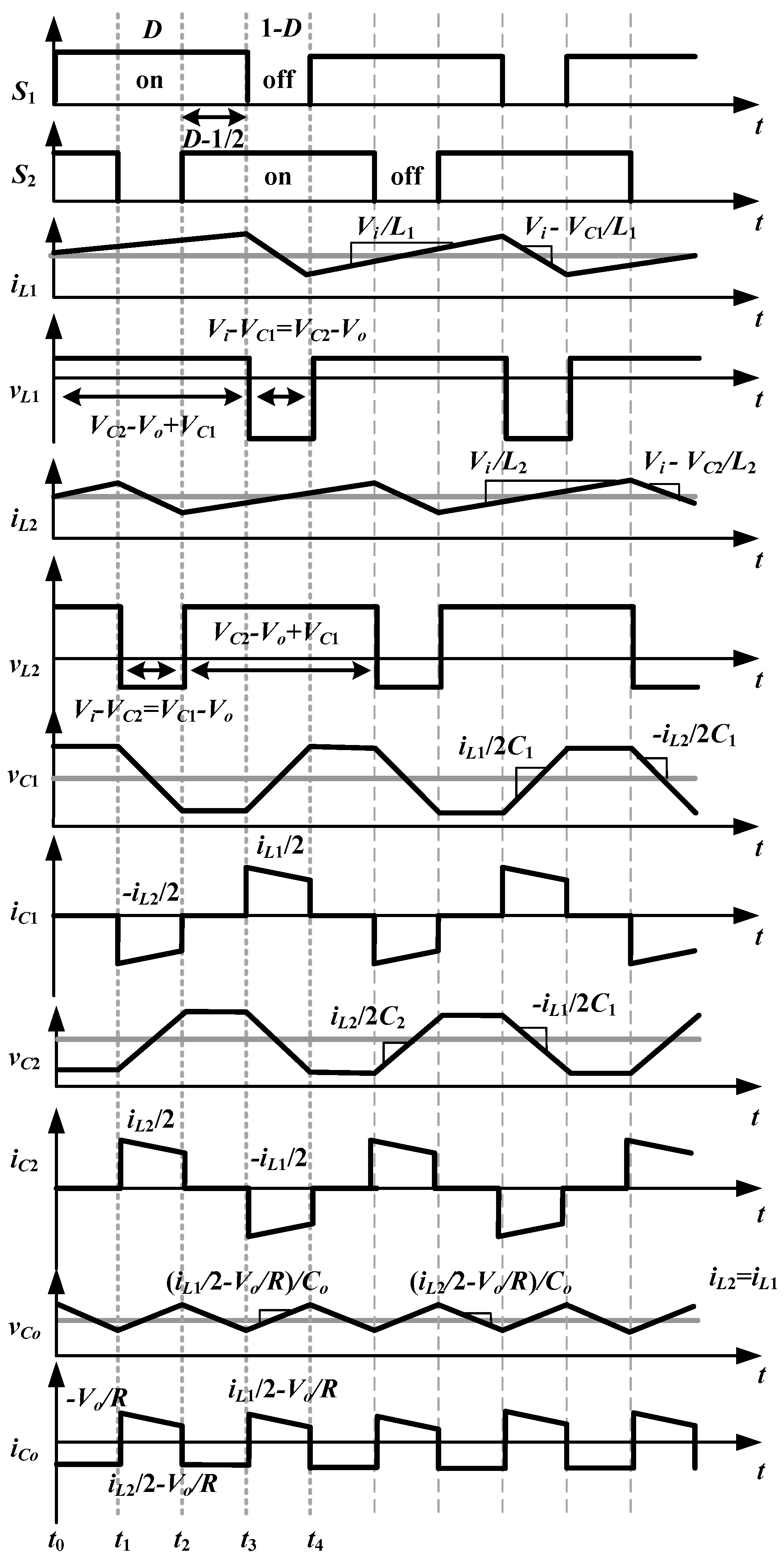

2. Converter Topology and Operation Principles

- (1)

- Mode 1 [t0–t1] and Mode 3 [t2–t3]: In these two modes, the active switches S1 and S2 are switched on while the diodes, D1 and D2 are reverse-bias. The current in the inductors, iL1 and iL2, increase to store energy in L1 and L2, respectively. The output power for the back-end amplifier is provided by capacitor Co. The total current iLt and inductor currents of L1 and L2 are expressed below.

- (2)

- Mode 2 [t1–t2]: The active switch S1 remains conducting and S2 is switched off. D1 is reverse-bias and D2 is forward-bias. While the current iL1 increase to store energy in L1, the energy stored in inductor L2 is now released through D2, C2, C1, and Co to the output. The total current iLt and inductor currents of L1 and L2 can be expressed as follows:

- (3)

- Mode 4 [t3–t4]: S2 is switched on and S1 is switched off. D2 is reverse-bias and D1 is forward-bias. The energy stored in L1 is released through D1 to charge capacitor C1 and Co. The total current iLt and inductor currents of L1 and L2 can be expressed as follows:

3. Analysis of Steady-State

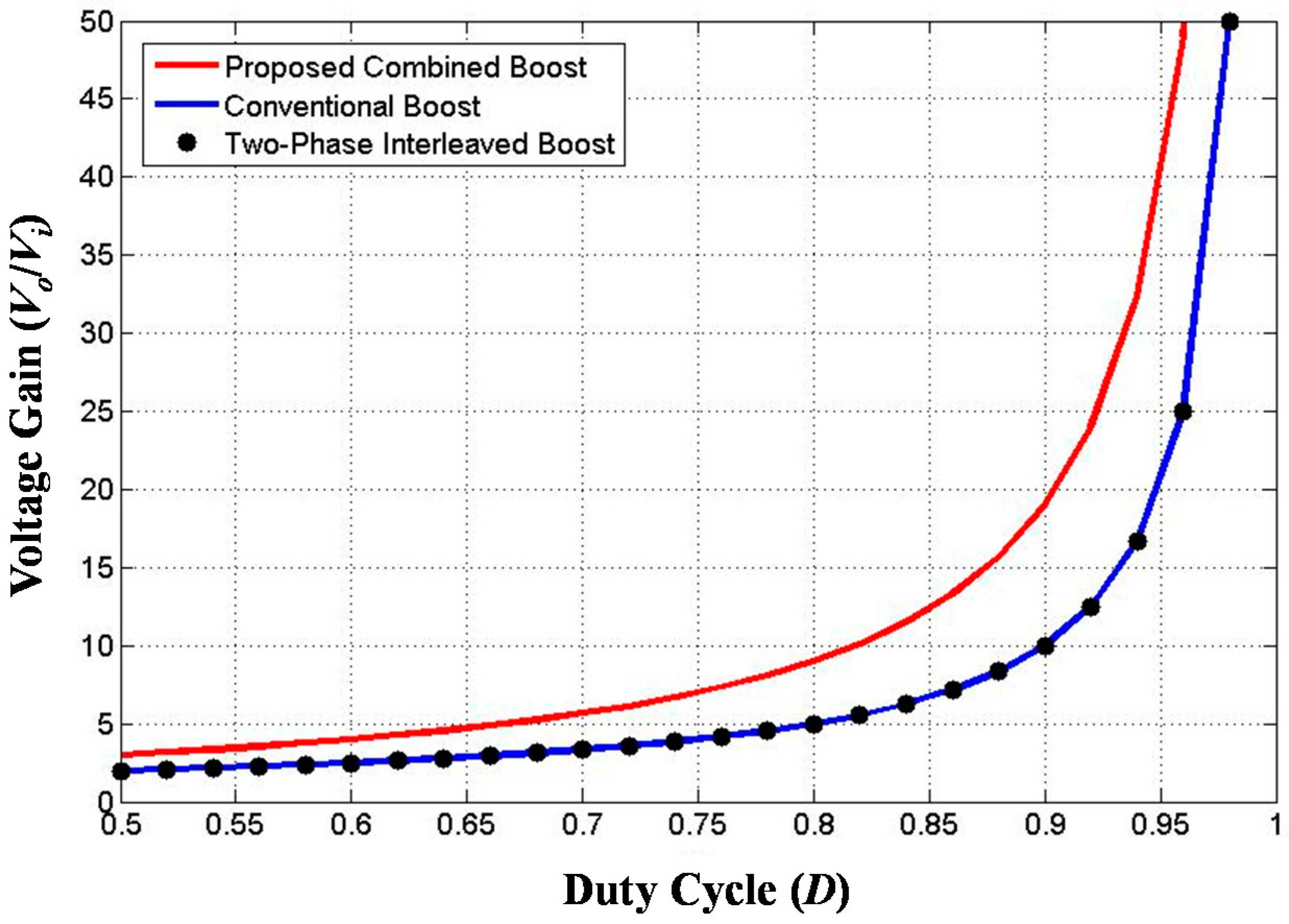

3.1. Voltage Gain

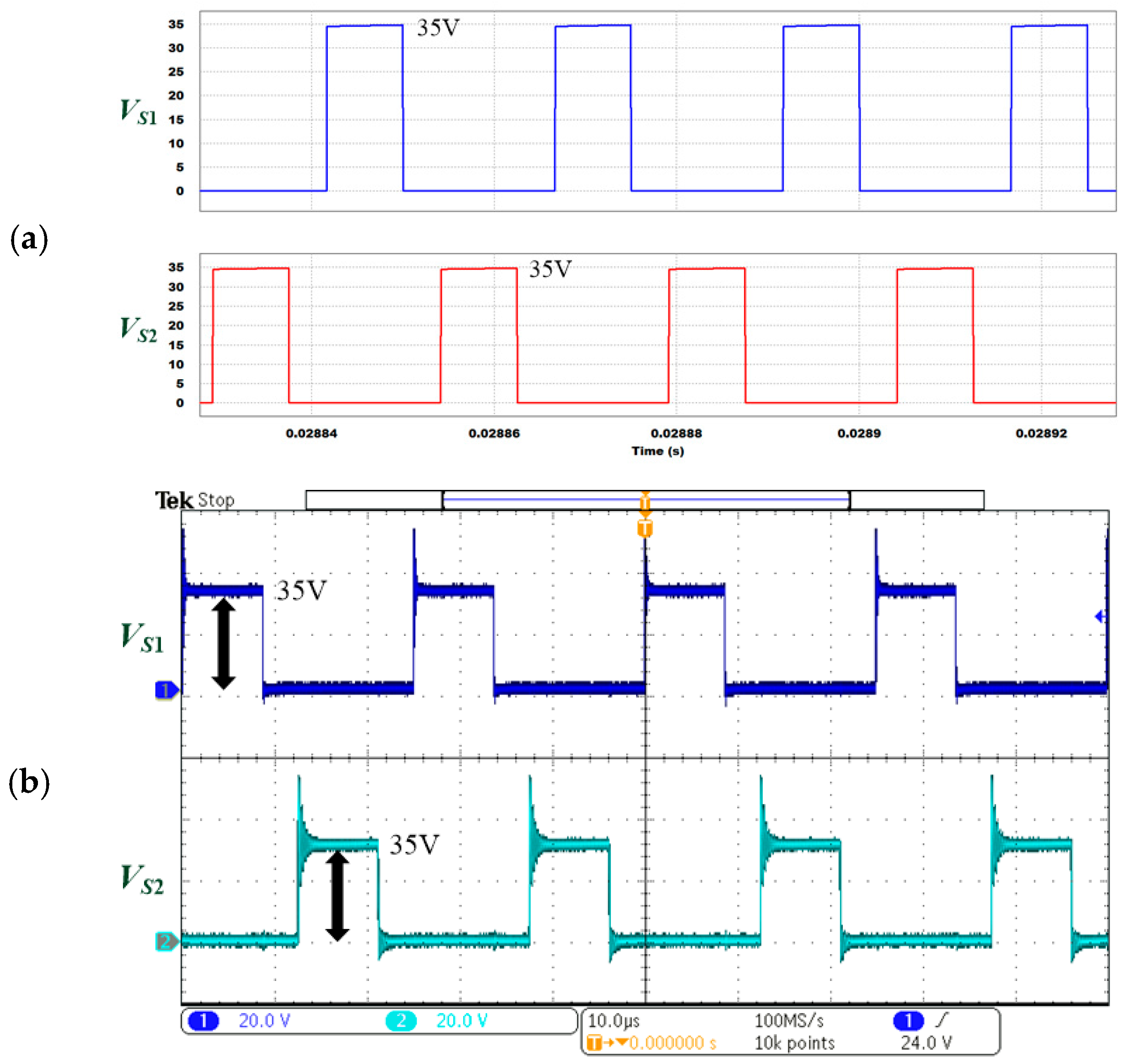

3.2. Voltage Stress of the Switches

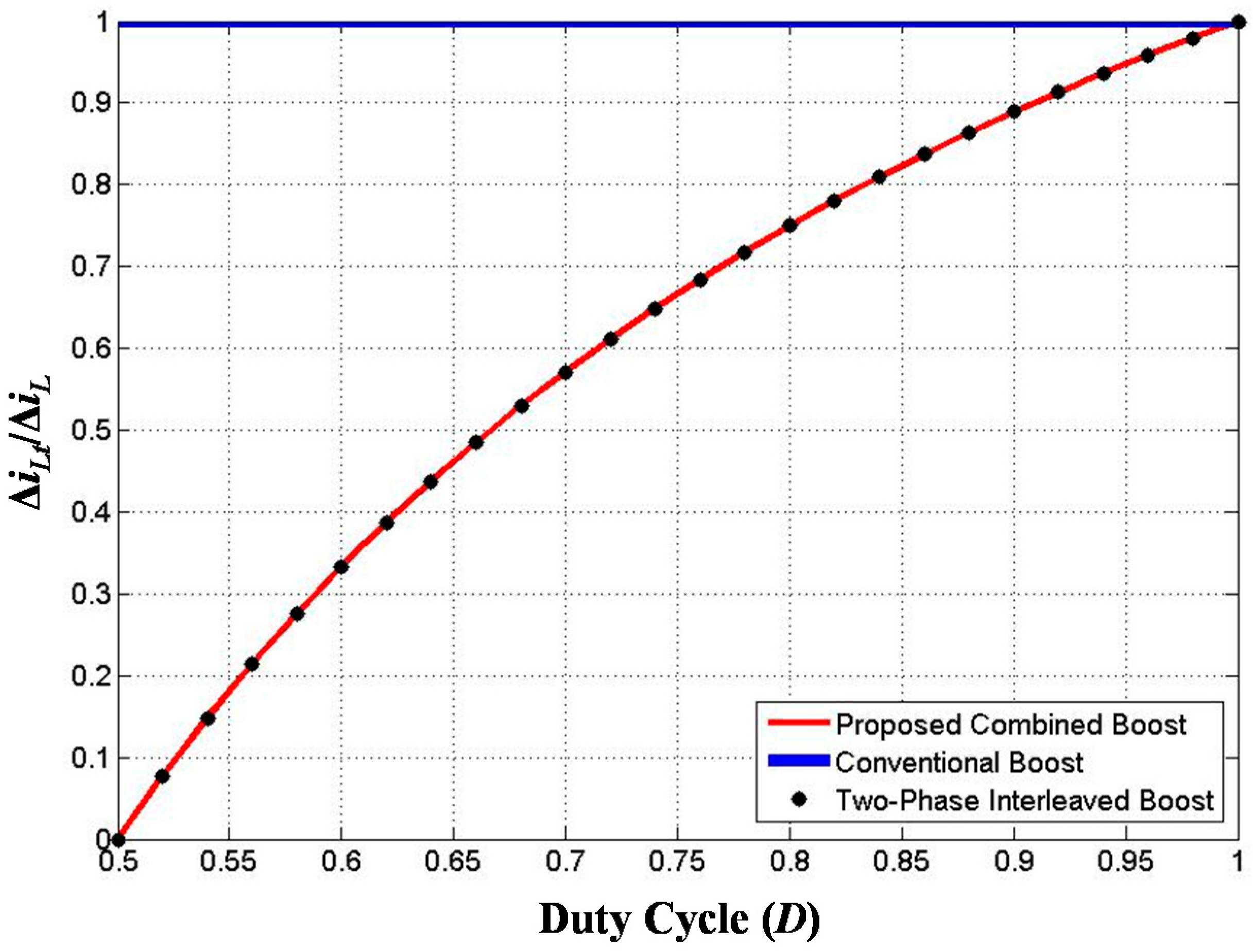

3.3. Inductor Current Ripples

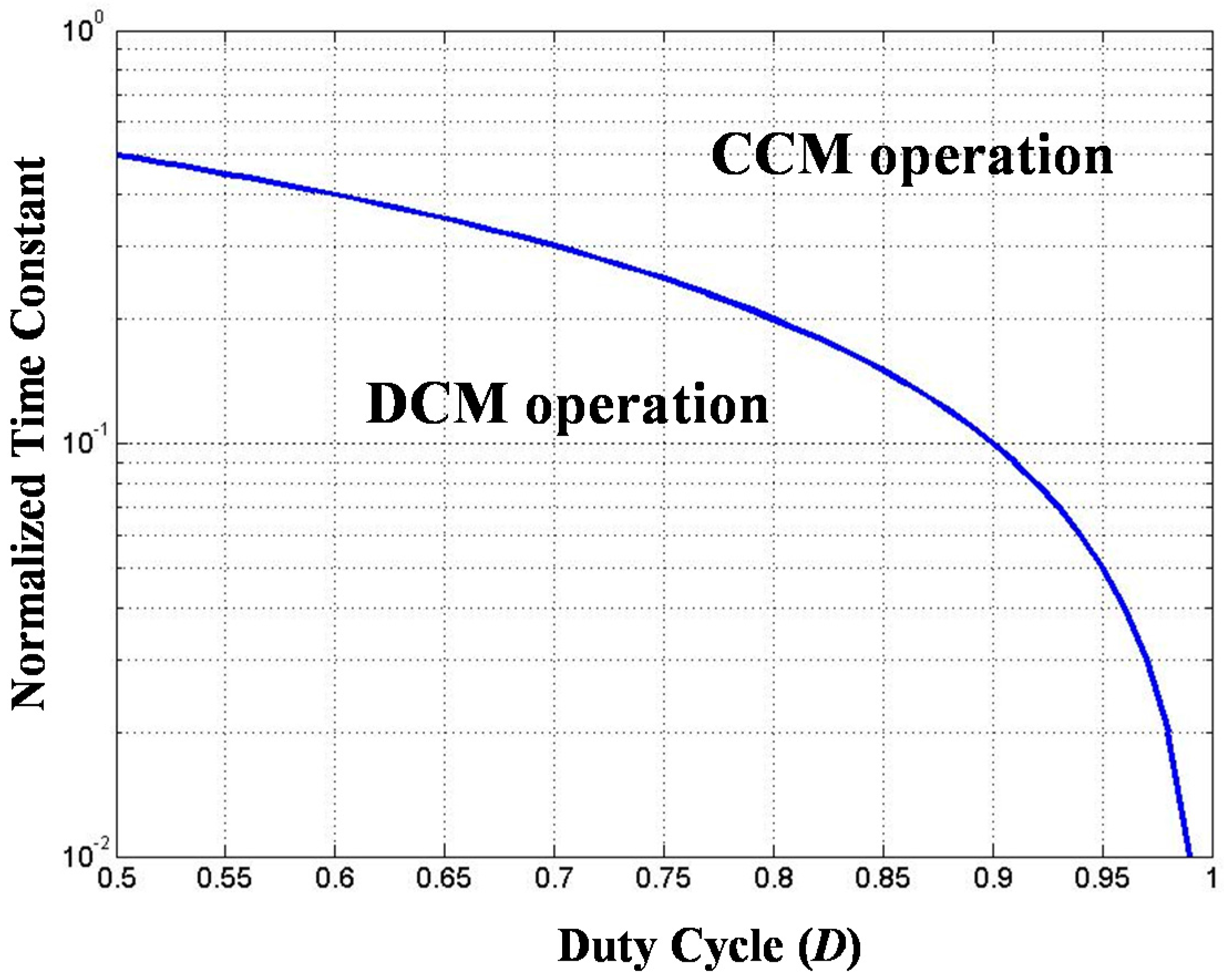

3.4. The Mode for Boundary Conduction

3.5. Component Stress and Loss

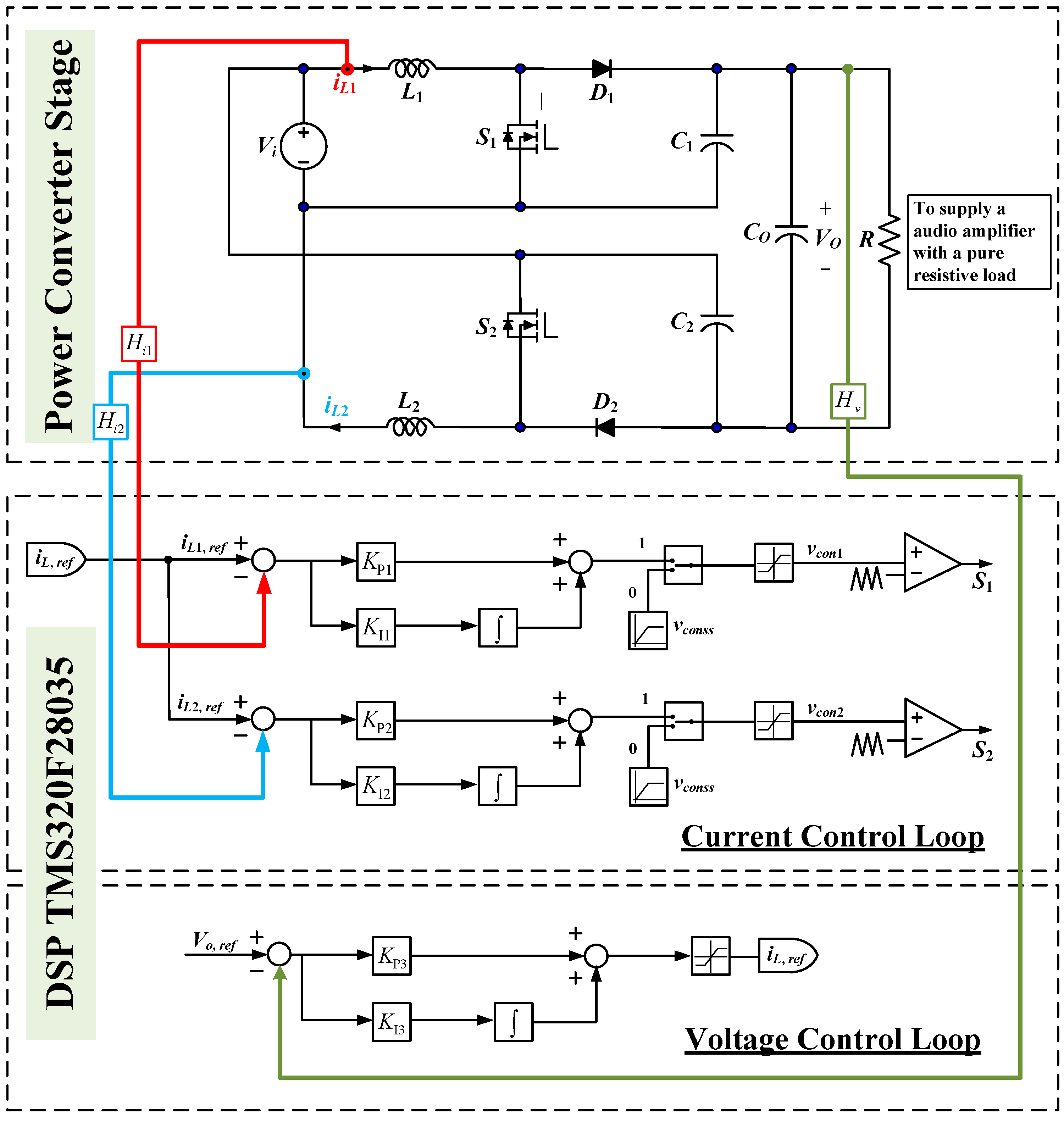

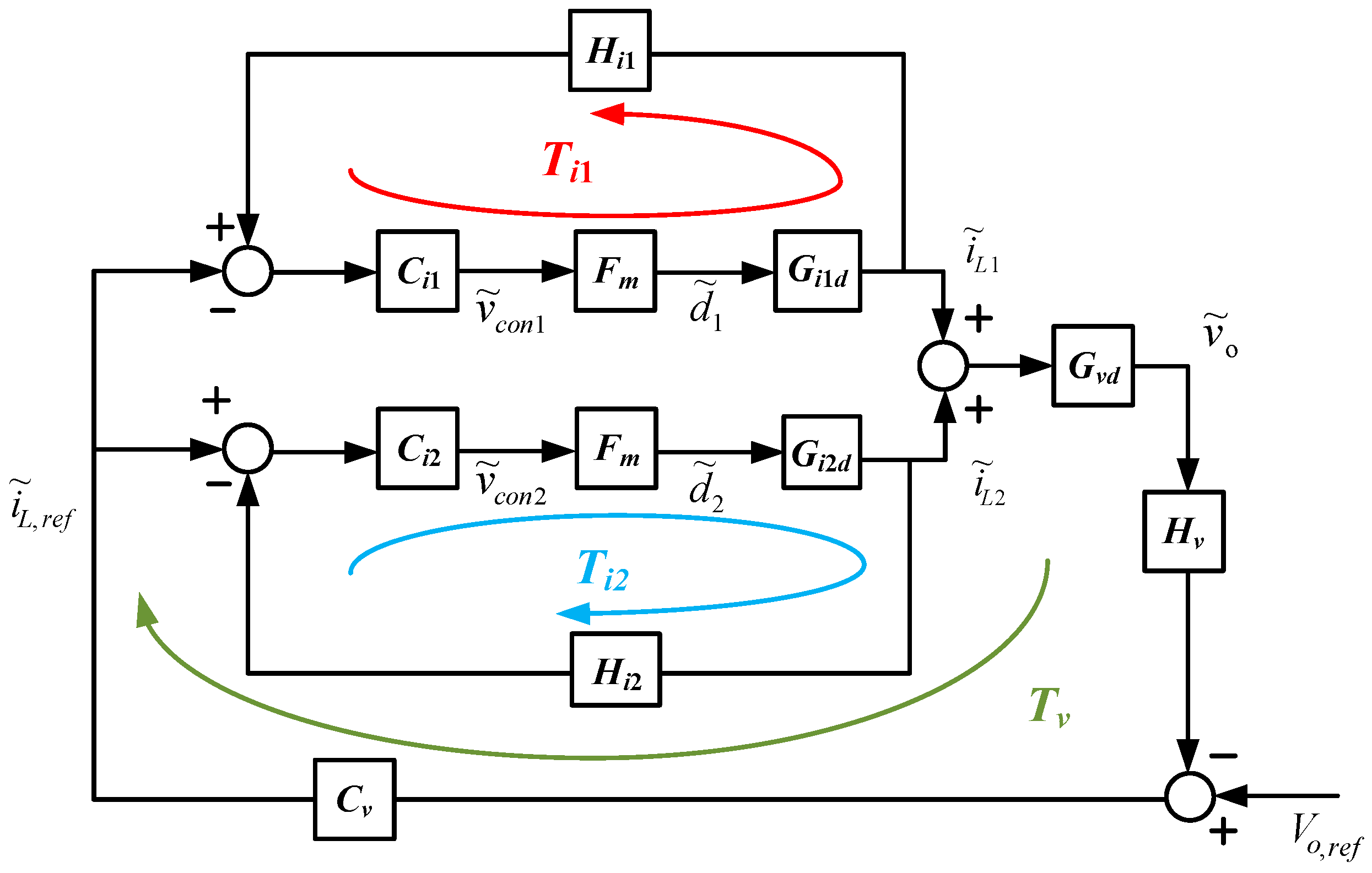

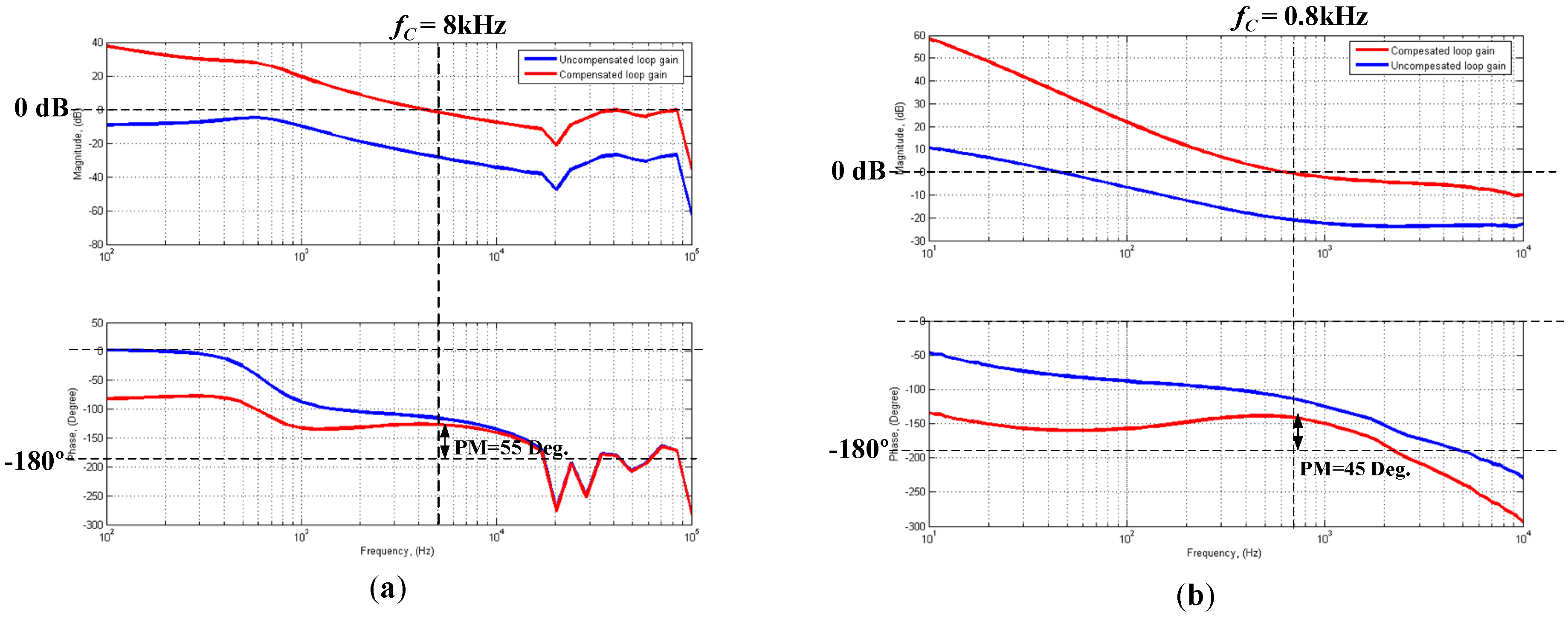

4. Converter Control Strategy

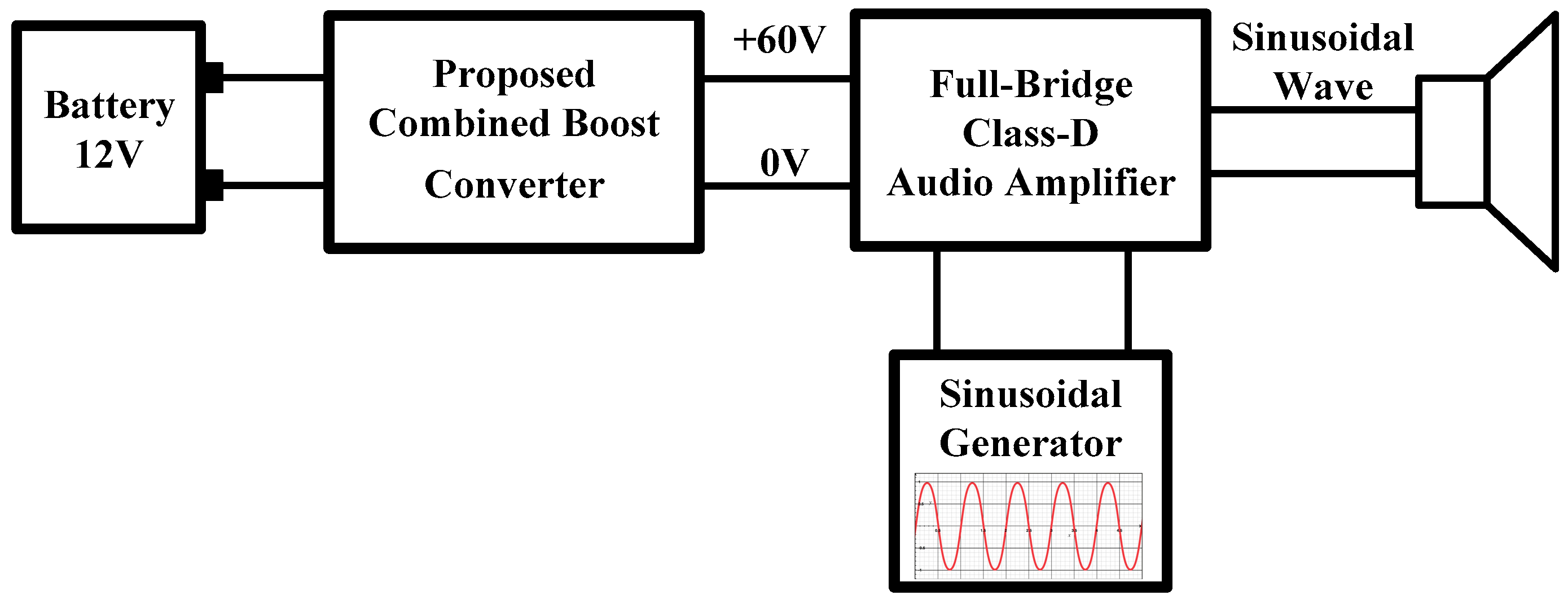

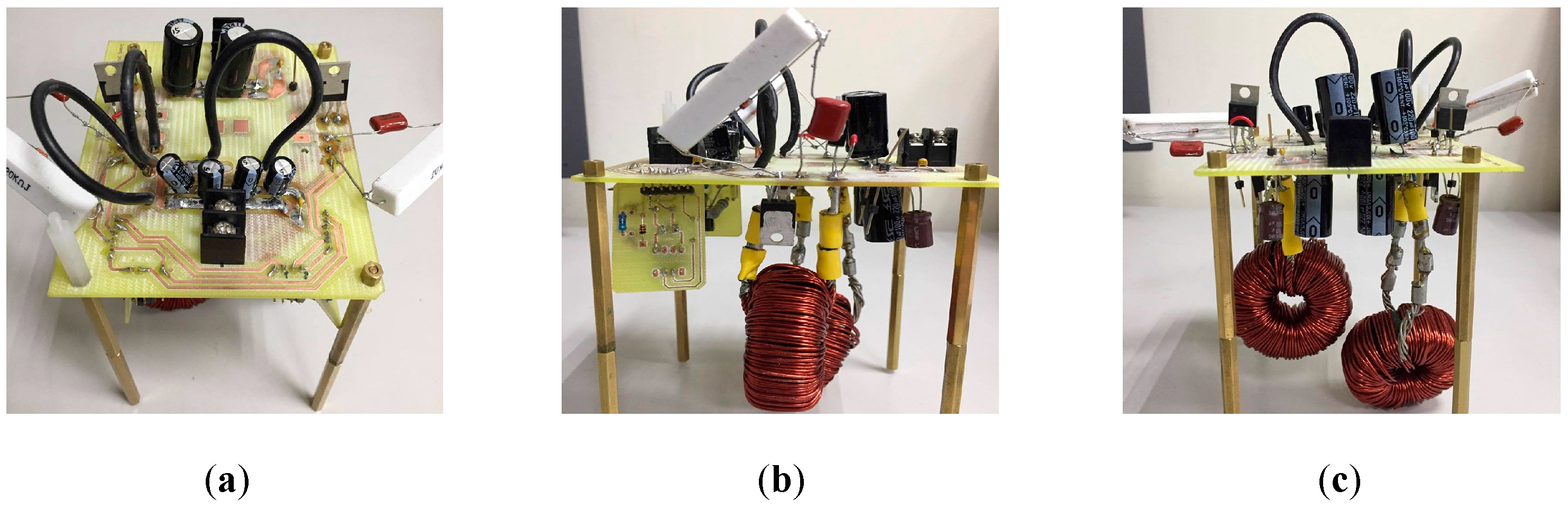

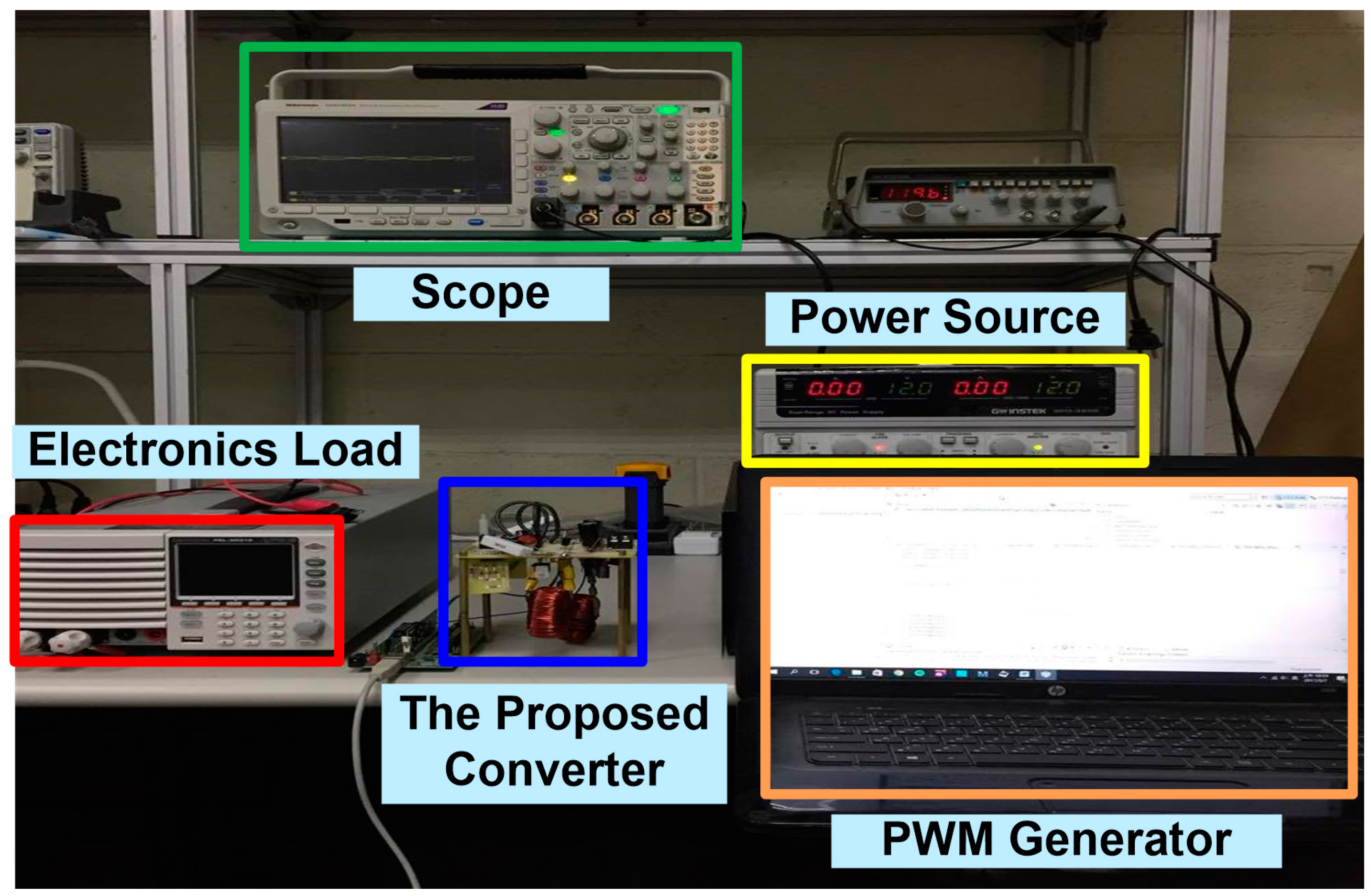

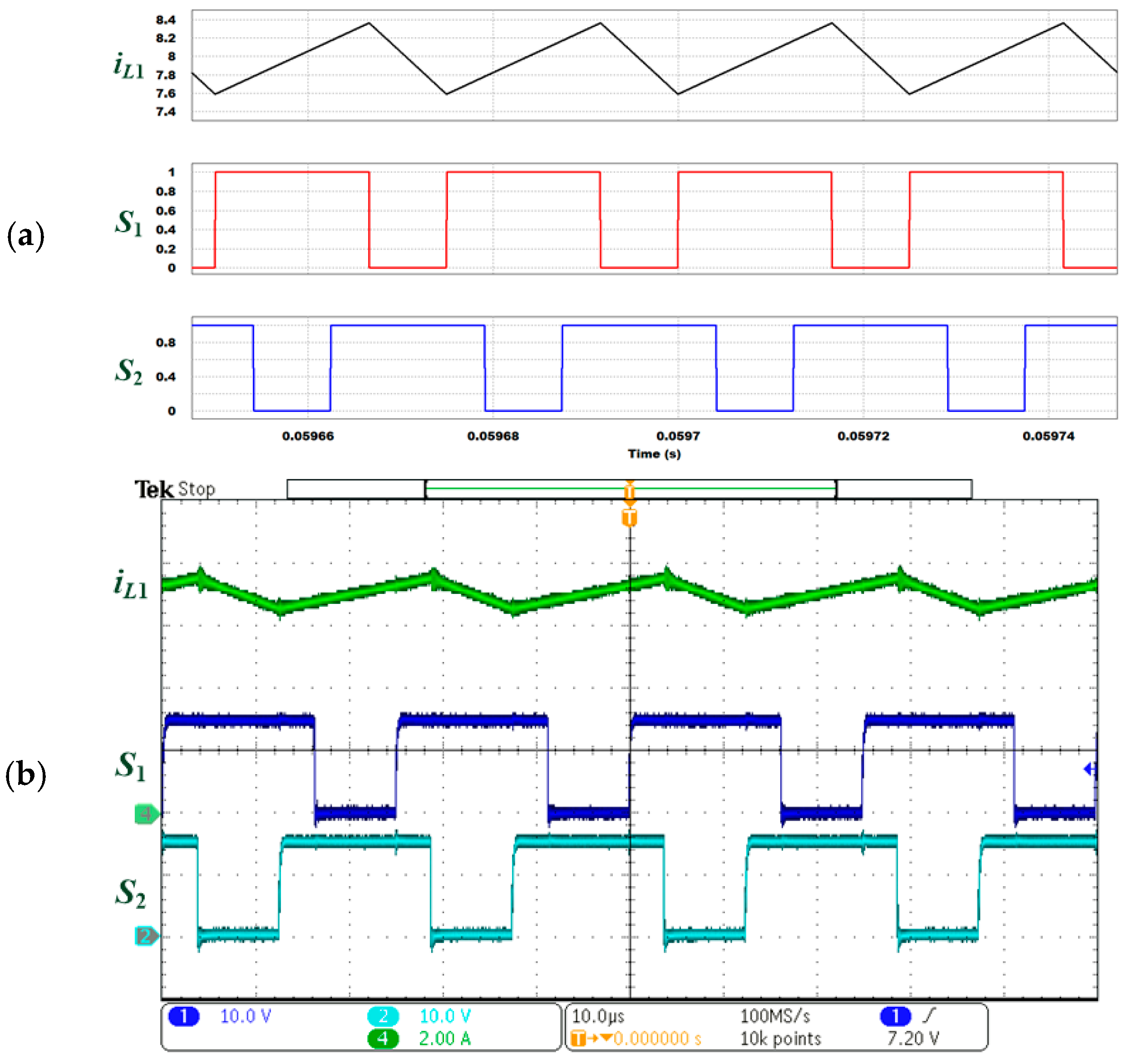

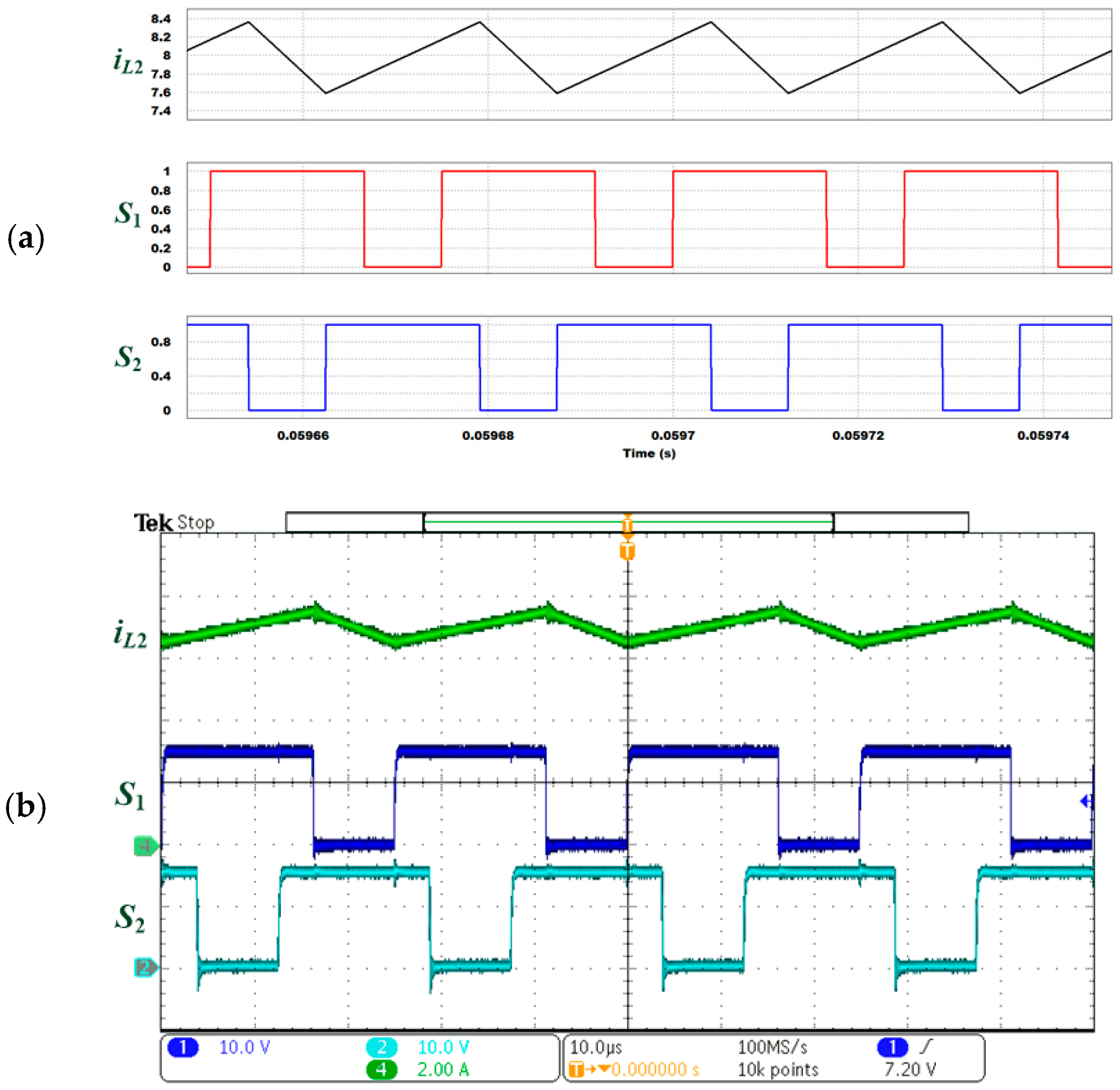

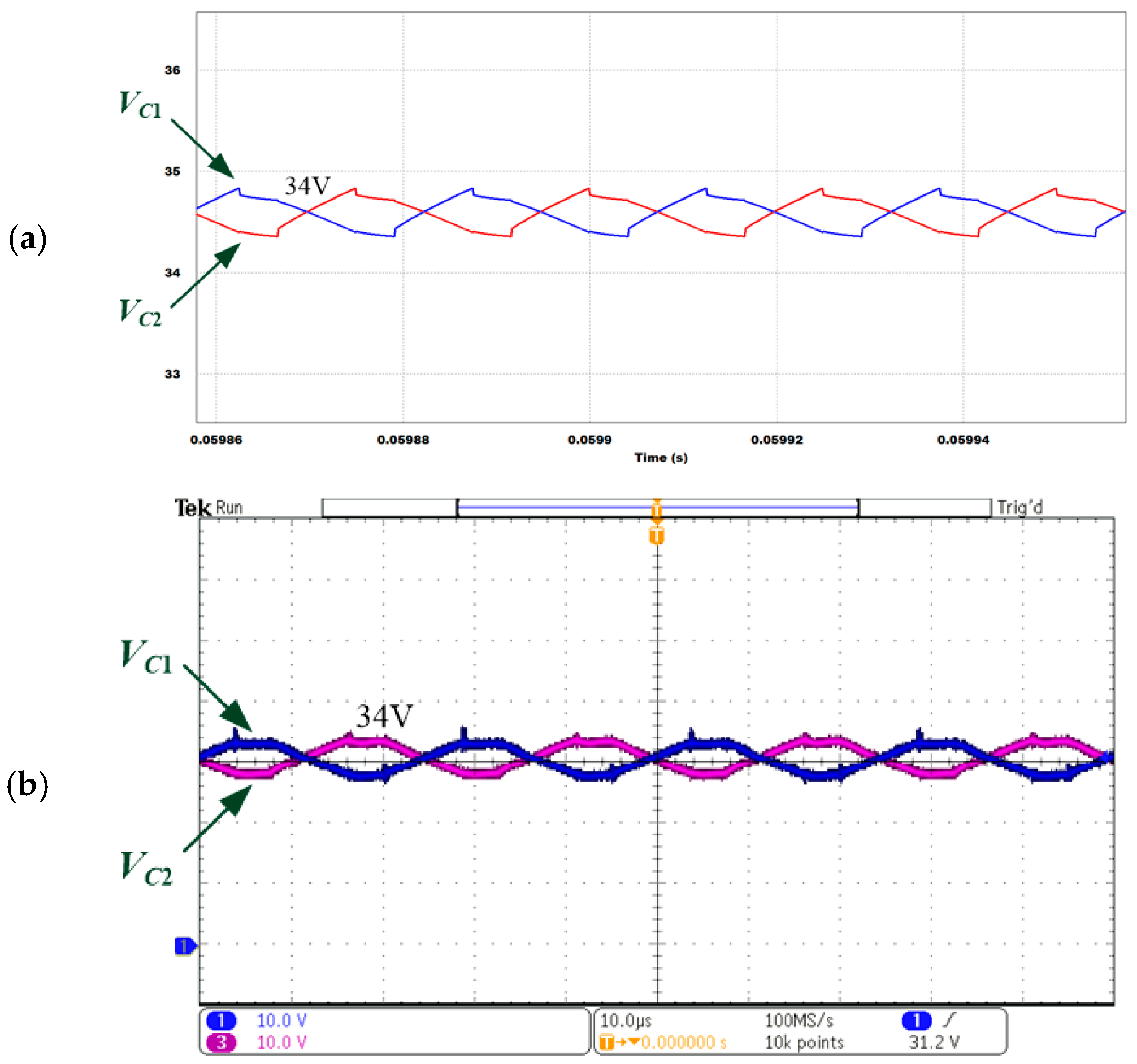

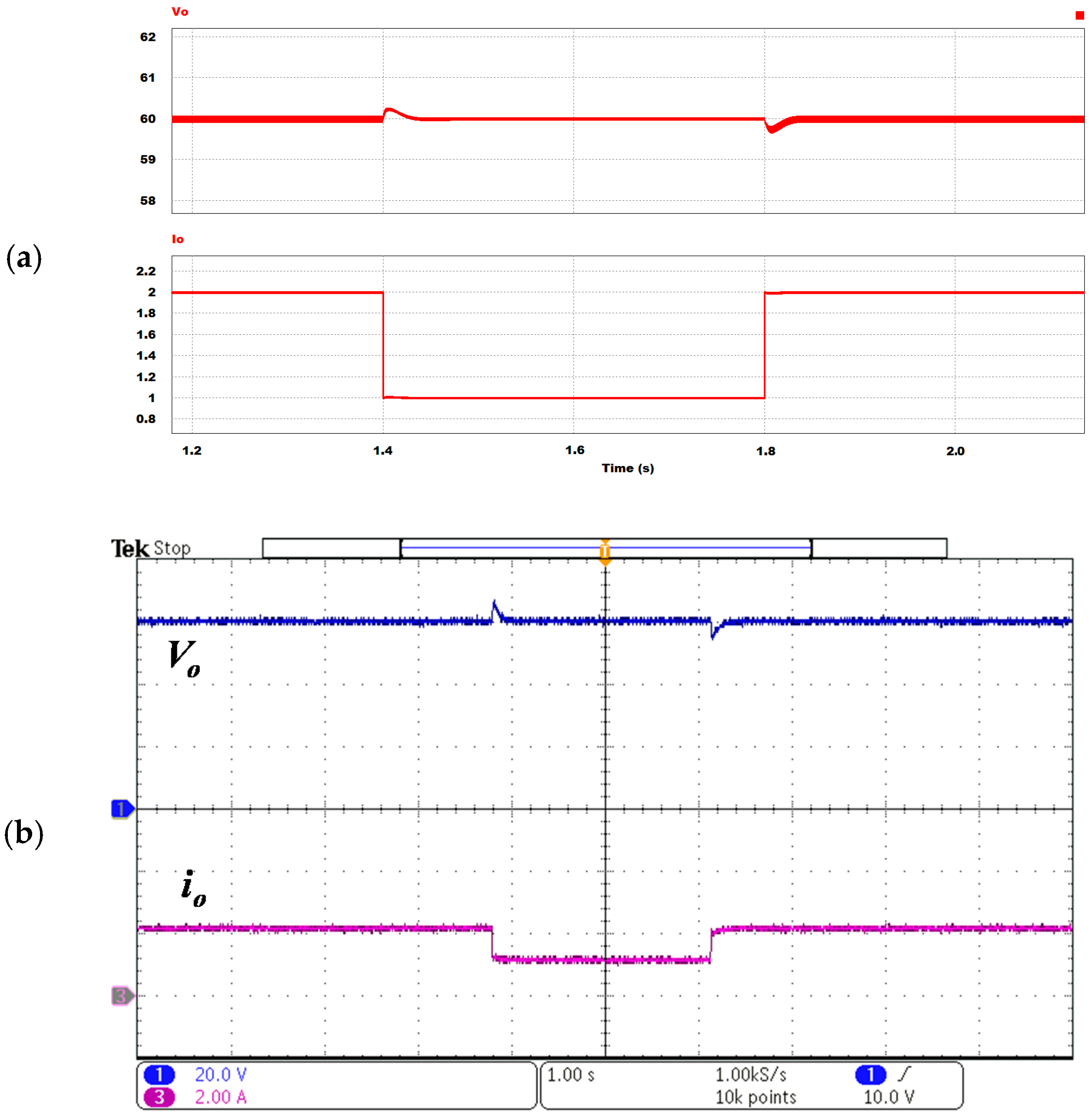

5. Simulated and Experimented Results

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Kim, C.-E.; Moon, G.-W. High-efficiency low-profile on-board DC/DC converter for digital car audio amplifier. Electron. Lett. 2004, 40, 571–572. [Google Scholar] [CrossRef]

- Kim, C.-E.; Han, S.-K.; Moon, G.-W. A New High Efficiency and Low Profile On-Board DC/DC Converter for Digital Car Audio Amplifiers. J. Power Electron. 2006, 6, 83–93. [Google Scholar]

- Kim, C.-E.; Moon, G.-W.; Han, S.-K. Voltage doubler rectified boost-integrated half bridge (VDRBHB) converter for digital car audio amplifiers. IEEE Trans. Power Electron. 2007, 22, 2321–2330. [Google Scholar] [CrossRef]

- Lee, B.-H.; Kim, C.-E.; Moon, G.-W. A New Non-isolated ZVZCS Voltage Doubler Rectified Boost-integrated Half-Bridge (VDRBIHB) DC/DC Converter for Digital Car Audio Amplifier Power Supply. In Proceedings of the Power Electronics Specialists Conference, Orlando, FL, USA, 17–21 June 2007; pp. 331–336. [Google Scholar]

- Franceschini, G.; Lorenzani, E.; Cavatorta, M.; Bellini, A. 3boost: A high-power three-phase step-up full-bridge converter for automotive applications. IEEE Trans. Ind. Electron. 2008, 55, 173–183. [Google Scholar] [CrossRef]

- Berkhout, M.; Dooper, L.; Krabbenborg, B. A 4 Ω 2.65 W Class-D Audio Amplifier With Embedded DC–DC Boost Converter, Current Sensing ADC and DSP for Adaptive Speaker Protection. IEEE J. Solid-State Circuits 2013, 48, 2952–2961. [Google Scholar] [CrossRef]

- Lai, C.-M.; Lee, Y.-H.; Lin, Y.-C.; Ku, C.-W. Study and Analysis of a Battery-Powered High Step-Up Front-End Converter for Automotive Audio Amplifier. In Proceedings of the 2016 IEEE Vehicle Power and Propulsion Conference (VPPC), Hangzhou, China, 17–20 October 2016; pp. 1–4. [Google Scholar]

- Reatti, A. Low-cost high power-density electronic ballast for automotive HID lamp. IEEE Trans. Power Electron. 2000, 15, 361–368. [Google Scholar] [CrossRef]

- Zhao, Q.; Hu, Y.; Lee, F.C.; Sabate, J.A.; Li, F. A high efficiency DC/DC converter as the front-end stage of high intensity discharge lamp ballasts for automobiles. In Proceedings of the Third International Power Electronics and Motion Control Conference, Beijing, China, 15–18 August 2000; pp. 752–756. [Google Scholar]

- Zhao, Q.; Lee, F.C. High-efficiency, high step-up DC–DC converters. IEEE Trans. Power Electron. 2003, 18, 65–73. [Google Scholar] [CrossRef]

- Yang, L.S.; Liang, T.J.; Chen, J.F. Transformerless DC–DC converters with high step-up voltage gain. IEEE Trans. Power Electron. 2009, 56, 3144–3152. [Google Scholar] [CrossRef]

- Divakar, B.; Cheng, K.W.E.; Wang, D.; Ping, D.; Kwok, K. Implementation of a voltage multiplier integrated HID ballast circuit with dimming control for automotive application. IEEE Trans. Power Electron. 2009, 56, 2479–2492. [Google Scholar] [CrossRef]

- Tomm, F.L.; Seidel, Á.R.; Campos, A.; Dalla Costa, M.A.; do Prado, R.N. HID lamp electronic ballast based on chopper converters. IEEE Trans. Power Electron. 2012, 59, 1799–1807. [Google Scholar] [CrossRef]

- Babu, T.; Balakrishnan, A.A. Quadrupler DC converter for high intensity discharge lamp applications, Circuit. In Proceedings of the 2015 International Conference on Circuit, Power and Computing Technologies (ICCPCT), Nagercoil, India, 19–20 March 2015; pp. 1–6. [Google Scholar]

- Silva, C.E.; Bascope, R.P.; Oliveira, D.S. Proposal of a new high step-up converter for UPS applications. In Proceedings of the 2006 IEEE International Symposium on Industrial Electronics, Montreal, QC, Canada, 9–13 July 2006; pp. 1288–1292. [Google Scholar]

- Da Câmara, R.A.; Cruz, C.M.; Torrico-Bascopé, R.P. Boost based on three-state switching cell for UPS applications. In Proceedings of the 2009 Brazilian Power Electronics Conference, Bonito-Mato Grosso do Sul, Brazil, 27 September–1 October 2009; pp. 313–318. [Google Scholar]

- Araújo, S.V.; Torrico-Bascopé, R.P.; Torrico-Bascopé, G.V. Highly efficient high step-up converter for fuel-cell power processing based on three-state commutation cell. IEEE Trans. Power Electron. 2010, 57, 1987–1997. [Google Scholar] [CrossRef]

- Lelie, M.; Rothgang, S.; Masomtob, M.; Rosekeit, M.; Doncker, R.W.D.; Sauer, D.U. Design of a Battery System for a Fuel Cell Powered UPS ApplicationWith Extreme Temperature Conditions. In Proceedings of the 2013 35th International Telecommunications Energy Conference ‘Smart Power and Efficiency’ (INTELEC), Hamburg, Germany, 13–17 October 2013. [Google Scholar]

- Lai, C.-M. A battery-powered single-stage three-phase high step-up converter topology for micro DC-UPS. IEICE Electron. Express 2014, 11, 20140852. [Google Scholar] [CrossRef]

- Emadi, A.; Rajashekara, K.; Williamson, S.S.; Lukic, S.M. Topological overview of hybrid electric and fuel cell vehicular power system architectures and configurations. IEEE Trans. Veh. Technol. 2005, 54, 763–770. [Google Scholar] [CrossRef]

- Camara, M.B.; Gualous, H.; Gustin, F.; Berthon, A. Design and new control of DC/DC converters to share energy between supercapacitors and batteries in hybrid vehicles. IEEE Trans. Veh. Technol. 2008, 57, 2721–2735. [Google Scholar] [CrossRef]

- Khaligh, A.; Li, Z. Battery, ultracapacitor, fuel cell, and hybrid energy storage systems for electric, hybrid electric, fuel cell, and plug-in hybrid electric vehicles: State of the art. IEEE Trans. Veh. Technol. 2010, 59, 2806–2814. [Google Scholar] [CrossRef]

- Shahin, A.; Hinaje, M.; Martin, J.; Pierfederici, S.; Rae, X.; Rael, S.L.; Davat, B. High voltage ratio DC–DC converter for fuel-cell applications. IEEE Trans. Power Electron. 2010, 57, 3944–3955. [Google Scholar] [CrossRef]

- Ardi, H.; Ahrabi, R.R.; Ravadanegh, S.N. Non-isolated bidirectional DC–DC converter analysis and implementation. IET Power Electron. 2014, 7, 3033–3044. [Google Scholar] [CrossRef]

- Thounthong, P. Control of a three-level boost converter based on a differential flatness approach for fuel cell vehicle applications. IEEE Trans. Veh. Technol. 2012, 61, 1467–1472. [Google Scholar] [CrossRef]

- Yang, L.-S.; Liang, T.-J. Analysis and implementation of a novel bidirectional DC–DC converter. IEEE Trans. Power Electron. 2012, 59, 422–434. [Google Scholar] [CrossRef]

- Pavlovsky, M.; Guidi, G.; Kawamura, A. Assessment of coupled and independent phase designs of interleaved multiphase buck/boost DC–DC converter for EV power train. IEEE Trans. Power Electron. 2014, 29, 2693–2704. [Google Scholar] [CrossRef]

- Lai, C.-M.; Lin, Y.-C.; Lee, D. Study and implementation of a two-phase interleaved bidirectional DC/DC converter for vehicle and dc-microgrid systems. Energies 2015, 8, 9969–9991. [Google Scholar] [CrossRef]

- Lai, C.-M. Development of a novel bidirectional DC/DC converter topology with high voltage conversion ratio for electric vehicles and DC-microgrids. Energies 2016, 9, 410. [Google Scholar] [CrossRef]

- Lin, Y.-S.; Hu, K.-W.; Yeh, T.-H.; Liaw, C.-M. An electric-vehicle IPMSM drive with interleaved front-end DC/DC converter. IEEE Trans. Veh. Technol. 2016, 65, 4493–4504. [Google Scholar] [CrossRef]

- Lai, C.-M.; Pan, C.-T.; Cheng, M.-C. High-efficiency modular high step-up interleaved boost converter for DC-microgrid applications. IEEE Trans. Ind. Appl. 2012, 48, 161–171. [Google Scholar] [CrossRef]

- Mohr, M.; Franke, W.; Wittig, B.; Fuchs, F. Converter systems for fuel cells in the medium power range—A comparative study. IEEE Trans. Power Electron. 2010, 57, 2024–2032. [Google Scholar] [CrossRef]

- Li, W.; He, X. Review of nonisolated high-step-up DC/DC converters in photovoltaic grid-connected applications. IEEE Trans. Power Electron. 2011, 58, 1239–1250. [Google Scholar] [CrossRef]

- AN-9010 MOSFET Basics. Available online: https://www.fairchildsemi.com/application-notes/AN/AN-9010.pdf (accessed on 27 July 2017).

- STPS8H100 Spec. Available online: http://www.st.com/en/diodes-and-rectifiers/stps8h100.html (accessed on 5 June 2017).

| Items | State |

|---|---|

| RMS current stress on S1 (iS1) | |

| RMS current stress on S2 (iS2) | |

| RMS current stress on L1 (iL1) | |

| RMS current stress on L2 (iL2) | |

| RMS current stress on Lt (iLt) | |

| RMS current stress on D1 (iD1) | |

| RMS current stress of D2 (iD2) | |

| RMS current stress of C1 (iC1) | |

| RMS current stress of C2 (iC2) | |

| RMS current stress of Co (iCo) |

| Items | State |

|---|---|

| Total loss of S1 | |

| Total loss of S2 | |

| Conduction loss of L1 | |

| Conduction loss of L2 | |

| Total loss of D1 | |

| Total loss of D2 | |

| Conduction loss of C1 | |

| Conduction loss of C2 | |

| Conduction loss of Co |

| Specification | Value |

|---|---|

| Input Voltage, Vi | 12 V |

| Output Voltage, Vo | 60 V |

| Duty Cycle, D | 0.67 |

| Switching Frequency, fsw | 40 kHz |

| Output power, Po | 120 W |

| Specification | Value |

|---|---|

| MOSFET | IPP080N06NG |

| Diode | STPS8H100 |

| Load Resistance, R | 30 Ω |

| Inductors, L1 and L2 | 250 μH |

| Filter Capacitors, C1 and C2 | 10 μF |

| Output Capacitor, Co | 1000 μF |

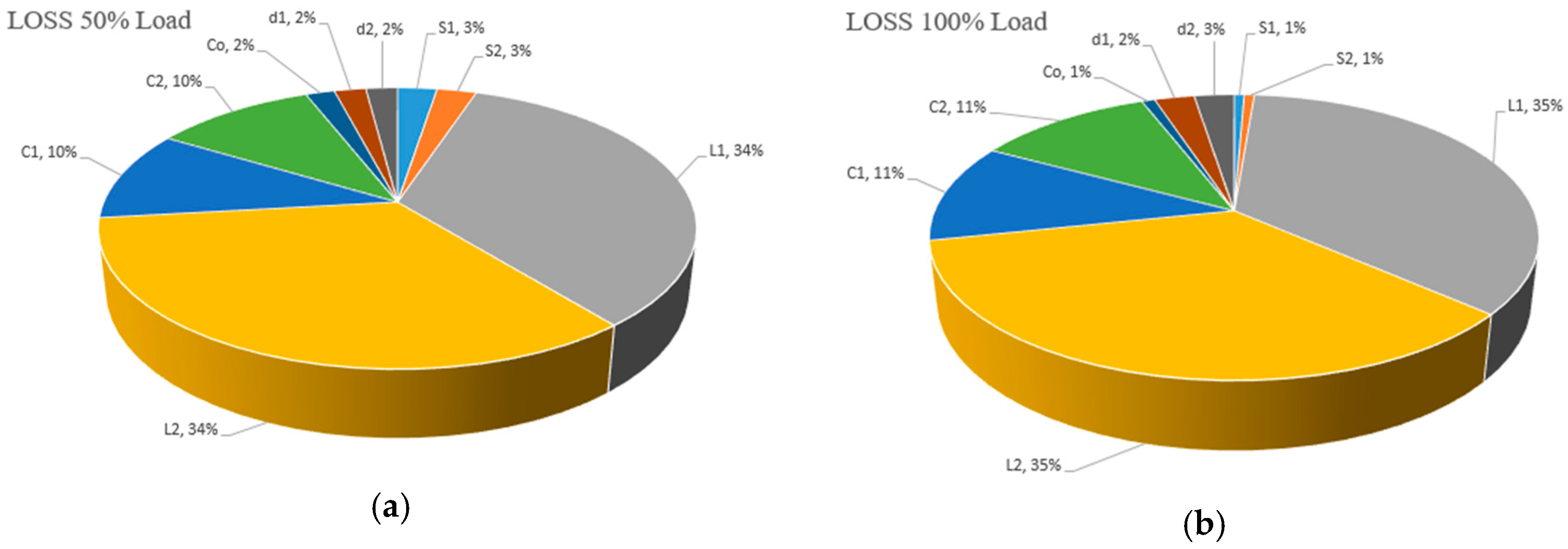

| Items | Results (50% Load) | Results (100% Load) |

|---|---|---|

| Switching loss of S1 | 0.049 W | 0.059 W |

| Switching loss of S2 | 0.049 W | 0.059 W |

| Conduction loss of L1 and L2 | 0.64 W | 3.2 W |

| Conduction loss of D1 and D2 | 0.0384 W | 0.23 W |

| Conduction loss of C1 and C2 | 0.196 W | 1.02 W |

| Conduction loss of Co | 0.035 W | 0.075 W |

| Total losses | 1.8828 W | 9.134 W |

| Calculated Efficiency | 98.5% | 92.4% |

| Measured Efficiency | 97.3% | 89.1% |

| Items | Topology | |||

|---|---|---|---|---|

| This Converter | [11] | [19] | [24] | |

| Switching control structure | two-phase | single-phase | three-Phase | single-phase |

| Input current ripple | Low | High | Low | Medium |

| Voltage gain | (1 + D)/(1 − D) | (1 + D)/(1 − D) | (3+ nD − D2 )/(1 − D) | 1/(1 − D)2 |

| High-side voltage | 60 V | 60 V | 200 V | 62.5 V |

| Low-side voltage | 12 V | 12 V | 24 V | 10 V |

| Number of main power devices | 4 | 3 | 8 | 4 |

| Number of storage components | 5 | 4 | 8 | 5 |

| Maximum efficiency | 98.7% | 92.1% | 92.3% | 92.5% |

| Realized prototype power rating | 120 W | 40 W | 100 W | 100 W |

| BOM Cost | Low | Low | High | Medium |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lai, C.-M.; Cheng, Y.-H.; Teh, J.; Lin, Y.-C. A New Combined Boost Converter with Improved Voltage Gain as a Battery-Powered Front-End Interface for Automotive Audio Amplifiers. Energies 2017, 10, 1128. https://doi.org/10.3390/en10081128

Lai C-M, Cheng Y-H, Teh J, Lin Y-C. A New Combined Boost Converter with Improved Voltage Gain as a Battery-Powered Front-End Interface for Automotive Audio Amplifiers. Energies. 2017; 10(8):1128. https://doi.org/10.3390/en10081128

Chicago/Turabian StyleLai, Ching-Ming, Yu-Huei Cheng, Jiashen Teh, and Yuan-Chih Lin. 2017. "A New Combined Boost Converter with Improved Voltage Gain as a Battery-Powered Front-End Interface for Automotive Audio Amplifiers" Energies 10, no. 8: 1128. https://doi.org/10.3390/en10081128